Abstract

Under the background of China as a big coal-hungry country lasting till 2050, deep mining becomes more and more significant. However, deep coal seams usually have a very complex geological structure like Karst collapse columns, and excavation is often accompanied with water-inrush accidents, restricting the development of the coal industry. In order to study on seepage problems on fractured rock accompanying with mass loss during excavation in coal mines with karst collapse columns, researchers studied on water-inrush mechanism in karst collapse columns directly, researched on seepage behavior of fractured rock with pressure as the basis of studying on water-inrush mechanism indirectly, studied the fluid flow change in fractured rock regarding the change of liquid flow type in fractured rock as seepage instability, and observed and studied the phenomenon of mass loss during seepage in succession. In the following research, (1) the cementation, lithology, and match rate of testing samples, which are the foundation of the simulation study, need to be determined in more detail; (2) migrated particles in fractured rock should be distributed which are from migration, corrosion, erosion, and abrasion; (3) multi-permeate agents in the fractured geological structure, their diffusion and convection, and the related chemical reactions should be involved; (4) more and more contemporary mathematical methods will be introduced to help us to study the complex dynamic system; and (5) experimental equipment needs to be designed and improved. What we did before, do now, and will do later is to penetrate the mysteries of seepage problems on fractured rock accompanying with mass loss during excavation in coal mines with karst collapse columns.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Today, China is a big coal-hungry country; the total amount of coal has reached 3.88 billion tons in 2016, and coal will still be the major energy source in China from now on to 2050. Due to the increasing demand for coal resources and gradual exhaustion of the shallow resources, deep excavation is more and more common in most coal mines in China.

However, deep coal seams usually have very complex geological structure (Xie et al. 2015), such as faults and Karst collapse columns (see Fig. 1), and the excavation is often accompanied with water-inrush accidents, which seriously restricts the development of the coal industry (Miao and Qian 2009; Dong 2010).

A major water-inrush accident in karst collapse column happened in Fangezhuang Coal Mine, Kailuan, on June 2, 1984, the largest accident in the world’s mining history. The maximum water inflow reached 2053 m3/min, and the poured-out collapse column fillings were about 65,653 m3, which contained clay, coal-rock waste, and rock blocks. Rock blocks were rubbed and scoured as round pebbles in the transportation process with water flow. The accident caused not only hundreds of thousands of people’s difficulties in water for production and living but also ground collapse and buildings’ collapse, resulting in a direct economic loss of 500 million RMB. The existence of the typical fractured geological structure of karst collapse column is the root of a water-inrush accident in this mine.

Karst collapse columns are fractured rock with variable porous and fracture structures, which are formed by mixing various fractured rock blocks of different sizes and cemented together through muddy and siliceous thin layers on their surfaces under the self-gravity of collapse columns or ground pressure. Mining in coal mines with karst collapse columns is often accompanied with water-inrush accidents, the main influence factors, and the mechanism of which needs to be researched to ensure the safe production of the coal industry. This is not a trivial question, but one that we are willing to explore in the current paper.

The main influence factors of water inrush in karst collapse columns are high water pressure, the through-flow channels, and certain mining stress. On one hand, pores and fractures in surrounding rock develop and expand under mining, and the stress field and the seepage field inside and around Karst collapse column change; subsequently, the network of cracks in the surrounding rock and the porous structure change evidently. On the other hand, fractured rock blocks undergo dissolution, erosion, and abrasion, and the resultant fine particles migrate and lose with the interior coal-rock waste and grains under the entrainment of water flow. As a consequence, the density, porosity, and permeability parameters are time-varying during the mass loss. When mass loss develops to a considerable degree, regional-connected pipe flow channels are formed inside the fractured rock and the confined water penetrates the roof and floor of coal seams through these channels. As the mass loss is going on, flow type changes from seepage to pipe flow, resulting in water-inrush accidents. Hence, the research on seepage problems of fractured rock mass accompanying with mass loss during excavation in a coal seam penetrated by a karst collapse column is of great scientific significance for revealing the water-inrush mechanism and prevention of water-inrush accidents.

The water-inrush mechanism in karst collapse columns

Water inrush in karst collapse columns is mostly considered to result from mining (Yin et al. 2008). During mining, fractures are developed and expanded in the surrounding rock and connected with the fractured geological structure, then water flow channels are formed; finally, water inrush happens indirectly.

