Abstract

In karst area, existing methods used to determine whether single pile is embedded into rock masses cannot ensure that there is no steep rock surface around the pile tip or that there is no cave within a certain range under the pile ending, and thus, there are great safety risks for the pile foundations. Based on the building foundation survey and the pile foundation engineering practice in karst terrain, this paper establishes a probability model for embedment of single pile into rock masses which considers the degree of foundation dissolution and the pile diameter, deduces the depth distribution formula for the rock-embedding probability of single pile, and verifies the rationality of the proposed probability model with a project instance. According to the results, the degree of ground dissolution and the pile diameter are the main influencing factors to the rock-embedding probability of single pile; the proposed model properly reflects the pattern that the rock-embedding probability of single pile decreases with the rise of the foundation dissolution degree and with the increase of the pile diameter. The project instance shows that, overall, the theoretical rock-embedding probability is 10% smaller than the actual rock-embedding probability of single pile, and this difference is less than 5% in the depth range with a small dissolution ratio; so, the proposed probability model for embedment of single pile into rock masses is of high engineering accuracy. All data used in the proposed rock-embedding probability model for single pile is only from site investigation, which contains cheap, abundant, and reliable available data sources; so, this model can be used to evaluate the reliability of the embedment of single pile into rock masses in the karst terrain.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Ensuring the reliable embedment of pile foundations into rock steep rock surface around the pile ending and that there should be masses is the key to the safety of pile foundations in the karst terrain (Wong et al. 2011; Niu et al. 2015; Xu et al. 2020). The basic requirement is that there should be no be no cave within a certain range under the pile bottom so as to avoid instability of the single pile due to insufficient thickness of the karst cave roof (Perrotti et al. 2019; Alemdag et al. 2019; Wu et al. 2019). The conditions of single pile embedding into rock masses are cross-sectional of pile tip enters the rock. The thickness of intact rock bellow pile tip is not less than 5 m. The rock-socketed thickness of pile tip should be deducted.

Within the scope of engineering construction in Karst Area, there are dolines, clints, ditches and grooves, caves, and fissures and other karst forms with irregular geometric shapes, various sizes, and uncertain locations (Parise et al. 2015; Knez et al. 2012; Zhang et al. 2020; Cao et al. 2020; Shi et al. 2020; Anchuela et al. 2015; Andriani and Parise 2017; Andriani et al. 2015). Due to the limitations of the existing survey means, the morphological features of karst at the site cannot be adequately identified by either drilling or geophysical method (Pazzi et al. 2018; Martel et al. 2018; Drahor 2019; Bu et al. 2019). In engineering practice in China, in order to ensure that the pile foundation meets the rock-embedding requirements, the embedment of the pile foundation into rock masses is usually checked initially in the construction survey of pile foundations on a one-pile-one-hole basis and finally confirmed after the pile hole is formed: dug piles are visually inspected down the hole; for punching piles, several points of the pile bottom are checked with the reinforcing bars or hanging cones. However, the above methods cannot ensure that the single pile ending is embedded into rocks reliably: first, even if the cross-section of the pile bottom touches rocks, there would be no guarantee that there is no free surface around the pile tip. If below the pile tip is a steep rock surface or a clint, a free surface is very likely to appear around the pile. Secondly, there is no guarantee that the thickness of the rock stratum below the pile tip can meet the design requirements. Practice of karst survey shows that, when a small-caliber survey hole is shifted by several centimeters, the thickness and depth of the exposed cave roof will likely be very different and even cannot reveal the hidden caves. Therefore, reliable embedment of pile foundations into rock masses in the karst terrain still needs further studies.

In order to provide basis for the analysis and evaluation on the reliability of the embedment of single pile into rock masses at building sites in karst terrain, this paper, based on the building foundation surveys in the karst terrain and the pile foundation engineering practices, establishes a probability model for embedment of single pile into rock masses which considers the degree of foundation dissolution and the pile diameter, deduces the depth distribution formula for the rock-embedding probability of single pile, and at lastly verifies the rationality of the proposed probability model with a typical project instance.

Construction of the probability model for embedment of single pile into rock mass

Let the diameter of the survey hole be d, and the diameter of the pile hole be D, and that the survey hole is arranged within the pile hole, i.e., d ≤D, as shown in Fig. 1.

