Abstract

This study aimed to carry out the Life Cycle Analysis (LCA) targeting to decide the better management system for sludge from both Activated Sludge Process (ASP) and from Upflow Anaerobic Sludge Blanket (UASB). Using the SimaPro® software, three post-use scenarios were applied to this process for each type of sludge: Scenario A, which consisted of the option of disposing of UASB sludge in a sanitary landfill; Scenario B, in anaerobic digestion (AD) with the generation of biogas and electricity and use of digested sludge; and Scenario C, the use of UASB sludge as an agricultural fertilizer. Besides, we carried out the analysis of heavy metals in the sludge before and after the AD using the Scanning Electron Microscopy. The elements found with a marked presence in the treatment of UASB and ASP sludge samples, before and after AD, were, among others: Oxygen, Carbon, Aluminum, Silicon, and Iron. The energy avoided for UASB sludge is 0.0502 MJ. For activated sludge, it is 0.00173 MJ. The use of activated sludge as an agricultural fertilizer (Scenario C) presented the best performance in eight of the eleven categories due to the presence of products avoided in the process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Many industries and companies currently have concentrated efforts and studies on activities that affect the environment, demonstrating that environmental analysis has become an important factor in identifying a project’s feasibility. Thus, it is necessary to emphasize the need to return to nature what belongs to it, with less contaminating potential.

This is the case of domestic sewage sludge, which is rich in nutrients that, through appropriate treatment, there is the possibility of obtaining biofertilizer, biogas, electricity, and treated wastewater, provided that it meets the discharge standards, according to the current legislation, being water that can be used for less noble purposes. However, every product has environmental impacts at all stages of its life cycle, from its production, through its use and maintenance, to its disposal or recycling/reuse.

When submitted to a treatment system, some components of wastewater are concentrated in variable proportions in the sludge. Several organic and mineral components give fertilizer characteristics to sludge [1]. However, other components are undesirable due to their environmental and sanitary risk, whose presence is variable, depending on the characteristics of the sewage (healthy population or not or even, presence of chemical contaminants from the sewage by receiving industrial wastewater) and the treatment system: heavy metals; various organic pollutants; and pathogenic microorganisms [1]. Pathogenic microorganisms have their own and variable survival capacity due to multiple conditions both in soil and water. Inadequate disposal of sludge containing contaminants, such as hazardous pollutants in a landfill, the treatment of toxic wastewater in soil or ponds, and leaks in networks and WWTPs are potential sources of surface water and groundwater contamination, as well as in soil. The adsorption and concentration of hazardous pollutants in sludge may also make it inconvenient for its use in agriculture [1].

Therefore, it is necessary to study all phases of its life cycle to minimize the negative environmental impacts of a product, making the necessary modifications. One tool that allows studies of this type to be carried out is Life Cycle Analysis (LCA) [2]. The general categories of environmental impacts that need to be considered include resource use, human health, and ecological consequences. The LCA methodology includes the definition of objective and scope, inventory analysis, impact assessment, and result interpretation. In general, this process involves associating inventory data with specific environmental impacts and understanding these impacts [3].

An LCA study was carried out by Zhu et al. [4] using SimaPro® 7.3 to evaluate the environmental impact of a lab-scale batch subcritical water decomposition (SCWD) operation for a mass (in kilogram) of Perfluorooctane sulfonic acid (PFOS) waste treatment. The authors used the IMPACT 2002+ environmental model to estimate the 15 midpoint and four endpoint environmental damages. Zhu et al. [4] studied the total negative impact of the SCWD process for 1 kg of PFOS waste treatment on human health, ecological quality, climate change, and resources. The upgrading of energy efficiency and catalytic effectiveness were concluded by Zhu et al. [4] as two critical factors to decrease the environmental impact from the SCWD process for the treatment of PFOS waste.

Usapein and Chavalparit [5] evaluated the environmental impact of alternative waste management practices for bio-sludge, including landfilling with landfill gas utilization systems, cement kilns, and composting, compared with conventional landfills. They carried out this study at midpoints and damage levels using the IMPACT 2002+ method. The results from Usapein and Chavalparit [5] shown that landfilling with landfill gas utilization systems presented the most significant potential for greenhouse gas (GHG) decreased compared with conventional landfills. The cement kiln option demonstrated the maximum potential for aquatic acidification, terrestrial acidification, and nitrification. According to these authors, the fertilizer option has shown the lowest potential for those impacts, and the potential for aquatic eutrophication and terrestrial ecotoxicity was highest in this option. As analyzed by Usapein and Chavalparit [5], the endpoint exhibited that the fertilizer option had a high performance concerning human health and climate change. The authors recommended it for selection as the priority for bio-sludge disposal in Thailand.

Padeyanda et al. [6] conducted a study using LCA to evaluate various recycling facilities of food waste Daejeon Metropolitan City (DMC) in Korea. Their results indicated that among the different recycling methodologies presently in practice, the scenario with wet and dry feed site conduced to higher global warming potential (GWP) and higher acidification potential (AP), while scenarios with wet feed site one and with wet feed site two resulted in the lowest impact. This fact was explained by Padeyanda et al. [6] as principally due to the emission produced during the treatment stage. For eutrophication potential (EP), scenario one with composting site contributed to higher environmental impacts due to the emission of ammonia produced during the treatment process. In contrast, in the case of photochemical ozone creation potential (POCP), all recycling facilities’ collection stage resulted in higher impacts on the environment because of fossil fuel combustion [6].

Yi and Jang [7] analyzed the flows of materials and energy regarding the environmental impact of solid refuse fuel (SRF) plants using LCA and compared them with an incineration plant. According to their results, SRF products presented numerous energy potentials depending on the treatment method of MSW and replaced the current fossil fuels by SRF combustion. Yi and Jang [7] preconized that global impacts were primarily influenced by energy consumption, particularly drying methods in the production of SRF, and affected the weighting analysis results. Besides, the authors concluded that the SRF plant with a bio-drying option was the best effective practice in the weighting analysis.

Yu and Li [8] conducted a hybrid LCA to compare all MSW incineration and individual anaerobic digestion of Restaurant Food Waste (RFW) and other MSW incineration concerning the actual situation. Their results showed that individual anaerobic digestion decreases 10.6% carbon emission than all MSW incineration. This could occur mainly due to the higher heat value of incineration feedstock and higher electricity yield. Also, RFW separation would decrease acidic gasses emission due to the substitution effect of more energy products. Overall, source sorting of RFW is a sustainable model of MSW management in Shenzhen, China. The result obtained by Yu and Li [8] provided quantitative support for the plan of RFW separation from MSW. Four MSW management systems were compared by Chi et al. [9] for in Hangzhou: the mixed collection system (50.77% of the MSW is landfilled and 49.23% incinerated); the scenario represented the current system under the source-separated collection; a new incineration plant (short-term); and food waste biological treatment techniques according to the city’s plan (long-term). These authors showed that a total of 30, 18, 28, and 29% of global warming, acidification, nutrient enrichment, and photochemical ozone formation could be saved after source separation, respectively. The short- and long-term MSW plans could offer a positive effect on environmental improvements [9].

The life cycle environmental impacts of four sludge management scenarios were studied by Cartes et al. [10], concentrating on the evaluation of current practices and advanced anaerobic digestion (AD) using a sequential pretreatment (PT). They used as LCIA method the IPCC (climate potential), CML (abiotic potential), Accumulated Exceedance (acidification potential and terrestrial eutrophication potential), and EUTREND model as implemented in ReCiPe (freshwater eutrophication potential and marine eutrophication potential) [10]. According to Alyaseri and Zhou [11], ReCiPe was an upgraded method from the Eco-indicator 99, and it reports the impacts on the environment or health in 17 categories. Results from Cartes et al. [10] showed that AD scenarios presented lower potential impacts than lime stabilization scenarios in all assessed categories, including abiotic depletion, acidification, climate change, and eutrophication in terrestrial, marine, and freshwater ecosystems [10].

