Abstract

Risk assessment methodology for chemicals in Shenyang Chemical Industrial Park (SCIP) was established from the realities of frequent environmental pollution emergencies, just for the sake of quantitatively describing the risk levels of the chemicals, and for conducting priority control for those typical ones among them. Meanwhile vapor pressure (PV), median lethal concentration (LC50), combustibility and explosibility (CE), popularity (P) and detection frequency (DF) are selected as the risk assessment index for the chemicals, and then the weight from each assessment indicator on the surveillance levels for those chemicals has been identified. Finally, Fuzzy Comprehensive Evaluation (FCE) was adopted to work out the surveillance assessment level for each chemical in SCIP. The results show that 14 chemicals with relatively high-risk levels have been identified based on the above methods. Study on the risk assessment methodology for SCIP shall avail judgment on the risk levels for chemicals, allowing better management and control for chemicals accordingly.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the rapid development of science and technology, chemical industry plays a critical role in accelerating the development of other industries (Wang and Feng 2005; Martin Del Campo et al. 2014); however, environment pollution is increasingly perilous at the same time, resulting in frequent environmental pollution emergencies (Shi and Zeng 2014; Zhang et al. 2014). At the moment, the surveillance management and research for the chemicals are still at the early stage (Han et al. 2013). Especially in a chemical industry park (Chrysoulakis et al. 2005; Zhao et al. 2013), there is a great number of chemicals with high density, due to the aggregation of enterprises in the park, along with complicated chemical process and huge unit scale, so hazards and extra serious accidents are occurred possibly (Wei et al. 2007; Hou 2012; Shao et al. 2013). In recent years, serious environment pollution accidents frequently occurred especially in chemical industry or heavy chemical industry, for instance the Songhua River Pollution in 2005, blue-green algae bloom crisis in Taihu Lake in 2007 (Zhang et al. 2010), aniline leakage in Tianji Coal CIP in Changzhi, and Shanxi in 2012 (Yuan et al. 2013). All these serious pollution accidents turn out to be severe threats to the harmonious development of Chinese socio-economy, as well as to be devastating damages to the ecological environment (Liu et al. 2006; Gupta et al. 2002). According to the incomplete statistics, since the year of 2000, the economic loss, due to serious environment pollution accidents, simply amounts to more than 10 million RMB per year (Ministry of Environmental Protection 1991–1998). Therefore, concerns on environment risk surveillance management become more noticeable than ever, and priority surveillance and control for chemicals in the CIP need to be carried out desperately.

Studies on priority surveillance and management of the chemicals with focusing on environmental pollution firstly started in the United States of America (USA), subsequently other countries such as Japan and European Union (EU), carried out studies on priority control for environmental pollutants (European Commission 1999; US EPA 2009; Guillen et al. 2012). Screening and monitoring study on pollutant priority control began since the end of last century in China (Song and Dai 2009; Chen 2006; Fu et al. 1990), mostly covering screening and sorting pertinent to physicochemical property such as chemical state and toxic effects. There is a lack of quantitative consideration in terms of social concern about pollutant accident frequency, as well as in term of the threshold quantity. For example, Wang et al. (2005) screened some organics under key control from the surface water in Liao River Basin, and Lou (2002) studied the sorting priority of organic pollutants in the maritime space by way of osculation value method. Nevertheless, there are fewer studies on the chemicals in CIP, an area with high environmental risks, and there is still a lack of systematic and full-scale analysis and assessment method; studies with qualitative methods are commonly adopted instead. While FCE is an approach based on fuzzy mathematics, widely applied in the environment field, with applications reported relatively in river health assessment and spatial–temporal variations of water quality in small watershed (Zhu et al. 2009; Wu et al. 2011; Aryafar et al. 2013). Based on the theory of fuzzy mathematics, qualitative assessment shall be converted into quantitative assessment, namely to make a comprehensive evaluation for something or some object with the help of fuzzy mathematics.

