Abstract

Iranian sour cherries (Prunus cerasus) were coated with fresh Aloe vera gel or treated with hot water (40 ± 2 °C) for 2 min and stored for 17 days at 4 ± 1 °C. The physicochemical characteristics of gel coated and hot water treated samples were compared with untreated fruit during the cold storage period. Untreated fruit showed increased respiration rate, rapid weight loss and colour change, accelerated aging and ripening. On the contrary, sour cherries, particularly those coated with gel significantly delayed the above mentioned parameters allowing a fruit storability extension. The sensory analysis in both treatments revealed beneficial effects in terms of delaying dehydration, maintenance of fruit visual aspect without any detrimental effect on taste, aroma or flavours. Consequently, Aloe vera gel coating and immersion in hot water maintained the properties during postharvest storage of sour cherries and could be introduced as two valuable, simple and non-contaminating treatments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sour cherry is one of the most appreciated fruit by consumers in Iran due to its exquisite taste. Skin colour (Serrano et al. 2005), total soluble solid and acidity ratio (TSS/TA) are the main quality parameters of sour cherries and both determine consumer acceptance (Crisosto et al. 2003). Sour cherries deteriorate rapidly as consequence of weight loss, colour changes, softening, surface pitting and loss of acidity (Bernalte et al. 2003). Several postharvest technologies have been used to control decay, but the postharvest use of chemicals as fungicides is restricted in most countries and consumers demand agricultural commodities without pesticide residues (Wilcock et al. 2004).

Edible coatings are used to improve food appearance and conservation and act as barriers during processing, handling and storage. They do not solely retard food deterioration or enhance its quality, but also are safe due to natural biocide activity, or due to the incorporation of antimicrobial compounds (Petersen et al. 1999). Different compounds have been used as edible coatings to prevent commodity weight loss, including wax, milk proteins, cellulose, lipids, starch, zein, and alginate (Cha and Chinnan 2004). Derivatives of fatty acids and polysaccharides decreased sweet cherry fruit respiration rate and weight loss (Alonso and Alique 2004). In addition, edible coatings based on chitosan alone or in combination with hypobaric treatments reduced postharvest decay in sweet cherry (Romanazzi et al. 2003). Currently, there is an increasing interest in the use of Aloe vera gel in the food industry, being used as a source of functional foods in drinks, beverages and ice creams (Moore and MacAnalley 1995).

Mild heat treatment has recently emerged as a potential alternative to chemical treatment in maintaining quality of fresh products. Researchers found that a mild heat treatment was beneficial to maintain the quality of packaged fresh pears (Abreu et al. 2003), and retain texture in fresh-cut cantaloupes (Lamikanra et al. 2005). The mechanism by which a heat treatment maintained quality of fresh produce is believed to be associated with the synthesis of a heat shock protein (Loaiza-Velarde et al. 2003). Loaiza-Velarde and Saltveit (2001) found that a hot water treatment at 50◦C for 90 s, applied either after or before cutting, effectively inhibited lettuce and celery browning by diverting protein synthesis to heat shock protein and phenylalanine ammonia-lyase. There are also studies reporting that a mild heat treatment significantly reduced the decline of peroxidase and/or super oxide dismutase activities of grapes (Kou et al. 2006) and inhibited ripening in various fruits (Paull and Chen 2000).

The aim of this work was to investigate the effect of coating Iranian sour cherry with fresh Aloe vera gel or exposing them to hot water, on the change in physicochemical parameters relating to fruit quality during cold storage. To the best of our knowledge, this is the first work which addresses direct treatment of sour cherry with untreated inexpensive gel and hot water.

Materials and methods

Plant material and experimental design

Sour cherry (Prunus cerasus) was picked from a garden in Isfahan in July 2009 and transferred in a cool box to Shiraz for this study within 24 h of harvest. It was ensured all the fruits used in the experiments are almost the same size (average diameter approximately 15.51 ± 0.05 mm), colour and shape and they have no bruise, damage or marks. They were cleaned and sorted before storing in a refrigerator at 4 ± 1 °C. This is typically the temperature that most fruit stores keep their packaged products. One third of the sour cherries were treated in cold distilled water (15 ± 1 °C) which served as control. The other third was exposed to distilled water at 40 ± 1 °C for 2 min and allowed to cool down to room temperature before storage (Fawcett 1936). The rest was treated with pure untreated Aloe vera gel which was taken from fresh plant. The method here is to use a knife to remove the thick skin and resin of the Aloe vera leaf, leaving only the gel. All samples were air dried for 15 min before packaging made of poly ethylene terephthalate (gas and water resistant) and wrapped with low density poly ethylene (low gas resistant) and stored at 4 ± 1 °C and 65 % relative humidity (RH) in permanent darkness for 17 days. Each batch of samples weighed 100 ± 5 g (around 20 to 25 cherries). Samples were analysed for all parameters on days of 0, 3, 7, 14 and 17.

