Abstract

Purpose

The extraction of polyphenols from a waste product from the food industry, the shell of the chestnut fruit, was examined with the aim of analyzing the potential of the extracts for the formulation of wood adhesives, for leather tanning and as natural antioxidants.

Methods

Experiments were planned according to a 23 factorial design to analyze the influence of temperature and Na2SO3 and NaOH concentrations on extraction yield and on different extract properties: Stiasny number, total phenols, tannins and non-tannins contents, tannin/soluble solids ratio, proanthocyanidins content, antioxidant activity, average molecular weights, surface tension and power law rheological parameters of extract aqueous solutions.

Results

Extraction yields in the range 26.1–56.4% together with extract Stiasny numbers higher than 84 and total phenols contents and FRAP antioxidant activities in the range 10.86–33.33 g GAE/100 g shell and 92.05–166.32 mmol AAE/100 g shell, respectively, demonstrated the potential of chestnut shell extracts in the formulation of adhesives and as sources of antioxidant compounds. Additionally, the surfactant character and pseudoplastic behaviour of chestnut shell extracts solutions could improve wood wettability when used in adhesive formulation. Under a range of operating conditions, extracts with tannin content higher than 10% and tannin/soluble solids ratio higher than 0.6 were obtained that could be used as tanning agents.

Conclusions

The experimental design performed demonstrated the capacity of chestnut shell extracts for the applications proposed and allowed selecting the optimal extraction conditions for obtaining not only high quality extracts but also high extraction yields.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

For the past two decades, there has been a revival of the use of renewable resources. Due to the limited reserves of fossil fuels and the broad availability of renewable resources, these are especially appealing as a source of materials and energy. The integral utilization of crops and the use of waste streams in certain industries will grow in importance leading to a more sustainable way of producing materials. The Galician (NW of Spain) food industry uses ~7000 t/year of chestnut fruits (from the Castanea sativa species) in the production of different derivatives, such as marron glacé, chestnut purée, etc. where chestnut shell (around 10% by weight of the chestnut) is removed in the peeling process. The aim is the valorisation of this renewable industrial waste as a raw material for the production of tannin extracts for various applications, namely, as phenol substitutes in the formulation of wood adhesives, as chrome derivatives substitutes in leather tanning and as a source of antioxidant compounds.

Resins based on natural products such as tannin adhesives are already in industrial use, however, new challenges are arising due to the introduction of more severe standards regarding the emission of formaldehyde from bonded wood products together with the increasing costs of oil-derived synthetic resins. The interest is centred on the formulation of adhesives in which the total content of natural material is increased coupled with the total elimination of formaldehyde, which could be achieved using glyoxal, a non-volatile non-toxic aldehyde, which has been already tested in lignin and tannin adhesives for particleboards [1–5].

At present, one of the major problems of the leather industry is the effluent pollution due to presence of acid salts of trivalent chrome, which account for the 70% of all the leather manufactured today. Although the use of vegetable tannins is restricted for certain applications, the interest of the leather industry in the use of metal free tanning systems has promoted the search for new and more profitable tannin sources, either for coming from local species with the subsequent cost reduction or for coming from abundant and low cost forest or industrial waste products [6].

The growing interest in the substitution of synthetic food antioxidants by natural ones has promoted the investigations towards the search of new raw materials among the plant kingdom. Vegetable materials contain many compounds with antioxidant activity. Among them, a large amount of high and low molecular weight polyphenols have been studied and proposed for protection against lipid oxidation [7]. Various studies have been carried out on the obtaining of antioxidants from several plant materials such as fruit, various vegetables, herbs and spices, different parts of tree species, fruit shells, etc. [8–14]. The main interest is the exploitation of those ones that, in addition, are agricultural, forest or industrial wastes as is the case of chestnut shell.

A preliminary study on tannin extraction from chestnut shell was carried out in a previous work [15]. In the present study the extraction process was optimized using the experimental design and response surface methodology. The influence of extraction agents concentration (Na2SO3, alone or combined with NaOH) and temperature on extraction yield and on various extract properties which determine its potential for the applications proposed were investigated.

