Abstract

Characterization of zeolitic tuff from Jabal Hannoun (HN) and Mukawir (MR) was carried out to examine the ability of using low-cost natural materials in domestic wastewater treatment. The grain size between 0.3 and 1 mm (0.3–1 mm) of the HN and MR has the highest total zeolite grade (faujasite–phillipsite and phillipsite–chabazite) and suitable cation exchange capacity. They were used as fixed-bed ion exchangers and adsorbents. The zeolitic tuff efficiently removed the organic and nitrogen compounds, Pb and Zn from the effluent. One bed volume (1 BV) of the zeolitic tuff is capable to remove up to 95 % of total organic carbon form 500 BV of the effluent. The removal percent of total nitrogen by HN and MR is close to 95 and 90 %, respectively. The zeolitic tuff has an excellent efficiency to remove Pb and Zn from the effluent. 1 BV of HN completely cleans Zn and Pb from 680 and 730 BV of the effluent, respectively, whereas 1 BV of MR is able to clean completely Zn and Pb from 500 and 685 BV of the effluent, respectively. The greater performance of the HN compared with the MR may be explained by its higher zeolites grade and presence of faujasite.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Natural zeolites are abundant and low cost resources, which are crystalline hydrated aluminosilicates of alkali and alkaline earth cations that consist of infinitely extending three-dimensional networks of AlO4 5− and SiO4 4− tetrahedra, linked by the sharing of all oxygen atoms. The intracrystalline voids make up 20–50 % of the total crystal volume of most zeolites (Breck 1974). Many Zeolites are known to have an affinity for ammonium ion (Cooney et al. 1999); further, they lose most of bound water molecules without affecting the integrity of their molecular structure. They also have an excellent cation exchange capacity among other naturally occurring products, which enables them to be used as cation exchangers (Wang and Peng 2010). They frequently display good selectivity for heavy metal cations, which makes them valuable for the purification of industrial wastewater (Colella 1996; Ibrahim et al. 2002; Bedelean et al. 2010).

Zeolites are also excellent adsorbents (Crini 2006; Rawajfiha et al. 2010), which have uniformly sized pore opening, channel systems and cages (McCuster and Baerlocher 2001) throughout the crystal structure. Naturally occurring zeolites are hydrophilic (having an affinity for polar molecules, such as water) and generally contain aluminum (US EPA 1999). Due to their high cation exchange ability as well as to their molecular sieve properties, natural zeolites have been widely used as adsorbents in separation and purification processes in the past decades (Wang and Peng 2010). Zeolites fascinating and wonderfully properties, such as their ion-exchange properties, their sorption capacity, their shape selectivity and their catalytic activity, are essentially determined by their structures (McCuster and Baerlocher 2001).

Water scarcity in Jordan is one of the most important national problems, especially with the huge increase in population and the increase of demand of water for domestic, industrial, and agricultural uses (Scott et al. 2001; Salameh and El-Naser 2005).

Khirbet es Samra is the largest wastewater treatment plant in Jordan. The treatment plant is composed of three types of ponds: two anaerobic and four facultative ponds, which empty into four maturation ponds (Al Kharabsheh 1999). The sewage treatment plants aim at getting rid of chemicals and organic pollutants so that the treated effluent can be safely disposes off into surface water resources (lakes and dams), used in agriculture and industry, or used to recharge the groundwater without affecting its quality. The treated effluent (TE) of Khirbet es Samra plant is discharged to Wadi Dhuleil, which joins Zarqa River and reaches King Talal Dam, after traveling about 40 km (Al Kharabsheh 1999). The TE is stored at the dam for a period of 4 months during winter.

Treated effluent disposed from any treatment plant usually contains both organic and inorganic (heavy metals) pollutants. According to Al Kharabsheh (1999), the average COD and BOD content of the TE is 288 and 270 mg/L, respectively. These pollutants affect surface and groundwater (Al Kharabsheh 1999).

Total organic carbon (TOC) is the amount of carbon bound in an organic compound and is often used as a non-specific indicator of water quality. Since the early 1970s, TOC has been recognized as an analytic technique to measure water quality during the drinking water purification process. TOC in source waters comes from decaying natural organic matter (NOM) and from synthetic sources. Humic acid, fulvic acid, amines, and urea are types of NOM. Detergents, pesticides, fertilizers, herbicides, industrial chemicals, and chlorinated organics are examples of synthetic sources (Hendricks 2010).

