Abstract

With the trend toward taller and more flexible building structures, the use of vibration control devices, passive as well as active, as means of structural protection against strong wind and earthquakes have received significant attention in recent years. A mass-damper shaking table system has been considered as means for vibration suppression to external excitation and disturbances. No explicitly system identification of the plant dynamics, no membership function and thus no fuzzification–defuzzification operation are required. For effective control performance, a neural classifier controller with genetic algorithm is developed. Compared with the conventional neural network and fuzzy controller, the neural classifier controller using genetic algorithm has been presented with the effectiveness of the vibration suppression control. Experimental results show that the neural classifier controller remains effective for building structure vibration suppression under free vibration and forced vibration excitation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Neural network’s abilities in self-learning, parallel construction, high memorial capacity, generalization, and noise insensitive are particular suitable for system identification and control. System identification and active vibration control using artificial neural networks (ANNs) have thus been the focus of research in recent years. Experimental studies of structure control are also carried out successfully. Yang and Lee [1–4] developed three neural networks for system identification, on-line state estimation and vibration suppression of a composite structure. Chen et al. [5] proposed a five-layer neuro-fuzzy system to vibration suppression for a building structure. Yan et al. [6] developed a fuzzy-neural network controller with adaptive membership functions for vibration suppression of truss structure. Cavallo et al. [7] presented a MIMO output feedback control law to show how the singular perturbation theory can be used to tackle the problem of active vibration control. Li et al. [8, 9] proposed a genetic algorithm based back-propagation neural network suboptimal controller for system identification, state estimation and vibration suppression of a modular robot. Kundu et al. [10] developed the method for modeling flexible structures with distributed parameters as reduced-order models with lumped parameters. Design of flexible structures is considered as a feedback search procedure where a new solution is assigned a fitness value and the genetic algorithm (GA), iterates until a satisfactory design solution is achieved. In Minato and Ohsumi [11], a building is assumed to be subjected to random wind and/or seismic disturbances. Such disturbances are essentially random and have mutually different characteristics, so that an effective control method is proposed by constructing two types of controllers. Itoh et al. [12] presented an evolutional compensator design for motion control systems using genetic algorithms. The control system is composed of a robust two-degrees-of-freedom compensator based on the coprime factorization description. However, such learning control systems typically employ neural network to learn the characteristics or inverse dynamics of controlled systems. Network training is performed based on-line observation of the input and output of the plant. The operation may take much time due to time-consuming learning of the back propagation method.

In this paper, a neural classifier combined with active mass damper (AMD) system is developed and applied to vibration suppression of a building structure. The control gains of the neural classifier (NC) controller can be successfully tuned online via the genetic algorithm, instead of solving complicated mathematical equations. The fitness vibration control for online tuning the control gains of the neural classifier controller is established by the optimum design approach.

2 Neural classifier

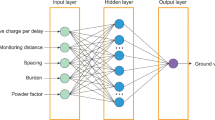

Among various neural network models, backpropagation network (BPN) is the most popular for it can learn the mapping of any complexity. A three-layer feedforward neural network trained by backpropagation algorithm with sufficient neurons in the hidden layer has been shown to have the desired functional approximation capabilities with an arbitrary degree of accuracy. The neural classifier is a three-layer feedforward neural network that consists of input, hidden, and output layers; each layer contains several processing elements or perceptions with sigmoidal nonlinearities.

The basic concept behind the proposed vibration controller is to utilize a multi-layered neural network to obtain a classification from the system input–output measurements and to produce a control signal proportional to the classification. What makes the control scheme using neural classifier unique is that the neural classifier is a classifier rather than an estimator or identifier of plant dynamics or direct mapping of trajectories. A backpropagation neural classifier is shown in Fig. 1. The neural network approach is to generate an approximation to the classification regions from input–output measurements (based on the empirical data) and to use them as feedforward rules to calculate the appropriate control gain. This is different from many other neural network controls in that the neural network is a classifier rather than an inverse of the plant. For instance, in conventional axis control systems, accurate mathematical model to construct unstructured uncertainties and unmodelled dynamics is difficult, if not impossible. In systems with coupled nonlinearities, it is quite difficult to obtain the dynamics of the plant and hence, it is an advantage to design the controller to be independent of plant dynamics.

