Abstract

The effects of 1-methylcyclopropene (1-MCP) on physicochemical properties and sensory characteristics of Fuji apple fruits stored at 2 °C for 9 months in air were investigated. The soluble solid content, titratable acidity (TA), sugars, sorbitol, organic acids, and phenolic compounds were evaluated in this study. We also determined volatile profiles using headspace solid-phase microextraction and gas chromatography–mass spectrometry. Instrumental textural properties and descriptive sensory analysis were also conducted in this study. The correlation coefficients between physicochemical and sensory properties were investigated. In comparison with the untreated apples, those treated with 1-MCP exhibited higher acidity (i.e., higher TA and organic acids), antioxidant total polyphenol content, sum of individual polyphenol content, force linear distance, lower volatile content, b* (yellowness), and fructose and sucrose levels, after long-term cold storage. A significant difference was observed in sensory attributes such as red color of apple peel, textural properties (with peel and without peel), sweet taste, and sour taste between 1-MCP-treated and untreated apples. Sensory attributes related to textural properties (i.e., P_Hardness and Crunchiness) showed positive correlation with instrumental textural properties (force peak and force linear distance) (p < 0.05). A significant positive correlation was observed between red color of apple peels (sensory attribute) and a* (redness) (p < 0.05) and between sour taste and shikimic acid (p < 0.05).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

An estimated worldwide yearly production of apples is 63 million tons [1]. As apples are ripened, the respiratory rate and ethylene production are dramatically increased [2]. High level of ethylene affects apple quality and may cause fruit softening. Thus, maintaining apple quality is of great interest to retain the freshness of apple fruits. Ethylene perception inhibitor, 1-methylcyclopropene (1-MCP), has been extensively used to delay fruit ripening in global market. By binding to its receptors, 1-MCP inhibits ethylene activity, thereby prolonging the freshness of apples [3, 4]. 1-MCP treatment is known to prolong apple freshness during storage by helping apple pulp firmness retention, reducing wound rates, maintaining soluble solid content (SSC, °Brix) and titratable acidity (TA), and suppressing aroma volatile production [2, 5,6,7]. These factors determine the overall quality of apples quality.

Apples are excellent sources of antioxidant phenolic compounds, including catechin, procyanidin, phloridzin, quercetin, caffeic acid, and chlorogenic acid [8, 9]. The polyphenolic composition depends on cultivar [9, 10]. During cold storage, antioxidant activity of 1-MCP-treated ‘Empire’ and ‘Delicious’ apple peels was higher than that of untreated apple peels [11]. In comparison with the untreated ‘Delicious’ apple peels, those treated with 1-MCP showed higher total flavonoid levels but lower chlorogenic acid level [12]. 1-MCP-treated ‘Empire’ apple peels had higher total phenolic concentrations than untreated counterparts [13]. However, 1-MCP-treated ‘Empire’ apple pulp displayed lower total phenolic concentrations than the untreated ‘Empire’ apple pulp [13]. Thus, 1-MCP treatment may affect the nutritional qualities of apple fruits. Post-harvest conditions affect sugar contents and acidity of apples.

Studies on the sensory assessment of 1-MCP-treated apple fruits after long-term cold storage are limited. Sensory attributes such as odor, taste, and texture were retained for 1-MCP-treated ‘Anna’ apples stored for only 5 weeks at 0 °C [14]. A study determined consumer responses to 1-MCP-treated apples stored for 6 months [15] and evaluated SSC, TA, and volatiles but not descriptive sensory analysis.

The effect of 1-MCP treatment on apple quality parameters including individual organic acids, sugars, polyphenolic composition, and aromatic volatiles is unclear. Moreover, there is little information available on the 1-MCP treatment effect on sensory perception of these physicochemical properties.

In this direction, the present study was conducted with the following objectives: (1) to determine the 1-MCP treatment effect after long-term cold (air) storage on individual organic acids, sugars, polyphenolic composition, volatile aroma, and textural properties, and (2) to investigate the correlation between physicochemical and sensory properties.

Materials and methods

Reagents

Chlorogenic acid, epicatechin, catechin, quercetin aglycone, phloridzin dihydrate, and rutin were obtained from Sigma-Aldrich (MO, USA). Cyanidin-3-O-arabinoside, cyanidin-3-O-galactoside, cyanidin aglycone, quercetin-3-O-rhamnoside, quercetin-3-O-glucoside, quercetin-3-O-galactoside, and quercetin-3-O-arabinoside were purchased from Extrasynthese (Genay, France). High-performance liquid chromatography (HPLC)-grade acetonitrile and methanol were supplied by Burdick and Jackson (Muskegon, MI, USA). Other reagents used were obtained from Sigma-Aldrich (St. Louis, MO, USA) and Junsei (Tokyo, Japan).

