Abstract

Myanmar has been notably underrepresented in recent studies of archaeometallurgy in Southeast Asia, despite its richness in both mineral and cultural resources and its potentially central role in long-distance exchange networks linking India, China and peninsular neighbours. Here, we present original analytical data on copper-base artefacts from several Bronze Age and Iron Age sites in Myanmar. Observed microstructures range from as-cast, worked, to fully annealed; compositions include leaded copper, low-tin to high-tin bronzes, and arsenical copper/bronze. Lead isotope analyses indicate that the metal originates from different geological sources, including several that match the lead isotope signatures of known prehistoric copper mines in Thailand and Laos. These archaeometallurgical data, including evidence for secondary copper-base production, more than double those currently available for Myanmar and document the presence of multiple local alloying and working traditions, perhaps chronologically differentiated, as well as identifying possible links to primary mineral sources across the region. Overall, this adds significant new information to the emerging picture of Southeast Asian prehistoric metallurgy at the crossroads of several major ancient cultures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

This paper lies at the confluence of two developing sub-disciplines: the first, that of Myanmar’s later prehistory in its continental Southeast Asian context; the second, that of Southeast Asian archaeometallurgy in its global context. Commencing with Myanmar’s later prehistory, as per much of Southeast Asia, initial archaeological interest concentrated on historical sites perceived as the source culture of the post-colonial nation state, i.e. Pyu cities from the early-mid first millennium AD and late first millennium-early second millennium AD Bagan (Aung Thaw 1968, 1972; Gutman and Hudson 2004, 2008; Myint Aung 1970; Stargardt 1990). These historical sites, with massive brick-built architectural remains, are also noticeably visible in the landscape. A prehistoric focus developed in the late 1990s when the then Ministry of Culture Department of Archaeology responded to chance finds reported by local people, particularly those discovered near the village of Nyaung’gan, Budalin Township, Sagaing Division (Fig. 1).

Map showing Myanmar’s location in Southeast Asia and some of its major cities (left) and sites discussed in the text (right). Red sites have been excavated by the Franco-Myanmar mission; black sites were either excavated by the Department of Archaeology and/or looted; green sites indicate the known regional primary copper producers

Two seasons of excavation in 1998/1999 at Nyaung’gan, a cemetery on the northwestern edge of a dormant volcano, revealed 43 inhumations with a range of burial goods including copper-base alloys but without iron/steel or glass artefacts. On this basis, Nyaung’gan was attributed a Bronze Age date, the first for Myanmar, although no radiometric determinations were available (Han 1999; Moore and Pauk 2001; Myint 2003; Tayles et al. 2001). A conference organised by the then Myanmar Ministry of Culture in January 1999, to present the findings of the Nyaung’gan excavations and seek out international collaborations, led directly to the founding of the Mission Archéologique Française au Myanmar by Prof. Jean-Pierre Pautreau in 2001. The next 12 seasons saw the investigation of ten prehistoric sites by the Franco-Myanmar team in the Samon Valley south of Mandalay (Fig. 1), all of which were Iron Age (c. 500 BC to c. 500 AD) cemeteries with one instance at Yan Gon Gwi of Neolithic occupation (early second millennium BC, Pautreau et al. 2010b). This international collaboration, Myanmar’s first for archaeology, furnished a substantial database for late prehistoric funerary behaviour in central Myanmar (e.g. Coupey 2012; Coupey et al. 2011; Pautreau 2007; Pautreau et al. 2010a), which has been added to by independent excavations of the Mandalay Department of Archaeology. Despite these advances the number of scientifically excavated prehistoric sites remains low compared to some Southeast Asian countries, particularly Thailand and Vietnam, and those with radiometric determinations are rarer still. Because of this data disparity it has been difficult to integrate Myanmar’s late prehistoric period with that of the wider region, so every new batch of evidence can be critical for exposing past populations’ ways of life, interactions and/or movements.

The latter sub-discipline, Southeast Asian archaeometallurgy, experienced a strong start in the 1970s and 1980s, relative to other regional archaeological specialisations. Metal artefact studies came first and were especially concentrated in Thailand: Robert Maddin and Tamara Stech/Stech-Wheeler (Stech and Maddin 1988; Wheeler and Maddin 1976) at the northeastern Thai sites of Non Nok Tha and Ban Chiang; and Nigel Seeley and Warangkhana Rajpitak (Rajpitak and Seeley 1979; Seeley and Rajpitak 1984) at the northeastern Thai site of Ban Na Di and at the west-central site of Ban Don Tha Phet. Vietnamese researchers were notably active in studying prehistoric bronze assemblages (e.g. Sinh 1989). Research on primary production was also precocious and highly effective under the aegis of the ‘Thailand Archaeometallurgy Project’, founded in 1984 by Vincent C. Pigott and Surapol Natapintu (Natapintu 1988; Pigott 1984, 1986, 1988, 1998; Pigott and Natapintu 1988; Pigott and Weisgerber 1998; Pigott et al. 1997) to investigate copper mining and smelting loci at Phu Lon in northern Thailand and in the Khao Wong Prachan Valley of central Thailand (Fig. 1, see also Bennett 1988, 1989). This work was complemented by secondary production studies, namely of foundry crucible remains, by William Vernon (Vernon 1996–1997, 1997), at several of the sites mentioned above. Nevertheless, despite these promising beginnings for Southeast Asian archaeometallurgy, what singularly failed to coalesce was the widespreadFootnote 1 application of the lead isotope methodology for provenance research, which was being used with success in a number of cultural contexts by the 1980s (e.g. Brill and Wampler 1967; Gale and Stos-Gale 1982; Mabuchi et al. 1985; Stos-Gale and Gale 1982; Yener 1986). Regional archaeometallurgical research maintained a limited profile throughout the mid-late 1990s and early 2000s but began to revive in the mid-2000s, above all with the discovery of a third major prehistoric copper production locale at Sepon in central Laos (Pryce et al. 2011a; Sayavongkhamdy et al. 2009; Tucci et al. 2014). The last decade has seen a notable increase in studies of prehistoric metal production and consumption at scales ranging from individual sites to regional technological traditions (summarised in Pryce 2014) but what has, arguably, transformed archaeometallurgy’s contribution to the Southeast Asian archaeological endeavour is the development of coherent, though by no means uniformly distributed, copper-base metal provenance sampling programmes applying lead isotope analyses. Two research groups have been active so far, the first being that led by Professor Yoshimitsu Hirao (e.g. Hirao and Ro 2013), and the second by the lead author (e.g. 2014). The major difference between these complementary programmes has been their sampling strategy; the former analysing a large proportion or the entirety of assemblages from a small number of sites from Cambodia, Thailand and Vietnam, thus offering the potential for the detailed interpretation of intra-site variation. The latter has reduced sampling (generally 10–20 artefacts per site) from dozens of sites across Mainland and Island Southeast Asia and includes production assemblages (minerals and slag), thus offering a hazy but comprehensible picture of large-scale exchange networks. The entire regional database is in desperate need of expansion in order to propose interpretations of reasonable certainty, and certain countries are particularly under-represented: Malaysia, Myanmar and the Philippines.Footnote 2 In the frame of the Mission Archéologique Française au Myanmar (“MAFM”), we seek with this paper to begin to redress the second of these geographical lacunae.