In this paper, based on the fuzzy set theory with FCE as a model, influencing factors during assessment were quantified to establish aggregative indicator set, weight set and evaluation set of surveillance were also established in the CIP (Najafi et al. 2014; Md Rejaur et al. 2014). Then with help of setting-up and transformation of the fuzzy relation matrix, comprehensive evaluation on the surveillance for the chemicals in the CIP was achieved to provide effective surveillance and control methods to the environment authorities of the CIP.

Research area

SCIP located in the western urban area of Shenyang, the capital city of Liaoning Province, and the largest city in Liao River Basin (Bu et al. 2013; Lv et al. 2014), is 2 km east to Shenyang Economic Development Zone, 1.1 km north to Jingshen Highway, 900 m south to Provincial Highway and 3 km from the north bank of the Hun River (Zheng et al. 2014), as shown in Fig. 1. The planned area of SCIP is from the Development Road in the north, to Daqingduizi Village in the east, from Dapan Town in the south and to Gaohua Town in the west. The SCIP is 10 km from east to west, 3 km wide from south to north, and it occupies a total area of 30 km2 with a built-up area of 14.8 km2. The total population in the CIP amounts to 10,455. According to the surface water quality standards, the water in the Hun River and Xi River around the SCIP is inferior of V type and pollution discharge has surpassed the water environment capacity (Hu and Su 2011). The multitude of chemical enterprises, complicated internal classifications, and the unreasonable industry structure inside the SCIP, together with the residential areas around the SCIP, so in case of fire, explosion or chemical leakage, disastrous domino effect would take place easily. Thus, risk level assessment for chemicals in SCIP is much critical to risk management.

Methodology

Description of the FCE method

Decision making for environmental risk assessment is often not positive or negative absolutely (Antunes et al. 2014; Simpson et al. 2014). Many variables can affect the object to be evaluated, and relationships between the variables and the object are difficult to be predicted by precise mathematics. The FCE is an effective means to address these problems with uncertain and fuzzy boundary. The idea of the FCE is that the contributions of multiple related actors are comprehensively considered according to weight factors, and the fuzziness is decreased using membership functions (Chen and Wei 2000).

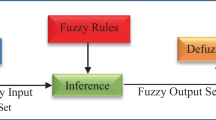

The basic procedure of the FCE is that: establishing the evaluation factor (viz. index) set and grading level set of the evaluated object first; and then the fuzzy evaluation matrix being calculated after determining weight factor and membership vector of each evaluation factor; finally, the object class being achieved based on the fuzzy arithmetic on the fuzzy evaluation matrix and weight vector of factors (Ling et al. 2013; He et al. 2014). The steps of risk level assessment for the chemicals in the SCIP are shown in Fig. 2 (Liu et al. 2014). With reference to the evaluation results, the chemical risk levels shall be evaluated for the better management and control for them.

Establishing the evaluating index and grading level sets

Screening and establishing the evaluating index set U

On the basis of the lists of chemicals in different environment pollution incidents, as well as those under priority control nationwide; with reference to the chemicals categories in the Technical Guidelines for Environmental Risk Assessment on Projects (HJ/T 169-2004), investigations were carried out for these industrial enterprises of the SCIP. The focus was on the environment impact and health effect of chemicals. Then chemicals with higher detection rate, excessive output or use, hard to be degraded, bioaccumulation and persistence shall be selected preferentially, and pollutants with serious damage to health possibly, shall be selected, too.

The evaluating index set \(U = \left\{ {U_{1} , U_{2} , \ldots , U_{\text{m}} } \right\}\) for the chemicals in the SCIP was established, \(U_{1} , U_{\text{m}}\) defined as evaluating index regarding risk level evaluation of the chemicals in SCIP. According to the chemical characteristics of SCIP, evaluating index includes environmental exposure, substance toxicity, popularity, combustibility and explicability, which are judged by various indices, such as vapor pressure (PV), median lethal concentration (LC50), combustibility and explicability (CE), popularity (P) and detection frequency (DF), So, based on the above idea of chemicals’ risk level analysis, a evaluating index system for risk level of SCIP was established:

PV in the evaluation set, represents substance volatility, and evaporation rate relates to liquid PV level, so substance with higher PV is usually volatile; LC50 mainly represents exposure density to the environment and toxicity of these chemicals; CE represents the possibility of explosion accident; P mostly means the frequency of these chemicals in the list of different priority control pollutants at home and abroad; DF refers to the detection frequency of chemicals in the environment pollution accident statistics over 30 years, and the more frequent, the higher for the risk level for them.