Alyaseri and Zhou [11] used a full-scale WWTP in Missouri, USA, for a case-study in which multiple hearth incineration is the existing process, whereas the authors proposed fluid bed incineration and AD as the alternatives. For this purpose, they used the ReCipe method; the study revealed that variation in LCA results of multiple hearth incineration is 63.4% for a single endpoint score of 57.9 mPt. Results from Alyaseri and Zhou [11] on the two alternative processes, it is 54.6% probable that the fluid bed incineration would have more environmental impact than AD. Garfí et al. [12] evaluated the environmental impact of three alternatives for wastewater treatment using an LCA comparing a conventional WWTP as ASS with two nature-based technologies (i.e., hybrid constructed wetland and high rate algal pond systems). The authors [12] carried out the LCA with the software SimaPro® 8, using the ReCiPe midpoint method. Garfí et al. [12] showed that nature-based solutions were the most environmentally friendly alternatives, while the conventional WWTP presented the worst results because of its high electricity and chemical consumption. Brockmann et al. [13] aimed to evaluate the environmental performances of the novel oxygenic photogranules (OPG) biomass system treatment system compared to an ASS system using LCA. The authors [13] used midsize WWTP. Environmental impacts were estimated by [13] in SimaPro® (version 9.0.0.35, PRé Consultants) utilizing the Ecoinvent database version 3.5 and the Environmental Footprint life cycle impact assessment method. Results from Brockmann et al. [13] showed that the authors identified electricity consumption associated to artificial lighting, the fate of the generated biomass (renewable energy and replacement of mineral fertilizer), and the nitrogen flow in the OPG system as primary contributors to the potential environmental impact of the OPG treatment system. Nonetheless, Brockmann et al. [13] preconized that a non-optimized OPG scenario’s environmental impact was usually lower than for an ASS reference system.

Singh et al. [14] studied the LCA and impact of a biogas plant based on the municipal sewage sludge at WWTP (in Delawas, Jaipur–Rajasthan, India), evaluating the environmental effects originated as a result of basic systems of biogas production. They also studied the impact of biogas use as an alternative fuel employing ReCiPe and midpoint methods. Their results showed that the building of the plant was insignificant to the entire life cycle impacts. According to Singh et al. [14], biogas plant showed negative GHG emissions (− 0.2385 kg CO2eq/m3) related to coal-based electricity plants, and digestate produced could represent an attractive option to replace chemical fertilizer. Biogas production and agricultural spreading contributed − 3.059. 108 kg CFC-11 eq/m3 toward beneficial effects. It may be attributed to the avoidance of electricity and artificial fertilizers. Singh et al. [14] indicated that sewage sludge-based biogas plant showed a beneficial impact on the environment.

Resende et al. [15] estimated the environmental impact of two decentralized, small-scale wastewater treatment systems coupled to constructed wetlands. One system consisted of a vertical and a horizontal flow wetland, and the second one comprised a vertical subsurface flow wetland with artificial aeration. An LCA based on data from two actual pilot structures was carried out modeled in open LCA software, with the aid of Ecoinvent 3.3 data, and the impact assessment was based on the ReCIPe method [15]. Resende et al. [15] have shown that foreground emissions such as direct GHG released from the septic tank and nutrients released in the effluent have motivated potential impacts associated to Photochemical Oxidants, Climate Change, and Freshwater Eutrophication. Artificial aeration could decrease the area required to install the system, and electricity consumption was accountable for only 7% of total Climate Change related potential impact [15]. The analysis of the aerated wetland has revealed that the operation stage presented the most significant environmental impact potential for all analyzed impact categories, showing results fluctuating between 64% for Human Toxicity and 100% for Freshwater Eutrophication [15].

Lutterbeck et al. [16] studied a wastewater treatment system's performance on a Brazilian rural property by LCA. Their studied system consisted of an upflow anaerobic sludge blanket (UASB) combined with an anaerobic filter, four subsurface flow constructed wetlands, and two photoreactors. They used an EcoInvent unit from SimaPro® 7.3.3 and with the Recipe midpoint and endpoint level indicators. Their results, which were obtained by the analysis of the endpoint H inventory network, presented that 67.3% of the environmental impacts were related to the construction. In comparison, 32.7% were associated with the system's operation. The phototreament (45%) and anaerobic (36%) units were accountable for the highest environmental burdens of the construction phase [16].

Nonetheless, studies that comprise the WWTP sludge from among the possible resolutions for activated sludge system and UASB wastewater treatment in small- and medium-cities in developing-countries, as in Brazil, are still missing.

Therefore, this study aims to present the different environmental impacts generated from sludge management from the most common domestic sewage treatments in Brazil, such as UASB (anaerobic) and ASP (aerobic) sludge. For this purpose, the LCA was used, as these are processes that allow using biogas generated during its AD. LCA is a standardized procedure applied according to the ISO 14,040 series and consists of four stages: definition of objective and scope, life cycle inventory (LCI), life cycle impact assessment (LCIA), and life cycle interpretation [17, 18]. Three post-use scenarios were applied to this process for the 2 types of sludge (UASB and ASP), totaling a combination of 6 scenarios. In this way, the aim was to enable the proper management of sludge in types of WWTPs most used in Brazil, considering the demand for energy in the country. With this, the present work sought to assess its environmental feasibility within the scope of sustainable development and the circular economy’s assumptions. In this way, to make possible the proper management of sludge from WWTPs throughout Brazil, especially if the country’s demand for energy is considered. The present study aims to benefit the energy self-sufficiency of WWTPs in Brazil and improve environmental sustainability. For this purpose, LCA principles and laboratory analyses were used. This study tries to serve as a starting point for developing future research that prioritizes the use of clean technologies to minimize environmental impacts.

Materials and methods

Definition of the place of study and laboratory infrastructure

The municipality of Itajubá is in the southern region of the state of Minas Gerais, Brazil. Data from Cañote et al. [19] about the analysis of the substrate’s physical–chemical parameters before and after the AD of the studied sludge. Also, tests were carried out in the period between August 15, 2016, until April 15, 2017, in an Environmental Quality Study of Natural Resources Institute of Federal University of Itajubá (CEQUAM/IRN/UNIFEI) laboratory. The analysis of heavy metals was performed in the Scanning Electron Microscopy (SEM) equipment, using micro-analysis by Energy Dispersive X-Ray Spectrometer or EDS (Energy-Disperse X-Ray Spectroscopy), at LCE/IEM/UNIFEI.

Life cycle assessment (LCA) methodologies

SimaPro® software [20] was used to perform the LCA, using the CML 2000 method (midpoint) to characterize the impacts using inventories present in its database. This software was selected because several studies utilized it for similar studies as it was carried out by Zhu et al. [4], Garfí et al. [12], Brockmann et al. [13], Lutterbeck et al. [16], and Silva [26]. According to Rana et al. [21], the most usual and widely used software for LCA analysis of MSW is SimaPro® because this software, in general, treats the waste as a set of separate fractions and not as in entirety mass. This characteristic provides it an advantage over other usually utilized software [21]. However, the application of LCA software is often dependent on the need of the study. The LCA results depend on the following: data treatment; various databases; models and methods of impact assessment, which have been developed and implemented in specific software tools to subsidy in developing LCA studies [22]. Concerning the openLCA®, it was observed by Silva et al. [22] that some metadata were missing in the import process (for example, the administrative information and process information). Besides, the authors [22] verified that these missing metadata had to be manually handled in the software to preserve data consistent with the original data.

