Abstract

We present the results of metallographic, elemental, and lead isotope analyses of one slag and 27 copper-base artefacts from northern Vietnam. These artefacts come from four sites: Dai Trach, Thành Dên, Gò Mun, Xuân Lâp and are attributed to the Đồng Đậu (ca. 1300–1000 BC), Gò Mun (ca. 1000–700 BC), and Đông Sơn (ca. 700 BC–100 AD) cultures, the two former being Bronze Age (18 samples) and the latter Iron Age (10 samples). Twenty-two of the samples have as-cast microstructures, with one having been quenched, three evidencing working and annealing, and one too corroded to tell. Despite variable corrosion levels, all metal samples are identified as bronzes, rather than copper, though seven are leaded bronzes. All the leaded alloys are Iron Age, which is typical for the region. Lead isotope results were notable, in that none of the study samples is consistent with the known prehistoric Southeast Asian copper production signatures, an unusual occurrence in recent regional provenance research. There is some compatibility with Thai Bronze Age copper-base artefacts, but generally it seems there was only weak overlap in exchange systems between northern Vietnam and southern Mainland Southeast Asia, with northern Laos as a possible frontier zone. Further archaeometallurgical prospection and characterisation in northern Vietnam are needed to identify primary production loci, but sources in the southern Chinese provinces of Yunnan, Guangxi, and Guangdong are also probable.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Northern Vietnam and the origins of the Mainland Southeast Asian Bronze Age

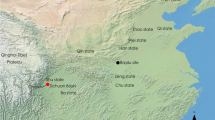

The ‘origin’, or more likely origins, of the Mainland Southeast Asian (MSEA) Bronze Age has been a topic provoking significant global interest for over half a century (e.g. Higham et al. 2019; Pryce et al. 2018a). This was largely due to unexpected dates published in the 1960s and 1970s for 4th millennium BC copper metallurgy at the northeastern Thai sites of Non Nok Tha (Solheim 1968) and Ban Chiang (Gorman and Charoenwongsa 1976), during the very early days of regional scientific archaeology and associated dating techniques (radiocarbon and thermoluminescence). These dates were then among the earliest in the world, implying MSEA might have been an independent centre of invention for metallurgy (critiqued in Higham 1996: 34). Doubts about the likelihood of this revelation were expressed at the time (Higham 1975; Muhly 1981) and the errant chronology has now been completely overthrown in the academic literature (Higham and Higham 2009; Higham et al. 2019, 2015, 2020; Pryce et al. 2018b, in preparation; White 1986)—though it persists in some museum displays and travel guides. Based on the solid Thai and Myanma chronological data cited above, some MSEA social groups transitioned from the Neolithic to the Bronze Age in the final centuries of the 2nd millennium BC, though there was likely a great deal of regional variation, with some essentially hunter-gatherer groups remaining to the present day. Radiocarbon dates from central Laos (Cadet et al. 2019; Pryce et al. 2011a) are compatible, though the northern Lao chronology remains uncertain (Pryce and Cadet 2018; Shewan et al. 2021). Cambodian Bronze Age sites are few, with Samrong Sen lacking radiometric dates as it was excavated in the 19th century (Mansuy 1902) but Koh Ta Meas, in the Western Baray at Angkor, provided a single ca. 1000 BC date (Pottier 2006). Notably, the Bronze Age dates for Yunnan have recently been brought into alignment with those of MSEA (Yao et al. 2020), and those for Guangxi and Guangdong are likewise placed in the range 1200–1000 BC, albeit with less secure radiometric dating (e.g. Allard 2018; Ciarla 2007). Given all regional specialists concur on there being no evidence for MSEA interaction with South Asia’s 2nd millennium BC ‘Copper Hoard Culture’ (e.g. Agrawal 1971; Pryce 2014; Yule 1997), there is general agreement on a proximal Chinese source or sources for MSEA copper metallurgy, in the southern provinces of Yunnan, Guangxi, and/or Guangdong (Higham 1996; Higham et al. 2011b, 2019; Pigott and Ciarla 2007; Pryce et al. 2010; White 1988; White and Hamilton 2009). What is not yet well understood, and what this paper hopes to contribute to, is the range of routings and/or timings for these technological transmissions (Pryce 2018; Pryce et al. 2014). A brief glance at a regional map (Figs. 1 and 2) demonstrates that northern Vietnam might be an important area for cultural transmissions between East and Southeast Asia, lying simultaneously on the present-day political (though not ecological) frontier, as well as the terminus of the Red River running ca. 900 km NW up to its source in the mountains south of Lake Erhai (Dali). There are of course other potential riverine routes from Yunnan into MSEA, most notably the Mekong into Laos, Thailand, Cambodia, and southern Vietnam, the Salween into eastern Myanmar and Thailand, and the Irrawaddy into northern Myanmar, there being hints of the latter already detected (see Pryce et al. 2018a). Likewise, there might have been a complete maritime bypass of northern Vietnam, with Guangxi and/or Guangdong copper-base metal products, metallurgical knowledge, and possibly practitioners crossing central Vietnam into central Laos and northeast and/or peninsular Thailand (see Pryce 2018). Nevertheless, we should give some thought to technological transmissions from China to MSEA via northern Vietnamese territories and/or populations.