Apple samples and storage

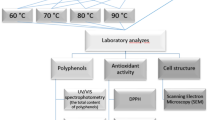

‘Fuji’ (Malus domestica Borkh.) apples were purchased from Chung-Ju Apple grower’s Agricultural Cooperative in South Korea. All fruits were harvested from early to mid-November, 2014. Based on soluble solids content, harvested apple fruits were at commercial maturity stage [16]. Apples with uniform size were selected for this study. Apples were stored overnight at 0–2 °C before 1-MCP treatment. 1-MCP treatment was performed in Korea Food Research Institute. Half of the apple samples were treated with 1 μL/L 1-MCP (Dongbu Farm Hannong, Korea) for 24 h at 0–2 °C in sealed 135-L containers. 1-MCP at 1 μL/L is known to be effective for most apple varieties [17]. Five replicates of 100 fruits for 1-MCP-treated and untreated samples were stored for 9 months at 2 °C in air. Randomly selected apple fruits from each replicate were used to make a composite sample of 1-MCP-treated or untreated apples for each analysis.

Analysis of color

Hunter a*, b*, and L* parameters were determined using a colorimeter (Chroma Meter, CR-400, Minolta Co., Ltd., Osaka, Japan). Calibration of the colorimeter was conducted using the manufacturer’s standard white tile (L = 98 a = −0.49, b = 1.96). The color was analyzed on six points on the surface of each fresh apple, including the upper (around apple stem end), middle, and bottom (around apple blossom end) parts. Fifteen apples were measured for color analysis.

The total color difference (ΔE*) between apples before and after 9-month air (cold) storage (control or 1-MCP-treated) was calculated using below equation:

ΔE* lower than 1 indicated no obvious color difference for human eyes. ΔE* higher than 3 indicated an obvious color difference for human eyes.

Analysis of pH, soluble solid content (SSC), and titratable acidity (TA)

Apple juice was produced using a juicer (Angel juicer, Angelia, Korea); the juice was centrifuged with 10,621×g at 4 °C for 20 min. The supernatant was filtered through a 0.2-μm membrane filter for the analysis of pH, SSC, and TA. SSC (°Brix) was measured with a refractometer (PR-32a, ATAGO, Tokyo, Japan) using diluted apple juice. TA was determined by titrating the juice with 0.1 N NaOH solution to reach pH 8.2 [19]. The TA result was expressed as g malic acid/mL juice.

Organic acids and sugar analysis

Organic acids (citric acid, malic acid, and shikimic acid) and sugars (fructose, glucose, sucrose, and sorbitol) were analyzed in the apple juice. Briefly, apple juice was centrifuged at 10,621×g at 4 °C for 20 min, followed by tenfold dilution. The supernatant was filtered through a 0.2-μm PTFE filter. Determination of organic acids was performed by HPLC system (Jasco, Japan) equipped with a quaternary pump (PU-2089 plus), a thermostated column compartment (CO-2060plus), an autosampler (AS-2051plus), and a UV detector (2075plus) at 210 nm wavelength. Separation of organic acids was performed on a Grace Prevail Organic Acid column (4.6 mm × 150 mm, 5 μm). Column temperature was 40 °C. The mobile phase used was 25 mM K2HPO4 (pH 2.8) with the flow rate of 0.8 mL/min. Injection volume was 20 μL.

Sugar levels were analyzed using an Agilent 1260 Infinity HPLC system (Germany) equipped with a quaternary pump (G1311B), a thermostated column compartment (G1330B), an autosampler (G1329B), and a RI detector (G1362A). Injection volume was 10 μL. Separation of sugars was performed on an YMC-Pack Polyamine II (4.6 mm × 250 mm, 5 μm) column. Column temperature was 35 °C. The mobile phase used was acetonitrile:water [75:25 (v/v)] with the flow rate of 1 mL/min.

Extraction for measuring total phenolic and flavonoid contents and antioxidant activity

Apple peels were separated using a fruit and vegetable peeler (Rotato Express, B2NE, Zhejiang, China) after coring apples to remove the core and pips from apples. The thickness of peel was 1.6 mm. Apple samples were dipped in liquid nitrogen immediately after separating peel from the pulp. Frozen samples were crushed into coarse pieces. Peel and pulp were freeze-dried using an FD5510 lyophilizer (Ilshin Lab Co., Ltd., Korea). The freeze-dried samples were vacuum-sealed and stored at −80 °C until analysis.