Materials and Methods

Material

Chestnut fruit (C. sativa) shell (a mixture of the outer brown peel and the inner pellicle) was supplied by a food factory, Marrón Glacé, S.L. (Ourense, Spain). It was air-dried till equilibrium moisture content, ground in a hammer mill, sieved and the fraction of particle size between 0.1 and 2 mm was selected. Chemical composition of chestnut shell was determined in a previous work [16].

Extraction and Concentration

The extraction experiments were carried out in a 2-L Pyrex glass reactor with mechanical stirring and temperature control. Chestnut shell and water were mixed at room temperature, heated and, once the selected temperature was attained, the alkali was added and contact time begun to run. After one hour the suspension was vacuum filtered, the solid residue was washed with water until a nearly colourless filtrate was obtained and the extract together with the first water washings were concentrated by spray-drying. The solid was dried at room temperature in order to calculate the extraction yield as the weight loss percentage of the starting raw material. The extraction operational conditions used are shown in the Design of experiments section. The analyses of the extracts were carried out in duplicate and the results averaged.

Extract Analysis

The methods employed to analyze extract tannin content were selected considering the various extract applications proposed: adhesive components (Stiasny number), tanning agents (the hide-powder test) or antioxidants (total phenols content).

The Stiasny number of the extracts was determined according to the procedure proposed by Yazaki and Hillis [17]. The extract (0.25 mg) was dissolved in distilled water (100 mL) and 2.5 mL of 10 M HCl (Panreac, Barcelona, Spain) and 5 mL of 37% formaldehyde (Panreac, Barcelona, Spain) were added. The mixture was heated under reflux for 30 min. The suspension was filtered through a sintered glass filter, the precipitate washed with hot water and then dried at 105°C until constant weight.

To determine the extract non-tannin content, an aqueous solution of extracts (100 mL), previously vacuum filtered through a 0.45 μm filter (to determine the extract soluble solids), were added to 6.25 g of hide-powder (Freiberg hide-powder, FILK, Germany). The suspension was stirred for 20 min, then left 10 min resting and finally filtered through a sintered glass filter. Fifty millilitres of filtrate were evaporated to determine the non-tannins. The tannins (%) were obtained as the difference between the soluble solids (%) and the non-tannins (%). The tannin concentration in the extract aqueous solution must be between 3.75 and 4.25 g/L, otherwise the analysis should be done again adjusting the extract concentration.

Total phenols content was determined by the Folin-Ciocalteu method [18]: to 0.5 mL of an aqueous solution of the extract, 2.5 mL of Folin-Ciocalteu reactive (Panreac, Barcelona, Spain), previously diluted with water (1:10, v/v), and 2 mL of a 75 g/L sodium carbonate (Panreac, Barcelona, Spain) aqueous solution were added. The mixture was kept 5 min at 50°C and, after cooling, the absorbance at 760 nm was measured. The phenols content was calculated as a gallic acid equivalent from the calibration curve of gallic acid (Panreac, Barcelona, Spain) standard solutions (2–40 μg/mL) and expressed as g gallic acid equivalent (GAE)/100 g of extract (on dried basis).

The proanthocyanidins were evaluated by the vanillin method [19]: 1 mL of aqueous extract was mixed with 2 mL of freshly prepared vanillin (Panreac, Barcelona, Spain) solution (1 g/100 ml 70% H2SO4 (Scharlau, Barcelona, Spain)) and maintained 15 min at 20°C, and then the absorbance was measured at 500 nm. The calibration was carried out with catechin (Sigma–Aldrich, St. Louis, USA) aqueous solutions of 2–40 μg/mL.

