Abstract

Purpose

Brewers spent grain (BSG) is a by-product of the brewing process corresponding to around 85% of total by-products generated. The great number of publications over the last 5 years, on the biotechnological applications of BSG, represents the increased scientific interest on it. This critical, state of the art review aims at gathering and analysing the most recent scientific efforts on the biotechnological potential of Brewer’s spent grain and on its evaluation as a feedstock for high added value products.

Methods

The assiduous bibliographic retrospection focused on the latest scientific reports. The consideration of all relevant scientific articles was thorough and critical. The classification of the scientific efforts was made not only according to the end-products but also according to the biotechnological approach adopted.

Results

BSG has been used in a wide range of biotechnological applications such as substrate for enzymes production, as a source for value-added products (antioxidants, monosaccharides, oligosaccharides, xylitol, arabitol, bioethanol, biogas or lactic acid) or for the production of functional proteins and lipids. Its applications as a carrier in various bioprocesses have also been reported.

Conclusion

The implementation of BSG’s fractionation in industrial scale seems to be the next step in BSG’s exploitation. A fractionation process which allows the exploitation of biomolecules belonging to different classes, produced from one feedstock (BSG) may be used as a pattern for the implementation of the biorefinery concept in industrial scale, as long as the methods adopted ensure the functionality of the potentially valuable components.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Generation of Brewers Spent Grain

Brewers spent grain (BSG) is the main solid by-product of the beer production process (brewing). Figure 1 shows BSG’s generation during this process which consists of six key stages: Malting, milling, mashing, brewing, cooling and fermentation. During the enzymatic conversion (mashing) of barley starch to fermentable sugars (mainly maltose, and maltotriose) and non-fermentable sugars (dextrins), proteins are also partially degraded to polypeptides and amino acids. After this hydrolytic process, a filtration step (lautering) follows and finaly a sweet liquid (wort) is produced. Wort contains the fermentable sugars to be converted to ethanol in the fermentation stage of the brewing process. The insoluble, undegraded part of the malted barley grain is allowed to form a bed in the mash tun and the sweet wort is filtered through it (lautering). The residual solid fraction obtained after this stage is known as BSG [1]. Depending on the kind of beer produced, adjuncts (other cereals, usually maize or wheat) may be added to the barley malt. In these cases, at the end of the mashing process, the insoluble part of these grains is separated with the undegraded part of the malted barley grain [2].

Composition of BSG

The chemical composition of BSG varies according to barley variety, harvest time, malting and mashing conditions, and the quality and type of adjuncts added in the brewing process [3]. It mainly consists of barley grain husks while fragments of endosperm may also be present. Thus the composition of BSG as described in the literature contains mainly hemicellulose in the form of arabinoxylans from the barley grain, cellulose and significant quantities of proteins and lignin. Lipids and residual endosperm starch can also contribute of the dry weight of BSG, while the presence of minerals and vitamins has also been reported [4]. As shown in Table 1, non-starch polysaccharides (NSP: Arabinoxylan, cellulose/glucan) constitute from 30% up to 50% of BSG dry weight, with arabinoxylan to be the most abundant ingredient (20–40% w/w). Most bibliographic data report an arabinose to xylose ratio about 0.5, while barley husk arabinoxylans have been reported to have lower arabinose to xylose ratios than xylans in the inner part of the grain. Traces of rhamnose and galactose have also been found in BSG [1, 12]. Protein content varies a lot (10–30%), depending on brewing technology, on adjuncts used and on the malt/beer source [7]. The most abundant proteins in BSG are hordeins (prolamins in barley), glutelins, globulins and albumins with hordeins to constitute the major part [5]. During the brewing process most of them remain in BSG as they are located inside the aleuronic cells and in the starchy endosperm fragments. Lignin represents about 15–25% of total dry weight, while starch content remains in most cases under 5%.

Commercial Potential of BSG

According to FAO (http://faostat.fao.org/) more than 176 million tonnes of beer from barley were produced worldwide in 2008 and about 168 million tonnes in 2009. BSG represents about 85% w/w of the total solid by-products (spent grain, trub, spent hops, spent yeast and diatomaceous earth slurry from filtration) generated during the brewing process which correspond to an annual production of more than 34 million tones of wet BSG (8.5 million tones of dry BSG). BSG has a low commercial value as it is usually sold as by-product for livestock feed due to its high content of un-degradable protein and water soluble vitamins [13]. Wet BSG needs to be used in close proximity to the plant producing them, since it contains large amounts of water (75–80%) and transportation can be expensive. Thus, a common practice is to discard BSG to landfill which, if left uncontrolled can lead to environmental problems. On the other hand, the water that it contains maybe very advantageous to livestock producers in areas where water quality and supply are limited.

The low commercial value of BSG and the problems associated with its disposal as co-product for livestock feed has lead the industry and scientific community in exploring alternative exploitation ways. Various potential applications for BSG have been explored taking advantage of its physicochemical properties. It has been used in building materials [14]. or as a raw material in paper manufacturing industry due to its low ash content and its high amount of fibrous material [15]. Energy production from BSG through direct combustion is another alternative proposed in the past [16, 17] although environmental issues are connected with this use due to significant quantities of NOx generated and dust particle emissions. It has also been used for the production charcoal bricks [1] and also tested as adsorbent for several types of compounds [18].

Biotechnological Potential of BSG

A comparison between the recently published works on BSG’s commercial potential and older articles which are summarised in the concise review on BSG general applications by Mussatto et al. [1], show that the published works have significantly increased over the last 6 years. The majority of them are studies dealing with biotechnological applications. Later reviews dealing with BSG show the growing general interest in the by-products of the brewing industry but they do not focus neither thoroughly describe the biotechnological potential and applications of BSG [2, 19].

Most of the potential uses mentioned in Sect. 1.3 have limited applicability in industrial scale. Many potential biotechnological applications have been investigated as an alternative to overcome the environmental problems associated with BSG’s disposal and/or combustion. Although of low calorific value and high moisture content, and thus, not suitable for direct energy production, BSG has a very “interesting” and promising composition for biotechnological applications due to high protein, hemicellulose and phenolics contents. During the past decade the increased number of publications dealing with this by-product and the results obtained as well, have shown that compounds obtained from BSG’s degradation (or fractionation) would be of industrial interest. This review article is focused on the biotechnological processing of BSG with regard to its potential uses in the food, chemical, pharmaceutical and biofuels industry.

BSG as a Substrate for Microorganisms’ Cultivation and Enzymes Production

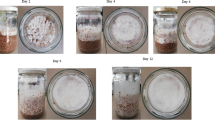

BSG has been used as a substrate for the cultivation of fungi, bacteria and mushrooms due to its physical properties such as particle size, volume weight, specific density, porosity and water holding capacity (BSG particles’ size varies from 2 to 5 μM. BSG can contain up to 85% moisture, its average density is about 450 g L−1 and its packing density may be from 450 g L−1 up to 900 g L−1 [1]). Moreover, the high polysaccharide, minerals and protein contents make BSG able to support cultivation of many microorganisms as a sufficient source for most necessary ingredients, under various cultivation conditions (Fig. 2). Most of these attempts aimed at producing hydrolytic enzymes such as amylases, cellulases, hemicellulases and proteases. Table 2 summarises the most recent attempts on enzyme production using BSG as the substrate.

BSG as appears in SEM (scaning electron microscopy) photos. a Untreated material. b Fungal growth on BSG under submerged conditions. c Fungal growth under solid state conditions. All samples were gold coated. Observations were made under high vacuum using Solid State Detector for photos a and b while c is a digital mixture from two detectors (Everhart–Thornley Detector and Solid State Detector)

Amylases

Amylases family includes α-amylase (EC 3.2.1.1, classification adopted by the International Union of Biochemistry and Molecular Biology where enzymes are classified in classes and subclasses defined according to the reaction catalyzed) β-amylase (EC 3.2.1.2) and amyloglucosidase or glucoamylase (EC 3.2.1.3). Amylases are of great significance in present-day biotechnology. Although they can be derived from several sources, such as plants, animals and micro-organisms, the enzymes from microbial sources generally meet industrial demands. Known as excellent hydrolytic enzyme producers, many Aspergillus strains have been tested using BSG as substrate for amylases production. Earlier Francis et al. [21] and more recently Xu et al. [22] reported that impressive amount of α-amylase was produced from Aspergillus oryzae using BSG as the substrate under solid state cultivation. The same study concluded that the enzyme production obtained from BSG was favourably compared to those by the same microorganism grown on other agro-industrial products (wheat bran supplemented with soluble starch, mix of wheat bran, sunflower oil meal and sugar beet oil cake, coconut oil cake with or without added starch) supplemented with organic nitrogen sources under various conditions.

Patel et al. [23] and lately, Hashemi et al. [24] have shown that BSG was able to support α-amylase production even when used as the sole provider of minerals and nutrients in the culture broth while it was proven beneficial for enzyme production when used as an additive in rich cultivation medium. Adeniran et al. [25] have also shown that BSG was able to support β-amylase and amyloglucosidase production. However, the BSG’s composition presented in that study is in contrast with most data in the literature, raising questions about the nature and origin of the material used.

