Abstract

Internal erosion is the most common reason which induces failure of embankment dams besides overtopping. Relatively large leakage is frequently concentrated at defects of impervious element, and this will lead to eventual failure. The amount of leakage depends not only on integrity of impervious element, but also on dam height, shape of valley, shape of impervious element and water level in reservoir. The integrity of impervious element, which represents the relative level of seepage safety, is not easy to be determined quantitatively. A simple method for generalization of steady seepage state of embankment dams with thin impervious element is proposed in this paper. The apparent overall value of permeability coefficient for impervious element can be obtained by this method with reasonable accuracy and efficiency. A defect parameter of impervious element is defined as an index to characterize seepage safety of embankment dams. It equals the ratio of the apparent overall value of permeability coefficient to the measured value in laboratory for intact materials. Subsequently, seepage safety of three dams is evaluated and the evolution of defect level of impervious element of dams is investigated. It is proved that the newly proposed method in this paper is feasible in the evaluation of relative seepage safety level of embankment dams with thin impervious element.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Embankment dams are generally constructed of earthfill and/or rockfill due to technical and economic reasons (Novak et al. 2007). According to the World Register of Dams by ICOLD (2017), embankment dams account for about 76% of all registered dams.

High embankment dams often include two component elements, i.e., impervious water-retaining element and supporting element. As for the impervious element, compacted fine-grained silty or clayey earthfills, or artificial materials, e.g., asphalt, concrete or geomembrane, are often employed to prevent leakage. Different types of coarser fills ranging up to coarse rockfills are often compacted into designated zones to provide both structural stability and good drainability.

Relatively thin impervious elements are popularly employed in existing embankment dams, particularly in high embankment dams and reinforcement projects. Generally, there are two types of thin impervious elements. (1) The first type is thin impervious element in which artificial materials are generally used. For instance, the surface membranes or central diaphragms are thin impervious elements with thickness ranging from mm-order to m-order, for which artificial materials such as asphalt, concrete or geomembrane are employed. The maximum thickness of concrete face of 233-m-height Shuibuya Concrete Faced Rockfill Dam (CFRD) is 1.1 m; meanwhile, the maximum thickness of concrete cutoff wall of 240 m-height Changheba earth core rockfill dam is 1.4 m. Changheba earth core rockfill dam is 1.4 m. (2) The second type is thin impervious element in which nature materials are employed. The central and inclined earth cores are also classified into thin impervious elements according to Hunter and Fell (2003), if the core width increases at less than or equal to 0.5 times the vertical distance below the crest, i.e., both upstream slope and downstream slope are less than or equal to 1:0.25 for central cores. Most constructed high earth core rockfill dams (ECRD) have thin earth core, such as 300-m-height Nurek ECRD in Tajikistan, 265-m-height Nuozhadu ECRD in China, 262-m-height Manuel Moreno Torres (Chicoasén) ECRD in Mexico and 260-m-height Tehri ECRD in India.

Some embankment dams built on overburden have anti-seepage systems with a combination of thin impervious element in the embankment and concrete cutoff wall in overburden which may connect to grouting curtain in bed rock. Also, the combination itself forms a generalized thin impervious element.

Internal erosion or piping which is associated with migration of fine particles is one of main failure modes of embankment dams besides overtopping (Penman 1986). It accounts for about 39% of embankment dam failures in China (Chen 2012), and it is also responsible for about 37% of embankment dam failures abroad (Foster et al. 2011). Rational evaluation of leakage and early judgement for the initialization and development of the internal erosion and piping are necessary for providing warning and treatment which may reduce the casualties, postpone dam failure and even avoid dam breach. Thus, a simple approach is proposed in this paper to evaluate the seepage safety of embankment dams with thin impervious element including CFRDs.

Exploring the seepage safety evaluation method according to leakage monitoring data

Difficulties in evaluation of internal erosion and piping in high embankment dams

For the impervious materials such as soil, hydraulic gradient is usually employed to indicate internal erosion and piping, as expressed in the regulations of many nations (USACE 1993; China NDRC 2007). Nevertheless, hydraulic gradient is a value at scattered points, which does not indicate erosion and piping phenomena along a successive path. Irrespective of the fact that reliable criterion of internal erosion failure for geostructures such as embankment dams is under investigation, continuously distributed numerical modeling for hydraulic gradient field is required for judgement.