Concerning the system’s functional unit and flow, the Life Cycle Inventories (LCI) construction considered only the WWTP stage using the UASB and ASP sludge. Information on the collection and transportation stages of raw sewage, implementation, and decommissioning of the WWTP and equipment were not assessed. The product system to be analyzed consisted of receiving sludge (from UASB and ASP) from domestic sewage treatment, disposed of in a sanitary landfill. Also, two different mechanisms for the use of sludge are analyzed. The “gate-to-grave analysis” approach was adopted for the present study, as suggested by Todd and Curran [23], discarding the initial stages of sludge production, that is, obtaining raw domestic sewage. The period of analysis of this LCA covers a horizon of 15 years.

It is worth mentioning that the data regarding the production and yield of biogas and methane were obtained from Cañote et al. [19] for the Sanitation Company of Minas Gerais (Copasa) and Fânia WWTPs (Itajubá in the state of Minas Gerais, MG). Copasa WWTP serves 95% of 970,000 inhabitants, with a sewage sludge flow of 552.9 m3/day. It consists of an anaerobic reactor of the UASB type, with dimensions of 15. 15. 5,6 m. The laboratory analyzes by Cañote et al. [19], referring to sludge samples, allowed to estimate methane production and yield, as well as the content of other gasses in biogas.

Cañote et al. [19] studied emissions generated by sludge during AD, and these values obtained by the authors were used in the present LCA study. The other emissions, referring to biogas burner (flare), landfill, transportation, and agricultural fertilizer, were obtained through the survey of inventories presented in the consulted literature [24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40]. In the present study, analyses were carried out to know the class of heavy metals present in the sludge. This data is used in the data inventory phase. Cañote et al. [19] presents more detail about the sludge characteristics obtained from the UASB and the ASP systems.

In this work, it was established as the boundary of the system from the stage of discharge of UASB and activated sludge until its final disposal in a sanitary landfill or agricultural areas. The South of Minas region was adopted as the geographical boundary, specifically, Itajubá-MG, where biogas installations were planned, but they were not installed yet (Fig. 1). South of Minas region As a technological boundary, conventional technologies (internal combustion) for electricity generation from biogas and drying to prepare agricultural fertilizers were adopted.

The three scenarios proposed for LCA analysis are described below and are a combination of sludge management systems for both UASB and ASP through three different processes (scenarios A, B, and C). It results, therefore, in 6 different scenarios.

Scenarios for UASB and ASP sludge

In all combinations, both UASB and ASP sludge, scenarios A, B, and C consist of the same management practice.

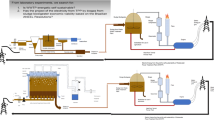

Scenario A

In Scenario A, the sludge is placed in the drying bed for 35 days. When it reaches a humidity of 60% (sludge cake), it is transported to a sanitary landfill. It must be considered that during this period, the water loss process occurs, which can be through evaporation or drainage to the soil (the bottom of the drying bed is constructed in a way that allows this flow, directing to pipes that return this fluid for the raw sewage treatment system), and the emission of gasses, such as methane, carbon dioxide, hydrogen sulfide (Fig. 2a).

Scenario B

In scenario B, the sludge is taken to an anaerobic batch digester with a hydraulic retention time (HRT) of 25 days. The biogas is stored in a gasometer and then sent to the motor-generator for electricity generation, using a compressor. The need for a flare to burn excess gas is emphasized. After the HRT period, the digested sludge to be used as an agricultural fertilizer is removed from the anaerobic digester and transported to the agricultural area for final disposal. Next, there is another batch of the anaerobic digester (Fig. 2b).

Scenario C

In Scenario C, the sludge is placed in the drying bed for 35 days to obtain agricultural fertilizer. The sludge must be transported to the agricultural area for final disposal (Fig. 2c).

Sludge management system

Figure 3a shows the UASB sludge management system’s boundary and Fig. 3b for the ASP sludge management system. The dashed line limits the system boundary.

The ISO 14,044 standard establishes that allocation should be avoided, whenever possible, and suggests, for this, the expansion of the product system, to include the additional functions related to co-products [3]. Thus, the allocation of co-products was carried out by allocating physical properties. The allocation criterion used in this study must represent the co-products’ dominant characteristics that give rise to a need to allocate environmental loads. In this study, the allocations made followed the following criteria: energy criterion, when products are energy inputs or derive from energy resources in the respective inventoried process unit and mass criterion, for the other cases [32]. The input data for SimaPro® for each scenario is explained as follows. However, a summary of such data can be consulted in the supplementary material tables (S.1 to S.22). There is a table (S.23) and a text explaining all environmental impacts assessed in this study in the supplementary material.

For the impact assessment, the CML (Chain Management by Life Cycle Assessment) method was adopted, due to its scientific rigor [11]. As the current Library, Ecoinvent 3—allocation, default—unit was adopted and as the Replacement Library, Ecoinvent 3—allocation, default—system, as it was performed by Alyaseri and Zhou [11] and Garfí et al. [12]. The authors also used the Ecoinvent database available in SimaPro® software to fill in data gap of air and water emissions from wastewater sludge treatment process [11].

Characterization of UASB sludge scenarios

For a question of LCA analysis, functional unit (FU) emissions calculations of 1 ton of total solids (TTS) of UASB sludge are considered. However, the utilization and energy balance in the biogas generation’s function were dimensioned for a population of 97,000 inhabitants.

Concerning Scenario A for UASB sludge, they were considered as net emissions, as described below:

-

From the Drying Bed: part of the water present both in the scenario with UASB sludge and in the ASP sludge is evaporated (water vapor emissions), and the part that is percolated is redirected to the reactors, not being considered as liquid emission.

-

From sanitary landfill: normally, the amount of leachate generated in sanitary landfills is calculated as a percentage of precipitation [33]. Barros [34] presents a review of the methods for quantifying leachate slurry in sanitary landfills. The Swiss Method was applied, as recommended by Barros [34] (Eq. 1).

$$Q=\frac{1}{{t}_{\mathrm{eq}}}\times P \times A \times K$$(1)

where: Q = average slurry or leachate flow (L/s); P = average annual precipitation (mm), being 1000 mm; A = surface area of the land (m2), being 125 m2; teq = time in seconds equivalent to 1 year (31,536,000 s/year); K = coefficient according to the degree of compaction of waste: 0.25 to 0.50 for poorly compacted landfills; and 0.15 to 0.25, for highly compacted landfills.

Table 1 shows the results of the slurry or leachate flow into the landfill that will receive UASB sludge from the drying bed (Scenario A) or the anaerobic digester (Scenario B).

Considering a period of 15 years, the values of 468.75 m3 and 281.25 m3 of slurry were obtained for weakly compact landfills and highly compacted landfills, respectively. However, for Scenario A, it was considered that the landfill that will receive the material will be the weakly compacted landfill. According to Barros [34], the slurry can be collected and sent to treatment ponds (for example, anaerobic or optional), or it can be recirculated in the landfill to encourage its use as a bioreactor to treat this liquid. The second option was adopted for scenario A.

For Scenario A for UASB and ASP sludges, they were considered as gaseous emissions, as follows:

-

From the Drying Bed: the production of gasses generated by the UASB sludge and the ASP sludge while remaining in the drying beds is shown in Table 2, considering 1000 kg of total sludge solids. The calculation was based on the tests performed by Silva [28], in which the sludge remains in the drying bed for a 35-day HRT period, and the methane production is 11 Nml CH4/gVS using an amount of 28.7 kg of sludge, generating a total of 3.35 kg of biogas emissions in the drying bed phase. Therefore, when working with 1000 kg of total sludge solids, a total of 116.72 kg of biogas emissions is generated. Besides the liquid and gaseous emissions, it was considered the output of the material referring to the occupation of a drying bed area, equal to 200 m2 (Cited in SimaPro® as Land use I-II, LLS).