Let the area ratio between the pile hole and the survey hole be m′, which is:

At karst construction sites, most of the rock-embedded piles have a diameter of 0.8~3.0 m, and survey holes have a diameter of no greater than 108 mm. In many areas, the diameter of a survey hole is usually 75 mm or even less; so, the area ratio m′ is greater. If the pile diameter is between (0.8~3.0) m, and the diameter of the survey hole is 75 mm, then according to Formula (1), m′ is 113.8~1600. Therefore, compared with the plane coverage of a pile hole, the survey hole is very small and can be regarded as a point in the pile hole. From the probability point of view, on a plane at an elevation of H, each survey hole can be seen as a random test E carried out within the plane coverage of the pile hole, and then the embedment of the pile into rocks is the set of the results of the m′ random E tests. According to the above explanation, the relationship between a single pile and survey hole is exactly the relationship between the sample value and sample group in statistics. The area of a single survey hole represents a sample value, and the area of a pile hole represents m ' collection of sample values.

On the plane at an elevation H, if the coverage of a survey hole is filled with rock and the thickness of the intact rock stratum below the hole bottom meets the design requirements, it is called an “rock-embedment” event on this plane; otherwise, it is called a “non-rock-embedment” event. As shown in Fig. 2, in any plane above the elevation H1, the coverage of the survey hole is in the soil layer; so, the random test results would all be “non-rock-embedment” events; in any plane between the elevation H1~H2, part of the survey hole is filled with soil, and part of it is filled with rocks, and the random test results would still be “non-rock-embedment” events; in any plane below the elevation H2, the coverage of the survey hole is filled with rocks. If the difference between the elevation of this plane and the elevation H3 is no less than the thickness of an intact rock stratum required for a pile tip in the design (usually 3 times that of the pile diameter and no less than 5.0 m), the test result would be an “rock-embedment” event; otherwise, it would be an “non-rock-embedment” event. As mentioned above, the possible results of each random test E are {rock-embedment; non-rock-embedment}.

Based on the results of the m′ random tests, the embedment of the single pile in the plane at the elevation of H can be determined using the following method: when the results of the m′ random tests are all “rock embedment,” it is deemed that the single pile is “embedded into rocks”; otherwise, it is deemed as “not embedded into rocks.”

Optimization of the probability model for embedment of single pile into rock mass

Construction practice in the karst terrain shows that, when the pile diameter is less than 3.0 m, if the peripheral edge of the pile is in contact with the rocks, it indicates that the pile has been embedded into rocks. So, the analysis on the rock embedment of single pile with a diameter of less than 3.0 m can be simplified into the analysis on rock embedment of the peripheral edge of the pile, and there is no need to analyze the m′ areas of the pile tip section one by one. As shown in Fig. 1, let the thickness of the annular region on the edge of the pile hole be d. According to the size of the survey hole, it can be divided into m areas, which means m random tests should be carried out. The criterion for the embedment of single pile into rocks is the results of the m random tests are all “rock-embedment” events. The calculation formula for m is:

Within the scope of the drilling depth, the rock embedment at the survey hole is confirmed: when the survey hole is “not embedded into rocks” at the elevation H, in the random tests, it is definite that single pile at the elevation H cannot be embedded into rocks; when the survey hole is “embedded into rocks” at the elevation H, at least it can be certain that part of the pile hole is “embedded into rocks.” The number of areas embedded into rocks has something to do with the dissolution degree at the elevation H.

Whether tectonics, lithology, and groundwater differ from each other or not, the dissolution ratio r can characterize the degree of carbonatite dissolution in the plane at the elevation H, which shows an exponential attenuation trend with the decreasing elevation, (Cao et al. 2014a, b; Cao et al. 2016). It can be expressed as:

where a and b are constants, and H0 is the initial elevation.

The dissolution ratio r stands for the percentage of the dissolved area in the statistical area. So, the number of non-dissolved areas on the edge of the pile shown in Fig. 1 is m(1 − r), and the probability of the other mr areas “embedded into rocks” is (1 − r).