The Jordanian Standard 893/2006 issued by the Jordanian Institution for Standards and Metrology (JISM) for “Reclaimed Domestic Wastewater (RDW)” has been set to specify the conditions that the RDW discharged from wastewater treatment plants should comply with, in order to be discharged or used (Uleimat 2011). The standard according to Seder and Abdel-Jabbar (2011) has three primary components: (a) reclaimed water discharged to streams, wadis or water bodies, (b) reclaimed water for reuse, and (c) allowable limit for properties and criteria for use in artificial recharge for ground water. It is not permitted to dilute by mixing reclaimed water before being discharged from wastewater treatment plants with pure water intentionally to comply with the requirements set in this standard. And it is prohibited to use it for irrigating vegetables that are eaten uncooked (Uleimat 2011). According to the standards, official and specialized concerned parties must always work towards improving the effluent quality to levels, may be, exceeding those presented in this standard to ideally use the reclaimed water and protect the environment.

Many methods have been adopted to remove organic matter substances from water resources: coagulation/flocculation separation, ion exchange, adsorption by activated carbon and membrane filtration (Hendricks 2010). Among these methods, adsorption is regarded as a promising method for the removal of these substances. So, it is very necessary and significant to explore new adsorbents with high adsorption capacity and efficiency to remove organic matter from water. The presence of abundant natural zeolites of high quality, mainly those of faujasite and phillipsite in Jordan, has initiated great interest in the utilization of these zeolites in water treatment. Several investigations were carried out to use natural zeolites as ion exchangeable material such as Ibrahim (1996); Al Dwairi (2007, 2009); Ibrahim and Jbara (2009); Hussein (2010); Al-Rawajfeh et al. (2011); Al Dwairi and Al-Rawajfeh (2012); Taamneh and Al Dwairi (2013).

The idea of treating lead- and zinc-contaminated solutions with natural zeolite has recently shown good promise and has been proposed as an alternative to active carbon (Sublet et al. 2003). Zeolite minerals such as clinoptilolite, phillipsite, faujasite and chabazite have been investigated as a potential agent to treat heavy metal-contaminated wastewater, especially in the case of Pb and Zn (Hendricks 2010; Al Ebaisat 2011; Ibrahim 2001; Salem and Akbari Sene 2011).

The main objective of this project is to use the zeolitic tuff as an ion exchanger and sorbent with very little preparation costs. Therefore, the removal of organic pollutants can be achieved by column or batch methods using zeolites as adsorbents. The former can be achieved using a column filled with a bed of known volume of the zeolitic tuff. Batch method is carried out by adding a weighted quantity of zeolitic tuff to a known volume of TE. The zeolitic tuff and TE are mixed until a condition of equilibrium is reached for exchange reaction.

Materials and methods

Two zeolite tuff samples were selected to be investigated and evaluated in the treatment of real pre-treated domestic wastewater. The samples were collected from: Jabal Hannoun (HN) and Mukawir (MR) (Fig. 1). 25 samples were collected from each location. The pre-treated wastewater was obtained from the effluents of Khirbet es Samra wastewater treatment plant.

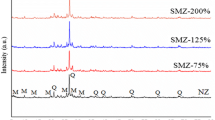

The HN is gray faujasite–phillipsite tuff, whereas the MR is reddish brown phillipsite–chabazite tuff. The zeolite tuff is poorly cemented and easily disintegrated; therefore size classification was carried out for the samples out without grinding. Size classification is used as a tool for zeolites grade (Ibrahim and Inglethorpe 1996). The grain size ranges between 0.3 and 1 mm was selected because it contains highest zeolite grade. The samples were subjected to characterization following the procedures described in Al Dwairi (2007). Zeolite grade was calculated using X-ray diffraction techniques as recommended by Ibrahim and Inglethorpe (1996). The physical properties were evaluated including attrition resistance test and acid solubility as described in Ibrahim (1996). Cation exchange capacity (CEC) was determined following Mercer and Ames (1978). The chemical composition of the rock samples and the TE were determined using the Atomic Absorption Spectrometer.

The TE from Khirbet es Samra wastewater treatment plant was used after filtering the suspended solids. Concentration of the organic matter and nitrogen content was determined as total organic carbon (TOC) and total nitrogen (TN) using Shimadzu TOC-VCPN instrument. The TOC content of the analyzed samples were measured by indirect methods by calculating the difference between the total carbon (TC) and the inorganic carbon (IC) using Shematsu TOC-VCPN instrument. The system includes an autosampler ASI-V and an NDIR detector. Concentration of the trace elements was determined using an ICP-Ms model Optima Perkin Elemer-3000 based the labs of the Water Authority of Jordan. Water analyses were carried out following the methods described in the Standard Methods for the Examination of Water and Wastewater (2012).

