Abstract

Surfactin and fatty acetyl glutamate (FA-Glu) were produced by Bacillus subtilis in 5-L fermentor. In a previous 50-mL shake flask study, sugar hydrolysates from soy hull, alfalfa and switchgrass were shown to support the growth of Bacillus strains. It was observed that glucose content and availability of hexose and pentose sugars in the hydrolysates played an important role in determining growth and product concentration. Growth, economic efficiency and product concentration of biosurfactants was compared in fermentations conducted in 5-L stirred tank bioreactor, on biomass hydrolysate-based growth media. Highest bacterial growth absorbance for surfactin and FA-Glu producing strains were at 3.5 and 3.3 absorbance units, respectively, for switchgrass hydrolysate media. Highest concentrations of products were observed in soy hull hydrolysate media (2.9 g/L and 0.28 g/L for surfactin and FA-Glu). Techno-economic analysis of the 5-L fermentations on the three biomasses showed surfactin cost estimate to be $6.63/kg for 97% pure product.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The world surfactant industry was valued at US $36,518 million in 2017 and has seen an upsurge in research and improvement in production and characterization of functional properties and usage [1]. The major proportion of surfactant production is from petrochemicals that are non-renewable, toxic and potentially harmful to the environment. Biosurfactants or bio-based surfactants that are derived through fermentation by microorganisms or enzymatic synthesis have been shown to be environment-friendly and similar in functional properties as petro-based surfactants. Microbial biosurfactants include surfactin, an extensively studied lipopeptide that consists of 12–16 fatty acid chain attached to a ring of 7 amino acids. Surfactin has been shown to lower the surface tension of water from 72 to 27 mN/m and is produced as a secondary metabolite by Bacillus species of bacteria in extremely hydrophobic environments for propagation and reproductive purposes [2]. One of the drawbacks of the potential use of surfactin as a commercial surface-active product is its limited solubility in water, due to the presence of hydrophobic amino acids in the polar ring of seven amino acids. To overcome this, Reznik et al. [3], developed a water-soluble variant of surfactin called fatty acetyl glutamate (FA-Glu), through genetic engineering of the Bacillus subtilis strain. The molecular structure of FA-Glu differs from surfactin in its polar moiety, where the ring of seven amino acids has been replaced by single glutamic acid residue linked to the same 12–16 carbon long fatty acid chain. Although biosurfactants such as surfactin and FA-Glu have the potential to replace non-biodegradable, petroleum-based surfactants, their extremely low yields on conventional carbohydrate substrates such as pure glucose and glycerol add to the cost of production, making these surfactants commercially unviable. This issue has been addressed by usage of low-cost, easily available, renewable agricultural waste biomass [3].

Biosurfactant synthesis has been linked to the type and availability of carbon sources in the fermentation media. Typically, a bio-surfactant is made up of a non-polar sugar moiety attached to a more polar functional group/groups such as peptide chains or alcohol residues [4]. The synthesis of this non-polar fraction is directly related to the carbon source in the fermentation substrate. This has led to an increase in the understanding of the effect of type and amount of fermentable carbohydrates to produce surfactin. Apart from simple sugar and sugar-based sources such as glucose, galactose, dextrose and glycerin, a variety of other renewable carbohydrate sources such as peanut oil, waste fried oil, crude glycerin has been utilized to increase production and yield of surfactin, where the yields of surfactin have ranged from 0.5 to 4 g/L in the fermentation broth [5].

Fermentation of simple six-carbon sugars by different strains of B. subtilis, a gram-positive bacterium has been conducted in a variety of fermentation scales and media to produce surfactin and other biosurfactants and various techno-economic evaluation studies on the commercial feasibility of biosurfactants such as rhamnolipids have led to two key findings of scale-up bottlenecks. First being the availability of cheap feedstock and the other being immense costs associated with downstream processing. Downstream processing of products derived from biological sources has lead to multiple unit operations which include, separation, concentration, and purification of target molecule [6]. Utilization of cheap fibrous or cellulosic biomass requires pretreatment to decrystallanize and delignify lignocellulosic matrix to enhance the action of hydrolyzing enzymes such as cellulases and hemicellulases [7]. This series of processes are unit operations that are cost intensive and need optimization of components involved to assess the economic viability of the process. Pilot-scale experiments to produce value-added biochemicals from cellulosic biomass such as ethanol have been conducted to assess their techno-economic efficiency, but no such study has been conducted on the utilization of fibrous biomass to produce biosurfactants such as surfactin and FA-Glu. The second bottleneck of additional costs associated with each unit operation in production and downstream processing has been improved upon by simulating industrial-scale downstream processing for purification and concentration of product and assessing processing and operating costs that adds significantly to the input cost of the target high-value molecule. In this study, we have attempted to incorporate pretreatment of fibrous biomass, extraction of fermentable sugars as a unit operation in the production of biosurfactants, to arrive at an input cost which is representative of an overall bio-refinery scheme for production of biosurfactants.