According to the pile foundation engineering practice at the karst terrain, when there are no more than 3 construction survey holes within the scope of the pile hole, the exposed maximum rock-embedding depth is very close to the actual rock-embedding depth of the singe pile. This indicates that, in a small known area, if the 3 points arranged on the edge of the area are “embedded into rocks,” it can be deemed that the whole area is “embedded into rocks.” In Fig. 1, if the shadow areas A on the two sides of the known area B are “embedded into rocks,” then the boundaries between this area B and the adjacent two shadow areas A are “embedded into rocks.” Accordingly, the four corners of the area B are “embedded into rocks,” and thus, the area B is also “embedded into rocks.” Therefore, the rock-embedding probability model for the pile hole can be determined based on the rock-embedding probability of the 0.5 mr area in the annular region in Fig. 1.

In the current practices of pile foundation construction survey, the pile diameter is usually the main basis for the layout form and number of survey holes. In the karst terrain in Guangxi, when the pile diameter is less than 1.0 m, there are no more than 2 survey holes for each pile hole, arranged symmetrically around the pile center. This survey plan is proved to be working in most cases. As a survey hole is far smaller than a pile hole, the above hole arrangement plan can also be used as the basis for the optimization of the probability model analysis. The probability model can be finally optimized as follows:

In Fig. 1, the known area A is “embedded into rocks,” then the two areas B adjacent to the area A are also “embedded into rocks.” Therefore, the minimum number of areas needed to calculate the rock-embedding probability of the outer ring of the pile hole is (mr/3) just like the number of the shadow areas A in Fig. 3.

The value of pile diameter D should be slightly larger than the actual pile diameter, so as to consider the rock mass entering into the rock within a certain range around the pile. However, the author does not recommend this, because it is difficult to unify the specific increase amount which has caused the lack of comparability between the results of different sites, which is not conducive to the summary of engineering experience. In engineering practice, the radius of pile is generally less than 1.5 m, which is generally no larger than the undulation degree of rock surface. In addition, the rock entering into pile core has been indirectly considered when solving the elevation distribution curve of dissolution ratio. Therefore, the random test sampling for the model of single pile entering into rock is reasonable.

Probability formula for embedment of single pile into rock mass

The rock-embedding probability of single pile in Fig. 1 depends on the rock-embedding probability of the annular region in the figure. Each area into which the annular region is divided is the same as that of the survey hole, which can be deemed as one random test E. The m(1 − r) areas are certain “rock embedment” events, and mr areas are random events with a rock-embedding probability of (1 − r), where the rock-embedding probability is determined based on the 0.5mr area. From this, the formula for the rock-embedding probability of single pile can be obtained:

where ηD is the rock-embedding probability of the single pile with a diameter of D in the plane at the elevation H.

In Formula (4), the term 0.5 mr is regarded as an integer in the inference process. It is not hard to find that, in reality, this term may not be an integer. But it still can be understood that the calculation of Formula (4) is still reasonable when this term is not an integer. Therefore, this term can be any real number above 0. Substitute Formula (2) into Formula (4), and the following can be obtained:

Formula (5) is the formula for the rock-embedding probability of the single pile when the survey holes are embedded into rocks. Let d =0.1 m, and Formula (5) can be approximately expressed as:

According to the experience of foundation subsoil inspection on the single pile of karst buildings, there are no large errors in the strata revealed by small-caliber survey holes, mainly because the absolute errors of the hole diameters are very small. In the current practices of surveys at the karst construction sites, the diameter d of a survey hole is usually (75–110) mm. If d is set to 0.1 m, the absolute deviation from the actual diameter is less than 2.5 cm. In most cases, these errors are acceptable in engineering; so, Formula (5) can be approximately expressed as Formula (6).

This probability model of single pile entry into rock is mainly used to estimate the pile foundation into rock at the design stage of pile foundation, in order to evaluate the difficulty of pile foundation forming and the technical economy of pile foundation scheme. So, instead of analyzing a specific part of the site, this model mainly considers the situation of pile foundation entering into rock within a certain range of the site. Although the scale and characteristics of karst caves, rock surface undulation, karst fractures, and other karst morphology development are uncertain, the stability of statistical law has been verified in the author’s previous study on the decay law of dissolution ratio along depth with a large number of engineering practices; so, the model built in this paper does not need to consider one by one the specific site of a single karst cave, local rock surface undulation, or karst fractures.