Cellulases and Hemicellulases

Cellulases and hemicellulases are two very large families of hydrolytic enzymes which play a main and crucial role in plant biomass bioprocessing. Some of their many industrial applications include cotton processing, paper industry, juice and fruit processing, and also applications as detergent enzymes and as animal feed additives. However, the most challenging application is the development of an economic process for the solubilization of lignocellulose material to serve as a renewable energy and carbon source. From the great majority of the reports on microbial production of cellulases and hemicellulases it is shown that the (usually lignocellulosic) substrate type has the greatest impact on lignocellulolytic enzymes secretion. Certain substrates may significantly stimulate lignocellulolytic enzyme synthesis without supplementation of the culture medium with specific inducers.

It has been a longtime since BSG was first used as substrate for lignocellulolytic enzymes production. Early attempts were made from 1978 to 1990 using Aspergillus awamori and Trichoderma reesei, respectively [1]. Similar works in 90’s showed that BSG could be used as carbon source and cellulase inducer for various microorganisms. It is microorganisms’ biodiversity the most invaluable source of carbohydrate active enzymes (CAZymes): Microorganisms belonging to largely different taxa such as Ascomycota, Basidiomycota, Actinomycetes, Bacilli, are known as good producers of cellulases and hemicellulases. However, representatives of the phylum Ascomycota (such as Aspergillus sp., Trichoderma sp., Fusarium sp., Neurospora sp.) have been most extensively studied for the production of lignocellulolytic enzymes. Many of those called filamentous fungi are natural degraders of lignocellulosic materials as many wild types grow naturally in such environments. Many of these fungi have been studied with regard to the production of cellulases and hemicellulases using BSG as substrate (or co-substrate) (Table 2).

Different techniques have been implemented for the production of xylanolytic enzymes from BSG (Table 2). Both submerged and solid state cultivations have given promising results. Microorganisms belonging to genera of Penicillium, Aspergillus, Humicola, Fusarium, Bifidobacterium have been successfully cultivated on BSG, secreting significant amounts of hemicellulolytic enzymes. Arabinofuranosidases, Feruloyl esterases (FAEs) and xylanases are the hemicellulolytic activities most frequently produced in large amounts using BSG. Earlier studies [1, 2] indicated that BSG could be a suitable substrate for xylanolytic enzymes production. More recently, Mandalari et al. [26] used BSG for the simultaneous production of xylanase and feruloyl esterase by Humicola grisea and Talaromyces stipitatus. In that work a comparative study between BSG and WB (Wheat Bran) cultures of H. grisea and T. stipitatus showed higher production not only for xylanase but also for Feruloyl esterase (FAE) on BSG, (probably due to a better solubilization of this material utilised by the fungi). The maximum xylanase activity by H. grisea on BSG was 16.9 U/mL, while maximum FAE activity was 0.47 IU/mL and 0.33 IU/mL on BSG and WB, respectively. Similar levels of xylanase activity were obtained by Terrasan et al. [27] using the mesophilic fungus Penicillium janczewskii. Activities as high as 15.19, 0.16 and 0.67 IU mL−1 were obtained for xylanase, β-xylosidase and α-l-arabinofuranosidase, respectively when 2% w/v BSG was used under submerged conditions as carbon source for xylanolytic production [27]. Aspergillus fumigatus was grown under solid state cultivation on BSG. The secreted cellulolytic activities measured were 5.03 IU g−1 and 17 IU/g for Filter Paper (FPA) and Endoglucanase (CMC) activities, respectively [28].

BSG has been used as a substrate for lignocellulolytic enzymes production by Fusarium oxysporum and by Neurospora crassa not only under submerged but also under solid state conditions [10, 29, 30]. BSG was used as the sole carbon source supplemented with inorganic minerals but also in combination with other agro-industrial residues resulting in all cases in very good levels of lignocellulolytic enzymes secretion. The production of a battery of xylanolytic enzymes (Xylanase, β-xylosidase, FAE, acetyl esterace and α-l-arabinofuranosidase) from BSG has also been reported by F. oxysporum in stired tank bioreactor under submerged [30] and under solid state conditions in horizontal bioreactor [29]. N. crassa was also found able to grow on BSG under solid state conditions (in horizontal bioreactor) producing activities as high as 1,073, 3.1, 5.7 and 0.52 IU g−1 dry carbon source for xylanase, α-l-arabinofuranosidase, acetyl esterase and feruloyl esterase, respectively [10]. However, in those studies it was shown that enzyme production increased when BSG was mixed with other agro-industrial residues in small quantities. Panagiotou et al. [31] used BSG as the substrate for the production of xylanase, FAE and α-l-arabinofuranosidase by Penicillium brasilianum under solid state cultivation, resulting in significant levels of produced activities. Medium composition as well as the pH and temperature were shown to be very important parameters for the production of feruloyl esterase, xylanase, and Arabinofuranosidase by P. brasilianum grown on BSG under solid state cultivation. Apart from biological factors (microorganism, inoculum) and the carbon source itself, the parameters that mostly affect the cellulolytic and hemicellulolytic enzyme production on BSG are moisture (under solid state cultivation), pH, nitrogen source and temperature. Organic nitrogen sources like corn steep liquor were in many cases favorable for enzymatic production, while optimal moisture levels vary according to other factors such as the microorganism involved, or the BSG particles’ size in the solid state culture [10, 28, 29, 31].

Apart from filamentus fungi, BSG has been proven a promissing substrate for other microorganisms such as Actinomycetes and Bacilli. Streptomyces malaysiensis [32] was able to grow and produce good levels of CMCases (720 UL−1) using solely brewer’s spent grain and corn steep liquor as low-cost substrates supplemented with a mineral source. The growth of Actinomycetes (Streptomyces sp.) using the protein fraction from BSG has been reported by Szponar et al. [33] concluding that medium composed of BSG protein fraction extract allowed the isolation of actinobacteria, especially Streptomyces, from soil samples, and enhanced the sporulation. The authors proposed the medium containing the BSG protein fraction as a cheap and easily preparable medium for the isolation and maintenance of unknown strains from culture collections which also could be suitable for screening, for the production of new biologically active substances and fast spores production. Lactobacilus strains have also found capable of growing on BSG producing hemicellulolytic enzymes. From all the lignocellulosic materials and residues (apple pectin, maize amylopectin, wheat bran, rye bran, larchwood arabinogalactan, BSG) that Szwajgier and al. [34] tested for FAE production using Lactobacilus acidophilus K1, BSG resulted in a remarkable (comparatively higher) FAE yield.

Bifidobacterium sp. strains have been cultivated for FAE production using BSG as the carbon source [35]. The supernatants obtained from B. longum KN 29 and B. catenulatum KD14 cultivations with BSG, exhibited FAE activities after 27 and 33 h. However, FAE activities detected in the supernatants of all Bifidobacterium strains cultivated using BSG were significantly lower than the corresponding FAE activities obtained using phenolic acids methyl esters as carbon sources. Media containing the polysaccharide and protein fractions of BSG have been used for Bifidobacteria and lactic acid bacteria cultivation without any additives by Novik et al. [36]. The results obtained in this study indicated that the protein and polysaccharide fractions of BSG could be used as components of media for cultivation of probiotic bacteria. The fact that both fractions were proved suitable for bacterial growth indicates that untreated BSG could also be applied for prebiotics production.

Proteases

Proteases are found in plants, animals and microorganisms. However, microorganisms are the preferred source of proteases due to their broad biochemical diversity and their susceptibility to genetic manipulation. An attempt for production of proteases by fungi using BSG as substrate showed that the protease production from BSG was significant under submerged conditions, while solid state cultivation was proven less effective [37].

BSG as Substrate for Mushrooms Cultivation

The carbon sources utilized by basidiomycetes in nature are usually of a lignocellulosic character. Thus, many researchers have used lignocellulosic residues for mushrooms cultivation. Cereals or their by-products are widely used as substrates or supplements, as they are generated in considerable amounts and contain increased levels of protein, fats and easily metabolized carbohydrates. The genus Pleurotus comprises some of the most popular edible mushrooms due to their favourable organoleptic and medicinal properties, fast mycelial growth and undemanding cultivation conditions. Early attempts on the cultivation of P. ostreatus, using BSG concluded that the fruit bodies of P. ostreatus grown on spent grain substrate had higher biological efficiency, higher amino acid content, and higher crude protein content than those cultivated on other reported substrates [1]. When Pleurotus species (P. ostreatus and P. Pulmonarius) were cultivated using BSG alone or mixed with maguey tequila bagasse, a higher growth rate and biomass production were achieved with the SBG agar than with malt extract agar while in the field phase, the mixture of SBG and bagasse resulted in earlier fruiting bodies formation [38]. More recently, Gregori et al. [39] cultivated P. ostreatus on BSG mixed with wheat bran and beech sawdust achieving significantly high biological efficiency. In that study the production of peroxidase was also monitored, showing that BSG with the addition of WB (wheat bran) was suitable as substrate for peroxidase production. However, the composition of BSG used in each case was a crucial factor not only for the biological efficiency of the cultivation but also for the enzyme activities produced.