To further improve these two bottlenecks and increase performance efficiency of the process, this study aims to (1) understand the effect of sugar mixtures derived from enzymatic hydrolysis on the production of two biosurfactants, namely surfactin and FA-Glu and, (2) compare cost effectiveness of a simulated pilot plant scale-up of the optimized process in producing these biosurfactants.

Materials and methods

Materials

Bacillus subtilis strains, B. subtilis T4151 (surfactin producing) and B. subtilis E4088 (FA-Glu producing) were obtained from Modular Genetics© Inc., Woburn, MA. Switchgrass and alfalfa were harvested at the Bio Century Research Farm at Iowa State University. Soy hulls were procured through Ag Processing, Inc., Eagle Grove, IA. Biomasses were dried in a convection step oven at 105 °C for 12 h, ground to 2 mm particle size in a Wiley ball mill and stored in Ziploc bags at 25 °C. The enzymes, NS22086, NS22083, and NS22119, whose activities were cellulase, hemicellulase, and pectinase/arabinase/xylanase, respectively, were obtained from Novozymes (North America, Inc, Ames, IA, USA).

Pretreatment and generation of hydrolysates

Three hundred grams of ground biomass (switchgrass, and alfalfa and soy hulls) was treated with liquid ammonia pretreatment in duplicates with 15% (w/v) ammonium hydroxide solution with a solid loading of 1:11 at 60 °C for 12 h in an incubator. These samples were then filtered through a Buchner funnel and the slurry and liquor were separated and multiple washing steps of the wet slurry was performed, till the wash water pH was below 8. Moisture content analysis of the biomass slurry was performed in a similar manner as described above in a convection above at 105 °C. After determination of moisture content and total solids in the slurry, 200 g equivalent dry solids for each pretreated combination sample were enzymatically hydrolyzed by a 1:1:1 combination of Novozymes enzymes obtained at two different enzyme loadings: 5% (v/v), 2.5% (v/v). A control without enzyme treatment was included. The pH was maintained at 5.0 with 0.1 M sodium acetate buffer. Reactions were carried out in 500-mL Erlenmeyer flasks for 24 h in a shaker incubator at 50 °C, 150 rpm. The hydrolysates were collected by centrifuging at 15,000×g for 20 min in a centrifuge (Thermo-Fisher, model Sorvall legend XTR). The hydrolysates and the remaining solids were weighed and stored in Ziploc bags at − 20 °C. Carbohydrate yield was calculated as the conversion of biomass solids to soluble carbohydrate (CHO), based on the starting dry weight CHO content [8].

Preparation of fermentation media

Generated hydrolysates were analyzed for total carbohydrate content and substituted for glucose equivalent of 2% carbohydrate in the growth media. The growth media for both strains of B. subtilis consisted of glucose as a control carbohydrate at 2% (w/v) concentration, 10% 1 M K-PO4 buffer, pH 7.5, 1% 1 M (NH4)2SO4, 2% 1 M glutamic acid, pH 7.0, 2% glucose, 1% trace metal solution containing 1 M HCl, MgCl2·6H2O, CaCl2·2H2O, MnCl2·4H2O, ZnCl2, FeCl3·6H2O and 1% thiamine–HCl [3]. The inoculum consisted of an overnight cell culture with an absorbance (A650) from 0.01 to 0.10. Inocula were grown in a seed medium containing 0.6% Na2HPO4, 0.3% KH2PO4, 0.05% NaCl, 0.1% NH4Cl, 0.3% yeast extract. In samples containing biomass hydrolysates as carbohydrates in growth media, the hydrolysates were analyzed for total carbohydrate concentration by the method described by Dubois et al. [9]. The hydrolysates were then heated at 100 °C for inactivation of the enzyme and sterile filtered for incorporation into growth media.