Project instance

Project profile

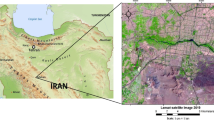

Jinsheng Square in Liuzhou is located in the former Donghuan Produce Market on the west side of Donghuan Avenue and north of Jianpan Road. The project owner thinks that raft foundation used for buildings 1–3# in the early stage of construction is too costly; so, pile foundation is adopted for buildings 4# and 5#. This paper only introduces the situation of building 5#. This building has 28 stories aboveground and one storey underground, built on a frame structure. Except in local areas where independent foundations are used due to low load and high strength of the soil layer, a total of 85 piles are designed for the whole building, among which 44 have a diameter of 0.8 m, 8 have a diameter of 1.4 m, 15 have a diameter of 1.5 m, 12 have a diameter of 1.8 m, and 6 have a diameter of over 1.8 m. The floor plan for the foundation is shown in Fig. 4. All single pile takes the underlying intact limestone layer as the pile tip bearing stratum, whose thickness should be no less than 3 times the pile diameter.

The site is made up of miscellaneous fill, silty soil, and red clay. The covering layer is 9.60~23.43 m thick, with an average thickness of 16.81 m. The tectonics conditions are relatively simple, because there is no obvious fault tectonics at the site or within the scope of 10 km. Regarding the hoar limestone in the underlying carboniferous system, during the construction survey, 47 survey holes reveal 69 karst caves, grooves, and fissures, which are all filled with soft plastic clay. The hole-encountering rate at the site is 55.29%, the line karst rate is 17.3%, the elevation difference between the rock surfaces revealed by adjacent holes is over 10 m, and the karst at the site is highly developed. The groundwater at the site is karst fissure water, which can bear some pressure. The elevation distribution function of dissolution ratio with a similar form to Formula (3) is obtained using the method in Reference Cao et al. (2014a), and the curve is shown in Fig. 5.

The original design of the site used manual dug cast-in-place piles, but according to the survey result of the dug pile at the site of building 4# adjacent to this site, the conditions of the karst foundation are very complex, making it very difficult to form a pile, so at last boring cast-in-situ piles are adopted. In the actual construction of the pile foundation, there are certain deviations between the actual rock-embedding depths of most pile holes and those revealed by the survey holes at the pile position. The deviations of the data revealed by 1/3 of the survey holes from actual data are over 1.5 m, and the maximum deviation is up to 8.1 m. This paper chooses the site as an instance to verify the rationality of the model constructed for the embedment of single pile into rock masses as it is very representative.

Data processing

Embedding one pile into rock mass is essentially a probabilistic problem of random trials, which probability model should be tested by a random trial with a certain sample size. From another point of view, a survey hole is a randomized trial, belonging to a sample, a pile hole belongs to a collection of survey holes, a group of small samples, and a pile foundation of a site belongs to a larger sample set. From single pile to group pile, it is essentially the expansion of the small sample number to the large sample number, and the statistical law obtained from this is more obvious and the statistical results are more reliable. Therefore, it is appropriate to verify this model through pile group verification.

First, the rock-embedding elevations of the survey holes are determined based on the construction survey data of the pile foundations, and the actual rock-embedding elevations of the piles are determined based on the pile foundation construction data.

The above elevation range is dispersed at an interval of 0.5 m. As elevation decreases, the sequence is:

H1>H2>…>Hi − 1>Hi>Hi + 1>…

However, the single pile at the site is classified into categories A, B, and C by pile diameter. Those with a diameter of 0.8 m fall within Cat. A, of which there are 44 in total; those with a diameter of 1.4–1.5 m fall within Cat. B, of which there are 23 in total; and those with a diameter of 1.5 m fall within Cat. C, of which there are 18 in total. They are so classified mainly to avoid excessively small sample sizes that make patterns not obvious. The number \( {N}_i^D \) of piles of each category embedded into rocks at the elevation Hi is calculated. And the actual rock-embedding probability \( {\eta}_{si}^D \) of the piles of each category is defined as follows:

where Ψk is the weight of a pile diameter in the pile category; \( {N}_k^D \) is the total number of piles with a certain pile diameter at the site, and for example; and if there are 44 piles with a diameter of 0.8 m at the site, the value should be 44; ND is the total number of piles of a certain category at the site, and for example, if there are 23 Cat. B piles at the site, which include those with a diameter of 1.4 m and 1.5 m, the value should be 23; k stands for the sequence number of a pile diameter; n stands for the total number of pile types in each category, and for example, if Cat. B piles include two types of piles—1.4 m and 1.5 m, and Cat. C piles include three types—1.8, 2.0, and 2.2 m, the number for Cat. B and C piles should be 2 and 3, respectively; \( {N}_{ki}^D \) is the number of piles of a certain type embedded into rocks at the elevation Hi; \( {N}_{ki}^d \) is the number of survey holes of a certain type embedded into rocks at the elevation Hi; and \( {N}_i^d \) is the number of survey holes embedded into rocks at the elevation Hi.