The freeze-dried apple powder sample (0.5 g) was homogenized in 10 mL methanol for 1 min and ultrasonicated for 15 min. The extract was centrifuged at 10,621×g at 4 °C for 15 min. The supernatant was filtered through a 0.20-μm PTFE filter. The extraction process was performed in triplicates. Extracts were divided into several aliquots and stored for 0–1 days at −80 °C until use.

Determination of total phenol content

By the modified Folin–Ciocalteu colorimetric method [20], the total phenolic concentration of the extract was measured in apple peel and pulp. Briefly, 40 μL diluted apple extract was mixed with 50 μL 1 N Folin–Ciocalteu reagent and incubated for 1 min. Then, 160 μL 2% sodium carbonate solution was added and incubated at 25 °C for 30 min in dark. The absorbance was monitored at 700 nm, and the result was expressed as μg gallic acid equivalent/g sample on dry weight basis (μg/g).

Determination of total flavonoid content

The total flavonoid concentration in the apple extract was measured by modified method of Morena et al. [21]. Briefly, 500 μL diluted apple extract was mixed with 100 μL 1 M aqueous potassium acetate and 100 μL 10% aluminum nitrate and incubated for 40 min at room temperature. Its absorbance was measured at 415 nm. And the results were expressed as quercetin equivalent on dry weight basis (DW) (μg/g).

Antioxidant activity estimation with 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS) assay

The total antioxidant activity of apple samples was measured using the ABTS radical scavenging assay [22, 23]. Briefly, 40 μL apple extract was mixed with 300 μL ABTS solution. The absorbance decrease was recorded at 734 nm. Results were expressed as μg Trolox equivalent/g apple sample DW (μg/g).

Determination of phenolic composition by UHPLC

The phenolic extraction and chromatographic separation were performed using a previously described method with slight modifications [24]. Briefly, 10 mL 80% methanol was added to 0.3 g of freeze-dried apple peel or pulp powder and sonicated for 15 min [25]. The sample was centrifuged for 10 min at 10,621×g at 4 °C, and the supernatant was dried under vacuum. Before analysis, the dried sample was reconstituted in 1 mL 1% formic acid in water. The extract was filtered through a 0.22-μm PTFE filter. Until analysis, the extracts were stored for 0–1 days at −20 °C.

Analysis of all extracts of pulp and peel was performed on an Acquity UPLC H-class UHPLC system (Waters, Eschborn, Germany). The injection volume was 10 μL. Separations of phenolic compounds were performed on an Acquity UPLC HSS T3 column (2.1 mm × 150 mm, 1.8 μm). The mobile phase comprised a gradient of 1% formic acid in water (A) and 1% formic acid in acetonitrile (B) as follows: 0–3 min, 5–18% B; 3–6 min, 18–20% B; 6–9 min, 20% B, 9–15 min, 20–45% B; 15–17 min, 45–95%. The flow rate was 0.4 mL/min. Phenolic compounds in apple samples were identified with the comparison of absorption spectra (200–495 nm) and retention time between unknown peaks and authentic standard peaks. Flavan-3-ol (catechin and epicatechin) and dihydrochalcone (phloridzin) were monitored at 280 nm; flavonols (rutin, quercetin-3-O-arabinofuranoside, quercetin-3-O-rhamnoside, quercetin-3-O-galactoside, and quercetin aglycone) at 360 nm; phenolic acid (chlorogenic acid) at 320 nm; and anthocyanins (cyanidin-3-O-arabinoside, cyanidin-3-O-galactoside, and cyanidin aglycone) at 499 nm. Quantification of all polyphenol compounds was achieved using commercial standards.

The quantification range for cyanidin-3-O-galactoside, chlorogenic acid, cyanidin-3-O-arabinoside, epicatechin, and phloridzin was 5–50 ppm, while that for catechin, cyanidin aglycone, rutin, quercetin-3-O-glucoside, quercetin-3-O-galactoside, quercetin-3-O- quercetin-3-O-rhamnoside, arabinofuranoside, and quercetin aglycone was 5–100 ppm. The linearity of all compounds (R 2) was over 0.99. Apple extracts that exceeded the linear range of the standard curve were diluted before injection. Spike recovery test was performed by adding known amount of standards to apple samples before extraction. The amount of standard added was equivalent to that reported in apples.

Analysis of textural properties

Textural properties of apple samples were analyzed using HD plus Texture Analyzer (Stable Micro Systems, Godalming, UK) with a pin as previously described [26]. Two parameters (force peak and force linear distance) were calculated for the recorded data. ‘Force peak’ is counted force peaks calculated above 10 g threshold, and ‘force linear distance’ is the force curve length after pericarp puncture [26]. We chose 30 fruits for each treatment.