Production of High Added Value Products from BSG: Fractionation into Basic Biochemical Classes

The exploitation of proteins, carbohydrates, lipids, phenolics and lignin contained in BSG, presupposes that the functionality of the ingredient in question is kept through the fractionation process. Chemical extractions, while achieving high quantities of released products, could destroy other components or reduce the bioactivity of the compounds recovered. Enzymatic fractionation and solubilization methods are preferable as they take advantage of enzymes’ high selectivity and thus allow more targeted and effective fractionation processes. Various approaches, implementing different enzymes’ families, are used in order to solubilize or isolate different ingredients.

Carbohydrates Fraction

Cellulose and arabinoxylan constitute the greater part of NSPs in BSG. Three types of enzymes are necessary for the complete conversion of cellulose to glucose: Endoglucanases (EG), cellobiohydrolases (CBH) and β-glucosidases (BG), while lately a forth type of enzymes (family GH61) has been reported to be concerned in cellulose hydrolysis although its role is not clearly defined yet [40]. Two stages could be distinguished in cellulose enzymatic hydrolysis: primary hydrolysis, involving the release of soluble intermediates from the surface of reacting cellulose molecules (EG, CBH) and secondary hydrolysis, involving hydrolysis of soluble intermediates to lower molecular weight intermediates (EG, CBH), and ultimately to glucose (EG, CBH, BG). A more complicated enzyme profile is needed for complete hemicellulose hydrolysis due to the presence of many different substitutes corresponding to different types of side bonds on this biopolymer. Xylanases, β-xylosidases, FAEs, acetyl esterases, glucuronidases, glucuronoyl esterases and α-l-arabinofuranosidases are the major types of enzymes involved in hemicellulose degradation. Enzymes work in synergy to break down arabinoxylan (AX), mainly due to the heterologous nature of the polysaccharide, and sidechain-acting enzymes are required to facilitate the access of the main-chain-acting xylanases to the polymers [41].

The sugars’ recovery process to be chosen depends on the desired extent of hydrolysis and on the products required. A mechanical or a chemical pre-treatment step is often applied in order to make polysaccharides more accessible to enzymes. The bioconversion of polysaccharides to monosaccharides necessitates the use of multienzyme cocktails, while the recovery of oligosaccharides demands the realization of the hydrolytic reactions in the absence of specific enzyme activities (in the absence of β-glucosidases in the case of cellulose). Accordingly, complete hydrolysis of the xylan backbone (Xylanase) prerequisites the cleavage of the side bonds, while xylooligosaccharides recovery prerequisites the absence of β-xylosidases. Moreover, the variety of hemicellulose in nature imposes specific enzymes selection according to the nature and the composition of each substrate [42]. Therefore, enzymatic processing of BSG polysaccharides can be targeted on specific products (oligosaccharides, monosaccharides) through the design of the enzyme mixtures used.

Enzymatic Processing of the Carbohydrates’ Fraction

Enzymatic recovery of mono- and oligo-saccharides A large percentage of the carbohydrates which are not digested in the human small intestine but provide fermentable carbon sources for bacteria that inhibit the large bowel are derived from cereals, and thus arabinoxylans [43]. Such polysaccharides (present in large quantities in BSG) can be degraded by the hydrolytic enzymes produced by the microorganisms into oligosaccharides. The oligosaccharides isolated through hydrolysis of the polysaccharides have potential as prebiotics with a large range of applications in food and pharmaceutical industry as they are ingested by the bacteria which in turn produce short-chain fatty acids and other metabolites [44].

Carvalheiro et al. [11] studied the production of xylo-oligosaccharides (XOS) from autohydrolysis of BSG in various temperatures for various time periods. In that study, autohydrolysis was conducted with the aim of establishing the optimal conditions for XOS production. However, it was shown that autohydrolysis of BSG hemicelluloses gave predominantly XOS that were randomly hydrolysed leading to sugar monomers via progressively shorter oligomers. Vegas et al. [45] produced significant amounts of XOS form BSG using similar methods but did not distinguish differences concerning the DP of the XOS produced. Hydrothermal treatment of BSG resulted in a wide variety of xylo-oligosaccharides with different structural features due to the partial release of the xylan substituents and cleavage of the xylan, depending on the xylan-structure of initial material. Under the study conditions significant amounts of xylo-oligosaccharides linked with arabinose were identified [46].

Early attempts on enzymatic degradation of BSG were made back in 80’s [1] (BSG’s hydrolysis using various commercial enzyme products results in extended variety of hydrolysis products, depending on the pretreatment (chemical or physical) of the initial material and the enzymes involved in the process. Similarly, the enzyme extracts from various Trichoderma spp. cultures had different effects on cellulose and hemicellulose bioconversion of BSG depended on the enzyme activities present [47], while more recently it was shown that treatment of BSG with Trichoderma ligninocellulolytic enzymes increased significantly the solubilized polysaccharides fraction [48].

As shown in Table 3, most of reports on enzymatic degradation of BSG polysaccharides have used multienzyme cocktails (complex commercial preparations or crude enzyme extracts). When multienzyme commercial preparations were used for the production of monosaccharides from BSG liquor obtained by autohydrolysis (liquid:solid 8:1, 190°C, 2 min), quite high yields were achieved with arabinose recoveries almost 75%, xylose recoveries about 63%, and glucose recovery close to 100% [49]. Mussatto et al. [50] investigated BSG’s cellulose conversion to glucose by the commercial Celluclast 1.5 L, as a function of the lignin and hemicellulose content in BSG. The study concluded that the lower the hemicellulose and lignin contents in the BSG sample, the better the performance of cellulose enzymatic hydrolysis into glucose. The same group studied the influence of agitation speed, enzyme loading and substrate concentration on enzymatic hydrolysis of cellulose from BSG, concluding that enzyme loading had the greater impact on glucose yield from all factors investigated [51]. Lately, Pierre et al. [52] performed a thermomechanical pretreatment (DIC: Détente Instantanée Contrôlée) prior to enzymatic hydrolysis. Under optimized conditions, the process achieved a very high glucose yield (close to theoretical) using the commercial enzymes Celluclast 1.5 L and Novozym-188. However, the cellulose saccharification yields calculated are based on the determination of total reducing sugars, which in combination with the extremely high content of starch in that material (23%w/w), make those results rather unclear.

Ligninocellulolytic enzymes produced by N. crassa [10] and F. oxysporum [30] successfully hydrolyzed cellulose and hemicellulose from untreated and alkali treated BSG. A battery of enzymes included in the crude enzyme extracts used in those studies resulted in high monosaccharides yields. The yield of saccharification by F. oxysporum enzymes reached 47% (40% of total pentose content and about 70% of total glucose content) based on total sugars content of the initial material, while the released sugars (glucose, xylose, arabinose) from pre-treated BSG using the enzyme extract from N. crassa achieved a yield about 50% of total pentose content and about 60% of total glucose in the material. Similar saccharification yields were achieved by Panagiotou et al. [31] using Penicilium brasilianum crude enzyme extract (maximum released levels of xylose and arabinose were 39 and 43%, respectively). In that study an increase in released arabinose: xylose ratio as a function of time was observed indicating a correlation between the arabinose content and the mode of action of xylanolytic enzymes. Lately the factors affecting cellulose and hemicellulose hydrolysis from BSG have been thoroughly described confirming this observation [42]. Cellulose conversion to glucose mainly depended on end-product inhibition and on enzyme dosage used, while the high arabinose to xylose ratio in alkali treated BSG was the main obstacle during hemicellulose hydrolysis by F. oxysporum enzyme extract. The cleavage of 1–3 bonds between arabinose substitutes and xylan backbone was found to be a prerequisite in order to achieve high xylose and arabinose release from BSG.

Important clues on the importance of the enzymes activities present in hydrolytic reactions on the kind of XOS and monosaccharides produced from BSG have also been demonstrated by Forsell et al. [12]. The enzyme activity profile used in that study had a significant impact on the chemistry of the oligosaccharides solubilised from BSG. Carbohydrate acting enzymes were also used together with proteases for BSG solubilization. It was shown that inhibition of protease/esterase activity made little difference in the solubilization of BSG by Depol 740, signifying that xylanase activity played a major role in solubilization. However, the results obtained suggested that a combination of proteolytic and glycolytic activity was required to deconstruct BSG [53].