This potential for northern Vietnamese archaeometallurgical research is heightened by the fact that late prehistoric excavations in the area tend to yield incomparably more copper-base artefacts than broadly contemporary sites in the rest of MSEA—the sheer difference in the mass of metal consumed, or at least surviving in the archaeological record, cannot be overlooked (Higham 1996, 2014; Murowchick 1988; Trinh 1990, 1979). This aspect must be tempered by the current reality that the northern Vietnamese Bronze Age is not as precisely dated radiometrically as central and northeastern Thailand and north-central Myanmar (Higham et al. 2015, 2020; Pryce et al. 2018b, in preparation), mainly due to most of the pertinent excavations having taken place in the 1950s and 1960s (Higham 2014: 167, 1996). That said, a broad consensus exists on the lower Red River cultural sequence and their approximate dates, with the Phùng Nguyên culture possibly straddling the Neolithic and Early Bronze Age during ca. 1800–1300 BC, followed by the Đồng Đậu culture from ca. 1300–1000 BC, the Gò Mun culture from ca. 1000–700 BC, which then led to the ‘Iron Age’ Đông Sơn culture spanning ca. 700 BC–100 AD, and overlapping with the Han conquest of northern Vietnam, Bắc thuộc, in 111 BC (Dung 2015; Huyền 1996; Liêm 2013; Phung 1993; Trinh 1990). The Phùng Nguyên culture’s status as part-Bronze Age rather than entirely Neolithic period is somewhat disputed, and in any event we were unable to access samples from Phùng Nguyên sites. We do though have a selection of 28 samples from four sites spanning the Đồng Đậu (14), Gò Mun (4), and Đông Sơn (10) cultures (see also Le Meur et al. 2021; Pryce et al. 2014 for Iron Age northern Vietnamese metallurgical data). There is an extensive and growing database for MSEA Iron Age (ca. 400 BC to AD 500, depending on the area) metallurgy but that for Bronze Age material is far smaller, reflecting the fewer sites discovered and the lesser quantities of metal they tend to yield (Pryce et al. 2014 and subsequent site-focused papers). Our 18 northern Vietnamese Bronze Age samples thus offer an essential insight into MSEA metallurgy at a critical chronological and geographical juncture.

Study sites

Dai Trach

Situated near the southern bank of the Duong River at 106.044083°E, 21.056258°N, Đại Trạch (Bắc Ninh Province) is a Đồng Dầu culture site. The Đồng Dầu sequence was 5–6 m deep and 3 ha in area, exposed over 550 m2 in four seasons in 1960s. The basal level is of the Phùng Nguyên period, with subsequent Đồng Đậu and Đông Sơn phases (Higham 2014: 151; Masanari 2005).

Gò Mun

On the southern bank of the Red River, 105.359245°E, 21.339359°N, Gò Mun (Phú Thọ Province) was excavated in four seasons between 1961 and 1971, with 1500 m2 exposed. Only one radiocarbon date is available (Bln-1278, Higham 1996, Figure 4.4), which places the site and its eponymous culture as a successor to the Đồng Dầu period (Higham 2014: 169; Phung 1993). In terms of metallurgy, bronze fishhooks were the most abundant category, followed by projectile points. Also found were 13 axes, seven chisels, one sickle, and a lostwax-cast seated individual. Thus, Gò Mun attests the use of copper-base alloys for tools, ornaments, weapons, and possible ritual applications. Bivalve moulds for axes and arrowheads again indicate onsite secondary production (Higham 2002: 152, Figure 4.15).

Thành Dên

Located at 105.425663°E, 21.295944°N, near the eastern bank of the Red River, Thành Dên (Vĩnh Phúc Province) was excavated in three seasons between 1983 and 1986, exposing 145 m2 to a relatively shallow depth of 1 m. Fourteen radiocarbon dates range from a 4000 BP outlier but concentrate between 1500 and 700 BC, with our samples attributed to the Đồng Đậu period (Ha Van Tan 1991 in Higham 1996: 38 & Figure 4.4). Furnace remains plus twenty crucible fragments and forty-six predominantly sandstone bivalve mould fragments for copper-base axes and fishhooks with a general similarity to Hong Kong assemblages were found at the site (Dung 2015; Higham 2014: 168, 2002: 152-3, 1996: 38, 96). As far as we are aware, these assemblages have not been analysed technologically but in the absence of significant quantities of reported slag, and applying the general rule of minimalist interpretation, we conclude there was secondary production activity on site, making objects of utilitarian form from raw or recycled metal imported from elsewhere.

Xuân Lâp

Four artefacts labelled ‘Xuân Lâp’ were submitted for analysis, referring to pre-excavation surface collections from a site in the same province as Gò Mun, for which we do not have the exact coordinates. The artefact typology, especially XL/4, a thap (a decorated ‘bucket’) is distinctly attributable to the Đông Sơn culture.

Assemblage

The 28 samples of this study were available for analysis from the Institute of Archaeology, Hanoi, and mainly consisted of fragmentary pieces. This limits the detailed typological analysis possible but we are able to determine a range of ornaments, tools, and weapons. Thus, our selection allows us to evaluate early north Vietnamese metal alloy choice and potentially raw material sourcing from both utilitarian and decorative morphologies (Fig. 3, Table 1).