The antioxidant capacity of the extracts was determined by means of the FRAP (Ferric reducing/antioxidant power) assay according to Szöllösi and Szöllösi-Varga [20]: 0.1 mL of an aqueous solution of the extracts were transferred to a test tube and 3.0 ml of freshly prepared FRAP reagent (25 mL acetate buffer, 300 mmol/L, pH = 3.6 (acetic acid and sodium acetate purchased from Panreac, Barcelona, Spain); 2.5 mL 10 mmol/L 2,4,6-tripyridyl-s-triazine (TPTZ) (Fluka, Seelze, Germany) in 40 mmol/L HCl (Panreac); 2.5 mL 20 mmol/L FeCl3 .6H2O (Panreac, Barcelona, Spain)) were added. The absorbance was recorded after 5 min at 593 nm. The relative activities of samples were calculated from the calibration curve of L-ascorbic acid (Panreac, Barcelona, Spain) (0.1–1 mmol/L) and the results were expressed as nmol ascorbic acid equivalent (AAE) per mg of extract (on dried basis) [21].

Average-molecular-weights of the extracts were determined by gel permeation chromatography (GPC). GPC analysis were performed with an Agilent Technologies 1100 chromatograph (Germany) equipped with a diode array detector. The column used was a HP-PL gel 5 μm Mixed-D protected with a PL gel 5 μm guard column. Tetrahydrofuran (THF) (Merck, Darmstadt, Germany) was used as eluent and the conditions used were: flow rate, 1 mL/min; column temperature, 30°C; injection volume, 20 μL; detection at 270 with a bandwidth of 15 nm. The calibration curve was obtained with polystyrene standards (Agilent Technologies, Waldbronn, Germany). The spray-dried extracts were acetylated previous to GPC analysis. Samples (20 mg) were acetylated with pyridine (Merck, Darmstadt, Germany)-acetic anhydride (Scharlau, Barcelona, Spain) (4 mL, 1:1 v/v) overnight at room temperature. The mixture was poured into distilled water (40 mL) and the precipitate obtained was recovered by vacuum filtration through a 20 μm nylon filter. The acetylated extracts were dissolved in THF (2–5 mg/mL) and analysed by GPC.

The surface tension of 10% (by weight) aqueous solutions of extracts was determined by the pendant drop method using the equipment Dataphysics OCA 15 plus (Filderstadt, Germany) and the software SCA 20. Ten microliter pendant drops were dosed at a rate of 0.11 μL/s. The measurement was repeated 15 times for each extract solution and the mean value was calculated.

The rheological behaviour of 25% (by weight) aqueous solutions of extracts was studied at 25°C in a Brookfield DV-II + viscometer (Middleboro, MA, USA) using a small sample adapter. The parameters of the power law, n, the power law index, and k, the consistency index were determined.

Design of Experiments

To analyse the influence of temperature (x1, 90–95–100°C), Na2SO3 concentration (x2, 1.5–3.0–4.5%, based on oven-dried material) and NaOH concentration (x3, 0.0–1.5–3.0%, based on oven-dried material) on several dependent variables, experiments were planned according to a full 23 factorial experimental design with three experiments in the central point (Table 1). The solid/liquid ratio was kept constant at 1/10 and the contact time was 1 h for all the experiments.

The dependent variables (Yj) selected were the extraction yield (Y1, % on oven-dried material) and the following extract properties: Stiasny number (Y2), total phenols content (Y3, g gallic acid equivalents (GAE)/100 g extract), FRAP antioxidant activity (Y4, nmol ascorbic acid equivalents (AAE)/mg extract), tannin content (Y5, g/100 g extract), non-tannin content (Y6, g/100 g extract), tannin/soluble solids (Y7, g/g), tannin content (Y8, g/100 g oven-dried material), proanthocyanidin content (Y9, g/100 g extract), number- and weight- average-molecular weight, Mn (Y10, Da) and Mw (Y11, Da), respectively, surface tension of 10% aqueous solutions of extracts (Y12, mN/m) and power law rheological parameters, the power law index, n (Y13) and the consistency index, k (Y14, Pa.sn).

Experimental results were analysed by linear regression using the backwards elimination method (SPSS 15.0 software) and fitted to polynomials of the form:

where x *1 , x *2 and x *3 are the independent variables coded at three levels −1 (lower limit), 0 (central point) and +1 (upper limit).

