Abstract

Prediction of physical and mechanical properties of rock materials using rebound-based hardness test methods is widely preferred in many fields of engineering and in the characterization of rock materials, because they are non-destructive, practical, and economical. In this study, 40 types of rocks with magmatic, metamorphic, and sedimentary origins, represented by travertine, limestone, marble, dolomite, granite, syenite, dunite, andesite, schist, gabbro, tuff, and ignimbrite were selected. First, dry unit weight (γd), open porosity (no), water absorption by weight (WAW), wide wheel abrasion (WA), and uniaxial compressive strength values were determined. After that, Shore C-2 scleroscope (HSC), L-type Schmidt hammer (HSL), and Leeb (HLD) rebound-based hardness tests were carried out on all samples, and then, hardness values by three methods were compared with the obtained parameters. The Leeb hardness test, which is more recent and innovative than the Shore and Schmidt hardness tests, was initially developed for metallic materials. However, the method has become increasingly popular in the determination of hardness of rock materials in laboratory as well as in field. In this study, the Leeb hardness test was found to be more useful due to its quick and precise measurement capabilities compared to Shore and Schmidt hardness tests. The results of the study reveal that the prediction of physical and mechanical properties of rocks can more precisely be determined by the HLD method than the HSL and HSC methods using the proposed equations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hardness is one of the distinguishing properties of rock-forming minerals and can be defined as a measure of scratchability or resistance to abrasion on a mineral surface. Since rocks are composed of mineral assemblages, the amount of mineral content having low or high hardness value determines the hardness value of the rock material. A measure of rock hardness can also be the degree of abrasion, which is the resistance of a rock against a grinding force. The abrasion resistance of a rock depends mainly on the mineralogical composition and the rock fabric (Siegesmund and Dürrast 2014).

Various hardness measurement tests have been proposed for different types of materials. In parallel with developing industry, hardness tests are mostly developed for metallic materials. In general, dynamic rebound hardness methods (Schmidt hammer, Shore scleroscope, Leeb hardness, etc.) are widely used, because they are economical and practical compared to static and indentation based hardness test methods (Brinell, Vickers, Rockwell, Knoop, Cherchar; ASTM 2013). Rebound hardness is a measure of the rebound of an object that is dropped or impacted on the surface of a rock. The degree of rebound is a function of the amount of the impact energy lost as plastic deformation and failure of a rock at the impact point (Atkinson 1993).

Another hardness assessment approach is the Mohs comparative hardness scale which is generally used to assess the mineral hardness of hand samples by scratching. However, as a qualitative scale, the Mohs is not useful in characterization of rock materials for engineering purposes.

The Leeb hardness criterion as a dynamic hardness test method, also known as Equotip Leeb hardness, was proposed in the mid-1970s for surface hardness measurements of metallic materials (Leeb 1979). This method was developed to offer a faster, more comfortable and practical hardness test, which could be applied in different test directions with a wider hardness scale (Kompatscher 2004). In the characterization of rock materials, L-type Schmidt hammer (HSL) and Shore C-2 scleroscope (HSC) have been widely preferred methods due to their practical and economical use for decades. However, the more recent Leeb hardness method (HLD) stands out for its precision and practicality. The measured HLD values ranging from 170 to 900 as well as the hardness value can be obtained throughout the device’s ability to measure the impact and rebound velocity of the impact body. The higher the rebound velocity, the harder the material surface.

Within the framework of a natural building stone characterization and quality assessment, uniaxial compressive strength (UCS) value of the building stones may be the most important parameter used by scientists, engineers, and practitioners. According to EN 1926 (2006), standard test samples can be cubes with 70 or 50 (± 5) mm edge sizes or cores with diameter and height are equal to 70 or 50 (± 5) mm. The lateral dimension (distance between opposite vertical faces) or the diameter of the sample can be related to the size of the largest grain in the rock by the ratio of at least 10:1. In addition, regarding building stones, ASTM (1999) suggests that standard test samples may be cubes, square prisms, or cylinders. The diameter or lateral dimension should not be less than 50.8 mm, and the ratio of height to diameter or lateral dimension should not be less than 1:1. The preparation of precise test specimens for UCS and other physical and mechanical tests is important for achieving reliable results, requiring time-consuming procedures by expert technicians, as well as the need for high-precision and expensive test systems. To overcome these limitations, many researchers have worked on faster, simpler, and non-destructive tests to estimate UCS and other parameters.

The main objective of this study is to correlate and predict some basic properties including γd, no, WAW, WA, and UCS values of 40 types of sedimentary, igneous, and metamorphic rocks by three rebound hardness test methods. In addition, the advantages of Leeb hardness test, conducted through a TIME® 5100 pen type pocket size hardness tester in the characterization of rock materials over HSC and HSL test methods, have been demonstrated.

Overview of previous studies

After its development, Leeb hardness (HLD) test became widespread due to its practical and economical use not only on metallic but also on rock materials. The majority of the studies on rocks are concentrated on the prediction of UCS values.