Training involves using the error signals, e, between the plant output signals and the desired signals (trajectories) as inputs to neural network. The neural classifier contains four units: preprocessing, neural network classifier, look-up table, and servo drive unit. The preprocessing part scales the error signal into the range of [−1, +1] and partitions it into several groups. The control gains are first tested by try-and-error and used in the experiment of shaking table. After the shaking table moving, the error signal and control gain are collected for neural classifier training. In this work, the center and the width of the error group are determined by a self-organized learning technique from the given training data to allocate the network resources efficiently by placing the domains of error group covering only the input–output space where data are present. Kohonen’s self-organized feature-map algorithm [13] is adopted to find the center of the error group. Each group clusters those error signals for which an appropriate control gain can be determined. These errors serve as inputs to the neural network classifier. The number of units in the input layer of the neural classifier is determined by the particular application and the number of trajectories to be followed. It performs the function of classification and/or mapping. Outputs of the neural network classifier will be mapping into the error region, in which it indicates the suitable control gain of look-up table. The look-up table determines the suitable control gain based upon the output decision produced from the neural network classifier. In particular, it relates the possible error regions and their corresponding control gains. The signal is then fed through the servo drive unit to generate the proper control gain to drive the plant to correct the deviation in the plant output. By classifying the errors into several categories and determining the control gain depending on the classification, a knowledge-based control structure is incorporated. The normalized error magnitudes of a shaking table system are considered within several domains of the displacement error. The corresponding error centers for classification is depicted in Table 1. The value of scaling factor and control actions are determined by the particular characteristics of the controlled plant and the tracking performance criterion. The control actions play an important role in tracking because they determine the region of variation of each control effort. In general, in order to obtain good tracking performance, control gains should be determined in tracking process. In particular, if the error signal falls in the error region, then the neural classifier will send a message to point out that the plant is off track, and the tracking controller will make some effort to direct the plant output back to the right track.

3 System design using genetic algorithm

There have been many algorithms evolved during the last 30 years: genetic algorithms, mainly developed in the USA by Holland [14], evolutionary strategies, developed in Germany by Rechenberg [15] and Schwefel [16] and evolutionary programming [17]. Each of these constitutes a different approach, however, they are inspired in the same principles of natural evolution. A good introductory survey can be found in Fogel [18]. The problem can be solved by using evolutionary algorithms in Fig. 2.

The fitness function is to evaluate each chromosome and an important connection between the GA and the system. A good fitness function can embody the requirement of the vibration control and evaluate the individuals properly. The vibration control system must have such performance: at the early stage, the amplitude can be reduced quickly; at the final stage, the main objective is to ensure the control stability. This design idea is useful for the fitness function. A general way of calculating the fitness is

where f(i) is the fitness of the individual i, K is the maximum of all the v(j) (j = 1, 2,…, n), a i (t) is the residual amplitude of the individual i at time t, and T is the upper limit of the control time which is constant. A new fitness function is given by

where the entire procedure of vibration control is divided into three stages: 0–T 1, T 1–T 2, T 2–T, a i (t) is the amplitude at time t for the ith individual, T is the upper limit of the control time, f(i) is the fitness of the individual i, and K is the maximum of all the v(j) (j = 1, 2,…, n).

The factors α, β, γ in Eq. 3 represent the weights used for the three stages: 0–T 1, T 1–T 2 and T 2–T, respectively. Here the stage 0–T 2 focuses on the high deamplification speed. In order to check this procedure in detail, this stage is divided into two stages 0–T 1 and T 1–T 2. Dividing the range of 0–T 2 into three or more stages is also allowed if needed, but this will increase the computation cost.

In the generation operation, the adjustment of these factors α, β, γ can control the direction of the generating operation. For example, in a certain generation, the best individual has a low deamplification speed at the stage of 0–T 2 but the stability at stage T 2–T is good. To improve the performance of the individual, some genes that can ensure the high deamplification speed are needed. If the factor α is increased with the other two factors being reduced, the genes which are in relation with the deamplification speed of the stage 0–T 1 will have the largest influence on the fitness value. With this change of the factor α, the generating operation can find the genes for rapid deamplification speed more feasibly. The adjustment of the factors α, β, γ is discussed in relation to Fig. 3a.

Figure 3a describes the three stages in one vibration suppressing procedure. Amplitude A 0 is the initial value. The values of amplitudes A 1 and A 2 are determined by the operators. The stage with amplitude from A 0 to A 2 is a stage at which the deamplification speed is used as the design criterion. The stage with amplitude from A 2 to 0 is the stability stage. Corresponding to A 1 and A 2, T 1 and T 2 can be calculated, thus the three stages of 0–T 1, T 1–T 2 and T 2–T are obtained.