The statistical analysis was performed using the analysis of variance (ANOVA) including the F-ratio, which established the global model significance (a 90% confidence level was selected), and the determination coefficients R 2 and adjusted R 2. In addition, experimental and predicted values for each dependent variable were compared. The significant factors affecting each dependent variable were selected according to the Student t test establishing a 90% confidence level.

Results and Discussion

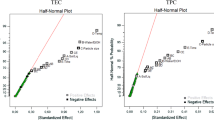

Table 1 shows the experimental results obtained for chestnut shell extractions according to the 23 factorial experimental design planned. The coefficients of the significant models (Eq. 1) are presented in Table 2 together with the correlation parameters and model significance. Figure 1 shows, as an example, the high correlation between the experimental values and those predicted by the model (Eq. 1) for the extraction yield (Y1) and the extract Stiasny number (Y2).

NaOH concentration was the most significant independent variable on the majority of dependent variables analysed. The exception were the tannin content (based on o.d. shell) that, however, depended on this variable through its interactions with sodium sulphite concentration and temperature, and the extract average-molecular-weights (Mn and Mw), that depended mainly on sodium sulphite concentration. For most of the dependent variables, temperature was the less significant variable (alone or its interactions).

As shown below, the analysis of the response surfaces obtained for the dependent variables analysed allowed selecting the optimal extraction conditions for obtaining a high extraction yield together with a high quality of the extracts, which depended on the application considered.

Extraction yield (Y1) increased with increasing Na2SO3 and NaOH concentrations and temperature. However, extract Stiasny number (Y2) decreased with increasing any of them, even though all values are in the range suggested by Yazaki et al. [22] as acceptable for the use of extracts in adhesive formulations (>65). Figure 2a and b show that at 90°C extraction yields higher than 50% and Stiasny numbers higher than 84 were obtained; however Stiasny number can increase significantly (~95) keeping acceptable extraction yields (~30%).

None of the independent variables analyzed influenced the total phenols content (Y3) of chestnut shell extracts. It is worth emphasizing that the values referred to the raw material, in the range 10.86–33.33 g GAE/100 g shell, were considerably higher than those obtained in the preliminary study (4.20–18.83 g GAE/100 g shell) [15] and than those of extracts of similar lignocellulosic materials used as sources of antioxidant compounds, such as Gevuina avellana hulls (1.03.10−3–4.23.10−3 g/100 g) [10] or almond hulls (0.0106–0.0412 g/100 g) [11].

No significant model was found for the extract antioxidant activity (Y4). However, it is noticed that, generally, an increase in NaOH concentration led to a decrease of the antioxidant activity. On the other hand, the extract antioxidant activity based on the raw mterial increased significantly compared with the preliminary study [15] (FRAP values in the range 92.05–166.32 mmol AAE/100 g o.d. shell as against 21.65–105.62 mmol AAE/100 g shell) due to the combination of high values of extraction yield and extract antioxidant activity. Proanthocyanidin content (Y9) depended only on NaOH concentration and the higher values were obtained for the extractions without NaOH. In addition, the high values obtained for the proanthocyanidin content confirmed the condensed character of the chestnut shell tannin extracts.

Both chestnut shell extract tannin content (Y5) and tannin/soluble solids ratio (Y7) increased with increasing Na2SO3 concentration and temperature and with decreasing NaOH concentration, whereas non-tannin content (Y6) decreased. The ranges of operating conditions which led to a tannin/soluble solids ratio (a measure of purity) higher than 0.6 were the more restricted the lower the extraction temperature. At 90°C that condition was only satisfied operating under the highest Na2SO3 concentration without NaOH. With respect to the extract tannin content (based on o.d. shell) (Y8), it is higher than 10%, the lower limit to be of commercial interest [6], under the whole range of conditions essayed. Moreover, tannin content amply exceeded the maximum value attained in the preliminary study (22.6 g/100 g o.d. shell). The response surfaces for the tannin content referred to the raw material (Y8) and the tannin/soluble solids ratio (Y7) in function of Na2SO3 and NaOH concentrations at 100°C are shown in Fig. 3a and b, respectively. Operating under the best conditions the tannin content and the tannin/soluble solids ratio took the values of 40.7 and 0.84%, respectively, and the corresponding extraction yield was 48.4%.