Theoretical researches

In order to predict and prevent water inrush in Karst collapse columns, scholars studied water inrush in coal mines with karst collapse columns theoretically, using elastic mechanics (including thin plate theory and thick plate theory), elastoplastic mechanics, fluid mechanics, nonlinear dynamics, and so on.

Yin et al. (2008; Liu et al. 2007a, b) simplified the water-rich collapse column into an infinite thick wall cylinder under the uniformly distributed pressure; divided water inrush in karst collapse columns into two modes, the shear failure water-inrush mode occurred at the bottom and the water-inrush mode for thick wall cylinder occurred at the side face; and gave theoretical criterions for water inrush in water-rich collapse column. For the shear failure water-inrush mode that occurred at the bottom, the limit value of ground water pressure was (Yin et al. 2008; Liu et al. 2007a)

While for the water-inrush mode for thick wall cylinder that occurred at the side face, the plastic limit pressure was (Yin et al. 2008; Liu et al. 2007b)

Based on thick plate theory, a mechanical model for water inrush of collapse columns was established, which indicated that the boundary conditions and strength of water-resisting strata played important roles in influencing water inrush of collapse pillars and determined the critical water-inrush pressure by both relative thickness and absolute thickness of water-resisting strata (Tang et al. 2011).

Song et al. (2011) derived the criteria of water inrush in collapse columns by the equations of an elliptical cross-section of a thick cylinder mechanical model (see in Fig. 2) by using complex functions, elastoplastic mechanics, and other related theories.

Thick-walled cylinder model and stress distribution (Song et al. 2011)

Xu et al. (2005, 2006) analyzed the mechanism to conduct water in karst collapse columns by the limit equilibrium principle; studied the stress distribution in the karst collapse column by the gravity, the pressure of ground water, and the other stress around; deduced the criterion of conducting water; and revealed the factors resulting in conducting water in karst collapse columns.

Wang and Li (2010) analyzed the changes of stress, strain, and plastic zone of the collapse column and its surrounding rock based on the theory of elastic-plastic mechanics and fluid mechanics, established a physical model of predicting water inrush caused by collapse columns, identified the hazardous area, and picked up the water-inrush criterion as follows:

Bai et al. (2013) established a mechanical model (a plug model) to describe the behavior of water seepage flow in coal mines with karst collapse columns. Considering the nonlinear relationship between groundwater inflow and factors, such as geological structure, aquifer, groundwater pressure, etc., Ma and Bai (2015) established a groundwater inflow prediction model of karst collapse column and presented a new parameter optimization scheme of nonlinear gray Bernoulli model using the genetic algorithm. Ma et al. (2015a) also created a numerical fast Lagrangian analysis of continua in a three-dimension model to understand the mechanical state of a coal seam penetrated by a karst collapse column during extraction.

Numerical simulations

Numerical simulation is the main method for researching water-inrush mechanism in fractured geological structures. Scholars use the FEM method and software, such as, RFPA, FLAC, and ANSYS, to simulate water inrush in coal seams with karst collapse columns.

Song et al. (2011) verified the analytical solution of stress distribution on the edge of the thick cylinder inside uniformly distributed pressure by FEM method. Zhang et al. (2009) used the FEM method to simulate the deformation of surrounding rock and seepage field of pore water with a full-water karstic collapse column during mining and discussed the influence of pore water pressure on the plastic deformation of surrounding rock (see Fig. 3).

Extension of plastic deformation region varying with mining (Zhang et al. 2009)

Li et al. (2009) investigated the activation of Karstic collapse columns by combined FEM method and RFPA2D-Flow, studied the influence of the height of karstic collapse columns and the magnitude of water pressure on the delayed time of water inrush, and illuminated the transformation of floor rock mass from water-resisting strata to inrush pathway.

Yin and Wang (2003) simulated the full excavation process in the coal seam existing in a collapse column by FLAC3D to study the effect of karstic collapse columns on surrounding rock mass yield and water inrush from coal floor. Wang and Yang (2009) simulated the full-water filling and non-water filling collapse columns and the collapse column in coal floor by FLAC3D to analyze the change in stress, strain, and plastic area of collapse column and its surrounding rocks. Li et al. (2013) used the rising level of confined water head and the change of seepage quantity as simplified criterion, simulated the whole water-inrush process of karst collapse columns which was water filled and water conducted in edge above confined water by the further developed FLAC3D, and acknowledged the characteristics of seepage and the dangerous water bursting area in the collapse column. Ma et al. (2015a) studied the mechanical behavior of a coal seam penetrated by a karst collapse pillar by FLAC3D based on a numerical fast Lagrangian analysis of continua in a three-dimensional model to understand the mechanical state of a coal seam penetrated by a karst collapse pillar during mining panel extraction, and analyzed the plastic zone development, as displayed in Fig. 4.

