Abstract

The identification of residues is traditionally based on the distinctive morphologies of the residue fragments by means of light microscopy. Most residue fragments are amorphous, in the sense that they lack distinguishing shapes or easily visible structures under reflected light microscopy. Amorphous residues can only be identified by using transmitted light microscopy, which requires the extraction of residues from the tool’s surface. Residues are usually extracted with a pipette or an ultrasonic bath in combination with distilled water. However, a number of researchers avoid residue extraction because it is unclear whether current extraction techniques are representative for the use-related residue that adheres to a flaked stone tool. In this paper, we aim at resolving these methodological uncertainties by critically evaluating current extraction methodologies. Attention is focused on the variation in residue types, their causes of deposition and their adhesion and on the most successful technique for extracting a range of residue types from the stone tool surface. Based on an experimental reference sample in flint, we argue that a stepwise extraction protocol is most successful in providing representative residue extractions and in preventing damage, destruction or loss of residue.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Optical residue analysis has proven to be an effective method for generating high-resolution data that help to solve specific questions in human evolution: uses of stone tools (Briuer 1976; Fullagar 1986; Hardy 2004; Lombard 2005) and grinding stones (Liu et al. 2010; Fullagar et al. 2015), hafting technology (Lombard 2005; Rots et al. 2011), plant use (Fullagar et al. 2006; Summerhayes et al. 2010) or cultivation (Denham et al. 2003) and diet reconstruction (Hardy and Moncel 2011). The method aims at identifying residues adhering to stone tool surfaces by using a combination of optical microscopes (stereomicroscope, metallurgical microscope) and lighting techniques (reflected and transmitted light) (Lombard and Wadley 2007; Fullagar 2014). It has been successfully applied to various time periods and regions (Haslam 2011), but it has also proven to have its limitations because certain residues may have an ambiguous appearance (Wadley et al. 2004; Monnier et al. 2012; Rots et al. 2016). The smearing or crushing of residues through use or the degradation of residues through taphonomic processes may remove their diagnostic features and hamper reliable identification.

The problem of the ambiguous appearance of residues can be partly overcome by extracting the residue and studying it under transmitted light. Transmitted light observation improves the visibility of diagnostic features (Briuer 1976; Fullagar 2006; Fullagar 2014) and allows the application of histological stains to highlight the morphological features (Lamb and Loy 2005; Smith et al. 2015) and/or confirm the chemical composition of residue fragments (Fullagar et al. 2015; Stephenson 2015). Extracted residues can also be analysed using other biochemical methods, such as gas chromatography (Regert 2004; Evershed 2008; Perrault et al. 2016), haemoglobin-specific chemical reagent test strip (Hb-CRTS) analysis (Matheson and Veall 2014) or crossover immunoelectrophoresis (CIEP) (Newman and Julig 1989).

A key question in the current methodological debate is whether the residues should be extracted from the stone tool or not and to what degree this may affect the results. A number of researchers contest the usefulness of residue extraction (Lombard and Wadley 2007; Langejans 2011), while others view it as a necessary step in an analytical protocol with the advantage of long-term preservation of the residues (Rots et al. 2016). If residue analysis is combined with use-wear analysis or other methods of lithic analysis, residue extraction is often a prerequisite as it is the only way to allow further handling, cleaning and analysis of the tools without a risk of contamination or residue destruction.

Residue extraction is carried out with different types of equipment (pipette extraction, ultrasonic bath) by using mainly distilled water as a solvent. However, the effect of these different techniques and the solvent used on the success rate of removing residues from various origin is not yet understood. A shared and rigorous methodological basis for residue extractions is still lacking despite residue analysis having been applied for at least 40 years (see Haslam 2011 for a review).

In this paper, we address these methodological problems by evaluating the success rate of the most frequently applied extraction methods within the field of optical residue analysis. The success rate is defined as the ability of an extraction technique to remove the selected residue from the stone tool surface and to collect it for further analysis while minimising the risk of loss and damage. In particular, we investigate the effect of three variables: (1) the processes of residue deposition, (2) the residue adhesion and (3) the extraction protocols used, and we propose a controlled procedure as a step towards a better-founded residue methodology.

Background

Current practices in residue analysis can be subdivided into three groups: (1) analysts who consider an on-tool observation sufficient for a reliable interpretation (Lombard 2005; Hardy et al. 2008; Langejans 2012); (2) analysts who try to incorporate both on-tool observation and transmitted light observation, in a sequential protocol (Shafer and Holloway 1979; Kealhofer et al. 1999; Fullagar 2015); (3) and analysts who only perform transmitted light observations (Perry 2004). The analytical choices that are made influence how to determine where different residues occur on tools and the cause of them being there (cf. Rots et al. 2016).

Residue extraction is undertaken by some analysts only. Langejans (2011) argues that residue extraction may bias the interpretation given the risk that not all will be extracted, which could result in an incomplete view of what is found on the stone tool. However, this has never been studied in detail, and systematic analysis is needed to clarify issues of potential bias and misinterpretation. Apart from the extraction techniques also, residue deposition and adhesion to the stone surface are essential factors to help understand whether some residues are more difficult to extract than other.

Residue types

Residues occurring on stone tools may be of plant, animal or mineral origin, with varying compositions. The residues relevant for this study can be subdivided into five groups, on the basis of the dominant compound in their chemical structure: carbohydrates, terpene and terpenoids, hydroxyapatite, amino acids and lipids. Carbohydrates (Cm(H2O) n ), and more specifically polysaccharides, are the dominant molecule for the majority of observed plant residues (starch, cellulose, hemicellulose, plant gums) (Torrence and Barton 2006). Terpene and terpenoids (C5H8) n are the most dominant chemical compounds in plant resins and are hydrocarbon compounds, built up from the small hydrocarbon called isoprene (Mills and White 1977; Langenheim 2003; Pollard and Heron 2008). The inorganic calcium hydroxyapatite (Ca10(PO4)6(OH)2) is the dominant chemical compound of bone and antler and represents 70% (by weight) of its matter, the other being 20% organic matter (e.g. collagen) and 10% water (O’Connor 1987; Pollard and Heron 2008). Amino acids are the building blocks of proteins, the most dominant macromolecule in many observed animal residues. Proteins include a wide range varying from structural proteins such as collagen (muscle, skin flakes) and keratin (hair, feathers, nails, horn) to metalloproteins like haemoglobin (red blood cells) (Brown and Brown 2011). Lipids comprise a group of fats deriving from both plants and animals (e.g. beeswax, adipose tissue, finger lipids) (Evershed 1993; Brown and Brown 2011).

