Abstract

The demands placed on global agricultural production arising out of population and income has grown almost tripled. In order to meet the increasing demand, it is mandatory to elevate the production by avoiding the usage of chemical fertilizers that makes the soil barren, unfertile and pollutes the environment as well as harmful to the consumers, where the biofertilizers came in to play. Microalgae can be played a pivotal role in building and maintaining soil fertility, subsequently increasing the growth as well as yield of several agricultural crops. But the reports on production of black gram were found to be scanty and thus this study focuses on its possible role. Algal extracts of varying concentrations were used as foliar sprays treatment and growth parameters; number of root nodules, yield attributes and quality parameters were measured. The implication of green algae as biofertilizer not only increases the yield characters but also improvises the soil physico-chemical properties. In addition, there was a subsequent increase in number of root modules, pigment compositions and yield attributes. Thus, the microalgae benefit the consumers by increasing the proximate composition and a mineral constituent is an added advantage. The results clearly depicted that the treatment of Chlorella vulgaris resulted in the identification of economically feasible, ecofriendly foliar spray treatment for the augmenting the maximum yield in black grams.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Black gram is the third important pulse crop in India. It is an annual pulse crop and native to central Asia that is also extensively grown in West Indies, Japan and other tropics/subtropical countries [1]. Among the total pulse produced, black gram occupies a cultivated area of 3.25 million hectares with production of 1.45 million tones in India [2]. Black gram (Vigna mungo L. Hepper) has a high nutritive value, which contains about 26% of protein, and also rich in potassium, phosphorus and calcium with substantial amount of sodium besides having elevated vitamin A, B1 and B3. It possess medicinal properties like healing diabetes, nervous disorders, hair disorders, digestive system disorders and rheumatic afflictions. In India, pulse production is very low due to the several factors but most important factor is nutrient management. The nutrient requirement of crop is met by the chemical fertilizers. Nevertheless, addition of fertilizers alone cannot meet the requirements of productivity in modern farming. Similarly, nutrient supply through organic manures and biofertilizers can hardly fulfill the need of a crop. Therefore, an integration of organic and inorganic nutrient sources sustains the productivity and may improve the soil properties [3].

Among the members of Chlorophyta, Chlorella strains are considered as competent candidates, which promoted plant growth when used individually as in lettuce [4]. In last few decades, some researchers conducted studies on potential uses of green algae as biofertilizers [4, 5]. Dry biomasses of green algae contain high percentage of macronutrients, considerable amount of micronutrients and amino acids [6, 7].

Liquid biofertilizer is increasingly available in the market as one of the alternatives to chemical fertilizer and pesticide. Traditionally liquid biofertilizer produced from fermentation of effective microorganisms was recommended to be used within 3 months. Nowadays, the production of ready to use liquid biofertilizer from microalgal cell extract is readily available in the market as it comprises the requirements to preserve organisms and deliver them to the target regions to improve their biological activity [8].

The combined treatment of Chlorella vulgaris and Spirulina platensis as effective biofertilizer were evidenced in terms of improvement in plant growth, yield and seed quality in rice [9] and maize [10]. Though the microalgae were proven to benefit the growth of several agricultural products, limited studies were carried out on black gram. Hence, this work concentrates to study the effect of liquid biofertilizer on green microalgae Chlorella vulgaris on growth parameters and to determine the importance of liquid biofertilizer application in order to improve the yield attribute and seed quality and productivity and avoid environmental pollution.

Materials and Methods

Experimental Site

The experiment was conducted during May 2017 at experimental field of CAS in Marine Biology, Faculty of Marine Sciences, Annamalai University, Tamil Nadu, India. The soil samples from 0 to 30 cm depth were collected randomly from different plots, prior to biofertilizer application to determine the textural class and fertility status of the field soil.

Experimental Design

Soil was collected from farmer’s field which is located in Aalapakkam, Cuddalore. The collected soil was filled in 5 kg capacity soil pots. The pots were arranged in completely randomized design and treated with 10 different concentrations of C. vulgaris extract by foliar spray method with three replications. The seed of green gram (Vigna mungo L.) were procured from the Tamil Nadu Agricultural University, Coimbatore, Tamil Nadu, India. The seeds, after thorough cleaning and removal of broken seeds, foreign materials and immature seeds and stored in airtight plastic jars at 25 °C. Before sowing, seeds were washed in running tap water and about five seed were sown per pot. Watering was done regularly upto 15 days, after that, watering was done at regular intervals (5 days).