Commercial proteases have also been tested for the solubilization of BSG’s carbohydrates [54]. Proteases were found able to remove residual glucose-based oligomers remaining after the mashing process, while small amounts of feruloylated arabinoxylan were also released. Those findings suggested that a starch/arabinoxylan portion of malted barley might be contained within a proteinaceous barrier which had either been untouched during malting and mashing, or was formed during the brewing process. BSG enzymatic degradation was studied in pilot scale proteolytic and glucolytic commercial enzymes [55]. Cellulose- and hemicellulose-derived oligosaccharides were produced by the action of the carbohydrate-degrading enzymatic cocktail, while the protease treatment released a peptide-enriched hydrolysate. Approximately half of the original BSG solids were solubilized during the two-stage enzymatic process (14 and 36% of initial BSG dry matter was liberated by carbohydrase and protease, respectively). Although the protease efficiently released the majority of BSG proteins, the carbohydrate matrix was proved much less accessible to enzyme attack [55]. Recently Robertson et al. [56] have used various commercial enzymes for BSG fractionation. Various combinations of enzymes (carbohydrate and protein-degrading enzymes) were involved in different enzymatic treatments. A significant proportion of BSG (25–30%) was solubilised but the release of polysaccharide components remained limited in all cases. It was speculated that complete hydrolysis of arabinoxylan prerequisite the delignification of the material. The cellulose remained almost intacted probably due to the lack of significant amount of cellulases in the enzyme cocktail used.

Enzymatic Production of Antioxidants from BSG The antioxidant activity of soluble dietary fiber fractions isolated from BSG was recently investigated by Fu et al. [57]. Both crude and grade (isolated by gel filtration chromatography) dietary fiber fractions showed antioxidant and free radical scavenging activities on hydroxyl radicals, on superoxide radical and on 2, 2-Diphenyl-1-picrylhydrazyl radical. Phenolic acids are the main antioxidant compounds present in cereals. BSG contains up to 8 mg of phenolic acids/g dry material. Their high antioxidant activity is well recognized with extended applications in food industry [42, 48, 57]. The enzymatic recovery of hydroxycinnamic acids, the main phenolic acids in BSG, can liberate a large proportion of these wall-bound phenolics [7]. The main hydroxycinnamic acids, ferulic (FA) and p-coumaric acid (pCA) are localized in the outermost layers of barley and thus through the brewing process they remain in BSG in significant quantities. Small quantities of p-hydroxybenzaldehyde are also present in BSG, as well as vanillin and diferulic acids formed through oxidative coupling during pant cell growth [58]. FA is probably the most abundant of all phenolic acids in BSG with an average content of alkali extractable FA about 2 mg/g dry BSG [59, 60].

FA released from plant cell wall by the action of feruloyl esterases (FAEs; E.C. 3.1.1.73) is an effective natural antioxidant with potential applications in the pharmaceutical and food industries. Moreover, there is a growing interest in the potential use of FA as feedstock for the biocatalytic conversion into other valuable molecules such as styrenes, polymers, epoxides alkylbenzenes, vanillic acid derivatives, protocatechuic acid-related catechols, guaiacol, catechol and vanillin [61]. FAEs, also known as cinnamoyl esterases, represent a subclass of carboxylic acid esterases that catalyses the hydrolysis of the ester bond between hydroxycinnamic acids and sugars present in plant cell walls. FAEs have been classified into four types (A-D) based on their specificity towards mono- and diferulates, for substitutions on the phenolic ring, and on their amino acid sequence identity [62]. FAEs synergistically work with xylanases, even though, unlike the studies with other AX-acting enzymes, there is no directly linked common substrate [63].

The great majority of reports on enzymatic liberation of hydroxycinnamic acids from BSG have been published over the last decade, showing the growing interest on BSG as a source of natural antioxidants (Table 3). Faulds et al. [64] achieved to liberate enzymatically about 65% of the total alkali extractable FA in BSG by the commercial xylanolytic enzyme extract Ultraflo. The observations suggested that liberation of FA and its dimeric forms present in BSG require the addition of more than one type of xylanase in the reaction mixture. Moreover it was speculated that FA is not solely attached to arabinoxylan in the barley cell wall, or that the cell wall polysaccharides in BSG hinder the accessibility of enzymes to the ferulates, due to processing treatments [64]. Enzyme extracts presenting FAE and xylanase activities, produced by Streptomyces avermitilis CECT 3,339 grown on BSG, were able to liberate 43% of the alkali extractable FA from BSG [65]. Even though equal activities of FAEs were used in those hydrolysis experiments, the differences in FA release observed reflected the significance of xylanase activity for efficient FA liberation as well as the significance of the substrate specificity for measuring the activities of different types of FAEs. Very low [66] or no FA release at all [67] has been observed from BSG when FAEs act in the absence of xylanase, while the type of xylanase (families 10 or 11) is significant for the type of hydroxycynamic acid release. In general, family 11 xylanases were the preferred synergistic partners with feruloyl esterases for the release of ferulic acid, while family 10 xylanases were preferred for the liberation of diferulic acid. The ability of the different xylanases to produce xylo-oligosaccharides from feruloylated polysaccharides is determined both by the enzyme’s specificity and by the location of feruloyl groups within the arabinoxylan chain. Consequently, the generation of feruloylated oligosaccharides of different length and structure by the different xylanases will contribute to the rate of ferulic acid release by the feruloyl esterases. [68]. It has also been suggested that sterically hindering surrounding polymers do not allow greater access for feruloyl esterases to the dimers although access to the monomer is not so restricted [69]. Moreover, the high complexity and/or the high arabinose content in BSG’s arabinoxylan also impact the enzymatic release of hydroxycynamic acids from this material. During hydrolysis the highly substituted xylose residues in the xylan backbone and the arrangement of feruloylated arabinose substitutions on the arabinoxylan significantly impact phenolics acids release.

The enzymatic production of feruloylated xylooligosaccharides from BSG, presenting high antioxidant potential, has been achieved by enzymatic treatments in the absence of FAEs, while the presence of FAE activity in the enzyme cocktail resulted in the production of free ferulic acid [12]. The presence of proteases in the enzyme cocktail also impacts FA release from BSG, although the proteases do not cleave the hydroxycinnamate ester linkages present on the arabinoxylan backbone, and thus do not behave as feruloyl esterases. BSG derived material, solubilised by proteases, contained up to 198 mg bound ferulic acid/g extract, which represented 8.6% of the total ferulic acid present in BSG [54]. The fact that FA release during reactions by crude enzyme extract of F. oxysporum was almost 2.5 folds higher than the one achieved by the synergistic action of a purified FAE (FoFaeC-12213) and T. longibrachiatum M3 xylanase was partially attributed in the presence of significant amounts of proteases in the crude extract. The treatment with proteases (Alcalase 2.5L or papain) simulating the protease content in the crude extract of F. oxysporum, enhanced significantly FA release by the monoenzymes FoFaeC-12213 and T. longibrachiatum M3 xylanase [60]. The above results show the crucial significance of the enzyme profile for the chemistry of the oligosaccharides produced during hydrolysis as well as the flexibility of the biotechnological processing for the production of antioxidants from agro-industrial residues.

Microbial Processing of the Carbohydrates’ Fraction

Currently, a number of added-value bioproducts such as organic acids, amino acids, vitamins, ethanol, butanediol, among others, are produced by fermentation using glucose or xylose as substrates. Agro-industrial by-products such as BSG are considered as cheap and promising raw materials for such processes, due to their high carbohydrates content and their extended availability. Several studies have dealt with the fermentation of sugars for the production of organic acids, sweeteners or ethanol by yeasts or fungi. The most recent scientific reports are summarized in Table 4.

Production of Xylitol from BSG Among the polyols produced by yeasts (especially by Candida guilliermondii, Candida parapsilosis, Candida tropicalis, and Candida boidini), xylitol and arabitol are of the greatest potential interest mainly due to their use as additives in food industry, and other characteristics that allow application in pharmaceutical products. Xylitol stands out among other sweeteners not only because it can be produced by biotechnological process, but also because it has important physicochemical and physiological properties. The key enzymes for xylitol production in yeasts and fungi are D-xylose reductase which, using either NADH or NADPH, reduces D-xylose to xylitol and predominantly, NAD-linked xylitol dehydrogenase which reoxidizes xylitol to D-xylulose. Xylitol accumulation in yeasts is sensitive to cultivation conditions. Among them, substrate and aeration are crucial for yeast growth and fermentation [70].

Hemicellulosic hydrolysates derived from agricultural residues are widely used as feedstocks for xylitol production. The use of BSG has received much attention due to the high xylose content in BSG (20–30% w/w). Besides, BSG contains a large variety of minerals that favor the bioconversion of xylose to xylitol by many yeasts which require oligoelements and vitamins for growth and for enhancing xylitol productivity. Xylitol production from BSG hydrolysate has been successfully performed by C. guilliermondii reaching 0.70 g of xylitol per g of xylose consumed [9].