Causes of residue deposition on stone tools

Residues can be deposited onto the stone tool through various processes before, during or after a tool’s life. Often residues are assumed to be linked with use. Rots et al. (2016) have recently shown that activities such as tool manufacture and hafting, as well as handling or post-depositional processes, may also lead to residue accumulation and that successful identification of tool use depends on the analyst’s awareness of the processes that may lead to residue accrual. Building on experimental work and available literature, we identify six stages during which residues can be deposited on stone tools: production, hafting or prehension, use, handling or incidents, environmental and modern contamination. Of these six, tool use is the most obvious one (Rots et al. 2016), but residue accumulation already starts during the production stage: contact with an organic or mineral hammer during knapping (Byrne et al. 2006) or retouching (Rots et al. 2016) may result in visible residues on the blank’s butt or along the retouched edges. Retouch residues, in particular, prove a source of confusion due to their location and directional appearance. Contact with the hand or a hafting medium during use may also result in residue deposition. Prehension residues generally consist of fat and skin flakes, while hafting residues are the result of a contact with the handle (Rots et al. 2011), bindings (Lombard 2006) and/or adhesives (Boëda et al. 1996; Regert 2004; Helwig et al. 2014). Various ethnographic and experimental studies (e.g. Akerman et al. 2002; Rots and Williamson 2004; Rots et al. 2016) have shown that incidental residues should not be ignored; they may originate from the handling of the tools (e.g. knapper’s or user’s blood) as well as the broader use context. Incidental residues that accumulate during the lifecycle of a stone tool need to be distinguished from environmental contamination residues (e.g. starch from plant processing activities, see Barton et al. 1998), which are accumulated after the tool is discarded due to various taphonomic processes (soil processes, wind, water). Finally, modern contamination residues are the result of handling during excavation, analysis or storage (Wadley et al. 2004; Pedergnana et al. 2016) and may consist of fat and skin flakes from hands, fat from plasticine, ink from labelling or fibres from clothing, etc. (Crowther et al. 2014; Pedergnana et al. 2016).

To identify use-related residues, most researchers focus on their spatial distribution and their morphological attributes. Spatial arguments include the location of the residue (Rots and Williamson 2004; Rots et al. 2011), its localised accumulation (Rots and Williamson 2004; Lombard 2008), its distribution (Lombard 2004) and the link with the used edge (Barton et al. 1998). Morphological arguments include the smearing of a residue (Gibson et al. 2004; Rots and Williamson 2004; Lombard 2008) and its directionality (Briuer 1976; Lombard and Phillipson 2010). Alternatively, the inclusion of use-wear and sediment analysis have been proposed to guarantee the link of a residue with tool use (Barton et al. 1998; Rots and Williamson 2004). The integration of use-wear analysis allows verifying that a residue is associated with other signs of use (e.g. Barton et al. 1998; Akerman et al. 2002; Rots et al. 2015). The analysis of the surrounding sediment allows detecting environmental contamination residues that may affect the interpretation of residues on stone tools (Williamson 1997; Barton et al. 1998): a residue present in a similar frequency on stone tool surface and in the surrounding sediment is probably not use-related.

Residue adhesion

The precise mechanisms of residue adherence to a stone tool surface are poorly understood (Hardy et al. 2008), but a basic understanding of these mechanisms is essential for creating successful extraction protocols. The bond between the residue fragment and the stone tool surface is caused by adhesion, in particular, physical adsorption which can be attributed to Van der Waal forces (Evans and Donahue 2005). In residue analysis on ceramics, the strong bonding between protein residues and mineral ceramic surfaces proved to have an important impact on the success rate of an extraction (Craig and Collins 2002; Barker et al. 2012). It may also play a key role in the survival of residues: the stronger the bond between the fragment and the stone tool surface, the more probable its resistance to physical agents of deterioration (water, wind, frost, soil compaction and creep) (Schiffer 1987). Earlier publications (Loy 1993; Barton 2007) suggest that the bondings between the residue deposit, the stone tool and the soil particles are central in the preservation of residues. A rapid dehydration of a residue, changes in its ionic composition and chemically charged nature of stone and soil particles form an hydrophobic, insoluble complex. This might explain why residues are able to withstand groundwater and microbial degradation over long periods of time. Barton (2007) also suggests that the variation in preservation within the same starch deposit might be explained by the bonding of the residue with the stone tool surface, which protects the inner part of the residue deposit of being attacked by the microorganisms.

We hypothesise that the adherence of a residue fragment to a stone tool surface is influenced by both its chemical composition and the action that causes the residue deposition. This hypothesis can only be validated by evaluating the adhesion degree of each residue type (e.g. starch, plant tissue, cellulose fibres, blood and collagen) and residue cause (production, hafting or prehension, use, handling or incidents, environment and modern contamination) (see in the following).

Solubility

The relative solubility of a residue may also have an impact on the success rate of a residue extraction (Veall and Matheson 2014). Some residues (e.g. mature collagen) are insoluble in water due to their specific chemical structure (Pollard and Heron 2008). A taphonomic process like heating will denature the proteins and increase their solubility as the overall molecular weight is reduced (Pollard and Heron 2008). Other residues (e.g. dried blood) will become insoluble after a period of time (Sensabaugh et al. 1971). Various solvents have been used in the past to overcome the problem of insolubility, but some of these may hamper subsequent analysis. In lithic residue analysis, researchers have overcome this problem of insolubility by mechanically breaking the bond between the stone tool surface and the residues with a pipette tip or ultrasonic waves (Fullagar 2014). This study will, amongst others, assess the effectiveness of mechanical methods of residue removal, which has not yet been studied.

Current practices in residue extraction

Extraction techniques

Current extraction methods for optical analysis of residues on stone tools are specifically intended to extract a wide range of residue types that may be present on a stone tool. These extraction techniques differ fundamentally from what has been used up to now within specialised “residue-specific” studies (such as protein analysis for CIEP). In the latter cases, extraction techniques intentionally target one particular residue or residue type with limited consideration of their potential destructive effect on other residue types. In the case of stone tools, this is not possible, and extraction should result in samples that are representative of the whole range of residue types that may occur on stone tools if extraction is to be a useful protocol.

Currently, three techniques are used for extracting residues from stone tools: pipette extraction, ultrasonic extraction and mechanical extraction with a scalpel or tweezers. The first technique uses an air displacement micropipette with disposable polypropylene (PP) pipette tips (Fig. 1a) (Fullagar 2006). A vacuum is created in the pipette by pushing out the air, and this vacuum is subsequently filled with distilled water, which is deposited in a preselected location on the stone tool. The area is agitated with the pipette tip, and after 1 min, the water and the detached residue are sucked back into the pipette.

The second technique uses the vibrations generated in an ultrasonic cleaning tank to dislodge the residues from the stone tool surface (Fig. 1b) (Fullagar 2006). The method is applied in medical, food and industrial sectors for cleaning contaminated surfaces (Mason 2015). By sending high-frequency sound waves through a liquid, cavitation bubbles are produced near the surface of the stone tool, and the implosion of these cavitation bubbles agitates the surface and dislodges the residue from the tool. The lower the frequency of the sound waves is, the heavier the agitation of the surface will be. While it is often assumed that the use of an ultrasonic cleaning tank necessitates the immersion of the entire stone tool, and thus results in the mixing of residues from different (active and non-active) parts of the stone tool, this is actually not the case. Nylon or polystyrene weighing boats allow the immersion of selected parts or edges of the tool. The weighing boats are filled with the chosen extraction solution and placed in the ultrasonic bath where they will float, and the part of the tool where the residues need to be extracted can be dipped in the solution while the tank is running (Fullagar 2006; Fullagar 2014).

An alternative to the use of an ultrasonic cleaning tank may be the ultrasonic scaler, which has been used previously to remove firmly adhering sediment from fragile bone fossils (Lopez-Polin et al. 2011). The advantage of this technique is that highly localised extractions are possible. While this technique proved effective for residue extraction, our tests have demonstrated that the scaler leaves obvious marks on the stone tool surface in the form of an extensive polish associated with striations (Fig. 1c). The necessity of using an ultrasonic scaler instead of other alternatives should, therefore, be critically examined before unnecessarily damaging the stone tools under study.

