Abstract

Brewers' spent grain (BSG) is the most abundant by-product of beer-brewing. BSG is rich in nutrients such as protein, fiber, minerals, and vitamins, and therefore it is conventionally used as low-cost animal feed. On the other hand, alternative utilization of BSG has gained increased attention during recent years due to technological progress in its processing and the emergence of the concept of circular economy. The valorization of BSG through biotechnological approaches is environmentally friendly and sustainable. This review was focused on recent advancements in the conversion of BSG into value-added products, including bioenergy (ethanol, butanol, hydrogen, biodiesel, and biogas), organic acids, enzymes, xylitol, oligosaccharides, and single cell protein, via biotechnological approaches. In addition, the potential applications of BSG as immobilization matrices in bioprocesses have been reviewed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In beer-brewing process, brewers' spent grain (BSG) is the most predominant by-product, constituting about 85% of total by-products generated (Lynch et al., 2016). BSG represents leftover insoluble portion of the barley grain following the mashing process and separation of sweet liquid wort (a process also known as lautering). The dry matter of BSG contains cellulose, hemicellulose, lignin, proteins, lipids, and an ash fraction, in addition to adhered soluble compounds, such as glucose, maltose, and malto-oligomers (Akermann et al., 2020; Mussatto, 2014). Several factors influence the chemical composition of BSG such as barley variety, harvest time, malting as well as mashing conditions, in addition to the type and quality of additives added in the brewing process (Amore et al., 2015). BSG is composed chiefly of protein (15–26%) and fiber (35–60%) (on a dry weight basis) (Ikram et al., 2017; Shen et al., 2019). Major proteins in BSG include hordeins, glutelins, albumins, and globulins. Hordeins (prolamins) are abundant, further classified as B (30 to 50 kDa), C (55 to 80 kDa), and D hordeins (95 kDa) according to their molecular weights (Ikram et al., 2017).

Since BSG is rich in protein, fiber, and other nutrients, it is extensively used in animal nutrition (e.g., pigs, fish, and poultry) and to a limited extent in human nutrition (Bonifacio-Lopes et al., 2020). It is a source of energy; the formation of bio-oil, bio-char, and permanent gases via pyrolysis of BSG has been reported (Mussatto, 2014). Other conventional applications of BSG include: pulp and paper production and as adsorbent for the removal of dyes from wastewater or organic compounds from waste gases (Bonifacio-Lopes et al., 2020).

Alternative utilization of BSG, especially as fermentation substrate, has gained momentum in recent years due to technological progress in its processing and the emergence of circular economy concept. The application of BSG as a potential substrate in different biotechnological processes is feasible due to its nutrients, ready availability, and cost-effectiveness. It has been used as a substrate in the production of value-added products, including biofuels (bioethanol, biobutanol, biogas, biohydrogen, and biolipids [for biodiesel]), organic acids (lactic acid and citric acid), enzymes (cellulases, xylanases, etc.), single cell protein, prebiotic oligosaccharides, xylitol and others. In addition, it has been used as carrier matrices for microorganisms in biotechnological processes. The present review firstly describes the nutritional components, preservation, and deconstruction methods of BSG. There were considerable developments in the valorization of BSG through biotechnological routes in recent years; therefore, primary objective of this article was to provide up-to-date information on biotechnological valorization of BSG.

Nutritional components

Essential amino acids in BSG include histidine, lysine, methionine, phenylalanine, and tryptophan, whereas non-essential amino acids including alanine, glycine, proline, and serine are abundant in barley hordeins (B, C, and D) (Huige 2006). High concentrations of leucine, glutamine, and asparagine have also been reported in BSG (Ikram et al., 2017). The dietary fiber is further classified as soluble fiber (β‐glucans, arabinogalactans, pectic polysaccharides, xyloglucans, and highly branched arabinoxylans) and insoluble fiber (cellulose, lignin, xyloglucans, galactomannans, and slightly branched arabinoxylans) based on its water solubility.

In addition, BSG is an important source of phenolic compounds such as hydroxycinnamic acids (p‐coumaric, ferulic, sinapic, and caffeic acids) (Ikram et al., 2017). Vitamins of BSG include water-soluble thiamine, riboflavin, niacin, pantothenic acid, pyridoxine, biotin, folic acid, and choline (a non-vitamin nutrient), and lipid-soluble vitamin E (tocopherols and tocotrienols). The predominant minerals in BSG are calcium, magnesium, phosphorus, and sodium, in addition to potassium, iron, copper, and manganese. BSG also contains lipids, waxes, essential oils, waxes, and tannins (Ikram et al., 2017).

Microbial spoilage and preservation

Because of high moisture (80–85%) and fermentable sugar contents, the keeping quality of wet BSG (the form obtained after lautering) deteriorate very quickly due to microbial activity (Aboltins and Palabinskis, 2015). In addition to this, the transport of wet BSG is cost-intensive and therefore it is generally sold to local farmers as cattle feed. Lowering the moisture level to about 10% has been suggested for extended storage of BSG and to attain microbiological stability in the product (Lynch et al., 2016).

The application of different organic acids (e.g., formic, acetic, lactic, and benzoic acids) can extend the aerobic stability of BSG by 4–5 days. Effects of different methods of storage, namely refrigeration at 4 °C, frozen storage, autoclave at 120 °C for 1 h, and fresh material at 20 °C, on microbiological quality of BSG and changes in compositional components have been compared (Robertson et al., 2010a). Among these, autoclaving has been recommended for long‐term stability of BSG, however compositional characteristics are more likely change with this method (Robertson et al., 2010b). Several physical methods of preservation, including freezing, freeze drying, oven drying, and the application of superheated steam, have been investigated. However, each method has its own merits and disadvantages, as discussed in a previous report (Lynch et al., 2016).

Deconstruction of BSG

Several treatment methods (e.g., chemical and enzymatic extraction) have been employed for the deconstruction of BSG to yield several high-value components such as proteins, carbohydrates, and phenolic compounds. In addition, such deconstruction treatments render solubilization of BSG components so that degradation products can be used as substrates for the fermentative production of value-added compounds. Compared with chemical methods, enzymatic approaches are generally considered environmentally friendly, the processing can be targeted towards specific products, and bioactivity in the produced fractions is more likely. Because of the complexity of the constituent polymers of BSG, the application of a wide range of enzymes (e.g., xylanases, acetyl esterases, glucuronidases, β-xylosidases, feruloyl esterases, glucuronoyl esterases and α-L-arabinofuranosidases) is necessary for complete hydrolysis.

Prior to enzymatic hydrolysis of BSG, a pre-treatment step is more beneficial since the lignocellulosic material has a rigid structure. Different dilute acid and alkali solutions (e.g., dilute H2SO4, dilute NaOH, KOH) are used as pretreatment agents to degrade the hemicellulose fraction and to obtain high glucose yields. Different physical and thermal pretreatments (e.g., milling, microwave radiation, and extrusion cooking) are also used (Macheiner et al., 2003).

Proteases may assist in complete deconstruction of BSG since insoluble proteins of BSG may entrap otherwise soluble carbohydrate components. Protease-assisted degradation of BSG proteins also supplies peptides and amino acids needed for microbial growth during fermentation (Lynch et al., 2016).

Biotechnological valorization approaches

Bioenergy

Bioethanol production

Ethanol is a renewable fuel and it can be produced from a wide variety of plant materials comprehensively known as ‘biomass’. In recent years, non-food bio-materials such as lignocellulosic biomass and bio-waste (e.g., corn cobs, sugarcane bagasse, corn stover, and wheat straw) are increasingly used as substrates for the production of second-generation (2G) ethanol. Since BSG is rich in fermentable carbohydrate content (15–30% cellulose and 10–25% hemicellulose), it can potentially be used for bioethanol production. High lignin content of BSG creates trouble when it is subjected to enzymatic hydrolysis. Therefore, the lignin barrier must be removed to release the carbohydrates. Acid or alkali treatments are standard approaches for the delignification of BSG. Pre-treatment of BSG using 5% NaOH at 25% w/v solids loading was found to be effective for maximal glucose liberation, and the fermentation of the resultant hydrolysates yielded an average ethanol concentration of 17.3 g/L (Wilkinson et al., 2014a). Dilute acid- and alkali-catalyzed hydrothermal pretreatments of BSG were investigated by Wilkinson et al. (2014b). At 25% solids loading, pretreatments with 1% (w/v) HCl and 3% (w/v) NaOH were found to be effective, and ethanol yields of 12–15 g/L were obtained. Liguori et al. (2015a) evaluated ethanol production from alkaline-acid pretreated and enzymatically saccharified BSG substrate. They showed a maximum ethanol concentration of 12.79 g/L with a volumetric productivity of 0.53 g/L⋅h using the strain Saccharomyces cerevisiae NRRL YB 2293. Rojas-Chamorro et al. (2017) compared sequential and simultaneous approaches for saccharification and fermentation (by S. cerevisiae) of pretreated BSG at different solid loadings. Results showed that sequential process was the best to achieve high ethanol concentration, especially at high solids loading of 15% w/v. They reported a maximum final ethanol yield of 37 g/100 g glucose in pretreated BSG. Broeker et al. (2017) tested a relatively gentle delignification method of wet oxidation with active chlorine. Results showed a significant reduction in lignin content and a remarkable increase of glucose yield for BSG. Pinheiro et al. (2019) carried out pretreatment of BSG by autohydrolysis at high solids loadings (up to 25%) and used whole slurry from the pretreatment as substrate for ethanol production. Their results indicated that the saccharification of pretreated BSG whole slurries at 20 and 25% solids loadings had resulted in glucose yields of 85.9 and 70.6%, respectively. Subsequent fermentation by S. cerevisiae strains yielded the highest ethanol level of 42.27 g/L.