Hack et al. (1993) investigated the Equotip hardness test for the prediction of discontinuity wall strength and UCS, and they pointed out that rebound values were affected by surface roughness and layer thickness of the material. Verwaal and Mulder (1993) studied on core samples with different diameters of crystalline and clastic limestone, sandstone, and artificial materials, they found a positive correlation between HLD and UCS values. Meulenkamp and Alvarez Grima (1999) used HLD values which were taken by type “C” impact device and they selected unit weight, porosity, grain size, and rock type as input parameters in the prediction of UCS values by artificial neural network (ANN) and regression analyses. Sandstone, limestone, dolomite, granite, and granodiorite rock types were tested and equations to estimate UCS values were proposed. The authors also stated that the prediction performance of ANN is better than regression. Kawasaki et al. (2002) studied the prediction of UCS from HLD on sandstone, shale, hornfels, granite, and greenschist from different parts of Japan. The authors proposed positive linear correlations between HLD and UCS values for each rock type.

Aoki and Matsukura (2008) investigated the estimation of UCS values from HLD values on tuff, sandstone, granite, gabbro, and limestone samples from Japan and andesite from Indonesia. They used type “D” impact device, and pointed out the advantages of the hardness test method and proposed a correlation equation between UCS and HLD values of tested samples by considering the data of Verwaal and Mulder (1993). They stated that UCS values of tested rock samples can be estimated with higher accuracy using both HLD and porosity values. Viles et al. (2011) investigated the rock hardness in relation to rock weathering on various types of sandstone, limestone, basalt, and dolerite in geomorphological and heritage science investigations in the field. Daniels et al. (2012) studied the estimation of strength of sandstone core samples from six reservoirs by HLD values. They used the equations proposed by Verwaal and Mulder (1993) and Aoki and Matsukura (2008). They pointed out that extended database of sandstone core samples from reservoirs around the world indicates that field-specific calibration is essential for such a correlation equation.

Coombes et al. (2013) used Equotip hardness values as a non-destructive tool for detecting the variation of the hardness of concrete, limestone and granite in coastal zone. Samples were attached to two meso-tidal rocky shore platforms in South West England and were exposed to atmospheric conditions for a period of 20 months. After 8 and 20 months, HLD values were taken, and as a result, it was pointed out by the authors that the hardness values of limestone were reduced, whereas surface hardnesses of concrete samples were increased. For granites, no statistical change was observed. Mol (2014) used Equotip hardness as the method to estimate the surface hardness of rocks. The researcher pointed out that the method is very suitable for monitoring and mapping the effects of surface weathering of rocks.

Güneş Yılmaz (2013) studied on the estimation of UCS values of marble, limestone, dolomitic limestone, dolomite, and travertine using Equotip hardness values. In the study, previous hardness measurement procedures were presented and a new methodology named as hybrid dynamic methodology was introduced. This method was expressed as combination of the surface rebound hardness and compaction ratio of a rock. The compaction ratio was defined as the ratio between the average surface hardness and the peak hardness obtained by ten repeated impacts at one point. Correlation equations were proposed, and it was mentioned that when apparent unit weight values are taken into consideration, significantly improved correlations were obtained. Hybrid dynamic hardness approach, determined by Equotip hardness values, was also used in the assessment of rock cuttability (Güneş Yılmaz et al. 2015).

Lee et al. (2014) worked on the estimation of UCS values of shale formations from HLD values. They proposed a UCS estimation equation for the shale formations with the aim of logging UCS variations with depth. Asiri et al. (2016) investigated the statistical relationship between HLD and UCS for sandstone. Sample size and number of HLD impact readings were evaluated and correlation equation was proposed for sandstones. Asiri (2017) tested sandstone, coal sandstone, limestone, dolostone, granite, greywacke, and schist samples, and presented a nonlinear relation between HLD and UCS. It is pointed out that HLD values can be used in field estimation of UCS values. Su and Momayez (2017) investigated the correlations between Equotip hardness, mechanical properties, and drillability of claystone, sandstone, limestone, conglomerate, siltstone, marble samples from Turkey, and granite, tonalite, mylonite, and granodiorite samples from USA. They found that the Equotip hardness could be reliably used for estimating the drillability of rocks with UCS values higher than 19 MPa and with drilling rate index lower than 70.

Güneş Yılmaz and Göktan (2018a) investigated the Schmidt and Equotip hardness as non-destructive test methods in the estimation of UCS values of basalt, limestone, andesite, tuff, travertine, and marble samples. They also proposed an equation which is a combination of these two methods in the prediction of UCS values. Corkum et al. (2018) studied the correlation of HLD and UCS values of sedimentary, igneous and metamorphic rocks, which are represented by sandstone, granite, and schist, respectively. Detailed investigations on impact numbers, based on statistical and average number of impacts in a test considering sample size, were performed. They proposed using trimmed mean of 12 impact readings based on the existence of outlier data. Correlation equations to estimate the UCS from HLD values for each rock type and for all rock types were also proposed. Güneş Yılmaz and Göktan (2018b) investigated the effect of Arch and V-shaped core holders on measured HLD values. They used basalt, limestone, andesite, tuff, agglomerate, travertine, and marble samples. They found a strong linear correlation between HLD values taken on both holders. They also proposed an estimation equation for UCS values of tested rocks.