Sites and samples

In Myanmar, as in much of Southeast Asia, and indeed most of the world, the unauthorised excavation of sites is a grave problem that threatens not only the integrity of the archaeological record but also the quality of the interpretations we can draw from it. However, it is sometimes necessary to engage with an imperfect world rather than railing ineffectively against the inevitable; and also to recognise that the reasons for unauthorised excavations can be varied as well as complex and not so easy to judge without detailed anthropological understanding (e.g. Vallard et al. 2015). Objects from unauthorised excavations are indisputably compromised in their context but, given the alternative of no scientific data at all, we have attempted to recover what information we can. The study assemblages can be grouped thus: artefacts from the sites of Htan Ta Pin, Kokkokhahla, Myin Oo Hle, Mon Htoo, Myinthe, Nyaung’gan, Oakaie and Supan held in museum and private collections; and artefacts excavated by the Mission Archéologique Française au Myanmar from the sites of Nyaung’gan, Oakaie 1, Oakaie 2 and Oakaie 3 during the 2014–2016 field seasons (Fig. 1).

Group 1

Where a site has been subject to an authorised excavation, we give a summary of those results to provide some context, even if the studied artefacts were recovered by unauthorised excavation.

-

Htan Ta Pin, situated in Pyaw Bwe township, was investigated by the Mission Archéologique Française au Myanmar in 2006 (Fig. 1). Thirty-six Iron Age graves with 23 extant inhumations, 17 adults and six children were found in the 41 m2 uncovered. Thirteen of the burials had associated grave goods of pottery, stone and glass beads and polished stone tools, but no metal artefacts were excavated nor radiometric dates obtained, though the presence of glass indicates an Iron Age date (Pautreau et al. 2010a: 52–83). A single bowl fragment (SEALIP/MY/HTP/1) from unauthorised excavations was studied (Fig. 2).

-

Kokkokhahla, situated in Wundwin township, was excavated by the Department of Archaeology in 2000 (Fig. 1). Eighty-five inhumations oriented north or northeast were discovered, in association with grave goods of stone and ceramic beads, pottery, iron/steel tools and copper-base alloys, including 2 spearheads, 2 axes, 3 bracelet fragments and 16 bundles of wire.Footnote 3 This assemblage would suggest an Iron Age date, post c. 500 BC, but no radiocarbon determinations are available. Three copper-base artefacts from unauthorised excavations were studied: a bangle, a wire bundle and a sword scabbard fragment (Fig. 3).

-

Mon Htoo, situated in Budalin township, was excavated by the Department of Archaeology in 2000 (Fig. 1). Thirty-seven inhumations were exposed, all but one of which was oriented N/S, in association with stone bracelets and beads, ceramics, bivalve shells and 15 copper-base artefacts (ten axes, two rings, one spear, one bell and one bracelet). A Bronze Age date was attributed based on the style of the assemblage and the absence of iron and glass. Three copper-base artefacts from unauthorised excavations were studied: one amorphous fragment, one platy fragment and a ring fragment (Fig. 4).

-

Myin Oo Hle, situated in Mahlaing township, was rescue excavated by the Department of Archaeology in 1999 in light of heavy looting (Fig. 1). Twenty-one inhumations oriented north (19) and east (2) were uncovered, associated with stone beads, bivalve shells, pottery and copper-base alloys; spearheads of various sizes and masses and wire bundles. The presence of iron/steel would again suggest a post c. 500 BC date. Two copper-base artefacts from unauthorised excavations were studied: one bell fragment and one spearhead fragment (Fig. 5).

-

Myinthe, situated in Yakainggyi township (Fig. 1), has never been formally excavated. Its date is unknown but probably Iron Age. One copper-base spearhead fragment was studied (Fig. 6).

-

Oakaie, situated in Budalin township (Fig. 1), has numerous Neolithic and Bronze Age deposits south of the modern village, several of which have been excavated by the Mission Archéologique Française au Myanmar in 2014–2016 (see below). A single copper-base arrowhead from unauthorised excavations and six fragments from authorised survey were studied (Fig. 7, see Moore and Pauk 2001: 42 for detail of the authorised finds).

-

Supan, located in Wundwin township, has never been formally excavated. Its date is unknown but probably Iron Age (Fig. 1). A single copper-base bowl was studied (Fig. 8).

Group 2 sites

MAFM investigations in the “Nyaung’gan Bronze Age Culture Area” in Budalin township began in 2014 as an attempt to confirm the eponymous site’s status as Myanmar’s first Bronze Age culture with a reliable series of radiometric dates, and also to add local socio-economic detail to its reconstruction (Fig. 9).

-

Oakaie 1 (OAI1), located 2.6 km southwest of the Nyaung’gan cemetery was investigated in 2014–2015. A total of 51 burials were exposed, indicating two burial strata and orientations (north and northeast) with finds of ceramics, stone beads and bracelets and bivalves. A single copper-base axe (SEALIP/MY/OAI1/1) suggested, in the absence of glass or iron, a Bronze Age date (Fig. 10). A series of published and as yet unpublished radiocarbon determinations on human bone and tooth apatite confirmed this was an early first millennium BC cemetery (Pryce et al. 2015).

-

Oakaie 2 (OAI2), located 700 m west of Oakaie 1 (Fig. 2), was investigated with five testpits in 2015 and corresponded to a settlement with dense sherd-packed and copper-base corrosion-flecked floors with sub-surface infant jar burials, as well as a single adult skeleton. A single copper-base rod (SEALIP/MY/OAI2/1) was the only intact metal artefact (Fig. 11). Yet to be published radiocarbon dates from six charcoal fragments and human tooth apatite from the adult burial indicate a late second millennium/early first millennium BC activity period.

-

Oakaie 3 (OAI3), located c. 200 m southwest of Oakaie 2, was excavated in 2016 with a single 4 × 4 m testpit in an area of especially dense surface assemblages of ceramics and lithics, as identified by 2015’s systematic intensive survey programme (Pryce and Kyaw 2015). The testpit reached sterile at 1.7-m depth, but material was concentrated in the first four layers, 1.05–1.15-m depth, including over 400 kg of ceramics (Aude Favereau, personal communication) as well as a complete lithic production assemblage for bangles and beads. All metallurgical samples were recovered in layers 1 and 2, the upper 300 mm, the four lower cultural layers being potentially ‘Neolithic’. Radiocarbon determinations of nine charcoal samples will be published elsewhere but indicate a 9th–13th c. BC occupation with a Neolithic/Bronze Age transition c. 1000 BC. Oakaie 3 produced a single Cu-stained heat-damaged ceramic, potentially a crucible fragment (SEALIP/MY/OAI3/1, Fig. 12), as well as the largest number of copper-base artefacts, nine, of which six were sampled (SEALIP/MY/OAI3/2–7, Figs. 13, 14, 15, 16, 17 and 18).

-

Oakaie 4, c. 1 km north of Oakaie 3, was also investigated in 2016 with a pair of testpits in what had been hoped to be a similarly dense activity area but proved to be otherwise and did not furnish any metal samples.