The grain size (0.3–1 mm) was used in the column experiments, with no pre-chemical treatment. The column experiments were operated under fixed conditions. The fixed zeolitic bed worked as an adsorbent and ion exchanger material (Treybal 1980). Twenty-one to twenty-five effluent water samples were collected from the columns at 10, 20, 30, 40, 60, 80, 100, 150, 200, 300, 400, 500, 600, 800, 1,000 ml, etc. The column experiment results were presented using breakthrough curves (S) (Treybal 1980).

In the batch experiments, the grain size (0.3–1 mm) was grinded using agate mortar to get a powdered zeolite. A fixed weight (0.5 g) of zeolitic tuff was mixed with 100 ml of TE in a 250-ml volumetric flask, followed by shacking using orbital shaker for a selected time (1, 4, 8, 12, and 24 h). The solution thereafter was filtered for analyses.

Results and discussion

Characterization

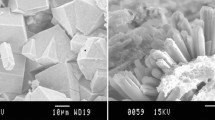

The grain fraction size (0.3–1 mm) was selected because it exhibits highest zeolite grade between 50 and 65 % and suitable physical properties (Table 1) (Ibrahim 1996). Scanning electron micrographs of the studied zeolite samples is shown in Fig. 2a, b.

Scanning electron micrograph of the, a phillipsite and b faujasite (Ibrahim 1996)

The chemical composition of the bulk and the grain size (0.3–1 mm) from the HN and MR is presented in Table 1 which reveals that the HN is characterized by higher SiO2 and Al2O3 content compared with the MR but have lower K2O content. MR displays very high CaO content up to 11.51 %, such percentage is related to the presence of secondary calcite in the sample. The great difference in the chemistry of the bulk samples and the size fractions (0.3–1 mm) is due to the fact that bulk samples contain abundant olivine, pyroxene and sideromelane which are Mg–Fe rich phases with no or very LOI %. The ferromagnesian phases are minor in the grain size (0.3–1 mm) but have abundant LOI %.

Table 1 shows that the grain size between 0.3 and 1 mm is characterized by higher Al2O3, K2O and LOI content. Meanwhile, it exhibits lower Fe2O3, MgO and TiO2 content compared with the bulk samples. This is most probably due to the higher zeolites percent in this size fraction rather than the bulk samples.

The resistance of the geological material to aggressive environment is emphasized as attrition resistance and stability under acid environment. The weight percentage of the fine particles that result from the sized zeolite after backwashing in aqueous solution represents the attrition resistance (Ghrir 1998). The results of attrition resistance test of the HN and MR are 5.5 and 4.5 %, respectively as listed in Table 1, which also shows value of the packed-bed density (about 1.0 g/cm3). The Na-CEC of the HN is 1.54 meq/g, whereas the CEC of the MR is 1.39 meq/g (Table 1).

The stability of the HN and MR under acid environment is acceptable. In detail, at pH 5 the HN and MR resist the acidic attack in the first 5 h, and then the zeolites structure starts to collapse, so they lose part of their crystallinity as indicated by X-ray diffraction. The residual crystallinity after 24 h is higher than 95 % for both samples. At pH 3, both samples lose about 75–80 % of their crystallinity (Fig. 3).

Chemical characteristics of the treated effluent (TE) from Khirbet es Samra is presented in Table 2. The presence of the organic pollutants in the TE is marked by the presence of 275 mg/L BOD and 54 mg/L TOC. Nitrogen occurs as NO3 and NH4. In addition to the presence of Na and Ca as competing ions, the TE contains about Pb, Zn, Ni and Cr.

Removal of organic pollutants

The operation condition of the column experiments are tabulated in Table 3. The results of the fixed-bed adsorption experiment using the MR and HN are illustrated in Fig. 4, which emphasizes the excellent performance of the two samples to remove the organic content from the TE. The TOC content in the original TE sample (C 0) is 54 mg/L as shown in Table 2. The breakthrough curves of the experiments exhibit typical S shape as shown in Fig. 4. About 98 % of the TOC value was removed from the TE before reaching the breakthrough point at 500 BV (1 BV = 40 cm3, Table 3), where the TOC value of this effluent is <0.01 mg/L. The exhausting point was reached using the MR and HN at about 800 and 780 BV, respectively. This indicates that both zeolitic tuff materials have almost similar behavior although they hold different zeolites type and grade (Table 1).