Compared with Eq. 1, the new fitness function shown in Eq. 3 can obtain the good gene more quickly. This can be explained with the help of Fig. 3b. The controller corresponding with individual I can damp quickly from amplitude A 1 to amplitude A 2 with the time consumption of t 1, but the damping ratio is low from amplitude A 2 to amplitude A 3 with the time consumption of t 3 − t 1. Individual II has the inverse condition with the damping time t 2 and t 3 − t 2 respectively. Individual I is then better than individual II with the fitness function in Eq. 1 and individual II has less chance to be retained. By improving the factor β in Eq. 3, the good genes determining the damping ratio in the period of A 2–A 3 can be found easily in individual II and a filial individual III is generated. Individual III has absorbed the good genes from both parental individuals I and II. In this paper, \( \alpha \int_{0}^{{T_{1} }} {a_{i} (t){\text{d}}t} \), \( \beta \int_{{T_{1} }}^{{T_{2} }} {a_{i} (t){\text{d}}t} \) and \( \gamma \int_{{T_{2} }}^{T} {a_{i} (t){\text{d}}t} \) can be determined by the control gains k 1, k 2 and k 3 in the Table 2.

4 Vibration suppression using neural classifier

A one-story shear-building structure model as shown in Fig. 4 is 300 × 210 × 205 mm and weights 5.4 kg. An AMD mounted on the top floor has a moving part 1 kg and maximum stroke ±50 mm. The columns interconnecting the floor are assumed to be massless and they are flexible to lateral deformation but rigid in vertical direction. The structure mass is concentrated at the floor level. Its natural frequency is at about 1.67 Hz. Two AC servo motors (MITSUBISHI HC-MF13 and MF73) are used: one for driving the mass damper mounted on the linear guideway (THK KR33) and the other for driving the building structure to simulate earthquake. Table 3 lists the specification of the AC servo motors. For safety concerns, the following devices are to ensure the reliability of AMD and avoid any dangerous malfunction on the building: a mechanical brake is combined with a limit switch to stop the auxiliary mass when it overruns a certain position, and an automatic switching function which cuts off the motor current in case of abnormal situation or power failure. A low-frequency accelerometer (KISTLER 8628B5) attached at the top floor to acquire the acceleration signal. The measurement of accelerometer is then integrated to yield the velocity signal by the integrator (G-TECH 350133) which is then integrated and filtered to displacement signal. The data acquisition is based on LAB-VIEW6.1 (National Instruments) and a PCI-6052E multifunction I/O board.

An experimental study is verified to show the effectiveness of the proposed vibration suppression scheme to control the building structure. Table 2 contains the information about decision rules, error centers, and corresponding control actions employed. The control gains are expressed by three control gains k 1, k 2, and k 3. The value of scaling factor and control gains k 1, k 2 and k 3 are determined by the particular characteristics of the plant and the vibration suppression performance criterion. In particular, the control gains k 1, k 2 and k 3 play an important role in the vibration process because they determine the range of variation of each control effort. In general, in order to obtain good vibration suppression performance, k 1, k 2, and k 3 should be selected by genetic algorithm.

In this study, the previous two steps of the error signals, [e(k), e(k − 1)], are used as the network input to generate the proper control action u. Five hundred training sets (input/output pairs) are collected for network training. A [2–8] BPN is used for modeling the input/output transfer function in which the number of hidden neurons is selected to be adequately small but enough to reduce the error function within a small percentage. It can be shown that the sum-squared error decreases when the training number increases. Within each range, 50 points are randomly selected as the training pattern. For instance, if the error signal falls in the error center group #3, the corresponding neural network output will be pattern (0 0 1 0 0 0 0) and, from the look-up table, the control gain u = k 3 .

To demonstrate the learning capability and the applicability of the proposed controller, various test cases are performed under different operating conditions. The tests are repeated with the neural classifier controller, fuzzy controller, neural network, and the results are compared with those of the neural classifier controller with the genetic algorithm. In the experiments, two kinds of vibration: a free vibration and a forced vibration are provided. First, the experimental results due to a free vibration response at the nominal condition are shown in Fig. 5; effective vibration suppression is obtained by on-line searching using genetic algorithm. In case k 1, k 2 and k 3 are 9.4, 8.1, and 2.0, a fast and effective vibration suppression is obtained. Figure 6 shows the free vibration response with the neural classifier controller and fuzzy controller switched on at about t = 1.9 second. This figure shows the free response of the building structure under an initial displacement in which the settling time of the open-loop system is more than 12 s whereas that of the closed-loop system is less than 3 s. The vibration is suppressed effectively. Figure 6 shows that the neural classifier with genetic algorithm controller has the capability in vibration suppression than the other controllers for most operation regions. The performances of the free vibration input for different error center groups are plotted in Fig. 7. It can be clearly seen that the neural classifier with genetic algorithm controller could maintain vibration suppression effectively under different error center groups. Figure 8a and b shows the forced vibration input and the response trajectory with the neural classifier controller at the nominal condition. A fast and effective vibration suppression is also obtained. The building structure with the proposed neural classifier controller is capable of vibration suppression with an AMD system.