-

From the Sanitary Landfill—Transportation: the gaseous emissions from the landfill start after the drying bed since the sludge must be transported to the landfill, where it is spread and compacted, using medium-sized machines, which use diesel. According to Silva [28], such machines release the following gasses: CO, NOx, and particulate material. Gutierrez [26] considered that the emissions generated in the landfill’s operation phase are due to spreading, compacting, and covering. The crawler tractor's fuel consumption factor was considered to be 1.82 l/km [29]. The distance between COPASA WWTP (UASB sludge) and CIMASAS landfill is 20.8 km (round trip). Considering the total traveled for spreading, compacting, and covering tasks as being 0.7 km (equivalent to 1.274 L of diesel), there is a total distance of 21.5 km. In this case, 39.13 L of diesel is needed (considering the diesel density equal to 840 kg/m3, the value of 1.07016 kg of diesel is obtained, as used in Simapro®), equivalent to 32.87 kg diesel or 420.79 kWh. The National Inventory of Atmospheric Emissions by Automotive Road Vehicles 2013: Base Year 2012 [27] was considered, with the emission factors of grams of pollutants per mileage of average vehicles (Cited in SimaPro® as Landfill Transport). Table 3 presents the summary of gaseous emissions generated by the truck used in the landfill filling process. Fugitive emissions are disregarded.

-

From the flare: after the closure of the landfill, there is a continuity in the biogas generation composed mainly of methane and carbon dioxide and in smaller proportions, by other gasses. Therefore, this equipment must be installed for burning biogas. Beylot [24] summarizes the emission factors from the combustion of biogas in flares, based mainly on data from USEPA. And from the gasses generated from biogas (CH4 + CO2 + CO) in the drying bed, the value of 3.35 kg of gasses is obtained and analyzed for 25 days. Considering that the analysis period is 15 years, it was multiplied by a time factor\(\left[\left(15 {\text{years}} \times 365\frac{{\text{days}}}{{\text{year}}}\right)/25 {\text{days}}\right]=219\). Thus, the total biogas equal to\(\left(3.35 \mathrm{kg} \times 219\right)=733.65 \mathrm{kg}\). Applying in the present study the methane yield factors obtained by Silva [13], that is, 0.0046 Nm3CH4/kgVS (4.6 Nm3CH4/tVS) for each ton of LLS (with 32.89% of VS for UASB sludge and 50.45% of VS for ASP sludge), the emissions generated by the mass flare of pollutants per volume of methane and the mass of pollutants for each ton of UASB bed sludge deposited in the landfill (Table 4).

As for solid emissions, both UASB and ASP sludge should be deposited in the landfill as a form of treatment/final disposal, generating leachate with the presence of solid materials. However, these are disregarded in this study.

In scenario B of AD, both for UASB sludge and ASP sludge, considering the generation of biogas and electric energy and the use of the digested sludge from AD, the net emissions from the landfill are the same as previously considered in scenario A. Slurry or leachate emissions were also disregarded since the leaked part is redirected to the reactors, not being assessed as net emission.

As for gaseous emissions, we mention:

-

From the Drying Bed (considered the same inventory as Scenario A).

-

From different stages: reactor emissions were referred to methane, in the form of direct emissions or leaks. Based on data from Silva [28], methane production from laboratory tests obtained a yield of 4.6 Nm3 CH4/ton VS (with 32.89% VS of UASB sludge and 50.45% VS of ASP sludge). Table 5 shows the gasses that make up the biogas generated for 25 days from UASB sludges using 2.68 kg of sludge, generating 0.548 kg of gasses, equivalent to 204.48 kg of biogas per ton of UASB sludge (Cited in SimaPro® as UASB Gross Sludge). This table also presents the values from activated sludge using 2.68 kg of sludge, generating 0.187 kg of gasses, equivalent to 69.67 kg of biogas per ton of ASP sludge.

However, the gaseous emissions involved in the combustion process come from the motor-generator’s combustion and the flare. Considering the small gas production, it was decided to use the typical combined cycle emission factors to use biogas (gaseous emissions from the reactor, motor-generator, and flare), presented by Beylot [24] as shown in Table 6. Applying the factors mentioned above for methane yield (4.6 Nm3 CH4/t VS) for each ton (1000 kg) of sludge (UASB with 32.89% VS and ASP with 50.45% VS), one obtains the emissions generated by the mass flare of pollutants per volume of methane and the mass of pollutants for each ton of UASB sludge used to generate electricity through a motor-generator (combustion). In LCA, this energy is considered as avoided electrical energy.

-

From the Drying Bed (considered the same inventory as Scenario A)

-

Both UASB and ASP sludge, digested and used as fertilizer: the sludge must be used entirely for agricultural fertilizer; then, they are only considered as solid emissions, and the elements obtained in heavy metal tests for sludge samples after AD.

-

From the Agricultural Area (Transport): it was considered that the emissions generated in the transport operation phase (total traveled) of the activated sludge digested from the drying bed to the agricultural area. According to Goedert et al. [30], the amount of equipment used to spread is calculated according to the time the equipment is used for the spreading operation and the mass/life ratio. Fuel consumption is assessed based on the time the tractor is in use, and the average fuel consumption per unit time. Knowing that the fuel consumption factor of the crawler tractor is 1.82 l/km [29] and that the chosen spreading area is located at a distance of 2 km from the storage area (drying bed) and the agricultural fertilizer is transported by a tractor and a spreader, requiring 3.64 L of diesel (considering the density of diesel equal to 840 kg/m3, we have the value of 3.0576 kg of diesel used in Simapro®), which are equivalent to 39.14 kWh. Transport requires a tractor and spreader (in this case) and fuel. The National Inventory of Atmospheric Emissions by Automotive Road Vehicles 2013: Base Year 2012 [27] was considered, with the emission factors of grams of pollutants by distance (in kilometers) of average vehicles (Cited in SimaPro® as Agricultural Area Transport).

Table 7 presents the summary of gaseous emissions generated by the truck used in the agricultural area’s fertilizer filling process. Fugitive emissions are disregarded.

As for solid emissions, UASB sludge, the same considerations were made in scenario B as for scenario A.

Concerning Scenario C for UASB sludge, they were considered as net emissions, as described below:

-

From the Drying Bed: in the drying bed, both the UASB and the ASP sludge, part of the water present in the sludge is evaporated (water vapor emissions), not being considered as liquid emission.

Regarding Scenario C for UASB and ASP sludge, they were considered as gaseous emissions, as described below:

-

From the Drying Bed: considered the same inventory as Scenario A.

-

From the Agricultural Area—Transport: considered the same inventory as Scenario B.

For Scenario C for UASB sludge, solid emissions were considered, as follows: UASB sludge should be used entirely for agricultural fertilizer. Therefore, only elements obtained from heavy metal tests for LUASB samples before AD are considered solid emissions. According to Goedert et al. [30], the mineral fertilizers avoided for this study, such as ammonium nitrate (33.5% N), potassium chloride (60% K2O), and triple superphosphate (45% of P2O5). The quantities of mineral fertilizers avoided are calculated based on the amount of available N, P, and K contained in the spread digested sludge. Thus, 27.55 kg N, 32.63 kg P, and 5.55 kg K were obtained. The generation of a total of 65.73 kg of fertilizer per ton of total solids was also obtained for both UASB and ASP sludge.

However, it was also considered the agricultural area (ha) that would be sFUficient to use 65.73 kg of fertilizer obtained in one ton of total UASB sludge solids, as well as for one ton of ASP sludge. According to the report made by FAO [25], consumption in different countries of fertilizer by type of nutrients per hectare of arable land is presented. In this study, the total generated for 2014 in Brazil (182 kg of fertilizers per hectare) was considered. The amount of fertilizer obtained in the process (65.73 kg NPK) could be used in an agricultural area of 0.361 ha.