The establishment of the evaluating index system also referenced the screening method of environment priority pollutants (Pei et al. 2013).

Defining the grading level set V for Chemicals in SCIP

A grading level set is composed of all evaluation results for the evaluated objective and usually expressed by fuzzy language. According to the effect degree of evaluating factors on the risk level of chemicals, we define four grades for the significance of the evaluating factors. The four grades consist of the grading level set

in which, the variables V 1, V 2, V 3 and V 4 represents high risks, relatively high risks, medium risks and ordinary risks, respectively. For each evaluating index, each variable, i.e., V 1, V 2, V 3 and V 4, must be given a value, which is called the index of gradation, to quantify the fuzzy languages: high risks, relatively high risks, medium risks and ordinary risks. According to requirements of risk level assessment of chemicals in SCIP, the grading level set was constructed by referencing the method of water environment security fuzzy comprehensive evaluation (Qiu et al. 2013). The expert opinions are especially introduced in the process of constructing the grading level set. In this way, the influential degree of the evaluating indices on the risk level of SCIP can be reflected quantitatively. Details are presented as the following: for evaluation factor set as to be established:

Evaluating index weight sets

Weight factors reflect the relative importance of each evaluation index to the evaluated objective. Slight changes of weight will have a significant impact on evaluation results. So, determining the weight factor of each index is as important as establishing the index system itself for the assessment. The relative significance of evaluating indexes, is

by means of relative probability significance for each evaluating index; while weight of evaluating indexes \(U_{i}\) is

and then impacts, as from PV, storage, LC50, CE, P plus DF, on the chemicals shall be identified, and the weight set for evaluating index is:

of which, a 1 ∼ a m is the evaluating index weight,

Establishment of fuzzy relation matrix R

First of all, r ij (as the membership) to

(as the grading level) for

(each evaluating index) in evaluating index set U shall be identified. The evaluating index set for each evaluating index is

and then the evaluating index set for all these evaluating indexes shall form R, an evaluation matrix with \(m \times n\) order, namely

Calculation of membership r ij shall be based on the triangular membership function, with the detailed calculation as to make the midpoint of each grade interval as a demarcation point. When the evaluation factor is in the middle of such an interval, membership of such an evaluation factor to this grade is defined as I, and in the middle of adjacent intervals defined as 0. For the bigger indicator in need of more surveillance, membership function of “high risks” in the first grade is:

And membership function of “relatively high risks” and “medium risks” in the second and third grade is:

And membership function of “ordinary risks” in the fourth grade is:

Fuzzy comprehensive evaluation (FCE)

FCE shall be implemented for the risk level of chemicals in SCIP, in accordance with weight set A and evaluating matrix R, and the evaluating matrix B is obtained as:

Of which, ∘ refers to the calculation of product summary, and evaluating matrix B was the fuzzy set on the evaluating index set V, a result vector of FCE for the risk level of chemicals in SCIP.In line with evaluating matrix B and values from grading level in the evaluating index set, the final evaluation result C was worked out as:

Then the final evaluation result as C shall be compared with values from evaluation grades from the evaluating index set V, and the evaluation results of risk levels for chemicals in SCIP shall be obtained. The evaluating index weight sets, fuzzy relation matrix and fuzzy comprehensive evaluation were constructed by referencing the method of water environment security fuzzy comprehensive evaluation (Qiu et al. 2013), fuzzy comprehensive assessment on spatio-temporal variations of water quality of a small catchment (Wu et al. 2011).

Evaluation results and analysis

Chemicals overview

The basic property of the 35 chemicals in SCIP, such as appearance and properties, CAS registry number, toxicity data, PV, CE, along with their frequency in the list of priority control pollutants, the number of times of priority pollutants list as issued worldwide and the detection frequency in the environment pollution accident statistics over the 30 years in China are shown in Supplement 1.