Thermoplastic extrusion pretreatment was used to disrupt BSG structure in the process of its bioconversion to ethanol by S. cerevisiae (Heredia-Olea et al., 2015). They did not observe any enzymatic and yeast inhibitors in extruded and enzymatically-hydrolyzed BSG, and final ethanol yield was 5.43 mL/L. The low ethanol yield was attributed to utilization of only glucose by the yeast as well as low free alpha-amino nitrogen (FAN) content in the medium. As BSG hydrolyzates contain both hexose and pentose sugars and yeasts are not capable of metabolizing pentose sugars, Mata et al. (2015) investigated fermentative ethanol production from BSG, following acid pre-treatment and enzymatic hydrolysis, using pentose-utilizing yeasts Pichia stipitis and Kluyveromyces marxianus. Their results showed that final ethanol yields of 0.0856 and 0.0308 g/g of sugars can be obtained for P. stipitis and K. marxianus, respectively, and these low yields could be due to the presence of fermentation inhibitors.

For improved bioconversion of BSG to ethanol, ultrasound pretreatment can be used. Hassan et al. (2020a) showed that ultrasound (US) pretreatment of BSG (20% US power, 60 min, 26.3 °C, and 17.3% w/v of biomass in water) resulted in a 2.1-fold increase of reducing sugar yield, subsequent fermentation using S. cerevisiae yielded an ethanol content of 17.73 g/100 g of pretreated BSG. Ravindran et al. (2019a) used nonthermal plasma-based pretreatment to enhance the enzymatic hydrolysis of BSG during bioethanol production from it. Results demonstrated that, following dielectric barrier discharge plasma treatment (28 kV) of BSG in water, the yield of reducing sugars was increased by 2.14 folds when compared with control, and subsequent fermentation by S. cerevisiae yielded 25.062 g/L ethanol.

Consolidated bioprocessing (CBP) is a low-cost approach for biomass processing. In CBP of lignocellulose to ethanol, different conversion steps, including saccharolytic enzymes production, polysaccharides hydrolysis, and fermentation of both pentoses and hexoses, are conducted in a single reactor (Van Zyl et al., 2007). Agarwal and Dinker (2013) used consolidate enzymatic system of Fusarium and Saccharomyces to increase ethanol production from BSG. They obtained an ethanol yield of 122 g/kg of BSG at optimal conditions with the mixed culture. Wilkinson et al., (2017) reported CBP approach to produce bioethanol from BSG. They showed the highest ethanol concentration of 37 g/L using A. oryzae and S. cerevisiae NCYC479 within 10 days. Though the ethanol productivity rates were low, the process required low water and energy inputs. Carrillo-Nieves et al. (2020) showed bioethanol production from BSG using the white-rot fungus Trametes hirsuta through CBP approach. They reported an ethanol yield of 0.3 g/L with BSG for 4 days of fermentation.

Simultaneous utilization of both pentoses and hexoses in ethanol fermentation has significant advantages, such as decreased process steps and energy consumption and increased ethanol concentration. Rojas-Chamorro et al. (2018) optimized phosphoric acid pretreatment conditions for maximum sugar recovery from BSG. They showed 92% recovery of total sugars in BSG following pretreatment (2% H3PO4 at 155 °C) and enzymatic hydrolysis. Subsequent fermentation of these mixed sugars (glucose from starch and hemicellulosic sugars) by the ethanologenic Escherichia coli SL100 yielded an ethanol concentration of 0.40 g/g, without detoxification, and overall ethanol yield was 17.9 g/100 g of raw BSG. Rojas-Chamorro et al. (2020a) showed that, at pretreatment temperature of 130 °C, H2SO4 concentration of 1% w/v, and treatment time of 26 min, maximum recoveries of 94% of hemicellulosic sugars in the pretreatment liquor and 90% cellulose in the pretreated solid can be achieved, with total recovery of starch. Subsequent fermentation of these pentoses and hexoses by an ethanologenic E. coli yielded 18.1 kg ethanol per 100 kg of dried BSG. Rojas-Chamorro et al. (2020b) applied co-fermentation approach to bio-convert mixed sugars in BSG into ethanol. They showed that > 90% of sugars in raw BSG can be recovered by pretreatment (with phosphoric and sulfuric acid) and subsequent enzymatic hydrolysis. Upon co-fermentation of the mixed sugars using an ethanologenic E. coli, ethanol concentrations of up to 39 g/L were obtained from non-detoxified hydrolysates. These studies indicate the potential of acid pretreatment, enzymatic hydrolysis, and ethanologenic E. coli strains for bioethanol production using BSG as sole substrate without the need for detoxification of the hydrolysate.

Biobutanol production

Biobutanol can be produced using the same feedstocks as bioethanol. The bacterium Clostridium beijerinckii has been historically used for ABE (acetone, butanol, ethanol) fermentation. Plaza et al. (2017) showed the fermentative production of butanol from pretreated and enzymatically hydrolyzed BSG using C. beijerinckii. They reported a total butanol yield of 75 g/kg of dry BSG and an ABE yield of 95 g/kg of dry BSG. Microwave-assisted (without acid or alkali) hydrothermal pretreatment has been shown effective for recovering fermentable sugars from BSG (López-Linares et al., 2019). In that study, under optimal pretreatment conditions of 192.7 °C and 5.4 min, the total recovery of fermentable sugars contained in BSG was 82%. Subsequent fermentation using C. beijerinckii yielded 46 kg butanol/t BSG and the overall ABE yield was 62 kg/t BSG. López-Linares et al. (2020) demonstrated that both pentoses and hexoses of BSG, which were obtained following microwave-assisted dilute acid pretreatment and enzymolysis, can be fermented to butanol (91 kg/t BSG) and ABE (138 kg/t BSG) by C. beijerinckii using a single bioreactor. In a similar study, Plaza et al. (2020) reported overall yields of 99.8 g butanol/kg BSG and 146.5 g ABE/kg BSG, following dilute acid pretreatment, enzymatic hydrolysis, and fermentation by C. beijerinckii. Fernández-Delgado et al. (2019) compared different pretreatment strategies on hydrolysis and fermentation of BSG for biobutanol production. Results showed that ozone pretreatment was ineffective for either the degradation of lignin or the recovery of fermentable sugars in the enzymatic process. On the other hand, both NaOH alkaline and peroxide alkaline methods have been shown to be highly successful as pretreatments of BSG for ABE production using C. beijerinckii. NaOH-pretreated BSG (15% BSG, 1% w/w NaOH) yielded 44.4 g butanol/kg and 54 g ABE/kg and H2O2-pretreated BSG (5% BSG, 60 min) yielded 45.1 g butanol/kg and 56.1 g ABE/kg (Fernández-Delgado et al., 2019). To delignify and detoxify milled BSG, laccase preparations from Pleurotus ostreatus were successfully used (Giacobbe et al., 2019). They showed phenols reduction up to 94% following laccase pretreatment. Subsequent enzymatic saccharification and ABE fermentation by Clostridium acetobutilycum yielded 7.83 g/L butanol and 12.6 g/L ABE in 190 h.