Mass and energy balance

The mass balance resulted in an average daily flow of UASB sewage sludge of 552.90 m3 day−1, with the flow of digested sludge at 82.935 m3 per batch, 15% of the initial flow of the processed sludge, considering 95% efficiency of sewage collection in Itajubá. In the end, the sewage sludge at the entrance of the station had a concentration of 624.67 mgCOD/L and 316.24 mgBOD/L, with reductions in the output of 44% and 84%, respectively. Such values are consistent with medium-sized cities presented in the literature, such as Tchobanoglous et al. [35], Von Sperling [36], and Jordão and Pessôa [37]. The production of biogas, based on the Chernicharo [38] model, resulted in a flow of 58.41 Nm3/day of biogas and 43.81 Nm3/day of methane, with a concentration of 75% CH4. The electric power produced in the generator set was 5.39 kW, generating 77.55 kWh/day, equivalent to 28.31 MWh/year.

Results

Analysis of UASB and ASP sludge before and after AD

Figure 4a shows the three-dimensional appearance of the image of the samples with great depth. It provides a compositional map where the light part indicates a greater presence of aluminum (Al) and sodium (Na) in greater quantity. Figure 4b shows the SEM/EDS mapping area analyzed, in which the approximate height of the peaks provides the identification of the element. The UASB sludge samples obtained from COPASA WWTP showed similar results before and after AD, with the following most representative values: 39.15% Oxygen, 36.84% Carbon, 5.46% Aluminum, 4.60% Silicon, 3.45% Iron, and 3.17% Calcium.

Table 8 presents the results obtained in the analysis of heavy metals carried out on UASB sludge samples before AD (quantity of dry sample used is 0.0071 g), which are considered as solid emissions in the LCA study. This table also shows the values for after AD.

Figure 5a shows the greater presence of the element silicon (Si), aluminum (Al), and calcium (Ca) in greater quantity. Figure 5b shows the concentrations of the elements assessed. The ASP sludge samples obtained from FANIA WWTP showed similar results before and after AD, with the following values being more representative: 39.21% Oxygen, 38.98% Carbon, 4.54% Silicon, 3.93% Aluminum, 3.70% Calcium, and 3.09% Iron; the most representative values of the analysis.

Table 9 presents the results obtained in the analysis of heavy metals made in the samples of activated sludge before AD (quantity of dry sample used is 0.0071 g), which are considered as solid emissions in the LCA study. This table also shows the values for after AD.

The analysis of heavy metals was carried out to assess the possibility of using sludge before and after AD as an agricultural fertilizer (as a source of nutrients for plants). The results show that it can be considered as an environmental solution since, in the treatments assessed before and after AD, there is a small percentage of heavy metals mixed in the samples. The elements found with a marked presence in the treatment of UASB sludge samples and activated sludge, before and after AD, were as follows: Oxygen (O), Carbon (C), Aluminum (Al), Silicon (Si), Iron (Fe), Calcium (Ca), Sulfur (S), Phosphorus (P), Sodium (Na), Chlorine (Cl), Potassium (K), Magnesium (Mg), Titanium (Ti), Zinc (Zn), and Cadmium (Cd), assessed as a percentage (%). However, in the case of Titanium (Ti) found in the samples, it may be due to the improper release of paint residues along with domestic sewage.

LCA of UASB sludge

Table 10 presents a summary of the results obtained for the eleven categories made in the analysis of scenarios A, B, and C of UASB sludge samples.

The negative impacts on the environment refer almost to the totality of the categories assessed, to the option of disposing of UASB sludge in a sanitary landfill (Scenario A), then of using UASB sludge as agricultural fertilizer (Scenario C) and finally, the generation of biogas and electric energy using the digested UASB sludge (Scenario B). Scenario B for UASB sludge has a smaller share in these impacts since it was the one that most generated environmental benefits.

The positive impacts on the environment are mainly represented by scenario B. This is explained by the fact that scenario B presents products avoided due to the generation of biogas, electricity, and digested sludge (replacing agricultural fertilizer). These products have undergone several conversion treatments, generating a positive contribution to the environment.

Scenarios A and C are representative of a high percentage of Global Warming. This fact is because, in Scenario A, the sewage sludge would go directly to the landfill; it was not considered collection (storage) and energy use from landfill gas, and this would require a high cost of investment of labor, materials, and transportation. The latter is the system's fundamental problem because diesel would be used as fuel (which contributes negatively to the environment). It is emphasized that in the simulations, energy, biogas, and digested sludge (digestate obtained after anaerobic digestion) were considered as avoided products. Besides, digestate should be disposed of in the agricultural area, previously analyzing its heavy metal content. The drying UASB sludge in the bed presents a considerable fraction in the categories of GWP and Photochemical Oxidants Formation Potential (POFP). Besides, in the simulations, concerning the landfill input and output, its leachate quantification was performed. In this case, the participation in categories involving toxicity in water is elucidated, probably because it considers the generation of leachate in the process.

In Scenario C, which analyzed sewage sludge as an agricultural fertilizer, collecting the gasses generated in the process resulting from the soil and the associated crop is not considered. It is emphasized that 100% use of UASB digestate as an agricultural fertilizer was considered. Thus, assuming a smaller percentage, the impact graph could vary slightly toward positive impacts’ values. However, given the significant difference between the values of positive and negative impacts presented, it can be concluded that the positive impacts would continue to outperform the negative ones.

Sludge from UASB or ASP has a negative impact on the Categories of Global Warming Potential (GWP) and Photochemical Oxidant Formation Potential (POFP) when gasses are not captured, collect, and reused.

The sludge anaerobic digestion process makes Scenario B the most significant contributor to human toxicity, presenting results 1.8 times higher than Scenario A. Flare in Scenario B is the main responsible for the results in this category because it is responsible for burning biogas excess in the anaerobic digestion process. The gasses generated cause problems to human health when they are inhaled. The biodigester emissions have a more significant negative contribution to the Human Toxicity Potential impact and Eutrophication Potential in this Scenario.

According to Singh et al. [14], CH4 and CO2 leakage from the plant significantly reduced climate change and gave(net) negative output. Resende et al. [15] preconized that direct GHG emissions from the septic tank drove Climate Change and Photochemical Oxidants' Formation. However, energy recovery from the anaerobic unit could greatly minimize the environmental pressure indexes [16]. Figure 6a presents the comparative result between the eleven environmental categories (impacts) for each UASB sludge samples scenario, generated by the SimaPro® software, through the column chart. In Fig. 6b, it is possible to verify the contribution of each scenario in the impact categories analyzed in terms of area.

Scenario B was the one with the best performance in seven of the eleven categories due to the presence of products avoided in the process. Thus, the indicators considered to have the best performance for this scenario were related to the potential of: Abiotic Depletion (ADP), Abiotic Depletion Fossil Fuels (ADPF), Global Warming (GWP), Depletion of Ozone Layer (DOLP), Freshwater Ecotoxicity (FWEP), Terrestrial Ecotoxicity (TEP), and Eutrophication (EUP).

It is observed in Fig. 6b that the points of Scenario B are closer to the center of the figure, that is, on the negative part of the radar, presenting the best result, corroborating with the total results of each scenario in Table 10.