-

Finally, the major objective for the 2016 season was to re-excavate the eponymous type-site for the “Nyaung’gan Bronze Age Culture Area” to provide direct radiometric dates, anthropological assessment of the human remains and technological study of their grave goods. Consequently, three 4 × 4 m testpits were opened at Nyaung’gan and a total of seven individuals exposed; this corresponding well with the reported number of burials per square metre identified by the Department of Archaeology’s excavations. A single socketed copper-base spear/arrowhead (SEALIP/MY/NYG3/1, Fig. 19) was recovered in the upper disturbed layers of NYG3. Radiocarbon determinations of tooth apatite are forthcoming but again, an early first millennium BC Bronze Age range is anticipated based upon ceramic affinities with OAI1 and OAI2 (Pryce et al. 2015; Aude Favereau, personal communication), with the possibility of some burials being pre-Bronze Age (i.e. ‘Neolithic’ but this period is yet to be well-defined for Myanmar).

In the absence of geological lead isotope data for the nearby copper mineralisations at Monywa, we analysed a single modern copper ingot from the Letpadaungtaung mine (Table 2). A single ingot signature is, of course, not a reliable characterisation of a mineral deposit, but it gives some indication of whether there is any relation between local copper resources and the ancient artefacts, and thus whether there was any local primary copper production in the Bronze Age (as suggested by Moore and Pauk 2001: 38).

Methodology

All the artefacts were studied for their technological and elemental compositional characteristics using optical microscopy (OM) and scanning electron microscopy with energy-dispersive X-ray spectrometry (SEM-EDS): the non-MAFM group at UCL Qatar in the frame of an archaeometry training course for Kalayar Myat Myat Htwe in September/October 2015; the MAFM samples were analysed at Laboratoire Archéomateriaux et Prévisions d’Alteration (LAPA) (CEA Saclay, France) for OM and at UCL Qatar for SEM-EDS in May/June 2016. Lead isotope ratios were obtained for all the excavated and a selection of the least-corroded private collection artefacts using multi-collector inductively coupled plasma mass-spectrometry (MC-ICP-MS) at the Curt-Engelhorn-Zentrum Archäometrie gGmbH (Mannheim, Germany) in April 2016. Artefacts for study were sampled in Myanmar using a jeweller’s saw, each fragment being halved again for OM and SEM-EDS on the one hand and MC-ICP-MS on the other.

Optical microscopy (OM)

The OM/SEM-EDS samples were mounted in resin and polished to a 1 μ finish before being etched with alcoholic ferric chloride to reveal their microstructure. Several of the highly corroded artefacts did not require etching, as their microstructure was revealed through preferential corrosion of certain phases. The LAPA samples were assessed on an Olympus BX51 metallurgical microscope under plane-polarised and cross-polarised light at regular magnifications from 50 to 1000, and micrographs of areas of interest captured on a Nikon D600 camera with NKRemote software. The UCL-Qatar samples were studied in the same manner under reflected light using a Leica DM2500P microscope with an attached camera Leica DFC290HD.

Scanning electron microscopy with energy-dispersive X-ray spectrometry (SEM-EDS)

The resin-mounted samples were re-polished to a 0.25 μ finish and then sputter-coated with carbon prior to analysis on UCL Qatar’s JEOL JSM6610-LV with an Oxford Instruments X-MaxN 50 energy-dispersive X-ray spectrometer, operated through Aztec software calibrated using industry standards. Operating conditions for analysis were as follows: accelerating voltage 20 kV, working distance 10 mm, process time 5, spot size adjusted between 58 and 59 to maintain a deadtime of 40% on cobalt metal, and an acquisition time of 60 s. The mean of two to five areas of 0.01 to 0.03 mm2 depending on sample size and porosity is given to account for sample heterogeneity. For fully corroded samples area analyses were taken of the central parts of the sections. For partially corroded samples, where intergranular corrosion extended into the core of the metal, the area analyses were taken to include the central least corroded area, but including both uncorroded grains and corroded phases. For objects, where a completely uncorroded core existed, only this part was analysed; henceforth, these objects are referred to in the text as ‘uncorroded’, even though they have significant corrosion affecting part of their fabric.

Multi-collector inductively coupled plasma mass-spectrometry (MC-ICP-MS)

All study samples were processed at the Curt-Engelhorn-Zentrum Archäometrie using their established protocol (Niederschlag et al. 2003), as employed with the Southeast Asian Lead Isotope Project (’SEALIP’) since 2009 (Pryce et al. 2011b). The potential crucible fragment (SEALIP/MY/OAI3/1) was sampled from the copper-stained adhering layer and not from the main body ceramic.

Results

OM

Of the 27 samples studied, 25 have identifiable microstructures, which evidence the use of working techniques resulting in as cast, annealed, cold and hot-worked and quenched metal structures in the assemblage (Fig. 20, Table 1).

Top row, left, as-cast microstructure to leaded copper arrowhead SEALIP/MY/NYG1/1; top right, cold-worked and annealed microstructure to bronze axe SEALIP/MY/OAI1/1 (courtesy Pira Venunan); bottom top right, hot-worked and quenched microstructure to high-tin bronze bowl SEALIP/MY/SP/1; middle row, left, inter-dendritic corrosion in KKH-S; middle row, right, inter-dendritic corrosion with uncorroded core in NG-6-2; bottom row, left, inter-dendritic corrosion and coring in SEALIP/MY/HTP/1; bottom row, right, fully corroded ghost texture exhibiting flattened grains and strain lines due to repeated cycles of cold-working and annealing in SEALIP/MY/OAI3/7

The potential crucible (SEALIP/MY/OAI3/1) was found to have vitrification in the ceramic matrix and a Cu-rich adhering layer with metallic prills (Fig. 21).

SEM-EDS

Metal samples

The elemental analyses identify the presence of five alloy types amongst the combined assemblage: copper, arsenical copper, leaded copper, bronze and high-tin bronze. Levels of 1 wt.% of, e.g. Sn, Pb and As were used as the cutoff for assigning uncorroded alloy types as bronze, leaded copper or arsenical copper, respectively. In addition to a numerical compositional threshold, a ‘high-tin’ bronze must have a β-phase and not merely be particularly high in tin as a result of copper depletion during burial.

Technical ceramic sample

The potential crucible from Oakaie 3, SEALIP/MY/OAI3/1, had a fabric composition of a typical non-refractory clay and bronze prills (Table 3)

.

Lead isotope characterisations

The study’s lead isotope data (Table 4) plot within the fields previously defined for prehistoric Southeast Asian copper-base production and consumption (Hirao and Ro 2013; Pryce et al. 2014). The new data present a high proportion of potential matches (Fig. 22), as compared to the norm for SEALIP (Pryce 2014), which are discussed below. The modern copper sample from the Letpadaungtaung mine near Monywa has a signature entirely unrelated to any of the ancient artefacts.