The theoretical rock-embedding probability \( {\eta}_i^D \) of the single pile of each category at the elevationHi. is calculated according to the following formula:

where ri is the dissolution ratio of the foundation at the elevation Hi, which is obtained directly from the elevation distribution function of dissolution ratio, and for the meanings of the other parameters, please refer to the preceding paragraphs.

The measured rock-embedding probability curves and theoretical rock-embedding probability curves of single pile with Cat. A, B, and C, as well as dissolution ratio distribution curves, are shown in Fig. 6.

The solution of the relationship between dissolution ratio r and the depth requires heavy workload of statistics which could be completed by the program developed by the author in the previous research process.

Errors of the rock-embedding probability of single pile at different elevations are calculated according to the following formula:

The rock-embedding probability error curve of single pile ΔηD(H) is shown in Fig. 7.

Result discussion

From Figs. 5 and 6, we can see that, with the elevation decreasing (the depth increasing) and the dissolution ratio at the site decreasing, the theoretical and measured values of the rock-embedding probability of single pile both increase. This indicates that the dissolution degree of foundation has a significant correlation with the rock-embedding probability of the single pile—the higher the dissolution degree of the site is, the smaller the rock-embedding probability of the single pile will be. When the dissolution ratio remains constant (at the same depth at the site), the actual rock-embedding probability of Cat. A pile (with a pile diameter of 0.8 m) is generally higher than that of Cat. B ones (with a pile diameter of 1.4 m and 1.5 m), and that of Cat. B ones is generally higher than that of Cat. C ones (with a pile diameter of 1.8 m, 2.0 m, and 2.2 m), indicating that, at the same dissolution degree, the rock-embedding probability of the single pile decreases with the increase of the pile diameter, which is consistent with the pattern shown by the theoretical probability curve of the single pile embedded into rocks.

From Fig. 7, it can be seen that, for Cat. A pile, at an elevation of 68.5 m or above (corresponding to a dissolution ratio of over 34%), the deviation between the theoretical and measured probabilities is 12~31.45%, and the average deviation is 25.11%, and at an elevation of less than 68.5 m (corresponding to a dissolution ratio of less than 34%), the deviation between the theoretical and measured probabilities is less than 7.5%, and the average deviation is less than 5%; for Cat. B piles, at an elevation of 67.0 m or above (corresponding to a dissolution ratio of over 25.9%), the deviation between the theoretical and measured probabilities is 13.78~26.41%, and the average deviation is 15.94%, and at an elevation of less than 67 m (corresponding to a dissolution ratio of less than 26.41%), the deviation between the theoretical and measured probabilities is less than 8%, and the average deviation is less than 5%; for Cat. C piles, at an elevation of 66.5 m or above (corresponding to a dissolution ratio of over 25.9%), the deviation between the theoretical and measured probabilities is 13.78~26.41%, and the average deviation is 15.94%, and at an elevation of less than 66.5 m (corresponding to a dissolution ratio of less than 23.61%), the deviation between the theoretical and measured probabilities is less than 8.4%, and the average deviation is less than 5%.

The above phenomena show that, when the dissolution ratio is small, the deviation between the theoretical and measured values of the rock-embedding probability of single pile will be small, but that, when the dissolution ratio is large, the deviation between the two will be large. The main reason is that, at a large dissolution ratio, the number of survey holes embedded into rocks is small, that is, the sample size for statistics is small. For example, for Cat. A pile, there are 10 survey holes embedded into rocks at an elevation of 68.5 m or above; for Cat. B piles, there are 8 embedded into rocks at an elevation of 67.0 m or above, and for Cat. C piles, there are 7 at an elevation of 66.5 m or above. Boring cast-in-situ pile construction technique is adopted for the pile foundation. There are great errors in the acceptance of the embedment of pile tips into rocks. In engineering practice, these errors are directly shown in the following aspects: in the depth range of the shallow strata where the dissolution degree is high, and the difference between the rock-embedding elevation of single pile and the rock-embedding elevation revealed by the survey hole at the pile position is often very large, but with the depth increasing, this deviation gradually decreases. Therefore, the measured rock-embedding probability of single pile above a certain depth does not necessarily reflect the real situation. In the depth range where the dissolution degree is high, the single pile has a high risk of “not being embedded into rocks.” In engineering practice, such single pile should be paid more attention to in the inspection of rock embedment.