The third extraction technique concerns the mechanical removal of residue by metal or plastic tools (scalpel, forceps and needle) (Regert 2004; Fullagar 2014). While this technique may be convenient for removing large pieces of residue, we stress that it may also cause wear traces in the contact zone. When using such techniques, care should be taken to document and map the exact extraction locations. Mechanical extraction is only useful for a small number of highly concentrated and visible residues, in particular glues, and does not qualify as a generally applicable procedure.

Consequently, only pipette and ultrasonic extraction are relevant extraction techniques for integration in standardised analytical protocols, given their broad application field and the minimal risk of damaging the stone tools.

Solvents

In optical residue analysis, distilled water (Fullagar 2014) generally acts as a transport agent to move the residue from the stone tool surface into a vial or onto a glass slide. Water is used here because it is pH neutral and excludes the risk of damaging residue from any type. Other solutions, in particular, the trimixture of ethanol, water and acetonitrile (EWA), have been proposed for extracting water-insoluble residues (Fullagar et al. 2015). The choice may, however, affect the subsequent chemical analysis (Veall and Matheson 2014). A recent study that analysed extractions by both H2O and EWA using gas chromatography-time-of-flight mass spectrometry (GC×GC-TOFMS) showed differences in the extraction of different chemical components (Perrault et al. 2016). Crossover immunoelectrophoresis (CIEP) aims at only identifying proteins and uses solvents that may be only effective for extracting proteins, like ammonium hydroxide (5%) (Shanks et al. 2005) or sodium dodecyl sulphate (SDS) (2%) (Gurfinkel and Franklin 1988), but these solvents may destroy or damage non-protein residues.

Materials and methods

Research goal

Extraction techniques are standardly applied in residue analysis, but their success rate in obtaining representative residue samples remains unknown. We suggest that the adhesion degree of the residue is the dominant variable affecting the success rate of extractions and that it is affected by two variables: residue type (e.g. amino acid, carbohydrate) and residue cause (e.g. tool use, contamination). The aim of our study is, therefore, to critically evaluate existing extraction techniques by (1) monitoring the residue deposition; (2) evaluating the adhesion of different residue types and causes; and (3) assessing their success rate at removing residues, including the associated risk of damaging the stone tool and/or losing or mixing residues from different origins and their potential for providing representative residue frequencies and types. We focus on two specific extraction techniques: pipette and ultrasonic bath extractions.

Dataset

An experimental set of 153 flint tools was knapped and used by an experienced knapper and a stone tool user (C. Lepers) without taking any precautions to prevent the deposition of incidental residues. Only flint tools were used, so the impact of the type and coarseness of the raw material on the deposition and adhesion of different residues was not studied. The tools were used outdoors to create a setting that is realistic for prehistoric conditions. Only residues derived from the systemic context (Schiffer 1972) are considered in this study. No burying experiments were performed, and post-depositional residues are thus excluded from this study.

Most of the tools (n = 68) were knapped using direct percussion with bone, antler or wooden hammers. Ten tools were produced using indirect percussion. Four tools were produced by pressure flaking using antler- and copper-tipped compressors. Tools that were knapped using stone hammers were not included. Sixty-six tools were retouched using direct percussion with bone, antler, wood and sandstone.

Thirty-eight tools were hafted: two on a bone handle, two on an antelope horn handle and 34 on a wooden handle (Table 1). Seven tools hafted on wood and one tool hafted on antelope horn were glued in the handle using a mixture of 70% natural spruce resin and 30% natural beeswax. Remaining tools were secured with leather bindings, except two tools that were secured by pressure into the marrow of a bone handle and two tools that were secured with sinew bindings. Tools were used for processing (adzing, cutting, grooving, perforating, scraping, shaving) various plant (soft plant and wood) and animal materials (antler, bone and hide) (Tables 2 and 3). Use durations varied from a single stroke up to 1 h. Most of the tools were dried and stored for at least 2 years before they were studied, and other tools were used and then immediately studied. In addition, nine archaeological tools and one experimental core were selected from a reference collection used for training students in lithic analysis. These were included to monitor the accumulation of handling residues within a context rich in modern contaminants.

Analytical protocol

Residues were examined in four subsequent phases:

-

1.

Residue mapping

The presence, distribution and density of all microscopically visible residues on the total set of 153 tools were recorded in order to identify the most suitable locations for systematic residue sampling. A grid system of 26 zones was created to facilitate the recording. For each zone, the residue density was evaluated on a scale from 1 to 4 (from isolated fragments to continuous and thick (Fig. 2b)). Association with the used edge (absent, weak, intermediate, strong), the degree of smearing (absent, weak, intermediate, heavy/significant/pronounced/…) and the directionality against the used edge (perpendicular, oblique, parallel) were recorded, considering their usefulness for the identification of the residue cause.

-

2.

Residue deposition

Residues were then examined with regard to use motion, worked material, use duration and prehensile mode in order to understand the processes through which the residues were deposited.

-

3.

Residue adhesion

Fifty-three residues observed on 42 experimental tools were subsequently selected to determine the adhesion degree, i.e. the strength of the bond between the residue and the stone tool surface, for different residue types and causes. The latter tools were selected across the use categories and are representative of the residue types (Table 4) and causes (Table 5) included in the study (see Supplementary information Table 1). The protocol chosen to determine the adhesion of a residue involves the use of an ultrasonic cleaning device. It is hypothesised that the adhesion degree varies and is both influenced by its chemical composition and the action that causes the residue deposition. A stepwise ultrasonic cleaning procedure consisting of 14 consecutive steps is used to obtain a relative estimate of residue adhesion (Table 6). Each step has a specific duration and intensity, and the gradual increase in time and force throughout the 14 steps of the cleaning cycle allows identifying the step in which a residue is dislodged from the stone tool. After each step, the tool was examined to determine how much residue was removed. The adhesion degree of a residue is expressed as a figure that corresponds to that step in the cleaning procedure that successfully extracted all microscopically visible adhering residues. Residues that could not be entirely removed during the last step were given number 15. The adhesion of residue types was defined by recording the absence/presence of residues and the percentage of removal (0, 12.5, 25, 37.5, 50, 62.5, 75, 87.5 or 100%). They present the removal in comparison with the initial state of the residue, prior to the cleaning experiment. The percentage of removal was calculated by comparing the state of density and size of a residue before any intervention and the state before and after each cleaning step by counting the residues. When the residue fragments were too numerous, the degree of change was estimated.

-

4.

Extraction technique

A total of 88 extractions (Table 7) were performed on a selection of 27 residues across different types and origins to evaluate the success rate of pipette and ultrasonic bath extractions. The selection includes residues from production, use, hafting and incidental contact with various materials, and residues within the same category were selected on the basis of their similar density, distribution and link with the used edge. Both extraction techniques were evaluated while taking into account the different variables that may impact the success rate of an extraction, such as pipette agitation and duration of ultrasonication. The techniques were evaluated by recording five attributes (amount, damage, loss, mixing with residue from other causes, complete removal) for every residue component (observed with low or high magnification). The amount of distilled water was kept constant for each pipette extraction (2 times 5 μl) and for each ultrasonic extraction (10 ml) to allow a comparison between the different extractions. The ultrasonic extractions were then centrifuged for 10 min at 1200 rpm, and the supernatant was removed until 10 μl of distilled H2O was left in the tube. As such, all residues from one ultrasonic extraction could be transferred to one slide to guarantee that all extracted residues were counted.