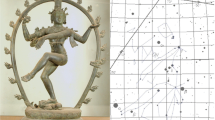

Bi-plot of lead isotope values. Previously published regional primary copper production systems are represented by triangles: green for Nil Kham Haeng and Non Pa Wai (Khao Wong Prachan Valley, central Thailand), yellow for Phu Lon (northern Thailand) and red for Puen Baolo and Thong Na Nguak (Sepon, central Laos), from Pryce et al. (2011b). Previously published data from Myanmar (Kan Gyi Gon, Myo Hla, Nyaung Gon and Ywa Gon Gyi) are represented by small circles, from Pryce et al. (2014) and Dussubieux and Pryce (2016). New data are represented by large circles and artefact types are labelled. Symbols are larger than error bars

Discussion

Working traditions

Ceramic evidence

Our interpretation of SEALIP/MY/OAI3/1 must be tempered by the fact that it is (a) a single sample, and (b) it was found in the plough soil (Fig. 23). It is indeed notable that no further examples were found within a 4 × 4 m testpit in a dense occupation deposit with extensive evidence for industry, albeit lithic. We consider it reasonable to suggest that, whilst this technical ceramic sample may not be in its exact deposition spot, it is unlikely to have migrated very far as the animal traction ploughshares still used only penetrate c. 200 mm and small bunded field systems on flat ground militate against long-distance artefact movement. So what does the ceramic represent? Its bloated matrix indicates exposure to high temperatures but what was thought to be a slag layer transpired to be copper-base corrosion only, with embedded metallic prills (Fig. 21). The absence of slag implies we can rule out, based upon the present evidence, the smelting of copper minerals at Bronze Age OAI3, which is also suggested by the modern Letpadaungtaung copper ingot’s lead isotope signature not plotting anywhere near any of the ancient metal artefacts. We can also probably dismiss the refining of impure raw copper, which would be expected to leave at least some non-metallic residue. In contrast, the high tin content of the analysed prill indicates active alloying to produce tin bronze (Rademakers et al., in press). We therefore conclude that the present sample represents secondary production, the melting and casting of a refined copper-base alloy, most likely from its constituent parts (copper and tin). Whilst this parsimonious interpretation does not entirely undermine earlier scholars’ hopes for a Bronze Age primary copper-base industry in proximity to Monywa’s copper reserves (Moore and Pauk 2001: 38), it does render them increasingly unlikely.

Metal evidence

Of the 25 identifiable microstructures, 13 are dendritic or cored, indicating the object was left as-cast, without further mechanical or thermal treatments (Table 1). Of those 13 samples, 5 are unidentifiable fragments, so we cannot be sure if their being left as-cast was appropriate to their usage, but this could be said to be the case for the five bangle, bowl and ring fragments. The remaining three samples were fragments of two arrows and one sword scabbard; of these we would not anticipate the arrows having optimal functional characteristics without further treatments. We must assume then that these artefacts were either considered serviceable as they were, or that they were never intended to be used for combat/hunting and were produced for mortuary purposes only (see Pryce 2011 for a Thai example).

A further two samples (MOH-S and SEALIP/MY/MT/1) possessed the equi-axed hexagonal crystal microstructure of as-cast unalloyed copper, which, as above, does not sit well with their formal identification as spearheads (Fig. 20). Again, we must consider whether these objects were intended to perform as or merely represent weapons.

Four of the 25 samples lack a dendritic microstructure, which in the absence of other features suggests they may have been annealed after casting. The samples consist of a bell, a rod and two bracelet fragments.

Five samples present the deformed grains indicative of cold-working, some with annealing twins, and one sample (SEALIP/MY/OAI3/7) that seems to have gone through several cycles of these processes. One of these samples is an unidentifiable fragment, and thus, we cannot evaluate the purpose of these post-casting treatments. Two further samples (SEALIP/MY/OAI/1–2, Fig. 7) are flattened, which would correspond well with their microstructures. The two remaining samples, however, an axe (Fig. 10) and a possible cutting tool (Fig. 18), could feasibly represent the adaptedness of working techniques to the presumed function of the artefact. The forming of a workable edge would require mechanical deformation and the heat treatment would have prevented micro-structural cracks propagating.

The final sample, bowl fragment SEALIP/MY/SP/1, presents the classic microstructure of a high-tin bronze (Fig. 20), in which the cast object is hot-worked within a narrow temperature band and then quenched (fast cooled) to prevent the development of a brittle δ-phase and retain the β-phase that forms the characteristic martensitic texture (Murillo-Barroso et al. 2010; Rajpitak 1983; Scott 1991; Srinivasan 2010). In this instance, the sequence of working techniques is essential for the production of such an artefact.

In summary, there is only limited correlation between heat and mechanical treatments, alloy composition, and the supposed function of an artefact but most artefacts seem to have been left as-cast.

Alloying traditions

Copper

Previous studies have shown that pure or near pure copper appear to have been used regularly in prehistoric central Myanmar and may indeed represent the signature of a primary source (Dussubieux and Pryce 2016; Pryce et al. 2014). Of the present study’s ancient metal samples (i.e. not the OAI3 crucible or the modern ingot), five were raw or unalloyed copper, whether corroded or not. These artefacts corresponded to: wire bundles from Kokkokhahla, as seen in previous studies (Dussubieux and Pryce 2016); ‘spearheads’ from Myin Oo Hle and Myinthe; an ‘arrowhead’ from Oakaie; and a bracelet fragment from OAI3 (Table 1). There is no a priori dissonance with a bracelet or wire being made from copper but it is mechanically unsuitable for arrowheads or spearheads as it cannot be significantly work-hardened. This suggests the types attributed to the Myin Oo Hle, Myinthe and Oakaie artefacts may relate only to their form and not their function, though of course a copper arrow/spearhead could still cause injury or death.

Arsenical copper

Arsenical copper has been reported relatively rarely in prehistoric Southeast Asia, but interpretation of our new data should be couched in caution. Firstly, at a regional level, very few prehistoric metal artefacts have been subjected to any laboratory study. Secondly, of those that have, there is the possibility that some arsenical alloys may have been misidentified as leaded due to the Pb-Lα/As-Kα spectral overlap in X-ray fluorescence spectra. Thirdly, previous studies seem to suggest significant recycling activity during the regional Iron Age to which Kokkokhahla is thought to date (Pryce et al. 2014). These repeated cycles, in addition to diluting any arsenic content with non-arsenical alloys, could also induce arsenic depletion through volatilisation and oxidation, and hence result in a lower presence in the archaeological record. These caveats aside, the Kokkokhahla bangle is thus of potential interest as a rare alloy type. Two other study samples could fall into this category, SEALIP/MY/OAI/1 and SEALIP/MY/OAI3/3 at 0.7 and 0.9 wt.% As, respectively, thus just below our alloy threshold.