The plastic zone development of a coal seam penetrated by a karst collapse column (Ma et al. 2015a)

Xu et al. (2006) studied the stress distribution in the Karst collapse column by ANSYS. Liu and Xiong (2007) studied the water-inrush mechanism and law using ANSYS through translating solid-fluid coupling equations (Yang and Zhao 1998) into thermal analysis problem.

Later, with the upsurge of multiphase flow research, COMSOL and PFC were widely used to simulate water-inrush problems in coal mines with karst collapse columns.

Yang et al. (2008) considered the water inrush due to karst collapse columns to be a coupled process and studied the complete fluid flow process in a confined aquifer, fractured zone, and tunnel using COMSOL Multiphysics based on Darcy equation in a confined aquifer, Brinkman equation in the fractured zone, and Navier-Stokes’s equation in the tunnel. Zhu et al. (2009) proposed a constitutive law for rock failure under coupled rock heterogeneity, deformation, and seepage; reproduced the complete water-inrush process in Fangezhuang Coal Mine by COMSOL; assessed the possibility for water inrush; and clarified the associated mechanical mechanism. Zhang et al. (2013) used COMSOL Multiphysics to obtain the distribution of the porosity and seepage velocity in the collapse column at different times and calculate the seepage discharge (see Fig. 5). Liu and Zhang (2017) analyzed the distribution of column pressure and different moment shear forces and obtained the corresponding curves at a different time by COMSOL.

Distribution of porosity and seepage velocity in the collapse column (Zhang et al. 2013)

Hu (2015) established a PFC/FLAC coupling model of coal floor with fractured geological structure; simulated meso-crack initiation during workface advancing; and investigated the rise, expansion, and inrush from the floor of the confined water.

Experimental researches

Experimental research is the most direct method to study water inrush in coal mines with karst collapse columns, which is always combined with theoretical study or numerical simulations.

Based on a TXFC-3 triaxial permeability instrument, Xiang (1993) carried out experiments on water inrush from natural hydraulic fracturing and pointed out that the natural hydraulic fracturing effect was an important reason of water inrush in a full-water Karstic collapse column. Based on the geological condition and mining technical conditions of the object workface, Wang et al. (2010) established a similar simulation using a self-developed special test system and studied the water-inrush process of collapse column both in the floor and through the coal seam by the similar simulation and numerical simulation software. To investigate the seepage mutation mechanism in the hidden collapse column, Zhang et al. (Zhang 2016; Zhang et al. 2016a, b) developed a fractured rock permeability test system, the experimental loading system of which was shown in Fig. 6, and conducted a series of experiments to examine the seepage in the collapse column under different floor damage conditions.

With the deepening of research, a single method cannot meet the needs any longer; scholars studied the field of water inrush in Karstic collapse column comprehensively using theoretical research, numerical simulation, experimental research, and so on.

The above studies expressed concern on the relationship between water inrush in coal seams with the fractured geological structure and the mining effect in surrounding rock but ignored the structural characteristics of the fractured geological structure itself. Taking the karst collapse column as an example, the columns are mainly accumulated by fractured rock blocks and silt, with high porosity and complex pore and fissure structure.

Water permeate behavior in fractured rock

In essence, water inrush in karst collapse columns is divided into two types. In the first type, due to mining, fractures are developed and expanded in the surrounding rock and connected with the fractured geological structure, then water flow channels are formed; finally, water inrush happens indirectly. In the second type, the fractured geological structure itself is the water flow channel, and water inrush happens directly (Yin et al. 2008). Researches in the second type mostly use the seepage theory of fractured rock as the research foundation.

Scholars (Kogure 1976; Mc Corquodal et al. 1978; Stephson 1984; Pradeep Kumar and Venkataraman 1995; Xu et al. 1998; Qiu et al. 2004; Gao and Wang 2007; Ding et al. 2010) firstly started their experimental researches on a non-pressure fractured rock since the 1970s, which could be taken as references for researches on fractured rock with pressure, even though the action of rock mass deformation and axial loading had not been considered.