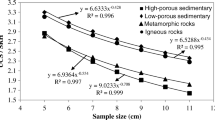

One of the factors relevant for obtaining the accurate and precise HLD values is the sample size. There are studies examining the change of HLD measurements regarding sample size or thickness. Verwaal and Mulder (1993) pointed out that a slight effect on the HLD measurement was observed for the samples having a thickness above 50 mm. Kawasaki et al. (2002) also observed the same result. Corkum et al. (2018) recommended that HLD tests would be performed on samples with a minimum volume of 90 cm3. Güneş Yılmaz (2013) concluded that HLD tests should be applied to the core samples with minimum diameter of 54 mm. It was observed that the previous findings support each other. In this study, cube samples with 7 cm edge sizes (only two rock types have 5 cm edge size) were used and sample size is not considered to have an effect on HLD measurements.

In this study, the correlation equations for estimating not only the UCS values but also physical and mechanical properties from HSC, HSL, and HLD hardness values for 40 types of rock groups have been investigated. This study contributes to the current knowledge on hardness tests of different origin rock materials. HLD and some physical and mechanical properties of rock materials were investigated for the first time with HLD values and related correlations were proposed.

Materials and methods

In this study, 40 different types of rock materials were collected from different areas of Turkey. To propose general correlation equations, sedimentary, metamorphic, and igneous origin rock types, which are widely used as building stones, were selected. Sedimentary rocks were represented by travertines (Trv-1 to 12), limestones (Lms-1 to 11), and dolomites (Dlm-1 and 2), metamorphic rocks were represented by marbles (Mrb-1 to 3) and schist (Sch-1), and igneous rocks were represented by granite (Grn-1 and 2), syenite (Syn-1), andesite (Ads-1), gabbro (Gbr-1), dunite (Dnt-1), tuff (Tff-1) ,and ignimbrites (Ign-1 to 4). 7 × 7 × 7 cm cubic samples were prepared in accordance with the ASTM (1999). However, Lms-12 and Ign-1 samples could be prepared as 5 × 5 × 5 cm. For each rock type two samples were prepared; however, Lms-9, Dlm-2, Mrb-3, Grn-1, Grn-2, and Ads-1 rocks were represented by one cubic sample. An overview of prepared samples is presented in Fig. 1.

First, dry unit weight (γd), open porosity (no) values, and water absorption by weight (WAW) values of all samples were determined. After that, wide wheel abrasion (WA) and sonic wave velocity (Vp) values were obtained. Throughout the aim of this study, Leeb (HLD), Schmidt (HSL), and Shore (HSC) hardness values of samples were measured. Finally, uniaxial compressive strength (UCS) values were determined. All tests except Shore hardness tests were carried out in geological engineering laboratories of the Pamukkale University.

Physical, abrasion, and strength properties of samples

Physical properties of samples

The basic physical parameters were obtained in accordance with the EN 1936 (2006) standard. γd values of all samples were ranging between 12.40 and 30.19 kN/m3, with average value of 23.57 kN/m3. One of the most important properties of building stones is porosity, since it affects the strength; it should be noted that porosity is a very important parameter affecting the strength, water absorption, and durability of rock materials. Open porosity values of selected rocks were determined between 15.22 and 30.20%, with an average of 24.16%. Ignimbrite samples due to their weak nature have the highest open porosity values, and the lowest values were determined for the gabbro samples. Under the control of open porosity, water absorption values were also obtained in a wide range. Results of all tests are given in Table 1. Significant correlations were observed between dry unit weight − open porosity and dry unit weight − water absorption by weight values of tested rocks. Negative linear correlations were observed between γd − no and γd − WAW parameters and are given in Fig. 2a, b, respectively. In Eqs. 1 and 2, equations are listed for both correlations:

where no: open porosity (%), γd: dry unit weight (kN/m3), and WAW: water absorption by weight (%).

Abrasion resistance of samples

Abrasion is a very important parameter especially for natural building stones to be used in places subject to continuous abrasive effects such as pedestrian or vehicle traffic. There are different test methods for the determination of abrasion resistance of building stones. The most recent abrasion test is called wide wheel abrasion test (WA). This test became widespread due to its practical use and accepted as a reference test method (Çobanoğlu et al. 2010; Karaca et al. 2010, 2012; Marini et al. 2011; Çobanoğlu and Çelik 2017). Abrasion resistance (WA) values of the samples were determined by the wide wheel abrasion test by following EN 14157 (2006) standard. The WA value, given in mm, represents the width of the abraded part measured on the sample at the end of the test. WA values of the samples were determined between 14.07 and 43.66 mm with an average value of 20.98 mm (Table 1). The influence of γd and no values on abrasion resistance of tested building stones was investigated, and a linear correlation equation was obtained. In Fig. 3a, a negative linear correlation between γd and WA values was observed (Eq. 3, R2 = 0.77), whereas a positive linear correlation (Eq. 4, R2 = 0.71) between no and WA values was observed (Fig. 3b):

where WA: abrasion resistance by wide wheel (mm), no: open porosity (%), and γd: dry unit weight (kN/m3).