Respiration rate

CO2 production rate was measured by placing each sample in a 2 L plastic container hermetically sealed with a rubber stopper for 30 min. A respiration rate measurement device (BW Honeywell GasAlertMicro5, USA) was also placed in the container. Results were the mean±SD of three determinations for each sample expressed as mg CO2. kg-1. hr-1.

Weight loss

Weight of individual lots was recorded following treatment (day 0) and at different intervals (days 3, 7, 14 and 17) during storage. Cumulative weight losses were expressed as percentage loss of initial weight.

Colour

Colour was determined using the Hunter Lab System (LOVIBOND, RT500, England). Sour cherry colour (L *, a * and b *), was determined on two sample points on the opposite sides of the equatorial region of each sour cherry. The colour values of a∗ and b∗ were further converted into hue angle [hue=tan−1 (b/a)].

Firmness determination – penetration test

Cherry firmness was determined by penetration test, using a texture analyzer (STEVENS- 80 LFRA, STEVENS, Germany) registering the force necessary to penetrate in the fruit by a probe of 6 mm diameter mounted on the machine and moved at the rate of 0.2 mms-1. The force necessary to penetrate in the fruit and the diameter of sour cherry were measured and results were expressed as the ratio between the force and the fruit diameter (g mm−1). Results were the means for each individual fruit.

Total soluble solids content and acidity determination

Total soluble solids concentration (TSS) was determined in the juice from four individual fruit from each lot with a refractometer (Carl Zeiss, 73959, West Germany) at 20 ± 1 °C and results expressed as the means of %TSS. The pH of the juice was recorded and then titratable acidity (TA) was determined by titration with 0.1 N NaOH up to pH of 8.1, using 1 ml of diluted juice in 25 ml distilled water and results were the means expressed as grams of malic acid equivalent per 100 g fresh weight. The ratio between TSS and TA was also calculated (Martinez-Romero et al. 2006).

Sensory evaluation

A semi-trained sensory panel of 10 individuals aged 25–45 years was used to evaluate the quality attributes of sour cherries. Panellists were instructed to cleanse their mouth with distilled water, chew the sour cherry and evaluate the samples. Colour, texture and taste of sour cherries were evaluated on a ranked scale of 1–6, where 6 = very bad, 5 = bad, 4 = medium, 3 = good, 2 = very good, and l = excellent. It is noteworthy that sensory evaluation was only performed on day 17. Accordingly fruits that ranked good or higher, considered as consumable.

Statistical analysis

Data for the physical, chemical and sensory parameters were subjected to analysis of variance (ANOVA). Mean comparisons were performed using Post Hoc Multiple Comparison Duncan test to examine if differences between treatments were significant at P < 0.05. All analysis was performed with SPSS software package version 15.0 for windows. For each batch, all analysis was performed in triplicate.

Results and discussion

Respiration rate and weight loss

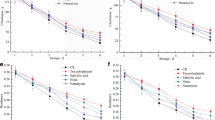

The CO2 production rate due to respiration at harvest was 13500 ± 100 mg/kg.hr, which increased over cold storage. This increase was higher in control than in Aloe-treated fruit. The final level of CO2 production in control samples, fruits exposed to hot water and Aloe vera treated samples were 14500 ± 500, 12000 ± 400 and 7500 ± 400 (mg CO2/kg.hr), respectively (Fig. 1). Aloe vera significantly could be a good barrier and have an important effect on decreasing the respiration rate of sour cherries. Hot water treatment delayed the decrease in antifungal concentrations generally observed after harvest (Prusky and Keen 1993). Decreasing the respiration rate may also be achieved through the ability of heat treatments to stabilise cell membranes, inhibit the synthesis of cell wall hydrolysing enzymes, and stimulate the production of antifungal compounds, or reduce the decrease in antifungal compounds present in harvested fruit (Schirra et al. 2000).

Weight loss was more significant for control samples than samples exposed to hot water or treated with the gel (Fig. 1). After 17 days of cold storage, the control samples lost as much as 15.52 ± 0.15 % of its initial weight. The percentage weight loss for samples treated with hot water was 14.23 ± 0.22 and for those treated with Aloe vera gel was 12.16 ± 0.19. The Aloe vera gel retarded the moisture loss and reduced respiration rates, these effects being similar to those obtained with other edible coatings (Romanazzi et al. 2003, Martinez-Romero et al. 2006). The mechanism for these positive effects is based on their hygroscopic properties, which enables formation of a barrier to water diffusion between fruit and environment, thus avoiding its external transference (Morillon et al. 2002). Similarly, the hot water treatment might retard skin damage, thus resulting in weight loss reduction.