The difference between the theoretical and measured rock-embedding probabilities of various piles at the site is generally less than 10%, which, specifically, is 6.44% for Cat. A pile, 4.90% for Cat. B piles, and 7.47% for Cat. C piles, all less than 10%.

In summary, the higher the dissolution degree of the foundation is and the greater the pile diameter is, the lower the rock-embedding probability of single pile will be. The probability model for embedment of single pile into rock masses proposed in this paper can properly show the actual rock-embedding probability of single pile.

In addition to this example project, the author has verified the model for dozens of other projects, and the results are still reliable.

From the above analysis, it can be seen that the probability model for embedment of single pile into rock masses proposed in this paper fully utilizes the pile foundation construction survey data and does not need to carry out extra tests or use extra test data, and the data are cheap, abundant, and reliable; so, the analysis method for the rock-embedding probability of single pile proposed in this paper is highly operable and the evaluation results are very project-specific.

Whether statistical function relationship between dissolution ratio and depth can reflect the foundation dissolution characteristics is directly related to the accuracy of this probability model. According to the author’s previous research results, the average distance from one borehole to another on the spot is no more than 15 m, and the number of boreholes that is no less than 12 is the requirement of the accuracy for the depth distribution function of foundation dissolution ratio, so are also one condition for affecting the accuracy of this model.

Finally, to be sure, the distribution ratio variation along depth is the base theory of this probability model; its feasibility has been tested with building engineering practice, but the model whether suitable for highway, railway, bridges, and other construction site or not, is still need to do further research.

Conclusions

-

(1)

The dissolution degree of the foundation and the pile diameter are the main influencing factors to the rock-embedding probability of single pile. The model proposed in this paper properly reflects the pattern that the rock-embedding probability of single pile in the karst terrain decreases with the rise of the dissolution degree and with the increase of the pile diameter.

-

(2)

In the shallow depth range where the dissolution ratio is large, the rock-embedding probability of single pile is low; so, during construction, the pile hole verification of such single pile should be strengthened to ensure the safety of the pile foundations.

-

(3)

The project instance shows that, overall, the theoretical rock-embedding probability is 10% smaller than the actual rock-embedding probability of single pile, and this difference is less than 5% in the depth range with a small dissolution ratio; so, the proposed probability model for embedment of single pile into rock masses is of high engineering accuracy.

-

(4)

The data used in the proposed rock-embedding probability model for single pile are all from site survey data with no extra test work needed; what is more, the data sources are cheap, abundant, reliable, operable, and highly project-specific.

Change history

28 September 2021

An Editorial Expression of Concern to this paper has been published: https://doi.org/10.1007/s12517-021-08472-7

References

Alemdag S, Zeybek HI, Kulekci G (2019) Stability evaluation of the Gumushane-Akcakale cave by numerical analysis method. J Mt Sci 16(9):2150–2158

Anchuela OP, Sainz AMC, Juan AP, Garbi HG (2015) Assessing karst hazards in urbanized areas: case study and methodological considerations in the mantle karst from Zaragoza city (NE Spain). Eng Geol 184(7):29–42

Andriani GF, Parise M (2017) Applying rock mass classifications to carbonate rocks for engineering purposes with a new approach using the rock engineering system. J Rock Mech Geotech Eng 9(2):364–369

Andriani GF, Parise M, Diprizio G (2015) Uncertainties in the application of rock mass classification and geomechanical models for engineering design in carbonate rocks. Eng Geol Soc Territory 5:545–548

Bu L, Li S, Shi S, Li L, Zhao Y, Zhou Z, Nie L, Sun H (2019) Application of the comprehensive forecast system for water-bearing structures in a karst tunnel: a case study. Bull Eng Geol Environ 78(1):357–373

