Abstract

This study conducted energy and economic analysis for biogas production from an Upflow Anaerobic Sludge Blanket (UASB) and activated sludge from the Copasa and Fânia® Wastewater Treatment Plants (WWTP), both of which are located in the city of Itajubá, Minas Gerais, Brazil. The methodology adopted for the research study included Physicochemical laboratory analyses of sludge samples. Furthermore, an experimental prototype of a sludge anaerobic digester (AD) that measured the characteristics of biogas and methane discharge was constructed and monitored. Lastly, economic viability analysis for using biogas energy was studied. The results show that the substrate, following processing using an AD, had reductions in all of the physiochemical parameters evaluated. Furthermore, CH4 yield in relation to volatile solids (VS) was 0.0046 Nm3CH4/kgSV (4.6 Nm3CH4/tSV), 32.89% VS for UASB sludge, 0.0019 Nm3CH4/kgSV (1.9 Nm3CH4/tSV), and 50.45% VS for activated sludge. UASB sludge samples had the best results, which were 1014.46 kWh/year of electrical energy generated at the Copasa WWTP. Economic feasibility analysis considered a project lifespan of 15 years for continuous power generation. The results showed a NPV of negative USD$-226,255.28, a LCOE of 1.40 USD/kWh, and an unfeasible Internal Rate of Return (IRR).

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

This study sought to analyze self-sufficient energy projects for Wastewater Treatment Systems by analyzing laboratory biogas production from sludge obtained in anaerobic processes (UASB) and from activated sludge. Both processes are based on Resolutions set forth by the Brazilian National Agency of Electric Energy and micro and mini electricity generation.

Introduction

One sustainable way of using waste generated daily in towns and cities includes new alternative technologies, which aid in processing solid waste (SW) with no pollution to the environment. Wastewater is rich in nutrients like nitrogen, phosphorus, potassium, calcium, and magnesium, which are essential for the development of certain cultures [1,2,3,4]. Furthermore, fertilizer and biogas can be generated using suitable treatment practices that generate effluent in launching patterns that are in accordance with current legislation, and water can also be reused for other purposes.

According to the World Bank [5], approximately one billion people lack access to clean drinking water, and nearly two billion people lack access to safe sanitation systems around the world. The Human Development Report [6] estimated that in 2025 more than three billion people will be living in countries with water problems, and this number will increase to over five billion by 2050.

Water is essential for a wide array of activities in developed societies. Many countries have tried to reduce water consumption to address this problem by using new alternative technologies, like sewage treatment.

Wastewater is often improperly disposed of in natural bodies of water, and pollutes waterways [7]. Wastewater Treatment Plants (WWTP) that have primary and secondary sedimentation processes are essential if this problem is to be abated. Most of the sewage sludge generated at WWTPs constitutes a significant fraction of the total organic matter and energy not recovered in the treatment process [2,3,4, 8].

Figure 1 shows the steps of two basic models (anaerobic and aerobic systems) for WWTPs as described by the Ministry of Labor and Employment (MLE) [9].

Fonseca [10] concluded that most sewage comes from domestic, industrial, agricultural, and hospital wastewater, and corresponds to 80% of the total volume of drinking water consumed. According to the Ministry of Labor and Employment (MTE) [9], infectious diarrhea and both hepatic and respiratory diseases are some of the diseases that can be spread in polluted water supplies. Examples of chronic diseases may include bronchial asthma and allergic alveolitis.

Figure 2 shows other types of sewerage sources, the levels of treatments used today, the main problems arising from bad sewage conditions, e.g. environmental (aesthetic and odors), social, or public health problems brought about by waterborne diseases. It also shows the water treatment costs. Additionally, sewage is divided according to whether it can be treated in a three-phase process. This is because solid fractions (sludge), liquid (water), gas (biogas) and the byproducts obtained from treatment must be separated. This is intended to minimize the pollutant load.

The term sludge has been used to designate solid WWTP byproducts [1]. The quantity and composition of sludge greatly varies depending on the origin of the sewage and treatment type applied to it. Sludge is composed mainly of organic materials (volatile solids, VS) and minerals (fixed solids, FS), in addition to water [11, 12]. Sludge is rich in organic matter (cellulose, hemicellulose, and lignin), is comparable to plant tissue, and is also a biomass [13, 14]. Sludge must be adequately treated using anaerobic digesters (AD) for example. Sludge must be treated not only to reduce pollution but also to produce renewable energy from waste in the form of biogas, electricity, and/or agricultural fertilizer [15,16,17].

Biogas is a clean and renewable source of energy that can be used as a substitute for other fuels in order to save energy in rural areas [18]. Biogas can also be used to reduce CO2 emissions and mitigate global warming [2,3,4, 19,20,21,22,23].

According to Aquino and Chernicharo [24], anaerobic digestion comprises complex metabolic processes, which take place in sequential steps and depend on the activity of at least three distinct groups of microorganisms: (i) fermentative (or acidogenic) bacteria, (ii) syntrophic (or acetogenic) bacteria; and (iii) methanogenic microorganisms. Table 1 show the main reactions during anaerobic digestion.

Table 2 shows the energy equivalence between various fuels and methane, which is determined using the lower calorific value (LCV) for each fuel.

Biogas is a mixture of gases resulting from biochemical reactions of the anaerobic decomposition of organic matter present in wastewater [25,26,27]. Biogas composition is: CH4 (50 to 80%), CO2 (20 to 40%), H2O (1 to 2%), O2 (0.1 to 1%), H2S (1 to 2%), N2 (0.5 to 2.5%) and CO (0 to 0.1%) [2, 4, 12, 13, 16, 25, 28,29,30,31].

Additionally, sludge after AD may be utilized in agricultural applications because it can improve the physical characteristics of soil and increase soil permeability, keeping water and nutrients in soils, allowing for higher concentrations of essential nutrients [32].

Fytili and Zabaniotou [15] conducted a review of methods used in Europe for sludge treatment, focusing on thermal processes (pyrolysis, gasification, and wet oxidation) and cement manufacturing (as fuel in the process).

In Brazil, 98 million inhabitants within urban populations had access to sewage networks in 2015. The volume of treated sewage increased from 3.764 billion m3 in 2014 to 3.805 billion m3 in 2015, corresponding to a 1.1% increase. Average water consumption in Brazil is 154.0 L per capita per day, a decrease of 4.9% when compared to 2014 [16]. However, Santos et al. [28, 33] stated that WWTP potential could reach a Power of 19.69 MW for anaerobic reactors, and 18.44 MW for activated sludge. These values may increase in the future because this study considered only existing WWTPs in Brazil. There were 897 WWTPs with UASB reactors for treatment, and 241 WWTPs with activated sludge treatment facilities in Brazil [34].