Methodology

The studied artefacts were all sampled using an ultra-fine jeweller’s saw, taking into account areas of existing damage (preferred) and corrosion (avoided), penetrating to raw metal when possible. The cut samples are in the order of millimetre size and might not be representative of object heterogeneity in terms of poor alloy mixing, segregation during cooling, or any unidentified joints or welds. The cut samples were then halved, for elemental/microstructural and isotopic analyses.

Optical microscopy (OM)

Cut samples were mounted in epoxy resin and ground using silicon carbide wet-dry paper (800–4000 grit), before final polishing with diamond pastes (3, 1, and 0.25 μm). The microstructure was then studied by OM (Leica LLM) before (for the corroded samples) and after etching with a ferric chloride solution to reveal the crystalline structures.

X-ray fluorescence (XRF)

XRF was used for the OM samples’ global elemental composition of major, minor, and (some) trace elements, conducted at the Laboratoire Archéomatériaux et Prévision de l’Altération (LAPA-IRAMAT/CEA) in Saclay, France. XRF data were obtained using a NITON XL 3t GOLDD+ portable XRF analyser in ‘laboratory mode’ (fixed stand) with a max 40-kV accelerating voltage and by using the ‘alloys’ mode. Certified Reference Materials (CRMs) were used to check accuracy and precision, with good results for major and minor components (Table 2). Eleven different CRMs were used: B10, B12, B31, UZ 52-3, B21, and L 20-1 from the Centre de Development des Industries de Mise en Forme des Matériaux, France, 71.32-4 and 51.13-4 from the Bureau of Analyzed Samples Ltd., England, and SRM 500, C1123, and 1275 from the National Institute for Standards and Technology (NIST). Note that light elements like phosphorous, silicon, aluminium, magnesium, and also sulphur at low concentrations were not reliably detected due to non-vacuum conditions. The analyses were performed on the mounted and polished sections, as per OM, using a 3-mm beam diameter, which allowed for reliable results as long as the sample was larger than this. Three such spot analyses were made for each sample to account for heterogeneity: corrosion and inclusions. Most of the samples were corroded to some degree.

Scanning electron microscopy with energy dispersive spectrometry (SEM-EDS)

The OM/XRF samples were then carbon coated for analysis in a JEOL 7001F instrument, in order to establish the global composition of samples too small for pXRF (<3 mm), those with intergranular corrosion, and also to study any inclusions. The SEM-EDS was operated in both secondary electron (SE) and backscattered electron (BSE) modes, using a 20-kV accelerating voltage, a 10-mm working distance with an Oxford Silicon Drift Detector, and processed using Oxford Instruments Aztec software. Detection limit was fixed at 0.5 wt% with a count rate of 4000/s (detection time of 40 s) used for a good resolution of pertinent peaks with respect to background noise. We consider that the relative quantification error (2 σ) is about 10% of the measured value. SEM-EDS accuracy was evaluated using the same mounted and polished CRMs as used for the pXRF analysis, and we obtained good results for the major elements (Table 2). Global composition for each sample was obtained by a mean of three to four area scans (0.4 mm2) per sample.

Multi collector—inductively coupled plasma—mass spectrometre (MC-ICP-MS)

Lead isotope analysis (LIA) was conducted at the Service d’Analyse des Roches et des Minéraux of the Centre for Petrographic and Geochemical Research (SARM-CRPG) in Nancy, France, using MC-ICP-MS after lead extraction (Manhes et al. 1980) and using Thallium NIST SRM 997 to correct for instrumental mass bias (Thirlwall 2002). All parameters were adjusted to obtain the closest values relative to NIST SRM 981 as determined by DSTIMS (Thirlwall 2002). More details about the instrumentation and its performance for lead isotope analysis are available in Cloquet et al. (2006) and Pienitz et al. (2015).

As a SEALIP/BROGLASEAFootnote 1 analytical programme, LIA was used to look not for ‘matches’ but rather ‘consistency’ with known and characterised production systems, in recognition that there could be other, as yet uncharacterised, isotopic compatibility of primary and/or secondary production systems, as well as recycling issues at play (e.g. Budd et al. 1993; Pryce et al. 2014, 2011b; Wilson and Pollard 2001)

Results

Technological analysis/optical microscopy

Of the 28 samples, 22 present as-cast structures, as seen by the extant dendrites and round inclusions (Fig. 4 and 5, Table 3). Three samples, a fish hook (DTR/7, Fig. 6), a socketed axe (GM/1, Fig. 7), and a spearhead (GM/2), have a homogenized microstructure with twinned crystals. This shows that the objects have been subjected to a cycle of hammering and annealing, which would be appropriate to their typology and presumed use, indicating some artisanal skill. The same can be said for the quenched microstructure of DTR/1, identified as scraper fragments. The leaded samples (Fig. 8) have lead inclusions, this element being immiscible in solid copper. Some of the bronzes have sufficient tin content to present a blue α+δ eutectoid phase, the prevalence of which depends on the cooling rates (Fig. 9).