Fermentation conditions

In this study, Eppendorf BioFlo® 310 5-L fermentation volume fermenter was utilized for all fermentation experiments. The fermenter was first autoclaved with all autoclavable components of the media and later sterile filtered components of the media along with approximately 200 mL of seed media of each strain were added aseptically. A flow rate of 5 mL/min/L of bioreactor volume was maintained at an agitator speed of 200 rpm at 37 °C at pH 7.0. These fermentation experiments were conducted for 48 h with periodic sampling of fermentation broth to measure cell density (absorbance), product concentration, and carbohydrate concentration in the broth in the 5-L fermentor. A carboy was set up to collect the foam generated; the remaining broth in the fermentor was collected separately in a vessel at the end of the fermentation. In all the 5-L fermentations, approximately 3.5–4 L of the total fermentation broth was collected as foam in the carboy. The two different collections, i.e., non-foaming broth in the fermentor and collected foam in the carboy, were, however, mixed together at the end of the fermentation to measure the final product concentration. The techno-economic evaluation was conducted to compare the costs associated with commercial surfactant production and market values of biosurfactants and commercial surfactants.

Analytical tests

The moisture content was measured by heating samples for 24 h at 105 °C in convection oven [10]. Carbohydrate in the hydrolysates was analyzed using the phenol–sulphuric acid assay [9] by adding, 0.5 mL 5% phenol solution to 0.5 mL of sample, followed by 2.5 mL 18M H2SO4. The resulting mixture was cooled and vortexed by measuring the absorbance at 490 nm. Sugars in the hydrolysates were measured by HPLC conducted isocratically with 0.005 M sulphuric acid as the mobile phase on an Accela 60057 HPLC unit equipped with a HyperREZXP carbohydrate H+ 8 µm column. Surfactin and FA-Glu analysis in the fermentation titer were analyzed for fermentation yield by LC-MS-Accurate Mass measurement on an Agilent 6540 QTOF, negative ion mode isocratically at 10:90 volume/volume ratio of water and methanol of 100 ppm surfactin and FA-Glu at a flow rate of 0.8 mL/min. Although growth absorbance sampling was done at 0, 3, 6, 9, 18. 24, 29 and 48 h marks, only 0, 24 and 48 h samples were analyzed for product concentration and distribution of sugars in the media, where the 48 h sample was collected from the final broth and foam mixture.

Techno-economic analysis

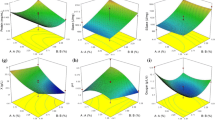

Techno-economic analysis was done for surfactin on soy hull hydrolysates, however, this can be assumed to be similar for generic biomass with similar hydrolysate composition. Surfactin concentration data ranging from 1.77 to 2.9 g/L and calculated media costs from 5-L fermentation experiments were used in a simulated 250-L fermentation that assumed processing of 15 kg of dry biomass. This 250-L fermentation included the eight steps shown in Fig. 1. As shown, biomass grinding was followed by homogenization, enzymatic treatment, solids separation, fermentation, centrifugation, drying, and product recovery and purification. Drying included a stream to enable the recycling of valuable enzymes and microorganisms. The process was assumed to generate lignin-rich and aqueous waste streams [11].

Cost estimation for media constituents, including procurement of specific media growth factors, nutrients (sugars, growth media, trace metal components etc.) was performed by scaling up the 250 L simulated data to commercial scale of 2000 metric tonne day dry biomass input. For biomass hydrolysate-based media, costs estimated were factored in for procurement, transportation and pretreatment of fibrous biomasses. The economic analysis follows the methodology described in previous studies by Hu et al. [12] and the process design developed by Choi and Lee [13]. Equipment costs were estimated using Aspen Process Economic Analyzer, and capital costs are based on Peters and Timmerhaus [14] installation factors (Fig. 2a) [14]. Operating costs were calculated based on simulated material and energy flow rates for 250-L fermentation using Aspen Plus™ version V8.8 (Aspentech, Bedford, MA, USA) and material prices as shown in Fig. 2b. Fixed costs including labor, taxes, and other miscellaneous costs such as maintenance and enzyme nutrients were determined using the National Renewable Energy Laboratories’ methods [15, 16]. Annualized capital costs were based on a 10% internal rate of return target, and taxes at 39% of net income, which is the common US corporate tax rate. Based on these parameters, a minimum product-selling price (MPSP) was estimated for the surfactin product.