Law N°11,445/2007 [35] outlines the Brazilian national guidelines for basic sanitation. In Article 2, Paragraph XV, appropriate technologies are defined by considering user payment capacity, and by adopting both gradual and progressive solutions. Similarly, the National Agency of Petroleum, Natural Gas and Biofuels (ANP) established the rules for approving quality controls and specifying biomethane in landfills and sewage treatment plants in Resolution ANP N°685/2017 [36]. Article 5, Section IV, states that biomethane producers must analyze the siloxane and halogen content using laboratory analysis, and that this should be done monthly if the previous tests show levels between 0 and 75% of the limit value.

This study seeks to propose an energy sufficient domestic sewage treatment system (DSTS) in Brazil for improving environmental sustainability, using laboratory analyses of biogas production from activated sludge and sludge obtained from anaerobic processes (Upflow Anaerobic Sludge Blanket) at the Copasa and Fânia® wastewater treatment plants (WWTPs). Both plants are located in Itajubá, MG, Brazil. This study can serve as a starting point for developing future studies that also seek to use clean technologies to minimize environmental impacts.

Materials and Methods

Definition of Case-Study Site

Itajubá is located in the southern region of the state of Minas Gerais, Brazil. The study area is shown in Fig. 3, with details as to the location of the Copasa and Fânia® plants. The city is located 856 m above sea level, has an annual average temperature of 19.5 °C [38], and atmospheric pressure of 0.89 atm. According to a statistical forecast from the Brazilian Institute of Geography and Statistics [17], the city population was 97,000 inhabitants in 2017. The experiments conducted in this study were performed between August 15th 2016 and April 15th 2017 at the Solid Waste, Hydrogeology and Water Quality Laboratory (LABRES, in Portuguese). The Total Organic Carbon (TOC) analysis, was developed at the Laboratory of Studies in Environmental Quality Center (CEQUAM, in Portuguese). Both laboratories are located at the Federal University of Itajubá (UNIFEI, in Portuguese). The organic material and reductions in the organic matter content were analyzed, characterized, and quantified before and after anaerobic digestion.

Source Author via Google Maps® [37]

The study area and locations of the Copasa and Fânia® plants.

Excess-sludge from the Fânia® WWTP activated sludge system was collected shortly after it was generated in the secondary settler and disposed of in the drying bed. At the Copasa WWTP, sludge was collected from an excess-sludge outlet at the UASB before being placed in the drying bed. 50 L were collected from each sample, and these were stored in 50L polyethylene bags in a freezer at – 10 °C. The Sample bags were cleaned before sampling.

The analysis was performed according to the Standard Methods for Examining Water and Wastewater (APHA [39]), based on Ribeiro et al. [29] and Felca et al. [4]:

-

biochemical oxygen demand (BOD5), method 5210 B (incubator at 20°C for 5 days);

-

chemical oxygen demand (COD), 5220 D method (closed reflux digestion and spectrophotometric reading);

-

temperature, method 2559 B (mercury thermometer);

-

total solids (TS), method 2540 B (stove at 103–105 °C);

-

total fixed solids (TFS);

-

total volatile solids (TSV), method 2540 E (muffle at 550 °C);

-

pH, 4500-H+-B method (potentiometric);

-

total nitrogen (TN), method 4500-Norg-C (Kjeldahl method); and

-

total organic carbon (TOC), method 5310 B (high temperature combustion).

Heavy metal analysis was conducted using Scanning Electron Microscopy (SEM) equipment and scattered X-Ray Energy Spectra Spectroscopy (EDS) microanalysis, at the Structural Characterization Laboratory (LCE, in Portuguese), of the Federal University of Itajubá (UNIFEI).

Flowchart of Study

Figure 4 shows the methodology applied in this study.

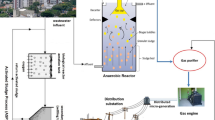

Four anaerobic digesters were assembled for each type of sample assessed. These were distributed in different experimental units (EUs) based on the study of Ribeiro et al. [29]. Anaerobic sludge experimental units were called LUASB1 LUASB2 LUASB3 LUASB4 because sludge came from an UASB WWTP. Aerobic sludge experimental units were called LA1, LA2, LA3, and LA4 since sludge came from an aerobic WWTP. The total volume of each mini-digester was 3.5 L with a useful substrate area of 2.63 L and an internal gasometer to store 0.875 L of biogas. Each apparatus operates as a batch reactor. An inlet cap is used to add substrate, and biodigesters were manually shaken to homogenize the substrate and stimulate microbial activity between two and three times a day. Figure 5 shows the dimensions of the biodigester (or experimental unit, EU), the substrate, the components, and the biogas generation.

Pressure and Volume Measurements

To calculate pressure and volume generated in the EU, a “U” pressure gauge was used, and results were corrected to standard temperature and pressure (STP) conditions. Digesters with samples were placed in a tank with water heated to 35°C using 75 W aquarium resistance and a thermostat equation for the hydraulic retention time (HRT), for 25 days for the AD. Table 3 shows STP and HRT equations used in this study.

Composition of Biogas (Equipment of GEM 5000)

A GEM 5000® (Series Number 501944) Gas Extraction Monitor®, produced by the LandTec® company was used to analyze the biogas composition, providing percentage volumes for methane (CH4) carbon dioxide (CO2), and oxygen gas (O2), in parts per million (ppm) for carbon monoxide (CO) and hydrogen sulfide (H2S). A gas outlet valve on the biodigester was closed and coupled to a gasometer purge/valve connected to the measuring analyzer port to take the measurements.

Available Biogas, Power, and Energy

It is possible to calculate the electrical energy that biogas can generate from the thermal energy, according to Chernicharo [41] and Lima and Passamani [11]. This can be verified in Table 4. According to CENBIO [21], Santos et al. [42], Lora and Venturini [43] and Barros [25], a 35% average engine efficiency value can be adopted (micro-turbine, gas turbine, or internal combustion engine, ICE) because the efficiencies are very similar one to another. Variation of the biogas lower calorific values (LCV) is given as function of methane concentration (CH4), according to Iannicelli ([44], apud Avellar [45]). The LCV of biogas is estimated between 465.43 and 11661.02 kcal/m3. Methane (CH4) generated in the anaerobic digestion is rapidly separated from the liquid phase due to its low water solubility, leaving the reactor in the gaseous phase. Carbon dioxide (CO2) is much more soluble in water, leaving the reactor partly in a gaseous phase and partly dissolved in the effluent [40]. According to Von Sperling [46], carbon dioxide can never serve as an energy source because its carbon is in the highest oxidation state possible. On the other hand, methane is the most reduced form of organic material, and there may be a subsequent combustion process for energy use. Table 4 presents equations for the thermal and electrical energy calculations.

