Abstract

The application of powdered layer double hydroxides (LDHs) in constructed rapid infiltration system (CRIS) appears to be an appreciable problem still unsolved due to the small particle size and the low density. Therefore, the core-shell zeolites/MgFe-LDHs composites were prepared via using co-precipitation method in present study. To investigate the practical applicability, a detailed organics, ammonia, and total phosphorus removal study were carried out in columns to treat the municipal wastewater. The scanning electron microscope (SEM) and energy dispersive spectrometer (EDS) results confirmed the successful synthesis of core-shell zeolites/MgFe-LDHs through coating on the surface of zeolites. Accordingly, the zeolites/MgFe-LDHs largely reduced the COD by 81.14 %, NH4 +-N by 81.50 %, and TP by 83.29 %. Phosphate adsorption study revealed that the equilibrium adsorption data were better fitted by Langmuir isothermal model, with the maximum adsorption capacity of 79.3651 mg/kg for zeolites/MgFe-LDHs and 38.4615 mg/kg for the natural zeolites. In addition, economic analysis indicated that the reagent cost of synthesis of zeolites/MgFe-LDHs was economical. Herein, the zeolites/MgFe-LDHs solved the natural zeolites problem for poor P removal and the application of powdered LDHs in the solid/liquid separation process, suggesting that it was applicable as potential substrates for the removal of organics, ammonia, and total phosphorus in CRIS.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Layered double hydroxides (LDHs), also known as hydrotalcite-like compounds or anionic clays are a large group of natural and synthetic layered materials. In the recent decades, due to their special structure and unique properties, LDHs have received considerable attention (Da Silva et al. 2014; Russell et al. 2015). It can be represented by the general formula of [M 1 − x 2+ M x 3+ (OH)2]x+ (A n−)x/n × mH2O, where M 2+ and M 3+ are the divalent and trivalent cations in the octahedral positions within the hydroxides layers. The value of x represents the molar ratio of M 3+/(M 2++M 3+) which was normally between 0.17 and 0.33. A n− is an exchangeable interlayer anion. The structure of LDHs is based on positively charged brucite-like sheets, and the positive charges are balanced by intercalation of anions in the hydrated interlayer regions (Yan et al. 2015; Qiu et al. 2015). LDHs have been studied for their potential use in a series of important fields, such as catalysis (He et al. 2011), biomedical science (Chandra et al. 2011; Choi and Choy 2011). There has also been considerable interest in utilizing LDHs to remove environmental contaminants since the environmental pollution has emerged as an important issue in the recent decades (Goh et al. 2008; Rojas 2012; Lin et al. 2015). However, LDHs were directly used in a dispersed powder form for the adsorption of oxyanions, especially, for the phosphate. Therefore, it presented appreciable problems for the application in the constructed rapid infiltration system.

Constructed rapid infiltration systems (CRIS) were widely used as an efficient alternative means of wastewater treatment over the world for far longer than the past 2 decades (Zheng et al. 2008; Jiang et al. 2011; Xu et al. 2011). Compared to conventional treatment technologies, it has been proved to be with low investment, low energy consumption and easy management (Wang et al. 2010; Lian et al. 2014). The contaminants’ removal processes include microbial degradation, sorption, sedimentation, filtration and precipitation (He et al. 2002; Li et al. 2004). However, the CRIS presented appreciable problems for the removal of nitrogen and phosphorus due to the limited oxygen availability in substrates and the inefficient adsorption of the saturated substrates, respectively. Therefore, the attention of the scientific community has to be focused on the selection of a substrate with a high removal capacity in order to obtain an efficient purification. In this regard, anthracite, zeolite, bio-ceramic, vermiculite, steel slag, and other natural minerals were gradually used as the substrates to improve the removal efficiencies of contaminates in recent years.