Preparation of Algal Extract

The concentrated slurry of the microalgae, Chlorella vulgaris (contains about 10% water) was washed with distilled water, re-concentrated by centrifugation, frozen and then remelted at the room temperature. The melted slurry was then centrifuged at 5000 rpm for 15 min, the resulting supernatant was used for foliar spray treatment.

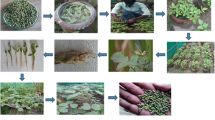

Application of Microalgae Extract as Liquid Fertilizer

The black gram was treated with foliar sprays treatment three times. The first spray was done at 10 days before blooming (first week or first month), then after berry sitting (first week of second month and) and the last one at 21 days later (the last week of the second month). One liter of algal cell extract solution was sprayed till run off.

-

1.

Control: Tap water

-

2.

0.5 ml Chlorella vulgaris cell extract in 100 ml tap water.

-

3.

1.0 ml (v/v) Chlorella vulgaris cell extract in 100 ml tap water.

-

4.

1.5 ml (v/v) Chlorella vulgaris cell extract in 100 ml tap water.

-

5.

2.0 ml (v/v) Chlorella vulgaris cell extract in 100 ml tap water.

-

6.

2.5 ml (v/v) Chlorella vulgaris cell extract in 100 ml tap water.

-

7.

3.0 ml (v/v) Chlorella vulgaris cell extract in 100 ml tap water.

-

8.

3.5 ml (v/v) Chlorella vulgaris cell extract in 100 ml tap water.

-

9.

4.0 ml (v/v) Chlorella vulgaris cell extract in 100 ml tap water.

-

10.

4.5 ml (v/v) Chlorella vulgaris cell extract in100 ml tap water.

-

11.

5.0 ml (v/v) Chlorella vulgaris cell extract in 100 ml tap water.

Sampling the Plant Material

Since it was not possible to study all the plants of experimental population at the successive stages of growth, hence only 5 plants in each plot were randomly selected and tagged properly for detailed studies such as growth parameters; number of root nodules, yield attributes and quality parameters were measured.

Growth Parameters

Plant height (in cm), shoot length (in cm), root length (in cm), fresh weight (in g) and dry weight (in g) were recorded in each treatment at 30 days and flowering stage with the help of centimeter scale and electronic balance.

Root Nodules Per Plant (Number)

The numbers of root were recorded in each plot at 30, 60 and 90 days. The plants were uprooted carefully and root nodules were separated after washing from the roots and counted the numbers.

Analysis of Physical and Chemical Properties of Soil

Before and after flowering stage experiment, the soil samples were taken from each treatment in major root zone (0–60 cm depth). Soil samples were analyzed by Government of Tamil Nadu Soil Analysis Centre Cuddalore district, Tamil Nadu, India.

Chlorophyll Content

Chlorophyll was estimated by the method of Holden [11]. 0.5 mg of black gram fresh leaf was ground in a mortar and pestle with 20 ml of 80% acetone. The homogenate was centrifuged at 3000 rpm for 15 min. The supernatant was stored. The pellet was resuspended with 5 ml of 80% acetone each time, until it become colourless. All the supernatant were pooled and utilized for chlorophyll determination. Absorbance was measured at 645 and 663 nm in Spectrophotometer. The chlorophyll content was determined by the following formula

Yield Attributes

The observations on yield attributes of black gram were recorded at the time of harvesting. The total numbers and weight of pods and seeds were counted.

Proximate Composition

The proximate components such as moisture [12], crude protein [13], crude lipid [14], ash content [12] were estimated. Total dietary fibre (TDF) was estimated by the non-enzymatic-gravimetric method [15]. The TDF was calculated by the following formulae

where, Wr is the mg residue, P is the % protein in the residue; A is the % ash in the residue, and Ws is the mg sample.

