Abstract

Geotechnical membrane is often used in dam engineering to prevent the seepage. But the research of the influence of impervious membrane on the seepage of a dam is not enough. Combining the indoor model experiment and numerical analysis methods, the influence of the impermeable membrane’s blanket length on the seepage of a dam had been carried out in present paper. By analyzing the results from these two methods, it was found that the seepage quantity of the dam linearly changed with the increase of the blanket length. Besides, bases on the numerical analysis method, the influence of different horizontal impervious blanket length on the seepage of a dam had been investigated, and the calculation formula for different thickness of the foundation had been fitted. Finally, the optimum length of horizontal blanket for different dam foundation was analyzed.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

China has a long coastline, and a large number of offshore and estuary dams have been constructed along the coastline. It was confirmed that there is a close relationship between the common diseases of the dam and the permeation. It was reported that 40.5% of the dam destruction were caused by dam seepage [1].

During the flood in 1998, many dangerous conditions were happened in dams along Yangtze River, and 54.5% of these dangerous conditions were the result of seepage failure. In history, more than 90% of the Yangtze River inrushes were caused by seepage failure [2]. The “Katrina” hurricane brought heavy damage to America, and the disaster survey report pointed out that the direct factor of dams’ destruction in New Orleans was seepage failure of dam foundation [3]. Studies indicated that the engineering reinforcement of embankment had met the requirements of national standard. However, due to lack of understanding on the dam foundation seepage failure, there are still some problems that need to be studied. Impervious geotechnical membrane can adapt to dam’s deformation due to its soft characteristics, so it is widely used in engineering. For example, Sichuan Tianwanhe Renzonghai rockfill dam, Sichuan Ganzi Huashan core film/gravelly soil core rockfill dam and Shandong Dezhou Datun plain reservoir are all representative membrane impermeable dam [4]. Whitfield [5] introduced the application of geotechnical impervious material in Roller compacted concrete dam. Messerklinger [6] introduced a seepage failure case of a geomembrane lining dam. Yuan et al. [7] studied the influence of blanket length to infinite deep pervious foundation dam with boundary element method, and revealed the relationship between the blanket length of the infinite deep pervious foundation dam and the upstream head. Yin et al. [8] analysed the length selection of impervious blanket in non homogeneous infinite deep pervious dam foundation, and gave the computing method about seepage of non homogeneous infinite deep pervious dam foundation by using model experiment. Combining with the engineering example, Wen et al. [9] analyzed the influence of the depth of cutoff wall, blanket length and permeability of overburden soil on the seepage control of a dam foundation, and concluded that the blanket could not effectively control the overburden foundation seepage. Xu et al. [10] used model experiment and numerical analysis methods to carry out the research on the selection of the impervious blanket length of the infinite deep pervious foundation. By developing a model experiment, Mao et al. [11] calculated the effective depth of impermeable membrane on earth rockfill dam.

Combining indoor model experiment and numerical analysis method, the influence of impermeable membrane’s blanket length on the seepage of a dam were systematically carried out, the conclusions could provide a reference for the design, construction and management of a dam.

2 Model Experiment

2.1 Experiment Method

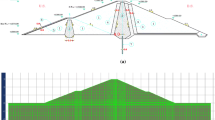

The indoor experiment was carried out by using a self-made seepage apparatus, which was shown in Fig. 1, and the tank’s size were 3.0 m × 0.5 m × 1.2 m. The water flew into the tank through the adjustable bin. The upstream water level could be adjusted by changing the bin’s height. There was a drainage outlet in the right wall of the tank. To observe the seepage process, the front face of the tank was made of organic glass. To gain the distribution of pore water pressure, a row of piezometric tubes were installed 200 mm above the bottom of the tank.

Sand was used to build the dam foundation to simulate the pervious characteristics of the foundation. In order to simulate the actual engineering, dam body was filled with silt. The soil was carried from a building foundation pit in Hangzhou. Basic physical property indexes of the filling materials were shown in Table 1. Common plastic film was selected as the material of impervious blanket.

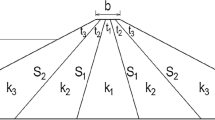

The width of the dam bottom was 185 cm, the width of the dam crest was 5.0 cm, the height of the dam foundation was 50 cm, the height of the dam body was 45 cm, and the slope ratio of the upstream slope and the downstream slope were 1:2. Hierarchical construction method was used for the filling of dam foundation and dam body, each layer thickness was 10 cm, and the filling compaction degree was controlled at 88%.