Theoretically, the numerical model can be obtained through back calculation of monitoring data. For most high embankment dams, pore pressure or water head at different positions and the leakage from some parts of embankment dams can be monitored. Nevertheless, both quantity and quality of the monitoring data may be limited because of the complexity in actual conditions. Steady state seepage is rarely reached in embankment dams due to the variation of water level with time. Moreover, water head distribution and leakage at a specific time are relevant to water level revolution history which is not easy to trace. Unsaturated state other than saturated seepage in the impervious element and ambiguous boundary conditions on downstream slope of the impervious element also increase the difficulty level of analysis. Therefore, the establishment of representative numerical models is time consuming and even hardly to achieve.

There is lack of practical methods to evaluate the leakage and possibility of internal erosion and piping dynamically, particularly for embankment dams other than CFRDs.

Studies on leakage estimation in embankment dams

Internal erosion or piping of embankment dams usually occurs in a progressive way. It takes time for the leakage to develop. Increasing leakage always reflects the trend of internal erosion or pipping in embankment dams (Fell et al. 2003). It may be a good choice to use leakage to identify the possibility of internal erosion or piping of embankment dams. However, due to varied heights and distinct valley shape, different impervious element materials, disparate thickness and various thickness profiles of impervious element, leakage value itself may not be employed directly to evaluate the possibility of internal erosion and piping.

Casinader and Rome (1988) proposed a simple method for CFRDs to estimate the expected leakage through concrete face. The geometry configuration of the CFRD was simplified in their method. The profile of the valley was approximated to a triangle, and hence the elevation of concrete face was simplified to a triangle also. The slope of both sides of face slab was uniform, and the incremental thickness of face slab was kept constant for per meter depth from the crest. The full supply level of the reservoir and the crest level of the dam were also assumed to be identical. Although it was not declared explicitly by Casinader and Rome (1988), water pressure head was assumed to fall evenly along thickness. Analytical formula of the relationship between leakage and coefficient of permeability of face slab was subsequently established. The coefficient of permeability in this formula is not that of contact concrete but an apparent overall value including the effect of crack and defect of sealing of joints. It was also suggested to obtain coefficient of permeability value from existing dams where appropriate parameters were known. The relationship between leakage and coefficient of permeability proposed by Casinader and Rome (1988) was actually a simplified description of the steady seepage process of CFRD. It was originally used to predict the leakage amount from CFRD. It reveals a possibility to develop methods to model the leakage, which may be used in evaluation of possibility of internal erosion and piping.

Study in this paper

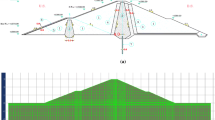

Actual profile of the valley is usually irregular. If the longitudinal section is not V-shaped, relatively large error may be introduced in calculation. Besides, the profile of impervious element of embankment dams other than CFRDs may be much more complicated than the simplification done to CFRDs. For CFRDs, both transverse section and longitudinal section or elevation (front view) are simplified, e.g., the cross section and longitudinal section of Hyttejuvet embankment dam in Fig. 1. The method proposed by Casinader and Rome (1988) may be inapplicable to embankment dams other than CFRDs.

Typical sections of Hyttejuvet earth core embankment dam (after Penman 1986)

For embankment dams other than CFRDs, because of low permeation resistance of impervious element and low drainage capacity of supporting element, it is concerned that leakage through the impervious element is detrimental to the dam’s safety. Therefore, it is important to evaluate the leakage and possibility of internal erosion and piping dynamically. Meanwhile, it is required to carry out the relevant calculation in a quick and simple way.

A more elaborated approach to calculating the leakage by numerical integration or direct integration is proposed in this paper. In this approach, simplicity is not discarded and fewer idealizations are introduced. Arbitrarily shaped transverse section and longitudinal section of the impervious element can be dealt with. Diverse permeability coefficient values at different elevations are considered. The apparent overall value of the coefficient of permeability is obtained by back calculation from leakage. In the back calculation, steady seepage is assumed to be achieved. Instead of finite element analysis which is time consuming and complicate, this approach can provide the back-analysis value of apparent overall permeability value with reasonable accuracy and speed. Meanwhile, the computation results by the newly proposed simple approach show remarkable agreement with those by finite element analysis.