Biogas and bio-hydrogen

Anaerobic digestion of biomass or waste feedstock for biogas production is a well-known process. BSG has huge potential for biogas production. Colussi et al., (2016) evaluated biomethanization of BSG by performing biochemical methane potential tests. Results showed BSG specific methane production of 0.284 L CH4·g− 1 COD, corresponding to a conversion degree of 81.1%. Different organic wastes can be used as co-substrates (e.g., pig slurry, sewage sludge) in BSG-to-biogas anaerobic digestion. Goberna et al. (2013) showed a high methane yield upon using fermented BSG as an inoculum to bio-augment microbial consortia in the process of co-digestion of BSG with sewage sludge. BSG solubilization (the hydrolysis stage) is the rate-limiting step during its anaerobic digestion process because of lack of specific and sufficient extracellular enzymes. Hence, an enzymatic pre-hydrolysis step could be advantageous for increasing the rate of anaerobic digestion, however, this can in turn increase the cost of processing (Wang et al., 2015). As a remedy, the application of inexpensive crude multi-enzyme mixture produced via solid-state fermentation (SSF) process has been proposed by Bochmann et al. (2007). They observed increased hydrolysis of lignocellulose, enhanced biogas production, and improved quality of biogas (high CH4 and low CO2) with multi-enzyme application. The mixture of trub and BSG positively influences the volume of methane (Oliveira et al., 2018). They also observed the synergistic effect of co-digestion of trub, BSG, and crude glycerol, resulting in the highest methane yield of 573 L kg−1 and a biodegradability of 94%. Ochs and Kastner (2010) developed a combined H2 and CH4 producing process. Results showed that total biogas yield was 204.7–210.6 normal litre (NL) biogas/kg VS, with gas composition of 72.6% CH4, 22.9% CO2, and 4.5% H2.

Bochmann et al. (2015a; 2015b) investigated thermal (temperature range: 100 to 200 °C) pretreatment strategy to improve degradation rate and biogas yield from BSG. Pretreatment temperatures up to 160 °C positively influenced the degradation rate or biogas yield. For pretreated BSG, daily biogas yield was 430 NL × kg−1 and total methane yield (batch analysis) was 467.6 NL CH4 × kg−1. Malakhova et al. (2015) reported anaerobic fermentation of BSG into biogas in co-digestion with Jerusalem artichoke phytomass by mesophilic (+ 30 °C) and thermophilic (+ 55 °C) anaerobic methanogenic communities. Under thermophilic conditions, the highest total methane productions were 6–8 and 9–11 of L CH4 per 100 g of fermented BSG without and with co-digested Jerusalem artichoke, respectively. Zhang and Zang (2016) investigated biohydrogen production from BSG. They found that C/N ratio of BSG was suitable for H2 production and improved BSG solubilization was noted by pretreatment using calcined-red mud. Their results showed the highest specific H2 production of 198.62 mL/g VS from the pretreated BSG via anaerobic fermentation. Dudek et al. (2019) showed that the addition of biochar, which was produced from BSG via low-temperature pyrolysis (torrefaction), at a lower dose (5%) had improved biogas production rate significantly (227 dm3 kg−1 dry organic matter d−1) in anaerobic digestion of BSG.

Microbial lipids (biodiesel)

Microbial lipids are potential sources for biodiesel production. Sae-ngae et al. (2019) used BSG as a nutrient source for the cultivation of oleaginous yeasts. Among tested yeasts, Trichosporonoides spathulata yielded the highest lipid concentration of 62.9 mg/g substrate. Patel et al. (2018) used hydrolysates of organosolv-pretreated BSG for the cultivation of the oleaginous yeast Rhodosporidium toruloides. They reported a maximum lipid accumulation of 10.41 g/L (lipid content of 56.45%) and cell dry weight of 18.44 g/L under optimal conditions.

Production of organic acids

Organic acids such as lactic and citric acids have been fermentatively produced using BSG. Mussatto et al. (2007) produced L-lactic acid by fermenting BSG hydrolysate using Lactobacillus delbrueckii. In their study, BSG was chemically pre-treated before sachharification with cellulase and no nutrients were supplemented to the media. Results showed that a maximum lactic acid yield of 73% can be achieved. The supplementation of nitrogenous nutrients may increase lactic acid yield and productivity as BSG contains low concentrations of FAN (Djukić-Vuković et al., 2016). Juodeikiene et al. (2016) investigated the bioconversion of BSG to lactic acid by Lactobacillus sakei and two Pediococcus spp. strains. They observed a maximum l‐lactic acid concentration of 48.71 g/kg of BSG following its enzymatic hydrolysis (cellulase and hemicellulase complex) and fermentation (48 h) by Pediococcus pentosaceus KTU05‐9. Mussatto et al. (2008) noted increased lactic acid productivities upon the addition of yeast extract (0.53 g/L⋅h with 5 g/L) and MRS broth medium components devoid of carbon source (0.79 g/L⋅h) to BSG hydrolysates. They showed that pH-controlled fermentation of MRS components-supplemented media yielded the highest lactic acid concentration of 35.54 g/L. Pejin et al. (2015) showed increased lactic acid yields following the addition of yeast extract (0.5–5.0%) and calcium carbonate (2%) to BSG hydrolysates and fermentation by Lactobacillus fermentum and Lactobacillus rhamnosus. In L. fermentum fermentations, lactic acid yields were increased by 4–26% and 13% due to yeast extract and calcium carbonate addition, respectively. In L. rhamnosus fermentations, lactic acid yields were increased by 6–8% and 17% following yeast extract and calcium carbonate supplementation, respectively. Along with FAN source (yeast extract), pH control during fermentation of BSG hydrolysates has been shown to increase lactic acid yields (Pejin et al., 2017a). A significant improvement in the utilization of reducing sugars was noted upon pH control. They showed that, with yeast extract concentration of 50 g/L and reducing sugar content of 54 g/L, a maximum L-( +)-lactic acid concentration of 39.38 g/L, volumetric productivity of 1.69 g/L/h, L-( +)-lactic acid yield of 91.29%, and L. rhamnosus cell viability of 9.67 log CFU/mL can be achieved. Compared with batch fermentation, fed-batch fermentation of BSG with yeast extract and glucose addition had yielded significantly higher lactic acid concentration, volumetric productivity, and yield (Pejin et al., 2017b).

Liguori et al. (2015b) tested the potential of different Lactobacillus strains for lactic acid production from BSG. The strain L. acidophilus ATCC 43121 was found to be superior among those tested. They also found that aqueous ammonia soaking pretreatment prior to hydrolysis, yeast extract supplementation to BSG hydrolysate, and subsequent fermentation using the strain yielded 22.16 g lactic acid/L. Liang and Wan (2015) utilized BSG for carboxylic acid production through mixed culture fermentation. They showed that, under both acidic and alkaline conditions, lactic acid was the predominant component (9.2 and 6.7 g/L, respectively). On the other hand, the accumulation of volatile fatty acids was noted under the neutral condition.

Pejin et al. (2018) used BSG hydrolysate, malt rootlets extract (MRE), and soybean meal extract (SME) to produce L-( +)-lactic acid by a L. rhamnosus strain. The concentrations of FAN and essential minerals (Fe, Mg, Mn, and Zn) were increased by MRE and SME addition. In batch fermentation, the addition of 50% MRE led to a maximum lactic acid concentration of 25.73 g/L, with a yield of 86.31% and a volumetric productivity of 0.95 g/L h−1. In fed-batch fermentation, with 50% MRE addition, the concentration, yield, and volumetric productivity of lactic acid were further increased to 58.01 g/L, 88.54%, and 1.19 g/L h−1, respectively. Radosavljević et al. (2019) utilized BSG, brewer’s yeast (BY), malt rootlets (MR), and soy lecithin (SL) as raw materials in L-( +)-lactic acid fermentation. Brewer’s spent grain and malt rootlets (BSGMR) hydrolysate with added SL and BY extract was allowed for batch fermentation by L. rhamnosus. Results showed that, using BSG as a carrier, maximum lactic acid yield and volumetric productivity can be obtained. Radosavljević et al. (2020) showed that Tween 80 and yeast extract can be replaced by inexpensive BSG along with BY, MR, and SL in lactic acid fermentation. The highest lactic acid concentration of 70.17 g/L and a productivity of 1.22 g/L/h were obtained following fed-batch fermentation of BSGMR hydrolysate with BY extract and glucose. Akermann et al. (2020) showed that BSG liquor (the soluble components of BSG), which can be obtained from BSG by pressing, has the potential to be used as a substrate for lactate production using L. delbrueckii subsp. lactis. They concluded that the application of yeast extract produced from brewers’ yeast to BSG liquor yielded a maximum lactate concentration of 79.06 g/L, with a productivity of 4.93 g/L/h.