When analyzing Fig. 6a, it can be seen that in ten of the eleven categories analyzed, except for Global Warming Potential (GWP) and Marine Water Ecotoxicity Potential (MWEP), which had an impact with a minimum percentage, the largest participation in the impact comes from the sanitary landfill, which generates a negative contribution to the environment. The participation of the flare in the categories involving the Human Toxicity Potential (HTP), Fresh Water Ecotoxicity Potential (FWEP) (in a lower percentage), Marine Water Ecotoxicity Potential (MWEP), Acidification Potential (ACP), and Eutrophication Potential (EUP) stand out. The drying of UASB sludge in the bed presents a considerable fraction in the categories of Global Warming Potential (GWP) and Photochemical Oxidant Formation Potential (POFP). Concerning the inputs and outputs to the sanitary landfill, the quantification of leachate slurry in sanitary landfills was noteworthy in the software. In this case, participation in categories involving water toxicity is elucidated, probably because it considers the generation of leachate in the process.

When analyzing Fig. 6b, it can also be seen that in four of the eleven categories analyzed, except for the Acidification Potential (ACP), which had an impact with a minimum percentage, the greatest participation in the impact comes from the transport that takes place from the drying bed to the agricultural area, which generates a non-beneficial contribution to the environment. The participation of flare in the categories involving HTP, MWEP, and ACP stands out. In the use of the anaerobic digester, it appears that in all impact categories, except for GWP, MWEP, and EUP, the positive impacts outweigh the negative impacts since it contributes positively to the environment in seven of the eleven categories assessed. The raw UASB sludge has a negative impact on the GWP and POFP categories. In the software, energy, biogas, and digested sludge (sludge obtained after AD) were considered as avoided products, and the latter must be disposed of in the agricultural area, previously analyzing the heavy metal content that the sludge contains. Considering the energy avoided in the process is equal to 0.0502 MJ, the participation in categories involving ADPF (fossil fuels), GWP, HTP, ACP, and EUP is elucidated.

Still, when analyzing Fig. 6a, it can be seen that in eight of the eleven categories analyzed, the greatest participation in the impact comes from the transport that takes place from the drying bed to the agricultural area, which generates a non-beneficial contribution to the environment. The use of UASB sludge as an agricultural fertilizer presents a considerable fraction in the categories of GWP, POFP, and EUP. However, on the other hand, it contributes positively to the environment in eight of the eleven categories assessed. It should be noted that 100% of UASB sludge use as an agricultural fertilizer was considered. Thus, considering a smaller percentage, the impact graph could vary slightly in the values of positive impacts. However, given the great difference between the values of positive and negative impacts presented, it can be concluded that the positive impacts would continue to outweigh the negative ones.

However, it is observed that in the three scenarios A, B, and C, transportation (from the drying bed of Copasa WWTP to the agricultural area or the CIMASAS landfill in Itajubá—MG), in terms of fuel (Diesel), corresponds to a considerable fraction in the categories, contributing negatively to the environment.

LCA of ASP sludge

Table 11 presents a summary of the results obtained for the five categories chosen to analyze scenarios A, B, and C of ASP sludge samples.

The negative impacts on the environment refer almost to the totality of the categories assessed, to the option of disposal of activated sludge in landfill (Scenario A). Then, the generation of biogas and electric energy using digested sludge (Scenario B) and finally, the use of activated sludge as agricultural fertilizer (Scenario C) has smaller participation in these impacts since it was the one that most generated environmental benefits.

The positive impacts on the environment are mainly represented by scenario C. This is explained by the fact that scenario C presents avoided products such as digested sludge (agricultural fertilizer). Scenario B did not present itself as an environmentally feasible treatment due to the low amount of biogas and energy generated from the activated sludge.

Figure 7a shows the comparative result between the eleven environmental categories (impacts) for each scenario of ASP sludge samples, generated by the SimaPro® software, through the column chart presentation. Scenario C was the one with the best performance in eight of the eleven categories due to the presence of products avoided in the process. Thus, the indicators considered to have the best performance for this scenario are the potential of: ADP, ADPF, Depletion of the Ozone Layer (DOLP), HTP, FWEP, MWET, TEP, and ACP.

In Fig. 7b, it is possible to verify the contribution of each scenario in the impact categories analyzed in terms of area. It is observed that the points of Scenario C are closer to the center of the figure, that is, on the negative part of the radar, presenting the best result, corroborating with the total results of each scenario in Table 11.

When analyzing Fig. 6a, it can be seen that in ten of the eleven categories analyzed, except for GWP and MWEP that had an impact with a minimum percentage, the largest share in the impact comes from the sanitary landfill, which generates a negative contribution to the environment. The participation of flare in the categories involving HTP, FWEP (in a lower percentage), MWEP, ACP, and EP stands out. The drying of UASB sludge in the bed presents a considerable fraction in the categories of GWP and POFP. It is noteworthy that in the software concerning the inputs and outputs to the sanitary landfill, quantification of leachate slurry in sanitary landfills was performed. In this case, participation in categories involving water toxicity is elucidated, probably because it considers the generation of leachate in the process.

When analyzing Fig. 7a, it is observed that in seven of the eleven categories analyzed, except for ACP, which had an impact with a minimum percentage, the largest share in the impact comes from the transport that takes place from the drying bed to the agricultural area, which generates a non-beneficial contribution to the environment. The participation of flare in the categories involving HTP, FWEP (in a lower percentage), MWEP, and ACP stands out. When using the anaerobic digester, it appears that in all impact categories, except in HTP, MWEP, ACP, and EUP, the positive impacts outweigh the negative impacts since it contributes positively to the environment in six of the eleven categories assessed. The raw ASP sludge has a negative impact on the GWP and POFP categories. In the SimaPro® software, energy, biogas, and digested sludge (sludge obtained after AD) were considered as avoided products, and the latter must be disposed of in the agricultural area, previously analyzing the heavy metal content that the sludge contains. The energy avoided in the process is equal to 0.00173 MJ. In this case, participation in categories involving ADPF (Fossil fuels), GWP, HTP, ACP, and EUP is clarified.

Still, when analyzing Fig. 6a, it can be seen that in eight of the eleven categories analyzed, the greatest participation in the impact comes from the transport that takes place from the drying bed to the agricultural area, which generates a non-beneficial contribution to the environment. The use of ASP sludge as an agricultural fertilizer presents a considerable fraction in the categories of GWP, POFP, and EUP. However, on the other hand, it contributes positively to the environment in eight of the eleven categories assessed. It should be noted that 100% of ASP sludge use as an agricultural fertilizer was considered. Thus, considering a smaller percentage, the impact graph could vary slightly in the values of positive impacts. However, given the great difference between the values of positive and negative impacts presented, it can be concluded that the positive impacts would continue to outweigh the negative ones. However, according to Singh et al. [14] digestate handling stage contributed toward the freshwater eutrophication impact category in the function of emissions to the soil. On the other hand, in the case of marine ecotoxicity and freshwater ecotoxicity, the digestate handling state showed beneficial effects due to saving emissions toward the environment [14]. Brockmann et al. [13] related that optimizing digested biomass land application meaningly decreased the environmental impact in three categories: terrestrial eutrophication, acidification, and respiratory inorganics. The authors justified it because of the double effect of minimizing ammonia emissions from land application of digested biomass and growing the amount of replaced mineral fertilizers and associated emissions yields in a lower environmental footprint of the oxygenic photogranules biomass system for all impact categories studied.

However, knowing that in the three scenarios transportation (from the drying bed of Fania WWTP to the agricultural area or the CIMASAS landfill in Itajubá—MG), in terms of fuel (Diesel), corresponds to a considerable fraction in the categories, contributing negatively to the environment.