Risk material distribution

The categories of chemical enterprises in SCIP include industrial projects in petrochemical, chlor-alkali chemical, rubber products and fine chemicals. Furthermore the Shenyang Paraffin-Refinery Plant could be identified as a heavy chemical enterprise. Additionally there is a coal gasification enterprise, typical of coke-oven gas. Materials needed by these enterprises include raw material, accessories, intermediates, products and fuels of varieties, many of them are risk material, distributed among production facilities, storage tank and handling sections. According to the type of enterprise, risk material in SCIP can be distributed in the raw materials and finished products (Table 1).

Risk material in different enterprises include many combustible and explosive material such as crude oil, naphtha and LPG, and some chemicals such as benzene, ammonia, chlorine, epichlorohydrin, fuel gas which can be found in Table 1. All these materials are distributed in both storage and transportation system, which means prove to be of great potential hazards due to their frequent flow and transfer.

Risk evaluation results of the chemicals

Based on the evaluation method for the chemicals as described above, risk evaluation was conducted for 35 major chemicals, which were involved for the enterprises in SCIP. The results show that there were 14 sorts of materials with relatively high risks, 40 % of those investigated, such as crude oil, acetone, methanol, propiolic alcohol, propylene epoxide, ammonia, polypropylene, PPG, naphtha, diesel fuel, fuel gas, LPG, propene and coal gas, 12 sorts of materials with medium risks, 34 % of all, such as toluene, ethanol and isopropyl alcohol, in addition to 9 sorts of materials with ordinary risks such as acetic acid and sulfuric acid, as shown in Figs. 3 and 4.

Percentage of materials with risk level in different enterprises

On the whole, chemicals with different risk levels were distributed the most in chemical enterprises, followed by heavy chemical enterprises, least in coke-oven gas enterprises. Moreover, the percentage of risk materials in the raw material zone was higher than that in the finished product area, whereas cases in the heavy chemical enterprises are on the contrary, where percentage of the risk materials in the final product area was higher than that of raw material zone. In view of the risk levels, materials with medium risk level have a higher percentage in the chemical enterprises, while materials with relatively high-risk level have a higher percentage in the heavy chemical enterprises, as shown in Fig. 5.

Analysis of enterprise environment risk in CIP

Enterprises that store and use hazardous chemicals become part of a CIP. Although this reduces the environmental risk caused by the establishment of uncontrolled sites, it cannot eliminate the risk within the industrial park; on the contrary, CIP is surely of high risks, and would have accident chain reaction with serious consequences once an accident happened. We identify environmental risk sources within the chemical industry, and the mainly risk materials are organic substances including rude oil, acetone, methanol, propiolic alcohol, etc. Therefore, implement of priority monitoring for risk substances to CIP is needed.

Conclusions

With China’s rapid economic growth, chemical-related environmental issues have become increasingly prominent, and the environmental management of chemicals has garnered increased attention from the government. To better management and control risk of chemicals, foreign experience in risk management of industries need to be used, and risk assessment techniques from foreign environmental management should be applied in industrial chemicals. At the same time, a monitoring system should also be developed. In this paper, evaluation methodology for the chemicals risk level in a CIP has been established based on FCE. According to the established evaluation method of risk level, 14 sorts of materials with relatively high risks have been identified, 40 % of all, risks are still high in a sense. From the perspective of the enterprise categories, chemicals are mainly distributed in the raw material and finished product section. Regards the overall distribution of the risk materials, chemicals are most widely distributed in the chemical enterprises, next in the heavy chemical enterprises, and least in the coke-oven gas enterprises. It is suggested to set up a complete environment surveillance system with the purpose of conducting prior surveillance for the materials with high-risk level as assessed already; emergency plan and accident precautions for the environment risks both in the park and in the enterprises are suggested to be improved and implemented, safety level of the production unit to be averaged up, personnel and property safety to be safeguarded as well.