Due to the presence of inhibitory components (phenolics, furfural, acetic acid, etc.), some BSG hydrolysates (especially those produced under acid conditions) have to be treated prior to microbial utilization. Mussatto et al. [71] have used the yeast C. guilliermondii for the production of xylitol from BSG hydrolysate. The xylose-to-xylitol bioconversion from hydrolysate medium was decreased when condensed hydrolysate was used, fact that could be attributed to the high concentration of toxic compounds present. The treatment of such BSG’s hydrolysates with activated charcoal is a promising detoxifying method. Such treatments can partially remove the toxic compounds and increase xylitol production [72]. Recently, the inhibitory effects of certain compounds such as acetic acid, ferulic acid, and syringaldehyde on metabolism of C. guilliermondii during xylose to xylitol bioconversion were evaluated, concluding that although these compounds affect the growth of C. guilliermondii, their complete removal from the fermentation medium is not necessary in order to obtain efficient conversion of xylose to xylitol [73].

The sugars’ composition in the hydrolysate may also affect xylitol production. The presence of glucose (which is a more readily metabolized sugar), in the hemicellulosic hydrolysates constitutes one of the main problems affecting the xylose fermentation from such hydrolysates, as it influence the xylose uptake. It has been observed that the presence of glucose in the fermentation medium at a concentration of 1/5 that of xylose was enough to cause a strong inhibition of the xylitol production by C. guilliermondii, while the presence of arabinose did not affect xylose metabolism [74]. Other parameters such as the fermentative yeast used and the initial xylose concentration in the fermentation medium are also important for the final production of xylitol from BSG (as for any hemicellulosic hydrolysate). Earlier findings on the evaluation of the xylitol production by two yeast strains, namely C. guilliermondii and C. parapsilosis showed that the optimum initial xylose concentration differed for those two strains and this was reflected in the xylitol production. As an explanation, it was assumed that the activity of the xylose reductase enzyme was depended on the initial xylose concentration [75]. Experiments with different initial concentrations have shown that the optimum initial xylose concentration for the bioconversion to xylitol by C. guilliermondii was 70 g/L. In that case a significantly high fermentative performance by C. guilliermondii was observed (YP/S = 0.78 g/g, QP = 0.58 g/(l h), and YP/X = 5.81 g/g) [76]. These data confirm the significance of xylose concentration in the fermentation and also show that BSG is a promising alternative raw material to produce xylitol in large scale, due to the low cost, the high availability and the high fermentative parameters that can be achieved without the necessity of adding nutrients to the media formulated by the non-detoxified hydrolysate.

Production of Lactic Acid from BSG BSG has been proposed as an attractive alternative to replace costly raw materials (glucose, sucrose or starch) for the biotechnological production of lactic acid using Lactobacillus strains. Lactic acid is an important chemical that has both food and industrial applications. It is used as an acidification factor, flavor and preservative in the food and pharmaceutical industry. It is also used as a starting material for manufacture of biodegradable poly-lactate polymers as lactic acid polymers present several advantages, such as biodegradability, bioenvironmental compatibility, fabric ability, thermo plasticity, and high strength. In 2004, Shindo and Tachibana [77] investigated the feasibility of BSG fermentation to lactic acid using Lactobacillus rhamnosus. The optimized process (addition of Tween 80, repeated batch fermentation) resulted in 19 g/L of lactic acid from BSG hydrolysate (obtained after a steam explosion treatment followed by enzymatic treatment with glucoamylase, cellulase, and hemicellulase) with a total sugar concentration of 40 g/L.

Lactic acid production from cellulose pulp obtained after chemical pretreatment of BSG has also been reported by Mussatto et al. [78, 79] The glucose produced from cellulose pulp by enzymatic hydrolysis was converted into lactic acid by Lactobacillus delbrueckii. The control of pH during the fermentation as well as the supplementation of the culture medium with MRS broth (except carbon source) resulted in 35.54 g/L lactic acid (0.99 g/g glucose consumed) with an initial volumetric productivity about 0.82 g*L−1 h−1. Lately, a mixture of barley husks, spent grains and grain fragments was used for production of gluco- and xylo-oligosaccharides which were afterwards fermented by bacteria present in human faeces, resulting in significant lactic acid production [80]. Succinate, formate, acetate, propionate and butyrate were also generated during fermentations, confirming the prebiotic potential of the barley by-products assayed [61].

Ethanol Production from BSG Lately the use of starch and sugar crops as raw materials in the biofuels industry has been for the subject of discussion. More and more scientific efforts are being made towards an efficient technology for the biological conversion of lignocellulosic materials to second-generation biofuels. The enzymatic hydrolysis of cellulosic materials to produce fermentable sugars has an enormous potential in meeting global bioenergy demand through the biorefinery concept, since agri-food processes generate millions of tonnes of waste each year. BSG has the potential to serve as a low-cost feedstock for the production of ethanol since hemicellulose and cellulose content corresponds to 50–55% w/w of dry material. Although the annual production of BSG is not considerable if used as a feedstock for fuel ethanol, it could be significant in the case that the ethanol produced is used as a platform intermediate in chemical industry.

Consolidated bioprocesses have been applied for ethanol production from BSG using lignocellulolytic fungi such as F. oxysporum [29, 30] and N. crassa [10] which have also the ability of fermenting the released glucose and xylose to ethanol. In these studies, it was found that the alkali treatment of BSG prior to hydrolysis and fermentation stages, enhanced ethanol production by 50% compared to the non treated material. Although the cultivation technique and the aeration during the fermentation stage had a significant impact on BSG bioconversion to ethanol, the hydrolysis of carbohydrates was shown as the crucial stage of the process. Under submerged optimized conditions (air flow 0.01 vvm) an ethanol yield of 109 g ethanol per kg of dry alkali-pretreated BSG was achieved, corresponding to 60% of the theoretical yield based on total glucose and xylose content of the material.

Fermentations of BSG’s hydrolyzate by Pichia stipitis and Kluyveromyces marxianus have also been reported by White et al. [81]. In this case, combinations of dilute acid (HNO3) and enzyme treatments were developed to convert the hemicellulose and cellulose fractions to glucose, xylose and arabinose. The ethanol yields achieved were 4.2 and 3.0 g of ethanol per 100 g of BSG, for P. stipitis and K. marxianus, respectively. The arabinose content of BSG (9–12% w/w) was not converted to ethanol in none of the above efforts. This is not surprising, as arabinose is hardly fermented by microorganisms. Although several efforts have been done, all L-Arabinose-fermenting yeasts which have been identified or engineered, show very low ethanol production rate and yield [82, 83]. However, efforts are continuing on issues connected with arabinose conversion to ethanol such as an effective cross-membrane transporter for the C5 saccharides, the coupling of the enzymes to the glycolytic pathway and the skip of the inner cell redox imbalance, giving hope that the conversion of arabinose to ethanol could increase the overall yield of the process and highlight the use of C5-rich materials such as BSG as feedstocks for ethanol production.

Anaerobic Digestion of BSG

Anaerobic digestion (-methane production) is the process of decomposition of organic matter by a microbial consortium in an oxygen-free environment. This process is found in many naturally occurring anoxic environments and can be applied to a wide range of feedstocks including industrial and municipal waste waters, agricultural, municipal, food industry wastes, and plant residues [84]. The hydrolysis of lignocellulose and its conversion to methane is in general done in one reactor by a consortium of micro-organisms. The advantage of using a mixture of micro-organisms is that almost all products, like pentoses, hexoses, volatile products and even sometimes inhibiting compounds like furfural and soluble lignin compounds (in not too high concentrations) can be converted to methane after a period of adaptation.

Ezeonu and Okaka [85] were the first who used BSG as the carbon source for the production of biogas achieving degradation of approximately 60 and 40% for cellulose and lignin, respectively, while the operational efficiency of the digester was determined to be 26%. Bochmann et al. [86] applied a two-step anaerobic fermentation of BSG. The fatty acid concentration in the digester, the biogas production and the quality of the gases produced showed that BSG was very promising as substrate for lignocellulolytic enzymes production (used for pretreatment of the material prior to the fermentation) and also as carbon source in anaerobic digestion.

More recently, BSG has been chosen amongst other agro-industrial by products for a combined hydrogen and methane producing process by Ochs and Kastner [87] who concluded that a two-step fermentation generated less biogas but with a higher CH4 concentration. In that study the performed combined fermentation runs had a total biogas yield of 204.7–210.6 L biogas/kg volatile solids. A pretreatment step is often considered as an option in biogas production processes aiming at an easily degradable substrate. Lately, Sežun et al. [88] tested several types of pretreatment methods (mechanical, alkali, acid, thermo-chemical) to facilitate the use of BSG as the sole carbon source for biogas production. None of tested pretreatment methods produced a material that would be readily converted into biogas by a steady state process. All anaerobic digestion experiments were terminated after 2–3 hydraulic retention times due to irreversible reduction of biogas production. p-Cresol was designated as a desicive compound for process inhibition when its concentration in the reaction mixture exceeded a crucial value (115–240 mg L−1).