Natural zeolites are aluminum-silicate crystals and have the skeleton-like structure which has been identified as a porous material. Its internal cavities and channels are capable of accumulating massive liquidity strong cations and presented the cations exchange properties with the NH4 + and Na+. More particularly, the exchange process showed no change to the crystal structure of the zeolites. Due to its worldwide distribution, large deposits, low cost, high porosity, and its neutral chemical structure, zeolites are considered to be an appropriate material for the removal of NH4 +-N from urban and industrial wastewater (Filippidis and Kantiranis 2007; Milan et al. 2001). Generally speaking, the natural zeolites presented the efficient removal performance of ammonia but faced the problems of the organic and total phosphorus removal. It has been reported that the removal rates of organic and total phosphorus were 62.0 and 40.5 % (Stefanakis et al. 2009), and 30.6 and 51.9 % (Yalcuk and Ugurlu 2009), respectively. In particular, the inefficient removal performance and the clog in the CRIS appeared to be appreciable problems when the adsorption reaches the saturation. Herein, it is imperative to find a way to improve the removal rates.

In summary, the main issues of LDHs and natural zeolites were that powder LDHs presented appreciable problems for the application in the constructed rapid infiltration system due to the small size, the low specific density and the solid/liquid separation process. On the other hand, poor removal performances of organic and total phosphorus were obtained by the natural zeolites. Additionally, there are no research studies on CRIS in the field scale of using the combination of LDHs and natural zeolites to removal pollutant from the municipal wastewater. In this regard, LDHs were used to coat on the surface of the zeolites to synthesize zeolites/LDHs composites and reached the aim of improving the removal capacity, solving the application of powdered LDHs in constructed rapid infiltration system.

As preliminary experiments showed LDHs could be synthesized in the alkaline conditions by co-precipitate method (Zhang et al. 2013) and in situ coated on the natural anthracite (Zhang et al. 2015a, b). Natural zeolites were selected in the present study by using MgCl2·6H2O and FeCl3·6H2O in the alkaline conditions to synthesize MgFe-LDHs. The MgFe-LDHs were in situ coated on the zeolites to synthesize the core-shell zeolites/MgFe-LDHs for the purpose of providing a reference for controlling and strengthening the purification effect in constructed rapid infiltration system. Herein, the present research was aimed to synthesize, to characterize, and to study the removal performance of COD, NH4 +-N, and TP. The adsorption properties for phosphate were further evaluated by using batch experimental method. Besides, the economical of synthesizing zeolites/MgFe-LDHs were also investigated in this study.

Material and methods

Characterization of the system

Column experiments were simulated as the constructed rapid infiltration systems which were operated indoors. The units contained two test columns (PVC, H = 40 cm, d = 8 cm) which were filled with the zeolites/MgFe-LDHs and the natural zeolites (d = 0.5–2.0 mm), respectively. The true and bulk density of the natural zeolites was 1.93 and 1.32 g/cm3 in this study which were purchased from Zhengzhou City, Henan, China. The specific surface area of the natural zeolites was 7.40 m2/g. Under intermittent operation, the raw water collected from Shahu Sewage Treatment Plant (Wuhan, China) after a thin grill was filled into the top of the columns and flowed out of from the bottom after 12-h hydraulic retention time (HRT), indicating that the hydraulic loading rate (HLR) was 0.25 m/day. The pH value of the raw water fluctuated between 7.13 and 7.37. The purification experiments started at October 2013 and lasted for 18 weeks. The indoor temperatures were 18–30 °C with the average of 22 °C. The characteristics of the raw water are shown in Table 1.

Preparation of zeolites/MgFe-LDHs

MgFe-LDHs were prepared by the co-precipitation method (Das et al. 2006). The 1.50 mol/L MgCl2 and 0.75 mol/L FeCl3 solutions with the metal mole ratio (M 2+/M 3+) of 2:1 were added simultaneously to a beaker containing 2 L distilled water and clean zeolites. The water temperature was stably maintained at 80° with continuous heating and stirred for 4 h. During that period, the pH of the solution was maintained at 11∼12 by the addition of 25 % wt NaOH. In order to separate from suspension, the mixed compounds were centrifuged for 10 min at a speed of 1000∼1500 r/min and thoroughly washed with deionized water until the effluent obtained a neutral pH. At last, the composites were oven-drying at 100 °C for 16 h giving product of zeolites/MgFe-LDHs.

Physicochemical characterization

The crystal morphologies of these materials were probed by scanning electron microscopy (SEM, S4800, Hitachi, Japan). Chemical compositions were analyzed by a field emission scanning electron microscopy equipped with Energy Dispersive Spectrometry (EDS, Oxford Instrument X-Max 50, England). Brunauer-Emmett-Teller (BET) surface area were analyzed by N2 adsorption at −196 °C using a sorptometer (ASAP-2020, Micromeritics, USA). All the characterizations were examined in Material Research and Testing Center, Wuhan University of Technology.