Furthermore, a defect parameter is introduced in this paper for embankment dams with thin impervious element to denote the integrity of the impervious element and the possibility of internal erosion and piping. The defect parameter is defined as the ratio of apparent overall value of the coefficient of permeability to design value of intact impervious materials.

The application of the approach to evaluating the leakage is also shown in this paper. The approach is feasible, and the defect parameter is a suitable index to characterize the relative level of seepage safety, or possibility of internal erosion and piping, not only for CFRDs but also for embankment dams with thin impervious element. Since the calculation can be conducted in a quick and unmanned way, the approach is suitable for dynamic safety analysis by computer.

Simple approach to estimating leakage through impervious element

Fundamental simplifications and idealizations

The concept and range of thin impervious element in accumulation of seepage flux

Idealized cross section and transverse section of thin impervious element in an embankment dam are shown in Fig. 2. Generally, any part of geostructures with small thickness in embankment and foundation can be named as thin impervious element, provided that the coefficient of permeability of that part is much lower than that of other parts, and most of hydraulic gradient is concentrated in that part.

It is often difficult to differentiate leakage from each part of generalized impervious element in practice, except for asphaltic concrete face dam in which membrane seepage is measured separately. Each part of the generalized impervious element, such as curtain, cutoff wall, earth core, can be taken into consideration in the proposed approach, by assuming that the contribution to total leakage of that part is not neglected and that the leakage from that part is actually monitored in total leakage.

However, the reasonable permeability coefficient of “contact” curtain is often not available, because of the complexity in grouting executing and in geological conditions. Moreover, the leakage through the curtain is often not measurable in practice. Hence, the leakage through curtain is generally not included in analysis. For most cases, only leakage through embankment and overburden (the leakage from bed rock is not considered) is incorporated in the approach.

Pore water pressure distribution in impervious element may be complicated at the position where elevation exceeds reservoir water level. If reservoir water level is kept low for a long time, water pressure in these places may turn negative. Nonetheless, reservoir water level is always changing. On account of that the permeability coefficient of impervious element is relatively low enough, and even much lower at unsaturated state, it is assumed that no seepage flux occurs outside impervious element above reservoir water level. Therefore, this part of impervious element is not considered in the analysis.

Generalization of seepage field in embankment dams

First, it is assumed that water head loss does not drop in supporting zone with high permeability but concentrate in thin impervious element. Second, Darcy’s law is assumed to be applicable for seepage in thin impervious element. Hydraulic gradient along seepage path in thin impervious element is kept constant. Moreover, the flow through the concrete is laminar. Third, pore water pressure values at downstream surface of impervious element are assumed to be equal to zero. Thus, water heads at downstream surface of impervious element equal elevation. It is implicated that downstream surface of impervious element is not potential but definite seepage boundary. Furthermore, according to the assumption that impervious element is thin enough, seepage directions are assumed to be orthogonal to medial surface of impervious element.

Definitions

Cartesian coordinates are introduced, with x-axis positive direction pointing from left bank to right bank of river valley, y-axis positive direction from upstream to downstream, z-axis positive direction from lower elevation to high elevation.

A bottom-to-up non-straight direction tangential to medial axis (in any transverse section) of impervious element is defined as the length coordinate of “l.”

As shown in Fig. 2, the thickness of impervious element at length coordinate l along the orthogonal directions of medial axis is defined as \( LY\left( l \right) \), a function of length coordinate ”l.” The width of impervious element along the axis of the dam at length coordinate l is defined as \( WX\left( l \right) \).

Upstream reservoir water level is \( H_{u} \), and the downstream one is \( H_{d} \).

Calculation of leakage from homogeneous impervious element

The impervious element is divided into several thin strips which are horizontal in x direction (dam axis direction). The cross section of each strip is parallelogram with its long side parallel to assumed seepage direction, i.e., the direction orthogonal to medial surface of impervious element. Suppose the height of each thin strip is dz (length is dl) and the elevation at bottom of the strip is z (the length coordinate equals l).