Researches on seepage behavior of fractured rock with pressure are the basis of studying on the second type of water-inrush mechanism in coal mines with karst collapse columns. The research team (Miao et al. 2003, 2004, 2009; Sun et al. 2003; Ma et al. 2007a, b; 2009; Liu et al. 2003, 2012; Huang et al. 2005; Li et al. 2008; Miao et al. 2011; Ma et al. 2014, 2015b; Yu et al. 2016; Wang et al. 2014a; 2013a, b, c; Kong et al. 2013; Yu et al. 2015) in China University of Mining and Technology had carried out a series of related theoretical and experimental researches on the permeability of fractured rock with pressure.

Miao et al. (2003, 2004, 2009) thought that seepage in fractured rock mass disobeyed Darcy’s Law and considered it as a nonlinear dynamic system and analyzed the stability and bifurcation of the system by Lyapunov’s first method (see Fig. 7).

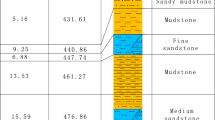

Based on the test system measuring seepage properties of broken rock (see Fig. 8), permeability of fractured rocks with pressure were tested by loading control method and porosity control method (Sun et al. 2003; Ma et al. 2007a, 2007b, 2009; Liu et al. 2003, 2012; Huang et al. 2005; Li et al. 2008; Miao et al. 2011; Ma et al. 2014, 2015b; Yu et al. 2016), as listed in Table 1; the former was used to test permeability under different seepage velocities when the axial loading keeps stable, while the later was used to test permeability and non-Darcy β factor under different seepage velocities when the porosity keeps stable.

Test system measuring seepage properties of fractured rock (Miao et al. 2004)

Wang et al. examined the permeability characteristics of disc-shaped sandstone during bending and shearing deformation, analyzed variation characteristics of the peak load (Wang et al. 2014a, 2013a), measured the permeability and non-Darcy flow β factor of fractured coal samples under five different porosity levels, studied on the type change of liquid flow in fractured coal samples (Wang et al. 2013b), tested the permeability characteristics of fractured coal with different grain sizes under two experimental schemes (Wang et al. 2013c), and tested the permeability of crushed gangues with six different particle sizes during compaction (Kong et al. 2013).

Yu et al. (2015) used the original designed compacting device and seepage experiment system of fractured rock to complete the seepage experiment of cemented fractured mudstone and analyzed the influence of cementing material, water pressure, fractured mudstone size distribution, and initial porosity on seepage characteristics.

In the above researches, water flow in fractured rock was considered as stable in the seepage process, which obeyed or disobeyed Darcy’s Law. Actually, it can be observed that when a water-inrush accident happens, large numbers of rock blocks, coal, and rock blocks with different sizes rush out with water, and suddenly the water flow type changes.

Fluid flow change in fractured rock

Scholars’ studies on fluid flow change started at the beginning of this century, experimentally and theoretically.

In the beginning, scholars could not study further on fluid flow change using the MTS testing system but could only discuss seepage stability by the sign of the non-Darcy β factor theoretically (Li 2006; Li et al. 2007; Chen et al. 2010). Whether the non-Darcy flow β factor is negative, is the flag for the theory of seepage instability to explain water inrush (Li 2006; Li et al. 2007; Chen et al. 2010), because when the non-Darcy flow β factor is positive, the permeability of non-Darcy flow is less than that of Darcy’s flow, and the seepage system is stable; the seepage flow would be instable when the non-Darcy flow β factor is negative, and water inrush may happen. The formula is as follows:

Based on the traditional theory of seepage mechanics, the non-Darcy flow β factor cannot be negative, so seepage instability cannot occur. Restricted by the supercharger volume in the seepage circuit in the MTS815 rock mechanics servo system, deficiencies existed in references (Li 2006; Li et al. 2007; Chen et al. 2010). Therefore, if the loaded axial pressure is lower or the specimen’s porosity is larger, the variable range of seepage velocity is small, the test time is short, the pressure gradient is little, and seepage is difficult to reach turbulence state, so the phenomenon of piping and breakdown does not occur.