Phosphate adsorption studies

The phosphate adsorption experiments were carried out in aqueous solution by using the zeolites/MgFe-LDHs and natural zeolites as the adsorbent, respectively. Standard phosphate solutions were prepared using KH2PO4 (GR) dissolved in distilled water. Ten-gram adsorbent was mixed with 100-mL phosphate solutions at various initial concentrations (0, 1, 2, 4, 8, 16, 32, 64 mg-P/L) in a series of 250-mL conical flasks. Experiments using blank samples were also carried out by using adsorbents and distilled water instead of phosphate solution. All the experiments were carried out in duplicates at the indoor temperature (25 ± 1 °C). After continuous shaking over in a thermostatic shaker at the speed of 120 rpm for 24 h, the adsorbents were separated from the mixture by the filtration process and the residual concentration of phosphate were measured by the standard methods (APHA 2005). Amount of phosphate adsorbed on per unit mass of adsorbents was computed using the formula (Eq. (1)):

where q e is the phosphate uptake (mg P/kg), C o is the initial concentration (mg/L), C e is the final equilibrium concentration (mg/L), V is the volume of solution (L), and m is the mass of the adsorbent (g).

Langmuir (Eq. (2)) and Freundlich equation (Eq. (3)) were used to describe the adsorption isotherm data. These equations can be expressed in linear form as follows:

where q e is the amount of phosphate adsorbed per unit mass of adsorbent (mg/kg), C e is the equilibrium phosphate concentration in solution (mg/L), q m is the theoretical maximum sorption capacity (mg/kg), and K L is Langmuir adsorption equilibrium constant, as for the K f and n which are the Freundlich adsorption equilibrium constant.

Water quality analysis

Water samples were collected from the effluent at the bottom of the columns in each batch and immediately analyzed for chemical oxygen demand (COD), ammonia (NH4 +-N), and total phosphorus (TP). COD, TN, NH4 +-N, TP, and phosphate were measured by potassium dichromate method, UV spectrophotometry method after alkaline potassium persulfate digestion, Nessler’s reagent colorimetric method, Anti-Mo-Sb spectrophotometry method after potassium persulfate digestion, and anti-Mo-Sb spectrophotometry method, respectively (APHA 2005).

Statistical analysis

In order to investigate the statically significant differences of the removal rates between the zeolites/MgFe-LDHs and the natural zeolites, a one-way ANOVA at 95 % significance level was used to examine the removal performance. Post hoc multiple comparisons were also performed by using the Bonferroni test. As the number of the data for the zeolites/MgFe-LDHs and the natural zeolites was the same, Levine’s test for homogeneity of variance and normality was bypassed. All the statistical analyses were determined by Excel 2007 and SPSS 19.0 software (SPSS Inc., Chicago, IL, USA). Statistical was defined as p < 0.05, and the p value was also called significant (two-tailed) value in the t test (SPSS 2003).

Results and discussion

Apparent characteristic of the zeolite/MgFe-LDHs

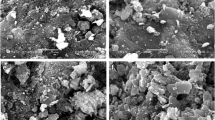

The results obtained from the SEM pictures of the zeolites/MgFe-LDHs (Fig. 1b) showed a mass of overlapping crystals like the layer stacked on the surface area which was typical for layered double hydroxides and the surface of the layer stacked aggregated lots of nano-particles. Comparatively, the morphologies of natural zeolites (Fig. 1a) aggregated a mass of disorganized particles, and the right surface area showed relatively smooth and flat. These results implied the successful fabrication of core-shell zeolites/MgFe-LDHs composites which formed a highly porous network and were responsible for the high surface of LDH materials. Herein, the natural zeolites physical characteristics were changed by virtues of coating MgFe-LDHs on the surface area.