Leaded copper

As is so often the case, critical evidence is consistently: (a) represented by a single sample, and/or (b) comes from a dubious context. Both these limitations apply to the heavily leaded (c. 20 wt.%) copper arrowhead found in the first 100 mm spit of testpit NYG3 at Nyaung’gan in 2016 (Figs. 24 and 25). Testpit ‘NYG3’ was located immediately adjacent to testpit ‘1’, excavated in 1998, as most of the bronzes found 20 years ago came from the central area of this elongate trench. The upper layers of NYG3 were disturbed and could potentially have been part of the compacted spoil heap from the former trench just 1.5 m distant. Whilst the arrowhead was not in direct association with any of the three burials from NYG3, Nyaung’gan has not presented any evidence of having later periods of use, so it is within reasonable certainty to assume the artefact is contemporary with the rest of the site, i.e. Bronze Age or earlier. This is of interest because the sole leaded copper of the current assemblage could also be one of the few leaded alloys identified in Bronze Age Southeast Asia. The only other contenders we are aware of include a leaded bronze casting drip from Phu Lon, a copper mine in northern Thailand (Pryce 2013; Pryce et al. 2014; Pryce et al. 2011a), an amorphous fragment from Ban Tong (BT 905/1716) in northeast Thailand, containing c. 6 wt.% Pb, 1.5 wt.% As and 9 wt.% Sb (Project n.d.), and possibly some examples from MP3 levels (c. 7th c. BC) at Non Nok Tha (Joyce White, personal communication; Higham et al. 2014). The Phu Lon artefact can probably be discounted as the excavator believes it could have been washed into the gallery in which it was found (Vincent C. Pigott, personal communication), Phu Lon itself is only dated broadly to the first millennium BC without detailing whether first half (Bronze Age) or second half (Iron Age), or both (Pigott and Weisgerber 1998; Pryce et al. 2011a), and Non Nok Tha’s chronology has also been contested over the years. Thus Nyaung’gan’s leaded copper arrowhead could reasonably represent one of the first incidences of either the smelting of lead minerals or co-smelting Cu-Pb ores in Southeast Asia, or the acquisition of either lead or leaded alloys from further afield. As per the copper examples discussed above, leaded copper would not make for a very hard arrowhead but it would be easy to produce and would function nonetheless.

Bronze

The majority of the studied assemblage falls under the category of ‘bronze’, in that they contain more than 1 wt.% Sn and less than 1 wt.% Pb or As. There is a significant and fairly continuous range of Sn values, from 3.3 (SEALIP/MY/OAI2/1) to 24.8 (KKH-S) wt.%. This latter sample, alongside SEALIP/MY/MHT/1 and SEALIP/MY/MHT/2 with more than 22 wt.% Sn, are not considered high-tin bronzes as their low analytical totals suggest they are substantially corroded and that Cu depletion may be exaggerating the original Sn values. The wide range of values suggests alloying may not have been closely controlled but as so many of the artefacts are either ornaments or mere fragments we cannot really assess the adaptedness of alloy choice.

High-tin bronze

A single artefact (SEALIP/MY/SP/1) presented a classic high-tin bronze composition and structure as determined from an uncorroded matrix, and it does not have a secure context (Figs. 8 and 20). The bowl, looted from Supan, is thus one of 21 such bowls currently identified as high-tin by SEALIP (Pryce et al. 2014, plus data awaiting publication). High-tin bowls with the added characteristics of a hot-worked and quenched microstructure and engraved geometric and/or naturalistic design motifs are thought to be of South Asian origin or influence (Bennett and Glover 1992; Rajpitak and Seeley 1979; Srinivasan 2010). The Supan bowl matches all the technical characteristics to be included within the regional corpus of such material culture.

Lead isotope characterisation and provenance

Khao Wong Prachan Valley (central Thailand) copper production system

It is remarkable that of the 19 ancient samplesFootnote 4 for which LI data were obtained, 8 appear to be highly consistent with known prehistoric Southeast Asian copper production signatures, as compared to less than 10% for the complete SEALIP database (Pryce et al. 2014). Of these, perhaps the most striking is the seemingly perfect correspondence between the Nyaung’gan arrowhead (SEALIP/MY/NYG3/1), possibly one of the earliest leaded alloys in Southeast Asia, and the signature of the Khao Wong Prachan Valley copper smelting sites in central Thailand (Fig. 22). Unfortunately, delving deeper into the available datasets suggests that this cannot be identified as the source of the metal analysed here. At c. 20 wt.% Pb, the arrowhead is no borderline or accidental leaded alloy. However, lead minerals have not been reported during geological prospection in the Khao Wong Prachan Valley (William Vernon’s 1988 report cited in Pryce 2009: 55–56) and the raw copper product has been analysed as having only 100–200 ppm Pb (Pryce et al. 2011b: Table 3). As any added lead, as most likely to have been the case to reach c. 20 wt.% Pb, would have entirely overwhelmed the trace lead isotope signature of the copper minerals, it implies there was a Bronze Age lead producer of a very similar geological age to the Khao Wong Prachan Valley copper ore deposits. Only a much better understanding of Southeast Asian ore geochemistry could help resolve this but much of the area remains unexplored, and when the data exist they are frequently proprietary.

Far more convincing is the fragment of the round section bracelet from OAI3 (SEALIP/MY/OAI3/5), which had an uncorroded 99 wt.% copper core and lead isotope ratios that correspond very well indeed to the Khao Wong Prachan Valley. The lack of correspondence between ancient metal samples from Cambodia, Laos, Vietnam and Thailand and the Khao Wang Prachan LI production signature has previously been noted as problematic (Pryce et al. 2014: 289), given the intensity and scale of copper smelting at the sites of Non Pa Wai and Nil Kham Haeng (Pryce et al. 2010). It was suggested that this phenomenon may have been due to extensive recycling during the Iron Age and/or sampling bias, including “consumption markets, perhaps west through Thailand and across the Salween River into Myanmar” (Pryce et al. 2014: 289). The OAI3 copper bracelet fragment certainly gives increased credence to the latter proposition. We note that SEALIP/MY/OAI3/5’s nickel content, not a component subject to volatilisation, was below detection limit but is present at about 2000 ppm in raw Khao Wong Prachan Valley copper as analysed by LA-ICP-MS (Pryce et al. 2011b: Table 3), which could have been more sensitive than the ED-XRF used for the samples in the present study.

Sepon (central Laos) copper production system

Since the discovery of the central Lao copper mining locale at Sepon in the mid-2000s, it has been increasingly realised through excavation and provenance programmes that it was one of, if not the, largest copper producers in prehistoric Southeast Asia (Pryce et al. 2014; Tucci et al. 2014). What would have once been an enormous surprise, the strong consistency of six central Myanmar samples with the Sepon LI signature (Fig. 22), should probably only be seen as a continuation of this trend. The samples in question: a corroded bronze fragment collected south of Oakaie village (SEALIP/MY/OAI/2), one uncorroded bronze bracelet fragment (SEALIP/MY/OAI3/2), two corroded bronze ring and bracelet fragments (SEALIP/MY/OAI3/3–4), an uncorroded bronze ring fragment from Mon Htoo (SEALIP/MY/MHT/3) and the high-tin bronze bowl from Supan (SEALIP/MY/SP/1) can all be considered unleaded alloys and thus feasibly made with raw materials from Sepon, located at the opposite side of continental Southeast Asia, some 1200+ geodesic kilometres distant. Of course, the standout sample is the high-tin bronze bowl, which, as mentioned above, would generally be interpreted as a South Asian import. The Supan evidence, tempered as it must be in acknowledgement of it having been looted, suggests that ‘true’ high-tin bronze bowls, bearing all the technical and stylistic characteristics, were sometimes made with Southeast Asian raw copper; presumably in Southeast Asia unless primary copper was exported across the Bay of Bengal and reimported as finished product. This is before we compare the wealth of Southeast Asian tin deposits and the relative poverty of those in South Asia (Schwartz et al. 1995; Upadhyay 2007) and the evidence for late first millennium BC tin production (cassiterite cementation) on the Upper Thai-Malay Peninsula (Murillo-Barroso et al. 2010; Pryce et al., in press). Such a finding would also be in full agreement with SEALIP’s growing high-tin bronze database, which indicates multiple production centres and links between consuming populations (Pryce and Bellina, in preparation).