Ultrasonic wave velocity measurements

A Pundit Lab (2014) ultrasonic test device with transmitter and receiver transducers of 54 kHz bandwidth was used to measure the longitudinal ultrasonic wave velocity (Vp) values. Ultrasonic wave velocity is a widely used parameter in the characterization of rock materials, which is used in indirect estimation of physico-mechanical parameters of rocks. It is practical and economical to use, and does not require well-prepared samples, which is why became a widespread method. Ultrasonic wave velocity values were determined as 1.952 and 7.128 km/s for ignimbrite (Ign 3-1) and dolomite (Dlm 1-1) samples, respectively. Vp measurement results are shown in Table 1. Between Vp and no values of tested samples, a negative linear correlation was determined. In this correlation, metamorphic rock data were found to be outside the general trend, which is possibly due to anisotropic internal structure of schist and marble samples. Determination coefficient for this correlation was obtained as 0.68 (Eq. 5, Fig. 4a). Distribution of γd and Vp values was also investigated and correlation between these two parameters was determined as a power function with 0.70 determination coefficient value (Eq. 6, Fig. 4b):

where, no: open porosity (%), Vp: longitudinal wave velocity (km/s), and γd: dry unit weight (kN/m3).

Uniaxial compressive strength tests

Uniaxial compressive strength (UCS) is a very important mechanical parameter for rocks. UCS tests on all cubic samples were carried out in dry conditions in accordance with ASTM (1999) standard. 2000 kN load capacity compression test system was used and the loading rate was kept between 0.5 and 1 MPa/s. Minimum and maximum UCS values of the samples were determined as 6.12 and 202.34 MPa which correspond to weak and very strong rock class, respectively (ISRM 2007). It should be noted that UCS values of selected samples vary within a very wide range. Therefore, the proposed correlation equations, obtained from such a wide range, will be very useful and can be utilized for general use. UCS values of all samples were given in Table 1. Correlations between UCS and other test data were investigated. Significant correlations between UCS − γd, UCS − no, and UCS − WA values were obtained and presented in Fig. 5a–c, respectively. UCS − γd and UCS − no correlations were given in logarithmic functions with 0.75 and 0.60 determination of coefficient values respectively, and these correlation equations were given in Eqs. 7 and 8:

where, UCS: uniaxial compressive strength (MPa), γd: dry unit weight (kN/m3), and no: open porosity (%).

Çobanoğlu and Çelik (2017) proposed a correlation equation for the prediction of WA values from UCS values (Eq. 9). In this study, a slightly stronger correlation between UCS and WA values was observed (Eq. 10). Data scatter for this correlation is also presented in Fig. 5c:

where UCS in MPa and WA in mm.

Hardness tests

Leeb hardness tests (HLD)

Pen Type Leeb Hardness Tester (TIME® 5100) used in this study is a pocket size electronic hardness tester with a built-in type “D” impact body and a tip made of tungsten carbide (Fig. 6a). Different types of impact bodies with different impact energies are available for Leeb hardness test devices. These impact bodies can be selected according to the physical condition and hardness of a material. In general, type “D” impact body is commonly used. The impact energy and weight of this body is 11 N mm and 5.5 g, respectively. When the impact body loaded by a spring mechanism is released, it hits to the material surface and rebounds. At a distance of 1 mm from the material surface, impact and rebound velocities of the body are determined depending on the voltage generated by the coil inside the device. Although the device can be used in different directions, in this study, all tests are carried out holding the HLD device downwards. In Fig. 7, typical time-dependent recorded voltage values (+U, −U) during a test are given. HLD values are determined by the following equation (Leeb 1979):

where, HLD: Leeb hardness value (with type “D” impact device), Vrebound: rebound velocity of the impact body, Vimpact: impact velocity of the body.