Many of the samples present intergranular corrosion products, which will have impacted XRF analyses to a lesser or greater extent depending on the degree of corrosion. Three samples (XL/3, DTR/8, and TD/6) are entirely composed of corrosion products, meaning their elemental (Table 3) and lead isotope (Table 4) compositions must be viewed with caution, but their microstructures remain identifiable (Table 3).

DTR/1, a scraper fragment, has a very fine microstructure, suggesting quenching. In combination with its elevated tin content (see the “Elemental analyses – XRF + SEM-EDS” section, Table 3), doubtless exaggerated by corrosion, the resulting object would have been very hard but likely brittle.

Elemental analyses – XRF + SEM-EDS

The studied assemblage contains just two classes of copper-base alloy, bronze (20) and leaded bronze (7), using 1 wt% as the cut-off for major alloying components and 0.5 wt% as the cut-off for minor contaminants (often evidence of corrosion). The elemental data display a wide range of tin (Fig. 10) and lead (Fig. 11) contents. We are inclined to view the variation as clouded due to the degree of corrosion, as shown by concentrations of iron, aluminium, and silicon, and the general discrepancy between pXRF global compositional data and SEM-EDS compositional data targeting less corroded areas (Table 3). Therefore, we lack good evidence for multiple sub-categories of bronze ratios or deliberate adaptation of alloy to use—though this may still have been the case—and we cannot make a serious evaluation of standardisation in these circumstances. What is clear, however, is that there is no pure or effectively pure copper and all the leaded alloy samples are Iron Age. We are thus dealing with assemblages that are, at a minimum, alloyed and possibly recycled, rather than raw product coming from the primary production loci. In provenance terms, this means that our LIA data must be discussed with respect to copper networks, as well as lead exchange systems for the seven thus-alloyed samples.

Lead isotopes

With respect to the study results in isolation, plus an example signature for north Vietnamese copper (Nhon [Lao Cai Province], see Pryce et al. 2014), the isotope ratios have a general coherence but the sites and alloy types (leaded vs unleaded) are mixed rather than forming discrete clusters (Table 4, Fig. 12). The one slag sample, TD/7, does have reasonable compatibility with a number of metal samples but none is consistent with the Nhon slag data. It should be noted there are tens if not hundreds of uncharacterised copper deposits in northern Vietnam (Workman 1977). Three of four leaded Xuân Lâp samples group well, and are consistent with a Đông Sơn period (Iron Age) leaded bronze spearhead (DTR/12) and a corroded axe from Dai Trach (DTR/8) but as a reminder that copper (trace lead) and lead signatures can overlap, GM/2 (0.7 wt. % Pb in a corroded matrix) also plots in this area. Three Dai Trach artefacts (DTR/5, 7, and 11) are plot closely near the top-centre of Fig. 12, which could represent a shared primary or secondary copper source. Finally, a potential group consisting exclusively of unleaded alloys (as far as the corroded matrices permit us to evaluate) plots towards the bottom but the level of compatibility is not high and not to be relied upon as indicating shared raw material sources. To make some sense of the study data, we must incorporate existing SEALIP/BROGLASEA datasets for MSEA copper production and Bronze Age consumption (Fig. 13).

LI ratios seen for the study assemblages and Nhon copper slag samples (data from Pryce et al. 2014); error bars are smaller than symbols

Study and published SEALIP/BROGLASEA data for MSEA copper production and Bronze Age consumption. Nil Kham Haeng/Non Pa Wai represent central Thai production, Phu Lon northern Thai production, and Thong Na Nguak/Puen Baolo central Lao production. Production site artefacts/imports/exotics are marked; error bars are smaller than symbols

Here, we see that our new data are not consistent with any of the known prehistoric MSEA copper production centres in central and northern Thailand and central Laos: the Khao Wong Prachan Valley, Phu Lon, and the Vilabouly Complex, respectively (Cadet et al. 2019; Pryce et al. 2014, 2011a). For the leaded artefacts, all Iron Age, there are no MSEA primary production signatures available for comparison (Pryce 2012). It may appear there is compatibility with central Lao copper production but this area of the complete dataset plot (n=1000+, not shown here as it would be incomprehensible) is densely populated and the SEALIP/BROGLASEA programme has always been extremely conservative about what constitutes a claim for ‘provenance’. The study data do not match available Yunnan copper production signatures, from Guangfentou in Yunnan Province (Zou et al. 2019), and none are known for Lingnan (Guangxi and Guangdong). There is, however, some consistency with a few MSEA Bronze Age artefact signatures from Ban Non Wat (SEALIP/TH/BNW/4 - copper axe, Pryce 2011), Ban Chiang (SEALIP/TH/BC/5 - tanged arrowhead, Pryce 2019), and the sole bronze artefact from the Phu Lon production site (SEALIP/TH/PL/10 - axe, Pryce et al. 2014). As some other Ban Non Wat and Ban Chiang Bronze Age samples do present high consistency with central Thai and central Lao primary copper production, it suggests there is weak network overlap between northeast Thailand and the present study area. Where northern Vietnam Bronze Age copper-base metal signatures currently stand out from the rest of MSEA is by not matching any known production centre. We are, at present, limited to saying where the metal is not from, and LIA is a reliable method for making this interpretation.