In batch experiments, a 0.5 g of the HN and MR was contacted with 100 ml of the TE at variable contact time. The results in Fig. 5, indicating that the two zeolitic tuff samples exhibit same trend in the removal of TOC. The figure shows that the TOC removal is a fast process and proportionally increases with the increase of contact time in the first 8 h. The removal efficiency decreases thereafter. In detail, the MR and HN samples are able to remove about 55 % of the TOC in the first hour of contact time and about 65 % after 8 h. The samples continue to remove the organic matter with the increase of the contact time between 8 and 24 h, but with a very slow rate (Fig. 5).

Removal of nitrogen

Total Nitrogen (TN) is the sum of nitrate–nitrogen (NO3–N), nitrite–nitrogen (NO2–N), ammonia–nitrogen (NH3–N) and organically bonded nitrogen. TN is sometimes regulated as an effluent parameter for municipal and industrial wastewater treatment plants (Stenholm et al. 2009). Faujasite, phillipsite and chabazite have a great affinity to exchange ammonia–nitrogen from wastewater (Ibrahim 1996).

With regards to the removal of total nitrogen from the TE using a fixed-bed of MR and HN zeolitic tuff, the results are displayed in Fig. 6 which reveals the efficiency of the two samples in the removal of the total nitrogen. As shown in Table 2, the C 0 of total nitrogen in the original TE sample is equal to 194 mg/L. Table 2 indicates that most of the total nitrogen in the TE is related to the presence of NH4. Using the HN sample, the concentration of total nitrogen was <5 mg/L in the early collected effluent at BV = 2 and continue to be <10 mg/L at the breakthrough point (BV = 45). This indicates a removal percent is close to 95 %. The MR sample achieves slightly lower removal percent equal to 90 % before reaching the breakthrough point at 40 BV. The exhausting point was reached using the MR and HN at about 78 and 100 BV, respectively. The slight higher performance of HN in the removal of total nitrogen compared with MR is attributed the presence of faujasite in the HN sample. It is well demonstrated by Ibrahim (1996, 2001) that the efficiency of faujasite to remove ammonia–nitrogen (NH3–N) from water is higher than the efficiency of phillipsite and chabazite.

Removal of heavy metals

Zinc (Zn+2)

Removal of Zn+2 (C 0 = 1.86 mg/L) from the TE sample is presented in Fig. 7 using HN and MR zeolitic tuff. The removal process reflects the high efficiency of HN zeolitic tuff. Presence of an uncompleted S curve indicates that the experiment was not finished. The breakthrough point occurs at BV = 680 and the exhaustion point occurs at BV = 1,150. MR zeolitic tuff also exhibits high efficiency with breakthrough point at BV = 500 and the exhaustion point at 890 BV. It is obvious from Fig. 7 that the efficiency of HN zeolitic tuff is higher than the efficiency of MR. This result is due to the higher zeolites grade in HN (65 %) compared to MR (50 %) (See Bedelean et al. 2010). Also, it might be related to the presence of faujasite which has both an experimental and calculated surface area ranging between 903 and 1132 m2/g (Yates 1968).

Lead (Pb+2)

The initial concentration of Pb+2 is 1.18 mg/L (Table 2). The percentage removal is represented by the breakthrough curve as shown in Fig. 8 for HN and MR zeolitic tuff, which indicates that the breakthrough point of HN zeolitic tuff occurs at BV = 730 and the exhaustion point occurs at BV = 1,220. Figure 8 shows also that the breakthrough point for MR zeolitic tuff occurs at BV = 685 and the exhaustion point occurs at BV = 1,140.

It was indicated by Salem and Akbari Sene (2011) that the removal efficiency of Pb from effluents is proportional to surface area and cation exchange capacity of the sorbent. Faujasite removes more lead than phillipsite and chabazite in the same chemical condition (Ibrahim 1996). In this way the percent removal of Pb increases with the increment of contact time; pH of suspension and amount of adsorbents (Salem and Akbari Sene 2011).

Conclusion

The physical and chemical characterization of the Jordanian zeolitic tuff from Jabal Hannoun and Mukawir show that they have high zeolitic grade, high attrition resistance, backed-bed densities, good permeability and high resistance to aggressive environment. The results enable both zeolitic tuffs to be used as exchanger media in domestic wastewater treatment.