Number and weight average molecular weights, Mn (Y10) and Mw (Y11), respectively, are parameters of great importance for the use of tannins in the formulation of adhesives. Both Mn and Mw increased with decreasing the three independent variables. Under these conditions, as mentioned before, extract Stiasny number increased while extraction yield decreased.

With respect to the surface tension of the aqueous solutions of extracts, from 52.66 to 60.72, it was significantly lower than that of water (74.15 mN/m), which demonstrated the surfactant character of chestnut shell tannin related to an improved wetting behaviour when used in adhesive formulations for wood panels. The surface tension was independent of the extraction conditions as no independent variable or interaction was found to be significant.

Finally, the rheological behaviour of aqueous solutions of extracts has been analysed and, as shown in Table 1, the power law index (Y13) was below one in all cases, showing a pseudoplastic behaviour. This behaviour is of great interest for the application of the tannin extracts in adhesive formulations because as the adhesive is subject to stress during its application, its apparent viscosity decreases allowing for better flow. The power law index depended only on NaOH concentration and the extract solutions deviated more from the Newtonian character the higher the NaOH used in the extraction stage. Neither variable was found to be significant on the consistency index for chestnut shell extracts.

Conclusions

The extraction of polyphenolic compounds from the shell of the chestnut fruit for their application in the formulation of wood adhesives, in leather tanning and as a source of antioxidant compounds was optimized. Extraction yields higher than 50% and Stiasny numbers higher than 84 were achieved. Chestnut shell extracts showed total phenols contents higher than those obtained for other similar lignocellulosic materials and high values of the FRAP antioxidant activity. The extract tannin content (on o.d. shell) was higher than 10%, the lower limit to be of commercial interest, under the whole range of conditions essayed. However, the tannin/soluble solids ratio, a measure of extract purity, only went beyond 0.6 operating under a limited range of alkali concentrations and at high temperature. The surface tension of extract aqueous solutions demonstrated the surfactant character of chestnut shell extracts, that could led to an improved wood wettability when used in adhesive formulation. In addition, the pseudoplastic behaviour of the aqueous solutions also contributes to a better adhesive application.

References

Ballerini, A., Despres, A., Pizzi, A.: Non-toxic, zero emission tannin-glyoxal adhesives for wood panels. Holz Roh Werkst. 63, 477–478 (2005)

El Mansouri, N., Pizzi, A., Salvadó, J.: Lignin-basedwood panel adhesives without formaldehyde. Holz Roh Werkst. 65, 65–70 (2007)

Amaral-Labat, G.A., Pizzi, A., Gonçalves, A.R., Celzard, A., Rigolet, S., Rocha, J.M.: Environment-friendly soy flour-based resins without formaldehyde. J. Appl. Polym. Sci. 108, 624–632 (2008)

Lei, H., Pizzi, A., Du, G.: Environmentally friendly mixed tannin/lignin wood resins. J. Appl. Polym. Sci. 107, 203–209 (2008)

Kim, S.: Environment-friendly adhesives for surface bonding of wood-based flooring using natural tannin to reduce formaldehyde and TVOC emission. Bioresour. Technol. 100, 744–748 (2009)

Ahmed, A., Khirstova, P., Icho, G.: Comparative study of tannins of Acacia nilotica an indigenous tanning material in Sudan with Acacia mearnsii Suranaree. J. Sci. Technol. 12, 259–265 (2005)

Hagerman, A.E., Riedl, K.M., Jones, G.A., Sovik, K.N., Ritchard, N.T., Hartzfeld, P.W., Riechel, T.L.: High molecular weight plant polyphenolics as biological antioxidants. J. Agric. Food Chem. 46, 1887–1892 (1998)

Velioglu, Y.S., Mazza, G., Gao, L., Oomah, B.D.: Antioxidant activity and total phenolics in selected fruits, vegetables, and grain products. J. Agric. Food Chem. 46, 4113–4117 (1998)