References

Antunes IMHR, Albuquerque MTD, Sanches FAN (2014) Spatial risk assessment related to abandoned mining activities: an environmental management tool. Environ Earth Sci 72(7):2631–2641

Aryafar A, Yousefi S, Ardejani FD (2013) The weight of interaction of mining activities: groundwater in environmental impact assessment using fuzzy analytical hierarchy process (FAHP). Environ Earth Sci 68(8):2313–2324

Bu HM, Wan J, Zhang Y, Meng W (2013) Spatial characteristics of surface water quality in the Haicheng River (Liao River basin) in Northeast China. Environ Earth Sci 70(6):2865–2872

Chen XQ (2006) Discussing on the filtering method of prior controlled organic pollutants in water. Fujian Anal Test 15(1):15–17 (in Chinese)

Chen J, Wei Z (2000) A model of multi-objective comprehensive evaluation for power plant projects. Proc CSEE 22(12):152–155

Chrysoulakis N, Adaktylou N, Cartalis C (2005) Detecting and monitoring plumes caused by major industrial accidents with PLUME, a new software tool for low-resolution image analysis. Environ Model Softw 20(12):1486–1494

Commission European (1999) Study on the prioritization of substance dangerous to the aquatic environment. Office for Official Publications for the European Communities, Luxembourg

Fu DQ, Sun ZG, Zhou WM (1990) Screening program for priority control pollutants blacklist of water in China. Res Environ Sci 6(5):48–50 (in Chinese)

Guillen D, Ginebreda A, Farre M, Darbra RM, Petrovic M, Gros M, Barcelo D (2012) Prioritization of chemicals in the aquatic environment based on risk assessment: analytical, modeling and regulatory perspective. Sci Total Environ 440(S1):236–252

Gupta AK, Suresh IV, Misra J et al (2002) Environmental risk mapping approach: risk minimization tool for development of industrial growth centres in developing countries. J Clean Prod 10(3):271–281

Han L, Song YH, Si JH, Yu BF (2013) Study and application of major environmental risk source monitoring technologies within chemical industrial park. Res Environ Sci 26(3):334–340 (in Chinese)

He KQ, Jia YY, Chen WG, Wang RL, Luo HL (2014) Evaluation of karst collapse risks induced by over-pumping and karst groundwater resource protection in Zaozhuang region, China. Environ Earth Sci 71(8):3443–3454

Hou Y (2012) Environmental accident and its treatment in a developing country: a case study on China. Environ Monit Assess 184(8):4855–4859

Hu C, Su D (2011) Application of comprehensive water quality identification index in water quality assessment of Hun River. Ecol Environ Sci 20(1):186–192

Ling HB, Xu HL, Fu JY (2013) Evaluation of oasis land use security and sustainable utilization strategies in a typical watershed in the arid regions of China. Environ Earth Sci 70(5):2225–2235

Liu JG, Hu JY, Tang XY (2006) Global governance on environmentally sound management of chemicals and improvement requirements for China’s system. Res Environ Sci 19(6):121–126 (in Chinese)

Liu YH, Fang PP, Bian DD et al (2014) Fuzzy comprehensive evaluation for the motion performance of autonomous underwater vehicles. Ocean Eng 88:568–577

Lou WG (2002) Application of osculating method for the prior order and risk classification for the marine organic pollutants. Marine Environ Sci 21(3):43–48 (in Chinese)

Lv JP, Xu J, Guo CS, Zhang Y, Bai YW, Meng W (2014) Spatial and temporal distribution of polycyclic aromatic hydrocarbons (PAHs) in surface water from Liaohe River Basin, northeast China. Environ Sci Pollut Res 21(11):7088–7096

Martin Del Campo MA, Esteller MV, Exposito JL, Hirata R (2014) Impacts of urbanization on groundwater hydrodynamics and hydrochemistry of the Toluca Valley aquifer (Mexico). Environ Monit Assess 186(5):2979–2999

Md Rejaur R, Shi ZH, Cai CF (2014) Assessing regional environmental quality by integrated use of remote sensing, GIS, and spatial multi-criteria evaluation for prioritization of environmental restoration. Environ Monit Assess 186(11):6993–7009