Garfí et al. [12] studied and compared the potential environmental impacts of activated sludge and constructed wetland systems, including the both the construction and operation phases. But, in that case, the authors considered the whole system process of WWTP. Therefore, due to the high electricity and chemical consumption for the conventional WWTP operation, the environmental impacts were higher in activated sludge than in constructed wetland systems. In our study, the boundary limits do not consider the environmental impacts of the UASB or ASP WWTPs, just the produced sludge. Some authors [12, 39] preconized that the construction impacts could meaningly rise if we transported materials for nature-based systems implementation from a long distance or if systems and equipment had a shorter operation lifetime than that projected. In all scenarios studied by Garfí et al. [12], sludge transportation and disposal impacted the categories of Freshwater Eutrophication and Marine Eutrophication Potentials that accounted for around 15–20% of the overall impact.

Conclusions

This study presented the various environmental impacts generated from sludge management from the most common domestic sewage treatments in Brazil, e.g., UASB and ASP sludge. We used LCA and considered the energy use of biogas generated during its AD. Three post-use scenarios were applied to this process for the two abovementioned types of sludge, totaling six scenarios. Data concerning the production and yield of biogas and methane were obtained from Cañote et al. [19] for Copasa and Fânia WWTPs, Itajubá, in Minas Gerais, Brazil.

We also carried out the analysis of heavy metals to analyze the possibility of using digested sewage sludge after AD as an agricultural fertilizer since the samples assessed comply with all legislation parameters in force in Brazil. The elements found with a significant presence in the treatment of UASB sludge samples and activated sludge, before and after AD, were as follows: Oxygen (O), Carbon (C), Aluminum (Al), Silicon (Si), Iron (Fe), Calcium (Ca), Sulfur (S), Phosphorus (P), Sodium (Na), Chlorine (Cl), Potassium (K), Magnesium (Mg), Titanium (Ti), Zinc (Zn), and Cadmium (Cd), assessed as a percentage (%) of normalized concentrations. The main conclusions are presented as follows:

-

When analyzing the energy data, it was found that for each ton of total solids (TTS) of sewage sludge (FU used in LCA) submitted to AD. The energy avoided for UASB sludge is 0.0502 MJ. For activated sludge, it is 0.00173 MJ. The categories analyzed by the LCA were: abiotic depletion potential—fossil fuels, global warming potential, human toxicity potential, acidification potential, eutrophication potential.

-

In the LCA analysis for UASB sludge samples, it is verified that the negative impacts on the environment refer almost in all of the categories assessed to the option of the disposal of the UASB sludge in landfill (Scenario A). Following the use of UASB sludge as an agricultural fertilizer (Scenario C) and finally, the generation of biogas and electric energy using the digested sludge (Scenario B) presented the best performance in seven of the eleven categories. Positive impacts on the environment were obtained.

-

In the LCA analysis for ASP sludge samples, it is verified that the negative impacts on the environment refer almost in all of the categories assessed to the option of the disposal of the activated sludge in landfill (Scenario A). The generation of biogas and electric energy using the digested sludge (Scenario B) and, finally, activated sludge as agricultural fertilizer (Scenario C). This last scenario presented the best performance in eight of the eleven categories due to the presence of products avoided in the process. Thus, the indicators considered to have the best performance for this scenario, the potential of ADP, ADPF, DOLP, HTP, FWEP, MWET, TEP, and ACP.

-

Therefore, one can conclude that in the three scenarios transportation (from the drying bed of each WWTP to the agricultural area or the CIMASAS landfill in Itajubá—MG), in terms of fuel (Diesel), corresponds to a considerable fraction in the categories, contributing negatively to the environment.

-

The use of digested sludge as an agricultural fertilizer, since it improves the soil's properties by having a high content of organic matter, is beneficial in the biology and structure of the soil.

References

Silva SMCP, Fernandes F, Soccol VT, Morita DM (2014) Main contaminants of sludge (Principais Contaminantes do lodo). In: Andreoli CV, von Sperling M, Fernandes F (eds) Sewage sludge: treatment and final disposal (Lodo de esgotos: tratamento e disposição final), 2nd ed., Belo Horizonte: Ed. UFMG, p 444. ISBN: 978-85-423-0085-7

Ellen Macarthur Foundation (2015) Towards a circular economy: business rationale for an accelerated transition. p 20

Associação Brasileira De Normas Técnicas - ABNT (2001) NBR ISO 14040: Gestão ambiental—Avaliação do ciclo de vida—Princípios e estrutura. ABNT, Rio de Janeiro

Zhu J, Kang S, Xie Y et al (2013) Preliminary environmental impact assessment of PFOS waste treatment in a lab-scale batch subcritical water decomposition operation. J Mater Cycles Waste Manag 15:489–502. https://doi.org/10.1007/s10163-013-0162-5

Usapein P, Chavalparit O (2017) Life cycle assessment of bio-sludge for disposal with different alternative waste management scenarios: a case study of an olefin factory in Thailand. J Mater Cycles Waste Manag 19:545–559. https://doi.org/10.1007/s10163-015-0385-8

Padeyanda Y, Jang YC, Ko Y et al (2016) Evaluation of environmental impacts of food waste management by material flow analysis (MFA) and life cycle assessment (LCA). J Mater Cycles Waste Manag 18:493–508. https://doi.org/10.1007/s10163-016-0510-3

Yi S, Jang YC (2018) Life cycle assessment of solid refuse fuel production from MSW in Korea. J Mater Cycles Waste Manag 20:19–42. https://doi.org/10.1007/s10163-016-0541-9

Yu Q, Li H (2021) Life cycle environmental performance of two restaurant food waste management strategies at Shenzhen, China. J Mater Cycles Waste Manag. https://doi.org/10.1007/s10163-020-01157-5

Chi Y, Dong J, Tang Y et al (2015) Life cycle assessment of municipal solid waste source-separated collection and integrated waste management systems in Hangzhou, China. J Mater Cycles Waste Manag 17:695–706. https://doi.org/10.1007/s10163-014-0300-8

Cartes J, Neumann P, Hospido A et al (2018) Life cycle assessment of management alternatives for sludge from sewage treatment plants in Chile: does advanced anaerobic digestion improve environmental performance compared to current practices? J Mater Cycles Waste Manag 20:1530–1540. https://doi.org/10.1007/s10163-018-0714-9

Isam A, Jianpeng Z (2019) Handling uncertainties inherited in life cycle inventory and life cycle impact assessment method for improved life cycle assessment of wastewater sludge treatment. Heliyon 5(11):2793. https://doi.org/10.1016/j.heliyon.2019.e02793 (ISSN 2405-8440)

Marianna G, Laura F, Ivet F (2017) Life cycle assessment of wastewater treatment systems for small communities: activated sludge, constructed wetlands and high rate algal ponds. J Cleaner Prod 161:211–219. https://doi.org/10.1016/j.jclepro.2017.05.116

Brockmann D, Gérand Y, Park C, Milferstedt K, Hélias A, Hamelin J (2021) Wastewater treatment using oxygenic photogranule-based process has lower environmental impact than conventional activated sludge process. Biores Technol 319:124204. https://doi.org/10.1016/j.biortech.2020.124204 (ISSN 0960-8524)

Singh AD, Upadhyay A, Shrivastava S, Vivekanand V (2020) Life-cycle assessment of sewage sludge-based large-scale biogas plant. Bioresour Technol 309:123373. https://doi.org/10.1016/j.biortech.2020.123373 (ISSN 0960-8524)

Resende JD, Nolasco MA, Pacca SA (2019) Life cycle assessment and costing of wastewater treatment systems coupled to constructed wetlands. Resour Conserv Recycl 148:170–177. https://doi.org/10.1016/j.resconrec.2019.04.034 (ISSN 0921-3449)

Lutterbeck CA, Kist LT, Lopez DR, Zerwes FV, Machado ÊL (2017) Life cycle assessment of integrated wastewater treatment systems with constructed wetlands in rural areas. J Clean Prod 148:527–536. https://doi.org/10.1016/j.jclepro.2017.02.024