In order to overcome the defect of the small supercharger volume in the seepage circuit, Yao (2012) designed an equipment and the experiment system (see Fig. 9); tested the seepage mutation rule under the conditions of different proportion, axial pressure, and so on; and obtained the filling material flow velocity, porosity, water pressure, and flow volume as the time for fractured rock mass, but the equipment can test the fluid flow change for only about 3 min (see Fig. 10), which is the greatest shortage of this equipment. Ma (2013) improved Yao’s design, shortened the piston, and lengthened the overflow tank. The common defect of the above two test systems is that the precision of pressure control is not high enough.

Yao’s seepage test system (Yao 2012)

The permeability evolution in Yao’s research (Yao 2012)

Considering that the collapse column has experienced quite a long time of mass loss before water inrush, the test system should adapt to the requirement of longer time penetration and the inlet pressure of rock sample must keep stable. In accordance with these requirements, subsequently, Wang et al. (2013b, 2013c; Kong et al. 2013) measured the permeability and non-Darcy flow β factor of specimens under five different porosities; found that when the overall pressure of the relief valve was continuously increased until the specimen was broken down, the flow type of liquid in the specimen changed from seepage to pipe flow; and analyzed the correlation between the breakdown pressure gradient and the porosity and the relationship between the breakdown pressure gradient and the critical pressure gradient at seepage instability. However, water flow changing in fractured rock had been realized, but it could not be tested lasting for a long time under a stable pressure.

Subsequently, a new designed sustainable pressurized osmosis device for seepage test of rock mass was established, as shown in Fig. 11, which could control pressure stability. Based on this seepage test system, Wang carried out a series of seepage tests (Wang et al. 2014b, 2015a; Wang 2014), which could last for a longer time (about 18,000 s) with a stable water pressure (see Fig. 12).

Based on the collection of the mine typical fault and sink-hole, late-type water-inrush cases and the analysis of the features, Li et al. (2011) designed and conducted a water-inrush simulation experiment from structure of fractured zone under high water pressure, found that the water inrush from the structure fractured zone under high water pressure condition would be a conversion process of the “pore flow to crack flow to pipeline flow” with the inner composition structure variation, and pointed out that the vadose conversion would be the inherent mechanism of the late-type water inrush from the structure fractured zone, but which was not described qualitatively and quantitatively. Based on the example analysis of water inrush through fault in the fully mechanized top-coal caving face, Qiao et al. (2013) designed similar material simulation models of water inrush aroused by fault activation under different water pressures, including the coal mining under the hanging wall and foot wall of fault; verified that the water inrush aroused by fault activation in fully mechanized top-coal caving had experienced the process of pore fluid, fracture flow, and pipe flow; and identified the time when the pore fluid converses into fracture flow according to the variation law of filling emission quantity along with time, obtaining the time when the fracture flow converses into pipe flow according to the change law of voidage along with time, which explained the conversion phenomenon from seepage to flow of water inrush aroused by fault activation in fully mechanized top-coal caving, and was anastomotic with the expressive characteristics of field examples.

Even though the change of liquid flow type in fractured rock is regarded as seepage instability, which supplies the seepage instability theory test supports, mass migration and loss during seepage in fractured rock has not been considered, which had been observed in seepage tests for fractured rock, and it is the main factor of fluid flow change in fractured rock.

Mass migration and loss in seepage process of fractured rock

The phenomenon of mass loss in the seepage process of fractured rock was ignored in those researches above. In fact, a large quantity of fractured rock and coal were rushed out in the process of water inrush in collapse columns; outthrust had a great disparity in diameters. Scholars observed the phenomenon of mass loss during seepage and studied on this field in succession.

To study the water-inrush mechanism of collapse column and complete testing basis for water inrush of collapse column, a new seepage testing system for variable mass of fractured rock to test the nonlinear seepage characters of variable mass of fractured mudstone was designed (Chen et al. 2014a; b; Wang et al. 2014c, d, e, 2016a, 2017; Kong et al. 2017a, b) (see Fig. 13), containing a sustainable pressurized osmosis device and an open penetration instrument, which could realize particle migration.