Discussion and conclusion

Clearly, 28 data points must not be over-stretched in their interpretation, especially given that they represent a large and potentially critical area for understanding early Southeast Asian metallurgy (Pryce et al. 2014). Nevertheless, 18 of our samples date to the Bronze Age, a substantial proportion of the analysed contemporary regional examples (ca. 54 at the time of writing), from sites that are far fewer in number and generally have less in the way of metal material culture than their Iron Age counterparts (Pryce 2014). A straightforward reading of our new Bronze Age data for northern Vietnam is that they are not compatible with the known Southeast Asian prehistoric primary copper production signatures, nor is there strong compatibility with those other regional Bronze Age artefacts that are themselves not compatible with the known sources—i.e. there are no evident unknown source signatures. This minimalist reading of the available metallurgical data would suggest social networks between northern Vietnam and the rest of Mainland Southeast Asia operated at a lower rather than greater intensity, despite the apparent passage of Neolithic-behaving populations ca. 1000 years earlier (e.g. Higham et al. 2011a). More specifically, we do not see metallurgical evidence supporting interaction intensity between Bronze Age northern Vietnam and those areas for which we have complementary data, namely central and northeast Thailand, central Laos, and north-central Myanmar.

We remain at an intermediate stage of regional archaeometallurgical research but these findings are consistent with previous studies, in that there seems to be a major lacuna in Bronze Age evidence from northern Laos, which is obviously the critical zone for directly linking the two major areas under discussion (Myanmar lying at a considerable distance to the west). Pryce et al. (2014: 292) previously noted this tendency for what might be termed a ca. 450 geodesic kilometre ‘north Laotian data gap’, if one accepts, as do we, the prevalent hypothesis that early Mainland Southeast Asian metallurgy was proximally derived from technologies practiced in southern China (Higham 1996; Higham et al. 2015; Pryce et al. 2010; White 1988). The lead author’s subsequent suggestion (Pryce 2018; Pryce et al. 2018b) that the late 2nd millennium BC technological transmission may have been littoral via the Gulf of Tonkin and thus avoiding northern Laos, was only intended as a possible nuanced variation on the general north-to-south theme. Potential evidence to the contrary was noted at the site of Tam Pà Ping in Laos’ northern Houaphan province, only 60 km from the Vietnamese border, where a single bronze axe was found in a burial radiocarbon—dated to the 11th/10th c. BC (Pryce and Cadet 2018). At the time, Pryce (2018), Pryce et al. (2018b) proposed that Tam Pà Ping should perhaps be seen as an outlying northern Vietnamese Bronze Age culture site rather than a ‘Lao’ one. However, subsequent (unpublished) elemental and lead isotopic analyses have shown that the axe had an unusual antimony-rich composition that does not match this study’s or previous results, but its lead isotope ratios were highly consistent with the Vilabouly Complex copper production signature, located another ca. 450 km to the southeast (Fig. 1). Tam Pà Ping remains something of enigma but it does support the idea of northern Vietnamese metallurgy being separate from the rest of Bronze Age MSEA. A final piece of pertinent information comes from the Plain of Jars, ca. 70 km south of Tam Pà Ping in Xiangkhouang province. This ‘megalithic jar culture’ was long thought to be Iron Age due to assemblages including iron, glass, and carnelian beads (all regional post-500 BC type markers) in addition to copper-base ornaments. However, recent excavations have radiocarbon dated local burials to the late 1st and early 2nd millennium AD (O’Reilly et al. 2019), whilst optically stimulated luminescence sediment dates suggest the stone jars were positioned from 1240 BC to 660 BC (Shewan et al. 2021), which corresponds to the MSEA Bronze Age. However, there is no evidence to suggest prehistoric copper production activity in the area, despite extensive local copper deposits, and no clear occupation by a metal-using population—metallurgy not being adopted across MSEA at the same time, or even at all. Thus, for the time being, evidence of a northern Lao Bronze Age remains thin indeed.

For our Iron Age north Vietnamese samples, seven out of ten are leaded bronze; there is as yet no means to provenance to a regional lead source, as no such production site has been excavated and studied (Pryce 2012). The present study’s lead signatures are broadly consistent with those of other Iron Age MSEA leaded samples (Pryce et al. 2014), and in particular those recently analysed from the actual Đông Sơn site (Le Meur et al. 2021). This patterning suggests a common source or sources of lead used in Iron Age northern Vietnam, though there are outliers.

On the balance of probabilities, we consider it likely the present study’s samples were made from copper, tin, and lead probably produced in northern Vietnam itself (for copper and lead) or in the southern Chinese provinces of Yunnan, Guangxi, and/or Guangdong. The evidence suggests networks connecting the study area to northeast Thailand were present but weak. Much archaeometallurgical exploration is required in northern Vietnam, where the confluence of copper/bronze-rich archaeological assemblages and extensive metallogenic deposits makes the complete absence of local prehistoric production unlikely. However, for the earliest metals, we note the dominating presence of the Red River leading straight into Yunnan, and the geographically arbitrary border with Guangxi. Whilst none of the currently known signatures match, we hope ongoing work by BROGLASEA and other teams in the Dali, Kunming, and neighbouring areas will provide us with important new understanding of trans-regional metal production and consumption networks in the short to medium term, with all the precious information for human exchange and interaction such evidence would provide.