Protein Fraction

The barley prolamin (hordein) comprises 35–55% of the total barley grain proteins [5]. The lack of solubility of BSG proteins is one of the limitations for their more extensive applications. However, they can be solubilised by chemical or enzymatic methods. The resultant peptide hydrolysates can be used as food or feed ingredients or as peptones in the fermentation industry. Chemical methods for protein hydrolysis are difficult to be controlled and the derived products may present reduced nutritional qualities (destroyed amino acids, formation of unusual amino acids). On the other hand enzymatic hydrolysis occurs under mild conditions of pH and temperature, and has no significant impacts on amino acid structures and therefore has limited effects on the nutritional properties of resulting protein hydrolyzates [89].

In general, protein hydrolysis changes MW, charge and exposure of hydrophobic groups and reactive amino acid side-chains, with significant effects on functional properties (solubility, viscosity, sensory properties and emulsifying and foaming behaviour) of the resulting peptides. It has been found that peptides hydrolyzates derived from BSG after treatment with proteases presented improved functional properties compared to non treated proteins. Celus et al. [90] treated enzymaticaly BSG protein concentrate (prepared by alkaline extraction of BSG and subsequent acid precipitation) using various commercial proteases. Enzymatic hydrolysis of BSG protein concentrate improved emulsion and/or foam-forming properties. Results showed that the type of enzyme used was a key factor in determining the emulsifying and foaming capacities of the resulting hydrolysates. Physicochemical characterization of the hydrolysates indicated the importance of protein fragments with relatively high MW (exceeding 14.5 k) and high surface hydrophobicity for favorable technofunctional properties. Thus the proteases used in solubilization processes as well as the conditions of hydrolytic reactions (time, enzyme loading, temperature etc.) could be significant for the functionality and the economic value of the derived hydrolyzate.

The same group in a more recent study used Alcalase in order to investigate the connection between the physicochemical properties and the technofunctional properties of peptides hydrolyzates from BSG. It was found that the emulsifying and foaming properties were determined by different physicochemical properties of the proteins or peptides and neither MW nor hydrophobicity alone, determines the emulsifying and foaming properties of protein hydrolysates [91]. Alcalase has been determined as a very effective peptidase for solubilization of BSG proteins also by other groups. It was shown that a large fraction (up to 80%) of the proteinaceous material in BSG could be solubilized with commercial industrial peptidase preparations, in particular Alcalase, using a simple enzymatic hydrolysis step. Moreover, the peptides produced by Alcalase had lower average molecular weight than peptides produced by other less effective enzymes [92]. Promissing results on BSG fractionation and protein solubilization have been obtained by the combined action of carbohydrases and peptidases. One- and two-step protocols have been proposed taking 4–8 h and yielding combined or separate fractions of hydrolyzed oligosaccharides and liberated hydrolyzed protein. Optimized procedures resulted in the solubilization of >80% of the proteinaceous material, up to 39% of the total carbohydrates, and up to 42% of total dry matter in BSG [93].

Lipid Fraction

In barley grain the lipids are found as droplets surrounding the aleurone cells, which contain the protein matrix. Total lipid content ranges from 3.12% up to 3.56% (w/w). Average values reported for neutral lipids, glycolipids, and phospholipids are 71, 9, and 20%, respectively [94]. The lipid content in BSG is higher than that measured in barley grain, suggesting high levels of bound lipids which have potential as natural emulsifiers in food and cosmetic applications. BSG is an excellent source of sterol lipids that may be used after extraction as cholesterol lowering ingredients in foods and also contains glycosylated and esters of phenolic acids that can be used as antioxidative or emulsifying compounds. Other important lipids in BSG are glycolipids, phospholipids, and mono- and diacylglycerides.

Dried BSG is rich in tocotrienols (T3) and tocopherols and can be used to produce a valuable oil with the serum cholesterol–lowering functions of lipid-soluble T3 [95]. T3-rich oil from dried BSG is of great potential interest as a health-promoting, functional oil for human consumption. It has been recently shown that dried BSG can be separated into fractions enriched in fat and T3 by milling and sieving. The sieving fraction with particle sizes\500 μm has been identified as the most suitable for T3 extraction. Large-scale plants for drying BSG are already present, and common devices may be used to mill and sieve dried BSG. These easy-to-realize steps would make available large quantities of a dried BSG fraction simultaneously enriched with fat and tocochromanol, which could be subjected to cost-effective ethanolic extraction in large-scale oil extraction plants [95].

Malted spent grains have been used as co-substrate in solid state cultivation of the fungus Pythium ultimum in order to achieve fungal oil enriched in the polyunsaturated fatty acids (PUFA) arachidonic acid and eicosapentaenoic acid (EPA) [96]. It was shown that the fungus accumulated PUFA-rich lipid in higher yield when cultivated on a barley-malted grains-based substrate compared to other agro-industrial substrates. Mixture of barley and spent malt grains has also been proven suitable for γ-linolenic acid (an intermediate in the transformation of linolenic acid into prostaglandins which play an important physiological role in mammals) production by Cunninghamella elegans. As in EPA production, the supplementation of the substrate with vegetable oil enhanced γ-Linolenic acid production [97]. More recently, the production of EPA from BSG has been reported by Jacobs et al. [98]. However, EPA accumulation was enhanced by the addition of linseed oil to the substrate where EPA production reached more than 2.5 mg EPA per g of BSG. However, crucial parameters of this process (such as oxygen availability, C:N ratio, pH, incubation temperature, addition of nutrients and minerals, layer thickness and moisture content) are yet to be investigated. The optimization of the process with regard to these parameters could further increase EPA yield from BSG.

BSG as Carrier in Bioprocesses

Many studies have been carried out aiming to improve the performance of biotechnological processes by using immobilized-cell systems. Such systems are eco-friendly and have many advantages over suspended cell-systems; one of the most important is that immobilized cells completely maintain their biological functions with increased stability that may often lead to increased cell productivity. The choice of the carrier is essential in order to design an effective system for each particular purpose. Among other characteristics, the carrier must be able to maintain its physical integrity, being insoluble and stable under the chemical and thermal conditions of the bioprocess. Thus, in this sense, the use of lignocellulosic materials as carriers is an interesting alternative because they are natural, renewable, biodegradable, non-toxic, inexpensive and readily available. The preparation of BSG as carrier generally includes a pretreatment step for the hydrolysis of the residual starchy endosperm and partial removal of lignin (acid treatment, boiling, etc.), several washings, drying and optionally a sterilization step.

The water absorption index (WAI) and the critical humidity point (CHP) are crucial characteristics of materials for their use as carriers [99]. Generally, high WAI and low CHP values facilitate microbial growth and development. When BSG was studied comparatively with other lignocellulosic materials as carrier in microorganism cultivation for fructofuranosidase production, it was found that although BSG had a relatively high WAI value, it had also a low CHP, fact that did not make it so suitable as carrier for microorganism cultivation [99]. BSG has also been studied as a potential carrier for yeast immobilization for potential use in continuous beer fermentations [100, 101]. BSG seems to be a promising alternative to the available carriers showing high yeast loading capacity, demanding easy preparation (not requiring chemical modification) and beeing easily regenerated by simple washing in caustic. Not only it was found inert under fermentation conditions, but also its use in such applications does not require investments, being a brewery by-product. Similar observations have been made by Kopsahelis et al. [102] concluding that BSG could be used as cell immobilization supports without chemical treatment (e.g. delignification), which meant easier handling and lower costs. The yeast immobilization process on BSG was simple, without the use of additional nutrients, apart from glucose, which would add cost or provide undesirable effects on product quality. However, delignified BSG has also been used for yeast immobilization in glucose and grape must repeated batch fermentations [103–105]. BSG as carrier for continuous pectinase production with yeasts has also been investigated, as a possible alternative to the traditional batch process using fungal cultures [106].

Concluding Remarks and Future Perspectives

The biotechnological potential of BSG is reflected to the increased research interest dealing with such issues within the last 5 years. Enzymatic approaches to solubilise BSG are favoured as a means to recover selective high-value components, whereas chemical treatments can destroy potentially valuable components. Thus, biotechnological approaches have been proposed to fractionate carbohydrates, proteins and phenolic acids from BSG aiming at the generation of oligosaccharides, monosaccharides, peptides, antioxidants and functional lipids. Many of these approaches have achieved considerably high recovery yields using selected enzyme coctails. BSG has also the potential to be used in the biofuel industry or in other microbial conversion processes (xylitol or biogas production) without a change in agricultural waste management. The generation of high levels of fermentable sugars can be achieved implementing enzymatic or consolidated bioprocess methods, although a chemical pretreatment step is required in order to increase accessibility of carbohydrates to hydrolytic enzymes. Undoubtedly, consideration should be given to the generation of inhibitory compounds, which in high concentrations could hamper the subsequent microbial fermentation.