If downstream side of the strip is above the downstream level, i.e., \( H_{d} - z \le 0 \), the water head loss in the strip equals \( \left( {H_{u} - z} \right) \). If it is under the downstream level, i.e., \( H_{d} - z > 0 \), the water head drawdown in the strip equals \( \left( {H_{u} - H_{d} } \right) \). The function \( H\left( l \right) \) is introduced to denote the water head loss of the strip at length l (at height z), and then

The average hydraulic gradient in that strip can be computed as

If the permeability coefficient is not the same at different elevations, let \( k\left( l \right) \) indicate permeability coefficient in the thin strip, hence leakage from the thin strip of the impervious element is

Leakage through the whole impervious element can be calculated by integrating Eq. (3) from the bottom of the impervious element to upstream water level

where \( l_{\text{lowest}} \) is the length coordinate at bottom of impervious element, \( l_{{H_{u} }} \) is the length coordinate at the elevation \( H_{u} \).

Calculation of leakage from inhomogeneous impervious element

If there are multiple parts (in total n parts) of impervious element, the seepage discharge can be integrated as

\( k_{1} \left( l \right) \), \( k_{2} \left( l \right) \), \( k_{i} \left( l \right) \) and \( k_{n} \left( l \right) \) are the permeability coefficient at the 1st, 2nd, ith and nth parts of the impervious element. \( l_{{H_{1} }} \), \( l_{{H_{2} }} \), \( l_{{H_{i} }} \) and \( l_{{H_{n - 1} }} \) are the length coordinates at top of the 1st, 2nd, ith and (n − 1)th parts of the impervious element, respectively. If there is concrete cutoff wall in impervious element, then \( l_{\text{lowest}} \) is the length coordinate for the lowest point of the wall.

Validation of the proposed approach

The proposed approach is validated. The calculated results of steady state leakage discharge at specific upstream and downstream water levels by recommended simple approach and by three-dimensional finite element analysis (FEA) through ABAQUS software are compared. Two cases of different dam types are analyzed.

The first case is earth core rockfill dam of Nuozhadu with the height of 261.5 m. The typical cross section and longitudinal section are shown in Fig. 3. Crest length of the dam is 627.9 m. The top width of earth core is 10 m. Slope ratio of upstream and downstream surface of core is 1:0.2.

Typical sections of Nuozhadu earth core rockfill dam (after Kunming Engineering Corporation Limited 2006)

The second case is concrete-faced rockfill dam of Sanbanxi with the height of 185 m. The typical cross section and front view are shown in Fig. 4. Crest length of the dam is 423.75 m. Slope ratio for the upstream surface of face slab is 1:1.4. The thickness increases linearly with the decrease in the altitude. The value of the thickness is 0.3 and 0.913 m at top and bottom, respectively.

Typical sections of Sanbanxi CFRD (after Zhu et al. 2009)

The abutment slopes are not constant for both dams. Shape of impervious element cannot be expressed analytically. Seepage discharge can be calculated by numerical integration according to Eq. (5). Let the permeability coefficient of earth core of Nuozhadu and concrete face of Sanbanxi is 1 × 10−5 cm/s and 1.3 × 10−9 cm/s, respectively. The comparisons between suggested method and finite element analysis are shown in Tables 1 and 2. The results obtained from suggested method show good agreement with those by ABAQUS software. The differences are less than 10%, indicating that the suggested simple approach is feasible in steady state seepage analysis with adequate accuracy.

Definition of defect parameter of impervious element as index of seepage safety

Calculation of apparent overall value of permeability coefficient for impervious element

Apparent overall value of permeability coefficient \( k_{\text{overall}} \) for impervious element is back-analysis average value of permeability coefficient according to measured actual leakage flux \( Q_{\text{ms}} \left( {H_{u} , H_{d} } \right) \).

For homogeneous impervious element, apparent overall value of permeability coefficient can be simply calculated as

For inhomogeneous impervious element, apparent overall value of permeability coefficient is calculated as

Calculation of defect parameter of impervious element

Defects always exist in embankment dams and enlarge the seepage flux. Relative large seepage flux, which is frequently concentrated rather than dispersed uniformly in whole impervious element, often leads to internal erosion and eventual failure. Although it is difficult to find out where the defection is, high seepage discharge and high apparent overall value of permeability coefficient do represent a status of relative unsafety.

Furthermore, a parameter R named defect parameter of impervious element is introduced to describe the non-integrity status of impervious element. For homogeneous impervious element with a single value of permeability coefficient, defect parameter R is defined to equal the ratio of apparent overall value of permeability coefficient to measured value \( k_{\text{test}} \) by laboratory test of intact standard sample

Inhomogeneous impervious element may be divided into multiple parts with different coefficients of permeability. As an alternative solution, defect parameter R is also defined to be the ratio of measured actual leakage flux \( Q_{\text{ms}} \left( {H_{u} , H_{d} } \right) \) to reference seepage flux \( Q_{\text{ref}} \left( {H_{u} , H_{d} } \right) \).