Mineral Analysis

The mineral analysis of the black gram seed was determined by Khalil and Mannan [16] Calcium and magnesium were determined by Atomic Absorption Spectrophotometer [17].

Statistical Analysis

The values reported are the means and standard deviations (Mean ± SD) of three replicates.

Results

Effect of Algal Cell Extract on Growth Parameters of Vigna mungo (L.) at 30th day

The growth parameters of black gram treated with C. vulgaris at different concentration treatment at 30 days were shown in Table 1. The growth parameters such as plant height (33.6 ± 0.90), shoot height (7.8 ± 0.88), root height (6.4 ± 0.83), fresh weight (29.2 ± 0.80) and dry weight (8.0 ± 0.88) were found to be higher in plants treated with Chlorella vulgaris at a concentration of 4.5 ml cell extracts in 100 ml tap water followed by 5, 4, 3.5, 3, 2.0, 2.5, 1.5, 1.0, 0.5 of cell extracts in 100 ml tap water and control plants.

Effect of Algal Cell Extract on Growth Parameters of Vigna mungo (L.) at Flowering Stage

The growth parameters of black gram at flowering stage with different treatments were shown in Table 2. The growth parameters were recorded with increased values in plants treated with Chlorella vulgaris. The maximum plant height (39.4 ± 0.88 cm), shoot length (11.9 ± 0.85 cm), root length (9.8 ± 0.55 cm), fresh weight (28.4 ± 0.80 cm) and dry weight (9.5 ± 0.65 cm) were recorded in plant treated with C.vulgaris cell extracts at a concentration of 4.5 ml cell extracts in 100 ml tap water followed by 5, 4, 3.5, 3, 2.0, 2.5, 1.5, 1.0, 0.5 of cell extracts in 100 ml tap water and control plants.

Number of Root Modules of Vigna mungo (L.) at Different Days

Table 3 shows the number of root nodules of black gram treated with C.vulgaris cell extract at different concentration. The number of rood nodules found to be higher in C. vulgaris treated plants (4.0 ml and 4.5 ml concentration). The maximum number of root nodules (37, 71, and 98/4.0 ml and 42, 75 and 85/4.5 ml cell extracts in 100 ml tap water) were recorded in black gram at 30,60 and 90 days followed by 5, 4, 3.5, 3, 2.0, 2.5, 1.5, 1.0, 0.5 of cell extracts in 100 ml tap water and control plants.

Soil Analysis

Before and after flowering stage of the experiment, composite soil samples were analyzed and results of various physico chemical properties of soil were presented in Table 4. The higher amounts of physical and chemical properties were recorded in treatment with 4.5 ml cell extracts in 100 ml tap water concentration C.vulgaris extracts.

Lead Pigments in Vigna mungo (L.) at Flowering Stage

The pigments composition of black gram leaves at flowering stage were presented in Table 5. The pigments such as chlorophyll ‘a’ and chlorophyll ‘b’ content were recorded. The maximum chlorophyll a content (1.39 ± 0.95 mg/g) and chlorophyll b content (1.37 ± 0.90 mg/g) were observed in Chlorella vulgaris at 5.0 ml cell extracts in 100 ml tap water concentration treatments followed by 4.5, 4, 3.5, 3.0, 2.0, 2.5, 1.5, 1.0, 0.5 cell extracts in 100 ml tap water and control plants.

Yield Attributes of Vigna mungo (L.)

The yield attributes of black gram plants are given in Table 6. The seed yield characters include number of pods per plant, number of seeds (g) seeds per plants and weight of seed per plant (g), weight of seeds (g) were noted in superior values than that of C.vulgaris cell extract untreated plants control. The maximum number of values pot plant (55 in 4.5 ml and 52 in 5.0 ml) number of seeds per plants (206 in 4.5 ml and 201 in 5.0 ml) weight of pods per plant (23.8 ± 0.88 g in 4.5 ml treatment and 23.1 ± 0.65 g in 5.0 ml cell extracts in 100 ml tap water) weight of seeds per plant (27.2 ± 0.94 g in 5.0 ml and 24.6 ± 0.65 g in 4.5 ml cell extracts in 100 ml tap water) and weight of 100 such seeds (47.2 ± 0.15 g in 4.5 ml and 46.5 ± 0.18 g) were found in 4.5 ml and 5.0 ml cell extracts in 100 ml tap water followed by 4, 3.5, 3.0, 2.0, 2.5, 1.5, 1.0, 0.5 ml cell extracts in 100 ml tap water and control plants.