Analytical methods

Residues on the experimental stone tools were observed with a Zeiss stereomicroscope Discovery V.12 (magnifications up to ×120), a Zeiss Macro-Zoom microscope V.16 (magnifications up to ×180) and a Zeiss Imager metallurgical incident light microscope (magnification ×50–×100) with rotating polarisers and differential interference contrast (DIC). An ultrasonic bath Elmasonic P 120 H with frequencies of 37 and 80 kHz was used.

Pipette extractions were performed with a BRAND Transferpette ® S with PP tips, an adjustable volume of 2–20 μl with a precision of ±0.8% and a coefficient of variation of ≤0.4%. Distilled H2O was used as a transport medium. Plastic weighing boats were used as recipients in the ultrasonic bath. The pipette extractions were done by adding two drops of 5 μl of distilled water onto the stone tool surface. The solution was subsequently sucked into the pipette and immediately transferred onto a glass slide for observation. Extracted residues were observed using a Zeiss Axioscope A1 transmitted light microscope (magnification ×50–×1000) with rotating polarisers and DIC. Residue interpretations were based on an extensive reference collection available at TraceoLab, University of Liège.

Results

Residue causes and deposition

Based on the available experimental data combined with the five monitored attributes (location, smear, distribution, link with the used edge and density), a distinction could be made between different causes of residue deposition: production, hafting, prehension, use, incidental causes and contamination (cf. Table 8). This analysis also allowed to determine the variables of each residue cause that play a role in the residue deposition, in terms of smearing, distribution and density (Table 9).

Production residues form either during blank production or during retouching. On 26 of the 153 stone tools (17%), clear evidence of technological residues was recorded. All production techniques resulted in residue deposition: direct and indirect percussion and pressure flaking. The softer the hammer material, the more residues were left behind. The topography of the butt proved to determine the location and distribution of the residue: in the case of a multi-faceted butt, the residue was located on and near the ridges of the butt, and in the case of a flat butt, the residue was smeared onto the surface. Retouching with an organic hammer (wood, antler and bone) produced small patches of smeared residue, only found on the ventral face of the retouched edge. No clear retouch residues were observed on the used stone tools; they were possibly removed during use.

On 11 of the 29 (38%) hafted tools that were studied, hafting residues in the form of isolated fragments of wood tissue were observed on the non-active parts of the tools, often located on high points such as ridges and bulbs. These are areas where the friction between the haft and the stone tool is most important, as was previously observed for wear traces (Rots 2010).

Adhesives were identified on all three adhesive-hafted tools. Of the 29 tools that were hafted with leather bindings, only one had clear residues. The tool was used for adzing during 1 h, which is a high-pressure activity causing intensive friction with the bindings. This suggests that binding residues are only formed under specific conditions, i.e. during prolonged high-pressure actions such as percussion.

Skin flakes, categorised here as prehension residues, were identified on all used hand-held stone tools. On two of the 103 used tools (2%), residues of worked material were deposited on the non-active parts of the tool through handling.

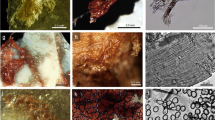

Use-related residues were found on all 103 used tools. The overall density of the residue varied depending on the material worked. Tools that were used for processing fresh animal material (fresh bone, fresh hide) had poor densities of small residue fragments adhering to their surfaces. Tools used to process starchy plants produced high densities. Rough, irregular surfaces proved to be beneficial for residue accumulation: the residues were pushed into surface irregularities (retouch scars and cracks) during use. Often the largest, most visually distinctive residue fragments (collagen fibres, connective tissue, plant tissue, cellulose fibres) were found in these areas that are difficult to see under incident light microscopy.

The distribution of the use-residue proved to be determined by the hardness of the material worked (Table 2) and the angle of the used edge. Residues from hard materials were only found on and near the used edges, while the distribution of residues from materials of intermediate hardness was influenced by the angle of the used edge. In the case of steep angles, the residues were accumulated on the outer edge only, whereas acute angles allowed the residues to disperse towards the inner parts of the tool. For very soft materials, residue distribution was not influenced by the edge angle, and the residues were dispersed all over the tool. If the tool was hafted, the boundary of the haft kept the use residue from dispersing further, resulting in a specific distribution.

On five out of 153 tools (3%), incidental residues were observed. On two stone tools, blood smears were found as evidence of injuries during knapping. On one tool, the blood was associated with connective tissue from the knapper. These incidental residues could easily be confused with use-related residues since they were located near the tool edge. On two stone tools, small deposits of gold were observed from the knapper’s ring.

Modern contamination caused by handling was observed in the form of skin flakes, finger grease, bone powder, cellulose fibres, fresh plant material and flour. These residues were mostly concentrated on and near the edges of the tool. Also, wood cellulose fibres were observed originating from the wooden storage trays on which the tools were placed after knapping.

Residue adhesion

Residue type

Of the 42 stone tools used for examining residue adhesion, the results suggest a strong relationship between the adhesion degree and the main chemical component of the residue (Fig. 3). Therefore, the residues are divided into five groups: carbohydrates, hydroxyapatites, lipids, terpenes and terpenoids and amino acids.

The carbohydrate group contains three different materials worked during the experiments: wood, soft plant and dry flour, and it shows the largest variation in the degree of residue adhesion. Wood tissue adhered to the stone tools much more strongly (step 8) than soft plant tissue (step 5) and dry flour (step 1). These differences can be explained by the hardness (i.e. the amount of friction during work) and the lignin content of the worked material.

For the terpene and terpenoid groups, resin mixed with beeswax was tested but could not be extracted with the extraction protocol, which demonstrates the very strong bond between the residue and the stone tool surface. It also implies that another extraction protocol needs to be used for such residue types (see in the following).

Hard animal materials (bone, antler) are mainly built out of biomineral tissue hydroxyapatite and seem to have a substantially poorer adhesion (mean value = step 8) than the materials in the amino acid group (mean value = step 13.5). We suggest that this difference can be explained by the difference in the proportion of amino acid present in the residue. While residues in the amino group have a very high amino acid ratio, biomineral residues only contain ca. 30% of amino acids.

The residues belonging to the amino acid group are derived from four different materials worked during the experiment: fresh meat, fresh hide and dry hide, but also skin flakes derived from handling the stone tools were tested. These residues proved to adhere strongly to the stone tools, but a difference in adhesion degree was observed between fresh and dry materials. While none of the fresh hide residues could be extracted using our procedure, up to 25% of the dry hide residues were removed after the first step (moving in water for 1 min), and the protocol succeeded in removing all of the residue (in step 12). It indicates that when fresh amino acid material is worked and its residue gets deposited onto the stone tool surface, the subsequent dehydration of the residue will strongly increase the bond between the residue and the stone tool surface.

For the lipid group, fat adhering to fresh hide and finger fat from handling were tested. Not a single lipid residue fragment could be removed using the extraction protocol employed in this study. This indicates that strong bonds are formed between the lipids and the stone tool surface. No difference in adhesion was observed between finger fat and the hide scraping lipids.

Cause of deposition

The cause of residue deposition proved to affect the adhesion degree in certain cases. In particular, the adhesion of water-soluble residues (carbohydrate and hydroxyapatite residues) was affected by the exerted pressure from the action responsible for the residue deposition in the case of hard materials. Results are discussed per cause of deposition.