As mentioned above, anaerobic digestion biogas is basically composed of methane, carbon dioxide, and other gases in smaller quantities. The LCV is calculated considering the volumetric percentage of the product gas components and the combustion enthalpy of these gases [47]. Since methane (CH4) is the energy constituent of biogas, the LCV of biogas is directly proportional to the amount of CH4 present in this biogas [30, 48, 49]. Therefore, values for the LCFV of biogas were obtained according to methane concentration (percentage) from the laboratory experiments carried out in this study (Eq. 23, [50]). Furthermore, engine operation was set to 16 h/day with a 0.60 ICE capacity factor [50].

Economic Feasibility

This study also evaluated the economic feasibility of producing electric energy by burning biogas derived from UASB sludge processed in ADs. It is necessary to estimate population projections in order to design UASB reactors and to assess their energy potential. We verified from a per capita sludge production index [30, 48] and from previously calculated biogas estimations that 5 kW of minimum available electrical power can be derived from biogas for use in ICEs from a population of 970 thousand inhabitants.

UASB reactors were sized by considering maximum wastewater discharge (Eq. 24) which, when multiplied by the hydraulic decanting time in reactors, results in the total reactor volume (Eq. 25). The area needed for the system can be calculated in Eq. 26.

where Qmax is the maximum discharge of wastewater sludge (m3/day); Q is the volume of sludge produced = 0.6 (L/hab day) [48]; P is the population of the city, adopting 970 thousand inhabitants; C is the Coefficient of population attended, equal to 95%; k1, k2 is the coefficients equal respectively to 1.2 and 1.5 (according to the Brazilian Association of Technical Standard—NBR 9649 [51]); Vtotal R is the total volume of the reactors; HRT is the hydraulic retention time, adopted as 8 h; and h is the height of the reactors calculated by the product between the HRT and the maximum speed in the reactor, 0.7 (m/h); and AR is the area of the reactors.

In the flowchart (Fig. 6) the steps taken in the generation of electrical energy may be observed in a simplified form.

Biogas generation in the anaerobic digester must be routed through a piping system to a gasometer. The gasometer accumulates and regulates the discharge of biogas generated while avoiding losses. It was not an exclusive hydrogen sulfide (H2S) removal system (desulphurizer) because this gas was not detected in the biogas measurements. Sequentially, the biogas entered into the compressor to ensure an adequate entry discharge in the moto-generator system. The biogas flowed through the compressor for economic calculations since generated energy is small. Therefore, the maximum possible quantity of gas is taken into the engine. We adopted an alternative gas generator for the internal combustion of biogas into electrical energy because of the 5–200 kW microgeneration power range [43]. These values matched the results obtained in our study. Next, a technical-economic model was drawn up using the equations in Table 5. Information on exchange rates from The Brazilian Central Bank [52, 53] was used in the calculations.

Economic viability calculations were performed for anaerobic and aerobic sludge samples taken from the UASB COPASA and Fânia WWTPs, respectively., The minimum number of people contributing to WWTPs was calculated in the case of activated sludge systems (aerobic sludge) and UASB (anaerobic sludge) to calculate the economic viability of generating power from sludge biogas at WWTPs. We also calculated the minimum tariff values for the project to be viable. 2.0 L/inhab year was considered for dense mixed aerobic sludge, and 0.50 L/inhab year for UASB discarded mixed anaerobic sludge, as recommended by Cassini [54].

Results and Discussion

Sludge Characterization

The results of physicochemical analysis of the affluence and effluence of AD experiment 1 (E1) and experiment 2 (E2) are presented in Tables 6 and 7, respectively. Also, the reduction of the organic load after HRT of AD are shown in both tables.

Measured values of the hydrogenionic potential (pH) in the substrate before and after the anaerobic digestion for E1 and E2 were in the range of 6.75 to 7.5. According to the study of Chernicharo [41], a pH range between 6.0 and 8.0 is favorable for the growth of methane-producing microorganisms.

In E1, the value of substrate effluence TOC before AD was 40.49 mg/L, and the carbon/nitrogen ratio (C/N) was 2.13. These values are acceptable compared to an ideal range of C:N 20–30 [25]. But, TOC analysis of E1 (effluence), and E2 (affluence and effluence) was not performed because the CEQUAM Laboratory was not available during the testing period. Thus, the carbon/nitrogen ratio (C/N) could not be measured due to the lack of substrate carbon content data.

TS concentrations for E1 and E2 effluence were smaller than DA affluence because microorganisms degraded an amount of organic matter in digestion. E1 resulted in a reduction of 52% and 95%, and in E2 resulted in a reduction of 85% and 79%, since the fraction corresponds to the organic part of solids present in the sample. In conclusion, the results obtained from substrate, after AD, showed a significant reduction of BOD organic load (or organic pollution).

Pressure, Volume, and HRT

Anaerobic sludge samples (LUASB) were deposited in EU LUASB1, LUASB2, LUASB3, and LUASB4 for E1 and E2. Activated sludge samples (LA) were placed in EU LA1, LA2, LA3, and LA4. Equations for normal STP conditions were applied for all EU results. The results of E1 and E2 are shown in Tables 8 and 9, respectively.

The experimental unit LA2 in E1, containing an aerobic sample had a greater hose displacement with higher volumes (9.14 × 10−4 m3) and pressure (Pa) 100138.75. This result was expected after analyzing the obtained values for VS, which were higher with respect to the anaerobic samples. Data from experimental unit LUASB2 were not considered since no pressure was detected and no displacement was observed on the “U” manometer. This likely occurred because of the air intake, possibly due to leakage, and as a consequence of lost biogas. It is possible to verify higher efficiencies of biogas generation for aerobic sludge. However, in the second experiment, the experimental unit LUASB4 containing an anaerobic sample, had higher volume (9.041 × 10−4 m3) and pressure (Pa) 100760.36. Although these values were only slightly smaller, they are representative of an experiment conducted at a laboratory-scale, with only 2.63 L of sludge. It is worth mentioning that that difference would be considerably greater on a larger scale.

The hydraulic retention time was obtained using 75 W aquarium resistance, and applying Eq. 2. Twenty-five (25) days were considered for both experiments, since the temperature used in both experiments was 35 °C. It is also important to remember that the HRT value must be greater in places with lower average annual temperatures, because the time is inversely proportional to the temperature. According to Jordão and Pessoa [55], any deviation of temperature or digestion may result in unsatisfactory performance.

Composition of Biogas

In E1, 12 readings (06 measurements for each type of sample) were taken, and in E2, 20 readings (10 measurements for each type of sample) were taken. These are presented in Table 10. A continuous analyzer was used in E1 for reading both substrates. All other measurements were taken using a GEM® 5000. CH4, CO2, O2, ppm of CO, and H2S, percentages were measured using a GEM 5000, in addition to pressure inside the gasometer and barometric pressure.