Proximate Composition of Vigna mungo (L) Seed Flour

The proximate composition of black gram seed flour treated with C.vulgaris cell extracts in different concentration were shown in Table 7. The proximate compositions were found to be higher in plant treated with 4.5 ml and 5.0 ml of C.vulgaris extracts. The maximum moisture content (8.76 ± 0.05 g/100 g and 8.84 ± 0.06 g/100 g), crude protein (25.62 ± 0.83 g/100 g and 25.96 ± 0.60 g/100 g), crude lipid (4.08 ± 0.16 g/100 g and 4.13 ± 0.09 g/100 g), total fibre (4.72 ± 0.09 g/100 g and 4.83 ± 0.09 g/100 g) and ash (3.39 ± 0.07 g/100 g and 3.45 ± 0.09/100 g) were found in 4.5 ml and 5.0 ml treatments. The moderate values were observed in 4 ml cell extracts in 100 ml tap water treatments followed by 3.5, 3.0, 2.0, 2.5, 1.5, 1.0, 0.5 ml cell extracts in 100 ml tap water and control plants.

Mineral Composition of Vigna mungo (L.) Seed Flour

The mineral composition of black gram seed flour with different concentration of C.vulgaris cell extract were shown in Table 8. The minerals composition viz sodium, potassium, calcium, magnesium and phosphorus were recorded in high amount with 4.5 ml and 5.0 ml treatments treated plants. The maximum values of sodium (2.99.52 ± 0.63 mg/100 g and 313.64 ± 0.68 mg/100 g), potassium (1679.48 ± 0.90 mg/100 g and 1688.22 ± 0.92 mg/100 g), calcium (443.7 ± 0.88 mg/100 g and 496.38 ± 0.90 mg/100 g), magnesium (292.11 ± 0.44 mg /100 g and 295.38 ± 0.63 mg /100 g) and phosphorus(4.81.26 ± 0.90 mg/100 g and 4.88.48 mg /100 g) were recorded in plants treated with 4.5 ml cell extracts in 100 ml tap water and 5.0 ml cell extracts in 100 mL tap water C.vulgaris cells extracts. Only calcium and magnesium content has slightly increased in 3.5 ml cell extracts in 100 mL tap water and 4.0 ml cell extracts in 100 mL tap water treatments.

Discussion

Application of C.vulgaris cell extract is an acceptable approach for obtaining high yield with good quality products that are safe for human consumption. The results showed that C.vulgaris cell extract at different concentration resulted in positive response to the studied parameters. The yield attribute characters recorded in this study including the proximate composition and minerals composition are in same line with those obtained by Mohamed.et al. [18].

It was evidenced from the present study that bio-fertilizer of C.vulgaris cell extract improved the growth of black gram. The effective performances on growth of black gram plant in terms of plant height, shoot length, root length, fresh weight and dry weight were enhanced by C.vulgaris cell extract as bio fertilizer. All these growth parameters have an effect on yield quantity and quality which also relies on culture practices and agriculture inputs as well. Plant height, shoot length, root length, fresh weight and dry weight were the significant growth parameters. In the field experiments, the growth parameters of black gram were registered with the application of C.vulgaris cell extracts in 30th days and flowering stage. Similar results were reported earlier by Singh et al. [19]. These results were also supported by Thakur and Panwar [20] who reported an increase in plant height by seed inoculation and fertilizer application. The microalgal treatment mixed with cow dung manure increased plant height growth, yield characters, biochemical and mineral components as well as the germinability of the seeds produced [10].