Girotto et al. (2019) used BSG as a substrate for biological monomers production in acidogenic fermentation. Alkaline-pretreated BSG yielded 62.0 g target monomers per liter substrate (with highest acetate yield of 36.7 g/L) following fermentation at an initial pH 9. Their results suggested that BSG is promising for use in implementing pathways for the valorization of volatile fatty acids, such as the production of polyhydroxyalkanoates.

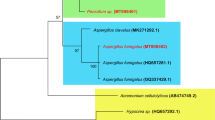

Pathania et al. (2018) produced citric acid using BSG as substrate under SSF conditions. They observed increased productions of citric acid by Aspergillus niger upon supplementations; up to 0.19% by peptone and 0.22% by potassium dihydrogen phosphate.

Enzyme production

BSG has been used as an inexpensive substrate for the fermentative production of enzymes. Several studies demonstrated successful growth of both fungal (e.g., Pleurotus, Lentinus, Aspergillus, Agrocybe, Trametes, and Neurospora) and bacterial (e.g., Bacillus subtilis and Streptomyces avermitilis) species on this substrate without the need of, in most cases, additional nutritional source. The production of various microbial extracellular enzymes, such as amylases, cellulases, xylanases, proteases, laccases, feruloyl esterase, and α-L-arabinofuranosidase, using BSG as substrate has been reported (Table 1).

Xylitol

Xylitol, a functional sweetener, can be produced from different lignocellulosic materials via fermentative process, though it is usually produced through chemical route. For xylitol production through either chemical or fermentation routes, xylose-rich hemicellulosic hydrolysates are the raw materials (Felipe Hernández-Pérez et al., 2019). BSG is a potential substrate for the fermentative production of xylitol because it produces xylose-rich hydrolysate upon fractionation and is a cost-effective feedstock. High fermentation yields can be obtained without the need for nutrient addition to the medium and hydrolysate detoxification (Mussatto and Roberto, 2008). BSG hydrolysate was used for xylitol production by C. guilliermondii (Mussatto and Roberto, 2005, 2008). Hemicellulosic fraction of BSG was hydrolyzed with dilute sulfuric acid to produce liquor rich in xylose, subsequent fermentation yielded a xylitol concentration of 0.7 g/g (Mussatto and Roberto, 2005). Under optimized conditions, a xylitol yield of 0.78 g/g and a productivity of 0.58 g/(L⋅h) were reported (Mussatto and Roberto, 2008). Davila et al., (2016) proposed a biorefinery approach for the production of ethanol, xylitol, and polyhydroxybutyrate from BSG. They suggested that total production cost for these bio-products can be decreased by 43% through a heat integration strategy, thereby reducing potential environmental impact of BSG processing. da Silva et al. (2020) have used hemicellulose liquor from BSG for the fermentative production of 2G ethanol and xylitol using Scheffersomyces stipitis and Pachysolen tannophilus. For S. stipitis, selectivity for ethanol over xylitol was relatively higher under aerobic conditions compared with under oxygen-limited conditions. For P. tannophilus, xylitol was preferentially produced under oxygen-limited conditions.

Prebiotic oligosaccharides

Xylooligosaccharides (XOS) and arabinoxylooligosaccharides (AXOS) are known to function as prebiotics via selectively favoring the growth of certain beneficial gut microorganisms. BSG is an interesting raw material for obtaining a mixture of prebiotic AXOS. Sajib et al. (2018) showed the production of AXOS of desired chain length by enzymatic hydrolysis of arabinoxylan, which was obtained from BSG. Xylanases of varying types were used for the hydrolysis. Amorim et al. (2018) used BSG for the fermentative production (single-step fermentation) of AXOS using B. subtilis; a maximum yield of 54.2 mg xylose equivalents/g of BSG was observed. Amorim et al. (2019) investigated one-step fermentative production of XOS using BSG as substrate. Under optimized conditions (20 g/L of BSG, pH 7.0, 30 °C, 3 days), a yield of 38.3 mg xylose equivalents/g of BSG was noted using Trichoderma reesei.

Single cell protein

Edible filamentous fungi can be used for food and feed purposes since they are a promising source of protein, fatty acids, and vitamins. Serba et al. (2020) used BSG as a raw material for the production of Aspergillus oryzae biomass with increased protein and polysaccharides content. They showed that the protein content of fungus grown on medium containing this by-product by SSF was three times higher than in fungus grown by submerged fermentation. Ogunjobi et al. (2011) also reported a significant increase in protein content with SSF of BSG by A. oryzae (after 35 days of fermentation) compared with unfermented control. In addition, a significant decrease in carbohydrate and fiber contents and increased ash contents were noted in the fermented BSG. To enhance nutritional value of BSG, Ibarruri et al. (2019) investigated SSF approach using Rhizopus sp. They found that, upon fermentation of BSG at 30 °C for 9 days, total protein and soluble protein concentrations of biomass were remarkably increased. In addition, the resultant biomass exhibited a modified amino acid profile (with high proportion of essential amino acids) and a high total polyphenol content, thereby an increase of antioxidant capacity. In another study, food-grade Rhizopus oligosporus was used to enhance the nutrient content of BSG via SSF (Cooray and Chen, 2018). They observed the enhancement of amino acids, vitamin, citric acid, and antioxidant levels in BSG upon the fermentation. Tan et al. (2019) showed the improvement of nutritional value of BSG via SSF using B. subtilis. Following fermentation, increased concentrations of amino acids (twofold), unsaturated fatty acids (1.7 times), and antioxidants (5.8 times) were noted, indicating the potential of the microorganism to degrade complex macronutrients to useful components. Aggelopoulos et al. (2013) showed that an increase of BSG content in substrate mixtures (consisting of different agro-industrial wastes) intended for growth of single cell protein producers led to an increase of cell mass: by twofold for S. cerevisiae and threefold for K. marxianus, under SSF. Aggelopoulos et al. (2018) showed protein enrichment of agro-industrial side streams and wastes, including BSG, with the edible mushroom Pleurotus ostreatus by SSF. They recognized BSG as a fungal cell growth-promoting ingredient. The obtained fermented mycelium-enriched product was rich in protein, aroma volatile compounds, and minerals.

As carrier matrices

BSG has been used as a lignocellulosic yeast carrier for continuous beer fermentation and found to possess a high yeast loading capacity, which is triggered by physicochemical and biochemical properties of both cells and carrier (Branyik et al., 2001; Pires et al., 2012). Pretreatments using caustic (NaOH) and acid-caustic (HCl + NaOH) were proposed for effective yeast adhesion to the carrier (Pires et al., 2012). Kopsahelis et al. (2007b) showed the suitability of BSG for psychrotolerant yeast immobilization in a very low temperature brewing. They observed increased productivities and fine quality green beers with low vicinal diketone, dimethyl sulfide, and amyl alcohol concentrations because of the immobilization. Mohammadi et al. (2011) showed that the immobilization of Saccharomyces ludwigii and Saccharomyces rouxii on BSG impacted their sugar utilization (could consume maltose) in brewing process. Dragone et al. (2007) used BSG for yeast immobilization in continuous primary beer fermentation using high-gravity worts. Tsaousi et al. (2011) prepared a thermally dried biocatalyst for low temperature winemaking using BSG as carrier. They immobilized a psychrotolerant yeast strain on delignified BSG, which was followed by a simple thermal drying. The resultant dried biocatalysts were used for repeated batch fermentations and were found to improve product quality (increased esters, low higher alcohols, and high alcohol productivity).

Kopsahelis et al. (2007a) used fresh, defrosted, and delignified BSG for yeast immobilization in ethanol fermentation from molasses. They observed higher fermentation rates and productivities using the BSG immobilized biocatalyst without additional nutrients input. Even for continuous ethanolic fermentation using molasses, the suitability of BSG as yeast carrier was established (Kopsahelis et al., 2012). They observed maximum ethanol concentrations in the range of 47.4–50.6 kg m−3 at 35 °C using non-sterilized molasses. In addition, no contamination was observed during 32 days of continuous operation; and the system exhibited high operational stability and high fermentation efficiency. Mussatto et al. (2009) used BSG as a carrier for the fermentative production of fructooligosaccharides (FOS) and β-fructofuranosidase from sucrose by Aspergillus japonicas. The cells exhibited good immobilization on this carrier (1.06 g/g carrier), with a FOS productivity of 5.39 g/L⋅h and a yield of 0.60 g/g total substrate. Radosavljević et al. (2019) showed that BSG can be used as a carrier (without pretreatment) in L-( +)-lactic acid production. They observed the highest lactic acid yields of 93.79 and 95.46% and volumetric productivities of 1.15 and 1.98 g/L/h in batch and repeated batch fermentations, respectively, using L. rhamnosus immobilized on this carrier. BSG was used for the immobilization of Lactobacillus paracasei in the process of simultaneous production of lactic acid and livestock feed using molasses and potato stillage as a combined substrate (Mladenović et al., 2019). As a low-cost biopolymer, BSG was used as support for kefir cells immobilization during whey-to-ethanol fermentation (Soupioni et al., 2013). Results showed that the prepared biocatalyst significantly increased the fermentation rate. The hydrophilic nature of cellulose has been shown to contribute to the protection of immobilized kefir cells and thus to their enhanced biocatalytic activity.