The most significant quantities of methane according to concentration (CH4) in E1 and E2 for UASB and in activated sludge were 24.1% (in 8.59 × 10−04 m3, Table 8), 27.6% (in 8.56 × 10−04 m3, Table 8), 75.0% (in 8.59 × 10−04 m3, Table 9), and 41.9% (in 8.56 × 10−04 m3, Table 9), respectively. Carbon dioxide (CO2) values were in the range of 0.2–38.6%, resulting in a 19.4% average CO2 value for total biogas generated (in 8.75 × 10−04 m3). In general, these results, are outside the scope established by Resolution N°685/2017 from the National Petroleum Agency [36], which sets maximum concentration specifications for biomethane at 10 mg/m3 H2S (maximum); 3% CO2 (maximum), 0.8% O2 (maximum); 90% CH4 (minimum); and 10% N2 + O2 + CO2 (maximum).

Figure 7 shows the biogas volume generated under STP conditions evaluated in test treatments with all L biogas values in concentrations of methane (CH4). Activated sludge in E1 had the highest volume of biogas, but a low methane (CH4) concentration (27.6%) or 8.56 × 10−04 m3 in this study., UASB sludge samples in E2 showed high concentrations (75.0%) of methane (CH4) or 8.59 × 10−04 m3.

Available Biogas, Power, and Energy Calculation

Laboratory Scale

After performing laboratory tests on the volume of gas generated at STP conditions, we measured biogas and electricity generation from the substrate (2.63 L of sludge). Tables 11 and 12 presented volume of biogas generated per day; volume (L) of methane generated per each liter of substrate (sludge) used, and volume of methane (in m3) per volume of substrate (in m3). This table also shows the methane yield (Nm3CH4) under other important parameters (kg of substrate, COD, BOD, TS, and VS). Sludge density was 1030 kg/m3 [56]. All values were used to perform WWTP scale projections (COPASA and Fânia® WWTPs) and to carry out economic feasibility studies.

Calculations were based on results of physicochemical parameters (variations) performed in both experiments. It was observed that E2 had the best results for both samples. The relationship of methane yield (Nm3CH4) with mass (in kg COD and kg BOD) was high in E1 activated sludge samples because it had small reductions in COD and BOD parameters, e.g., 21% and 59%, respectively. The relationship between methane production (Nm3CH4) and mass (in kg BOD) was also high in E2 for both samples (LUASB and LA), since the decrease in this parameter was negligible, e.g., 3% and 19%, respectively. UASB sludge samples had a methane yield of 0.0046 Nm3CH4/kgSV (4.6 Nm3CH4/tVS) with 32.89% of SV In E1, and activated sludge samples had yields of 0.0019 Nm3CH4/kgSV (1.9 Nm3CH4/tVS) with 50.45% of VS. In E2, UASB sludge samples had a high methane yield of 0.0384 Nm3CH4/kgVS (38.4 Nm3CH4/tVS) because they had little reduction in VS (with 7.46% of VS). With respect to the activated sludge samples in E2, this value was 0.0097 Nm3CH4/kgVS (9.7 Nm3CH4/tVS), with 17.57% of VS (Figs. 7, 8).

Energy Potential of Biogas Production at the Copasa and Fânia® WWTPs

Theoretical methane production calculations per gram or kilogram of COD were based on the Chernicharo [41] methodology, also presented by Lima and Passamani [11]. The following values were obtained using information provided from WWTPs and data obtained from a physical-chemical analysis of COD affluent and the effluent in this study, and by considering the regional weather conditions at Itajubá, MG:

-

UASB Sludge in E1 and E2:

In E1, the COD affluent (mg/L) was equal to 624.67 mg/L = 0.62467 kg/m3; COD effluence (mg/L) = 351.33 mg/L = 0.35133 kg/m3; and E2 a COD affluence (mg/L) = 679.67 mg/L equal to 0.67967 kg/m3; COD effluence (mg/L) = 407.33 mg/L = 0.40733 kg/m3. According to Tchobanoglous et al. [48], the volume of sludge produced by a treatment system using UASB reactors (treatment system at the COPASA WWTP) is 0.4 L/hab day. This treatment corresponds to 80% of a population, or 97,000 inhabitants, resulting in an average discharge of sewage sludge of 31.04 m3/day, generating biogas with methane concentrations from 24.1% in 8.59 × 10−04 m3 (E1) to 75.0% in 8.59 × 10−04 m3 (E2) of 0.000879 m3.

-

Activated sludge in E1 and E2:

In E1, the COD tributary affluence (mg/L) was equal to 85.67 mg/L = 0.08567 kg/m3, COD effluence (mg/L) = 68.0 mg/L = 0.068 kg/m3, and E2 had a COD affluence (mg/L) = 198.0 mg/L = 0.198 kg/m3, COD effluence (mg/L) = 48 mg/L = 0.048 kg/m3. According to Tchobanoglous et al. [30, 48], sludge volumes produced by conventional activated sludge with extended aeration (the treatments system at Fânia) is 5.05 L/hab day. Fânia has 250 employees, and an average sewage sludge discharge of 1.26 m3/day, generating biogas with a methane concentration of 27.6% in 8.56 × 10−04 m3 (E1) and 41.9% in 8.56 × 10−04 m3 (E2).

Tables 13 and 14 present values obtained in E1 and E2, respectively. The results are shown according to the methodology proposed by Chernicharo [41]. Theoretical electrical energy calculation tables are also given for treatment methods evaluated in this study.

UASB sludge treatment samples showed better results in both experiments because the average sewage sludge discharge at Copasa is higher than Fânia®. In E2 LUASB samples showed a considerable amount of electrical energy generated (1014.46 kWh/year), equivalent to 1.014 MWh/year. This could be generated by Copasa. Despite having high amounts of biogas in E1, LUASB samples generated lower amounts of electricity due to a low methane concentration (24.1% CH4). Greater biogas discharge is needed for higher energy generation given the low percentage of methane. In E2, the opposite happened for the LUASB samples, which had larger percentages of methane (75% CH4). This is shown in Table 11. In both activated sludge experiments electrical energy production was low at Fânia® because average sewage sludge discharge is lower than at Copasa.

Economic Feasibility

Activated Sludge (LA) Economic Feasibility

Fânia® generates small amounts of biogas. It cannot reach the minimum engine power (5 kW) requirements. Therefore, economic feasibility analysis was conducted for a comparison between biogas and Liquefied Petroleum Gas (LPG) with a 0.05 m3 LPG total volume. According to Barrera [57] and Pecora [27], 1 m3 of biogas has an energy value equivalent of 0.45 m3 of LPG. Fânia® can generate 0.15 m3 of biogas per day, the equivalent of 4.5 m3/month. Using data from the aforementioned authors, the quantity of the biogas generated monthly at Fânia® is equal to 2.025 m3 of LPG or 43 standard residential canisters. The price of a standard residential LPG canister in Brazil is 50.00 USD according to the Liquigás® Distributor. [31]. This would translate to a monthly savings of USD 2162.43 for Fânia®.

UASB Sludge (LUASB) Economic Viability

The economic feasibility of using AD for producing biogas to generate electricity from UASB biodigesters was also evaluated in this study.