Chemical composition of the natural zeolites and zeolites/MgFe-LDHs

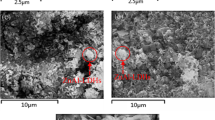

To further verify the feasibility of the coated method, the energy dispersive spectrometer (EDS) was utilized to measure the chemical composition of the zeolites before and after the experiments. According to energy spectrum results, it can be concluded that the compositions of the natural zeolites were Si, Al, Fe, K, and O element (Fig. 2a). Comparatively, the zeolites/MgFe-LDHs contained other elements, such as Mg, Na, and Cl (Fig. 2b). Therefore, the Mg element was successfully added on the surface of natural zeolites after the process of coating method.

Furthermore, compared with the main chemical composition of natural zeolites and zeolites/MgFe-LDHs (Table 2), the contents of Fe3+ and Mg2+ were higher for zeolites/MgFe-LDHs (5.54 and 2.02 %) than the natural zeolites (0.06 and 0 %), indicating that the coated method further changed the chemical composition of the zeolites. On the basis of the change of physical characteristics and chemical composition, it revealed that the way of co-precipitate synthesized LDHs in alkaline conditions and in situ coating on the zeolites substrates was feasible.

COD removal

The COD removal rates and average removal rates of the municipal wastewater treated by the natural zeolites and zeolites/MgFe-LDHs during the experiments are illustrated in Fig. 3a, d, respectively.

As shown in Fig. 3d, the average removal rates of the zeolites/MgFe-LDHs and natural zeolites were 81.14 % (53.00∼95.43 %) and 62.20 % (51.00∼72.99 %), respectively. Compared with the natural zeolites, the removal effect of the zeolites/MgFe-LDHs was more stable due to the smaller fluctuations (Fig. 3a) which indicated that the coated method to the substrates could enhance the average removal rates of COD. The statistical analyses between the natural zeolites and zeolites/MgFe-LDHs are shown in Table 3. The significant (two-tailed) value (p value) was 0.009 which was less than 0.05, indicating that there was significant difference between the two of them. In other words, zeolites/MgFe-LDHs actually improve the removal rates of the organic matter.

The average removal rates of COD with the natural zeolites obtained in this study (62.20 %) were much comparable to the result of 62 % in Stefanakis et al. (2009), but lower than the results of other studies, such as 70 % in Zhang et al. (2007b) and 79.9 % in Stefanakis and Tsihintzis (2012). The main reason for the higher efficiencies of zeolites in Stefanakis and Tsihintzis (2012) might attribute to the longer residence times (1 day). The other reason might associate with their relatively larger pores which allowed for the adsorption of solid particles and dissolved organics (Fachini and Vasconcelos 2006). The average removal rates observed both in the zeolites/MgFe-LDHs and natural zeolites were better than those recorded in other study; Zhang et al. (2013) obtained 58 % in zeolites/MgFe-LDHs and 48 % in natural zeolites, respectively. The more efficient removal performance attributed to the different particle size of the zeolites and the content of Mg2+ and Fe3+ after modification, which the values of this study (2.02 and 5.54 %, respectively) were much higher than those of Zhang et al. (2013) (0.10 and 1.12 %, respectively). The results showed that the high contents of Mg2+ and Fe3+ might promote the capacity of LDHs to efficiently coat on the zeolites and as a consequence, increase the removal efficiencies of COD.

Interestingly, the natural zeolites showed poorer removal rates of COD than anthracite and bio-ceramic under normal circumstances. However, after the coated method, the removal rates of COD with zeolites (81.14 %) were significantly enhanced and exceeded those of the natural anthracite (70 %) (Zhang et al. 2007a) and bio-ceramic (66 %) (Wu et al. 2010). Furthermore, it seemed that the zeolites/MgFe-LDHs obviously improved the removal capacity through the coated method. Due to the specific configuration of LDHs which is a kind of layered compounds with a porous surface structure, the zeolites/MgFe-LDHs promoted more small suspended organic matters to be intercepted than the natural zeolites. In other aspect, the high removal rates of zeolites/MgFe-LDHs for COD might relate to the sedimentation of suspended solids in the water (Zhang et al. 2009). Therefore, the main mechanism of COD removal in this study depends on the physical mechanisms.

NH4 +-N removal

The results depicted in Fig. 3b showed that the ammonia removal rates in the zeolites/MgFe-LDHs (67.27∼92.56 %) are more effective than the natural zeolites (45.49∼67.42 %), which were also consistent with the results of statistical analysis (sig. <0.01, Table 3). The average removal rates in the zeolites/MgFe-LDHs were 81.50 %, while in the natural zeolites were 57.01 % (Fig. 3d).

