Abstract

Purpose

Corncob hydrolysate, feather hydrolysate waste (FHW) and glutamate mill waste (GMW) are inexpensive raw materials derived from agricultural waste biomass. The aim of the study was to optimize the production of surfactin from the xylose-rich corncob hydrolysate and low-cost residues rich in organic nitrogen using Bacillus subtilis BS-37.

Methods

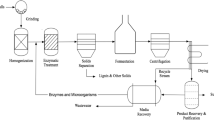

Hydrolysis of corncob was carried out with 1.5% H2SO4, FHW or GMW was used as nitrogen source to produce surfactin. Sugar compositions of corncob hydrolysate and surfactin titer were determined by HPLC. The dry weight method was used to measure biomass in fermentation broth.

Results

We discovered that the efficient surfactin producer B. subtilis BS-37 can use xylose as sole carbon source, but the addition of organic nitrogen sources was essential for surfactin production. Consequently, the xylose-rich corncob hydrolysate and low-cost residues rich in organic nitrogen were used to produce surfactin. Strain BS-37 was able to tolerate significant concentrations of several inhibitory compounds found in corncob hydrolysate, whereby acetic acid even enhanced surfactin production. Furthermore, NaOH-neutralized corncob hydrolysate was more suitable for surfactin production than the traditional Ca(OH)2-neutralized feedstock.

Conclusions

We achieved a maximal surfactin yield of 523 mg/L from NaOH-neutralized corncob hydrolysate and feather hydrolysate waste. Furthermore, the product contained 55.3% of the most desirable surfactin isoform C15. To our best knowledge, this is the first report of surfactin production with xylose as the main fermentable carbon source.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Surfactin is a secondary metabolite and a biological surface-active agent produced by Bacillus species. It was originally discovered in 1968 by Arima et al., in the culture supernatants of Bacillus subtilis [1]. Because of its biodegradability, environmentally benign nature and good stability in extreme environments, surfactin is gaining increasing attention as a valuable chemical with great potential in microbial enhanced oil recovery (MEOR). However, the low yields and high production costs of available processes severely restrict its commercial availability.

One way to reduce production costs is to use low-cost agroindustrial residues as fermentation feedstock. In previous work, several waste materials have been tested as carbon sources for the production of surfactin, but the yields are still far from ideal [2, 3]. Corncob is an important source of lignocellulosic biomass in the corn-processing industry, with more than 3.87 million tons generated every year in China [4]. However, most of the available corncob biomass is used as fuel or even burned directly in the fields, causing a plethora of environmental problems, including smog. In more sophisticated valorization approaches, the extraction of xylose by acid hydrolysis is a common way to pretreat corncob [5]. Since it is a major sugar component of abundant lignocellulosic biomass, the utilization of xylose has attracted great interest, holding the promise to sustainably recycle lignocellulosic biomass and circumvent excessive non-food usage of the much more valuable glucose. In spite of its promising characteristics, the utilization of xylose as the main fermentable carbon source for surfactin production has, to our best knowledge, not been reported before.

Generally, wild-type B. subtilis is not able to use xylose as sole carbon source, because it lacks a specific xylose uptake system [6]. However, there do exist rare reports of xylose-utilizing B. subtilis strains, possibly bearing mutations in xylose transporter genes [7, 8]. In our earlier studies, B. subtilis BS-37 was developed as an efficient surfactin producer with potential applicability in MEOR [9, 10]. Furthermore, since B. subtilis BS-37 is intrinsically able to use xylose as sole carbon source, it offers the possibility of using corncob as an economical and environmentally-friendly carbon source for the production of surfactin. The objective of this study is thus to investigate the possibility of using low-cost agroindustrial residues for commercially viable production of surfactin.

Materials and Methods

Materials and Feedstock Preparation

Feather hydrolysate waste (FHW) is the agroindustrial by-product that remains after the extraction of amino acids (l-Cys, l-Leu, l-Tyr, l-Arg) from feathers via acid hydrolysis. The main components of FHW are amino acids (18–20%), NH4Cl (20–25%) and peptides (<2%). The FHW used in this study was provided by Jiangsu XinHanLing Biologic Co., Ltd. The price of FHW is about 50 dollars per metric ton.