Volatile analysis

A 1-cm 50/30 µm solid-phase microextraction (SPME) fiber assembly coated with divinylbenzene/carboxen/polydimethylsiloxane (Supelco, Inc., Bellefonte, PA) was used for volatile analysis. Equilibration time was 5 min, and the SPME fiber extraction time was 30 min in the headspace of the vial containing 1 mL apple juice at room temperature (24 ± 1 °C). Following headspace extraction, SPME fibers were injected into gas chromatography (GC) and retained in the GC inlet for 1 min.

Volatile analysis was performed using gas chromatography–mass spectrometry (GC/MS) on a HP 6890 coupled to an Agilent 5973 mass selective detector (Agilent, Palo Alto, CA). Compounds were separated on a HP-5 ms column (30 m × 0.25 mm i.d., 0.25 µm film thickness, Agilent Technologies) by applying following temperature program: 40 °C for 3 min, increased to a final temperature of 165 °C at 5 °C/min. Sample injection was performed in split mode (10:1), and the injector temperature was 250 °C, with helium (99.999%) as a carrier gas at a flow rate of 1.0 mL/min. The transfer line, MSD source, and quadrupole temperatures were set to 280, 230, and 150 °C, respectively. Total ion chromatograms were collected in the ion range of 35 to 400 m/z.

Volatile compounds were tentatively identified by comparing the Kovats retention indices (K.I.) and/or mass spectrum with those reported in the NIST Mass Spectral Search Program (version 2.0 a) with <80% marked as a cutoff to match compounds. The K.I. was calculated from the retention time of C6–C40 n-alkanes. All analyses were performed in triplicate. The relative quantification of each volatile compound was performed on peak area/1000.

Descriptive sensory analysis

The descriptive sensory analysis was performed on apple samples from each treatment group (control and 1-MCP). Fifteen trained sensory panelists were recruited from the Korean Food Research Institute. There were six replicates per panelist; thus, a total number of 90 samples per treatment were analyzed. All evaluations were performed in sensory booths. To determine the appearance of apples with peel, whole-apple samples without peel nor cut was provided. To determine the rest of sensory attributes, three slices from each treatment, after cutting as a wedge form from apple stem to blossom end, were provided to each panelist in a white plastic cup with lid. Each cup was labeled with random three-digit code. Apple samples were provided in random order, and the slices were served with a cup of water to rinse mouths after tasting samples. To prevent browning reactions, apple slices were dipped into 0.2% ascorbic acid, 0.2% citric acid, and 0.5% chloride solution for 1 s and remaining water was removed before providing apple samples to panelists. Reference materials and a summary of attributes were provided to every booth.

Statistical analysis

Statistical analysis was performed using IBM SPSS statistics software (version 20.0, SPSS, Inc., Chicago, IL). Means and SD values were determined, and data are presented as mean ± SD. Significant differences between 1-MCP-treated and untreated apples in the same tissues (i.e., peel or pulp) were determined using an independent t test at p < 0.05. Associations between sensory attributes and physicochemical values were performed by Pearson’s correlation coefficient analysis at p < 0.05.

Results and discussion

Basic chemical measurements

Both 1-MCP-treated and untreated Fuji apples were evaluated for fruit weight (g), SSC (°Brix), TA, and ratio of SSC to TA after 9-month cold storage (Table 1). Moisture content and SSC were not significantly different (p < 0.05) between the 1-MCP-treated and untreated Fuji apples, consistent with that reported by Rupasinghe et al. [5] in McIntosh and Delicious apples exposed to 1-MCP treatment. However, 1-MCP-treated apples showed significantly higher TA (0.46 g malic acid/100 g) compared to the untreated apples (0.39 g malic acid/100 g) (p < 0.05). The higher TA values for 1-MCP-treated apples showed lower SSC/TA ratio as compared to the untreated apples. Improved TA was also reported in 1-MCP-treated and stored Fuji, Gala, Delicious, Ginger Gold, and Jonagold apples, as compared to TA in untreated apples [6, 27]. The 1-MCP acts as an ethylene inhibitor and thus suppresses respiration of apple fruits [2]. Reduced respiration may reduce loss of malic acid and improve TA value retention.

Sugar and organic acid analysis

Sugar (fructose, glucose, sucrose, and sorbitol) and organic acid (citric acid, malic acid, and shikimic acid) levels were determined in apple samples (Table 2). Sugars and malic acid are major substrates during aerobic respiration in apple fruits after harvest, leading to their consumption during storage. Sugars, organic acids, and sugar–acid balance are key components that determine the sweetness and sourness of apple fruits. Thus, the analysis of sugars and acids in apple fruits is crucial to understand the change in the apple quality during storage.