Miscellaneous

Saba et al. (2019) showed the suitability of BSG as substrate for earthworms in vermicomposting. Following 5 months of bioconversion, vermicomposts containing BSG only and BSG + cow manure (1:1) exhibited increased levels of total nitrogen and total humic substances like and reduced total organic carbon content, indicating higher mineralization and stabilization. Teixeira et al. (2020) demonstrated the production of high concentrations (24.9 g/L) of volatile fatty acids through anaerobic digestion of raw BSG, i.e. without any pretreatment. BSG hydrolysates were used as media to produce bacteriocins using Lactococcus lactis Tw11 and Enterococcus mundtii Tw492 (Paz et al., 2018). They showed that Tween 80 supplementation to the media stimulated the production and release of bacteriocins; When tested against Listeria monocytogenes CECT-934, inhibition halos of 15.46 and 24.47 mm were observed for L. lactis Tw11 and E. mundtii Tw492, respectively. Kim et al. (2020) employed BSG as a low-cost substrate for the production of paramylon, a potent immunomodulator from microalga Euglena gracilis. Results showed that paramylon content of 32.3% w/w and a yield of 0.11 g/g can be achieved.

Qiu et al. (2019) used BSG as a potential substrate for biocontrol fertilizer (BF) production using the entomopathogenic fungi Beauveria bassiana. The BF at a concentration of 1 × 10−2 g/mL (containing the 0.8 × 106 spores) exhibited high toxicity against Galleria mellonella larvae, with an LT50 of 3.6 days, and prompted plant growth. Silbir and Goksungur (2019) used BSG as substrate for the fermentative production of red pigment by Monascus purpureus. They reported a maximum pigment production of 22.25 UA500 through submerged fermentation. BSG was used as a substrate for the production of biomass of the medicinal fungus Hericium erinaceus via submerged cultivation (Wolters et al., 2016). To induce the secondary metabolite erinacine C production, the biomass produced was subjected to a second fermentation. Finally, biomass with erinacine C concentration of 174.8 mg/g for BSG was obtained and it has potential to be used in functional foods. Gupta et al. (2013) developed a fermented liquid product rich in neutraceuticals using BSG as raw material and Lactobacillus plantarum as inoculum. The finished product exhibited higher antioxidant capacity, with a shelf life of 15 days under refrigeration. Under optimal conditions, a production of 2.95 g/L lactic acid accompanied by a release of 135 mg quercetin equivalent (QE)/mL of flavonoid compounds, 268.6 mg gallic acid equivalent (GAE)/mL of phenolic compounds, 33.7 mg trolox equivalent (TE)/mL ferric reducing antioxidant power (FRAP), and 75.1% radical scavenging activity (RSA) was noted. Waters et al. (2012) used the lactic acid bacteria, L. plantarum, to ferment BSG. The incorporation of the resultant fermented BSG as an ingredient in wheat breads led to softer breads with increased springiness.

In conclusion, as the concept of circular economy is gaining momentum in recent years, biotechnology holds promise for reducing agro-industrial waste and improve sustainability. Being an abundant agro-industrial by-product and a rich source of fermentable carbohydrates and other nutrients, BSG is an ideal substrate for biotechnological production of value-added products. The success of biotechnological processes lies in their economic viability compared with chemical process counterparts. Co-utilization of pentoses and hexoses from BSG hydrolysate as well as consolidated bioprocessing approaches can potentially reduce process steps and energy consumption. However, the construction of efficient organisms for these purposes remains a challenge. The production costs of the value-added products could be significantly reduced by using bio-refinery approach (i.e. co-producing value-added products); the approach might need cost-effective and efficient downstream processing methods for maximum product recovery.

References

Aboltins A, Palabinskis J. Research in brewer’s spent grain drying process. 14th International Scientific Conference “Engineering for Rural Development” - 20–22.05.2015 pp. 230–235. Jelgava, Latvia (2015)

Agarwal M, Dinker A. Application of consolidate enzymatic system of Fusarium and Saccharomyces to enhance the production of ethanol from spent grain. Journal of Renewable and Sustainable Energy 5: 053112 (2013)

Aggelopoulos T, Bekatorou A, Pandey A, Kanellaki M, Koutinas AA. Discarded oranges and brewer’s spent grains as promoting ingredients for microbial growth by submerged and solid state fermentation of agro-industrial waste mixtures. Applied Biochemistry and Biotechnology 170: 1885–1895 (2013)

Aggelopoulos T, Bekatorou A, Plessas S, Koutinas AA, Nigam P. Upgrading of mixed food industry side-streams by solid-state fermentation with P. ostreatus. Recycling 3: 12 (2018)

Akermann A, Weiermüller J, Christmann J, Guirande L, Glaser G, Knaus A, Ulber R. Brewers’ spent grain liquor as a feedstock for lactate production with Lactobacillus delbrueckii subsp. lactis. Engineering in Life Sciences 20: 168–180 (2020)

Amore A, Parameswaran B, Kumar R, Birolo L, Vinciguerra R, Marcolongo L, Ionata E, La Cara F, Pandey A, Faraco V. Application of a new xylanase activity from Bacillus amyloliquefaciens XR44A in brewer's spent grain saccharification. Journal of Chemical Technology and Biotechnology 90: 573-581 (2015)

Amorim C, Silvério SC, Rodrigues LR. One-step process for producing prebiotic arabino-xylooligosaccharides from brewer's spent grain employing Trichoderma species. Food Chemistry 270: 86-94 (2019)

Amorim C, Silvério SC, Silva SP, Coelho E, Coimbra MA, Prather KL, Rodrigues LR. Single-step production of arabino-xylooligosaccharides by recombinant Bacillus subtilis 3610 cultivated in brewers’ spent grain. Carbohydrate Polymers 199: 546-554 (2018)

Bartolome B, Gómez-Cordovés C, Sancho AI, Diez N, Ferreira P, Soliveri J, Copa-Patiño JL. Growth and release of hydroxycinnamic acids from brewer’s spent grain by Streptomyces avermitilis CECT 3339. Enzyme and Microbial Technology 32: 140–144 (2003)

Bochmann G, Drosg B, Fuchs W. Anaerobic digestion of thermal pretreated brewers' spent grains. Environmental Progress and Sustainable Energy 34: 1092-1096 (2015a)

Bochmann G, Drosg B, Fuchs W. Anaerobic digestion of thermal pretreated brewers' spent grains. Environmental Progress and Sustainable Energy 34:1832-1832 (2015b)

Bochmann G, Herfellner T, Susanto F, Kreuter F, Pesta G. Application of enzymes in anaerobic digestion. Water Science and Technology 56: 29-35 (2007)

Bogar B, Szakacs G, Tengerdy RP, Linden JC, Pandey A. Production of α‐amylase with Aspergillus oryzae on spent brewing grain by solid substrate fermentation. Applied Biochemistry and Biotechnology 102/103: 453–461 (2002)

Bonifacio-Lopes T, Teixeira JA, Pintado M. Current extraction techniques towards bioactive compounds from brewer’s spent grain: a review. Critical Reviews in Food Science and Nutrition 60: 2730-2741 (2020)

Branyik T, Vicente A, Cruz JM, Teixeira J. Spent grains – a new support for brewing yeast immobilisation. Biotechnology Letters 23: 1073−1078 (2001)

Broeker T, Hoffarth M, Oppermann L, Wolff V, Neubauer P, Schneider J. Oxidation of brewers spent grain for the release of fermentable sugars by direct pretreatment in an electrolysis reactor. Brewing Science 70: 74-84 (2017)

Carrillo-Nieves D, Saldarriaga-Hernandez S, Gutiérrez-Soto G, Rostro-Alanis M, Hernández-Luna C, Alvarez AJ, Iqbal H, Parra-Saldívar R. Biotransformation of agro-industrial waste to produce lignocellulolytic enzymes and bioethanol with a zero waste. Biomass Conversion and Biorefinery https://doi.org/10.1007/s13399-020-00738-6 (2020)