Monosodium glutamate mill waste (GMW) was provided by Lotus Health Industry Holding Group Company (Henan, China). It contains glutamate (8–9%), leucine (0.1%), isoleucine (0.08%), glycine (0.8%), proline (0.5%), valine (0.2%) and aspartic acid (0.4%). The price of GMW is about 45 dollars per metric ton.

Corncob was collected in the fields around Ningyang county, P.R. China, and broken into roughly 1–5 mm pieces using a mechanical crusher. The dried fiber powder mainly consisted of 42% (w/w) cellulose and 28% (w/w) hemicelluloses [8]. Dilute-acid hydrolysis of corncob was carried out in 1.5% H2SO4 with a liquid/solid ratio of 6:1 (w/w) at 100 °C for 2 h. Subsequently, the mixture was filtered through four layer gauze (Xu Wei health materials co., LTD, China), and the filtrate was directly used as the corncob hydrolysate (CCH).

The Ca(OH)2-neutralized hydrolysate was prepared by overliming (adjusting the pH of the hydrolysate to 10.0) with Ca(OH)2 pellets and subsequently readjusting to 6.5 with 1 M H2SO4 under constant stirring. During this process, precipitated CaSO4 particles are formed, which can absorb a part of unfavorable factors, which are further removed when the corncob hydrolysates are filtered to remove the CaSO4 precipitate.

The NaOH-neutralized hydrolysate was prepared by adjusting the pH to 7.5 in one step by slowly adding 1 M NaOH under constant stirring. The resulting neutralized hydrolysate was directly added to the culture medium without filtering.

The sugar composition of the hydrolysates was determined using a published HPLC method [11].

Microorganism and Culture Media

Bacillus subtilis BS-37 is a mutant derivative of B. subtilis, obtained through screening [12]. The seed medium (Luria–Bertani) contained yeast extract (5 g/L, oxoid, UK), peptone (10 g/L, oxoid, UK), and NaCl (10 g/L). The surfactin production medium contained carbon source (20 g/L; xylose or corncob hydrolysate, 20 g/L total reducing sugars), nitrogen source [50 mM N; one of the following: FHW (1%, v/v), GMW (4%, v/v), monosodium glutamate (9.35 g/L), NH4Cl (2.68 g/L) or NH4NO3 (2 g/L) or (NH4)2SO4 (3.3 g/L)], and inorganic salts (10 g/L K2HPO4·3H2O, 0.2 g/L MgSO4·7H2O, 0.02 g/L FeSO4·7H2O).

All media were adjusted to pH 7.5 ± 0.1 with 1 M NaOH and sterilized by autoclaving at 121 °C for 20 min.

Cultivation Conditions

BS-37 was cultured in seed medium (250 mL unbaffled flasks containing 50 mL of medium) at 200 rpm and 37 °C for 12 h, after which 2% (v/v) of the resulting culture was used to inoculate the surfactin production culture (250 mL unbaffled flasks containing 50 mL of surfactin production medium), which was incubated at 37 °C and 200 rpm for 36–84 h.

Determination of Surfactin Isoforms by HPLC

Surfactin isoforms were quantified using a published HPLC method [9, 12]. Briefly, a 300 μL aliquot of cell-free supernatant obtained after fermentation was added to 1.2 mL methanol, shaken for 1 min, and separated by centrifugation at 10 956×g for 10 min at 4 °C. The supernatants were filtered through an 0.22 µm pore-size filter and used as samples for HPLC on a U-3000 system (Thermo fisher science, USA) equipped with a Synchronis C18 (4.6 × 250 mm, 5 μm, Thermo fisher science, USA) column and a UV detector (Thermo fisher science, USA). The system was operated at a flow rate of 0.8 mL/min, using a mobile phase comprising 90% (v/v) methanol, 10% (v/v) water and 0.05% trifluoroacetic acid. The analytes were detected at 214 nm. The authentic surfactin (98%) reference standard was purchased from Sigma. The total surfactin concentration was calculated by summing up the concentration of each congener. The relative proportions of the surfactin isoforms (C13-, C14- and C15-surfactin) were analyzed by comparing the peak areas of the individual isoforms to the sum of all surfactin peak areas in the sample.