The grain size (0.3–1 mm) of HN and MR zeolitic tuff has the highest total zeolitic grade (faujasite–phillipsite and phillipsite–chabazite between 65 and 50 %, respectively), high cation exchange capacity, suitable attrition resistance and high packed-bed density. These characteristics are important for using zeolitic tuff as fixed-bed ion exchanger. Jabal Hannoun and Mukawir zeolitic tuff are stable at pH 5. They lose (3 %) and (5 %) of there crystallinity after the attack by acid for 24 h.

The Jordanian zeolitic tuff from Jabal Hannoun and Mukawir are suitable for the purification of treated effluent from wastewater treatment plants. They efficiently removed the organic and nitrogen compounds as well as Pb and Zn from the effluent. It was shown that 1 BV of the zeolitic tuff is capable to purify the polluted water and remove up to 95 % the organic pollutant (TOC) form 500 BV of the effluent. The removal percent of total nitrogen by HN and MR, prior to reaching the breakthrough point at 45 and 40 BV, is close to 95 and 90 %, respectively. The zeolitic tuff (HN and MR) has an excellent efficiency to remove Pb and Zn from the effluent. One BV of HN will completely clean Zn and Pb from 680 and 730 BV of the effluent, respectively, whereas 1 BV of MR will completely clean Zn and Pb from 500 and 685 BV of the effluent, respectively, in the presence of competing cations (Na and Ca).

The greater performance of Jabal Hannoun samples compared with Mukawir sample may be explained by its higher grade of total zeolites and the presence of faujasite. This is in agreement with conclusions made by Ibrahim (2001). It was indicated that faujasite containing zeolitic tuff is always more efficient in removing heavy metals and ammonium from water than non-faujasite containing zeolitic tuff (Ibrahim 1996, 2001, 2002).

References

Al Dwairi R (2007) Characterization of the Jordanian zeolitic tuff and its potential use in Khirbet es Samra wastewater treatment plant. Ph.D. thesis, The University of Jordan, Amman, Jordan

Al Dwairi R (2009) The use of expendable local zeolite deposits for NH4 removal in municipal wastewater. Jord J Civil Eng 3:256–264

Al Dwairi R, Al-Rawajfeh A (2012) Removal of Cobalt and Nickel from wastewater by using Jordan low-cost Zeolite and Bentonite. J Univ Chem Technol Metall 47:69–76

Al Ebaisat H (2011) Elimination of ammonium and toxic heavy metals from waste water by means of zeolite volcanic tuff in South Jordan. Int J Acad Res 3:135–139

Al Kharabsheh A (1999) Ground-water quality deterioration in arid areas: a case study of the Zerqa river basin as influenced by Khirbet es-Samra waste water (Jordan). J Arid Environ 43:227–239

Al-Rawajfeh A, Al-Whoosh K, Al Dwairi R, Al-Maaberah A, Tarawneh A (2011) Pre-treatment of Desalination Feed Seawater by Jordanian Tripoli, Pozzolana, and Feldspar: batch Experiments. Chem Ind Chem Eng Q 17:163–171

Bedelean H, Măicăneanu H, Burcă S, Stanca M (2010) Investigations on some zeolitic volcanic tuffs from Cluj County (Romania), used for zinc ions removal from aqueous solution. Stud Univ Babeş Bol Geol 55:9–15

Breck D (1974) Zeolite molecular sieves: structure, chemistry and use. Wiley, London

Colella C (1996) Ion exchange equilibria in zeolite minerals. Miner Deposita 31:554–562

Cooney E, Booker N, Shallcross D, Stevens G (1999) Ammonium removal from wastewater using natural Australian zeolites: II pilot scale study using continuous packed column process. Sep Sci Technol 34:2741–2760

Crini G (2006) Non-conventional low-cost adsorbents for dye removal: a review. Bioresource Technol 97:1061–1085

Ghrir A (1998) The distribution, nature, origin, and economic potential of zeolite deposits in Uneiza, Mukawir, and Tell Hassan of Jordan. M.Sc. Thesis, University of Jordan, Jordan

Hendricks D (2010) Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological: Physical and Chemical. Boca Raton, FL: CRC Press. ISBN 10 1420061917

Hussein M (2010) Characterization of raw zeolite and surfactant-modified zeolite and their use in removal of selected organic pollutants from water. M.Sc. Thesis, Hashemite University, Jordan

Ibrahim K (1996) Geology, mineralogy, chemistry, origin and uses of the zeolites associated with Quaternary tuffs NE Jordan. Ph.D. Thesis, University of London, UK

Ibrahim K (2001) Evaluation of Jordanian faujasite tuff by comparison with other natural and synthetic zeolites. Environ Geol 40:440–445