Production residues from direct percussion using organic hammers (n = 3) have rather poor adhesion and could be extracted using the ultrasonic bath at 37 kHz at only 60–80% of its power (steps 5–7). Differences between bone, antler and wood residues were observed but cannot be considered significant.

Also, hafting residues from wood or horn (n = 4) proved to adhere poorly (step 4). Wood residues were removed more easily than horn residues: between 75 and 100% of the wood residue was removed by only moving the tool in water for 2 min (step 3). Horn residue adhered more strongly, given that it consists mainly out of amino acids (keratin) (step 6). Horn residues were removed after one ultrasonic bath at 70% power. The use duration did not seem to affect the adhesion of residues from wood hafting: wood residues from tools used for 5 min were as easily removed as those from tools used for 30 min.

Use-related residues (n = 27) displayed a large variety in degrees of adhesion in the case of the carbohydrate and hydroxyapatite residue groups, which was determined by the use motion and exerted pressure. A correlation could be observed between the use motion and the adhesion degree of the residue (Fig. 4a). For instance, bone residue from grooving bone during 30 min adhered less strongly than bone residue from a 1-s (severe) projectile impact. By contrast, there seems to be no direct relationship between use duration and the adhesion degree (Fig. 4b), even though an increase in use duration increases the likelihood of a temporary high pressure between the material worked and the stone tool surface, in the case of hard materials. The most strongly adhering residues were found right at the used edge where the pressure is usually the highest. Carbohydrate (e.g. starch from soft plant tissue) and biomineral residues (e.g. soaked antler) from working soft materials without high pressure did not stick to the tool surface as strongly (first extraction from step 1 onwards), for instance, residues that were deposited on dorsal aspects of scraper edges and other areas of relatively poor friction. The adhesion degree of protein and lipid residues seems not affected by the exerted pressure during use since these residues are deriving from soft material worked.

The only incidental residues (n = 3) observed consist of terpenes and terpenoids (resin), lipids (beeswax) and amino acid compounds (human blood). The former two are considered incidental in this case because the resin and beeswax mixture was preserved within a recycled handle; its transfer to the tool was accidental as no glue was used for their hafting. The blood was from an injury during knapping. An important difference in adhesion was observed between freshly deposited blood (less than a week old) (removed by step 1) (Fig. 3a Amino acid outlier value) and blood that was deposited more than 2 years ago, which could not be removed (step 15). This is an important observation as it has significant intriguing consequences for archaeological situations.

Modern contamination residues (n = 7) observed during the study were bone powder, cellulose fibres, fresh plant material, skin flakes, finger fat and flour. Since these residues were deposited through one and the same process (i.e. handling during 1 min), their adhesion degree was determined by their chemical composition. Skin flakes and finger fat could not be removed by the extraction procedure, while bone powder from handling through incidental contact with a bone fragment (step 2) and airborne cellulose fibres (step 1) could be removed after the first step.

Extraction equipment

In total, 88 extractions were performed on the 27 selected stone tools (Table 7), which include 32 pipette extractions and 56 ultrasonic extractions. The results do not only show a difference in success rate between pipette and ultrasonic extraction equipment but also depend on how the equipment was used (Table 10).

Pipette

Residue adhesion proved to play an important role when extracting with a pipette. When the stone tool surface and the liquid are not agitated with the pipette, only residues with a poor adhesion loosen (Fig. 5). Only starch granules (contamination and use), bone flakes (use), cellulose fibres (contamination) and plant tissue (contamination) could be partially removed with a pipette without agitation.

Gently agitating the surface sufficed to partially extract all residue components included in the test, except for plant exudate and blood. The latter two have a very strong adhesion, and also their deposition as very thin layers on the stone tool surface may hinder extraction. Pipettes never succeeded in extracting all the residues present in the preselected area. Nevertheless, agitation is essential to prevent a biased residue representation within the extraction that even favours contamination residues. An important caveat, however, is that gentle agitation proved to lead to residue damage if largely sized residues (e.g. large fragments of connective tissue, wood tissue or large resin blobs) are extracted.

An undeniable advantage of pipette extraction is that it can be done locally. This means that isolated residues (e.g. incidental residues or contamination) or residues that appear in patches (e.g. wood from hafting) can be removed without mixing them with residues from other causes. Only when residues from different causes are adjacent to each other or overlap, they may get mixed using this extraction procedure.

Ultrasonic bath

When using an ultrasonic bath, six of the 13 residue components (collagen fibres, red blood cells, beeswax and resin, plant exudate, skin flakes) could not be removed, even when increasing processing times to up to 30 min. For these residue types, an extraction with distilled water is not worthwhile, but alternative solvents could be considered. Interestingly, the mineral matrix was extracted in the case of fresh bone residues but not the organic compound, the collagen fibres.

Of the residues that could be extracted using ultrasonic cleaning (plant/wood tissue, cellulose fibres, starch granules, bone flakes, adipose tissue, connective tissue, muscle tissue), none could be extracted in their entirety. Increasing extraction times did not substantially improve residue removal. In the case of adipose tissue (strong adhesion), for instance, extended extraction times did not affect the number of extracted residue fragments. In the case of starch granules (rather poor adhesion degree), up to 90% of all extracted starch granules were removed after only 2 min of ultrasonication (Fig. 6). An increase in extraction time had the most effect on wood tissue up to a maximum of 5 min after which the wood tissue started to break up. The tissue typically broke up into plant cells, and in some cases, cellulose fibres were left behind on the stone tool surface. This implies that ultrasonic extraction times exceeding 5 min should be avoided for wood and plant tissue not to risk hampering interpretations.

In our experience, residue fragments present in very low densities should not be extracted using an ultrasonic bath. A single hair, coming from hide scraping was observed on one of the stone tools and could be extracted, but it could not be retrieved from the solution for further analysis. One should also realise that ultrasonication of large areas will increase the risk of mixing residues from different origins. This is particularly important in the case of residues that are situated away from the edge, such as wood tissue from hafting, dispersed use-related residues and contaminant cellulose fibres. All of these were observed in the same area on the surface of one of our experimental tools.

Discussion

Residue extraction, while commonly applied, proved to be one of the least controlled parts of current analytical protocols. Analysts have not yet critically evaluated the quantity and representativity of residues that are extracted through various protocols as opposed to those which remain on the stone tool. In addition, both the deposition and the adhesion processes of residues were still poorly understood. We demonstrated that the adhesion degree of a residue varies according to its chemical composition and its cause of deposition. Whether the observed differences in adhesion degree reflect a difference in the bond between the residue and the stone tool surface or whether it is determined by the relative solubility of the different residue types remains to be studied. It would require a chemical study that identifies the type of bond between the mineral stone surface and the different residue types. Overall, amino acid, lipid and terpene residues proved to adhere more strongly than carbohydrate and hydroxyapatite residues. A fresh deposition and the subsequent drying of amino acid, lipid and terpene residues proved to be essential for creating the strong bond between those residue types and the stone tool surface.

Also, the cause of residue deposition proved to affect the residue adhesion. Rots et al. (2016) have shown that identifying the residue cause is more complicated than has often been assumed. Their study identified six probable sources of residue deposition for stone tools: tool production, hafting/prehension, use, incidental contact with other materials, environmental contamination and modern contamination. Our study, in turn, has identified six attributes that are helpful in identifying residue cause: location, smearing, distribution pattern, relationship with the used edge, density and adhesion degree. The location of the residue on the stone tool has proven to be the most useful attribute for correctly identifying the cause of residue deposition. Technological use and hafting-related residues indeed tend to occur at specific locations on the tool. Only residues derived from soft or wet materials can be dispersed all over the stone tool without obvious clustering. The pressure exerted during use (or other processes) is important and may, in some cases, override the effect of the residue’s chemical composition. The exact conditions under which this overriding effect takes place are not yet clear, as the applied pressure on the material worked was not measured during this experiment.