Production of Biogas and Energy Calculations

The discharge of biogas and energy were calculated for a population of 970 thousand inhabitants, and 95% of the population had access to these treatment facilities. According to Lora and Venturini [43] 5 kW is the minimum power supply for engines. Table 15 shows the results of the electrical energy generated for this estimated population.

Electric power generated from biogas is equal to 5.39 kW for the proposed model when applying the Equations in Table 4. This is equivalent to 18870.84 kWh/ano (18.87 MWh/ano) of electric power. UASB reactors, compressors, gasometers, engines, and generators, along with their respective investment costs, e.g. piping, and O&M were all considered in the analysis. Distributed microgeneration was the system analyzed. This distribution system is outlined by the Brazilian National Electric Agency (ANEEL) in Normative Resolution nº 482/2012 [58] revised by Resolution nº 687/2015 [59]. Power installations with more than 75 kW and less than or equal to 5 MW are considered mico distribution units.

ANEEL [60] adopted rules to regulate Law nº. 12,111/2009 [61] and Decree no. 7246/10 [62] with respect to the costs of electrical energy produced in isolated systems (IS), and established procedures for calculating fuel consumption. According to these new resolutions, refunds for total expenses will be calculated by selling the energy produced in the IS. These costs include fuel, the power generation cost itself, and charges and taxes not taken by distributors. Before the changes only the cost of fuel was calculated for reimbursement.

All generated energy to be used in the WWTP processes was considered in this study. In so doing, we were able to avoid the fees and tariff costs from CEMIG [63] (a local electricity distributor).

Sizing the UASB Reactor

Table 16 shows the results of sizing the UASB reactors for AD sewage sludge digesters in order to calculate the energy balance and economic viability.

Mass and Energy Balances

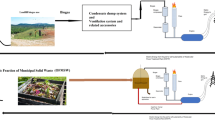

The main modeling results are shown in Fig. 9. Figure 10 shows the mass and energy balance, the conversion of (UASB) sludge organic matter into biogas and, subsequently, into electricity using a Sankey diagram.

Mass balance resulted in an average daily UASB sewage sludge discharge of 552.90 m3/day with a digested sludge discharge of 82.935 m3 per batch. This is equivalent to 15% of the initial discharge for processed sludge, which is 95% of the sewage collected from homes in Itajubá. Sewage sludge at entry was 624.67 mgCOD/L and 316.24 mgBOD/L with an output reduction of 44% and 84%, respectively. These values were suitable for medium-sized cities like those studied in Tchobanoglous et al. [30], Von Sperling [46], and Jordão and Pessoa [55]. Biogas production using the Chernicharo [41] model resulted in a biogas discharge of 58.41 Nm3/day, and 43.81 Nm3/day of methane with a concentration of 75% CH. Electrical power that could be produced in MTG would be 5.39 kW, generating 77.55 kWh/day, the equivalent of 28.31 MWh/year.

Investment Costs of the Main Equipment in the Biogas Line

Table 17 shows the acquisition costs of the equipment proposed in the biogas line for a population of 970 thousand inhabitants with a sewage sludge discharge of 552.9 m3. Cost data was obtained from CETESB [64], and equipment costs (USD/kW) were achieved from calculating installed power.

Table 18 shows the results of the initial investment, the O&M and labor costs, in addition to the technical and economic aspects for the population considered in this study.

Table 19 shows the results of the cash flow of the project considered in this study.

Figure 11 shows the results of the cash flow of the project considered in this study.

Table 20 shows results of NPV, LCOE, and IRR.

A 15-year scenario for a minimum commercial power motor-generator group (5 kW) resulted in a cash flow presented in Table 20 and Fig. 10. The net cash flow results in a—226,255.28 USD NPV, a 1.40 USD/kWh LCOE, and an unfeasible IRR. This was because the interest rate (i) for the NPV was greater than zero. There is no Minimum Acceptable Rate of Return (MARR) because the venture is not attractive at any interest rate. An investor would find any action impractical with a tariff rate at 0.156 USD/kWh, and an interest rate at 8%. Unit operation replacement would be needed in the 8th year. This cost was considered in the cash flow of Fig. 10 only to conclude that this project, according to the proposed conditions and model, is economically unfeasible due to the negative NPV result.

Economic Viability of Thermal Power Plant from Biogas Derived from WWTP Sludge

The minimum number of people contributing to a WWTP was calculated. This made it possible to study the economic viability of the thermal power plant using biogas derived from WWTP sludge (Fig. 12). Results as to the LCOE, e.g. the minimum tariff values for making the activated sludge system (aerobic sludge) and UASB (anaerobic sludge) systems economically viable, are presented in Fig. 13.

According to Fig. 12, NPV values are null, and then begin to go positive with 4,992,559 inhabitants (Power equal to 75.143 kW) and 1,248,109 inhabitants (P equal to 75.141 kW) respectively, for thermoelectric projects using biogas sludge from UASB sludge, and activated sludge systems. Figure 13 shows that the LCOE values are very large for both the UASB sludge and activated sludge projects. UASB sludge biogas values start at 2.82 US$/kWh and go to 0.1271 US$/kWh for 4,796,250 inhabitants. By contrast, these values start at 0.76 US$/kWh and go to 0.1271 US$/kWh with 1,198,900 inhabitants for biogas from activated sludge systems.

Conclusions

Physicochemical parameters in this study were within the permissible range mentioned in literature, and fit within current Brazilian legislation. They also showed significant reductions of pollution after the anaerobic process. For instance, the carbon/nitrogen ratio (C/N) was 2.13, and was acceptable when compared to the ideal range. Nevertheless, in both experiments E1 and E2, TS effluent concentrations were smaller than the affluence. This occurred because microorganisms degraded a considerable amount of the organic matter in the digester. There was a significant reduction of the organic load in the substrate (or organic pollution) after AD treatment for BOD. Of the 32 biogas measurements taken in this study, the highest concentration of methane (CH4) was in the UASB sludge samples (75% CH4 in 8.59 × 10−04 m3), and minimum and maximum values of carbon dioxide (CO2) were 0.2% in 8.56 × 10−04 m3 and 38.6% in 8.59 × 10−04 m3, respectively. Similar results for the methane yield compared to those in literature were obtained in Experiment 1 (E1), where the UASB sludge yield sample resulted in 0.0046 Nm3CH4/kgVS (4.6 Nm3CH4/tVS) with 32.89% of VS, and was 0.0019 Nm3CH4/kgVS (1.9 Nm3 CH4/tVS) with 50.45% of VS for activated sludge samples. UASB sludge samples had the best results.

E2 had a result of 1014.46 kWh/year for electrical energy generated at the WWTP, an equivalent of 1.014 MWh/year for Copasa. All the values were low in the activated sludge treatments for both experiments because Fânia® does not generate much sewage sludge.