Total sugar refers to the sum of fructose, glucose, sucrose, and sorbitol. Fructose was the major sugar regardless of 1-MCP treatment (7.27–7.74 g/100 g FW). Fructose and sucrose levels were significantly lower in 1-MCP-treated apples as compared to those in untreated apples (p < 0.05), indicating that 1-MCP treatment fails to prevent sugar loss in apple fruits.

In comparison with the untreated apples, those treated with 1-MCP showed significantly higher organic acid content (p < 0.05), consistent with that observed by Bizjak et al. [3].

Total flavonoids and phenolics, antioxidant activity in the peel and pulp of apples

Recently, many studies have determined the effect of 1-MCP treatment on antioxidant phenolic compound contents [12, 28]. The effect of 1-MCP on phenolic compounds varied with the apple cultivar type, post-harvest treatment, and storage conditions [29].

In comparison with the untreated apples, those treated with 1-MCP showed significantly higher values of total phenolics (peel and pulp), total flavonoids (peel), and ABTS (peel and pulp) (p < 0.001) (Table 3). Peels from 1-MCP-treated apples showed approximately 1.4-fold and 1.7-fold higher levels of total phenolics and total flavonoids, respectively, as compared to peels from the untreated apples. The effect of 1-MCP treatment on total phenolics and flavonoids varies with cultivars and tissues [6, 13]. Lu et al. [6] showed improved retention of total flavonoids in 1-MCP-treated apples after storage. On the contrary, retention of total phenolics was reduced in 1-MCP-treated Cripps Pink apple pulp [30]. Most of these studies failed to determine the individual polyphenol content in 1-MCP-treated and untreated apples after storage. Although the total phenolic content of apples may be stable, individual phenolic (flavonoid) content may vary during storage. The antioxidant potential depends on individual phenolic compounds, which may explain the overall antioxidant activities [31].

Analysis of phenolic compounds in apple peels and pulp

The individual phenolic composition in apple samples was determined using UHPLC (Table 4). Flavan-3-ols, dihydrochalcone, phenolic acid, anthocyanins, and flavonols in the 1-MCP-treated and untreated apple peels and pulp after storage were characterized by UHPLC. Typical chromatograms of an apple peel extract are given in Fig. 1. Levels of catechin, epicatechin, phloridzin, chlorogenic acid, rutin, quercetin-3-O-galactoside, quercetin-3-O-glucoside, quercetin-3-O-arabinoside, and quercetin-3-O-rhamnoside in the peel of apples ranged from 145–155, 69–70, 24–29, 100–105, 63–69, 181–220, 32–35, 85–111, and 56–72 μg/g dry weight (DW), respectively, while those of cyanidin-3-O-galactoside, cyanidin-3-O-arabinoside, cyanidin aglycone, and quercetin aglycone were 32, 3, 5, and 4 μg/g DW, respectively.

Representative UHPLC chromatogram of apple peel extract (control) monitored at 280, 320, 360, and 495 nm. Peaks correspond to (1) cyanidin-3-O-galactoside, (2) chlorogenic acid, (3) catechin, (4) cyanidin-3-O-arabinoside, (5) epicatechin, (6) cyanidin aglycone, (7) rutin, (8) quercetin-3-O-galactoside, (9) quercetin-3-O-glucoside, (10) quercetin-3-O-arabinofuranoside, (11) quercetin-3-O-rhamnoside, (12) phloridzin, and (13) quercetin aglycone

Only epicatechin, catechin, phloridzin, chlorogenic acid, rutin, and quercetin aglycone were detected in the pulp. Anthocyanins and quercetin glycosides such as cyanidin-3-O-galactoside, cyanidin-3-O-arabinoside, cyanidin aglycone, quercetin-3-O-arabinoside, quercetin-3-O-galactoside, quercetin-3-O-glucoside, and quercetin-3-O-rhamnoside were undetected in the pulp from both 1-MCP-treated and untreated apples. Apple peels are major sources of quercetin glycoside [32], consistent with our observations. Levels of catechin, epicatechin, phloridzin, and chlorogenic acid in the pulp of apples ranged from 116–134, 26–28, 8–10, and 100–108 μg/g DW, respectively. Levels of rutin, quercetin-3-O-galactoside, and quercetin aglycone were 1, 2, and 4 μg/g DW, respectively.