Nodulation is an important character of pulses crop which is directly proportional to the number of pods formation per plant and ultimately the productivity of black gram. All the different concentration treatments were found to differ significantly with varying concentrations of C.vulgaris cell extract with respect to formation of nodules per plant. Nodule number has significantly increased by treatments of either of the 4.5 ml and 5.0 ml treatments (42, 75, 85 plant− 1 and 38, 70, 80 plant− 1) with C.vulgaris cell extract amendment. Nodule biomass was also remarkably enhanced in treated plants. As a consequence of improved nodulation, a similar significant improvement in grain yield was also evidenced. Earlier, Dubey [21] obtained highest grain yield in soybean when host plant was inoculated with Bradyrhizobium in combination with N P K fertilizer. The inoculation with Bradyrhizobium increased 57% effective nodule, 77% dry mater production, 64% grain yield, and 40% hay yield over uninoculated control.

The physio-chemical properties of soil before and in flowering stage were presented in Table 4, where the plots treated with microalgae cell extract C. vulgaris at 4.0 ml and 4.5 ml concentration treatments showed higher available nutrients. It is obvious that application of microalgae extract favored the growth parameters in black gram which eventually get decomposed and mineralized and contribute for the available nutrient. Naseby et al. [22] reported that N mineralization was decreased when Pseudomonas strain were applied with organic manure.

The maximum values of chlorophyll ‘a’ and ‘b’ were observed in C.vulgaris cell extract in different concentration treatments. The pigments (Chlorophyll ‘a’ and ‘b’) were increased after flowering stage in the lettuce plant treated with C.vulgaris as biofertilizer and this report of Pervez et al., [23] was found to be similar to the present investigation.

Distinct positive effect of C.vulgaris cell extract was noticed on yield attributes characters viz. number of pods per plant (55), number of seeds per plant (206), weight of pods per plant (23.8 ± 0.88 g), weight of seeds per plant (24.6 ± 0.65 g) and weight of 100 seeds (47.2 ± 0.15 g) in 4.5 ml and 5.0 ml concentration treatments. The yield obtained after the seed inoculation with Rhizobium increased due to higher number of pods/plant, grains/pod, that are the major parameters in assessing the yield of black gram [24]. Shaheen and Rahmatullah [25] and Tariq et al. [26] also observed similar types of results in their findings with different treatment of phosphorus with Rhizobium. The proximate composition of black gram seeds in different concentration of C. vulgaris cell extract treatments showed maximum yield values after treatment. The major findings of the study were as follows: crude protein ranged from 20.2 to 29.3%, crude lipid 6.3–7.4%, total dietary fibre 8.7–10.5%, ash 3.3–5.5% and carbohydrates 49.9–61.2%. The energy level of the seed (1562–1597 kJ 100 g−1 DM) was comparable with commonly consumed Indian pulses. Mineral profiles, viz. sodium, potassium, calcium, magnesium, phosphorus, iron, copper, zinc and manganese ranged from 43.1 to 150.1, 778.1–1846.0, 393.4–717.7, 174.9–387.6, 98.4–592.1, 10.8–15.0, 0.9–2.2, 5.0–10.9, 3.9–4.3 mg 100(−1) seed flour, respectively [27,28,29,30,31].

The mineral composition of the investigated black gram seeds has maximum concentration of sodium, potassium, calcium, magnesium and phosphorus when compared with other legumes Phaseolus vulgaris, Vigna unguiculata, Pisum sativum and Lens culinaris [32]. Food legumes are a good source of minerals such as calcium, iron, copper, zinc, potassium and magnesium. According to Salunkhe et al. [33] the lentils had the highest ratio of cooked weight to dry weight, 2.94, and chickpeas had the lowest ratio, 2.07. Protein, fat, and ash values were generally in good agreement and moisture data were higher, and crude fiber values were much higher. In the present study, higher levels of minerals composition were observed.

Conclusion

Chlorella vulgaris cell extract of various concentration were used in the medium of foliar spray treatment method. The parameters like growth parameters, number of root nodules, yield attributes and quality analysis of seed were measured among which 4.5 and 5.0 ml concentrations provided with better results. C.vulgaris biofertilizer not only increases the yield characters but they also improve the soil physical and chemical parameters. They rejuvenate and cause no harm to the soil. Thus microalgae are eco-friendly and economically feasible bio-fertilizer meanwhile producing good quality seeds. Hence our results will be very useful to the farmers for a better livelihood in a sustainable way.