Notes

Southeast Asian Lead Isotope Project 2008–2015, subsequently Bronze and Glass as Cultural Catalysts and Tracers in Early Southeast Asia 2016–2020, projects.

References

Agrawal DP (1971) The Copper Hoards problem: a technological angle. Asian Perspect 12:113–9

Allard F (2018) The lives of shovels, vessels, and bells in early South China: memory, ritual, and the power of destination. In: Allard F, Linduff KM, Sun Y (eds.), Memory and Agency in Ancient China: Shaping the Life History of Objects. Cambridge University Press, Cambridge, pp. 50–71 https://doi.org/10.1017/9781108560726.004

Budd P, Gale D, Pollard AM, Thomas RG, Williams PA (1993) Evaluating lead isotope data: further observations. Archaeometry 35:241–246

Cadet M, Sayavongkhamdy T, Souksavatdy V, Luangkhoth T, Dillmann P, Cloquet C, Vernet J, Piccardo P, Chang N, Edgar J, Foy E, Pryce TO (2019) Laos’ central role in Southeast Asian copper exchange networks: a multi-method study of bronzes from the Vilabouly Complex. J Archaeol Sci 109:104988. https://doi.org/10.1016/j.jas.2019.104988

Ciarla R (2007) Rethinking Yuanlongpo: the case for technological links between the Lingnan (PRC) and Central Thailand in the Bronze Age. East West 57:305–328

Cloquet C, Carignan J, Libourel G (2006) Atmospheric pollutant dispersion around an urban area using trace metal concentrations and Pb isotopic compositions in epiphytic lichens. Atmos Environ 40:574–587

Dung LTM (2015) Dịa điểm Khảo Cổ Học Thành Dền [The archaeological site of Thành Dền]. Nhà Xuất Bản Đại Học Quốc Gia, Hà Nội

Gorman C, Charoenwongsa P (1976) Ban Chiang: a mosaic of impressions from the first two years. Exped 18:14–26

Higham C, Higham T (2009) A new chronological framework for prehistoric Southeast Asia, based on a Bayesian model from Ban Non Wat. Antiquity 83:125–144. https://doi.org/10.1017/S0003598X00098136

Higham CFW (2014) Early mainland Southeast Asia: from first humans to Angkor. River Books, Bangkok

Higham CFW (2002) Early cultures of mainland Southeast Asia. River Books Ltd, Bangkok

Higham CFW (1996) The Bronze Age of Southeast Asia. Cambridge University Press, Cambridge

Higham CFW (1975) Aspects of economy and ritual in prehistoric Northeast Thailand. JAS 2:245–88

Higham CFW, Douka K, Higham TFG (2015) A new chronology for the Bronze Age of northeastern Thailand and Its Implications for Southeast Asian Prehistory. PLOS ONE 10:e0137542. https://doi.org/10.1371/journal.pone.0137542

Higham CFW, Guangmao X, Qiang L (2011) The prehistory of a Friction Zone: first farmers and hunters-gatherers in Southeast Asia. Antiquity 85:529–543

Higham CFW, Higham TFG, Douka K (2019) Dating the Bronze Age Of Southeast Asia. Why Does It Matter? J Indo-Pac Archaeol 43:43–67

Higham CFW, Higham TFG, Kijngam A (2011) Cutting a Gordian Knot: the Bronze Age of Southeast Asia: origins, timing and impact. Antiquity 85:583–598

Higham TFG, Weiss AD, Higham CFW, Ramsey CB, Guedes J. d’Alpoim, Hanson S, Weber SA, Rispoli F, Ciarla R, Pryce TO, Pigott VC (2020) A prehistoric copper-production centre in central Thailand: its dating and wider implications. Antiquity 94:948–965. https://doi.org/10.15184/aqy.2020.120

Huyền PM (1996) Văn Hoá Đông Sơn tính thống nhát và đa dạng [The culture of Đông Sơn : unity and diversity]. Nhà Xuất Bản Khoa Học Xã Hội, Trung Tâm Khao, Hà Nội

Le Meur C, Cadet M, Partner V, Foy E, Cloquet C, Dillmann P, Thote A, Pryce TO (2021) Typo-technological, elemental and lead isotopic characterization and interpretation of Đông Sơn miniature drums. J Archaeol Sci Rep 38. https://doi.org/10.1016/j.jasrep.2021.103017

Liêm BV (2013) Mộ thuyền trong vân hoá Đông Sơn ở Việt Nam [The boat burials of the Đông Sơn culture in Vietnam]. Nhà xuất bản từ điển bách khoa, Hà Nội

Manhes G, Allègre CJ, Dupré B, Hamelin B (1980) Lead isotope study of basic-ultrabasic layered complexes: speculations about the age of the earth and primitive mantle characteristics. Earth Planet Sci Lett 47:370–382. https://doi.org/10.1016/0012-821X(80)90024-2

Mansuy H (1902) Stations préhistoriques de Samrong-sen et de Longprao, Cambodge [Prehistoric sites of Samrong-sen and Longprao, Cambodia]. Schneider, Hanoi

Masanari N (2005) Settlement patterns on the Red River plain from the late prehistoric period to the 10th century AD. Bull Indo-Pac Prehistory Assoc 25:99–107