Reference seepage flux \( Q_{\text{ref}} \left( {H_{u} , H_{d} } \right) \) dictates the relationship between seepage discharge and water levels at upstream side and downstream side if the permeability coefficients of impervious element equal to laboratory test values of intact standard samples.

\( k_{{1 - {\text{test}}}} \), \( k_{{2 - {\text{test}}}} \), \( k_{{i - {\text{test}}}} \) and \( k_{{n - {\text{test}}}} \) are the reference values of permeability coefficient at the 1st, 2nd, ith and nth parts of impervious element, which is measured by laboratory test for intact standard sample.

In practice, \( Q_{\text{ref}} \left( {H_{u} , H_{d} } \right) \) can be pre-calculated if the designed or constructed configuration of embankment dam is determined. Then, rapid seepage safety level evaluation with low requirement for operator is achievable.

Application of the proposed simple approach

Sanbanxi CFRD

Sanbanxi CFRD in China is selected as an example, which has been put in service since 2007. Its details are shown above. Monitored seepage discharge and water level from 2006/06 to 2009/12 are introduced in analysis as shown in Fig. 5. (Zhu et al. 2009; Deng et al. 2015). Impermeability grade of slab concrete is W12 according to the relevant Chinese regulations, and the laboratory test permeability coefficient for concrete of face slab should be less than (1.3–2.6) × 10−9 cm/s (NEA of China 2009; Yao 2011). Thus, the corresponding test value of permeability coefficient \( k_{\text{test}} \) can be chosen as 1.3 × 10−9 cm/s.

Development of seepage discharge and variation of upstream water level of Sanbanxi CFRD (monitoring data) (after Zhu et al. 2009)

The defect parameter of impervious element at every calculation point of water level is figured up by the proposed simple approach, as illustrated in Fig. 6. Before the concrete face was damaged in July 2007, defect parameter was kept steady. After concrete face was damaged, defect parameter increased rapidly. The highest value reached about 9 times its original value. After reinforcement of the concrete face slab, defect parameter decreased to about 4 times its original value. But the reparation may be not thorough, defect parameter remained at 2000 which is much bigger than that before June 2007.

Campos Novos CRFD

The Campos Novos CRFD in Brazil is taken as another example. Its height is 202 m. The typical cross section and front view are shown in Fig. 7. Crest length of the dam is 590 m. Slope ratio for the upstream surface of face slab is 1:1.3. The thickness of the concrete face varies from 0.30 to 1.00 m as equations below.

Typical sections of Campos Novos CFRD (after Antunes et al. 2007)

The concrete face was damaged in 2006. And it was reinforced and refilled on November 26, 2006. Seepage discharge was kept growing with filling process. Monitored seepage discharge and water level during filling process after reinforcement of face slab are shown in Fig. 8 (Antunes et al. 2007).

Development of seepage discharge and variation of upstream water level of Campos Novos CFRD (monitoring data) (after Antunes et al. 2007)

If test value of permeability coefficient \( k_{\text{test}} \) of concrete face slab is assumed to be 1.3 × 10−9 cm/s, revolution of defect parameter can be calculated by the suggested simple approach, as illustrated in Fig. 9.

It should be noted that the changing trend of seepage discharge and that of defect parameter are not synchronous. There are two times of increasing of defect parameter during filling stage. The defect parameter tended to descend after December 28, 2016, although the water level was kept more than 620 m.

Hyttejuvet earth core rockfill dam

Hyttejuvet earth core embankment dam in Norway is selected to further show the application of the approach. It is well known for the sudden leakage in the first filling. Hyttejuvet dam has a maximum height of 93 m. The dam crest length of about 350 m. The upstream dam slope is 1:1.6 and the downstream dam slope is 1:1.6 below 700 m and 1:1.45 above the elevation. The typical section is shown in Fig. 1. The variation curve of water level and seepage flux is shown in Fig. 10.