The results obtained on the biotechnological production of high value products from BSG show that large scale applications could be the next step in biotechnological expoitation of this agro-industrial by-product. An eventual combined or simultaneous production of different bio-products could make the bioprocess economically efficient. This is the overall goal of the biorefinery production approach: The generation of a variety of goods from different biomass feedstocks, through a combination of technologies. To date Biorefining in a form that supports the full exploitation of the full potential of biomass does not exist. Most examples describe biorefining processes where a select of few molecular components are targeted. Lately the biorefinery concept has gained the attention of several scientists and industries due to the emerging research trends in the production of bio-based products. Some of the processes already described concerning the enzymatic fractionation of BSG into soluble carbohydrate and peptide fractions, lignin-cellulose-rich fractions etc., could be incorporated in a biorefinery approach. Such applications, exploiting biotechnological processes for the formation of functional food ingredients, non-food industrial precursors, and pharmaceutical compounds could add high value to a BSG based biorefinery. The fractionation of BSG and the exploitation of biomolecules of different classes could be used as a pattern for the implementation of the biorefinery concept in industrial scale, as the conversion of lignocellulosic biomass to higher value products requires fractionation methods ensuring the functionality of the potentially valuable components.

Abbreviations

- BG:

-

β-Glucosidases

- BSG:

-

Brewers spent grain

- CBH:

-

Cellobiohydrolases

- CHP:

-

Critical humidity point

- CMC:

-

Carboxy-methyl-cellulose

- EG:

-

Endoglucanases

- EPA:

-

Eicosapentaenoic acid

- FA:

-

Ferulic acid

- FAE:

-

Feruloyl esterase

- FAO:

-

Food and Agriculture Organization

- IU:

-

International units (μmol of roduct per min)

- MRS broth:

-

de Man, Rogosa and Sharpe broth

- NSP:

-

Non starch polysaccharides

- pCA:

-

p-Coumaric acid

- PUFA:

-

Polyunsaturated fatty acids

- SEM:

-

Scanning electron microscopy

- WAI:

-

Water absorption index

- WB:

-

Wheat bran

- XOS:

-

Xylo-oligosaccharides

References

Mussatto, S.I., Dragone, G., Roberto, I.C.: Brewer’s spent grain: generation, characteristics and potential applications. J. Cereal Sci. 43, 1–14 (2006)

Mussatto, S.I.: Biotechnological potential of brewing industry by-products. In: Singh nee’ Nigam, P., Pandey, A. (eds.) Biotechnology for Agro-Industrial Residues Utilisation, pp. 314–326. Springer Science+Business Media BV, Netherlands (2009)

Santos, M., Jiménez, J.J., Bartolomé, B., Gómez-Cordovés, C., Del Nozal, M.J.: Variability of brewers’ spent grain within a brewery. Food Chem. 80, 17–21 (2003)

Mussatto, S.I., Roberto, I.C.: Chemical characterization and liberation of pentose sugars from brewer’s spent grain. J. Chem. Technol. Biotechnol. 81, 268–274 (2006)

Celus, I., Brijs, K., Delcour, J.A.: The effects of malting and mashing on barley protein extractability. J. Cereal Sci. 44, 203–211 (2006)

Jay, A.J., Parker, M.L., Faulks, R., Husband, F., Wilde, P., Smith, A.C., Faulds, C.B., Waldron, K.W.: A systematic micro-dissection of brewers’ spent grain. J. Cereal Sci. 47, 357–364 (2008)

Robertson, J.A., I’Anson, K.J.A., Treimo, J., Faulds, C.B., Brocklehurst, T.F., Eijsink, V.G.H., Waldron, K.W.: Profiling brewers’ spent grain for composition and microbial ecology at the site of production. LWT-Food Sci. Technol. 43, 890–896 (2010)

Kanauchi, O., Mitsuyama, K., Araki, Y.: Development of a functional germinated barley foodstuff from brewers’ spent grain for the treatment of ulcerative colitis. J. Am. Soc. Brew. Chem. 59, 59–62 (2001)

Mussatto, S.I., Roberto, I.C.: Acid hydrolysis and fermentation of brewer’s spent grain to produce xylitol. J. Sci. Food Agric. 85, 2453–2460 (2005)

Xiros, C., Topakas, E., Katapodis, P., Christakopoulos, P.: Hydrolysis and fermentation of brewer’s spent grain by Neurospora crassa. Bioresour. Technol. 99, 5427–5435 (2008)

Carvalheiro, F., Esteves, M.P., Parajó, J.C., Pereira, H., Gírio, F.M.: Production of oligosaccharides by autohydrolysis of brewery’s spent grain. Bioresour. Technol. 91, 93–100 (2004)

Forssell, P., Kontkanen, H., Schols, H.A., Hinz, S., Eijsink, V.G.H., Treimo, J., Robertson, J.A., Waldron, K.W., Faulds, C.B., Buchert, J.: Hydrolysis of brewers’ spent grain by carbohydrate degrading enzymes. J. Inst. Brew. 114, 306–314 (2008)

Huige, N.J.: Brewery by-products and effluents. In: Hardwick, W.A. (ed.) Handbook of Brewing, pp. 501–550. Marcel Dekker, New York (1994)

Russ, W., Mörtel, H., Meyer-Pittroff, R.: Application of spent grains to increase porosity in bricks. Constr. Build. Mater. 19, 117–126 (2005)

Ishiwaki, N., Murayama, H., Awayama, H., Kanauchi, O., Sato, T.: Development of high value uses of spent grain by fractionation technology. Tech. Q. Master Brew. Assoc. Am. 37, 261–265 (2000)

Okamoto, H., Kitagawa, Y., Minowa, T., Ogi, T.: Thermal-catalytic conversion of high moisture spent grains to a gaseous fuel. Tech. Q. Master Brew. Assoc. Am. 36, 239–241 (1999)

Zanker, G., Kepplinger, W., Pecher, C.: Incineration of solid food waste: a project about spent grain. In: Oreopoulou, V., Russ, W. (eds.) Utilization of By-Products and Treatment of Waste in the Food Industry, pp. 273–281. Springer, USA (2007)

Chiang, P.C., Chang, P., You, J.H.: Innovative technology for controlling VOC emissions. J. Hazard. Mater. 31, 19–28 (1992)

Aliyu, S., Bala, M.: Brewer’s spent grain: a review of its potentials and applications. Afr. J. Biotechnol. 10, 324–331 (2011)

Benko, Z., Drahos, E., Szengyel, Z., Puranen, T., Vehmaanperä, J., Réczey, K.: Thermoascus aurantiacus CBHI/Cel7A production in Trichoderma reesei on alternative carbon sources. Appl. Biochem. Biotechnol. 137–140, 195–204 (2007)

Francis, F., Sabu, A., Nampoothiri, K.M., Ramachandran, S., Ghosh, S., Szakacs, G., Pandey, A.: Use of response surface methodology for optimizing process parameters for the production of α-amylase by Aspergillus oryzae. Biochem. Eng. J. 15, 107–115 (2003)

Xu, H., Sun, L., Zhao, D., Zhang, B., Shi, Y., Wu, Y.: Production of α-amylase by Aspergillus oryzae As 3951 in solid state fermentation using spent brewing grains as substrate. J. Sci. Food Agric. 88, 529–535 (2008)

Patel, A.K., Nampoothiri, K.M., Ramachandran, S., Szakacs, G., Pandey, A.: Partial purification and characterization of α-amylase produced by Aspergillus oryzae using spent-brewing grains. Ind. J. Biotechnol. 4, 336–341 (2005)

Hashemi, M., Razavi, S.H., Shojaosadati, S.A., Mousavi, S.M.: The potential of brewer’s spent grain to improve the production of α-amylase by Bacillus sp. KR-8104 in submerged fermentation system. New Biotechnol. 28, 165–172 (2011)

Adeniran, H.A., Abiose, S.H., Ogunsua, A.O.: Production of fungal β-amylase and amyloglucosidase on some nigerian agricultural residues. Food Bioprocess Technol. 3, 693–698 (2010)

Mandalari, G., Bisignano, G., Lo Curto, R.B., Waldron, K.W., Faulds, C.B.: Production of feruloyl esterases and xylanases by Talaromyces stipitatus and Humicola grisea var. thermoidea on industrial food processing by-products. Bioresour. Technol. 99, 5130–5133 (2005)

Terrasan, C.R.F., Temer, B., Duarte, M.C.T., Carmona, E.C.: Production of xylanolytic enzymes by Penicillium janczewskii. Bioresour. Technol. 101, 4139–4143 (2010)

Grigorevski-Lima, A.L., Da Vinha, F.N.M., Souza, D.T., Bispo, A.S.R., Bon, E.P.S., Coelho, R.R.R., Nascimento, R.P.: Aspergillus fumigatus thermophilic and acidophilic endoglucanases. Appl. Biochem. Biotechnol. 155, 321–329 (2009)

Xiros, C., Topakas, E., Katapodis, P., Christakopoulos, P.: Evaluation of Fusarium oxysporum as an enzyme factory for the hydrolysis of brewer’s spent grain with improved biodegradability for ethanol production. Ind. Crop Prod. 28, 213–224 (2008)