Results and Discussion

Xylose Can Be Used to Produce Surfactin

To our delight, when 20 g/L of xylose was used as the sole carbon source, the strain was able to produce surfactin. In order to further optimize the production, the effect of different nitrogen sources on cell growth and surfactin production were determined after 72 h of fermentation (Table 1). When inorganic nitrogen sources such as ammonium nitrate and ammonium chloride were used, xylose could be assimilated for cell growth, but did not support surfactin accumulation; the biomass yield reached 4.10–4.35 g/L, but surfactin production was undetectable. Production of surfactin requires the products of the srf operon, encoding the three subunits of surfactin synthetase that catalyze the thiotemplate mechanism of nonribosomal peptide synthesis (NRPS) to incorporate the seven amino acids into the surfactin lipopeptide. Some reports have shown the relationships among the regulatory factors governing srf transcription initiation [13]. However, it’s not clear how the regulatory factors produced in Bacillus spp. when utilizing pentose sugar as carbon source.

By contrast, organic nitrogen sources such as yeast extract (YE), monosodium glutamate (MSG), feather hydrolysate waste (FHW) and glutamate mill waste (GMW) were favorable for both cell growth and surfactin production. Among these, yeast extract resulted in the greatest production of biomass 4.05 g/L, while the maximum production of surfactin (370.3 mg/L) was obtained with FHW as nitrogen source. Since the organic nitrogen sources FHW and GMW are rich in amino acids and peptides, they can also be used as carbon source for cell growth. However, when used this way, these combined carbon–nitrogen feedstocks yielded only 85–91 mg/L of surfactin.

It is also important to note that B. subtilis produces different surfactin variants, and their relative abundance is affected by the composition of the available substrate [14]. The most notable of these surfactin isoforms is C15-surfactin. It has the highest surface activity and hemolytic activity [15]. Furthermore, our previous work suggested that a higher C15-surfactin content in the final product leads to a better oil-washing efficiency and oil displacement efficiency [9]. Thus, the efficient production of C15-surfactin is of particular importance. However, the C15-surfactin proportion was not significantly influenced by the type of organic nitrogen source, ranging from 50 to 56%, which was similar to the proportion produced with glucose as carbon source [9].

Thus, it is most noteworthy that xylose could be assimilated for cell growth instead of surfactin accumulation when only inorganic nitrogen sources were available in the medium. In other words, organic nitrogen sources were essential for surfactin production by BS-37 when xylose was used as sole carbon source. However, organic nitrogen sources such as yeast extract and peptone are much more expensive than inorganic nitrogen sources, which can result in unacceptably poor process economy. To solve this problem, we found that organonitrogen-rich residues such as feather hydrolysate waste and glutamate mill waste were suitable low-cost (<50 dollars/ton) organic nitrogen sources.

Distribution of Sugars in Corncob Hydrolysate (CCH)

Acid pretreatment is one of the most popular methods used to attain high free sugar yields from lignocellulosic biomass [16]. Table 2 lists the components of neutralized and non-neutralized corncob hydrolysates, which had similar compositions. Xylose, arabinose, acetic acid, glucose and glycerol were released by hydrolytic pretreatment with diluted-acid, with xylose being the most abundant, taking up about 70% of the monomeric sugars. Importantly, both Ca(OH)2-neutralized and NaOH-neutralized hydrolysates contained sufficient soluble sugars to meet the 2% (w/v) carbohydrate requirement of the culture media.