Typical generated voltage pattern during an HLD test (after Leeb 1979)

HLD criterion was originally developed for metallic materials and a standard procedure was proposed for steel products by ASTM (2002). However, a hardness measurement procedure for rocks is not yet standardized. Researchers have been determining the HLD values with their own test methodologies (Verwaal and Mulder 1993; Aoki and Matsukura 2008; Güneş Yılmaz 2013; Lee et al. 2014; Su and Momayez 2017; Güneş Yılmaz and Göktan 2018a, b; Corkum et al. 2018). These HLD measurement approaches can be divided into two groups. The first one is averaging the hardness values taken at different points and the second is averaging the repeated hardness values at the same points on the surface of a sample. In this study, repeating hardness measurement on the same point approach was not adopted. Some tested building stones such as granite, andesite, gabbro, etc. consisted of polyminerals. It is clear that different minerals will give different HLD values; for this reason, repeated impact values at one point can cause the hardness value to be obtained incorrectly. The authors believed that the best measurement method for HLD tests was to use the average of the measurements taken at different points distributed on the surface of a sample. In this study, different HLD measurement methods were tried, and eventually, the average of 20 HLD measurements taken at different points of a surface of a sample was found to be the best representative. This method is the same as the suggested method for Shore (C-2) hardness (HSC) measurement by ISRM (Altındağ and Güney 2006).

Schmidt hammer (HSL) and Shore C-2 scleroscope hardness tests (HSC)

For the purpose of this study, HSL measurements were taken on each sample (Fig. 6b). L-type Schmidt hammer with 0.735 Nm impact energy (Proceq 2016) was used in accordance with ISRM (Altındağ and Güney 2006). HSL method was first proposed for the determination of the strength of concrete as a non-destructive test method (Schmidt 1951; Hucka 1965) and then become widespread, and it has been used on rock materials especially for the estimation of UCS values in engineering practice (Katz et al. 2000; Kahraman 2001; Yılmaz and Sendir 2002; Yaşar and Erdoğan 2004; Aydın and Basu 2005; Shalabi et al. 2007; Büyüksağış and Göktan 2007; Çobanoğlu and Çelik 2008; Yağız 2009, Gupta et al. 2009; Bruno et al. 2013; Selçuk and Yabalak 2015; Momeni et al. 2015; Selçuk and Nar 2016). In all measurements, the hammer was held downwards. Compared to Schmidt hammer, Shore scleroscope is an older test method. A 2.44 g diamond-tipped hammer falls freely on the test surface and rebounds upward in a tube with a hardness scale ranging from 0 to 140 (Fig. 6c). The Shore scleroscope has been used in the characterization of rocks for a very long period of time (Koncagül and Santi 1999; Tumaç et al. 2007; Çobanoğlu and Çelik 2017). Schmidt can be used in both laboratory and field, while Shore can only be used in laboratory.

Correlation of test results

Correlations of hardness and physical properties of building stones

For the purpose of this study, estimation of physical properties from HLD, HSL, and HSC hardness values of studied rocks is investigated and the results are presented. In Table 1, all test parameters with hardness values are listed. Correlations of dry unit weight (γd) and HLD, HSL, and HSC values are presented in Fig. 8a–c, respectively. Correlation equations for γd − HLD, γd − HSL, and γd − HSC are given in Eqs. 12, 13, and 14 respectively. Reasonable and similar correlations between dry unit weight and hardness values were obtained in terms of determination coefficients. HSC test is found to be a little stronger than HLD and HSL method:

Slightly weaker correlations were obtained between open porosity (no) and HLD, HSL, and HSC hardness values (Fig. 9a–c). Open porosity could be a problem for HLD measurements. If the impact tip coincides with the pores during the test, the measurement may not be taken. Hardness measurement could be a problem for porous rocks such as travertine; therefore, the measurements should be taken more carefully for this type of rocks. In the correlation of hardness and open porosity values of tested rocks, HLD method was found to be stronger than HSL and HSC methods in the estimation of no values from hardness values, which are given in Eqs. 15, 16, and 17:

Water absorption values of samples were also investigated. WAW values were exponentially decreased with increasing hardness values. Correlations of HLD, HSL, and HSC hardness values with WAW values are given in Fig. 10a–c, respectively. Correlations equations are also given in Eqs. 18, 19, and 20:

Statistically significant correlations were obtained for estimating some physical properties of rocks. It was observed that the data of ignimbrite samples were far from the obtained correlation curves. It is thought that this situation is caused by the textural and mineralogical structure of ignimbrite samples. It should be noted that the hardness values can practically be used in the characterization of physical properties of rock materials. It is also concluded in this study that HLD method was found to be more successful than HSL and HSC methods in terms of estimating performance and ease of use.

Correlations of hardness and mechanical properties of rocks

Abrasion resistance by wide wheel abrasion test (WA) and UCS tests results were investigated as mechanical properties. Estimation of these parameters from hardness values of tested rocks were compared. It is clear that abrasion is associated with surface hardness. In the scope of this study, strong correlations between abrasion and hardness were determined. In Fig. 11a–c, correlations of WA − HLD, WA − HSL, and WA − HSC are given, respectively. Hardness tests can be used to estimate the abrasion resistance of building stones. All correlations were found in exponential forms and can practically be used in the prediction of WA values. In Eqs. 21, 22, and 23, correlation equations for the prediction of abrasion resistance of rock materials from HLD, HSL, and HSC are listed, respectively:

The most important mechanical property of rocks is UCS. Therefore, the practical estimation of this parameter attracts the attention of many researchers. Estimation of UCS values from HLD, HSL, and HSC values was investigated. HLD values were found to be more effective in the prediction of UCS values than HSL and HSC. Throughout the scope of the study, it has been shown that HLD values can be used successfully in the estimation of UCS values of tested rock samples ranging from weak to very strong. In Fig. 12a, b, c, correlations of UCS to HLD, HSL, and HSC are given, respectively. Within the scope of this study, the following equations (Eqs. 24, 25, and 26) are proposed for the estimation of UCS values of rock represented by sedimentary, metamorphic, and igneous origin:

This study contains the data of rocks represented by 40 types of rocks. Therefore, proposed correlation equations can widely be used in practice and properties of rock materials can be predicted with considerable accuracy using the proposed equations. The previously proposed equations with measurement methods for the practical estimation of UCS values from the measured HLD values for the different rock types are given in Table 2.

Although Leeb hardness criterion was developed to measure the surface hardness of metallic materials, applicability to use on rock materials has been investigated by various researchers. In this study, it was determined that the recent HLD test can be used successfully in the estimation of technological and quality parameters of rocks both in laboratory and in field for various fields in engineering practice. In this study, it is concluded that the use of HLD hardness values in rock material characterization is more advantageous and useful than the HSL and HSC methods. Equations for the estimation of the basic properties of rock materials from HLD values are summarized in Table 3.

Correlation of hardness tests

Surface hardness methods are widely preferred in the estimation of the physical and mechanical properties of rocks due to their practical and economical use. HLD, HSL, and HSC hardness values of all samples were correlated with each other (Fig. 13a–c). Between these methods, reasonable correlations were obtained. In this study, determination of HLD values by pocket size hardness test device found to be faster, easier, and comfortable than HSL and HSC methods. In rock characterization, both in laboratory and in field HLD tests would be very useful. In the correlation of 40 stone types, the best fit equations were found as linear functions. The strongest correlation was determined between HLD − HSC (Eq. 27) and HLD − HSC (Eq. 28) methods; however, between HSL and HSC (Eq. 29), a weaker correlation was observed:

Güneş Yılmaz and Göktan (2018a) correlated the Schmidt and Leeb hardness values and proposed the following linear equation (Eq. 30):

Reasonable correlations between three rebound hardness measurement methods were obtained for the selected rocks. The power of the correlation between HLD and HSC is thought to be due to an effect of the similarity of these two rebound test methods to each other in terms of their impact energies and similar dimension of impact tip. However, impact energy of the Schmidt hammer of type L is about 67 times higher than the Leeb has. The lower impact energy of HLD can be considered as a less destructive test than the Schmidt hammer, especially tests on weak stones such as tuff and ignimbrites.

Another difference between hardness tests is the hardness scale. Leeb hardness test device gives the HLD value between 170 and 900. However, HSL and HSC values have a range between 0–100 and 0–140, respectively. More accurate hardness values of rocks can be given using Leeb method than Schmidt hammer and Shore scleroscope methods.

Conclusions

Estimation of the physical and mechanical properties of natural building stones has become increasingly widespread utilizing not only practical and economical tests but also non-destructive test methods. Pen type Leeb hardness tester used in this study showed some advantages over Schmidt hammer and Shore scleroscope such as practical use, determination of precise hardness value ranging from 170 to 900, instant data acquisition, applicability to weak rocks due its lower impact energy, and usability in both laboratory and field.

Although there is no suggested or standardized test method for Leeb hardness measurements on rock materials, various HLD measurement methods have been proposed by different researchers. In the context of this study, average of 20 HLD measurements taken at different points of a surface of a sample was found to be the best representative measure for the hardness of tested stones.

Surface hardness of a rock material is a parameter closely related to other physical and mechanical properties. γd, no, WAW, WA, and UCS parameters of 40 types of building stones of sedimentary, metamorphic, and igneous origin were determined and correlated with HLD values. Reasonable correlation equations, which will be beneficial for the practitioners, scientists, and various people from related fields, were proposed.

Correlation of HLD values with more test data of different types of natural building stone would be further contribution to propose more general predictive equations. Furthermore, investigation of anisotropy and weathering properties of rock materials with HLD values is suggested as future studies.

