Abstract

A key factor for the success or failure of a dental implant is the manner in which stresses are transferred to the surrounding bone. This depends on the type of loading, bone–implant interface, the shape and characteristics of the implant surface and the quality and quantity of the surrounding bone. This study was done to evaluate the pattern of stress distribution with two different implant designs in four different densities of bone using 3D finite element analysis. Graphic pre-processing software Ansys version 10 was used for creating the geometric configuration of a section of the mandible with a missing first molar. Eight 3D models of this section restored with implant-supported all ceramic crowns were created. Four of these models were created to simulate a single threaded implant placed in four different densities of bone (D1, D2, D3 and D4). The other four models were created to simulate a single cylindrical implant placed in four different densities of bone (D1, D2, D3, and D4). The Poisson’s ratio (μ) and Young’s modulus (E) of elasticity of the material were incorporated into the model. An average vertical load of 400 N was applied on the occlusal surface of the first molar between the buccal cusp, central fossa and the marginal ridge. Maximum Von Mises stresses in all the eight models were observed at the crestal region or neck of the implant. The stresses observed were more for the threaded implants in all the four densities of bone when compared to that of the cylindrical implants. The study concluded that the cylindrical implant design was more favorable in softer bone than the threaded implant design.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The application of dental implants for Prosthodontics reconstruction can be traced back to ancient Egypt where sea shells were hammered into human jaw bone to replace missing teeth [1]. Since the late 1960s when the dental implants were introduced for the rehabilitation of completely edentulous patients, an awareness and subsequent demand for this form of therapy has increased [2]. A key factor for the success or failure of a dental implant is the manner in which stresses are transferred to the surrounding bone. This depends on the type of loading, bone–implant interface, the shape and characteristics of the implant surface and the quality and quantity of the surrounding bone [3]. The interrelationship between the bone quality, quantity and the design of the implant play a vital role for clinical success. A compromise in any of these factors will often lead to implant failure [4–6]. The density of available bone in an edentulous site is the determining factor in treatment planning, and will determine implant design, surgical approach, healing time and if initial progressive bone loading is feasible during prosthetic reconstruction [2]. The various implant designs like the threaded, cylindrical or the tapered design have been shown to have a profound influence on implant biomechanics and stress distribution in the surrounding bone. Finite element analysis has been used in the field of medicine and dentistry since many decades. It can simulate the interaction phenomena between implants and the surrounding tissues [7, 8]. The effect of different implant designs on stress distribution in different bone densities have not been studied extensively using finite element analysis. Hence this study was done to evaluate the pattern of stress distribution with two different implant designs in four different densities of bone using 3D finite element analysis. The objectives of the study were: to analyze the pattern of stress distribution around a threaded implant and a cylindrical implant when placed in four different densities of bone and also to determine the most favorable implant design for the different bone densities.

Methodology

This study was conducted using finite element models to evaluate the pattern of stress distribution in a mandibular section of bone with a missing first molar restored with an implant-supported all ceramic crown.

Finite Element Model

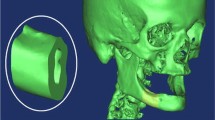

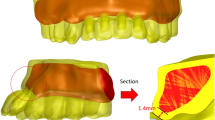

Graphic pre-processing software Ansys version 10 was used for creating the geometric configuration of a section of the mandible with a missing first molar. Eight 3D models of this section restored with implant-supported all ceramic crowns were created. Four of these models were created to simulate a single threaded implant placed in four different densities of bone (D1, D2, D3 and D4) [Model-T, Figs. 1, 2, with elements 150,802 and nodes 28,298]. The other four models were created to simulate a single cylindrical implant placed in four different densities of bone (D1, D2, D3, and D4) [Model-C, Figs 3, 4, with elements 247,975 and nodes 46,527], thereby totally eight 3D models were created. The average height of the mandibular section in the first molar region was 28 mm and width was 12 mm. The dimension of the standard threaded implant was 4 × 10 mm (Innova implant system) and that of the standard cylindrical implant was 4.1 × 9 mm (Innova implant system).

Material Properties

All materials used in the model were considered to be homogenous, isotropic and linear elastic. The Poisson’s ratio (μ) and Young’s modulus (E) of elasticity of the material were incorporated into the model as shown in Table 1 [2, 3, 9].