Ca(OH)2-Neutralized Corncob Hydrolysate (CCH) as Sole Carbon Source

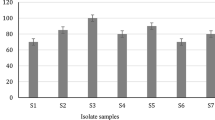

When Ca(OH)2-neutralized CCH, containing 20 g/L of sugar, was used as sole carbon source, and low-cost organic nitrogen sources such as feather hydrolysate waste (FHW, 1% v/v) and glutamate mill waste (GMW, 4% v/v) were used as nitrogen sources, the fermentation results were as shown in Fig. 1. While the biomass yield was 3.0–3.2 g/L, almost the same as in pure xylose medium, the surfactin titers were much lower, about 40 or 70% of the titers obtained in pure xylose medium. Thus, further investigation of the effects of potential inhibitory compounds in CCH on surfactin production was needed.

Surfactin production by Bacillus subtilis BS-37 using Ca(OH)2-neutralized corncob hydrolysate (CCH) as sole carbon source. a FHW (feather hydrolysate waste) as nitrogen source; b GMW (glutamate mill waste) as nitrogen source; filled circle biomass; filled square surfactin titer; filled triangle total residual sugar. Strain BS-37 was grown in shake-flask culture at 200 rpm and 37 °C for 84 h. Error bars correspond to the standard deviation of three replicates

The Effect of Inhibitory Compounds on Surfactin Production

The potential inhibitory compounds produced during hydrolysis mainly encompass hemicellulose decomposition products, which can be divided into three main groups based on their origin: weak acids, furan derivatives, and phenolic compounds [17]. The four well-known inhibiting compounds formic acid, acetic acid, furfural and 5-hydroxymethyl furfural (5-HMF) were selected for a more detailed analysis of their effects on cell growth and surfactin production. The results are shown in Table 3.

In the presence of 15 mM formic acid, the biomass and surfactin production were 86 and 98% of the values observed in the control, respectively. When the titer of formic acid reached 65 mM, both biomass and surfactin production were significantly inhibited, reaching only 58 and 56% of the control, respectively. A slight decrease of the C15-surfactin proportion in the total product could also be observed, ranging from 50 to 54.5% versus 58.2% in the control.

Interestingly, acetic acid exhibited no inhibitory effects. On the contrary, it actually enhanced both cell growth and surfactin production in a concentration-dependent manner (Table 3). This can probably be attributed to the slightly basic fermentation broth, set to pH 7.5, which may have minimized the toxicity of acetic acid. In the presence of 100 mM acetic acid, the maximum biomass and surfactin yields reached 4.09 g/L and 566.6 mg/L, respectively, which was 31 and 58% higher than in the control. However, a slight decrease of the C15-surfactin proportion in the products was observed, since it ranged from 51.3 to 52.6%, versus 58.2% in the blank.

By contrast, while furfural was not harmful to cell growth, it seriously inhibited surfactin production (Table 3). In the presence of 12 mM furfural, the biomass and surfactin yields were 92 and 59% of those in the control. In the presence of 12 mM 5-HMF, the biomass and surfactin yields were 41 and 79% of those in the control. The C15-surfactin proportions in the product were not significantly influenced by either furfural or 5-HMF.

We can thus conclude that strain BS-37 is able to tolerate significant concentrations of inhibitory byproducts of hydrolysis. Perhaps the most interesting observation is that acetic acid can improve both cell growth and surfactin production of B. subtilis BS-37 when using xylose as sole carbon source. Thus, suitable treatment procedures for corncob hydrolysate should be developed to facilitate surfactin production by BS-37, taking into account this acetate preference.