Incidental residues may pose a problem for interpretations that rely on the mapping of the residue location. Incidental residues are difficult to identify correctly, as their distribution may overlap with residues from other causes, and they may show a degradation degree similar to that of functional residues. For this reason, the attribution of a residue to a specific cause should not solely rely on its distribution, but on an entire set of attributes. Moreover, technological and use-wear data (Akerman et al. 2002; Rots et al. 2016) are best integrated into residue studies that overcome interpretative problems of incidental residues. Taphonomic residues pose specific interpretative difficulties, and a correct attribution necessitates adapted protocols during excavation and analysis, such as a comparison of the residue frequencies between used artefacts, unused artefacts and the associated sediments (Barton et al. 1998).

Residue adhesion proved to impact the success rates of extraction protocols, and it is thus a crucial factor to take into account when analysing residues on stone tools. The adhesion experiments presented here dealt with modern reference samples and were not designed to evaluate the impact of time and taphonomic processes on the adhesion properties of residues. However, the results hold some clues for understanding which residues are potentially more resistant to mechanical taphonomic processes (e.g. frost, water percolation). Freshly deposited amino acid (e.g. blood) and lipid residues (e.g. fat), if allowed to dry after deposition, form strong hydrophobic bonds, which are resistant to these taphonomic processes, independent of their cause of deposition. Hydroxyapatite and carbohydrate residues are the most resistant to these processes if they derive from hard materials (e.g. bone, wood) and if they are the result of an activity involving high pressure (e.g. spear thrusting). If the exerted pressure with which the residue is deposited is low (e.g. accidental airborne residues), these residues will only survive in archaeological contexts when important mechanical taphonomic processes were.

The extraction method proves to influence the success rate of residue extraction, i.e. the degree to which a representative residue sample can be collected. The use of a pipette allows targeting small specific areas, which is particularly useful for residues with a clear patterning and/or limited extension (e.g. production residues only present on the platform). In addition, it minimises the risk of mixing residues derived from different causes. A direct transfer to a glass slide reduces the number of transfers and minimises the risk that some extracted residue stays behind in a recipient, and the quantity of the solution used for the extraction can be adapted to each situation. It guarantees concentrated residue samples and, as a consequence, shorter analysis times. Mechanical disruption (by manual agitation with the pipette or ultrasonic waves) is essential for breaking up the bond between the residue components and the stone tool surface and thus for extracting the residue. If the tool surface is not agitated during pipette extraction, only residues with a poor adhesion (e.g. airborne contamination residues) will be removed, which results in an incomplete and biased sample of the residues present on the stone tool surface.

Ultrasonication using distilled water is a less efficient way of extracting residues from a stone tool surface, but it is the preferable option for poorly adhering residues that are dispersed all over the tool (e.g. starch or dry bone). It is not suitable for extracting strongly adhering residue components unless other solvents are used, which explains the use of ammonia or sodium dodecyl sulphate as a solvent in protein analysis (Newman and Julig 1989; Craig and Collins 2002; Shanks et al. 2005). Extractions using an ultrasonic bath for more than 5 min are best avoided as it may damage or destroy.

This study also showed that certain recent contamination residues, such as skin flakes and finger fat, adhere strongly to the stone tool surface due to their chemical composition and in spite of their incidental deposition. They could not be removed using the extraction techniques tested here, and their deposition should this be avoided. In use-wear analysis, ethanol and acetone are part of the standard cleaning protocol (Keeley 1980; Plisson 1985; Vaughan 19851985) to remove these contaminants and allow the observation of use-wear. These solvents are thus likely to damage archaeological residues, and they should only be used to remove remaining residues after all required extractions are performed.

Since gentle water-based cleaning techniques cannot remove these contaminants, their deposition on the stone tool surface should be avoided at all times. The use of starch-free gloves for the handling of stone tools that are intended to be examined for residues is thus advisable from the moment of excavation onwards.

Four issues have to be taken into account when designing extraction protocols for flaked stone tools:

-

1.

After an initial screening of the tools under magnification, a superficial rinsing may be required to remove poorly adhering contamination residues (e.g. airborne starch and cellulose). This controlled rinsing should be performed gently, with distilled water and without brushes or finger wiping, in a clean lab environment.

-

2.

An on-tool microscopic analysis needs to be performed, prior to extraction, to map the location of the residues, to identify the different residue types, to attribute each to a likely cause of deposition and to assess the adhesion of the observed residues. Specific areas of interest can be identified to orientate the extraction.

-

3.

Breaking the bond between the residue and the stone tool surface is essential for obtaining a successful extraction. This can be done by gently agitating the stone surface with the pipette tip or by using an ultrasonic bath. Harsh agitation through pipette contact or enduring ultrasonic waves may lead to residue damage, in particular for plant tissues. Pipette agitation or extractions should thus always be gentle, and they are preferably performed in several shorter intervals (2–5 min) rather than in one extended session (<15 min).The selection of the extraction equipment should be based on the density and adhesion properties of the targeted residue.

-

(a)

Residues with poor densities (e.g. one hair fragment) or only present in an isolated location (e.g. production residues) should always be extracted with a pipette, to minimise the risk of loss.

-

(b)

Strongly adhering residues (amino acid, lipid or terpene residues) cannot be extracted with an ultrasonic bath and distilled water; they can only be partially removed with a pipette.

-

(a)

-

4.

In a final stage, when the water extractions are completed and the majority of the carbohydrate and hydroxyapatite residues are extracted, protein and lipid residues should be extracted with a specific solvent (e.g. SDS 2%, ammonium hydroxide 5% for proteins or E.W.A. for lipids) in order to guarantee a reliable representation of all residue types.

Conclusion

This study identified important building blocks for the development of reliable extraction protocols instead of proposing one final protocol. An on-tool residue observation with both stereo and metallurgic microscopes is a necessary condition not only to identify the different residue types and causes, but also to demarcate different residues present on a single stone tool. The chemical composition and, in some cases, the freshness of the worked material determine the bonding strength between the residue and the stone tool surface. Materials containing high amounts of amino acids, lipids and terpenes proved to form a stronger bond with the flint surface than materials consisting mainly of carbohydrates or biominerals such as hydroxyapatite. The adhesion degree of weakly bonded residues increased if the pressure exerted during use or during other processes leading to residue accumulation is high. The choice of an adequate extraction technique has to be based on the nature and the distribution of the residues. Pipette extractions that involve the agitation of the solvent proved most successful. Extractions with an ultrasonic bath were generally less effective, but they proved nevertheless useful in specific cases of dispersed, poorly adhering residues. However, enduring exposure of residues to ultrasonic waves may lead to damage of those residues. Since acetone or ethanol damage archaeological residues, they should only be used after the required water-based extractions are performed. Further experimental work will help to improve our understanding of the hierarchy and the combined effect of different factors that contribute to the adhesion strength of residues.