Ammonia removal mainly related to the mass loading, the operation regime (loading and resting periods) and the nitrifying bacteria employed in the constructed rapid infiltration system. Nitrification is the principal transformation mechanism that reduces the concentration of ammonia nitrogen to oxidized nitrogen. Particularly, there has been a typical biological denitrification process which is the ammonia eventually converted to nitrogen by degradation of the nitrifying bacteria (Zhang et al. 2013).

In this present study, the average removal rates of ammonia (57.01 %) in natural zeolites were lower than 78 % obtained in Stefanakis and Tsihintzis (2012), revealing that the natural zeolites in this study did not exhibited the high selectivity for ammonia (Saltali and Sari 2007). The reason may relate to the different particle size and the limited aeration in the columns. Wang and Li (2013) reported that the removal rates of the modified zeolites were 91.4 % when the HLR was 0.139 m/day. In other words, the removal rates tended to increase with the decrease of hydraulic load which were coincided with the results in this study. Compared with the zeolites/MgFe-LDHs, the removal rates still showed a great difference of 24.5 % which were operated under the same conditions. The high removal rates may attribute to several reasons. One reason was the surface of the zeolites/MgFe-LDHs which was coarser than before (Fig. 1) so as to provide a favorable environment and large surface area for the nitrifying bacteria to perch and grow. The other reasons were the cation exchange capacity (CEC) of the materials played a large role in the retention of ammonia and subsequent processing within the constructed rapid infiltration system (Gisvold et al. 2000). It was apparently that the zeolites/MgFe-LDHs showed more content of Mg2+ and Fe3+ which in turn to enhance the exchange capacity.

Indeed, the Na and K element was an important factor which influenced the ammonium uptake. The zeolites coated with MgFe-LDHs presented that the concentrations of Na and K were approximately one and three times higher than the natural zeolites, respectively (Table 2). The selectivity of ion exchange on zeolites was found to in the sequence of K+ > NH4 + > Na+ > Ca2+ > Mg2+ (Zhu et al. 2011), while the ammonium uptake on the cation exchange sites was reported to follow the order: Na+ > K+ > Ca2+ > Mg2+ (Sprynskyy et al. 2005). Therefore, Na element was found as the most benefit element for the zeolites in ammonia removal (Sarioglu 2005).

TP removal

The results obtained in Fig. 3c, d indicated that the zeolites/MgFe-LDHs were more effective for TP removal than the natural zeolites, and the significant (two-tailed) value was 0.000 which was less than 0.05 (Table 3). The removal rates of the zeolites/MgFe-LDHs varied between 53.61 and 92.93 % with an average of 83.29 %, while in the natural zeolites were 33.73∼72.46 % and 54.69 % in average. Under normal circumstances, the removal rates of TP by the natural zeolites were less efficiently than the anthracite and bio-ceramic. However, the zeolites/MgFe-LDHs removal rates of TP (83.29 %) exceeded those of the natural anthracite (60 %) (Zhang et al. 2007a) and bio-ceramic (58 %) (Wu et al. 2010), implying that the zeolites/MgFe-LDHs efficiently improved the removal capacity through the coated method.

It is obvious that the key mechanisms of phosphorus removal from wastewater in the constructed rapid infiltration system are physicochemical processes, such as the fixation of phosphate by iron and aluminum in the substrates (Ayoub et al. 2001). In this study, the high TP removal rates of zeolites/MgFe-LDHs might relate to the decrease of Si element. It was reported that the more Si element contained in the substrates, the lower removal rates for the phosphorus (Drizo et al. 1999). The other reason may be due to the porous structure of LDHs and the feature of layered metal compounds, which could strengthen the physicochemical processes so as to promote the degradation of TP. Cheng et al. (2009) recorded that the adsorption capacity of the MgFe-LDHs for phosphate was about 25 mg P/g. And, it is generally believed that the adsorption capacity can be enhanced by increasing the anion exchange capacity of the LDHs (Goh et al. 2008). In this regard, the sorption characteristics of the zeolites/MgFe-LDHs are a major mechanism at the early stage in the constructed rapid infiltration system when it operates until the substrate reached saturation. Furthermore, the different materials, hydraulic loading rates, and ways of coating method may further cause the different purification effect of phosphorus. Therefore, the results obtained in this study were lower than those of Wang and Li (2013), which reported an 86.9 % removal rate of phosphorus in coated zeolites when HLR was 0.093 m/day.