References

Mathur, N., Singh, J., Bohra, S., Bohra, A., & Vyas, A.: Changes in morpho-biochemical characteristics of moth bean in Indian thar desert-due to sulphur and iron nutrition. Eurasian J. Agric. Environ. Sci. 1(1), 51–57 (2006)

Anonymous.: (2011) Field Guide Mungbean and Urdbean, National Center for IPM, IARI New Delhi, Department of Agriculture and Co-operation (GoI), pp. 1–40

Gill, M.A., Naimat, A., Nayar, M.M.: Relative effect of phosphorus combined with potash and Rhizobium phaseoli on the yield of Vigna aureus. J. Agric. Res. 23, 279–282 (1987)

Faheed, F.A., Fattah, Z.A.: Effect of Chlorella vulgaris as bio-fertilizer on growth parameters and metabolic aspects of Lettuce plant. J. Agric. Soc. Sci. 4(1965), 165–169 (2008)

Vig, R., Dobos, A., Molnar, K., Nagy, J.: The efficiency of natural foliar fertilizers. Időjárás 116(1), 53–64 (2012)

Mahmoud, M.S.: Nutritional status and growth of maize plants as affected by green microalgae as soil additives. J. Biol. Sci. 1, 475–479 (2001)

El-Fouly, M.M., Abdalla, F.E., Shaaban, M.M.: Multipurpose large scale production of microalgae biomass in Egypt. Proc. 1st Egypt. Etalian Symp. Biotechnol. 21–23, 305–314 (1992)

Hedge, D.M.: Biofertilizers for cereal production in India—a review. Ind. J. Agri. Sci. 69, 12–16 (1999)

Dineshkumar, R., Kumaravel, R., Gopalsamy, J., Sikder, M.N.A., Sampathkumar, P.: Microalgae as bio-fertilizers for rice growth and seed yield productivity. Waste Biomass Valor. 9, 793–800 (2017). https://doi.org/10.1007/s12649-017-9873-5

Dineshkumar, R., Subramanian, J., Gopalsamy, J., Jayasingam, P., Arumugam, A., Kannadasan, S., Sampathkumar, P.: The Impact of using microalgae as biofertilizer in maize (Zea mays L.). Waste Biomass Valor (2017). https://doi.org/10.1007/s12649-017-0123-7

Holden, M.: Chlorophylls. In: Goodwin, T.W. (ed.), Chemistry and Biochemistry of Plant Pigments, pp. 461–488. Academic Press, New York, (1965)

A.O.A.C.: Protein Quality Evaluation, pp. 1–66. Food and Agricultural Organization of the United Nations, A.O.A.C., Rome (1991)

Lowry, O.H., Rorebrough, N.J., Farr, A.L., Randall, R.J.: Protein measurement with folin phenol reagent. J. Biol. Chem. 193, 265–275 (1951)

Folch, J., Lees, M., Sloane Stanley, G.H.: A simple method for the isolation and purification of total lipids from animal tissues. J. Biol. Chem. 226, 497–509 (1957)

Li, B.W., Cardozo., M.S.: Determination of total dietary fiber in foods and products with little or no starch, nonenzymatic-gravimetric method: collaborative study. J. AOAC Int. 77(3), 687–689 (1994)

Khalil, I.A., Mannan, F.: Colorimetry and Flame photometry. In: Khalil, I.A., Mannan, F. (eds.) Chemistry One (Bioanalytical chemistry), 2nd edn, pp. 131–157. Taj Printing Press, Peshawar (1990)

A.O.A.C.: Official Methods of Analysis, 15th edn, pp. 425–437. A.O.A.C., Washington (2005)

Mohamed, H.A., Gomaa, A.M.: Faba bean growth and green yield and it is quality as influenced by the application of bioorganic farming system. J. Appl. Sci. Res. 1, 380–385 (2005)

Singh, R.V., Sharma, A.K., Tomar, R.K.S.: Response of chickpea to sources and levels of sulfur. Int. Chickpea Pigeonpea Newsl. 10, 20–21 (2003)

Thakur, A.K., Panwar, J.D.S.: Effect of Rhizobium VAM interactions on growth and yield of mung been under filed condition. Indian J.Plant Pathol. 38, 62–65 (1995)