The upstream water level and downstream water level were selected as 20 cm and 7 cm, respectively. In order to avoid the water oozing out from the leakage of blanket and slope, membrane was laying on the surface from dam body to foundation. Membrane was 50 cm larger than the tank’s width. The extra membranes in two sides were pasted on the inner wall of the tank firmly by using vaseline, and there was no large air bubble under the membrane. Besides, the junction of membrane and foundation was covered by sand to prevent the membrane floating and water seeping through the underside of the blanket. It was shown in Fig. 2.

After finish laying membrane on the dam, water was slowly poured from the inlet end. For the difference of the water levels between the upstream and downstream, seepage occurred. The piezometric tubes’ water level and the drainage quantity from outlet end could be measured directly. The readings of piezometric tubes would not recorded until the readings did not change and the drainage quantity was kept stable during every three minutes. Finally, the flow rate was calculated based on the seepage quantity.

2.2 Experiment Results

The lengths of the membrane were selected as 20 cm, 40 cm, 60 cm and 80 cm, which were 1–4 times of the upstream water level. The experiment without membrane was also carried out for contrast. The seepage quantity of these 5 groups experiments were list in Table 2.

3 Numerical Analysis

3.1 Numerical Analysis Method

The numerical analysis was carried out by using seep/w module of the software Geo-Studio. Seep/w was developed to analyze porous material from simple saturated steady-state problems to complex, saturated unsaturated variable problem. In this paper, saturated material was selected to simulate the permeable dam foundation, and unsaturated material was selected to simulate the dam body.

3.2 Compared with the Model Experiment

In order to make a comparative analysis of indoor model test and numerical calculation, the parameters of the numerical analysis were selected as 100 times of the sizes of the laboratory model. Those were, the width of the dam bottom was 185 m, the width of the dam crest was 5 m, the height of the dam foundation was 50 m, the height of the dam body is 45 m, and the slope ratio of the upstream slope and the downstream slope were 1:2. The saturated permeability coefficient of the dam body and dam foundation were 5.68 × 10−7m/s and 1 × 10−14m/s. The calculation results were shown in Table 3.

Compared the results of indoor model test to numerical analysis, the comparative figure was plotted in Fig. 3.

From Tables 2 and 3, it could be found that, the seepage quantity of the dam was linearly changed with the blanket length. This indicated both the indoor model test and numerical analysis method were correct and reliable. The difference values between these two methods were 17.94%, 13.76%, 11.52%, 6.59%, 1.60% for the membrane length were 0, 1, 2, 3, 4 times of the upstream water level, respectively. The difference values of two methods decreased with the increase of the upstream blanket length. This was probably due to the limitation of experimental conditions, membrane and foundation could not fit tightly enough when the membrane was short.

3.3 Numerical Analysis Results

Selected the head difference of upstream and downstream H as a benchmark. The height of dam foundation was selected in the range of 1H to 5H, the blanket length was in the range of 1H to 12H. The seepage results were list in Table 4.

3.4 Analysis and Discussion

Based on Table 4, following figure could be drawn.

From Fig. 4, it was found the seepage quantity decreased with the increase of blanket length, and the curve gradually tended to be gentle. The curves could be considered as linear change when the blanket length was smaller than 100, this was in consistent with Fig. 3. Comparing the 5 curves in Fig. 4, it could also be found that, with the increase of dam foundation height, the seepage quantity decreased rapidly and achieved the gentle range quickly.

By divided the dam seepage quantities with the seepage quantity without blanket, following ratios of seepage quantity with blanket to that of without blanket could be written.

Based on Table 5, the ratio curve of seepage quantity with blanket to that of without blanket could be drawn as Fig. 5.

The relationships in Fig. 5 could be fitted as a polynomial:

Where k was the proportion of dam seepage quantity with blanket to that of without blanket, hl was blanket length, and a, b, c were fitting coefficients.

The fitted coefficients a, b and c were list in Table 6.

After gained the relationship of the ratio of seepage quantity with blanket to that of without blanket for different foundation height, the minimum value and the corresponding blanket length could be computed. The minimum seepage quantities and optimum membrane blanket lengths for five foundation heights were list in Table 7 and plotted in Fig. 6.

The relationship in Fig. 6 could be formulated as:

Where Kmin was the minimum value of the ratio of seepage quantity with blanket to that of without blanket, and ht was the thickness of the dam foundation.