Sour cherry quality parameters

Hue angle diminished sharply in control fruit after cold storage indicating over-ripening of fruits, which is considered detrimental, with the colour redder and darker. Contrarily, Aloe-treated and hot water treated sour cherries maintained the typical red bright colour of recently harvested fruit even after 17 days of cold storage.

The main colour changes were observed on Hue angle, which diminished during cold storage (Fig. 1). However, significant differences were found between control and treated sour cherries. A sharp reduction in hue angle was experienced by sour cherries for all untreated samples after 7th day. The hue angle was observed to be maintained during 17 days cold storage in those sour cherries coated with the gel and the samples immersed in hot water. It is more likely that hot water treatment reduced rots through reduced skin damage and improved ability to retard disease development. Thus, hot water could maintain colour during cold storage of sour cherry.

Since sour cherries lose water during storage, the texture becomes more compacted and condensed and hence some shrinkage of fruits was observed (reduced diameter from 15.51 ± 0.05 to 12.5 ± 0.2). Therefore, the higher force is required to penetrate the flesh. Aloe vera treatment was also effective in maintaining sour cherry firmness, since no significant changes were observed in treated samples from those measured at harvest. An accelerated aging process however was observed in control fruit (Fig. 1). The delayed aging observed in the treated samples could be due to the inhibitory effect of Aloe vera gel and hot water on cell wall degrading-enzymes. The softening process in sour cherries is dependent on the increase in polygalacturonase, ß-galactosidase and pectinmethylesterase activities, being responsible for fruit quality loss (Remon et al. 2003). Hot water treatment was valuable to maintain the texture of sour cherries, as it can stabilise cell membranes and inhibit the synthesis of cell wall hydrolysing enzymes and delay the aging of sour cherries through storage. The coating with A. vera led to a lower increase in the TSS:TA ratio, which indicates that control fruit presented a more pronounced aging development than coated sour cherries, similarly to that found in starch-coated strawberry (Mali and Grossmann 2003), and could be related to the higher respiration rate found in uncoated fruit. Furthermore, the A. vera coating could produce a modification of the internal atmosphere, showing similar effects to sweet cherry fruit under MAP conditions (Serrano et al. 2005).

TSS and TA at harvest were 15.05 ± 1.32 oBrix and 1.44 ± 1.10 tartaric acid equivalents, respectively and the TSS/TA ratio was 10.39 ± 1.56. This ratio slightly increased in control, hot water-treated and Aloe-treated fruit during cold storage, reaching values of 29.34 ± 1.65, 25.44 ± 1.41 and 18.45 ± 1.24, respectively (Fig. 1). It was observed that the TA in control and hot water treated samples decreased more than TA in Aloe vera coated samples. It was shown that Aloe vera gel could be more effective than hot water in retarding deterioration. Aloe vera known to show some antimicrobial property which may have helped in prevention of deterioration of sour cherry.

Sensory analyses

During the chain of production, storage and retailing, sour cherry fruit appearance is used to judge the overall quality. In our experiment, the highest scores for sour cherry visual aspect were given to the Aloe-treated fruit compared with the control after 17 days of cold storage, which became significantly different from hot water treated fruit and control (Fig. 1). These results indicated moderate-severe symptoms of dehydration and browning in control after 17 days of storage and slight on fruit treated with A. vera gel or hot water. Browning is typically developed during sweet cherry storage which has been associated with fruit ripening (Clayton et al. 2003), and also due to dehydration (Schick and Toivonen 2002). Thus, the effect of A. vera coating in delaying the loss of quality could be attributed to its effect on the inhibition of water diffusion and in turn, fruit dehydration and browning. A. vera gel imparted an attractive natural-looking sheen to the sour cherry fruit, quite close to the freshly harvested fruit. The visual aspect of the fruit is usually correlated to the overall quality, as has been observed in sour cherry, since the results obtained for fruit texture and taste were significantly better in Aloe-treated fruit compared with control. Although panellists did not perceive development of “off-flavours” in sour cherries as a consequence of Aloe treatment, they reported taste deterioration in those untreated samples (control) and exposed to hot water (Fig. 1).

Conclusions

A. vera gel coating or immersion in hot water, could be an innovative commercial application and an alternative to the use of postharvest chemical treatments for extending the shelf life quality of sour cherry. It is widely accepted that the most important parameters determining sour cherries acceptability by consumers are bright red colour, firmness, and the ratio of TSS/TA. Aloe vera gel or hot water treatment can be successfully used for overall quality retention on sour cherry since they were effective in reducing the weight loss and lower the respiration rate during postharvest storage. In addition, Aloe vera gel delayed colour changes, softening and TA losses, maintaining fruit quality.