Results and discussion

Compositional analysis of biomass hydrolysates

Table 1 shows the solid recovery percentage of pretreatment of each biomass and their respective carbohydrate conversion percentage. All solids in three pretreatments of 300 g each (duplicates) were recovered at approximately 70% after multiple washing and filtration steps. The higher loss in solids could be explained by process being a batch process and higher losses in washing. The carbohydrate conversions in all three pretreatments of biomasses yielded 73.28, 77.22, 76.88%, respectively, for switchgrass, alfalfa and soy hulls. These carbohydrate conversions were very similar to 5 g ammonium hydroxide and ultrasonication pretreatment done in our previous study [17]. Table 2 shows the monomeric sugar distribution of the three biomass hydrolysates utilized as carbohydrate source for bacterial fermentation. Switchgrass contained three major monomeric sugars, glucose being the only hexose sugar and arabinose and xylose being the two pentose sugars. Similarly, biomass hydrolysate sugar distribution in alfalfa, contained glucose as the only hexose sugar and xylose and arabinose as the pentose sugars. However, soy hulls showed a relatively equal amount of glucose and xylose along with a similar percentage of another hexose sugar: galactose.

Growth of Bacillus subtilis strains on select pretreatment hydrolysates and their comparison with shake flask level experiments

Shake flask level fermentation on the same B. subtilis strains were reported in our previous study [17]. We reported that the three best-performing biomasses in terms of bacterial growth were switchgrass, alfalfa, and soy hulls. The sugar distribution in hydrolysates of switchgrass and alfalfa were very similar, as both contained a majority percentage of glucose followed by xylose and other monomeric sugars. Soy hull hydrolysates, on the other hand, had equal proportions of glucose, xylose, and galactose. Fermentation media for both strains contained 2% (w/v) of carbohydrate content in both studies for consistency of scale-up validation. The carbohydrate percentage conversion of the three pretreated biomasses: switchgrass (SW), alfalfa (AA) and soy hulls (SH) had very similar performance compared to our previous study at smaller scale pretreatment (5 g dry sample). In our previous study, Sharma et al. [17], we optimized the pretreatment conditions for generating sugar hydrolysates from a variety of biomasses. The overall magnitude of growth absorbance was higher in shake flask experiments, as cells were constantly lost in the foam collected in the carboy and 50-mL experiments retained all the cells as no foam was being collected. A similar pattern of growth absorbance, however, was observed when these strains were grown on selected, three best-performing fibrous feedstocks: switchgrass, alfalfa, and soy hulls along with a glucose control to conduct 5-L fermentation experiments (Fig. 3a, b). The effect of different monomeric sugar distribution in hydrolysates was shown to affect the growth patterns of both Bacillus strains. One key finding of our previous study was that hydrolysates with a predominance of glucose in monomeric distribution, i.e., switchgrass and alfalfa showed higher growth absorbance than the glucose control than soy hull-based media, and this pattern of growth was observed in this 5-L scale-up study as well [17]. This pattern was consistent with other studies with the finding that maximum availability of hexose sugars in the hydrolysate composition led to the highest growth of B. subtilis. Since biosurfactant-producing strains of B. subtilis have shown to prefer hexose sugars over pentoses, switchgrass and alfalfa-based media showed increased growth over soy hull-based media as competitive uptake of equal amounts of hexoses and pentoses in the soy hull media might have hampered the cell density. But as previous studies such as Ibrahim and Steinbüchel [18] have shown that high cell density does not always lead to higher production of a target molecule in bacterial fermentations, so the concentration of surfactin and FA-Glu produced 50-mL shake flask level fermentation broth and 5-L fermentations broths were compared.