NaOH-Neutralized CCH as Sole Carbon Source

The NaOH-neutralized CCH, containing 20 g/L of sugar, was directly used as carbon source without filtering, and either FHW (1% v/v) or GMW (4% v/v) was used as nitrogen sources to produce surfactin. The fermentation results are shown in Fig. 2. Although the sugar composition of the CCH neutralized using the two procedures was similar, the surfactin titers of cultures grown using NaOH-neutralized hydrolysate were almost two times higher than the values obtained using Ca(OH)2-neutralized hydrolysate. When GMW was used as nitrogen source, BS-37 reached a maximum biomass of 3.10 g/L at 60 h and a maximum surfactin yield of 462.9 mg/L, with 48.5% C15 at 84 h. Compared to GMW, FHW was more suitable for surfactin production, since the titer reached up to 523.3 mg/L at 72 h of fermentation. The composition of the resulting surfactin was also improved, with 55.3% C15. Since our further studies indicated that Ca2+ is not an inhibitory factor for surfactin production, the exact reason why NaOH-neutralization was better than Ca(OH)2-neutralization remains unknown.

Surfactin production by Bacillus subtilis BS-37 utilizing NaOH-neutralized corncob hydrolysate. a FHW (feather hydrolysate waste) as nitrogen source; b GMW (glutamate mill waste) as nitrogen source; filled circle biomass; filled square surfactin titer; filled triangle total residual sugar. Strain BS-37 was grown in shake-flask culture at 200 rpm and 37 °C for 84 h. Error bars correspond to the standard deviation of three replicates

Ca(OH)2-neutralization has been reported to result in better fermentability of hydrolysates used for ethanol production by Pichia stipitis due to the precipitation of ‘toxic compounds’ [18]. Furthermore, Ca(OH)2 was widely used to neutralize diluted-acid hydrolysates of lignocellulosic biomass, and the hydrolysates detoxified in this manner have been used to produce many kinds of bio-based chemicals, such as fumaric acid, lactic acid and poly-(γ-glutamic acid) [7, 19, 20]. In our work, strain BS-37 showed excellent surfactin-producing capacity and high inhibitor tolerance in the fermentation of the pentose sugars present in lignocellulose-derived hydrolysates. The NaOH-neutralized hydrolysate was directly used as carbon source without filtering or centrifugation, making the acid hydrolysis procedure simpler and more economical.

In recent years, surfactin has gained considerable attention as an alternative to synthetic surfactants due to its unique properties. Encouraging results have been obtained during the last decade in the production of surfactin using low-cost raw materials derived from agricultural waste biomass [2, 3, 21,22,23,24,25,26,27]. More recently, Sharma et al. optimized the pretreatment of fibrous biomass and used the growth of biosurfactant-producing bacteria as a benchmark for the yield of biomass-derived fermentable sugars [28]. However, they did not provide production titers. Table 4 presents the yields of surfactin obtained by different investigators using inexpensive agro-based feedstocks. In these reports, the main fermentable carbon source was glucose or sucrose, and none of them focused on xylose. Surfactin titers in some reports were expressed as yields of crude extract, and the production capacity in these reports was higher, perhaps indicating lower purity. In general, the production of surfactin was no more than 500 mg/L with agro-based substrates. Slivinski et al. obtained the highest yield of surfactin (809 mg/L) with okara (tofu dregs) and sugarcane bagasse in solid-state fermentation (SSF) [21]. In this work, we obtained a relatively high yield (523 mg/L) from xylose-rich biomass, opening a new avenue for the valorization of this exceedingly abundant bioresource.

Conclusions

In this study, we demonstrated that lignocellulosic biomass and organonitrogen-rich residues are potential low-cost substrates for the production of surfactin. The maximum surfactin production was 523 mg/L using NaOH-neutralized corncob hydrolysate and feather hydrolysate waste, which are both very inexpensive feedstocks. To our best knowledge, this is the highest surfactin yield obtained with a non-recombinant microorganism cultured on xylose-rich lignocellulosic biomass to date.