Ministry of Environmental Protection (1991-2008) China statistical yearbook [M]. Chinese Environment Science Press, Beijing

Najafi A, Karimpour MH, Ghaderi M (2014) Application of fuzzy AHP method to IOCG prospectivity mapping: a case study in Taherabad prospecting area, eastern Iran. Int J Appl Earth Obs Geoinf 33:142–154

Pei SW, Zhou JL, Liu ZT (2013) Research progress on screening of environment priority pollutants. J Environ Eng Technol 3(4):362–367 (in Chinese)

Qiu N, Ge JH, Zhang XJ (2013) Research of water environment security fuzzy comprehensive evaluation method. China Rural Water Hydropower 6:61–65 (in Chinese)

Shao CF, Yang J, Tian XG, Ju MT, Huang L (2013) Integrated environmental risk assessment and whole-process management system in chemical industry parks. Int J Environ Res Public Health 10(4):1609–1630

Shi WF, Zeng WH (2014) Application of k-means clustering to environmental risk zoning of the chemical industrial area. Front Environ Sci Eng 8(1):117–127

Simpson MWM, Allen DM, Journeay MM (2014) Assessing risk to groundwater quality using an integrated risk framework. Environ Earth Sci 71(11):4939–4956

Song QW, Dai JG (2009) Priority control pollutants and emergency engineering technology of water environment. Chinese Building Industry Press, Beijing

US EPA (2009) Chemical prioritization: ranking chemicals of concern to Scotland′s environment: phase 1. Surface waters. US EPA, Washington DC

Wang SY, Feng BX (2005) Emergency response and management of city disaster. Chongqing Press (in Chinese)

Wang L, Wang YP, Lu YH, Su N (2005) The sifting of priority control organic pollutants in Hunhe river of liaohe basin in Shenyang city. Environ Monit China 21(6):59–62 (in Chinese)

We LJ, Duo YQ, Yu LJ (2007) Research on the method and procedure of safety planning for chemical industry parks. Chin Safety Sci J 17(9):45–51 (in Chinese)

Wu YM, Chen QW, Li J (2011) Fuzzy comprehensive assessment on spatio-temporal variations of water quality of a small catchment. Acta Sci Circumst 31(6):1198–1205 (in Chinese)

Yuan P, Peng JF, Tian ZY, Song YH (2013) Strengthen the corporate environmental risk prevention actively respond to environmental emergencies. Environ Prot 3:5–55 (in Chinese)

Zhang XJ, Chen C, Ding JQ, Hou AX, Li Y, Niu ZB, Su XY, Xu YJ, Laws EA (2010) The 2007 water crisis in Wuxi, China: analysis of the origin. J Hazard Mater 182(1–3):130–135

Zhang Y, Deng YF, Zhao YP, Ren HQ (2014) Using combined bio-omics methods to evaluate the complicated toxic effects of mixed chemical wastewater and its treated effluent. J Hazard Mater 272(5):52–58

Zhao JS, Joas R, Abel J, Marques T, Suikkanen J (2013) Process safety challenges for SMEs in China. J Loss Prev Process Ind 26(5):880–886

Zheng BH, Lei K, Liu RZ, Song SS, An LH (2014) Integrated biomarkers in wild crucian carp for early warning of water quality in Hun River, North China. J Environ Sci China 26(4):909–916

Zhu HN, Yuan XZ, Zeng GM, Jiang HW, Liang J, Zhao NN, Zhang Z (2009) An integrated fuzzy model based on interval numbers for assessment of environmental health risks of water sources. Acta Sci Circumst 29(7):1527–1533 (in Chinese)

Acknowledgments

This work was financially supported by the EU-China Environmental Sustainability Program (No. DCI-ASIE/2013/323-261) and Major Science and Technology Program for Water Pollution Control and Treatment (2012 ZX07202-002, ZX07202-005).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Han, L., Song, Y., Duan, L. et al. Risk assessment methodology for Shenyang Chemical Industrial Park based on fuzzy comprehensive evaluation. Environ Earth Sci 73, 5185–5192 (2015). https://doi.org/10.1007/s12665-015-4324-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12665-015-4324-8