It should be noted that for both samples (UASB and activated sludge), subsequent biogas electrical power (kW) resulted in smaller values. This means that it is not viable to generate electric energy at either WWTP studied. It is worth noting that there would be methane emission reductions that could help mitigate GHGs responsible for global warming. A project using a minimum motor-generator (5 kW) at a population of 970 thousand inhabitants would be economically unfeasible due to negative NPV and IRR values. In the case where NPV values are null and then go positive, electricity could be generated from sludge biogas with 1,248,109 inhabitants (power equal to 75.141 kW) for the activated sludge system. For biogas from UASB sludge, the population would be 4,992,559 inhabitants (Power equal to 75.143 kW). The power from UASB sludge DA should be considered in addition to the power generated using biogas from the sewage treatment process itself. The population contributing to the use of biogas from UASB sludge would be impractical for only one WWTP, due to the extension of the sewage collection network itself.

References

Andreoli, C., et al.: Sewage Sludge: Treatment and Final Disposal. Principle of Biological Treatment of Wastewater, vol. 6, 2nd edn. UFMG, Belo Horizonte (2014)

Bernal, A.P., Santos, I.F.S.D., Silva, A.M.S., Barros, R.M., Ribeiro, E.M.: Vinasse biogas for energy generation in Brazil: an assessment of economic feasibility, energy potential and avoided CO2 emissions. J. Clean. Prod. 151, 260–271 (2017). https://doi.org/10.1016/j.jclepro.2017.03.064

Center for Conservation Of Energy – CCE: Biogas Technical Guide. JE92, Algés (2000)

Felca, A.T.A., Barros, R.M., Tiago Filho, G.L., Santos, I.F.S., Ribeiro, E.M.: Analysis of energy potential of biogas generated by the anaerobic sludge: case study—South of Minas Gerais, Brazil. Sustain. Cities Soc. 4, 139–153 (2018). https://doi.org/10.1016/j.scs.2018.04.035

The World Bank: Sustaining water for all in a changing climate. http://siteresources.worldbank.org/NEWS/Resources/sustainingwater.pdf (2010). Accessed 5 Nov 2017

Human Development Report: Power, poverty and the global water crisis. http://hdr.undp.org/sites/default/files/reports/267/hdr06-complete.pdf (2006). Accessed 28 Mar 2017

Campello, R.: Performance of Upflow Anaerobic Sludge Blanket (UASB) operating under conditions of temperature typical of temperate regions. 94 f. Dissertation (Master’s Degree in Water Resources and Environmental Sanitation) – Federal University of Rio Grande do Sul (Universidade Federal do Rio Grande do Sul). Porto Alegre, Brazil (2009)

Zhang, G., Zhao, Q., Jiao, Y., Wang, K., Lee, D.J., Ren, N.: Efficient electricity generation from sewage sludge using biocathode microbial fuel cell. Water Res. 46(1), 43–52 (2012). https://doi.org/10.1016/j.watres.2011.10.036

Ministry of Labor and Employment—MLE: Manual of Procedures for Auditing in the Basic Sanitation Sector (Manual de Procedimentos para Auditoria no Setor Saneamento Básico), p. 31. Cap.2 (2002)

Fonseca, A.R.: Social and ecological technologies applied to the treatment of sewage in Brazil. Dissertation (Master in Science in the area of Public Health)—Department of Health and Environmental Sanitation, National School of Public Health, São Paulo. 2005. Cap.6. Rio de Janeiro. Brazil (2008)

Lima, A.C.G., Passamani, F.C.: Assessment of the energy potential of biogas produced in the UASB reactor of the WWTP-UFES. 106 f. Course Completion Work (Bachelor’s Degree in Environmental Engineering)—Department of Environmental Engineering, Federal University of Espírito Santo (Universidade Federal do Espírito Santo), Vitória, Espírito Santo (2012)

França Júnior, A.T.: Analysis of energy from biogas produced in sewage treatment station. Dissertation (Master in Mechanical Engineering)—Paulista State University “Júlio de Mesquita Filho”, São Paulo-SP, Brazil (2008)

Grosser, A., Neczaj, E., Singh, B.R., Almås, Å.R., Brattebø, H., Kacprzak, M.: Effect of anaerobic sewage sludge and grease trap sludge and municipal solid waste co-substrates. Environ. Res. 155, 249–260 (2017). https://doi.org/10.1016/j.envres.2017.02.007

Romdhana, M.H., Lecomte, D., Ladevie, B., Sablayrolles, C.: Monitoring of pathogenic microorganisms contamination during heat drying process of sewage sludge. Process Saf. Environ. Prot. 87(6), 377–386 (2009). https://doi.org/10.1016/j.psep.2009.08.003

Fytili, D., Zabaniotou, A.: Utilization of sewage sludge in EU application of old and new methods—a review. Renew. Sustain. Energy Rev. 12(1), 116–140 (2008). https://doi.org/10.1016/j.rser.2006.05.014

The Brazilian National Information System on Environmental Sanitation—NISS. Ministry of the Cities. Diagnosis of Water and Sewerage Services—2015 (2017). http://www.snis.gov.br/diagnostico-agua-e-esgotos/diagnostico-ae-2015. Accessed 28 Mar 2017

The Brazilian Institute of Geography and Statistics—IBGE: Directorate of Research, Coordination of Population and social indicators. Estimates of the resident population with reference date July 1st, 2017 (Estimativas da população residente com data de referência 1º de julho de 2017). http://www.cidades.ibge.gov.br/xtras/temas.php?codmun=313240&idtema=130&search=minas-gerais%7Citajuba%7Cpopulation-estimate-2015-&lang. Accessed 24 Mar 2017

Yu, L., Yaoqiu, K., Ningsheng, H., Zhifeng, W., Lianzhong, X.: Popularizing household-scale biogas digesters for rural sustainable energy development and greenhouse gas mitigation. Renew. Energy 33(9), 2027–2035 (2008). https://doi.org/10.1016/j.renene.2007.12.004

Figueiredo, N.J.V.: Use of landfill biogas for electric power generation and gas lighting—case study. Monography—School of Engineering. Universidade Mackenzie, São Paulo (2007)

Lima, F.P.: Energy in the Treatment of Sewage: Technological and Institutional Analysis for Energy Conservation and Biogas Use. Dissertation (Master in Energy—PIPGE). University of São Paulo (USP), São Paulo (2005)

National Reference Center on Biomass—CENBIO: Project Installation and Tests of a Demonstration Unit of Electricity Generation from Sewage Treatment Biogas (ENERG-BIOG). Final Technical report, p. 222. ENERG, São Paulo (2004)

Purwanto, H., Akiyama, T.: Hydrogen production from biogas using hot slag. Int. J. Hydrog. Energy 31(4), 491–495 (2006). https://doi.org/10.1016/j.ijhydene.2005.04.021