The finite element model was divided into small elements. Each element was considered to be interconnected at a number of discrete points called nodes. Each model was meshed by elements defined by ten nodes and three degree of freedom in tetrahedral nodes. The displacement of each of these nodes was calculated to determine the maximum Von Mises stresses throughout the structure.

Loading and Boundary Conditions

Based on previous studies pertaining to masticatory loads, an average vertical load of 400 N was applied [10] on the occlusal surface of the first molar between the buccal cusp, central fossa and the marginal ridge [11]. A support was provided at the inferior surface of the model and also at the distal ends of the mandibular section to simulate the action of the muscles and ligaments [12].

The Von Mises stresses were analyzed in all the eight models at the following sites:

-

(a)

Cancellous bone

-

(b)

Cortical bone

-

(c)

Crown

-

(d)

Implant–bone interface

Results

Maxmium Von Mises Stress in the Different Bone Densities with the Threaded Implant (Fig. 5)

The height of each bar depicts the maximum stress level. The color of the bar denoted the different models or bone densities.

-

1.

The stress level was observed least in cancellous bone and maximum in the implant and considerably higher in the crown.

-

2.

The heights of the bars in the crown region were almost equal indicating that the decrease in bone density does not affect the stress level, similar interpretation holds good for cancellous bone.

-

3.

The heights of the bars in cortical bone and in the implant increases corresponding to the bone density (T1, T2, T3 and T4). Hence the decrease in bone density increased in stress level (Table 2).

Table 2 Maximum Von Mises stress (MPa) on and around threaded implant in different densities of bone

Maxmium Von Mises Stress in the Different Bone Densities with the Cylindrical Implant (Fig. 6)

The height of each bar depicts the maximum stress level. The color of the bar denoted the different models or bone densities.

-

1.

The stress level was least in cancellous bone and maximum in implant and considerably higher in the crown.

-

2.

The heights of the bars in the crown region where almost equal indicating that the decrease in bone density did not affect the stress level; similar interpretation holds good for cancellous bone, cortical bone and the implant (Table 3).

Table 3 Maximum Von Mises stress (MPa) on and around cylindrical implant in different densities of bone

Discussion

Osseointegrated dental implants have been a well accepted and predictable treatment modality for the rehabilitation of partially and completely edentulous patients. Long-term success rates as high as 95 % for mandibular implants and 90 % for maxillary implants have been reported. The success of dental implants depends on various factors like implant design, bone density, type of prosthesis and loading of implants, oral microflora and parafunctional forces. Misch [13] has classified bone density into four types: D1 is dense cortical bone, D2 is porous cortical and coarse trabecular bone, D3 is porous cortical bone (thin) and fine trabecular bone, and D4 is fine trabecular bone. Different implant designs have been suggested for different bone densities because bone has a ten-fold difference in strength and flexibility between D1 and D4 bone qualities.

Finite element analysis has been used for many years in industry to provide analytical solutions to problems involving complex geometrical forms [8]. In 1976, Weinstein et al. were the first to use FEA in implant dentistry; subsequently, FEA was applied rapidly in the field of implant dentistry. [3] The results of this study showed that the maximum Von Mises stresses were observed at the crestal region or the neck of the implant for both the threaded and cylindrical types in all the four densities of bone. This is in similar to the results obtained by various other studies that demonstrated that bone loss begins around the implant neck due to higher bone stresses at the crestal region [9].

The results also showed that a decrease in bone density causes an increase in stress level around the neck of the implants, especially for the threaded implants; whereas the stress level was not influenced to a great extent by bone density in the case of cylindrical implants. This is consistent with the results obtained in a study conducted by Sevimay and Turhan [2] which utilized the 3D finite element analysis to analyze the effect of different bone densities on stress distribution. They concluded that higher stress magnitudes were seen in D3 and D4 bone as the trabecular bone is weaker and there is less resistance to deformation than in the other bone qualities modeled.