The fitting curve correlation coefficient 0.9437 showed that the fitting was reliable. From Eq. (2), it could be seen that, with the increase of the dam foundation thickness, the minimum seepage quantity of the dam was gradually reduced.

4 Conclusions

Combining indoor model experiment and numerical analysis method, the influence of impermeable membrane’s blanket length on the seepage of a dam were studied. The results of these two methods were in accordance with each other well.

The seepage quantity decreases with the increase of blanket length, there is a linear relationship among them when the blanket length is small. With the increase of the height of dam foundation, the seepage quantity decreased rapidly and achieved the gentle range quickly.

The relationship between the ratio of seepage quantity with blanket to that of without blanket and the blanket length can be expressed by a polynomial.

The relationship of minimum seepage quantity and dam foundation height can also be formulated as a polynomial. With the increase of the thickness of dam foundation, the minimum seepage quantity of the dam was gradually reduced.

References

Gu, W.: Principle and Application of Seepage Calculation. Chinese Building Materials Industry Press, Beijing (2000)

Water Resources Department of Construction and Management: Analysis of dam danger in the Yangtze River and the Songhua River happened in 1998 flood. China Flood Control Drought Relief 19(4), 20–24 (1998)

Seed, R.B., Bea, R.G., Abdelmalak, R.I., Athanasopoulos, A.G., Boutwell, G.P., Bray, J.D., Briaud, J.-L., Cheung, C., Cobos-Roa, D., Cohen-Waeber, J., Collins, B.D., Ehrensing, L., Farber, D., Hanemann, M., Harder, L.F., Inkabi, K.S., Kammerer, A.M., Karadeniz, D., Kayen, R.E., Moss, R.E.S., Nicks, J., Nimmala, S., Pestana, J.M., Porter, J., Rhee, K., Riemer, M.F., Roberts, K., Rogers, J.D., Storesund, R., Govindasamy, A.V., Vera-Grunauer, X., Wartman, J.E., Watkins, C.M., Wenk Jr., E., Yim, S.C.: Investigation of the Performance of the New Orleans Flood Protection System in Hurricane. University of California-Berkeley, State of California (2006)

Shu, Y., Wu, H., Jiang, X.: Technical progress of pervious membrane used in seepage control of reservoir dam in China. Geotech. Eng. J. 38(S1), 1–9 (2016)

Whitfield, B.L.: Geomembrane application for an RCC dam. Geotext. Geomembr. 14, 253–264 (1996)

Messerklinger, S.: Failure of a geomembrane lined embankment dam-case study. Geotext. Geomembr. 42, 256–266 (2014)

Yuan, Y., Shi, K., Li, Y., et al.: The influence of blanket length to seepage of infinite deep pervious foundation. Hydroelectric Power 33(1), 34–36 (2007)

Yin, H., Shi, K., Mao, H.: The selection of impervious membrane length used in non homogeneous infinite deep dam foundation. J. Water Resour. Water Eng. 22(2), 62–65 (2011)

Wen, L., Fan, Y., Chai, J., et al.: Numerical analysis on the effect of seepage control measures of deep overburden foundation. J. Water Resour. Water Eng. 25(1), 127–132 (2014)

Xu, Y., Shi, K., Xu, Q., et al.: The influence of micro porous membrane to seepage of infinite deep permeable foundation. J. Water Resour. Water Eng. 24(1), 89–92 (2013)

Mao, H., Wang, X., He, Y.: A Pilot study of the method choice about the blanket length over earth-rock dam on the infinite deep pervious foundation. In: International Conference on Electric Technology and Civil Engineering, pp. 5698–5701 (2011)

Acknowledgments

This paper is funded by National Natural Science Foundation of China under the contract No. 51678533.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Yu, L., Zhang, Z., Tu, C., Zhang, J., Wu, D. (2018). Study on the Influence of Impermeable Membrane’s Blanket Length on the Seepage of a Dam. In: Hu, L., Gu, X., Tao, J., Zhou, A. (eds) Proceedings of GeoShanghai 2018 International Conference: Multi-physics Processes in Soil Mechanics and Advances in Geotechnical Testing. GSIC 2018. Springer, Singapore. https://doi.org/10.1007/978-981-13-0095-0_24

Download citation

DOI: https://doi.org/10.1007/978-981-13-0095-0_24

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-0094-3

Online ISBN: 978-981-13-0095-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)