Ibrahim K (2002) Application of Jordanian faujasite–phillipsite tuff in ammonium removal. In: Aiello R, Giordano G, Testa F (eds), Stud Surf Sci Catal. vol 142, Elsevier, pp 1767–1773

Ibrahim K, Inglethorpe S (1996) Mineral processing characteristics of natural zeolites from the Aritayn formation of northeast Jordan. Mineral Deposita 31:589–596

Ibrahim K, Jbara H (2009) Removal of paraquat from synthetic wastewater using phillipsite–faujasite tuff from Jordan. J Hazard Mater 163:82–86

Ibrahim K, Nasser Ed-Deen T, Khoury H (2002) Use of natural chabazite–phillipsite tuff in wastewater treatment from electroplating factories in Jordan. Environ Geol 41:547–551

McCuster L, Baerlocher C (2001) Zeolite structures. In: van Bekkum H, Flanigen EM, Jacobs AA, Jansen JC (eds) Introduction to zeolites sciences and practice, 2nd edn., Stud Surf Sci Catal 137:37–69

Mercer B, Ames L (1978) Zeolite ion exchange in radioactive and municipal wastewater treatment. In: Sand L, Mumpton FA (eds) Natural zeolites; occurrence, properties and uses. Pergamon Press Co., Oxford, pp 451–462

Rawajfiha Z, Al Mohammad H, Nsour N, Ibrahim K (2010) Study of equilibrium and thermodynamic adsorption of α-picoline, β-picoline, and γ-picoline by Jordanian zeolites: phillipsite and faujasite. Micropor Mesopor Mater 132:401–408

Salameh E, El-Naser H (2005) Jordan’s water situation-impacts of recently implemented policies on the water sector, Hydrogeol. Umwelt Würzburg 33(13):1–16

Salem A, Akbari Sene R (2011) Removal of lead from solution by combination of natural zeolite–kaolin–bentonite as a new low-cost adsorbent. Chem Eng J 174:619–628

Scott C, El-Naser H, Hagan R, Hijazi A (2001) Facing water scarcity in Jordan: reuse, demand reduction, energy and transboundary approaches to assure future water supplies. Am Geophys. Union, Spring Meeting, abstract # H22E–03

Seder N, Abdel-Jabbar S (2011) Safe use of treated wastewater in agriculture Jordan case study. Arab Countries Water Utilities Association

Standard Methods for the Examination of Water and Wastewater (2012). 22nd edition. American Public Health Association (APHA), American Water Works Association (AWWA) and Water Environment Federation (WEF)

Stenholm A, Holmström S, Ragnarsson A (2009) Total nitrogen in wastewater analysis: comparison of Devarda’s alloy method and high temperature oxidation followed by chemiluminescence detection. J Anal Chem 64:1047–1053

Sublet R, Simonnot M, Boireau A, Sardin M (2003) Selection of an adsorbent for lead removal from drinking water by a point-of-use treatment device. Water Res 37:4904–4912

Taamneh Y, Al Dwairi R (2013) The efficiency of Jordanian natural zeolite for heavy metals removal, applied water science, vol 3, No. 1

US EPA, Technical Bulletin (1999) Choosing an adsorption system for VOC: carbon, zeolites or polymers? Off Air Qual Plan Stand Res, Triangle Park, NC 27711EPA 456/F-99-004

Treybal R (1980) Mass-transfer operations, 3rd edn., McGraw-Hill Higher Education; Technol Eng, ISBN 10 0070666156

Uleimat A (2011) Wastewater management in Jordan, 6th International Water Association Specialist Conference on efficient use and management of water. 29 March–2 April 2011, Dead Sea, Jordan

Wang S, Peng Y (2010) Natural zeolites as effective adsorbents in water and wastewater treatment. Chem Eng J 156:11–24

Yates D (1968) Studies on the surface area of zeolites, as determined by physical adsorption and X-ray crystallography. Can J Chem 46:1695–1701

Acknowledgments

Thanks are due to the Hashemite University and the University of Jordan for supporting the analysis. Thanks are also due to the editors and reviewers of this article for their critical comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al Dwairi, R.A., Ibrahim, K.M. & Khoury, H.N. Potential use of faujasite–phillipsite and phillipsite–chabazite tuff in purification of treated effluent from domestic wastewater treatment plants. Environ Earth Sci 71, 5071–5078 (2014). https://doi.org/10.1007/s12665-013-2911-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12665-013-2911-0