Xiros, C., Christakopoulos, P.: Enhanced ethanol production from brewer’s spent grain by a Fusarium oxysporum consolidated system. Biotechnol. Biofuels. 2, 4 (2009)

Panagiotou, G., Granouillet, P., Olsson, L.: Production and partial characterization of arabinoxylan-degrading enzymes by Penicillium brasilianum under solid-state fermentation. Appl. Microbiol. Biotechnol. 72, 1117–1124 (2006)

Nascimento, R.P., Junior, N.A., Pereira Jr, N., Bon, E.P.S., Coelho, R.R.R.: Brewer’s spent grain and corn steep liquor as substrates for cellulolytic enzymes production by Streptomyces malaysiensis. Lett. Appl. Microbiol. 48, 529–535 (2009)

Szponar, B., Pawlik, K.J., Gamian, A., Szwajcer Dey, E.: Protein fraction of barley spent grain as a new simple medium for growth and sporulation of soil Actinobacteria. Biotechnol. Lett. 25, 1717–1721 (2003)

Szwajgier, D., Jakubczyk, A.: Production of extracellular ferulic acid esterases by Lactobacillus strains using natural and synthetic carbon sources. Acta Sci. Pol. Technol. Aliment. 10(3), 287–302 (2011)

Szwajgier, D., Dmowska, K.: Novel ferulic acid esterases from Bifidobacterium sp. produced on selected synthetic and natural carbon sources. Acta Sci. Pol. Technol. Aliment. 9, 305–318 (2010)

Novik, G.I., Wawrzynczyk, J., Norrlow, O., Szwajcer-Dey, E.: Fractions of barley spent grain as media for growth of probiotic bacteria. Microbiology 76, 804–808 (2007)

Sandhya, C., Sumantha, A., Szakacs, G., Pandey, A.: Comparative evaluation of neutral protease production by Aspergillus oryzae in submerged and solid-state fermentation. Process Biochem. 40, 2689–2694 (2005)

Lara, M., Arias, A., Villasenor, L.: Cultivation of Pleurotus ostreatus and P. Pulmonarius on spent brewer’s grain and tequila maguey bagasse. In: Sánchez, J.E., Huerta, G., Montiel, E. (eds.) Mushroom Biology and Mushroom Products, pp. 323–330. Autónoma del Estado de Morelos, Mexico (2002)

Gregori, A., Švagelj, M., Pahor, B., Berovič, M., Pohleven, F.: The use of spent brewery grains for Pleurotus ostreatus cultivation and enzyme production. New Biotechnol. 25, 157–161 (2008)

Harris, P.V., Welner, D., McFarland, K.C., Re, E., Navarro Poulsen, J.C., Brown, K., Salbo, R., Ding, H., Vlasenko, E., Merino, S., Xu, F., Cherry, J., Larsen, S., Lo Leggio, L.: Stimulation of lignocellulosic biomass hydrolysis by proteins of glycoside hydrolase family 61: structure and function of a large, enigmatic family. Biochemistry 49, 3305–3316 (2010)

de Vries, R.P., Kester, H.C.M., Poulsen, C.H., Benen, J.A.E., Visser, J.: Synergy between enzymes from Aspergillus involved in the degradation of plant cell wall polysaccharides. Carbohydr. Res. 327, 401–410 (2000)

Xiros, C., Katapodis, P., Christakopoulos, P.: Factors affecting cellulose and hemicellulose hydrolysis of alkali treated brewers spent grain by F. oxysporum enzyme extract. Bioresour. Technol. 102, 1688–1696 (2011)

Van Craeyveld, V., Swennen, K., Dornez, E., Van de Wiele, T., Marzorati, M., Verstraete, W., Delaedt, Y., Onagbesan, O., Decuypere, E., Buyse, J., De Ketelaere, B., Broekaert, W.F., Delcour, J.A., Courtin, C.M.: Structurally different wheat-derived arabinoxylooligosaccharides have different prebiotic and fermentation properties in rats. J. Nutr. 138, 2348–2355 (2008)

Gibson, G.R., Probert, H.M., Van Loo, J., Rastall, R.A., Roberfroid, M.B.: Dietary modulation of the human colonic microbiota: updating the concept of prebiotics. Nutr. Res. Rev. 17, 259–275 (2004)

Vegas, R., Alonso, J.L., Domínguez, H., Parajó, J.C.: Manufacture and refining of oligosaccharides from industrial solid wastes. Ind. Eng. Chem. Res. 44, 614–620 (2005)

Kabel, M.A., Carvalheiro, F., Garrote, G., Avgerinos, E., Koukios, E., Parajó, J.C., Gírio, F.M., Schols, H.A., Voragen, A.G.J.: Hydrothermally treated xylan rich byproducts yield different classes of xylo-oligosaccharides. Carbohydr. Res. 50, 47–56 (2002)

Szakács, G., Urbánszki, K., Tengerdy, R.P.: Solid-state enzymes for fiber hydrolysis. ACS Symp. Ser. 769, 190–203 (2001)

Napolitano, A., Lanzuise, S., Ruocco, M., Arlotti, G., Ranieri, R., Knutsen, S.H., Lorito, M., Fogliano, V.: Treatment of cereal products with a tailored preparation of Trichoderma enzymes increases the amount of soluble dietary fiber. J. Agric. Food Chem. 54, 7863–7869 (2006)

Duarte, L.C., Carvalheiro, F., Lopes, S., Marques, S., Parajó, J.C., Gírio, F.M.: Comparison of two posthydrolysis processes of brewery’s spent grain autohydrolysis liquor to produce a pentose-containing culture medium. Appl. Biochem. Biotechnol. 113–116, 1041–1058 (2004)

Mussatto, S.I., Fernandes, M., Milagres, A.M.F., Roberto, I.C.: Effect of hemicellulose and lignin on enzymatic hydrolysis of cellulose from brewer’s spent grain. Enzyme Microb. Technol. 43, 124–129 (2008)

Mussatto, S.I., Dragone, G., Fernandes, M., Milagres, A.M.F., Roberto, I.C.: The effect of agitation speed, enzyme loading and substrate concentration on enzymatic hydrolysis of cellulose from brewer’s spent grain. Cellulose 15, 711–721 (2008)

Pierre, G., Sannier, F., Goude, R., Nouviaire, A., Maache-Rezzoug, Z., Rezzoug, S.-A., Maugard, T.: Evaluation of thermomechanical pretreatment for enzymatic hydrolysis of pure microcrystalline cellulose and cellulose from brewers’ spent grain. J. Cereal Sci. (2011). doi:10.1016/j.jcs.2011.06.004

Faulds, C.B., Robertson, J.A., Waldron, K.W.: Effect of pH on the solubilization of brewers’ spent grain by microbial carbohydrases and proteases. J. Agric. Food Chem. 56, 7038–7043 (2008)

Faulds, C.B., Collins, S., Robertson, J.A., Treimo, J., Eijsink, V.G.H., Hinz, S.W.A., Schols, H.A., Buchert, J., Waldron, K.W.: Protease-induced solubilisation of carbohydrates from brewers’ spent grain. J. Cereal. Sci. 50, 332–336 (2009)

Forssell, P., Treimo, J., Eijsink, V.G.H., Faulds, C.B., Collins, S., Schols, H.A., Hinz, S.W.A., Myllymäki, O., Tamminen, T., Zoldners, J., Viljanen, K., Waldron, K.W., Buchert, J.: Enzyme-aided fractionation of brewer’s spent grains in pilot scale. J. Am. Soc. Brew. Chem. 69(2), 91–99 (2011)

Robertson, J.A., Castro-Mariñas, L., Collins, S.R.A., Faulds, C.B., Waldron, K.W.: Enzymatic and chemical treatment limits on the controlled solubilization of brewers’ spent grain. J. Agric. Food Chem. 59, 11019–11025 (2011)

Fu, Q., Yu, X., Li, L., Liu, G., Li, B. 2011. Antioxidant activities of soluble dietary fiber extracted from brewers’ spent grain. Adv. Mat. Res. 233–235, 2824–2827 (2011)

Mandalari, G., Faulds, C.B., Sancho, A.I., Saija, A., Bisignano, G., LoCurto, R., Waldron, K.W.: Fractionation and characterization of arabinoxylans from brewers’ spent grain and wheat bran. J. Cereal Sci. 42, 205–212 (2008)

Hernanz, D., Nuñez, V., Sancho, A.I., Faulds, C.B., Williamson, G., Bartolomé, B., Gómez-Cordovés, C.: Hydroxycinnamic acids and ferulic acid dehydrodimers in barley and processed barley. J. Agric. Food Chem. 49, 4884–4888 (2001)

Xiros, C., Moukouli, M., Topakas, E., Christakopoulos, P.: Factors affecting ferulic acid release from brewer’s spent grain by Fusarium oxysporum enzymatic system. Bioresour. Technol. 100, 5917–5921 (2009)