Phosphate adsorption isotherms

Phosphate adsorption isotherms were used to determine the distribution of phosphate between solution and solid phased of the zeolites/MgFe-LDHs and natural zeolites, respectively. The adsorption isotherms of zeolites/MgFe-LDHs and natural zeolites to phosphate are shown in Fig. 4. The values of all the constants are shown in Table 4, and the linear plots of Langmuir and Freundlich models are shown in Fig. 5.

It can be observed that the correlation coefficient (R 2) of natural zeolites and zeolites/MgFe-LDHs in Langmuir and Freundlich equation were higher than 0.90 (Table 4). Comparatively, the Langmuir equation showed better fitted than the Freundlich equation with the values of R 2 > 0.98, implying that the adsorption on the surface was homogeneous and formation of monolayer coverage of phosphate on the surface of the adsorbent.

Based on the values of q m (Table 4), theoretical phosphate adsorption capacity for zeolites/MgFe-LDHs (79.3651 mg/kg) was about two times higher than the natural zeolites (38.4615 mg/kg) calculated by the Langmuir equation. The results were coincided with the K f values in Freundlich equation which represented the adsorption capacity of the adsorbents. In other words, the higher K f values indicated the adsorption capacity of zeolites/MgFe-LDHs that were higher than the natural zeolites. Furthermore, the higher theoretic maximum adsorption capacity for zeolites/MgFe-LDHs (79.3651 mg/kg) can attribute to its high surface area, abundant adsorption sites, and macro-porous networks on the surface of the zeolites.

Economic analysis

In order to evaluate economic of synthesizing MgFe-LDHs and in situ coating on the natural zeolites, the prices of the reagents (MgCl2·6H2O, FeCl3·6H2O, NaOH) applied in the coated method were provided by the Alibaba Website. The prices were RMB ¥3.30/kg for industrial FeCl3·6H2O, RMB ¥1.00/kg for industrial MgCl2·6H2O, and RMB ¥2.10/kg for industrial sodium hydroxide. Moreover, taking into consideration of the far differences between the conditions of industry and laboratory, parts of costs were not included in this study such as the electricity and the pay for workers. After a rough estimation, the reagents cost of synthesis of zeolites/MgFe-LDHs was RMB ¥0.0395/kg, indicating that the combination of co-precipitation to synthesis MgFe-LDHs and in situ coating on the natural zeolites is economical.

Conclusion

The present study showed that MgFe-LDHs hydrotalcite was synthesized by magnesium chloride hexahydrate, iron(III) chloride hexahydrate, and sodium hydroxide using co-precipitation method, and MgFe-LDHs were in situ coated on the natural zeolites to synthesis zeolites/MgFe-LDHs composites. Synthesis was ascertained by adopting various characterizing method such as SEM and EDS chemical analysis. The purification experiments results indicated that compared to the natural zeolites removal rates of COD (62.20 %), NH4 +-N (57.01 %), and TP (57.69 %), the zeolites/MgFe-LDHs largely increased by 18.94, 24.49, and 28.26 %, respectively. The adsorption of phosphate from aqueous solution by the zeolites/MgFe-LDHs and natural zeolites were better fitted to the Langmuir equation. The maximum theoretical phosphate adsorption capacity was 79.3651 mg/kg for zeolites/MgFe-LDHs and 38.4615 mg/kg for the natural zeolites. According to the rough estimation, the reagents cost of synthesis of zeolites/MgFe-LDHs was RMB ¥0.0395/kg.

The main removal mechanisms of zeolites/MgFe-LDHs for COD, ammonia, and total phosphorus have been proposed to surface adsorption, cation exchange, and precipitation. More particularly, the zeolites/MgFe-LDHs in this study enhanced the removal capacities in TP and ammonia, solving the zeolites problem for poor P removal and the application of powdered LDHs in CRIS. Herein, the zeolites/MgFe-LDHs were probably a kind of potential substrates to treat the organic, ammonia, and total phosphorus in CRIS.