References

Altındağ R, Güney A (2006) ISRM suggested method for determining the shore hardness value for rock. Int J Rock Mech Min 43:19–22

Aoki H, Matsukura Y (2008) Estimating the unconfined compressive strength of intact rocks from Equotip hardness. Bull Eng Geol Environ 67(1):23–29

Asiri Y (2017) Standardized process for field estimation of unconfined compressive strength using Leeb hardness. MSc thesis, Dalhousie University, p 174

Asiri Y, Corkum AG, El Naggar H (2016) Leeb hardness test for UCS estimation of sandstone. In: Canadian Geotechnical Society, p 11

ASTM (1999) Standard test method for compressive strength of dimension stone (Designation: C 170). Annual Book of ASTM Standards

ASTM (2002) Standard test method for Leeb hardness testing of steel products. ASTM International A956-12

ASTM (2013) Standard hardness conversion tables for metals relationship among Brinell hardness, Vickers Hardness, rockwell hardness, superficial hardness, Knoop Hardness, Scleroscope hardness, and Leeb hardness. ASTM International E140-12b

Atkinson RH (1993) Hardness test for rock characterization. In: Hudson JA (ed) Comprehensive rock engineering: principles, practice and projects. Rock testing and site characterization, vol 3. Pergamon, Oxford, p 1011

Aydın A, Basu A (2005) The Schmidt hammer in rock material characterization. Eng Geol 81:1–14

Bruno G, Vessia G, Bobbo L (2013) Statistical method for assessing the uniaxial compressive strength of carbonate rock by Schmidt hammer tests performed on core samples. Rock Mech Rock Eng 46:199–206

Büyüksağış İS, Göktan RM (2007) The effect of Schmidt hammer type on uniaxial compressive strength prediction of rock. Int J Rock Mech Min 44:299–307

Çobanoğlu İ, Çelik SB (2008) Estimation of uniaxial compressive strength from point load strength, Schmidt hardness and P-wave velocity. Bull Eng Geol Environ 67:491–498

Çobanoğlu İ, Çelik SB (2017) Assessments on the usability of Wide Wheel (Capon) test as reference abrasion test method for building stones. Constr Build Mater 151:319–330

Çobanoğlu İ, Çelik SB, Alkaya D (2010) Correlation between “wide wheel abrasion (capon)” and “Bohme abrasion” test results for some carbonate rocks. Sci Res Essays 5(22):3398–3404

Coombes MA, Feal-Pérez A, Naylor LA, Wilhelm K (2013) A non-destructive tool for detecting changes in the hardness of engineering materials: application of the Equotip durometer in the coastal zone. Eng Geol 167:14–19

Corkum AG, Asiri Y, El Naggar H, Kinakin D (2018) The Leeb hardness test for rock: an updated methodology and UCS correlation. Rock Mech Rock Eng 51:665–675

Daniels G, McPhe CA, Sorrentino YC, McCurdy P (2012) Nondestructive strength index testing applications for sand failure evaluation. In: SPE Asia Pacific oil and gas conference and exhibition, society of petroleum engineers, p 12

EN 14157 (2006) Natural stones—determination of abrasion resistance. European Standard, p 19

EN 1926 (2006) Natural stone test methods—determination of uniaxial compressive strength. European Committee for Standardization, p 20

EN 1936 (2006) Natural stone test methods—determination of real density and apparent density, and of total and open porosity. European Committee for Standardization, p 11

Güneş Yılmaz N (2013) The influence of testing procedures on uniaxial compressive strength prediction of carbonate rocks from Equotip hardness tester (EHT) and proposal of a new testing methodology: hybrid dynamic hardness (HDH). Rock Mech Rock Eng 46(1):95–106

Güneş Yılmaz N, Göktan RM (2018a) Comparison and combination of two NDT methods with implications for compressive strength evaluation of selected masonry and building stones. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-018-1382-7

Güneş Yılmaz N, Göktan RM (2018b) Analysis of the Leeb hardness test data obtained by using two different rock core holders. Süleyman Demirel Univ J Nat Appl Sci 22(1):24–31

Güneş Yılmaz N, Tumaç D, Göktan RM (2015) Rock cuttability assessment using the concept of hybrid dynamic hardness (HDH). Bull Eng Geol Environ 74:1363–1374

Gupta V, Sharma R, Sah MP (2009) An evaluation of surface hardness of natural and modified rocks using Schmidt hammer: study from northwestern Himalaya, India. Geografiska Annaler 91A(3):179–188

Hack HR, Hingira J, Verwaal W (1993) Determination of discontinuity wall strength by Equotip and ball rebound tests. Int J Rock Mech Min Geomech Abs 30(2):151–155

Hucka V (1965) A rapid method of determining the strength of rocks in situ. Int J Rock Mech Min Geomech Abs 2:127–134

ISRM (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. In: Ulusay R, Hudson JA (eds) Suggested methods prepared by the commission on testing methods, ISRM, Compilation arranged by the ISRM Turkish National Group, p 628

Kahraman S (2001) Evaluation of simple methods for assessing the uniaxial compressive strength of rock. Int J Rock Mech Min 38:981–994

Karaca Z, Deliormanli AH, Elçi H, Pamukcu C (2010) Effect of freeze-thaw process on the abrasion loss value of stones. Int J Rock Mech Min 47(7):1207–1211

Karaca Z, Güneş Yılmaz N, Göktan RM (2012) Considerations on the European standard EN 14157 test methods: abrasion resistance of natural stones used for flooring in buildings. Rock Mech Rock Eng 45:103–111