References

Akerman K, Fullagar R, van Gijn A (2002) Weapens and wunan: production function and exchange of Kimberley points. Aust Aborig Stud 1:13–42

Barker A, Venables B, Stevens SM, et al (2012) An optimized approach for protein residue extraction and identification from ceramics after cooking

Barton H (2007) Starch residues on museum artefacts: implications for determining tool use. J Archaeol Sci 34:1752–1762. doi:10.1016/j.jas.2007.01.007

Barton H, Torrence R, Fullagar R (1998) Clues to stone tool function re-examined: comparing starch grain frequencies on used and unused obsidian artefacts. J Archaeol Sci 25:1231–1238

Boëda E, Connan J, Dessort D et al (1996) Bitumen as a hafting material on Middle Palaeolithic artefacts. Nature 380:336–338. doi:10.1038/380336a0

Briuer F (1976) New clues to stone tool function: plant and animal residues. Am Antiq 41:478–484

Brown TA, Brown K (2011) Biomolecular archaeology: an introduction. Wiley, Hoboken

Byrne L, Ollé A, Vergès JM (2006) Under the hammer: residues resulting from production and microwear on experimental stone tools. Archaeometry 48:549–564. doi:10.1111/j.1475-4754.2006.00272.x

Craig OE, Collins MJ (2002) The removal of protein from mineral surfaces: implications for residue analysis of archaeological materials. J Archaeol Sci 29:1077–1082. doi:10.1006/jasc.2001.0757

Crowther A, Haslam M, Oakden N et al (2014) Documenting contamination in ancient starch laboratories. J Archaeol Sci 49:90–104. doi:10.1016/j.jas.2014.04.023

Denham TP, Haberle SG, Lentfer C et al (2003) Origins of agriculture at Kuk Swamp in the highlands of New Guinea. Science 301:189–193. doi:10.1126/science.1085255

Evans AA, Donahue RE (2005) The elemental chemistry of lithic microwear: an experiment. J Archaeol Sci 32:1733–1740. doi:10.1016/j.jas.2005.06.010

Evershed RPR (1993) Biomolecular archaeology and lipids. World Archaeol 25:74–93. doi:10.1080/00438243.1993.9980229

Evershed RP (2008) Organic residue analysis in archaeology: the archaeological biomarker revolution*. Archaeometry 50:895–924. doi:10.1111/j.1475-4754.2008.00446.x

Fullagar R (1986) Use-wear and residues on stone tools: functional analysis and its application to two southeastern Australian archaeological assemblages (Unpublished Ph.D. thesis). La Trobe University, Melbourne

Fullagar R (2006) Starch on artefacts. Anc Starch Res:177–203

Fullagar R (2014) Residues and usewear. In: Balme J, Paterson A (eds) Archaeology in practice: a student guide to archaeological analyses. Wiley, Hoboken, pp 232–265

Fullagar R (2015) The logic of visitation: tool-use, technology and economy on Great Glennie Island, southeastern Australia. Quat Int 385:219–228. doi:10.1016/j.quaint.2015.05.066

Fullagar R, Field J, Denham T, Lentfer C (2006) Early and mid Holocene tool-use and processing of taro (Colocasia esculenta), yam (Dioscorea sp.) and other plants at Kuk Swamp in the highlands of Papua New Guinea. J Archaeol Sci 33:595–614. doi:10.1016/j.jas.2005.07.020

Fullagar R, Hayes E, Stephenson B et al (2015) Evidence for Pleistocene seed grinding at Lake Mungo, south-eastern Australia. Archaeol Ocean 50:3–18. doi:10.1002/arco.5053

Gibson NE, Wadley L, Williamson BS (2004) Microscopic residues as evidence of hafting on backed tools from the 60 000 to 68 000 Howeisons Poort layers of Rose Cottage Cave, South Africa. South African Humanit 16:1–11

Gurfinkel DM, Franklin UM (1988) A study of the feasibility of detecting blood residues on artifacts. J Archaeol Sci 15:83–97

Hardy BL (2004) Neanderthal behaviour and stone tool function at the Middle Palaeolithic site of La Quina, France. Antiquity 78:547–565. doi:10.1017/S0003598X00113213

Hardy BL, Moncel M-H (2011) Neanderthal use of fish, mammals, birds, starchy plants and wood 125-250,000 years ago. PLoS One 6:e23768. doi:10.1371/journal.pone.0023768

Hardy BL, Bolus M, Conard NJ (2008) Hammer or crescent wrench? Stone-tool form and function in the Aurignacian of southwest Germany. J Hum Evol 54:648–662. doi:10.1016/j.jhevol.2007.10.003

Haslam M (2011) Mountains and molehills: sample size in archaeological microscopic stone-tool residue analysis. In: Terra Australis. pp 47–79

Helwig K, Monahan V, Poulin J, Andrews TD (2014) Ancient projectile weapons from ice patches in northwestern Canada: identification of resin and compound resin-ochre hafting adhesives. J Archaeol Sci 41:655–665. doi:10.1016/j.jas.2013.09.010

Kealhofer L, Torrence R, Fullagar R (1999) Integrating Phytoliths within use-wear/residue studies of stone tools. J Archaeol Sci 26:527–546. doi:10.1006/jasc.1998.0332

Keeley LH (1980) Experimental determination of stone tools uses: a microwear analysis. University of Chicago Press, ChicagoLondon

Lamb J, Loy T (2005) Seeing red: the use of Congo Red dye to identify cooked and damaged starch grains in archaeological residues. J Archaeol Sci 32:1433–1440. doi:10.1016/j.jas.2005.03.020

Langejans GHJ (2011) Discerning use-related micro-residues on tools: testing the multi-stranded approach for archaeological studies. J Archaeol Sci 38:985–1000. doi:10.1016/j.jas.2010.11.013

Langejans GHJ (2012) Middle Stone Age pièces esquillées from Sibudu Cave, South Africa: an initial micro-residue study. J Archaeol Sci 39:1694–1704. doi:10.1016/j.jas.2011.12.036

Langenheim J (2003) Plant resins: chemistry, evolution, ecology, and ethnobotany

Liu L, Field J, Fullagar R et al (2010) What did grinding stones grind? New light on Early Neolithic subsistence economy in the Middle Yellow River Valley, China. Antiquity 84:816–833

Lombard M (2004) Distribution patterns of organic residues on Middle Stone Age points from Sibudu Cave, Kwazulu-Natal, South Africa. South African Archaeol Bull 59:37–44

Lombard M (2005) Evidence of hunting and hafting during the Middle Stone Age at Sibidu Cave, KwaZulu-Natal, South Africa: a multianalytical approach. J Hum Evol 48:279–300. doi:10.1016/j.jhevol.2004.11.006

Lombard M (2006) Direct evidence for the use of ochre in the hafting technology of Middle Stone Age tools from Sibudu Cave. South African Humanit 18:57–67

Lombard M (2008) Finding resolution for the Howiesons Poort through the microscope: micro-residue analysis of segments from Sibudu Cave, South Africa. J Archaeol Sci 35:26–41. doi:10.1016/j.jas.2007.02.021

Lombard M, Phillipson L (2010) Indications of bow and stone-tipped arrow use 64 000 years ago in KwaZulu-Natal, South Africa. Antiquity 84:635–648. doi:10.1017/S0003598X00100134

Lombard M, Wadley L (2007) The morphological identification of micro-residues on stone tools using light microscopy: progress and difficulties based on blind tests. J Archaeol Sci 34:155–165. doi:10.1016/j.jas.2006.04.008