Biosurfactant concentrations in fermentation broths for 50-mL and 5-L scales

Figure 4a, b show the titers of surfactin and Fa-Glu for each fibrous biomass hydrolysate media and glucose-based media at the fermentation end point (72 h for 50-mL and 48 h for 5-L experiments). The highest Fa-Glu and surfactin concentrations achieved for both strains were reported for soy hull hydrolysate containing media in both scales of the study. This finding is consistent with the finding of Marti et al. [19], where higher titers of FA-glu were observed for soy hull-based media compared to glucose at same carbohydrate compositions. The relationship between cell density and product formation is clearly not correlational as observed by multiple studies on similar approaches for surfactin production. Our findings on higher product titers for both surfactin and FA-glu on pretreated soy hull hydrolysates were similar to Khan et al. [20], where although similar or higher cell densities were observed with glucose-based growth media, presence of hexoses such as xylose in both the studies led to higher production of surfactin compared to media which either had predominance of glucose like switchgrass and alfalfa hydrolysates or purely glucose-based media.The higher cell densities for glucose-rich carbohydrate sources for B. subtilis strains, in particular, may be a result of a shorter stationary phase in the growth kinetics as observed in our studies at 50-mL and 5-L scales. In Fig. 5a, b, it can be observed that in both surfactin and FA-glu titer curves for 50-mL and 5-L scales the highest production of these molecules was around the 24–40 h period where the growth absorbance curves show a prolonged stationary phase for soy hull-based media.

Figures 6 and 7 show the uptake of each component monomeric sugar at different time points during the fermentation from the HPLC sugar analysis of the periodic fermentation broth samples. Switchgrass and alfalfa hydrolysate containing media for both the strains were found to contain a predominance of a number of hexose sugars (xylose and arabinose) compared to soy hulls where glucose, galactose, and xylose were equally distributed according to a percentage. It has been shown in the past by Park et al. [21] that B. subtilis strains were unable to grow on media containing xylose as the sole carbon source as they did not contain xylose-specific transcription, but Khan et al. showed that the presence of xylose in the media increased the yield of surfactin compared to media that only contained glucose. This could be attributed to the reliance of this bacterial strain on glucose availability for a catabolic uptake needed for higher growth and cell density and a dependence on xylose to stress the strain into producing surfactin, which is essentially a secondary metabolite. In our previous study, we were able to successfully demonstrate the growth of these strains on hydrolysates containing a distribution of pentose and hexose sugars, but growth depended heavily on a number of hexose sugars present in the hydrolysates [17]. Although it was successfully shown that these strains could grow and produce significantly more cell density in fermentation cultures containing a variety of pentose and hexose sugars, the current study reports the difference in production titers and growth patterns for both 50-mL shake flask experiments and 5-L bioreactor experiments. Since previous studies [22,23,24] have shown that synthesis and titer of production are linked with metabolic uptake and availability of hexose sugars and pentose sugars in the growth media, soy hull hydrolysates are carbon sources that performed better than switchgrass and alfalfa and this observation has been consistent in both scales of study. De vuyst and Vandamme [22] in their study on understanding the effect of carbon source in fermentation media showed how different sugars affected growth metabolism for Lactobacillus and subsequently impacted the production of nisin [20]. Similarly, Lengeler et al. [23] and Stulke and Hillen [24] proved how most bacterial evolution created a dependence on availability of glucose in the media for catabolic uptake for rapid growth and reproduction and how subsequent availability of other pentose and hexose sugars along with other environmental conditions such as the presence of certain protein components affected the expression of genes related to the production of intermediates responsible for eventual synthesis of target biomolecules such as secondary metabolites and high-value compounds.

This selective uptake for biosynthesis can be further explained by the fact that biosurfactants being secondary metabolite products depend upon the balance between rapidly available sugars for growth and presence of other sugars than those that could be utilized for synthesis of secondary metabolites such as biosurfactants in the case of gram-positive bacteria like B. subtilis. Figures 6 and 7 confirm this hypothesis, since glucose being the most readily available and abundant sugar in all three biomass hydrolysates utilized in bacterial growth media, is rapidly consumed in both bacillus strains. Since alfalfa and switchgrass consist of a higher proportion of glucose and little or no other hexose sugar, a higher growth absorbance for both strains is observed. However, both strains produced the highest amount of biosurfactant in media containing soy hull hydrolysate; glucose is readily utilized for growth by microbes, then followed by other sugars like xylose, arabinose, and galactose for more biosurfactant synthesis. It is important to note here, that a mixture of glucose and xylose sugars in the fermentation media could improve overall yield of these value-added chemicals. However, at both fermentation scales, even the best-performing biomass-based media, i.e., soy hulls did not produce surfactin and FA-Glu statistically has similar yields compared to the glucose control, better sugar formulations and the recovery method improvement might lead to significantly higher yields. Since surfactin and FA-glu yields were observed for all biomasses to be comparable to glucose-based control, a techno-economic evaluation of the use of these cheaper feedstocks as a comparison to highly purified glucose was performed.