Colussi I, Cortesi A, Gallo V, Vitanza R. Biomethanization of brewer's spent grain evaluated by application of the Anaerobic Digestion Model No. 1. Environmental Progress and Sustainable Energy 35: 1055–1060 (2016)

Cooray ST, Chen WN. Valorization of brewer’s spent grain using fungi solid-state fermentation to enhance nutritional value. Journal of Functional Foods 42: 85-94 (2018)

da Silva EG, Borges AS, Maione NR, Castiglioni GL, Suarez CA, Montano ID. Fermentation of hemicellulose liquor from Brewer's spent grain using Scheffersomyces stipitis and Pachysolen tannophilus for production of 2G ethanol and xylitol. Biofuels, Bioproducts and Biorefining 14: 127-137 (2020)

Davila JA, Rosenberg M, Cardona CA. A biorefinery approach for the production of xylitol, ethanol and polyhydroxybutyrate from brewer’s spent grain. AIMS Agriculture and Food 1: 52-66 (2016)

de Castro AM, Castilho LR, Freire DMG. Multivariate optimization and supplementation strategies for the simultaneous production of amylases, cellulases, xylanases, and proteases by Aspergillus awamori under solid-state fermentation conditions. Applied Biochemistry and Biotechnology 175: 1588-1602 (2015)

Dhillon GS, Kaur S, Brar SK. In-vitro decolorization of recalcitrant dyes through an ecofriendly approach using laccase from Trametes versicolor grown on brewer's spent grain. International Biodeterioration and Biodegradation 72: 67-75 (2012)

Djukić-Vuković A, Mladenović D, Radosavljević M, Kocić-Tanackov S, Pejin J, Mojović L. Wastes from bioethanol and beer productions as substrates for L (+) lactic acid production: a comparative study. Waste Management 48: 478-482 (2016)

Dragone G, Mussatto SI, Almeida e Silva JB. High gravity brewing by continuous process using immobilised yeast: effect of wort original gravity on fermentation performance. Journal of the Institute of Brewing 113: 391–398 (2007)

Dudek M, Świechowski K, Manczarski P, Koziel JA, Białowiec A. The effect of biochar addition on the biogas production kinetics from the anaerobic digestion of brewers’ spent grain. Energies 12: 1518 (2019)

Felipe Hernández-Pérez A, de Arruda PV, Sene L, da Silva SS, Kumar Chandel A, de Almeida Felipe, MDG. Xylitol bioproduction: state-of-the-art, industrial paradigm shift, and opportunities for integrated biorefineries. Critical Reviews in Biotechnology 39(7): 924–943 (2019)

Fernández-Delgado M, Plaza PE, Coca M, García-Cubero MT, González-Benito G, Lucas S. Comparison of mild alkaline and oxidative pretreatment methods for biobutanol production from brewer’s spent grains. Industrial Crops and Products 130: 409–419 (2019)

Francis F, Sabu A, Nampoothiri KM, Ramachandran S, Ghosh S, Szakacs G, Pandey A. Use of response surface methodology for optimizing process parameters for the production of α-amylase by Aspergillus oryzae. Biochemical Engineering Journal 15: 107–115 (2003)

Francis F, Sabu A, Nampoothiri KM, Szakacs G, Pandey A. Synthesis of α‐amylase by Aspergillus oryzae in solid‐state fermentation. Journal of Basic Microbiology 42: 320–326 (2002)

Giacobbe S, Piscitelli A, Raganati F, Lettera V, Sannia G, Marzocchella A, Pezzella C. Butanol production from laccase-pretreated brewer’s spent grain. Biotechnology for Biofuels 12: 47 (2019)

Girotto F, Kusch S, Lavagnolo MC. Biological metabolites recovery from beverage production solid residues through acidogenic fermentation. Detritus 5: 19–28 (2019)

Goberna M, Camacho MDM, Lopez-Abadia JA, García C. Co-digestion, biostimulation and bioaugmentation to enhance methanation of brewer’s spent grain. Waste Management and Research 31: 805–810 (2013)

Gupta S, Jaiswal AK, Abu-Ghannam N. Optimization of fermentation conditions for the utilization of brewing waste to develop a nutraceutical rich liquid product. Industrial Crops and Products 44: 272–282 (2013)

Hashemi M, Razavi SH, Shojaosadati SA, Mousavi SM. The potential of brewer's spent grain to improve the production of α‐amylase by Bacillus sp. KR‐8104 in submerged fermentation system. New Biotechnology. 28: 165–172 (2011)

Hassan SS, Ravindran R, Jaiswal S, Tiwari BK, Williams GA, Jaiswal AK. An evaluation of sonication pretreatment for enhancing saccharification of brewers' spent grain. Waste Management 105: 240–247 (2020a)

Hassan SS, Tiwari BK, Williams GA, Jaiswal AK. Bioprocessing of brewers' spent grain for production of xylanopectinolytic enzymes by Mucor sp. Bioresource Technology Reports 9: 100371 (2020b)

Heredia-Olea E, Pérez-Carrillo E, Serna-Saldívar SO. Effect of extrusion conditions and hydrolysis with fiber-degrading enzymes on the production of C5 and C6 sugars from brewers’ spent grain for bioethanol production. Biofuel Research Journal 2: 203-208 (2015)

Huige NJ. Brewery by‐products and effluents. In Handbook of Brewing ed. Priest, F.G. and Stewart, G.G. pp. 670–729. Boca Raton: CRC Press (2006)

Ibarruri J, Cebrián M, Hernández I. Solid state fermentation of Brewer’s spent grain using Rhizopus sp. to enhance nutritional value. Waste and Biomass Valorization 10: 3687–3700 (2019)

Ikram S, Huang L, Zhang H, Wang J, Yin M. Composition and nutrient value proposition of brewers spent grain. Journal of Food Science 82: 2232–2242 (2017)

Juodeikiene G, Klupsaite D, Zadeike D, Cizeikiene D, Vidziunaite I, Bartkiene E, Cernauskas D. Bioconversion of agro‐industrial by‐products to lactic acid using Lactobacillus sakei and two Pediococcus spp. strains. International Journal of Food Science and Technology. 51: 2682–2691 (2016)

Kim S, Lee D, Lim D, Lim S, Park S, Kang C, Yu J, Lee T. Paramylon production from heterotrophic cultivation of Euglena gracilis in two different industrial byproducts: Corn steep liquor and brewer's spent grain. Algal Research. 47: 101826 (2020)

Knob A, Beitel SM, Fortkamp D, Terrasan CRF, Almeida AFD. Production, purification, and characterization of a major Penicillium glabrum xylanase using brewer's spent grain as substrate. BioMed Research International. Article ID: 728735 (2013)

Kopsahelis N, Agouridis N, Bekatorou A, Kanellaki M. Comparative study of spent grains and delignified spent grains as yeast supports for alcohol production from molasses. Bioresource Technology 98: 1440–1447 (2007a)

Kopsahelis N, Bosnea L, Bekatorou A, Tzia C, Kanellaki M. Alcohol production from sterilized and non-sterilized molasses by Saccharomyces cerevisiae immobilized on brewer's spent grains in two types of continuous bioreactor systems. Biomass and Bioenergy. 45: 87–94 (2012)

Kopsahelis N, Kanellaki M, Bekatorou A. Low temperature brewing using cells immobilized on brewer’s spent grains. Food Chemistry. 104: 480–488 (2007b)

Kotlar CE, Agüero MV, Roura SI. Statistical optimization of a novel low-cost medium based on regional agro-industrial by-products for the production of proteolytic enzymes by Bacillus cereus. Preparative Biochemistry and Biotechnology 42: 406–425 (2012)

Laba W, Piegza M, Kawa‐Rygielska J. Evaluation of brewer's spent grain as a substrate for production of hydrolytic enzymes by keratinolytic bacteria. Journal of Chemical Technology and Biotechnology 92: 1389–1396 (2017)

Leite P, Silva C, Salgado JM, Belo I. Simultaneous production of lignocellulolytic enzymes and extraction of antioxidant compounds by solid-state fermentation of agro-industrial wastes. Industrial Crops and Products 137: 315–322 (2019)

Liang S, Wan C. Carboxylic acid production from brewer’s spent grain via mixed culture fermentation. Bioresource Technology 182: 179–183 (2015)

Liguori R, Soccol CR, Porto de Souza Vandenberghe L, Woiciechowski AL, Faraco V. Second generation ethanol production from brewers’ spent grain. Energies 8: 2575–2586 (2015a)