‘Phu Lon’ (northern Thai?) copper production system and the remainder

Recently published (Dussubieux and Pryce 2016) LI and elemental data for copper wire bundles from Iron Age cemeteries of central Myanmar have underlined the likelihood of their being raw product from a primary producer. The question is, ‘which primary producer?’ The Myanmar copper wires are highly consistent with a single Phu Lon sample, which is a bronze axe rather than production debris, but all fall within the diffused northern Thai copper production signature (Pryce et al. 2014; Pryce et al. 2011a); ‘diffused’ probably due to the presence of multiple mineralisations around the first millennium BC mining and smelting locale of Phu Lon (Kamvong and Zaw 2009) (Table 4). So, were the copper wires from central Myanmar made with raw copper from Phu Lon, or was the bronze axe from Phu Lon made with the same raw materials as that used for the wires? At present, we simply do not know but we do note that one of the present study’s samples, the copper spearhead from Myinthe (SEALIP/MY/MT/1) is also highly consistent with this as yet unconfirmed primary production signature. Given the relative positions of the two areas, we should also consider that these data provide evidence for a terrestrial exchange network that traversed the intervening Shan Highlands rather than descending the Irrawaddy, circumnavigating or traversing the Thai-Myanmar-Malay Peninsula, and mounting the Mekong.

Hereon, the data are decreasingly clustered and correspondingly their interpretation increasingly blurred but there are several potential consistency trends worth highlighting. Firstly, the Cu-stained ceramic fragment from OAI3 (SEALIP/MY/OAI3/1), a priori secondary production evidence, plots in the region of the sole tin-tainted (c. 0.1 wt.%) copper wire from Nyaung Gon that did not cluster with the copper signature discussed in the previous paragraph (Fig. 22). That is, there is a possible match between the copper source used for an Iron Age wire and a Bronze Age foundry, though these could of course be separated temporally by only a couple of centuries. The next close correspondence comes between a corroded bronze from Mon Htoo (SEALIP/MY/MHT/1) and the uncorroded bronze axe (the sole copper-base find) from the OAI1 cemetery, which is reasonable as they are thought to have a similar date and are located only 20 km apart. The final fragment of corroded Mon Htoo Bronze Age bronze (SEALIP/MY/MHT/2) plots in the vicinity of a corroded bronze vase from Iron Age Myo Hla, situated c. 240 km to the south-southeast. Finally, three artefacts plot in relative proximity on the more radiogenic axis of the data distribution (Fig. 22): an uncorroded bronze from the area south of Oakaie (SEALIP/MY/OAI/1, presumably Bronze Age), a corroded bronze platy object, possibly a cutting tool, from Bronze Age OAI3 (SEALIP/MY/OAI3/7), and an uncorroded bronze bell fragment from Iron Age Myin Oo Le (SEALIP/MY/MOH/1). What historical meaning can be attributed to these latter possible matches is unclear but to say they represent human interaction activity spanning hundreds of years and hundreds of kilometres of central Myanmar territory does not seem unreasonable.

Conclusion

This paper set out to contribute to two converging sub-disciplines: Myanmar’s later prehistory and Southeast Asian archaeometallurgy. Commencing with the latter, our microstructural and elemental compositional study of 27 Bronze and Iron Age copper-base artefacts and one Bronze Age Cu-stained technical ceramic have produced important new data for regional prehistoric metallurgy databases. Whilst the majority of the artefacts were made from bronze, there were also five copper artefacts, three arsenical copper/bronze alloys, a high-tin bronze and a leaded copper. The arsenical alloys are of particular interest as the type is relatively unknown in prehistoric Southeast Asia. The leaded copper arrowhead from Nyaung’gan is also unusual as one of the few leaded alloys known from the regional Bronze Age; the lead isotope signature for this artefact is probably a false match for the Khao Wong Prachan copper production centre of central Thailand, indicating the presence of an as yet unknown turn of the second/first millennium BC lead production locale somewhere in or bordering Southeast Asia. The 25 identifiable microstructures reveal the use of as-cast, annealed, cold and hot-worked and quenched working techniques, with limited evidence of adaptedness to alloy type and supposed artefact usage and a predominance of leaving objects as-cast.

The study’s impact upon our understanding of Southeast Asian late prehistory is derived mainly from the lead isotope data. Eight of the 19 samples for which data were available indicated consistency with known regional copper production centres. The Nyaung’gan arrowhead was, as mentioned above, a false match as it must relate to a lead production signature but a copper bracelet from Oakaie 3 is highly compatible with the central Thai Khao Wong Prachan copper production system—the first such evidence of exchange networks identified between these areas. This is followed up by six study samples that are consistent with the Sepon production signature of central Laos; again, a first link between these areas and especially striking for the Supan sample as it is a high-tin bronze bowl that would normally be attributed a South Asian origin based on morpho-stylistic criteria. Finally, we see a further, potentially upland, exchange network linking central Myanmar sites, in this case, Myinthe, and the northern Thai copper production system at Phu Lon previously identified by Dussubieux and Pryce (2016).

Despite the relatively low sample numbers of the present study, the combined impact of morpho-stylistic, technological, elemental and isotopic analyses has been to link late prehistoric Myanmar ever more closely to multiple areas of its immediate and adjacent neighbours during the first millennium BC, once again demonstrating the taut efficacy of targeted archaeometallurgical research.

Notes

Vincent C. Pigott did conduct some preliminary LI analyses of Thai lead minerals with Tom Chase, but they were not published and regional isotope archaeology did not spring forth at this juncture.

Comparative data are also rare in neighbouring Yunnan and absent in Northeast India.

See Dussubieux and Pryce (2016) for a detailed explanation of the wire bundles, but in summary, they are found interred with some individuals and may represent a means of exchange or commodity money due to their regular size and number and to their frangibility.

SEALIP/MY/LPDT/1 is a modern copper sample from the Letpadaungtaung mine near Monywa.