Cao XF, Zhang JS, Liu ZK, Meng F, Deng GD (2014a) Dissolution degree distribution law with depth in building ground in karst terrain. J Central South Univ (Science and Technology) 45(8):2787–2792

Cao XF, Zhang JS, Liu ZK, Wang HL, Meng F (2014b) Quantitative analysis method for dissolution degree distribution feature with elevation. J Central South Univ (Science and Technology) 45(7):2339–2345

Cao XF, Liu ZK, Li HL (2016) Dissolution distribution rules with depth at building ground in southwestern karst area, China. J Guilin Univ Technol 36(2):253–259

Cao XF, Tang HG, Liu ZK, Li HL (2020) Dissolution features of karst foundations at different depth sections. Int J Des Nat Ecodyn 15(2):145–153

Drahor MG (2019) Identification of gypsum karstification using an electrical resistivity tomography technique: The case-study of the Sivas gypsum karst area (Turkey). Eng Geol 252:78–98

Knez M, Kogovsek J, Liu H, Mulec J, Petric M, Ravbar N, Slabe T (2012) Karstological study of the new Kunming airport building area (Yunnan, China). Environ Earth Sci 67(1):273–283

Martel R, Castellazzi P, Gloaguen E, Trepanier L, Jaime G (2018) ERT, GPR, InSAR, and tracer tests to characterize karst aquifer systems under urban areas: the case of Quebec City. Geomorphology 310:45–56

Niu JR, Oyediran IA, Liu DA, Huang X, Cui ZD, Wang HJ, Shi XS (2015) Quantitative foundation stability evaluation of urban karst area: case study of Tangshan, China. Soils Found 55(3):493–503

Parise M, Closson D, Gutierrez F, Stevanovic Z (2015) Anticipating and managing engineering problems in the complex karst environment. Environ Earth Sci 74(12):7823–7835

Pazzi V, Di F, Michele D, Maria C, Tommaso B, Federica M, Federico F, Katia I, Emanuele F (2018) Integrated geophysical survey in a sinkhole-prone area: microgravity, electrical resistivity tomographies, and seismic noise measurements to delimit its extension. Eng Geol 243:282–293

Perrotti M, Lollino P, Fazio NL, Parise M (2019) Stability charts based on the finite element method for underground cavities in soft carbonate rocks: validation through case-study applications. Nat Hazards Earth Syst Sci 19(10):2079–2095

Shi TT, Chen ZH, Wang Q, Zhang W, Luo MM, Wang NT (2020) Features of oxygen and hydrogen isotopes in waters from the karst mountains, Xiangxi River Basin. Int J Des Nat Ecodyn 15(5):667–675

Wong CT, Yim KP, Leung MK, Fung SC (2011) Rock-socketed large diameter bored pile and geophysical survey in Cavernous Karst Area: Tin Shui Wai Public Library Cum Indoor Recreation Centre. Procedia Eng 14:1744–1751

Wu J, Li SC, Xu ZH, Zhao J (2019) Determination of required rock thickness to resist water and mud inrush from karst caves under earthquake action. Tunn Undergr Space Technol 85:43–55

Xu ZH, Huang X, Li SC, Lin P, Shi XS, Wu J (2020) A new slice-based method for calculating the minimum safe thickness for a filled-type karst cave. Bull Eng Geol Environ 79(2):1097–1111

Zhang BH, Xie YH, Li HL, Liu BC (2020) Distribution pattern of rock face dissolution degree with depth in building foundation in the karst terrain of southwest China. Int J Des Nat Ecodyn 15(2):261–268

Funding

This work was financially supported by the Guangxi Natural Science Foundation with Grant No. 2018GXNSFAA138139, Guangxi Key Laboratory of New Energy and Building Energy Saving with Grant Nos. 17-J-21-6 and 19-J-21-26.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Responsible Editor: Ahmed Farouk

This article is part of the Topical Collection on Big Data and Intelligent Computing Techniques in Geosciences

Rights and permissions

About this article

Cite this article

Cao, X., Tang, H., Li, H. et al. Probability model for embedment of single pile into rock masses at building sites in karst terrain. Arab J Geosci 14, 1339 (2021). https://doi.org/10.1007/s12517-021-06797-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-06797-x