Chen et al. (2014a, b) established a method for calculating permeability parameters of the variable mass of fractured rock based on the time series of pressure gradient and seepage velocity and studied the time-varying rules of losing weight, porosity, permeability, non-Darcy flow β factor of mudstone during the seepage process. Wang and Kong et al. (Wang et al. 2014c, d, e, 2016a, 2017; Kong et al. 2017a, b) recorded and calculated the duration time of seepage burst, weight of gushed particle, change rate of gushed particle weight, and change rate of porosity and obtained the change rules under seepage pressure and initial porosity (see Fig. 14); they also established a non-Darcy seepage dynamic system for fractured rock with mass loss based on the accelerated experiment on permeability for fractured mudstone with mass loss and considered the effect of the accelerated factor on the rate of mass loss, but they had not considered the mass loss resulting from corrosion, erosion, and abrasion by water-rock interaction.

The curve of the change rate of porosity φ′ changing with initial porosity φ0 (Wang et al. 2014e)

These researches are great steps forward to study the permeability of fractured rock with mass loss, but the test device was simple and still needs further improvement. Wang, Kong, and Chen et al. improved the test devices for seepage of fractured rock with mass loss (Wang and Kong 2017; Wang and Kong 2015; Wang et al. 2014f, 2015b, 2016b, c; Kong et al. 2016a, b, c, d; Wang and Kong 2018), such as the new test systems in Fig. 15, which provided an experimental basis for the further study on seepage in fractured rock with mass loss.

Besides, Bai (2008) picked up a seepage stability model (plug model) to describe the water-inrush mechanism in collapse columns; he thought that the changing of porosity resulted from the mass transfer in fractured rock, considering both mass loss and mass supply, but he had not analyzed the reason of mass loss further. Yao et al. (Yao 2012; Yao et al. 2013, 2014, 2018) thought that the varying of mass and permeability parameters of fractured rock were because of particle migration in collapse columns, which eventually led to water inrush; he coupled the deformation of fractured rock structure, seepage, and particle migration and established a fluid-solid coupling dynamic model of fractured rock considering mass loss, but his research had certain limitations: it seemed water flow as linear Darcy flow, and its testing time was so short that it could not describe time-change rules of fractured rock with mass loss completely.

The above references studied the problem of mass loss of fractured rock in seepage process, which provides a reference for the seepage problem of fractured rock with mass loss during excavation in mines with karst collapse columns.

Expectations

Presently, the prepared samples in seepage tests are mainly un-cemented fractured rock, which is simulated by kinds of sizes of the single-lithology rock blocks in a certain match rate. Actually, fractured rock in karst collapse columns is mixed by various fractured rock blocks of different sizes, different lithology, and cemented together through muddy and siliceous thin layers on their surfaces. The cemented fractured rock has lower permeability and higher mechanical properties. After the external disturbance, the cementation is easily destroyed, the integrity of the rock declines rapidly, reappears loose, and the permeability increases. In addition, cemented fractured rock will hydrate with water, and the permeability will increase further. In further research, it is of great significance to research permeability characteristics and the mass loss and migration laws in cemented fractured rock, and it is very important to study the lithology and match rate of the testing samples, which will be much closer to the actual situation of fractured rock in karst collapse columns.

In previous research work, scholars studied the characteristics of physical quantities, for example, strain, stress, porosity, permeability, etc. More factors should be introduced to discuss the water flow in fractured rock, such as the triple effects of surface roughness (Zeng et al. 2018; Jin et al. 2017), self-affine fracture (Zeng et al. 2018; Jin et al. 2017), scale and size effects (Jin et al. 2017), and so on.

Currently, the mass migration and loss have been considered in the researches on water inrush in coal mines with karst collapse columns. In our previous studies, particle migration and loss were observed and tested, but we have not distributed migrated and lost particles clearly. How to distribute particles which are from migration, corrosion, erosion, and abrasion will be one of the most urgent problems to solve.

When studying the phenomenon of the mass migration and loss in fractured rock, we even took water as seepage agent and took the seepage as a single fluid. Actually, fine particles also permeate in the fractured geological structure, and perhaps the diffusion, convection of fine particles in water, and the related chemical reactions are involved, which is one of the directions of the next step. It is noteworthy that water that acted as the seepage agent now is the Newton fluid, while the mixed water-fine particles that acted as the seepage agent will be the non-Newton fluid (Du et al. 2017). If we took particle as another seepage agent, we have not described the movement of the migrated particles in fractured rock during the seepage process yet, which is complex, nonlinear, and time-varying. Confirming the fluid type of the seepage induced water-inrush accident in coal mines with karst collapse columns, establishing the movement equations of seepage agent(s) and analyzing the complexity, nonlinearity, and the time-varying characteristics of the movement of particles in fractured rock are our aims in our continuous researches.