There was no significant difference between 1-MCP-treated and untreated apples in levels of most phenolic compounds (p < 0.05). However, the sum of flavan-3-ols, dihydrochalcone, phenolic acids, anthocyanins, and flavonols in pulp and peels of 1-MCP-treated apples was significantly higher than that in the pulp and peels of untreated apples (p < 0.05). In particular, levels of catechin and chlorogenic acid in 1-MCP-treated apple pulp were significantly higher than those in untreated apple pulp (p < 0.05). Flavonoids are known to protect oxidation of vitamins C and E during food storage [33]. Thus, the high phenolic content of 1-MCP-treated apple fruits may contribute to the improved retention of freshness and storage ability of apples.

Hunter color values (L*, a*, and b*) and textural properties of apple samples

No significant difference was observed in Hunter color values of L* and a* for peel surface from 1-MCP-treated and untreated apples (p < 0.05). However, b* (yellowness) values were significantly lower for 1-MCP-treated apples (Table 5). L*, a*, and b* of harvested apples before storage were 47.3 ± 3.9, 21.1 ± 2.6, and 19.2 ± 2.5, respectively.

The total color difference (ΔE*) between harvested apples and 1-MCP-treated stored apples was 1.1. ΔE* between harvested apples and untreated apples (stored for 9 months without 1-MCP treatment) was 3.0. Thus, color retention was improved for 1-MCP-treated apples.

Crispness is associated with the freshness of apples and evaluated from force peak and force linear distance [26]. The force linear distance value for 1-MCP-treated samples was significantly higher (2677.1 ± 256.9) than that for the control apples (1555.8 ± 253.8) (p < 0.001).

Volatile analysis of apple samples

Volatile compounds are indicators of apple quality [2]. Figure 2 shows volatile profiles of 1-MCP-treated and untreated apples. These volatile compounds may be grouped into alcohols (butanol, 2-methyl-1-butanol, and hexanol) and esters (ethyl 2-methylbutanoate, 2-methylbutyl acetate, butyl propanoate, butyl butanoate, hexyl acetate, butyl 2-methylbutanoate, 2-methylbutyl 2-methylbutanoate, hexyl butanoate, hexyl 2-methylbutanoate, and hexyl hexanoate).

In comparison with the untreated apples, those treated with 1-MCP exhibited significantly reduced levels of volatile compounds such as butanol, ethyl 2-methylbutanoate, hexanol, butyl propanoate, butyl butanoate, hexyl acetate, butyl 2-methylbutanoate, hexyl butanoate, hexyl 2-methylbutanoate, and hexyl hexanoate (p < 0.05). This observation is in agreement with that previously reported in Gala and Empire apples [15, 28]. 1-MCP treatment inhibits fruit ripening during storage, leading to decreased production of alcohols, aldehydes, and esters during ripening [15, 28]. However, 1-MCP-treated apples showed higher level of 2-methyl-1-butanol as compared to control apples (p < 0.01).

Apple sensory attributes

The descriptive sensory attributes such as appearance, aroma, texture, and taste of stored apple samples were analyzed by panelists (Table 6). Mean intensity scores for significant sensory attributes of 1-MCP-treated and untreated samples after long-term cold storage are shown in Table 7. There was no difference in the mean intensity score for apple pulp color, aroma, juice taste, astringent taste, and crispness between 1-MCP-treated and untreated samples. Although the crispness value for 1-MCP-treated apples (6.5 ± 1.5) was higher than that for untreated apples (4.4 ± 1.5), the difference was not significant (p < 0.05). Although the panelists failed to recognize the crispness difference between samples, differences were observed for textural properties between samples as shown above. Previous studies have reported the beneficial effect of fruit firmness after 1-MCP treatment [3, 4].

In comparison with untreated apples, those treated with 1-MCP showed higher score for hardness and glossiness and lower score for dryness and wounding of apple peel (p < 0.05), indicative of fruit freshness. Similar results were reported for pulp samples, wherein 1-MCP-treated pulps showed higher score for hardness, juiciness, and crunchiness and lower score for flouriness (p < 0.05). In comparison with untreated apples, those treated with 1-MCP exhibited less sweet but sourer taste.

Correlation coefficients between sensory attributes and physicochemical parameters

Correlation coefficients between physicochemical parameters and sensory attributes are shown in Tables 8, 9, 10, 11, and 12. No significant correlation was observed between moisture, SSC, and L* and any sensory attributes (p < 0.05). Textural parameters were significantly correlated with many sensory attributes. In particular, force linear distance showed a significant positive correlation with P_Hardness (r = 0.869), P_Glossiness (r = 0.833), and Crunchiness (r = 0.750), while they exhibited a significant negative correlation with P_Dryness (r = −0.782) and P_Wounding (r = −0.867) (p < 0.05). Firmness-related sensory attributes such as P_hardness and crunchiness were correlated with force linear distance. 1-MCP-treated apples displayed a firm texture that correlated with force linear distance. 1-MCP treatment may suppress ethylene production and delay the flesh firmness loss, resulting in changes in sensory characteristics.