Katz O, Reches Z, Roegiers JC (2000) Evaluation of mechanical rock properties using a Schmidt Hammer. Int J Rock Mech Min 37:723–728

Kawasaki S, Tanimoto C, Koizumi K, Ishikawa M (2002) An attempt to estimate mechanical properties of rocks using the Equotip hardness tester. J Soc Eng Geol 43(4):244–248

Kompatscher M (2004) Equotip—rebound hardness testing after D. Leeb. In: Conference on hardness measurements theory and application in laboratories and industries, pp 66–72

Koncagül EC, Santi PM (1999) Predicting the unconfined compressive strength of the Breathitt shale using slake durability, Shore hardness and rock structural properties. Int J Rock Mech Min 36:139–153

Lee JS, Smallwood L, Morgan E (2014) New application of rebound hardness numbers to generate logging of unconfined compressive strength in laminated shale formations. In: 48th US rock mechanics—geomechanics symposium, vol 2, pp 972–978

Leeb D (1979) Dynamic hardness testing of metallic materials. NDT Int 12(6):274–278

Marini P, Bellopede R, Perino L, De Regibus C (2011) Optimisation of an abrasion resistance test method on natural stones. Bull Eng Geol Environ 70:133–138

Meulenkamp F, Alvarez Grima M (1999) Application of neural networks for the prediction of the unconfined compressive strength (UCS) from Equotip hardness. Int J Rock Mech Min 36(1):29–39

Mol L (2014) Measuring rock hardness in the field. In: Nield J, Clarke L (eds) Geomorphological techniques. British Society for Geomorphology, p 8

Momeni E, Nazir R, Armaghani DJ, Mohamad ET (2015) Prediction of unconfined compressive strength of rocks: a review paper. Jurnal Teknologi 77(11):43–50

Proceq (2014) Pundit lab/Pundit lab + ultrasonic instrument operating instructions. Proceq SA, p 31

Proceq (2016) Portable nondestructive concrete testing instrument. Proceq SA, p 10

Schmidt E (1951) Investigations with the new concrete test hammer for estimating the quality of concrete. Schweizer Archive angerwandte Wissenschaft Technik (Solothurn) 17(5):139

Selçuk L, Nar A (2016) Prediction of uniaxial compressive strength of intact rocks using ultrasonic pulse velocity and rebound-hammer number. Q J Eng Geol Hydroge 49(1):67–75

Selçuk L, Yabalak E (2015) Evaluation of the ratio between uniaxial compressive strength and Schmidt hammer rebound number and its effectiveness in predicting rock strength. Nondestruct Test Eva 30(1):1–12

Shalabi FI, Cording EJ, Al-Hattamleh OH (2007) Estimation of rock engineering properties using hardness tests. Eng Geol 90(3):138–147

Siegesmund S, Dürrast H (2014) Physical and mechanical properties of rocks. In: Siegesmund S, Snethlage R (eds) Stone in architecture, properties, durability, 5th edn. Springer, Berlin

Su O, Momayez M (2017) Correlation between Equotip hardness index, mechanical properties and drillability of rocks. Dokuz Eylul Univ J Sci Eng 19(56):519–531

Tumaç D, Bilgin N, Feridunoğlu C, Ergin H (2007) Estimation of rock cuttability from shore hardness and compressive strength properties. Rock Mech Rock Eng 40(5):477–490

Verwaal W, Mulder A (1993) Estimating rock strength with the Equotip hardness tester. Int J Rock Mech Min Geomech Abs 30(6):659–662

Viles H, Goudie A, Grab S, Lalley J (2011) The use of the Schmidt Hammer and Equotip for rock hardness assessment in geomorphology and heritage science: a comparative analysis. Earth Surf Proc Land 36(3):320–333

Yağız S (2009) Predicting uniaxial compressive strength, modulus of elasticity and index properties of rocks using the Schmidt hammer. Bull Eng Geol Environ 68(1):55–63

Yaşar E, Erdoğan Y (2004) Estimation of rock physicomechanical properties using hardness methods. Eng Geol 71(3):281–288

Yılmaz I, Sendir H (2002) Correlation of Schmidt hardness with unconfined compressive strength and Young’s modulus in gypsum from Sivas (Turkey). Eng Geol 66(3):211–219

Acknowledgements

Portable hardness test device used in this study was financially supported by Pamukkale University Scientific Research Projects Coordination Unit under a project (no.: 2018KRM002-392); this support is gratefully acknowledged. Hardness measurements by Shore C-2 scleroscope were taken in the mining engineering department of Süleyman Demirel University; the authors wish to thank Prof. Dr. Raşit Altındağ and Dr. Deniz Akbay for their kind support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Çelik, S.B., Çobanoğlu, İ. Comparative investigation of Shore, Schmidt, and Leeb hardness tests in the characterization of rock materials. Environ Earth Sci 78, 554 (2019). https://doi.org/10.1007/s12665-019-8567-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-019-8567-7