Souza, S.N.M.: Manual for generating electricity from biogas in rural areas. Dissertation (Master in Energy Engineering in Agriculture)—State University of Western Paraná—UNIOESTE CCET. http://portalpos.unioeste.br/media/File/vanderleia.schmidt/Manual_Geracao_Energia_Eletrica_Biogas.pdf (2016). Accessed 23 Apr 2017

Aquino, S.F.D., Chernicharo, C.A.L.: Build up of volatile fatty acids (vfa) in anaerobic reactors under stress conditions: causes and control strategies. Engenharia Sanitária e Ambiental 10(2), 152–161 (2005). https://doi.org/10.1590/S1413-41522005000200009

Barros, R.M.: The Treaty on Solid Waste: Management, Usage, and Sustainability, p. 376. Interciência; : Acta, Rio de Janeiro, Minas Gerais (2012). ISBN 978-85-7193-295-1

Neves, L.C.M., Converti, A., Penna, T.C.: Vessoni. Biogas production: new trends for alternative energy sources in rural and urban zones. Chem. React. Eng. 32, 1147–1153 (2009)

Pecora, V.: Implementation of a Demonstration Unit of Electricity Generation from Sewage Treatment Biogas Residential District of USP: Case Study. Dissertation (Master’s degree in Engineering of Energy)—Program of Inter-units of Post-graduation in Energy (PIPGE, in Portuguese), University of São Paulo, São Paulo (2006)

Santos, I.F.S., Vieira, N.D.B., Nóbrega, L.G.B., Barros, R.M., Tiago Filho, G.T.: Assessment of potential biogas production from multiple organic wastes in Brazil: impact on energy generation, use, and emissions abatement. Resour. Conserv. Recycl. 131, 54–63 (2018). https://doi.org/10.1016/j.resconrec.2017.12.012

Ribeiro, E.M., Barros, R.M., Tiago Filho, G.L., Santos, I.F.S., Sampaio, L.C., Santos, T.V., Silva, F.G.B., Silva, A.P.M., Freitas, J.V.R.: Power generation potential in posture aviaries in Brazil in the context of a circular economy. Sustain. Energy Technol. Assess. 18, 153–163 (2016). https://doi.org/10.1016/j.seta.2016.10.009

Tchobanoglous, G., Burton, F., Stensel, D.: Wastewater Engineering: Treatment and Reuse, 5th edn, p. 1819. Mcgraw-Hill, New York (2003)

Liquigás Distributor S.A.: Cylinders for residences. http://www.liquigas.com.br/wps/portal (2017). Accessed 5 Nov 2017

Ponsa, S., Pagans, E., Sanchez, A.: Composting of dewatered wastewater sludge with various ratios of pruning waste used as a bulking agent and monitored by respirometer. Biosys. Eng. 102(4), 433–443 (2009). https://doi.org/10.1016/j.biosystemseng.2009.01.002

Santos, I.F.S., Barros, R.M., Tiago Filho, G.T.: Electricity generation from biogas of anaerobic wastewater treatment plants in Brazil: an assessment of feasibility and potential. J. Clean. Prod. 126, 504–514 (2016). https://doi.org/10.1016/j.jclepro.2016.03.072

The Brazilian National Water Agency—ANA: Atlas Sewage, pollution of Watersheds 2017 (2017). http://atlasesgotos.ana.gov.br/. Accessed 14 Oct 2017

Brazil. Law No. 11,445 of January 5, 2007. Establishes national guidelines for basic sanitation; amends Laws Nos. 6,766, December 19, 1979, 8,036, May 11, 1990, 8,666, June 21, 1993, 8,987, February 13, 1995; repeals Law N°6,528 of May 11, 1978; and makes other arrangements. Official Journal of the Union, Jan. 08, 2007 and rectified in Jan. 11, 2007. http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2007/lei/l11445.htm. Accessed 24 Jan 2018

National Agency of Petroleum, Natural Gas and Biofuels – ANP. Resolution ANP N° 685 of 06/29/2017. It establishes the rules for the approval of quality control and the specification of biomethane from landfills and sewage treatment plants for vehicular use and residential, industrial and commercial facilities to be marketed throughout the national territory. Official Journal of the Union, Jan. 08, 2007 and rectified in Jan. 11, 2007. https://www.legisweb.com.br/legislacao/?id=345545. Accessed 24 Jan 2018

Google Maps. Minas Gerais—Brazil. https://www.google.com/maps/place/Minas+Gerais/@-18.6808123,-47.8305411,4z/data=!4m13!1m7!3m6!1s0xa690a165324289:0x112170c9379de7b3!2sMinas+Gerais!3b1!8m2!3d-18.512178!4d-44.5550308!3m4!1s0xa690a165324289:0x112170c9379de7b3!8m2!3d-18.512178!4d-44.5550308. Accessed 11 Jan 2020

Climate-date. ORG. Global climatic data. https://es.climate-data.org/. Accessed 15 2016

The American Public Health Association—APHA: Standard Methods for the Examination of Water and Wastewater, 22nd edn. APHA, WWA, WPCR, New York (2012)

Unidad de Planeación Minero Energética—UPME: Formulation of a Basic Program for Applications of Standardization of Alternative Energies and Dissemination: Guide for the Implementation of Systems of Production of Biogas Plants. Document ANC-0603-19-01, p. 47, UPME, Bogota D.C. (2003)

Chernicharo, C.A.L.: Principles of Biological Treatment of Wastewater. Anaerobic Reactors, vol. 5. Department of Sanitary and Environmental Engineering—UFMG, Belo Horizonte (2005)

Santos, A.H.M., et al.: Conservation of Energy: Efficiency of Installations and Equipment, p. 467. FUPAI, Itajubá (2001)

Lora, E.E.S., Venturini, O.J.: Biofuels, p. 1200, 1st edn. Interciência, Rio de Janeiro (2012). ISBN 9788571932289

Iannicelli, L.A.: Recycling Energy from Biogas from a Brewing Industry. 83 f. Dissertation (Master’s Degree in Mechanical Engineering)—University of Taubaté (Universidade de Taubaté), Taubaté, (2008)

Avellar, L.H.N.: The Valorization of the Agroindustrial Byproducts Aiming to Cogeneration and Reduction of Environmental Pollution. Doctoral Thesis, Faculty of Engineering, UNESP (2001)

Von Sperling, M.: Principles of Biological Treatment of Wastewater: Introduction to the Quality of Water and Sewage Treatment, 3rd edn. Department of Sanitary and Environmental Engineering, Editora UFMG, Belo Horizonte (2005)

Figueiredo, F.A.B.: Cashew Nut Shell Pyrolysis and Gasification: Evaluation of Gas, Liquid and Solid Production. 96f. (Master’s Degree in Mechanical Engineering). Campinas State University (Universidade Estadual de campinas), Campinas (2009)