To further validate the effectiveness of the neural network controller, suppressing vibration response under Ji-Ji Earthquake, Taiwan on 21 September 1999 of Richer scale 7.1 is conducted. Figure 9a shows the time history of ground acceleration record in which the maximum value is 862 gal (1 gal = 1 cm/s2). Because the experimental model can not sustain such earthquake magnitude, the maximum acceleration is reduced to about 20%, 172 gal in order to simulate the earthquake signal. Figure 9b shows the vibration response of the building structure under Ji-Ji Earthquake can reduce largely by using neural classifier controller with genetic algorithm. The above experimental results show that satisfactory performance can be achieved by using the neural classifier controller with genetic algorithm.

5 Conclusions

Focused on the optimization of the genetic algorithm for the neural classifier controller used in the active vibration control, the controller design of vibration control for the building structure has been developed, and then the characteristics of the vibration suppression control have been analyzed. Based on the design, a fitness function for the genetic algorithm has been presented to evaluate the performance of the control gains k i . Through the result analysis, it can be found that the fitness function with the control actions can evaluate the performances of the deamplification speed and the stability at different stages. Compared with the conventional neural network and fuzzy controller, the neural classifier controller using genetic algorithm has also been presented with the effectiveness of the vibration suppression control. Experimental results show that the neural classifier controller remains effective for building structure vibration suppression under free vibration, forced vibration and Ji-Ji Earthquake (21 September 1999) excitation.

References

Yang SM, Lee GS (1997) Vibration control of smart structures by using neural networks. J Dyn Syst Meas Control ASME 119(1):34–39

Yang SM, Lee GS (1997) A neural network design methodology for structural control. In: 1997 ASME Design Engineering Technical Conferences, paper no. DETC97/VIB-3775

Yang SM, Lee GS (1997) System identification of smart structures using neural networks. J Intellect Mater Syst Struct 8(10):883–890

Yang SM, Chen CJ, Huang WL (2006) Structural vibration suppression by a neural-network controller with a mass-damper actuator. J Vib Control 12(5):495–508

Chen CJ, Yang SM, Wang ZC (2009) System identification by neuro-fuzzy model with Sugeno and Mamdani fuzzy rules. J Aeronaut Astronaut Aviat 41(4):263–270

Yan SZ, Zheng K, Li Y (2005) Vibration suppression of adaptive truss structure using fuzzy-neural network. In: Wang J, Liao X, Yi Z (eds) Advances in neural networks-ISNN05. Springer, LNCS 3498, Part III, pp 155–160

Cavallo A, De Maria G, Natale C (2001) Second order sliding manifold approach for vibration reduction via output feedback: experimental results. IEEE/ASME Int Conf Adv Intell Mechatron Proc 2:725–730

Li Y, Liu Y, Liu X (2005) Active vibration control of a modular robot combining a BP neural network with a genetic algorithm. J Vib Control 11(1):3–17

Li Y, Liu Y, Liu X, Peng ZY (2004) Parameter identification and vibration control in modular manipulators. IEEE/ASME Trans Mechatron 9(4):700–705

Kundu S, Seto K, Sugino S (2002) Genetic algorithm application to vibration control of tall flexible structures. IEEE Proc Electron Design Test Appl 333–337

Minato J, Ohsumi A (2003) Control for high-rise buildings subjected to wind and seismic disturbances. In: SICE 2003 annual conference, vol 1, pp 535–539

Itoh K, Iwasaki M, Matsui N (2004) Optimal design of robust vibration suppression controller using genetic algorithms. IEEE Trans Ind Electron 51(5):947–953

Kohonen T (1988) Self-organization and associative memory. Springer, Berlin

Holland JH (1975) Adaptation in natural and artificial systems. The University of Michigan Press, Ann Arbor

Rechenberg I (1973) Evolutionsstrategie—Optimierung Technischer Systeme Nach Prinzipien der Biologischen Evolution. Frommann-Holzboog, Stuttgart

Schwefel HP (1981) Genetic algorithms and simulated annealing. Wiley, Chichester

Fogel LJ, Owens AJ, Walsh MJ (1966) Artificial intelligence through simulated evolution. Wiley, New York

Fogel DB (1994) An introduction to simulated evolutionary optimization. IEEE Trans Neural Netw 5(1):3–14

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, CJ. Structural vibration suppression by using neural classifier with genetic algorithm. Int. J. Mach. Learn. & Cyber. 3, 215–221 (2012). https://doi.org/10.1007/s13042-011-0053-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13042-011-0053-9