References

APHA (2005) Standard methods for the examinations of water and wastewater, 21st edn. APHA and AWWA and WEF DC, Washington

Ayoub GM, Koopman B, Pandya N (2001) Iron and aluminum hydroxy (oxide) coated filter media for low-concentration phosphorus removal. Water Environ Res 73(4):478–485

Chandra S, Barick KC, Bahadur D (2011) Oxide and hybrid nano-structures for therapeutic applications. Adv Drug Delivery Rev 63(14/15):1267–1281

Cheng X, Huang XL et al (2009) Phosphate adsorption from sewage sludge filtrate using zinc-aluminum layered double hydroxides. J Hazard Mater 169(1/3):958–964

Choi SJ, Choy JH (2011) Layered double hydroxide nano-particles as target-specific delivery carriers, uptake mechanism and toxicity. Nanomed 6(5):803–814

Da Silva ES, Prevot V, Forano C et al (2014) Heterogeneous photocatalytic degradation of pesticides using decatungstate intercalated macroporous layered double hydroxides. Environ Sci Pollut Res 21:11218–11227

Das J, Patra BS, Baliarsingh N et al (2006) Adsorption of phosphate by layered double hydroxides in aqueous solutions. Appl Clay Sci 32(3/4):252–260

Drizo A, Frost CA, Grace J et al (1999) Physico-chemical screening of phosphate removing substrates for use in constructed wetland systems. Water Res 33(17):3595–3602

Fachini A, Vasconcelos MTSD (2006) Effects of zeolites on cultures of marine micro-algae: a brief review. Environ Sci Pollut Res Int 13(6):414–417

Filippidis A, Kantiranis N (2007) Experimental neutralization of lake and stream waters from N. Greece using domestic HEU-type rich natural zeolitic material. Desalination 213(1/3):47–55

Gisvold B, Odegaard H et al (2000) Enhanced removal of ammonia by combined nitrification/adsorption in expanded clay aggregate filters. Water Sci Technol 41(4/5):409–416

Goh KH, Lim TH et al (2008) Application of layered double hydroxides for removal of oxyanions: a review. Water Res 42(6/7):1343–1368

He JT, Zhong ZS, Tang MG et al (2002) Experimental research of constructed rapid infiltration wastewater treating system. China Environ Sci 22(3):239–243 (In Chinese)

He J, Wei M et al (2011) Preparation of layered double hydroxides. Struct Bond 119:89–119

Jiang X, Ma MC, Li J et al (2011) Analysis of microbial molecular ecology techniques in constructed rapid infiltration system. J Earth Sci 22(5):669–676

Li ZY, He TB, Yang XM et al (2004) Development of constructed rapid infiltration system and its application. China Water Wastewater 20(10):30–32 (In Chinese)

Lian YL, Xu MY, Zhong YM et al (2014) Ammonia oxidizers in a pilot-scale multilayer rapid infiltration system for domestic wastewater treatment. Plos One 9(12):1–18

Lin Y, Zeng ZK, Zhu JR et al (2015) Facile synthesis of ZnAl-layered double hydroxide microspheres with core-shell structure and their enhanced adsorption capability. Mater Lett 156:169–172

Milan Z, Sanchze E et al (2001) Influence of different natural zeolite concentrations on the anaerobic digestion of piggery waste. Bioresour Technol 80(1):37–43

Qiu XH, Sasaki KK, Osseo-Asare K et al (2015) Sorption of H3BO3/B(OH)4 − on calcined LDHs including different divalent metals. J Colloid Interface Sci 445:183–194

Rojas R (2012) Layered double hydroxides applications as sorbents for environmental remediation. In: Carillo AC, Griego DA (eds) Hydroxides, synthesis, types and applications. Nova Science Pub Inc, New York, pp 39–71

Russell SJ, Godwin AA, Moses OA et al (2015) A review of iron species for visible-light photocatalytic water purification. Environ Sci Pollut Res 22:7439–7449

Saltali K, Sari A (2007) Removal of ammonium ion from aqueous solution by natural Turkish zeolite for environmental quality. J Hazard Mater 141(1):258–263