Among organic acids and sugar contents, citric acid and sorbitol showed no significant correlation with any sensory attributes (p < 0.05). Although 1-MCP-treated apples showed lower acidity (higher organic acid content) than untreated apples, the sour taste showed no significant correlation with malic acid that is the major organic acid in apples. However, a significant positive correlation was recorded between sour taste and shikimic acid (r = 0.430, p < 0.05). TA also showed positive correlation with these sensory attributes (p < 0.05). Thus, apples with high acidity showed better freshness-related sensory attributes. Sweet taste showed no correlation with any sugars.

Phenolic compounds are responsible for astringency, bitterness, and color of fresh apples and processed products [34]. In comparison with the untreated apples, 1-MCP-treated apples showed significantly higher levels of total phenolics, total flavonoids, and several individual polyphenol compounds. However, no significant difference in astringency and color of pulp was observed between treatment groups. Total phenolics (peel and pulp), total flavonoids (peel), and ABTS (peel and pulp) showed positive correlation with P_Hardness, P_Glossiness, and Crunchiness and negative correlation with P_Red, P_Dryness, and P_Wounding (p < 0.05). Negative correlation was shown for phloridzin (peel), chlorogenic acid (peel), and catechin (pulp) (p < 0.05).

There was no significant difference for aroma-related sensory attributes between 1-MCP-treated and untreated apples. Hence, the correlation between volatile compounds and sensory attributes was not analyzed.

In summary, 1-MCP-treated apples contained significantly higher TA, organic acids, antioxidant polyphenolics, textural parameters (force linear distance), lower sugars, volatile contents, and b* (yellowness) as compared to the untreated apples after 9-month storage. Sensory attributes such as pulp color (yellowness and greenness), aroma (sweet aroma and apple juice aroma), juice taste, astringent taste, and crispness showed no significant difference between 1-MCP-treated and untreated apples. However, the red color of apple peel, textural properties (with peel and without peel), sweet taste, and sour taste were significantly different between 1-MCP-treated and untreated apples. In addition, a positive correlation was observed between sensory attributes related to textural properties such as P_Hardness and Crunchiness and force peak as well as force linear distance (p < 0.05). A significant positive correlation was shown between red color of apple peels and a* (redness) (p < 0.05) and sour taste and shikimic acid.

References

Yara North America. World Apple Production. http://www.yara.us/agriculture/crops/apple/key-facts/world-apple-production/

Watkins CB (2006) The use of 1-methylcyclopropene (1-MCP) on fruits and vegetables. Biotechnol Adv 24:389–409

Bizjak J, Slatnar A, Stampar F, Veberic R (2012) Changes in quality and biochemical parameters in ‘Idared’ apples during prolonged shelf life and 1-MCP treatment. Food Sci Technol Int 18:569–577

Tatsuki M, Endo A, Ohkawa H (2007) Influence of time from harvest to 1-MCP treatment on apple fruit quality and expression of genes for ethylene biosynthesis enzymes and ethylene receptors. Postharvest Biol Technol 43:28–35

Rupasinghe H, Murr D, Paliyath G, Skog L (2000) Inhibitory effect of 1-MCP on ripening and superficial scald development in ‘McIntosh’ and ‘Delicious’ apples. J Hortic Sci Biotechnol 75:271–276

Lu X, Ma Y, Liu X (2012) Effects of maturity and 1-MCP treatment on postharvest quality and antioxidant properties of ‘Fuji’ apples during long-term cold storage. Hortic Environ Biotechnol 53:378–386

Watkins CB (2007) The effect of 1-MCP on the development of physiological storage disorders in horticultural crops. Stewart Postharvest Rev 3:1–6

Boyer J, Liu RH (2004) Apple phytochemicals and their health benefits. Nutr J 3:5–19

Lee J, Chan BLS, Mitchell AE (2017) Identification/quantification of free and bound phenolic acids in peel and pulp of apples (Malus domestica) using high resolution mass spectrometry (HRMS). Food Chem 215:301–310

Wojdyło A, Oszmiański J, Laskowski P (2008) Polyphenolic compounds and antioxidant activity of new and old apple varieties. J Agric Food Chem 56:6520–6530

MacLean DD, Murr DP, DeEll JR (2003) A modified total oxyradical scavenging capacity assay for antioxidants in plant tissues. Postharvest Biol Technol 29:183–194

MacLean DD, Murr DP, DeEll JR, Horvath CR (2006) Postharvest variation in apple (Malus × domestica Borkh.) flavonoids following harvest, storage, and 1-MCP treatment. J Agric Food Chem 54:870–878