Liguori R, Soccol CR, Vandenberghe LPDS, Woiciechowski AL, Ionata E, Marcolongo L, Faraco V. Selection of the strain Lactobacillus acidophilus ATCC 43121 and its application to brewers’ spent grain conversion into lactic acid. BioMed Research International Article ID: 240231, 9 pages (2015b)

López-Linares JC, García-Cubero MT, Lucas S, Coca M. Integral valorization of cellulosic and hemicellulosic sugars for biobutanol production: ABE fermentation of the whole slurry from microwave pretreated brewer's spent grain. Biomass and Bioenergy 135: 105524 (2020)

López-Linares JC, García-Cubero MT, Lucas S, González-Benito G, Coca M. Microwave assisted hydrothermal as greener pretreatment of brewer’s spent grains for biobutanol production. Chemical Engineering Journal 368: 1045–1055 (2019)

Lynch KM, Steffen EJ, Arendt EK. Brewers' spent grain: a review with an emphasis on food and health. Journal of the Institute of Brewing 122: 553–568 (2016)

Macheiner D, Adamitsch BF, Karner F, Hampel WA. Pretreatment and hydrolysis of brewer’s spent grains. Engineering in Life Sciences 3: 401–405 (2003)

Malakhova DV, Egorova MA, Prokudina LI, Netrusov AI, Tsavkelova EA. The biotransformation of brewer’s spent grain into biogas by anaerobic microbial communities. World Journal of Microbiology and Biotechnology 31: 2015–2023 (2015)

Mandalari G, Bisignano G, Curto RL, Waldron KW, Faulds CB. Production of feruloyl esterases and xylanases by Talaromyces stipitatus and Humicola grisea var. thermoidea on industrial food processing by-products. Bioresource Technology 99: 5130–5133 (2008)

Mata TM, Tavares TF, Meireles S, Caetano NS. Bioethanol from brewers’ spent grain: pentose fermentation. Chemical Engineering Transactions 43: 241–246 (2015)

Matsakas L, Antonopoulou I, Christakopoulos P. Evaluation of Myceliopthora thermophila as an enzyme factory for the production of thermophilic cellulolytic enzymes. Bioresources 10: 5140–5158 (2015)

Mladenović D, Djukić‐Vuković A, Stanković M, Milašinović‐Šeremešić M, Radosavljević M, Pejin J, Mojović L. Bioprocessing of agro‐industrial residues into lactic acid and probiotic enriched livestock feed. Journal of the Science of Food and Agriculture 99: 5293–5302 (2019)

Mohammadi A, Razavi SH, Mousavi SM, Rezaei K. A comparison between sugar consumption and ethanol production in wort by immobilized Saccharomyces cerevisiae, Saccharomyces ludwigii and Saccharomyces rouxii on brewer's spent grain. Brazilian Journal of Microbiology 42: 605–615 (2011)

Mussatto SI. Brewer's spent grain: a valuable feedstock for industrial applications. Journal of the Science of Food and Agriculture 94: 1264–1275 (2014)

Mussatto SI, Roberto IC. Acid hydrolysis and fermentation of brewer's spent grain to produce xylitol. Journal of the Science of Food and Agriculture 85: 2453–2460 (2005)

Mussatto SI, Roberto IC. Establishment of the optimum initial xylose concentration and nutritional supplementation of brewer's spent grain hydrolysate for xylitol production by Candida guilliermondii. Process Biochemistry 43: 540–546 (2008)

Mussatto SI, Aguilar CN, Rodrigues LR, Teixeira JA. Fructooligosaccharides and β-fructofuranosidase production by Aspergillus japonicus immobilized on lignocellulosic materials. Journal of Molecular Catalysis B: Enzymatic 59: 76–81 (2009)

Mussatto SI, Fernandes M, Mancilha IM, Roberto IC. Effects of medium supplementation and pH control on lactic acid production from brewer's spent grain. Biochemical Engineering Journal 40: 437–444 (2008)

Mussatto SI, Fernandes M, Dragone G, Mancilha IM, Roberto IC. Brewer’s spent grain as raw material for lactic acid production by Lactobacillus delbrueckii. Biotechnology Letters 29: 1973–1976 (2007)

Ochs DFD, Kastner DFV, Ahrer W. KombiGas: Combined methane and hydrogen production for the application in the stationary motor. Chemical Engineering Transactions 21: 1261–1266 (2010)

Ogunjobi AA, Mejeha OK, Fagade OE. Protein enrichment of brewery spent grains using Aspergillus oryzae. AU Journal of Technology 15: 53–56 (2011)

Okita H, Yamashita H, Yabuuchi S. Production of microbial enzymes using brewers' spent grain. Hakko Kogaku Kaishi 63: 55–60 (1985)

Oliveira JV, Alves MM, Costa JC. Biochemical methane potential of brewery by-products. Clean Technologies and Environmental Policy 20: 435–440 (2018)

Panagiotou G, Granouillet P, Olsson L. Production and partial characterization of arabinoxylan-degrading enzymes by Penicillium brasilianum under solid-state fermentation. Applied Microbiology and Biotechnology 72: 1117–1124 (2006)

Pathania S, Sharma S, Kumari K. Solid state fermentation of BSG for citric acid production. Indian Journal of Natural Products and Resources 9: 70–74 (2018)

Paz A, da Silva Sabo S, Vallejo M, Marguet E, de Souza Oliveira RP, Domínguez JM. Using brewer's spent grain to formulate culture media for the production of bacteriocins using Patagonian strains. LWT - Food Science and Technology 96: 166–174 (2018)

Pejin J, Radosavljević M, Kocić‐Tanackov S, Djukić‐Vuković A, Mojović L. Lactic acid fermentation of brewer's spent grain hydrolysate by Lactobacillus rhamnosus with yeast extract addition and pH control. Journal of the Institute of Brewing 123: 98–104 (2017a)

Pejin J, Radosavljević M, Kocić‐Tanackov S, Mladenović D, Djukić‐Vuković A, Mojović L. Fed‐batch L‐(+)‐lactic acid fermentation of brewer's spent grain hydrolysate. Journal of the Institute of Brewing 123: 537–543 (2017b)

Pejin J, Radosavljević M, Mojović L, Kocić-Tanackov S, Djukić-Vuković A. The influence of calcium-carbonate and yeast extract addition on lactic acid fermentation of brewer's spent grain hydrolysate. Food Research International 73: 31–37 (2015)

Pejin J, Radosavljević M, Pribić M, Kocić-Tanackov S, Mladenović D, Djukić-Vuković A, Mojović L. Possibility of L-(+)-lactic acid fermentation using malting, brewing, and oil production by-products. Waste Management 79: 153–163 (2018)

Piegza M, Łaba W, Kancelista A, Witkowska D, Kawa-Rygielska J. Evaluation of brewer's spent grain as a substrate for Trichoderma hydrolytic enzymes production and source of majorly fermentable sugars. Acta Scientiarum Polonorum – Biotechnologia 14: 17–32 (2015)

Pinheiro T, Coelho E, Romaní A, Domingues L. Intensifying ethanol production from brewer’s spent grain waste: use of whole slurry at high solid loadings. New Biotechnology 53: 1–8 (2019)

Pires EJ, Ruiz HA, Teixeira JA, Vicente AA. A new approach on brewer’s spent grains treatment and potential use as lignocellulosic yeast cells carriers. Journal of Agricultural and Food Chemistry 60: 5994–5999 (2012)

Plaza PE, Coca M, Yagüe SL, Fernández‐Delgado M, Linares JCL, García‐Cubero MT. Efficient use of brewer's spent grain hydrolysates in ABE fermentation by Clostridium beijerinkii. Effect of high solid loads in the enzymatic hydrolysis. Journal of Chemical Technology and Biotechnology. 95: 2393–2402 (2020)

Plaza PE, Gallego-Morales LJ, Peñuela-Vásquez M, Lucas S, García-Cubero MT, Coca M. Biobutanol production from brewer’s spent grain hydrolysates by Clostridium beijerinckii. Bioresource Technology 244: 166–174 (2017)

Qiu L, Li JJ, Li Z, Wang JJ. Production and characterization of biocontrol fertilizer from brewer’s spent grain via solid-state fermentation. Scientific Reports 9: 480 (2019)

Radosavljević M, Pejin J, Pribić M, Kocić-Tanackov S, Romanić R, Mladenović D, Djukić-Vuković A, Mojović L. Utilization of brewing and malting by-products as carrier and raw materials in L-(+)-lactic acid production and feed application. Applied Microbiology and Biotechnology 103: 3001–3013 (2019)