Tchobanoglous, G., Burton, F., Stensel, D.: Wastewater Engineering: Treatment and Reuse, 4th edn, p. 1334. Metcalf & Eddy Inc., Mcgraw-Hill, New York (2002)

Brazil. National Secretariat of Environmental Sanitation. Probiogas. State of the art dry methanization (O estado da arte da tecnologia de metanização seca) / Probiogas technology; organizers, Ministry of Cities, Deutsche Gesellschaft für Internationale Zusammenarbeit GmbH (GIZ); author, Luis Felipe de Dornfeld Braga Colturato. - Brasília, DF: Ministry of Cities, 2015. 97 p. ISBN 978-85-7958-040-6

Okamura, L.A.: Assessment and improvement of the calorific power of biogas from municipal solid waste 109f. (Master’s Degree in Mechanical Engineering). Federal Technological University of Paraná. Program of Postgraduate in Environmental Science and Technology, Curitiba (2013)

The Brazilian Association of Technical Standards (Associação Brasileira de Normas Técnicas) ABNT: NBR 9649—Design of Sanitary Sewage Collecting Grids. ABNT, Rio de Janeiro (1986)

The Brazilian Central Bank: Calculator of the Citizen. https://www3.bcb.gov.br/CALCIDADAO/publico/exibirFormCorrecaoValores.do?method=exibirFormCorrecaoValores&aba=1 (2018a). Accessed 1 Feb 2018

The Brazilian Central Bank: Conversion of Currencies. http://www4.bcb.gov.br/pec/conversao/conversao.asp (2018b). Accessed 24 Jan 2018

Cassini, S.T.: Digestion of Organic Solid Waste and Biogas Utilization, p. 210. ABES, RIMA, Rio de Janeiro (2003). Il. PROSAB Project

Jordão, E.P.; Pessôa, C.A: Treatment of Domestic Sewage, 4th edn. ABES, Rio de Janeiro (2005)

Embrapa Environment: Physical and Chemical Attributes of Degraded Area Treated with Sewage Sludge. Technical Circular. Jaguariúna, São Paulo. November, 2011, ISSN 1516-4683. http://www.cnpma.embrapa.br/download/circular_21.pdf. Accessed 24 Mar 2017

Barrera, P.: Biodigesters: Energy, Fertility and Sanitation for the Countryside, 2nd edn., p. 106. Ícone, São Paulo (2003)

National Electricity Energy Agency—ANEEL: Normative Resolution nº 482, of april 17, 2012. Normative Resolution nº 482/2012—it establishes the general conditions for the access of microgeneration and distributed minigeration to the systems of distribution of electric energy, the system of compensation of electric energy, and gives other measures. http://www2.aneel.gov.br/cedoc/ren2012482.pdf. Accessed 16 Oct 2017

National Electricity Energy Agency—ANEEL: Normative Resolution nº 687, of november 24, 2015. Normative Resolution No. 687/2015—Alters Normative Resolution No. 482 of April 17, 2012, and Modules 1 and 3 of the Distribution Procedures - PRODIST. http://www2.aneel.gov.br/cedoc/ren2015687.pdf. Accessed 22 Oct 2017

National Electricity Energy Agency—ANEEL: Normative Resolution nº 801, of December 19, 2017. http://www2.aneel.gov.br/cedoc/ren2017801.pdf. Accessed 22 Oct 2018

Brazil. Law no. 12,111, of December 10, 2009. Provides for electricity services in Isolated Systems; amending Laws 9,991, of July 24, 2000, 9,074, of July 7, 1995, 9,427, of December 26, 1996, and 10,848, of March 15, 2004; repeals provisions of Laws 8,631 of March 4, 1993, 9,648 of May 27, 1998, and 10,833 of December 29, 2003; and makes other arrangements. Official Journal of the Union, Dec. 10, 2009. http://www.planalto.gov.br/ccivil_03/_Ato2007-2010/2009/Lei/L12111.htm. Accessed 22 Jan 2018

Brazil. Decree no. 7,246, of July 28, 2010. Regulates Law No. 12,111, of December 9, 2009, which provides for the transmission of international interconnections in the National Interconnected System (SIN) and makes other arrangements. Official Journal of the Union, Jul. 29, 2010. http://www.planalto.gov.br/ccivil_03/_Ato2007-2010/2010/Decreto/D7246.htm. Accessed 24 Jan 2018

The Energetic Company of Minas Gerais—CEMIG: Values of fees and sale of energy services (Valores das taxas e serviços de venda de energia). https://www.cemig.com.br/pt-br/atendimento/Paginas/valores_de_tarifa_e_servicos.aspx. Accessed 14 Oct 2017

The Environmental Company of São Paulo—CETESB: Biogas: Generation and Energy Use (Biogás Geração e uso Energético: Aterros), v. 1.0. The Brazilian Ministry of Science and Technology - The Environmental Sanitation Technology Company (Companhia de Tecnologia de Saneamento Ambiental). CETESB - São Paulo: MCT – SMA (2006a). http://www.cetesb.sp.gov.br/mudancasclimaticas/biogas/Softwares/16Softwares. Accessed 15 Sep 2017

Garcilasso, V.P.; Vescovo, E.: Generation of Electric Energy from Biogas from Sewage Treatment Using Gas Microturbine. Presentation held on the 4th Congress of Energy Cogeneration, São Paulo-SP, Brazil (2012). http://cenbio.iee.usp.br/download/documentos/apresentacoes/4ocongressocogeracao_workshop.pdf. Accessed 15 2017

Acknowledgements

The authors would like to thank the Brazilian National Council of Scientific and Technological Development (Conselho Nacional de Desenvolvimento Científico e Tecnológico, CNPq; the acronym in English), for the research Grant given to Prof. Regina Mambeli Barros (PQ2, Process Number: 303805/2018-8 and 301986/2015-0), and Prof. Electo Eduardo Silva Lora. We would also like to thank the Brazilian Coordination for the Improvement of Higher Education Personnel (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, Capes; the acronym in English) for granting the Master of Science scholarship to Susan J. B. Cañotes, Hellen Luisa de Castro e Silva, and the doctorate scholarship to Ivan Felipe da Silva dos Santos. We would like to thank the Minas Gerais State Agency for Research and Development (Fundação de Amparo à Pesquisa do Estado de Minas Gerais, FAPEMIG, in Portuguese) for granting financial support (Project PROCESS N.: TEC - APQ-03080-18 “Study of the potential of Greenhouse Gases mitigation prognostic in the state of Minas Gerais by the electric energy generation by biogas from anaerobic digestion of organic fraction of urban solid waste and wastewater treatment plant sludge”).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cañote, S.J.B., Barros, R.M., Lora, E.E.S. et al. Energy and Economic Evaluation of the Production of Biogas from Anaerobic and Aerobic Sludge in Brazil. Waste Biomass Valor 12, 947–969 (2021). https://doi.org/10.1007/s12649-020-01046-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01046-w