Dubey, S.K.: Response of soyabean (Glycine max) to biofertilizers with and without nitrogen, phosphorus and potassium on swell-shrink soil. Indian J. Agron. 43, 546–549 (1998)

Naseby, D.C., Way, J.A., Bainton, N.J., Lynch, J.M.: Biocontrol of Pythium in pea antifungal metabolite producing and non-producing pseudomonas strains. J. Appl. Microbiol. 90, 421–429 (2001)

Pervez, H., Ashraf, M., Makhdum, M.I.: Influence of potassium on gas exchange characteristics and water relations in cotton (Gossypium hirsutum L.). Photosynthetica 42, 251–255 (2004)

Shukla, S.K., Dixit, R.S.: Effect of rhizobium inoculation, plant population and phosphorus on growth and yield of summer green gram. Indian J. Agron. 41(4), 611–615 (1996)

Shaheen, A., Rahmatullah: Growth and nodulation of groundnut inoculation with rhizobium strain based on different carriers. Pak. J. Soil Sci. 12, 26–28 (1996)

Tariq, M., Khan, M.A., Perveen, S.: Response of maize to applied soil zinc. Asian J. Plant Sci. 1, 476–477 (2002)

Mohan, V.R., Janardhanan, K.: Chemical composition and nutritional evaluation of two little known species of Vigna. Food Chem. 48, 367–371 (1993)

Rao, B.S.N., Deosthale, Y.G., Pant, K.C.: Nutritive Value of Indian Foods. National Institute of Nutrition, Indian Council of Medical Research, Hyderabad (1989)

Vadivel, V., Janardhanan, K.: Chemical composition of the underutilized legume Cassia hirsuta L. Plant Foods Hum. Nutri. 55, 369–381 (2000)

Brravo, L., Siddhuraju, P., Sauvo-Calixto, F.: Composition of under exploited Indian pulses. Comparison with common legumes. Food Chem. 64, 185–192 (1999)

Tresina, P.S., Kala, K.B., Mohan, V.R., Vadivel, V.: The biochemical composition and nutritional potential of three varieties of Vigna mungo (L.) Hepper. Adv. Biores. 1, 6–16 (2010)

Meiners, C.R., Derise, N.L., Lau, H.C., Crews, M.G., Ritchey, S.J., Murphy, E.W.: The content of nine mineral elements raw and cooked mature dry legumes. J. Agric. Food Chem. 24, 1126–1130 (1976)

Salunkhe, D.K., Kadam, S.S., Chavan, J.K.: Chemical composition. In: Salunkhe, D.K., Kadam, S.S., Chavan, J.K. (eds.) Post Harvest Biotechnology of Food legumes, pp. 29–52. CRC Press Inc, Boca Rabon (1985)

Van Loon, L.C., Bakker, P.A.H.M., Pieterse, C.M.J.: Systemic resistance induced by rhizosphere bacteria. Annu. Rev. Phytopathol. 36, 453–483 (1998)

Ramamoorthy, V., Samiyappan, R.: Induction of defense related genes in Pseudomonas fluorescence treated chili plants in response to infection by Colletrichum cupsici. J. Mycol. Plant Pathol. 31, 146–155 (2001)

Bharti, V., Nardar, R., Kumar, V., Pandey, I.S.: Effect of irrigations level on yield, water use efficiency and economics of winter maize (Mdiar). J. Agron. 52(1), 27–30 (2007)

Acknowledgements

Authors are thankful to Dean and Director, CAS in Marine Biology, Faculty of Marine Sciences, Parangipettai for providing the lab necessary facilities. The first author is grateful to the UGC-RGNF, Govt. of India for the financial assistance (Name of the Awardee Award letter number and date of UGC Circular number and date (F1-17.1/2015-R. Dineshkumar 16/RGNF-2015-17-SC-TAM-24190 and January 2016).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Dineshkumar, R., Subramanian, J. & Sampathkumar, P. Prospective of Chlorella vulgaris to Augment Growth and Yield Parameters Along with Superior Seed Qualities in Black Gram, Vigna mungo (L.). Waste Biomass Valor 11, 1279–1287 (2020). https://doi.org/10.1007/s12649-018-0465-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0465-9