Techno-economic analysis

Table 3 shows that for the 2000 metric tonne scale-up simulation, a $50/t feedstock price was assumed for switchgrass. The NaOH price was $330/t which was within range of values found on chemical merchant sites. Enzymes were to be produced onsite avoiding the purchase of commercial enzymes. Wastewater and freshwater costs were estimated to be $0.05 and $0.23/t. Process heat was assumed to be purchased as steam for $17.06/MWh. Miscellaneous costs include nutrients, chemicals, and electricity which were estimated to contribute a small portion of production costs. The capital cost for this facility was estimated to be $240 million, and the various cost components are shown in Fig. 2b. The product separations and fermentation sections contribute $18.09 and $13.17 million to the total $59.2 million capital cost.

Based on results of simulated 250-L fermentation and subsequent simulation of commercial scale, biomass contributed the majority ($2.82/kg) of the product cost followed by the annualized capital cost ($2.0/kg) as shown in Fig. 2. Enzyme expenses are expected to be a small fraction of the total cost because of high recovery rates of the proprietary enzymes. The estimated product cost for switchgrass-based surfactin is $6.63/kg based on the laboratory experimental data.

While literature comparison of surfactin and other biochemical is available, the process conditions and feedstock composition vary widely, making such comparison not realistic. Makkar et al. [5] outlined how usage of low-cost input material for biosurfactant production through microbial fermentation could significantly reduce the cost of biosurfactants. Surfactin at 99% purity is available at a price of $191.5 for 10 mg vial [25]. This price when compared to our 97% pure surfactin estimated at 6.63$/kg is significantly lower; however, a purely commercial product at our simulated scale of a 2000 metric tonne biomass processing facility cannot be compared to the sigma price because of demand and scale factors. Makkar et al. stated that for biosurfactants like surfactin to become competent in market, their price should be less than or around $1/lb as that is how much synthetically produced chemical surfactants cost. However, a good comparison of our estimated surfactin cost can be made with other biosurfactants that are either produced commercially or where costs have been estimated with similar techno-economic analyses. Ashby et al. [26] estimated a price of 2.95$/kg of sophorolipids and Lang and Wullbrandt [27] estimated a price of $5/kg for rhamnolipids and that both of these biosurfactants that can be produced through renewable and cheap input materials. Surfactin with its higher surface activity compared to both these biosurfactants has the potential to become competent as a commercial surfactant with our estimated price of 6.63/kg. However, a price range of 2–3$/kg is most desirable which can be achieved through a combination of yield and product recovery improvements, and advances in resource use efficiency and recycling.

Conclusions

This study has been successful in demonstrating the increase in the scale of utilization of fibrous biomass hydrolysates as substitutes for carbon source in the place of glucose. The study has provided significant data to prove that the yield of these biosurfactants is related to type and amount of monomeric sugar distribution. A thorough economic evaluation of this process shows the economic and environmental viability and need to substitute glucose and other food-based sugars with renewable and cheap fibrous biomass, accounting for costs of pretreatment and enzyme utilization at various scales of production.

References

Panjiar N, Sachan SG, Sachan A, Biosurfactants (2017) A multifunctional microbial metabolite. In: Kalia V (ed) Microbial applications, vol 2. Springer, Cham, pp 213–229

Ishigami Y, Osman M, Nakahara H, Sano Y, Ishiguro R, Matsumoto M (1995) Significance of β-sheet formation for micellization and surface adsorption of surfactin. Colloids Surf B 4:341–348

Reznik GO, Vishwanath P, Pynn MA, Sitnik JM, Todd JJ, Wu J, Jiang Y, Keenan BG, Castle AB, Haskell RF, Smith TF, Somasundaran P, Jarrell KA (2010) Use of sustainable chemistry to produce an acyl amino acid surfactant. Appl Microbiol Biotechnol 86:1387

Pacwa-Płociniczak M, Płaza GA, Piotrowska-Seget Z, Cameotra SS (2011) Environmental applications of biosurfactants: recent advances. Int J Mol Sci 12:633–654