References

Arima, K., Kakinuma, A., Tamura, G.: Surfactin, a crystalline peptidelipid surfactant produced by Bacillus subtilis: isolation, characterization and its inhibition of fibrin clot formation. Biochem. Biophys. Res. Commun. 31, 488–494 (1968)

Ramirez, I.M., Vaz, D.A., Banat, I.M., Marchant, R., Alameda, E.J., Roman, M.G.: Hydrolysis of olive mill waste to enhance rhamnolipids and surfactin production. Bioresour. Technol. 205, 1–6 (2016)

De Oliveira, D.W.F., Franca, I.W.L., Felix, A.K.N., Martins, J.J.L., Giro, M.E.A., Melo, V.M.M., Goncalves, L.R.B.: Kinetic study of biosurfactant production by Bacillus subtilis LAMI005 grown in clarified cashew apple juice. Colloids Surf. B. 101, 34–43 (2013)

Yao, X.W., Xu, K.L., Li, Y.: Physicochemical properties and possible applications of waste corncob fly ash from biomass gasification industries of China. Bio. Resour. 11, 3783–3798 (2016). doi:10.15376/biores.11.2.3787-3798

Wang, G.S., Lee, J.W., Zhu, J.Y., Jeffries, T.W.: Dilute acid pretreatment of corncob for efficient sugar production. Appl. Biochem. Biotechnol. 163, 658–668 (2011)

Lindner, C., Stulke, J., Hecker, M.: Regulation of xylanolytic enzymes in Bacillus subtilis. Microbiology 140, 753–757 (1994)

Tang, B., Lei, P., Xu, Z.Q., Jiang, Y.X., Xu, Z., Liang, J.F., Feng, X.H., Xu, H.: Highly efficient rice straw utilization for poly-(gamma-glutamic acid) production by Bacillus subtilis NX-2. Bioresour. Technol. 193, 370–376 (2015)

Zhu, F., Cai, J., Zheng, Q., Zhu, X.C., Cen, P.L., Xu, Z.N.: A novel approach for poly-gamma-glutamic acid production using xylose and corncob fibres hydrolysate in Bacillus subtillis HB-1. J. Chem. Technol. Biotechnol. 89, 616–622 (2014)

Liu, Q., Lin, J.Z., Wang, W.D., Huang, H., Li, S.: Production of surfactin isoforms by Bacillus subtilis BS-37 and its applicability to enhanced oil recovery under laboratory conditions. Biochem. Eng. J. 93, 31–37 (2015)

Yi, G., Liu, Q., Lin, J., Wang, W., Huang, H., Li, S.: Repeated batch fermentation for surfactin production with immobilized Bacillus subtilis BS-37: two-stage pH control and foam fractionation. J. Chem. Technol. Biotechnol. 92, 530–535 (2017)

Zhang, L., Li, X., Yong, Q., Yang, S.T., Ouyang, J., Yu, S.: Impacts of lignocellulose-derived inhibitors on L-lactic acid fermentation by Rhizopusoryzae. Bioresour. Technol. 203, 173–180 (2016)

Zhu, L.Y., Xu, Q., Jiang, L., Huang, H., Li, S.: Polydiacetylene-based high-throughput screen for surfactin producing strains of Bacillus subtilis. PLoS ONE 9, e88207 (2014)

Cosby, W.M., Vollenbroich, D., Lee, O.H., et al.: Altered srf expression in Bacillus subtilis resulting from changes in culture pH is dependent on the Spo0K oligopeptide permease and the ComQX system of extracellular control. J. Bacteriol. 180(6), 1438–1445 (1998)

Liu, J.F., Yang, J., Yang, S.Z., Ye, R.Q., Mu, B.Z.: Effects of different amino acids in culture media on surfactin variants produced by Bacillus subtilis TD7. Appl. Biochem. Biotechnol. 166, 2091–2100 (2012)

Liu, X.Y., Ren, B.A., Gao, H., Liu, M., Dai, H.Q., Song, F.H., Yu, Z.Y., Wang, S.J., Hu, J.C., Kokare, C.R., Zhang, L.X.: Optimization for the production of surfactin with a new synergistic antifungal activity. PLoS ONE 7, e34430 (2012)

Lee, J., Li, P., Lee, J., Ryu, H.J., Oh, K.K.: Ethanol production from Saccharina japonica using an optimized extremely low acid pretreatment followed by simultaneous saccharification and fermentation. Bioresour. Technol. 127, 119–125 (2013)