Radosavljević M, Pejin J, Pribić M, Kocić‐Tanackov S, Mladenović D, Djukić‐Vuković A, Mojović L. Brewing and malting technology by‐products as raw materials in L‐(+)‐lactic acid fermentation. Journal of Chemical Technology and Biotechnology 95: 339–347 (2020)

Rana SS, Janveja C, Soni SK. Brewer's spent grain as a valuable substrate for low cost production of fungal cellulases by statistical modeling in solid state fermentation and generation of cellulosic ethanol. International Journal of Food and Fermentation Technology 3: 41–55 (2013)

Ravindran R, Sarangapani C, Jaiswal S, Lu P, Cullen PJ, Bourke P, Jaiswal AK. Improving enzymatic hydrolysis of brewer spent grain with nonthermal plasma. Bioresource Technology 282: 520–524 (2019a)

Ravindran R, Williams GA, Jaiswal AK. Evaluation of brewer's spent grain hydrolysate as a substrate for production of thermostable α-amylase by Bacillus stearothermophilus. Bioresource Technology Reports 5: 141–149 (2019b)

Robertson JA, I'Anson KJA, Treimo J, Faulds CB, Brocklehurst TF, Eijsink VG, Waldron KW. Profiling brewers' spent grain for composition and microbial ecology at the site of production. LWT - Food Science and Technology 43: 890–896 (2010a)

Robertson JA, I'Anson KJA, Brocklehurst TF, Faulds CB, Waldron KW. Effect of storage conditions on the microbial ecology and biochemical stability of cell wall components in brewers' spent grain. Journal of Agricultural and Food Chemistry 58: 7266–7272 (2010b)

Rojas-Chamorro JA, Cara C, Romero I, Ruiz E, Romero-García JM, Mussatto SI, Castro E. Ethanol production from brewers’ spent grain pretreated by dilute phosphoric acid. Energy and Fuels. 32: 5226–5233 (2018)

Rojas-Chamorro JA, Romero-García JM, Cara C, Romero I, Castro E. Improved ethanol production from the slurry of pretreated brewers’ spent grain through different co-fermentation strategies. Bioresource Technology 296: 122367 (2020b)

Rojas-Chamorro JA, Romero I, López-Linares JC, Castro E. Brewer’s spent grain as a source of renewable fuel through optimized dilute acid pretreatment. Renewable Energy 148: 81–90 (2020a)

Rojas-Chamorro JA, Romero I, Ruiz E, Cara C, Castro E. Comparison of fermentation strategies for ethanol production from pretreated brewers spent grain. Chemical Engineering Transactions 61: 637–642 (2017)

Saba S, Zara G, Bianco A, Garau M, Bononi M, Deroma M, Pais A, Budroni M. Comparative analysis of vermicompost quality produced from brewers’ spent grain and cow manure by the red earthworm Eisenia fetida. Bioresource Technology 293: 122019 (2019)

Sae-ngae S, Cheirsilp B, Suksaroj TT, Intharapat P. Acid hydrolysis of brewers’ industrial wastes and their use for lipid production by oleaginous yeasts. Journal of Water and Environment Technology 17: 336–344 (2019)

Sajib M, Falck P, Sardari RR, Mathew S, Grey C, Karlsson EN, Adlercreutz P. Valorization of brewer’s spent grain to prebiotic oligosaccharide: production, xylanase catalyzed hydrolysis, in-vitro evaluation with probiotic strains and in a batch human fecal fermentation model. Journal of Biotechnology 268: 61–70 (2018)

Serba E, Pimenov N, Mochalina P, Overchenko M, Borscheva Yu, Sharikov A, Rimareva L. Production of Aspergillus oryzae RCAM 01133 biomass with increased protein and polysaccharides content using by-products of food industry. Agronomy Research 18: 290–300 (2020)

Shen Y, Abeynayake R, Sun X, Ran T, Li J, Chen L, Yang W. Feed nutritional value of brewers’ spent grain residue resulting from protease aided protein removal. Journal of Animal Science and Biotechnology 10: 78 (2019)

Silbir S, Goksungur Y. Natural red pigment production by Monascus purpureus in submerged fermentation systems using a food industry waste: Brewer’s spent grain. Foods 8: 161 (2019)

Soupioni M, Golfinopoulos A, Kanellaki M, Koutinas AA. Study of whey fermentation by kefir immobilized on low cost supports using 14C-labelled lactose. Bioresource Technology 145: 326–330 (2013)

Souza DT, Bispo ASR, Bon EPS, Coelho RRR, Nascimento RP. Production of thermophilic endo-β-1,4-xylanases by Aspergillus fumigatus FBSPE-05 using agro-industrial by-products. Applied Biochemistry and Biotechnology 166: 1575–1585 (2012)

Tan YX, Mok WK, Lee J, Kim J, Chen WN. Solid state fermentation of brewers’ spent grains for improved nutritional profile using Bacillus subtilis WX-17. Fermentation 5: 52 (2019)

Teixeira MR, Guarda EC, Freitas EB, Galinha CF, Duque AF, Reis MA. Valorization of raw brewers’ spent grain through the production of volatile fatty acids. New Biotechnology 57: 4–10 (2020)

Terrasan CRF, Temer B, Duarte MCT, Carmona EC. Production of xylanolytic enzymes by Penicillium janczewskii. Bioresource Technology 101: 4139–4143 (2010)

Tisma M, Jurić A, Bucić‐Kojić A, Panjičko M, Planinić M. Biovalorization of brewers’ spent grain for the production of laccase and polyphenols. Journal of the Institute of Brewing 124: 182–186 (2018)

Tsaousi K, Velli A, Akarepis F, Bosnea L, Drouza C, Koutinas AA, Bekatorou A. Low-temperature winemaking by thermally dried immobilized yeast on delignified brewer's spent grains. Food Technology and Biotechnology 49: 379–384 (2011)

Van Zyl WH, Lynd LR, den Haan R, McBride JE. Consolidated bioprocessing for bioethanol production using Saccharomyces cerevisiae. In Biofuels. Advances in Biochemical Engineering/Biotechnology ed. Olsson, L. Vol 108, pp. 205–235. Berlin Heidelberg: Springer (2007)

Wang H, Tao Y, Temudo M, Bijl H, Kloek J, Ren N, van Lier JB, de Kreuk M. Biomethanation from enzymatically hydrolyzed brewer’s spent grain: impact of rapid increase in loadings. Bioresource Technology 190: 167–174 (2015)

Waters DM, Jacob F, Titze J, Arendt EK, Zannini E. Fibre, protein and mineral fortification of wheat bread through milled and fermented brewer’s spent grain enrichment. European Food Research and Technology 235: 767–778 (2012)

Wilkinson S, Smart KA, Cook DJ. Optimisation of alkaline reagent based chemical pre-treatment of brewers spent grains for bioethanol production. Industrial Crops and Products 62: 219–227 (2014a)

Wilkinson S, Smart KA, Cook DJ. A comparison of dilute acid-and alkali-catalyzed hydrothermal pretreatments for bioethanol production from brewers' spent grains. Journal of the American Society of Brewing Chemists 72: 143–153 (2014b)

Wilkinson S, Smart KA, James S, Cook DJ. Bioethanol production from brewers spent grains using a fungal consolidated bioprocessing (CBP) approach. BioEnergy Research 10: 146–157 (2017)

Wolters N, Schabronath C, Schembecker G, Merz J. Efficient conversion of pretreated brewer’s spent grain and wheat bran by submerged cultivation of Hericium erinaceus. Bioresource Technology 222: 123–129 (2016)

Xiros C, Topakas E, Katapodis P, Christakopoulos P. Evaluation of Fusarium oxysporum as an enzyme factory for the hydrolysis of brewer's spent grain with improved biodegradability for ethanol production. Industrial Crops and Products 28: 213–224 (2008b)

Xiros C, Topakas E, Katapodis P, Christakopoulos P. Hydrolysis and fermentation of brewer’s spent grain by Neurospora crassa. Bioresource Technology 99: 5427–5435 (2008a)

Xu H, Sun L, Zhao D, Zhang B, Shi Y, Wu Y. Production of α‐amylase by Aspergillus oryzae As 3951 in solid state fermentation using spent brewing grains as substrate. Journal of the Science of Food and Agriculture 88: 529–535 (2008)

Zhang J, Zang L. Enhancement of biohydrogen production from brewers’ spent grain by calcined-red mud pretreatment. Bioresource Technology 209: 73–79 (2016)

Acknowledgements

None.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Puligundla, P., Mok, C. Recent advances in biotechnological valorization of brewers' spent grain. Food Sci Biotechnol 30, 341–353 (2021). https://doi.org/10.1007/s10068-021-00900-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-021-00900-4