The stability of the nonlinear dynamic model of a seepage system for fractured rock with mass loss is analyzed to determine whether water inrush happened in coal mines with karst collapse columns. In this nonlinear dynamic model, the movement equations of seepage agent(s); the constitutive relation of rock strata, stress-strain-seepage, etc.; the kinds of coupled relationships; the time-varying boundary conditions; and more and more equations and control parameters are involved. In further research, we should introduce more and more contemporary mathematical methods to help us to confirm these control parameters in the nonlinear dynamic model, such as genetic algorithm, gray theory, and fuzzy mathematics, perhaps which will help us to obtain the important achievements even if a breakthrough in water-inrush mechanism in coal mine with karst collapse columns.

The experiment is an important means of studying seepage problems on a fractured rock with mass loss during excavation in coal seams with karst collapse columns; it is necessary to improve the existing seepage testing system, which is also a hot point in further days.

In addition, micro-seepage and multi-scale seepage (Chen and Yu 2015) are new viewpoints on the research on the water-inrush mechanism in a coal mine with karst collapse columns. What we did before, do now, and will do later is to penetrate the mysteries of seepage problems on fractured rock accompanying with mass loss during excavation in coal mines with karst collapse columns.

References

Bai HB (2008) Seepage characteristics of top stratum of ordovician system and its application study as key aquifuge. China University of Mining & Technology, Xuzhou

Bai HB, Ma D, Chen ZQ (2013) Mechanical behavior of groundwater seepage in Karst collapse pillars. Eng Geol 164(18):101–106

Chen ZQ, Yu BY (2015) Research progress of seepage mechanics in rock mass affected by mining. J Southwest Petr Univ (Sci Technol Ed) 37(3):69–76

Chen ZQ, Li SC, Pu H, Huang XW (2010) Coupling dynamics of creep and seepage of mining rock. The Science Publishing Company, Beijing

Chen ZQ, Wang LZ, Kong HL, Yao BH (2014a) Study on nonlinear seepage test of variable mass of broken rock. Saf Coal Min 45(2):15–17

Chen ZQ, Wang LZ, Kong HL, Ni XY, Yao BH (2014b) A method for calculating permeability parameters of variable mass of broken rock. Chin J Appl Mech 31(6):927–932

Ding DX, Li GY, Xu WP, Zhang ZJ, Rao L (2010) Regularities for saturated water seepage in loose fragmented medium. Chinese Journal of Geotechnical Engineering 32(2):180–184

Dong SN (2010) Some key scientific problems on water hazards frequently happened in China’s coal mines. J China Coal Soc 35(1):66–71

Du F, Li ZH, Jiang GH, Chen ZQ (2017) Types and mechanism of water-sand inrush disaster in west coal mine. J China Coal Soc 42(7):1846–1853

Gao YF, Wang Y (2007) Influences of saturation manners and mudstone contents on seepage coefficient of rockfill. Chinese Journal of Rock Mechanics and Engineering 26(S1):2959–2963

Hu XY (2015) Study on mechanism of fault activation and water-inrush through insidious fault in mining floor. China University of Mining & Technology, Xuzhou

Huang XW, Tang P, Miao XX, Chen ZQ (2005) Testing study on seepage properties of broken sandstone. Rock Soil Mech 26(9):1385–1388

Jin Y, Dong JB, Zhang XY, Li X, Wu Y (2017) Scale and size effects on fluid flow through self-affine rough fractures. Int J Heat Mass Transf 105:443–451

Kogure K (1976) Experimental study on permeability of crushed rock. Memoirs of the Defense Academy 16(4):149–154

Kong HL, Chen ZQ, Wang LZ, Shen HD (2013) Experimental study on permeability of crushed gangues during compaction. Int J Min Process 124:95–101

Kong HL, Wang LZ, Chen ZQ et al (2016a) A fractured rock penetration test device with continuous sand injection by multiple channels. China Patent, 201610203991.2

Kong HL, Wang LZ, Chen ZQ et al (2016b) A syringe type fractured rock penetration test device for continuous sand injection, China Patent, 201610202812.3

Kong HL, Wang LZ, Chen ZQ et al (2016c) A pumping station type fractured rock penetration test device for continuous sand injection, China Patent, 201610204790.4