Palmqvist, E., Hahn-Hagerdal, B.: Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresour. Technol. 74, 17–24 (2000)

Vanzyl, C., Prior, B.A., Dupreez, J.C.: Production of ethanol from sugar-cane bagasse hemicellulose hydrolyzate by Pichia-stipitis. Appl. Biochem. Biotechnol. 17, 357–360 (1988)

Xu, Q., Li, S., Fu, Y.Q., Tai, C., Huang, H.: Two-stage utilization of corn straw by Rhizopus oryzae for fumaric acid production. Bioresour. Technol. 101, 6262–6264 (2010)

Maas, RHW, Bakker, R.R., Jansen, M.L.A., Visser, D., De Jong, E., Eggink, G., Weusthuis, R.A.: Lactic acid production from lime-treated wheat straw by Bacillus coagulans: neutralization of acid by fed-batch addition of alkaline substrate. Appl. Microbiol. Biotechnol. 78, 751–758 (2008)

Slivinski, C.T., Mallmann, E., de Araujo, J.M., Mitchell, D.A., Krieger, N.: Production of surfactin by Bacillus pumilus UFPEDA 448 in solid-state fermentation using a medium based on okara with sugarcane bagasse as a bulking agent. Process. Biochem. 47, 1848–1855 (2012)

De Faria, A.F., Teodoro-Martinez, D.S., Barbosa, GND, Vaz, B.G., Silva, I.S., Garcia, J.S., Totola, M.R., Eberlin, M.N., Grossman, M., Alves, O.L., Durrant, L.R.: Production and structural characterization of surfactin (C-14/Leu(7)) produced by Bacillus subtilis isolate LSFM-05 grown on raw glycerol from the biodiesel industry. Process. Biochem. 46, 1951–1957 (2011)

Cortes-Camargo, S., Perez-Rodriguez, N., Oliveira, RPD, Huerta, BEB, Dominguez, J.M.: Production of biosurfactants from vine-trimming shoots using the halotolerant strain Bacillus tequilensis ZSB10. Ind. Crop. Prod. 79, 258–266 (2016)

Gudina, E.J., Fernandes, E.C., Rodrigues, A.I., Teixeira, J.A., Rodrigues, L.R.: Biosurfactant production by Bacillus subtilis using corn steep liquor as culture medium. Front. Microbiol. 6, 59 (2015)

Gurjar, J., Sengupta, B.: Production of surfactin from rice mill polishing residue by submerged fermentation using Bacillus subtilis MTCC 2423. Bioresour. Technol. 189, 243–249 (2015)

Abdel-Mawgoud, A.M., Aboulwafa, M.M., Hassouna, NAH: Optimization of surfactin production by Bacillus subtilis isolate BS5. Appl. Biochem. Biotechnol. 150, 305–325 (2008)

Nitschke, M., Pastore, G.M.: Production and properties of a surfactant obtained from Bacillus subtilis grown on cassava wastewater. Bioresour. Technol. 97, 336–341 (2006)

Sharma, R., Lamsal, B.P., Colonna, W.J.: Pretreatment of fibrous biomass and growth of biosurfactant-producing Bacillus subtilis on biomass-derived fermentable sugars. Bioprocess. Biosyst. Eng. 39, 105–113 (2016)

Acknowledgements

This work was supported by the National Science Foundation of China (No. 21576133) and the Program for Innovative Research Team in University of Jiangsu Province. The authors wish to express their sincere gratitude to Prof. Jia Ouyang (Nanjing Forestry University) for providing the corncob hydrolysate analysis platform.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, C., Lin, J., Wang, W. et al. Cost-Effective Production of Surfactin from Xylose-Rich Corncob Hydrolysate Using Bacillus subtilis BS-37. Waste Biomass Valor 10, 341–347 (2019). https://doi.org/10.1007/s12649-017-0052-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0052-5