Standardization IOF (1997) Environmental management: life cycle assessment: principles and framework. ISO

Standardization IOF (2006) Environmental management: life cycle assessment; requirements and guidelines. ISO

Cañote SJB, Barros RM, Lora EES, Del Olmo OA, Dos Santos IFS, Piñas JAV, Ribeiro EM, De Freitas JVR, De Castro ESHL (2021) Energy and economic evaluation of the production of biogas from anaerobic and aerobic sludge in Brazil. Waste Biomass Valoriz 12:947–969. https://doi.org/10.1007/s12649-020-01046-w

PRé Sustainability BV (2014) LCA software for fact-based sustainability. https://simapro.com/. Acessed 31 Oct 2017

Rana R, Ganguly R, Gupta AK (2019) Life-cycle assessment of municipal solid-waste management strategies in Tricity region of India. J Mater Cycles Waste Manag 21:606–623. https://doi.org/10.1007/s10163-018-00822-0

Silva DAL, Nunes AO, Piekarski CM, VadS M, de Souza LSM, Rodrigues TO (2019) Why using different life cycle assessment software tools can generate different results for the same product system? A cause–effect analysis of the problem. Sustain Prod Consum 20:304–315. https://doi.org/10.1016/j.spc.2019.07.005

Todd JA, Curran MA (eds.) (1999) Streamlined life-cycle assessment: a final report from SETAC North America Streamlined LCA Workgroup. Pensacola, Florida: SETAC

Beylot A, Villeneuve J, Bellenfant G (2013) Life Cycle assessment of landfill biogas management: sensitivity to diffuse and combustion air emissions. Waste Manag 33(2):401–411. https://doi.org/10.1016/j.wasman.2012.08.017

Programa De Las Naciones Unidas Para El Desarrollo—PNUD (2011) Ministerio de Energia. Organización de las Naciones Unidas para la Alimentación y la Agricultura. FAO, Global Environment Facility—GEF, Manuel de Biogás. Santiago de Chile: FAO, p 120. ISBN 978-95-306892-0. http://www.fao.org/3/as400s/as400s.pdf. Accessed 31 Oct 2017

Gutierrez GK (2014) Analysis and management of environmental impacts in domestic sewage treatment through life cycle assessment (Análise e gerenciamento de impactos ambientais no tratamento de esgoto doméstico mediante avaliação de ciclo de vida). Thesis (Doctorate in Sanitation, Environment and Water Resources), Federal University of Minas Gerais, Minas Gerais, p 46

Brazil (2013) National inventory of atmospheric emissions from motor vehicles by road 2013, base-year 2012 (Inventário Nacional de Emissões Atmosféricas por Veículos Automotores Rodoviários 2013, ano base 2012). http://www.feam.br/images/stories/inventário/inventário_Ar/2014-0527%20inventrio%202013.pdf. Accessed 26 Oct 2017

Silva APM (2016) Theoretical-experimental evaluation of the sludge disposal of sewage treatment plants in sanitary landfills with power generation (Avaliação Teórica-Experimental da Disposição de Lodos de Estações de Tratamento de Esgoto em Aterros Sanitários com Geração de Energia). Thesis (Doctorate in n Mechanical Engineering)—Federal University of Itajubá, 2016

Rodrigues CRB, Zoldan MA, Leite MLG, Oliveira I (2008) Computer systems to support the product life cycle analysis (LCA) tool (Sistemas computacionais de apoio a ferramenta análise de ciclo de vida do produto, ACV). In: National Meeting On Production Engineering (Encontro Nacional De Engenharia De Produção), 28, Proceedings. Rio de Janeiro

Goedert WJ (2006) Advances and challenges in research, development and innovation in soil fertility and plant mineral nutrition (Avanços e desafios em pesquisa, desenvolvimento e inovação em fertilidade do solo e nutrição mineral de plantas). Braz J Soil Sci (Rev Bras de Ciência do Solo) 31:34–37

Associação Brasileira De Normas Técnicas—ABNT (2009) NBR ISO 14.044: Gestão ambiental: requisitos e orientações. Rio de Janeiro

Rocha MH (2009) Use of life cycle analysis to compare the environmental performance of four alternatives for vinasse treatment (Uso da Análise do Ciclo de Vida para Comparação do Desempenho Ambiental de Quatro Alternativas para Tratamento da Vinhaça). Dissertation (Master of Science in Energy Conversion)—Institute of Mechanical Engineering, Federal University of Itajubá, Brazil, p 234

Obersteiner G, Binner E, Mostbauer P, Salhofer S (2007) Landfill modelling in LCA—a contribution based on empirical data. Waste Manag 27(8):S58–S74. https://doi.org/10.1016/j.wasman.2007.02.018

Barros RM (2012) Tratado sobre resíduos sólidos: gestão, uso e sustentabilidade. Interciencia, Rio de Janeiro

Tchobanoglous G, Burton F, Stensel D (2003) Wastewater engineering: treatment and reuse, 4th edn. Metcalf & Eddy Inc. Mcgraw-Hill, New York, p 1819

Von Sperling M (2005) Princípios do Tratamento Biológico de Águas Residuárias: Introdução à qualidade das águas e ao tratamento de esgotos. Belo Horizonte, MG: Departamento de Engenharia Sanitária e Ambiental, Editora UFMG, 3a ed

Jordão EP, Pessôa CA (2005) Tratamento de Esgotos Domésticos. Rio de Janeiro 4a ed

Chernicharo CAL (1997) Princípios do Tratamento Biológico de Águas Residuárias. Reatores Anaeróbios. Belo Horizonte MG 5:246

Dixon A, Simon M, Burkitt T (2003) Assessing the environmental impact of two options for small-scale wastewater treatment: comparing a reedbed and an aerated biological filter using a life cycle approach. Ecol Eng 20(4):297–308. https://doi.org/10.1016/S0925-8574(03)00007-7

Remy C (2010) Life cycle assessment of conventional and source-separation systems for urban wastewater management. Dissertation (Doktor der Ingenieurwissenschaften), Fakultät III –Prozesswissenschaften – der Technischen Universität Berlin. Technischen Universität Berlin, Berlin

Acknowledgements

The authors would like to thank the Brazilian National Council of Scientific and Technological Development (Conselho Nacional de Desenvolvimento Científico e Tecnológico, CNPq; the acronym in English), for the productivity in research Grant given to Prof. Regina Mambeli Barros (PQ2, Process Number: 303805/2018-8), and to Prof. Electo Eduardo Silva Lora. We would also like to thank the Brazilian Coordination for the Improvement of Higher Education Personnel (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior, Capes; the acronym in English) for granting the Master of Science scholarship (Finance Code 1) to Susan J. B. Cañotes, Hellen Luisa de Castro e Silva, and the doctorate scholarship to Ivan Felipe da Silva dos Santos. We would like to thank the Minas Gerais State Agency for Research and Development (Fundação de Amparo à Pesquisa do Estado de Minas Gerais, FAPEMIG, in Portuguese) for granting financial support (Project PROCESS N.: TEC—APQ-03080-18 “Study of the potential of Greenhouse Gases mitigation prognostic in the state of Minas Gerais by the electric energy generation by biogas from anaerobic digestion of organic fraction of urban solid waste and wastewater treatment plant sludge”).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We have no conflict of interest to declare. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cañote, S.J.B., Barros, R.M., Lora, E.E.S. et al. Life cycle assessment of upflow anaerobic sludge blanket sludge management and activated sludge systems aiming energy use in the municipality of Itajubá, Minas Gerais, Brazil. J Mater Cycles Waste Manag 23, 1810–1830 (2021). https://doi.org/10.1007/s10163-021-01253-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-021-01253-0