Kähkönen, M.P., Hopia, A.I., Vuorela, H.J., Rauha, J.P., Pihlaja, K., Kujala, T., Heinonen, M.: Antioxidant activity of plant extracts containing phenolic compounds. J. Agric. Food Chem. 47, 3954–3962 (1999)

Moure, A., Franco, D., Sineiro, J., Dominguez, H., Núñez, M.J., Lema, J.M.: Evaluation of extracts from Gevuina avellana hulls as antioxidants. J. Agric. Food Chem. 48, 3890–3897 (2000)

Pinelo, M., Rubilar, M., Sineiro, J., Núñez, M.J.: Extraction of antioxidant phenolics from almond hulls (Prunus amygdalus) and pine sawdust (Pinus pinaster). Food Chem. 85, 267–273 (2004)

Goli, A.H., Barzegar, M., Sahari, M.A.: Antioxidant activity and total phenolic compounds of pistachio (Pistachia vera) hull extracts. Food Chem. 92, 521–525 (2005)

Weber, H.A., Hodges, A.E., Guthrie, J.R., O’Brien, B.M., Robaugh, D., Clark, A.P., Harris, R.K., Algaier, J.W., Smith, C.S.: Comparison of proanthocyanidins in commercial antioxidants: grape seed and pine bark extracts. J. Agric. Food Chem. 55, 148–156 (2007)

Dudonné, S., Vitrac, X., Coutiére, P., Woillez, M., Mérillon, J.-M.: Comparative study of antioxidant properties and total phenolic content of 30 plant extracts of industrial interest using DPPH, ABTS, FRAP, SOD, and ORAC assays. J. Agric. Food Chem. 57, 1768–1774 (2009)

Vázquez, G., González-Alvarez, J., Santos, J., Freire, M.S., Antorrena, G.: Evaluation of potential applications for chestnut (Castanea sativa) shell and eucalyptus (Eucalyptus globulus) bark extracts. Ind. Crops Prod. 29, 364–370 (2009)

Vázquez, G., Fontenla, E., Santos, J., Freire, M.S., González-Alvarez, J., Antorrena, G.: Antioxidant activity and phenolic content of chestnut (Castanea sativa) shell and eucalyptus (Eucalyptus globulus) bark extracts. Ind. Crops Prod. 28, 279–285 (2008)

Yazaki, Y., Hillis, W.E.: Molecular size distribution of radiata. Pine bark extracts and its effect on properties. Holzforschung 34, 125–130 (1980)

Singleton, V.L., Rossi, J.A.: Colorimetry of total phenolics with phosphomolybdic—phosphotungstic acid reagents. Am. J. Enol. Vitic. 16, 144–158 (1965)

Swain, T., Hillis, W.E.: The phenolic constituents of Prunus domestica. The quantitative analysis of phenolic compounds. J. Sci. Food Agric. 10, 63–68 (1969)

Szöllösi, R., Szöllösi-Varga, I.: Total antioxidant power in some species of Labiatae (Adaptation of FRAP method). Acta Biologica Szegediensis 46(3–4), 125–127 (2002)

Maksimovic, Z., Malencic, D., Kovacevic, N.: Polyphenol contents and antioxidant activity of Maydis stigma extracts. Bioresour. Technol. 96, 873–877 (2005)

Yazaki, Y., Gu, R., Lin, Y., Chen, W., Nguyen, N.K.: Analyses of black wattle (Acacia mearnsii) tannins-relationship among the hide-powder, the Stiasny and the ultra-violet (UV) methods. Holzforschung 47, 57–61 (1993)

Acknowledgements

This work was funded by Ministerio de Educación y Ciencia, Plan Nacional de I + D+I (AGL2005-00273) and Xunta de Galicia (PGIDIT06PXIC265046PN). Authors are also grateful to Ministerio de Educación y Ciencia for a research grant awarded to J. Santos (BES-2006-13886).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vázquez, G., Freire, M.S., Santos, J. et al. Optimisation of Polyphenols Extraction from Chestnut Shell by Response Surface Methodology. Waste Biomass Valor 1, 219–225 (2010). https://doi.org/10.1007/s12649-010-9012-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-010-9012-z