When the magnitude of stresses are compared between the threaded and the cylindrical implants, it was seen that maximum Von Mises stresses observed for the threaded implants in D4 bone was more compared to that of cylindrical implants. In a study conducted by Siegele and Soltesz, the results showed that different implant shapes lead to significant variations in stress distribution in bone. [3] The stepped or the threaded implants induced greater stresses than the cylindrical shaped implants. The reason for this could be that the areas of threads would form the frontline of stress concentration due to the sharp line angles located at the sides. The success rate of cylindrical implants in D4 bone was higher than that of the threaded implants. This was attributed to the fact that cylindrical implants generate less lateral force in spongy D4 bone than the threaded implants [4].

The present study thereby suggests that in case of D4 density of bone a cylindrical implant design may be considered. This result is also supported by the fact that use of a threaded implant in D4 density bone can be difficult as the threads cannot be engaged by the spongy bone, where as a friction fit can be obtained with the cylindrical implant design. Hence from biomechanical and surgical points of views, cylindrical implant design may be considered for placement in D4 type bone.

Conclusion

-

1.

Maximum Von Mises stress was observed at the crestal region of the bone in all the models.

-

2.

Maximum Von Mises stress around the threaded implant was observed in the D4 type of bone when compared to the stress distribution in D1, D2 and D3 types of bone.

-

3.

Maximum Von Mises stress around the cylindrical implant was observed in the D3 type of bone when compared to the stress distribution in D1, D2 and D4 types of bone.

-

4.

When the stress distribution was compared between the threaded and cylindrical implant in D1, D2, D3, and D4 bone, maximum Von Mises stresses were observed around the threaded implant.

-

5.

In view of the above conclusions it may be inferred that the cylindrical type of implant design may be more suitable in softer bone.

References

Lee JH, Fria V, Lee KW, Wright RF (2005) Effect of implant size and shape on implant success rate: a literature review. J Prosthet Dent 94:377–381

Sevimay M, Turhan F (2005) Three-dimensional finite element analysis on the effect of different bone quality on stress distribution in implant-supported crown. J Prosthet Dent 93:227–233

Geng JP, Tan KBC, Liu GR (2001) Application of finite element analysis in implant dentistry: a review of the literature. J Prosthet Dent 85:585–598

Paul AF, Stpehen L, Wheeler, Lindsay JA (1993) Success and failure rates of cylinder implants in type IV bone. J Periodontol 64:1085–1087

Meijer HJA, Kupier JH, Starmans FJM, Bosma F (1992) Stress distribution around dental implants: influence of superstructure, length of implants, and height of mandible. J Prosthet Dent 68:96–102

Papavasilion G, Kamposiors P, Bayne SC, Felton DA (1996) Three-dimensional finite element analysis of stress-distribution around single tooth implants as a function of bony support, prosthesis type and loading during function. J Prosthet Dent 76:633–640

Vidyasagar L, Apse P (2004) Dental implant design and biological effects on Bone–implant interface. Stomato Balt Dent Maxil-facial 6:51–54

Germay A, Morgano SM (2004) Finite element analysis of three designs of an implant-supported molar crown. J Prosthet Dent 92:434–440

Lin CL, Kuo YC, Lin TS (2005) Effect of dental implant length and bone quality on biomechanical responses in bone around implants: a three-dimensional linear finite element analysis. Biomed Eng Appl Basis Commun 17:44–49

Anusavice KJ (1996) Mechanical properties of dental materials. In: Anusavice KJ (ed) Phillip’s Science of dental materials, 10th edn. Elsevier, Philadelphia, p 66

Misch CE, Bidez MW (2005) Occlusal considerations for implant supported prostheses. In: Misch CE (ed) Dental implant prosthetics. Mosby, Maryland Heights, pp 472–510

Yokoyama S, Wakabayashi N, Shiota M, Ohyama T (2004) The influence of implant location and length on stress distribution for three unit implant supported posterior cantilever fixed partial dentures. J Prosthet Dent 91:234–240

Misch CE (2005) Bone density: a key determinant for clinical success. In: Misch CE (ed) Dental implant prosthetics. Mosby, Maryland Heights, pp 130–141

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Premnath, K., Sridevi, J., Kalavathy, N. et al. Evaluation of Stress Distribution in Bone of Different Densities Using Different Implant Designs: A Three-Dimensional Finite Element Analysis. J Indian Prosthodont Soc 13, 555–559 (2013). https://doi.org/10.1007/s13191-012-0189-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13191-012-0189-7