Sarioglu M (2005) Removal of ammonium from municipal wastewater using natural Turkish (Dogantepe) zeolite. Sep Purif Technol 41:1–11

Sprynskyy M, Lebedynets M, Zbytniewski R et al (2005) Ammonium removal from aqueous solution by natural zeolite, Transcarpathian mordenite, kinetics, equilibrium and column tests. Sep Purif Technol 46:155–160

SPSS (2003) Analytical software, statistical package for the social science (SPSS) headquarters. SPSS, Chicago

Stefanakis AI, Tsihintzis VA (2012) Use of zeolite and bauxite as filter media treating the effluent of vertical flow constructed wetlands. Micropor Mesopor Mater 155:106–116

Stefanakis AI, Akratos CS et al (2009) Effluent quality improvement of two pilot-scales, Horizontal subsurface flow constructed wetlands using natural zeolite (clinoptilolite). Micropor Mesopor Mater 124(1/3):131–143

Wang H, Li XJ (2013) Removal of chemical nitrogen and phosphorus of micro-polluted water with modified zeolite subsurface wetland. Asian J Chem 25(15):8647–8649

Wang B, Zhang ZY, Li XM et al (2010) A full-scale treatment of freeway toll-gate domestic sewage using ecology filter integrated constructed rapid infiltration. Ecol Eng 36(6):827–831

Wu JL, Wang R, Xu D et al (2010) Long term performance of pilot-scale vertical flow constructed wetland using different substrates. China Environ Sci 30(5):633–638 (In Chinese)

Xu WL, Zhang JQ, Liu Y (2011) NH3-N degradation dynamics and calculation model of filtration bed height in constructed soil rapid infiltration. Chin Geogr Sci 21(6):637–645

Yalcuk A, Ugurlu A (2009) Comparison of horizontal and vertical constructed wetland systems for landfill leachate treatment. Bioresour Technol 100(9):2521–2526

Yan LG, Yang K, Shan RR et al (2015) Kinetic, isotherm and thermodynamic investigations of phosphate adsorption onto core-shell Fe3O4@LDHs composites with easy magnetic separation assistance. J Colloid Interface Sci 448:508–516

Zhang XL, Zhang S, He F et al (2007a) Differentiate performance of eight filter media in vertical flow constructed wetland: removal of organic matter, nitrogen and phosphorus. Fresenius Environ Bull 16(11):1468–1473

Zhang XL, Zhang S, He F et al (2007b) Effect of different filter media on the treatment performance of vertical flow constructed wetlands at high hydraulic loading. J Agro-Environ Sci 26(5):1905–1910 (in Chinese)

Zhang D, Gersberg RM, Keat TS (2009) Constructed wetlands in China. Ecol Eng 35(10):1367–1378

Zhang XL, Liu XT, Xu L et al (2013) Purification effect of vertical flow constructed wetlands using modified substrates coated by MgFe-LDHs. China Environ Sci 33(8):1407–1412 (In Chinese)

Zhang XL, Chen QZ, Guo L et al (2015a) Effects of varying particle sizes and different types of LDH-modified anthracite in simulated test columns for phosphorous removal. Int J Environ Res Public Health 12:6788–6800

Zhang XL, Guo L, Wang YF et al (2015b) Removal of oxygen demand and nitrogen using different particle-sizes of anthracite coated with nine kinds of LDHs for wastewater treatment. Sci Rep 5:15146

Zheng YX, Feng SY, Zhao XY (2008) Simulation study on constructed rapid infiltration for treatment of surface wastewater in town. Inter Fed Inf Process 259:851–858

Zhu WL, Cui LH, Ouyang Y et al (2011) Kinetic adsorption of ammonium nitrogen by substrate materials for constructed wetlands. Pedosphere 21(4):454–463

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 31270573, 31400435, 21476179).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Angeles Blanco

Rights and permissions

About this article

Cite this article

Guo, L., Zhang, X., Chen, Q. et al. Enhanced removal performance by the core-shell zeolites/MgFe-layered double hydroxides (LDHs) for municipal wastewater treatment. Environ Sci Pollut Res 23, 6749–6757 (2016). https://doi.org/10.1007/s11356-015-5910-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-5910-8