References

Aung Thaw U (1968) Excavations at Beikthano. Ministry of Union Culture, Rangoon

Aung Thaw, U (1972) Historical sites in Burma. Rangoon

Bennett A (1988) Prehistoric copper smelting in Central Thailand. In: Charoenwongsa P, Bronson B (eds) Prehistoric studies the stone and metal ages in Thailand. Thai Antiquity Working Group, Bangkok, pp. 125–135

Bennett A (1989) The contribution of metallurgical studies to south-east Asian archaeology. World Archaeol 20:329–351

Bennett A, Glover IC (1992) Decorated high-tin bronzes from Thailand’s prehistory. In: Glover I (ed) Southeast Asian archaeology 1990. Hull University, Centre for Southeast Asian Studies, pp. 187–208

Brill RH, Wampler JM (1967) Isotope studies of ancient lead. Am J Archaeol 71:63–77

Coupey A-S (2012) Management of sepulchral place and distribution of the deceased: the examples of some reduced burials from Iron Age sites in the Samon River’s Valley, Upper Burma. In: Tjoa Bonatz M-L, Reinecke A, Bonatz D (eds) Crossing Borders, 13th international conference of the European Association of Southeast Asian Archaeologists, vol 1. NUS Press, Singapore, pp. 84–95

Coupey, A.-S., Pautreau, J.-P. & Kyaw, A. A (2011) Les cimetières de l’âge du Fer dans la vallé de la Samon, KYO GON, Pyaw Bwe Township, Mandalay Division, Myanmar, Rapport de la mission 2011. Mission Archéologique Française au Myanmar

Dussubieux L, Pryce TO (2016) Myanmar’s role in Iron Age interaction networks linking Southeast Asia and India: recent glass and copper-base metal exchange research from the mission Archéologique Française au Myanmar. J Archaeol Sci Rep 5:598–614

Gale NH, Stos-Gale ZA (1982) Bronze Age copper sources in the Mediterranean: a new approach. Science 216:11–19

Gutman P, Hudson R (2004) The archaeology of Burma (Myanmar) from prehistory to Bagan. In: Glover IC, Bellwood P (eds) Southeast Asia—from prehistory to history. Routledge/Curzon, London, pp. 149–178

Han N (1999) Archaeological findings at Nyaunggan Bronze Age site. In: Anon (ed) Proceedings of the workshop on Bronze Age culture in Myanmar, 7 January 1999. Universities Historical Research Centre, Yangon, pp. 29–52

Higham CFW, Higham TFG, Douka K (2014) The chronology and status of Non Nok Tha, northeast Thailand. J Indo-Pacific Archaeol 34:61–75

Hirao Y, Ro J-H (2013) Chemical composition and lead isotope ratios of bronze artifacts excavated in Cambodia and Thailand. In: Yasuda Y (ed) Water civilisation: from Yangtze to Khmer civilisations. Springer, Tokyo, pp. 247–312

Hudson B (2008) Restoration and reconstruction of monuments at Bagan (Pagan), Myanmar (Burma), 1995–2008. World Archaeol 40:553–571

Kamvong T, Zaw K (2009) The origin and evolution of skarn-forming fluids from the Phu Lon deposit, northern Loei Fold Belt, Thailand: evidence from fluid inclusion and sulfur isotope studies. J Asian Earth Sci 34:624–633

Mabuchi H, Hirao Y, Nishida M (1985) Lead isotope approach to the understanding of early Japanese bronze culture. Archaeometry 27:131–159

Moore E, Pauk P (2001) Nyaung-gan: a preliminary note on a Bronze Age cemetery near Mandalay, Myanmar (Burma). Asian Perspect 40:35–47

Murillo-Barroso M, Pryce TO, Bellina B, Martinón-Torres M (2010) Khao Sam Kaeo - an archaeometallurgical crossroads for trans-Asiatic technological styles. J Archaeol Sci 37:1761–1772

Myint S (2003) The grave ceramics of Nyaunggan site. In: Tun T (ed) Ceramic traditions in Myanmar. Yangon, SEAMEO Regional Centre for History and Tradition, pp. 63–72

Myint Aung U (1970) The excavation at Halin. J Burma Res Soc 53:55–63

Natapintu S (1988) Current research on ancient copper-base metallurgy in Thailand. In: Charoenwongsa P, Bronson B (eds) Prehistoric studies: the Stone and Metal Ages in Thailand. Bangkok, The Thai Antiquity Working Group, pp. 107–124

Niederschlag E, Pernicka E, Seifert T, Bartelheim M (2003) The determination of lead isotope ratios by multiple collector ICP-MS: a case study of Early Bronze Age artefacts and their possible relation with ore deposits of the Erzgebirge. Archaeometry 45:61–100

Pautreau J-P (2007) Ywa Htin, Iron Age burials in the Samon Valley, Upper Burma. Mission Archéologique Française au Myanmar, Paris

Pautreau J-P, Coupey A-S, Kyaw AA (2010a) Excavations in the Samon Valley: Iron Age burials in Myanmar. Mission Archéologique Française au Myanmar, Chiang Mai

Pautreau J-P, Maitay C, Kyaw AA (2010b) Level of Neolithic occupation and 14C dating at Ywa Gon Gyi, Samon valley (Myanmar). Aséanie 25:11–22

Pigott VC (1984) The Thailand Archaeometallurgy Project 1984: survey of base metal resource exploitation in Loei Province, Northeastern Thailand. South-East Asian Stud Newsl 17:1–5

Pigott VC (1986) Pre-industrial mineral exploitation and metal production in Thailand. Masca J 3:170–174

Pigott VC (1988) The Thailand Archaeometallurgy Project. J Metals 40:36–37

Pigott VC (1998) Prehistoric copper mining in the context of emerging community craft specialisation in Northeast Thailand. In: Knapp AB, Pigott VC, Herbert EW (eds) Social approaches to an industrial past. Routledge, London, pp. 205–225

Pigott VC, Natapintu S (1988) Archaeological investigations into prehistoric copper production: the Thailand Archaeometallurgy Project, 1984–86. In: Maddin R (ed) The beginning of the use of metals and alloys: papers from the Second International Conference on the Beginning of the Use of Metals and Alloys, Zhengzhou, China, 21–26 October, 1986. MIT Press, Cambridge, pp. 156–162

Pigott VC, Weisgerber G (1998) Mining archaeology in geological context. The prehistoric copper mining complex at Phu Lon, Nong Khai Province, northeast Thailand. In: Rehren TH, Hauptmann A, Muhly JD (eds) Metallurgica Antiqua: in honour of Hans-Gert Bachmann and Robert Maddin. Bochum, Deutsches Bergbau-Museum Bochum, pp. 135–161

Pigott VC, Weiss A, Natapintu S (1997) Archaeology of copper production: excavations in the Khao Wong Prachan Valley, central Thailand. In: Ciarla R, Rispoli F (eds) South-east Asian Archaeology 1992. Proceedings of the Fourth International Conference of the European Association of South-east Asian Archaeologists. Rome, 28th September - 4th October 1992. Istituto Italiano per l’Africa e l’Oriente, Rome, pp. 119–157

Project, B. C. n.d. The Ban Chiang project metals database: searchable databases [Online]. Institute for Southeast Asian Archaeology [http://iseaarchaeology.org/metals-database/]

Pryce, T. O (2009) Prehistoric copper production and technological reproduction in the Khao Wong Prachan Valley of central Thailand. Ph.D., University College London

Pryce TO (2011) XIX Technical analysis of Bronze Age Ban Non Wat copper-base artefacts. In: Higham CFW, Kijngam A (eds) The excavation of Ban Non Wat: The Bronze Age. Bangkok, The Fine Arts Department, pp. 489–498

Pryce TO (2013) Corrigenda to isotopic and technological variation in prehistoric Southeast Asian primary copper production. J Archaeol Sci 40:2783

Pryce TO (2014) Metallurgy in Southeast Asia. In: Selin H (ed) Encyclopaedia of the history of science, technology, and medicine in non-western cultures. Springer Science + Business Media, Dordrecht, pp. 1–17