Muhly JD (1981) The Origin of Agriculture and Technology - Aarhus, Denmark, November 21-25, 1978. 2. Summary - the Origin of Agriculture and Technology - West or East-Asia. Journal Article workform (42) ISO Source Title Abbreviation: Technol. Cult. ISI Document Solutions: LK017 29-Character Source Title Abbreviation: Technol Culture 22, 125–148

Murowchick RE (1988) The development of early bronze metallurgy in Vietnam and Kampuchea: a reexamination of recent work. In: Maddin R (ed.). The Beginning of the Use of Metals and Alloys: Papers from the Second International Conference on the Beginning of the Use of Metals and Alloys, Zhengzhou, China, 21-26 October, 1986. MIT Press., Cambridge, Mass., pp. 182–199

O’Reilly D, Shewan L, Domett K, Halcrow SE, Luangkhoth T (2019) Excavating among the megaliths: recent research at the ‘Plain of Jars’ site 1 in Laos. Antiquity 93:970–989 https://doi.org/10.15184/aqy.2019.102

Phung HV (1993) Stages of development of Go Mun culture [in Vietnamese]. Khao Co Hoc 85:48–63

Pienitz R, Aebischer S, Cloquet C, Carignan J, Maurice C (2015) Disruption of the geochemical metal cycle during mining: multiple isotope studies of lake sediments from Schefferville, subarctic Québec. Chem Geol 412:167–178. https://doi.org/10.1016/j.chemgeo.2015.07.028

Pigott VC, Ciarla R (2007) On the origins of metallurgy in prehistoric Southeast Asia: the view from Thailand. In: Metals and Mining: Studies in Archaeometallurgy. Archetype, London, pp. 76–88

Pottier C (2006) Under the western Baray waters. In: Bacus EA, Glover IC, Pigott VC (eds) Uncovering Southeast Asia’s Past: Selected Papers from the 10th International Conference of the European Association of Southeast Asian Archaeologists. NUS Press, Singapore, pp 298–309

Pryce TO (2011) The excavation of Ban Non Wat: The Bronze Age. In: Higham CFW, Kijngam A (eds) XIX Technical Analysis of Bronze Age Ban Non Wat Copper-Base Artefacts. The Fine Arts Department, Bangkok, pp 489–498

Pryce TO (2012) Proceedings of the 5th Forbes Symposium on ancient Asian bronzes. In: Jett P, Douglas J (eds.), A Flux That Binds? The Southeast Asian Lead Isotope Project. Smithsonian, Washington D.C., pp 113–121

Pryce TO (2014) Metallurgy in Southeast Asia. In: Helaine S (ed) Encyclopaedia of the history of science, technology, and medicine in non-western cultures. Springer Science, Dordrecht, pp 1–17

Pryce TO (2018) Initiating discourse on the (multi?) directionality of the Mainland Southeast Asian Bronze Age transition. In: Choi J-Y, Park J-S (eds) Proceedings of the ninth international conference on the begining of the use of metals and alloys (BUMA-IX), 16-19 October 2017 International Center, Dong-A University, Busan, Korea. The Korean Institute of Metals and Materials, Seoul, pp 160–175

Pryce TO (2019) Lead isotope characterization and provenance of copper-base artifacts from Ban Chiang and Don Klang. In: White JC, Hamilton EG (eds.), Ban Chiang, Northeast Thailand, Volume 2C: The Metal Remains in Regional Context. University of Pennsylvania Press, Philadelphia, P.A., pp. 57–64

Pryce TO, Cadet M (2018) Ancient copper-base metallurgy in the Lao PDR. In: Patole-Edoumba E, Demeter F (eds) Pà Hang: La Montagne Habitée. 100000 Ans d’histoire de La Biodiversité et de l’occupation Humaine Au Nord Du Laos [Pà Hang: the Inhabited mountain. 100000 years of history, biodiversity and human occupation]. La Rochelle, pp 196–207

Pryce TO, Pigott VC, Martinon-Torres M, Rehren Th (2010) Prehistoric copper production and technological reproduction in the Khao Wong Prachan Valley of Central Thailand | SpringerLink. Archaeol Anthropol Sci 2:237–264

Pryce TO, Brauns M, Chang N, Pernicka E, Pollard M, Ramsey C, Rehren T, Souksavatdy V, Sayavongkhamdy T (2011a) Isotopic and technological variation in prehistoric primary Southeast Asian copper production. J Archaeol Sci 38:3309–3322

Pryce TO, Pollard M, Martinòn-Torres M, Pigott VC, Pernicka E (2011b) Southeast Asia’s first isotopically-defined prehistoric copper production system: when did extractive metallurgy begin in the Khao Wong Prachan Valley of central Thailand? Archaeometry 53:146–163

Pryce TO, Baron S, Bellina BHM, Bellwood PS, Chang N, Chattopadhyay P, Dizon E, Glover IC, Hamilton E, Higham CFW, Kyaw AA, Laychour V, Natapintu S, Nguyen V, Pautreau J-P, Pernicka E, Pigott VC, Pollard M, Pottier C, Reinecke A, Sayavongkhamdy T, Souksavatdy V, White J (2014) More questions than answers: the Southeast Asian Lead Isotope Project 2009–2012. J Archaeol Sci 42:273–294. https://doi.org/10.1016/j.jas.2013.08.024