Watkins CB, Nock JF, Whitaker BD (2000) Responses of early, mid and late season apple cultivars to postharvest application of 1-methylcyclopropene (1-MCP) under air and controlled atmosphere storage conditions. Postharvest Biol Technol 19:17–32

Pre-Aymard C, Fallik E, Weksler A, Lurie S (2005) Sensory analysis and instrumental measurements of ‘Anna’ apples treated with 1-methylcyclopropene. Postharvest Biol Technol 36:135–142

Marin AB, Colonna AE, Kudo K, Kupferman EM, Mattheis JP (2009) Measuring consumer response to ‘Gala’ apples treated with 1-methylcyclopropene (1-MCP). Postharvest Biol Technol 51:73–79

Drake S, Elfving D, Eisele T (2002) Harvest maturity and storage affect quality of Cripps Pink’ (Pink Lady®) apples. Hort Technol 12:388–391

Blankenship SM, Dole JM (2003) 1-Methylcyclopropene: a review. Postharvest Biol Technol 28:1–25

Francis FJ, Clydesdale FM (1975) Food colorimetry: theory and applications. AVI Publishing Co., Inc, Westport

Xu K, Wang A, Brown S (2012) Genetic characterization of the Ma locus with pH and titratable acidity in apple. Mol Breed 30:899–912

Singleton V, Rossi JA (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic 16:144–158

Moreno MIN, Isla MI, Sampietro AR, Vattuone MA (2000) Comparison of the free radical-scavenging activity of propolis from several regions of Argentina. J Ethnopharmacol 71:109–114

Arnao MB, Cano A, Acosta M (2001) The hydrophilic and lipophilic contribution to total antioxidant activity. Food Chem 73:239–244

Thaipong K, Boonprakob U, Crosby K, Cisneros-Zevallos L, Hawkins Byrne D (2006) Original article: comparison of ABTS, DPPH, FRAP, and ORAC assays for estimating antioxidant activity from guava fruit extracts. Food Compos Anal 19:669–675

Jakobek L, García-Villalba R, Tomás-Barberán FA (2013) Polyphenolic characterisation of old local apple varieties from Southeastern European region. J Food Compos Anal 31:199–211

Kim MJ, Kim JH, Kim JH, Kim YJ (2015) Comparative studies on the antioxidant capacities and catechin profiles of conventional and organic green tea. J Korean Soc Appl Biol Chem 58:475–480

Park DJ, Chun YG, Lee SH, Lee SJ, Kim BK (2016) Development of teeth probe for analysis of correlation between mechanical and sensory properties of apples. J Texture Stud 47:523–529

Fan X, Blankenship SM, Mattheis JP (1999) 1-Methylcyclopropene inhibits apple ripening. J Am Soc Hortic Sci 124:690–695

Lee J, Rudell DR, Davies PJ, Watkins CB (2012) Metabolic changes in 1-methylcyclopropene (1-MCP)-treated ‘Empire’ apple fruit during storage. Metabolomics 8:742–753

van der Sluis AA, Dekker M, de Jager A, Jongen WM (2001) Activity and concentration of polyphenolic antioxidants in apple: effect of cultivar, harvest year, and storage conditions. J Agric Food Chem 49:3606–3613

Hoang NT, Golding JB, Wilkes MA (2011) The effect of postharvest 1-MCP treatment and storage atmosphere on ‘Cripps Pink’ apple phenolics and antioxidant activity. Food Chem 127:1249–1256

Awad MA, de Jager A (2003) Influences of air and controlled atmosphere storage on the concentration of potentially healthful phenolics in apples and other fruits. Postharvest Biol Technol 27:53–58

Lee J, Mitchell AE (2012) Pharmacokinetics of quercetin absorption from apples and onions in healthy humans. J Agric Food Chem 60:3874–3881

Miller NJ, Ruiz-Larrea MB (2002) Flavonoids and other plant phenols in the diet: their significance as antioxidants. J Nutr Environ Med 12:39–51

Lea AG (1992) Flavor, color, and stability in fruit products: the effect of polyphenols. Plant polyphenols. Springer, Berlin, pp 827–847

Acknowledgments

The Korea Food Research Institute (Grant No. E0132200-05) provided financial support for this study. This research was supported by the Chung-Ang University Research Grants in 2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J., Jeong, MC. & Ku, KH. Chemical, physical, and sensory properties of 1-MCP-treated Fuji apple (Malus domestica Borkh.) fruits after long-term cold storage. Appl Biol Chem 60, 363–374 (2017). https://doi.org/10.1007/s13765-017-0288-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13765-017-0288-6