Lopez-Polin L, Bermúdez de Castro JM, Carbonell E (2011) Preparation of Pleistocene human bones with an ultrasonic scaler: the case of mandible ATD6-112 from Atapuerca (Spain). ArchéoSciences 35:235–239

Loy TH (1993) Prehistoric organic residue analysis: the future meets the past. In Spriggs M, Yen DE, Ambrose W, Jones R, Thorne A, Andrews A (eds) A community of culture: the people and prehistory of the Pacific. Australian National University, Canberra, pp 56–72

Mason TJ (2015) Ultrasonic cleaning: an historical perspective. Ultrason Sonochem. doi:10.1016/j.ultsonch.2015.05.004

Matheson CD, Veall M-A (2014) Presumptive blood test using Hemastix® with EDTA in archaeology. J Archaeol Sci 41:230–241. doi:10.1016/j.jas.2013.08.018

Mills J, White R (1977) Natural resins of art and archaeology their sources, chemistry, and identification. Stud Conserv 22:12–31. doi:10.2307/1505670

Monnier GF, Ladwig JL, Porter ST (2012) Swept under the rug: the problem of unacknowledged ambiguity in lithic residue identification. J Archaeol Sci 39:3284–3300. doi:10.1016/j.jas.2012.05.010

Newman M, Julig P (1989) The identification of protein residues on lithic artifacts from a stratified boreal forest site. Can J Archaeol 13:119–132

O’Connor TP (1987) On the structure, chemistry and decay of bone, antler and ivory. Archaeol bone, antler ivory 6–8

Pedergnana A, Asryan L, Fernández-Marchena JL, Ollé A (2016) Modern contaminants affecting microscopic residue analysis on stone tools: a word of caution. Micron 86:1–21. doi:10.1016/j.micron.2016.04.003

Plisson H (1985) Etude fonctionnelle d’outillages lithiques préhistoriques par l’analyse des micro-usures: recherche méthodologique et archéologique. Université de Paris I, thèse de doctorat.

Perrault K, Stefanuto P-H, Dubois L et al (2016) A new approach for the characterization of organic residues from stone tools using GC×GC-TOFMS. Separations 3:16. doi:10.3390/separations3020016

Perry L (2004) Starch analyses reveal the relationship between tool type and function: an example from the Orinoco valley of Venezuela. J Archaeol Sci 31:1069–1081. doi:10.1016/j.jas.2004.01.002

Pollard AM, Heron C (2008) Archaeological chemistry. Royal Society of Chemistry, Cambridge

Regert M (2004) Investigating the history of prehistoric glues by gas chromatography-mass spectrometry. J Sep Sci 27:244–254. doi:10.1002/jssc.200301608

Rots V (2010) Prehension and hafting traces on flint tools: a methodology. Universitaire Pers Leuven, Leuven

Rots V, Williamson B (2004) Microwear and residue analyses in perspective: the contribution of ethnoarchaeological evidence. J Archaeol Sci 31:1287–1299. doi:10.1016/j.jas.2004.02.009

Rots V, Van Peer P, Vermeersch PM (2011) Aspects of tool production, use, and hafting in Palaeolithic assemblages from Northeast Africa. J Hum Evol 60:637–664. doi:10.1016/j.jhevol.2011.01.001

Rots V, Hardy BL, Serangeli J, Conard NJ (2015) Residue and microwear analyses of the stone artifacts from Schöningen. J Hum Evol 89:298–308. doi:10.1016/j.jhevol.2015.07.005

Rots V, Hayes E, Cnuts D et al (2016) Making sense of residues on flaked stone artefacts: learning from blind tests. PLoS One 11:e0150437. doi:10.1371/journal.pone.0150437

Schiffer M (1972) Archaeological context and systemic context. Am Antiq 37:156–165

Schiffer M (1987) Formation processes of the archaeological record. University of New Mexico Press, Albuquerque

Sensabaugh GF, Wilson AC, Kirk PL (1971) Protein stability in preserved biological remains: II. Modification and aggregation of proteins in an 8-year-old sample of dried blood. Int J Biochem 2:558–568

Shafer H, Holloway R (1979) Organic residue analysis in determining stone tool function. In: Hayden B (ed) Lithic use-wear analysis. pp 385–399

Shanks OC, Hodges L, Tilley L et al (2005) DNA from ancient stone tools and bones excavated at Bugas-Holding, Wyoming. J Archaeol Sci 32:27–38. doi:10.1016/j.jas.2004.06.004

Smith M, Hayes E, Stephenson B (2015) Mapping a millstone: the dynamics of use-wear and residues on a Central Australian seed-grinding implement |. Aust Archaeol 80:70–79

Stephenson B (2015) A modified Picro-Sirius Red (PSR) staining procedure with polarization microscopy for identifying collagen in archaeological residues. J Archaeol Sci 61:235–243. doi:10.1016/j.jas.2015.06.007

Summerhayes GR, Leavesley M, Fairbairn A et al (2010) Human adaptation and plant use in highland New Guinea 49,000 to 44,000 years ago. Science 330:78–81. doi:10.1126/science.1193130

Torrence R, Barton H (2006) Ancient starch research. Left coast Press, Walnut Creek

Vaughan P (1985) Use wear analysis of flaked stone tools. University of Arizona Press, Tucson

Veall M-A, Matheson CD (2014) Improved molecular and biochemical approaches to residue analysis. In: Lemorini C, Nunziante Cesaro S (eds) An integration of use-wear and residues analysis for the identification of the function of archaeological stone tools. Archaeopress, Oxford, pp 9–26

Wadley L, Lombard M, Williamson B (2004) The first residue analysis blind tests: results and lessons learnt. J Archaeol Sci 31:1491–1501. doi:10.1016/j.jas.2004.03.010

Williamson BS (1997) Down the microscope and beyond: microscopy and molecular studies of stone tool residues and bone samples from Rose Cottage Cave. S Afr J Sci 93:458–464

Acknowledgements

We are grateful to all members of TraceoLab for their help and advice during the experiments and the preparation of this paper, in particular Christian Lepers for producing and using all the experimental stone tools examined in this study and Noora Taipale and Carol Lentfer for having revised the English text. Finally, we would like to thank the reviewers who have helped to improve this paper. This research was funded by the European Research Council under the European Union Seventh Framework Programme (FP/2007-2013) in the context of a starting grant (“EVO-HAFT”) attributed to Veerle Rots (ERC Grant Agreement no. 312283). Veerle Rots is also indebted to the Fund for Scientific Research (FNRS-FRS) (grant number: CQ 2011).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Table 1

Results of the adhesion test with the ultrasonic bath. The percentage of removal was calculated by comparing the state of density and size of a residue before any intervention and the state before and after each cleaning step by counting the residues. When the residue fragments were too numerous, the degree of change was estimated. Residue cause: P= production, H= Hafting, U= Use, I= Incidental, C= contamination. Condition: F= Fresh, D= Dry. Main chemical component: AA= Amino acids, CH= Carbohydrates, HY= Hydroxyapatite, LI= Lipids, TE= Terpenes and terpernoids (XLSX 15 kb).

Rights and permissions

About this article

Cite this article

Cnuts, D., Rots, V. Extracting residues from stone tools for optical analysis: towards an experiment-based protocol. Archaeol Anthropol Sci 10, 1717–1736 (2018). https://doi.org/10.1007/s12520-017-0484-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12520-017-0484-7