Pryce TO, Htwe KMM, Georgakopoulou M, Martin T, Vega E, Rehren T, Win Tin Tin, Win ThuThu, Petchey P, Innanchai J, Pradier B (2018a) Metallurgical traditions and metal exchange networks in late prehistoric central Myanmar, c. 1000 BC to c. AD 500. Archaeol Anthropol Sci 10:1087–1109. https://doi.org/10.1007/s12520-016-0436-7

Pryce TO, Kyaw AA, Kyaw MM, Win Tin Tin, Win ThuThu, Win KH, Mon MM, Aye MM, Htay SH, Mar AA, Bellina B, Bentley RA, Champion L, Colonna C, Cook AJ, Favereau A, Fuller DQ, Georjon C, Higham C, Htwe KMM, Iizuka Y, Innanchai J, Le Meur C, Peixoto X, Petchey P, Pinhasi R, Pradier B, Valentin F, Willis A, Zazzo A (2018b) A first absolute chronology for Late Neolithic to Early Bronze Age Myanmar: new AMS 14C dates from Nyaung’gan and Oakaie. Antiquity 92:690–708. https://doi.org/10.15184/aqy.2018.66

Shewan L, O’Reilly D, Armstrong R, Toms P, Webb J, Beavan N, Luangkhoth T, Wood J, Halcrow S, Domett K, Bergh JVD, Chang N (2021) Dating the megalithic culture of laos: Radiocarbon, optically stimulated luminescence and U/Pb zircon results. PLOS ONE 16:e0247167. https://doi.org/10.1371/journal.pone.0247167

Solheim WG (1968) Early bronze in Northeastern Thailand. Curr Anthropol 9:59–62

Thirlwall MF (2002) Multicollector ICP-MS analysis of Pb isotopes using a 207Pb - 204Pb double spike demonstrates up to 400 ppm/amu systematic errors in Tl-normalization. Chem Geol 184:255–279

Trinh S (1979) Vài nét về giao lưu văn hoá ở thời đại kim khí trong bối cảnh lịch sử Đông Nam Á. (Some features of cultural contacts in the Metal Age within the historical context of the South Eastern Asia) [in Vietnamese]. Khảo Cổ Học 3:49–63

Trinh S (1990) Spectrographic analysis of bronze artefacts in Go Mun and Dong Dau Cultures. Khao Co Hoc 1990:49–59

White JC (1988) Early East Asian metallurgy: the Southern tradition. In: Maddin R (ed.), The Beginning of the Use of Metals and Alloys: Papers from the Second International Conference on the Beginning of the Use of Metals and Alloys, Zhengzhou, China, 21-26 October, 1986. MIT Press., Cambridge, Mass., pp. 175–181

White JC (1986) A revision of the chronology at Ban Chiang and its implications for the prehistory of Northeast Thailand (Ph.D.). University of Pennsylvania, Philadelphia

White JC, Hamilton EG (2009) The transmission of early Bronze technology to Thailand: new perspectives. J World Prehistory 22:357–397

Wilson L, Pollard AM (2001) Handbook of archaeological sciences. In: Brothwell DR, Pollard AM (eds) The Provenance Hypothesis. John Wiley & Sons Ltd, Chichester, UK, pp 507–517

Workman DR (1977) Geology of Laos, Cambodia, South Vietnam and the eastern part of Thailand. Overseas Geological and Mineral Resources 50, Institute of Geological Sciences, London

Yao A, Darré V, Zhilong J, Lam W, Wei Y (2020) Bridging the time gap in the Bronze Age of Southeast Asia and Southwest China. Archaeol Res Asia 22:100189. https://doi.org/10.1016/j.ara.2020.100189

Yule P (1997) The copper hoards of Northern India. Exp. 39:22–32

Zou G, Cui J, Liu X, Li X, Min R (2019) Investigation of early Bronze Age civilizations in Yunnan: a scientific analysis of metallurgical relics found at the Guangfentou ruins in Jiangchuan. Archaeol Anthropol Sci 11:15–31. https://doi.org/10.1007/s12520-017-0530-5

Acknowledgements

We offer our warm thanks to the Vietnamese museum curators, archaeologists, and the relevant state authorities who provided us study and sampling access as well as export permits. We are also grateful for the comments of two anonymous reviewers, though any errors are our own.

Funding

The laboratory analyses presented here were financed by the French National Research project “Bronze and Glass as Cultural Catalysts and Tracers in Early Southeast Asia 2016-2020” (BROGLASEA, ANR-16-CE27-0011-01) directed by T.O. Pryce.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests. All samples were exported from Vietnam with the express permission of the relevant authorities.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pryce, T.O., Cadet, M., Allard, F. et al. Copper-base metal supply during the northern Vietnamese Bronze and Iron Ages: metallographic, elemental, and lead isotope data from Dai Trach, Thành Dên, Gò Mun, and Xuân Lâp. Archaeol Anthropol Sci 14, 16 (2022). https://doi.org/10.1007/s12520-021-01489-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-021-01489-9