References

Abreu M, Beirao-da-Costa S, Goncalves EM, Beirao-da-Costa ML, Moldao-Martins M (2003) Use of mild heat pre-treatments for quality retention of fresh cut ‘Rocha’ pear. Postharvest Biol Tec 30:153–160

Alonso J, Alique R (2004) Influence of edible coating on shelf life and quality of ‘Picota’ sweet cherries. Eur Food Res Tech 218:535–539

Bernalte MJ, Sabio E, Hernandez MT, Gervasini C (2003) Influence of storage delay on quality of ‘Van’ sweet cherry. Postharvest Biol Tec 28:303–312

Cha DS, Chinnan M (2004) Biopolymer based antimicrobial packaging a review. Crit Rev Food Sci Nutr 44:223–237

Clayton M, Biasi WV, Agar IT, Southwick SM, Mitcham EJ (2003) Postharvest quality of ‘Bing’ cherries following preharvest treatment with hydrogen cyanamide, calcium ammonium nitrate, or gibberellic acid. HortScience 38:407–411

Crisosto CH, Crisosto GM, Metheney P (2003) Consumer acceptance of “Brooks” and “Bing” cherries is mainly dependent on fruit SSC and visual skin colour. Postharvest Biol Tec 28:159–167

Fawcett HS (1936) Citrus diseases and their control, 2nd edn. McGraw Hill, New York

Kou L, Liu X, Huang Y, Gao W, Yan X (2006) Effect of heat treatment on protective enzymes and membrane lipid peroxidation of lightly processed ‘Red Globe’ grape. J Chinese Food Sci Technol 6:111–115

Lamikanra O, Bett-Garber KL, Ingram DA, Watson MA (2005) Use of mild heat pre-treatment for quality retention of fresh-cut cantaloupemelon. J Food Sci 70:53–57

Loaiza-Velarde JG, Saltveit ME (2001) Heat shocks applied either before or after wounding reduce browning of lettuce leaf tissue. J Am Soc Hortic Sci 126:227–234

Loaiza-Velarde JG, Mangrich ME, Campos-Vargas R, Saltveit ME (2003) Heat shock reduces browning of fresh-cut celery petioles. Postharvest Biol Tec 27:305–311

Mali S, Grossmann MVE (2003) Effects of yam starch on storability and quality of fresh strawberries (Fragaria ananassa). J Agric Food Chem 21:7005–7011

Martinez-Romero D, Alburquerque N, Valverde JM, Guillen F, Castillo S, Valero D, Serrano M (2006) Postharvest sweet cherry quality and safety maintenance by Aloe vera treatment: a new edible coating. Postharvest Biol Tec 39:93–100

Moore ED, MacAnalley BH (1995) A drink containing mucilaginous polysaccharides and its preparation. US Patent 5:443–830

Morillon V, Debeaufort F, Blond G, Capelle M, Voilley A (2002) Factors affecting the moisture permeability of lipid-based edible films a review. Crit Rev Food Sci Nutr 42:67–89

Paull RE, Chen NJ (2000) Heat treatment and fruit ripening. Postharvest Biol Tec 21:21–37

Petersen K, Nielsen PV, Lawther M, Olsen MB, Nilsson NH, Mortensen G (1999) Potential of biobased materials for food packaging. Trends Food Sci Technol 10:52–68

Prusky D, Keen N (1993) Involvement of preformed antifungal compounds in the resistance of subtropical fruits to fungal decay. Plant Dis 77:114–119

Remon S, Venturini ME, Lopez-Buesa P, Oria R (2003) Burlat cherry quality after long range transport, I optimisation of packaging conditions. Innovat Food Sci Emerg Tech 4:425–434

Romanazzi G, Nigro F, Ippolito A (2003) Short hypobaric treatments potentiate the effect of chitosan in reducing storage decay of sweet cherries. Postharvest Biol Tec 29:73–80

Schick JL, Toivonen PMA (2002) Reflective tarps at harvest reduce stem browning and improve fruit quality of cherries during subsequent shelf life. Postharvest Biol Tec 25:117–121

Schirra M, D’hallewin G, Ben-Yehoshua S, Fallik E (2000) Host-pathogen interactions modulated by heat treatment. Postharvest Biol Tec 21:71–85

Serrano M, Guillen F, Martìnez-Romero D, Castillo S, Valero D (2005) Chemical constituents and antioxidant activity of sweet cherry at different ripening stages. J Agric Food Chem 53:2741–2745

Wilcock A, Pun M, Khanona J, Aung M (2004) Consumer attitudes, knowledge and behaviour: a review of food safety issues. Trends Food Sci Technol 15:56–66

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ravanfar, R., Niakousari, M. & Maftoonazad, N. Postharvest sour cherry quality and safety maintenance by exposure to Hot- water or treatment with fresh Aloe vera gel . J Food Sci Technol 51, 2872–2876 (2014). https://doi.org/10.1007/s13197-012-0767-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-012-0767-z