Variation of seepage discharge and upstream water level of Hyttejuvet earth core rockfill dam (monitoring data) (after Sherad 1973)

If the test value of permeability coefficient is 1 × 10−7 cm/s, the changing process of defect parameter of impervious element over time can be calculated according to the approach, as shown in Fig. 11. It can be noted that the maximum defect parameter occurs before water level reaches peak. The defect parameter shows good consistency with seepage safety level of the Hyttejuvet embankment dam.

Summary and conclusions

A simple approach to calculating leakage through embankment dams with thin impervious element is proposed in this paper. By using this approach, dam height, shape of valley, shape of impervious element and water level in reservoir are taken into account. Then, the apparent overall value of permeability coefficient for impervious element can be obtained with reasonable accuracy and speed.

Defect parameter of impervious element is introduced to represent defect level of internal erosion. The defect parameter is defined as the ratio of overall value of permeability coefficient to laboratory test value for intact material.

The newly proposed approach and the concept of defect parameter are further applied in the case study. It is found that the proposed approach is feasible in seepage safety level evaluation of embankment dams with thin impervious element.

References

Antunes SJ, Vieira Xavier L, Custodio AS, Femandes PR (2007) Performance and concrete face repair at campos novos concrete face rockfill dam. In: Proceedings of the 27th National Seminar of Big Dams, Belem, Brasil, pp 1–15 (in Portuguese)

Casinader R, Rome G (1988) Estimation of leakage through upstream concrete facings of rockfill dams. In: Proceedings of the 16th international congress on large dams, ICOLD, San Francisco, USA, pp 283–310

Chen SS (2012) Breaking machanism and failure process simulation for embankment dams. China Water & Power Press, Beijing

Deng G, Wang XG, Wen YF, Yu S, Chen R (2015) Study on conceptualization method of deformation pattern and horizontal breakage of face slab of concrete faced rockfill dam. J Hydraul Eng 46(4):396–404 (in Chinese)

Fell R, Wan CF, Cyganizewicz J, Foster M (2003) Time for development of internal erosion and piping in embankment dams. J Geotech Geoenvir Eng ASCE 129(4):307–314

Foster M, Fell R, Spannagle M (2011) The statistics of embankment dam failures and accidents. Can Geotech J 37(5):1000–1024

Hunter G, Fell R (2003) The deformation behaviour of embankment dams. University Report No. R-416. The University of New South Wales. Sydney

International Commission on Large Dams (ICOLD) (2017) World Register of Dams. http://www.icold-cigb.org/GB/world_register/general_synthesis.asp

Kunming Engineering Corporation Limited (2006) Bidding and design report on the construction of the dam and cofferdam of Nuozhadu hydroelectirc station on the Lancang River in Yunnan Province (NZD/C3), pp 224–279

National Development and Reform Commission of the Government of the People’s Republic of China (China NDRC) (2007) Design specification for rolled earth-rock fill dams. DL/T 5395-2007, Beijing, China

National Energy Administration of the Government of the People’s Republic of China (NEA of China) (2009) Design specification for hydraulic concrete structures. DL/T 5057-2009, Beijing, China

Novak P, Moffat AIB, Naluri C, Narayanan R (2007) Hydraulic structures. Taylor and Francis, New York

Penman ADM (1986) On the embankment dam. Geotechnique 36:215–262

Sherad JL (1973) Embankment dam cracking. In: Hirschfeld RC, Poulos SJ (eds) Embankment dam engineering (casagrande volume). Wiley, New York, pp 271–353

United States Army Corps of Engineers (USACE) (1993) Engineering and design: seepage analysis and control for dams. EM 1110-2-1901, Washington, DC, USA

Yao NL (2011) Seepage prevention stuctures for a water conservancy project. China New Technol Prod 12:67 (in Chinese)

Zhu JJ, Li T, Du XJ (2009) Analysis on stress and strain before and after the face-slab damage of Sanbanxi dam. Dam Saf 6:46–48 (in Chinese)

Acknowledgements

The authors acknowledge the support of the National Key Research and Development Program of China (No. 2017YFC0404803), the National Nature Science Foundation of China (No. 51578196) and IWHR Research and Development Support Program (GE0145B562017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, G., Cao, K., Chen, R. et al. A simple approach to evaluating leakage through thin impervious element of high embankment dams. Environ Earth Sci 77, 25 (2018). https://doi.org/10.1007/s12665-017-7195-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-017-7195-3