Makkar RS, Cameotra SS, Banat IM (2011) Advances in utilization of renewable substrates for biosurfactant production. AMB Express 1:5

Winkler MA (1990) Chemical engineering problems in biotechnology. Springer Science & Business Media, New York

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis. Bioresour Technol 101:4851–4861

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory Analytical Procedure (LAP), National Renewable Energy Laboratory, Golden

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2005) Determination of ash in biomass. Laboratory Analytical Procedure (LAP), National Renewable Energy Laboratory, Golden

Ragauskas AJ, Beckham GT, Biddy MJ, Chandra R, Chen F, Davis MF, Wyman CE (2014) Lignin valorization: improving lignin processing in the biorefinery. Science 344:1246843. https://doi.org/10.1126/science.1246843

Hu W, Dang Q, Rover M, Brown RC, Wright MM (2016) Comparative techno-economic analysis of advanced biofuels, biochemicals, and hydrocarbon chemicals via the fast pyrolysis platform. Biofuels 6:57–67

Choi J, Lee S (1997) Process analysis and economic evaluation for poly(3-hydroxybutyrate) production by fermentation. Bioprocess Eng 17:335

Peters MS, Timmerhaus KD, West RE (2003) Plant design and economics for chemical engineers. McGraw-Hill Education, New York

Aden A, Ruth M, Ibsen K, Jechura J, Neeves K, Sheehan J, Wallace B, Montague L, Slayton A, Lukas J (2010) Lignocellulosic biomass to ethanol process design and economics utilizing co-current dilute acid prehydrolysis and enzymatic hydrolysis for corn stover. National Renewable Energy Laboratory, Golden

Humbird D, Davis R, Tao L, Kinchin C, Hsu D, Aden A, Schoen P, Lukas J, Olthof B, Worley M, Sexton D, Dudgeon D (2011) Process design and economics for biochemical conversion of lignocellulosic biomass to ethanol. National Renewable Energy Laboratory, Golden

Sharma R, Lamsal BP, Colonna WJ (2016) Pretreatment of fibrous biomass and growth of biosurfactant-producing Bacillus subtilis on biomass-derived fermentable sugars. Bioprocess Biosyst Eng 39:105

Ibrahim MHA, Steinbüchel A (2010) Zobellella denitrificans strain MW1, a newly isolated bacterium suitable for poly(3-hydroxybutyrate) production from glycerol. J Appl Microbiol 108:214–225

Marti ME, Colonna WJ, Reznik G, Pynn M, Jarrell K, Lamsal B, Glatz CE (2015) Production of fatty-acyl-glutamate biosurfactant by Bacillus subtilis on soybean co-products. Biochem Eng J 95:48–55

Khan AW, Rahman MS, Zohora US, Okanami M, Ano T (2011) Production of surfactin using pentose carbohydrate by Bacillus subtilis. J Environ Sci 23:S63–S65

Park YC, Jun SY, Seo JH (2012) Construction and characterization of recombinant Bacillus subtilis JY123 able to transport xylose efficiently. J Biotechnol 161:402–406

De vuyst LUC, Vandamme EJ (1992) Influence of the carbon source on nisin production in Lactococcus lactis subsp. lactis batch fermentations. Microbiology 138:571–578

Lengeler JW, Drews G, Schlegel HG (1999) Biology of the prokaryotes. Blackwell, New York

Stulke J, Hillen W (2000) Regulation of carbon catabolism in Bacillus species. Annu Rev Microbiol 54:849–880

Surfactin cost in Sigma Aldrich. http://www.sigmaaldrich.com/catalog/product/sigma/s3523?lang=en®ion=US. Accessed 10 Apr 2018

Ashby RD, McAloon AJ, Solaiman DKY et al (2013) J Surfactant Deterg 16:683

Lang S, Wullbrandt D (1999) Rhamnose lipids—biosynthesis, microbial production and application potential. Appl Microbiol Biotechnol 51:22

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, R., Lamsal, B.P. & Mba-Wright, M. Performance of Bacillus subtilis on fibrous biomass sugar hydrolysates in producing biosurfactants and techno-economic comparison. Bioprocess Biosyst Eng 41, 1817–1826 (2018). https://doi.org/10.1007/s00449-018-2004-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-018-2004-2