Pryce TO, Kyaw AA 2015 Rapport de la compagne de fouille 2015 de la Mission Archéologique Française au Myanmar. Chronologie et évolution des cultures des âges du Bronze et du Fer au Myanmar et leurs caractéristiques anthropologiques et technologiques : les sites de OAKAIE 1 & 2, Région de Monywa. Paris: Ministère des Affaires Etrangers et Européens et du Développement International

Pryce TO, Pigott VC, Martinón-Torres M, Rehren TH (2010) Prehistoric copper production and technological reproduction in the Khao Wong Prachan Valley of Central Thailand. Archaeol Anthropol Sci 2:237–264

Pryce TO, Brauns M, Chang N, Pernicka E, Pollard M, Ramsey C, Rehren TH, Souksavatdy V, Sayavongkhamdy T (2011a) Isotopic and technological variation in prehistoric primary Southeast Asian copper production. J Archaeol Sci 38:3309–3322

Pryce TO, Pollard M, Martinón-Torres M, Pigott VC, Pernicka E (2011b) Southeast Asia’s first isotopically-defined prehistoric copper production system: when did extractive metallurgy begin in the Khao Wong Prachan Valley of central Thailand? Archaeometry 53:146–163

Pryce TO, Baron S, Bellina B, Bellwood P, Chang N, Chattopadhyay P, Dizon E, Glover IC, Hamilton E, Higham CFW, Kyaw AA, Laychour V, Natapintu S, Nguyen V, Pautreau J-P, Pernicka E, Pigott VC, Pollard AM, Pottier C, Reinecke A, Sayavongkhamdy T, Souksavatdy V, White J (2014) More questions than answers: the Southeast Asian Lead Isotope Project 2009-2012. J Archaeol Sci 42:273–294

Pryce TO, Kyaw AA, Andia L, Champion L, Colonna C, Favereau A, Htwe KMM, Peixoto X, Pradier B, Willis A, Valentin F, Zazzo A (2015) Dating the Myanmar Bronze Age: Preliminary 14C dates from the Oakaie 1 cemetery near Nyaung’gan. J Indo-Pacific Archaeol 39:38–49

Pryce TO, Murillo-Barroso M, Biggs L, Martinón-Torres M, Bellina B (in press) The metallurgical industries. In: Bellina B (ed) Khao Sam Kaeo: a late prehistoric city of the Upper Thai-Malay Peninsula. Ecole française d’Extrême-Orient, Paris

Rademakers FW, Rehren TH, Pusch E (in press) Bronze production in Pi-Ramesse: alloying technology and material use. In: Ben-Yosef E, Goren Y (eds) Mining for Copper: essays in honor of Professor Beno Rothenberg. Tel Aviv, Institute of Archaeology of Tel Aviv

Rajpitak, W (1983) The development of copper-alloy metallurgy in Thailand in the pre-Buddhist period with special reference to high-tin bronze. Ph.D. Thesis, London: Institute of Archaeology

Rajpitak W, Seeley NJ (1979) The bronze bowls from Ban Don Ta Phet: an enigma of prehistoric metallurgy. World Archaeol 11:26–31

Sayavongkhamdy, T., Chang, N., Viengkeo, S. and Cawte, H (2009) The archaeology of Sepon, Lao PDR: archaeometallurgy, unexploded bombs & collaborations. 19th Congress of the Indo-Pacific Prehistory Association in Hanoi, Vietnam, 29th November to 5th December 2009

Schwartz MO, Rajah SS, Askury AK, Putthapiban P, Djaswadi S (1995) The Southeast Asian Tin Belt. Earth Sci Rev 38:95–293

Scott DA (1991) Metallography and microstructure of ancient and historic metals. The Getty Conservation Institute, Marina del Rey

Seeley N, Rajpitak W (1984) The bronze technology. In: Higham C, Kijngam A (eds) Prehistoric investigations in northeastern Thailand, vol S-231. BAR, Oxford, pp. 102–124

Sinh T (1989) Lead bronze alloys, the Hung Kinh and Dong Son Culture (in Vietnamese). Khảo Cổ Học 2:43–50

Srinivasan S (2010) Megalithic high-tin bronzes and peninsular India’s living prehistory. In: Bellina B, Bacus EA, Pryce TO, Wisseman-Christie J (eds) 50 years of Southeast Asian archaeology: essays in honour of Ian C. Glover. River Books, Bangkok, pp. 260–271

Stargardt W (1990) The ancient Pyu of Burma: vol. I, early Pyu cities in a man-made landscape. PACSEA, Singapore

Stech T, Maddin R (1988) Reflections on early metallurgy in Southeast Asia. In: Maddin R (ed) The beginning of the use of metals and alloys: papers from the Second International Conference on the Beginning of the Use of Metals and Alloys, Zhengzhou, China, 21–26 October, 1986. MIT Press, Cambridge, Mass, pp. 163–174

Stos-Gale ZA, Gale NH (1982) The sources of Mycenaean silver and lead. J Field Archaeol 9:467–485

Tayles N, Donnett K, Pauk PU (2001) Bronze Age (Myanmar): a report on the people from the cemetery of Nyaunggan, Upper Myanmar. Antiquity 75:273–278

Tucci A, Sayavongkhamdy T, Chang N, Souksavatdy V (2014) Ancient copper Mining in Laos: Heterarchies, incipient states or post-state anarchists? J Anthropol Archaeol 2:1–15

Upadhyay P (2007) Minerals and mining in ancient India. Kala Prakashan, Varanasi

Vallard, A., Bellina, B. and O. Evrard (2015) Cristalliser l’histoire. La seconde vie des perles préhistoriques en Thaïlande péninsulaire. Artefact. Techniques, histoire et sciences humaines (Hors-Série), p. 189–208

Vernon W (1996-1997) The crucible in copper-bronze production at prehistoric Phu Lon, northeast Thailand: analyses and interpretation. In: Bulbeck DF, Barnard N (eds) Ancient Chinese and Southeast Asian Bronze Age Cultures. SMC Publishing, Taipei, pp. 809–820

Vernon WW (1997) Chronological variation in crucible technology at Ban Chiang: a preliminary assessment. Bull Indo-Pacific Prehistory Assoc 16:107–110

Wheeler T, Maddin R (1976) The techniques of the early Thai metalsmith. Expedition 18:38–47

Yener KA (1986) The archaeometry of silver in Anatolia: the Bolkardag Mining District. Am J Archaeol 90:469–472

Acknowledgements

The excavation and study of material by the Mission Archéologique Française au Myanmar was conducted with the kind authorisation and support of the Myanmar Ministry of Religious Affairs and Culture and was financed by the French Ministry of Foreign Affairs and International Development. Kalayar Myat Myat Htwe’s training programme was financed by the generosity of Qatar Foundation. We also wish to express our gratitude for the administrative support of the French cultural attaché of the Institut français de Yangon, M. Charles Bonhomme, and his team. Finally, we offer our thanks to the two anonymous reviewers for their detailed and pertinent critique, though any remaining errors are our responsibility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pryce, T.O., Htwe, K.M.M., Georgakopoulou, M. et al. Metallurgical traditions and metal exchange networks in late prehistoric central Myanmar, c. 1000 BC to c. AD 500. Archaeol Anthropol Sci 10, 1087–1109 (2018). https://doi.org/10.1007/s12520-016-0436-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12520-016-0436-7