Kong HL, Wang LZ, Chen ZQ et al (2016d) An experimental device for water-sand two phase seepage in fractured rock, China Patent, 201610203660.9

Kong HL, Wang LZ, Huang XJ et al (2017a) Non-Darcy permeability parameters of broken rock accompanied by mass loss. Electron J Geotech Eng 22(1):119–130

Kong HL, Wang LZ, Huang QW et al (2017b) Non-linear seepage property of broken rock with mass loss. J Residuals Sci Technol 14(3):661–674

Li SC (2006) Nonlinear dynamic study on non-Darcy flow in broken rock mass. China University of Mining & Technology, Xuzhou

Li TZ, Ma L, Zhang LY (2007) Discussion about positive or negative sign of permeability indexes in non-Darcy flow of mudstone. J Min & Saf Eng 24(4):481–485

Li SC, Miao XX, Chen ZQ, Mao XB (2008) Experimental study on seepage properties of non-Darcy flow in confined broken rocks. Engineering Mechanics 25(4):85–92

Li LC, Tang CA, Zuo YJ, Li G, Liu C (2009) Mechanism of hysteretic ground water inrush from coal seam floor with Karstic collapse columns. J China Coal Soc 34(9):1212–1216

Li WP, Liu QM, Sun RH (2011) Theoretical and experiment study on vadose conversion of water inrush later occurred from structure broken zone. Coal Sci Technol 39(11):10–13

Li ZL, Wang LG, Hou HQ (2013) Research on water-bursting of Karst collapse columns considering the coupling relation between seepage and stress. Chin J Undergr Space Eng 9(5):1173–1178

Liu ZJ, Xiong CS (2007) Numerical simulation study on water inrush mechanism from collapse column. Chin J Rock Mech Eng 26(S2):4013–4018

Liu SX, Zhang BX (2017) Simulation analysis of collapse column water inrush factors of fluid solid coupling. Coal Technol 36(6):118–120

Liu WQ, Miao XX, Chen ZQ (2003) A testing method for determining the permeability of overbroken rock. J Exp Mech 18(1):57–61

Liu GL, Yin SX, Wang YB (2007a) Shear failure water inrush m ode at Karst sink hole bottom in North China coal field. Coal Sci Technol 35(2):87–89

Liu GL, Yin SX, Wang YB (2007b) Model of water inrush for thick wall cylinder at side face of paleo-sinkholes in North-China-type coalfields. J Eng Geol 15(2):284–287

Liu WQ, Fei XD, Fang JN (2012) Rules for confidence intervals of permeability coefficients for water flow in over-broken rock mass. Int J Min Sci Technol 22:29–33

Ma D (2013) Experimental research on non-Darcy flow seepage properties of broken mudstone with variable mass. China University of Mining & Technology, Xuzhou

Ma D, Bai HB (2015) Groundwater inflow prediction model of Karst collapse pillar: A case study for mining-induced groundwater inrush risk. Nat Hazards 76:1319–1344

Ma ZG, Miao XX, Li XH, Guo GL, Shi XS (2007a) Permeability of broken shale. J Min & Saf Eng 24(3):260–264

Ma ZG, Miao XX, Zhang F, Li YS (2007b) Experimental study into permeability of broken mudstone. J China Univ Min Technol 17(2):147–151

Ma ZG, Miao XX, Chen ZQ, Li YS (2009) Experimental study of permeability of broken coal. Rock Soil Mech 30(4):985–988

Ma D, Miao XX, Jiang GH, Bai HB, Chen ZQ (2014) An experimental investigation of permeability measurement of water flow in crushed rocks. Transp Porous Media 105:571–595

Ma D, Bai HB, Wang YM (2015a) Mechanical behavior of a coal seam penetrated by a Karst collapse pillar: Mining-induced groundwater inrush risk. Nat Hazards 75:2137–2151

Ma D, Bai HB, Chen ZQ, Pu H (2015b) Effect of particle mixture on seepage properties of crushed mudstones. Transp Porous Media 108:257–277

Mc Corquodal TA, Hannoura AAA, Sam Nasser M (1978) Hydraulic conductivity of rock fill. Journal of Hydraulic Research 16(2):123–137

Miao XX, Qian MG (2009) Research on green mining of coal resources in China: Current status and future prospects. J Min & Saf Eng 26(1):1–14

Miao XX, Chen ZQ, Mao XB, Chen RH (2003) The bifurcation of non-Darcy flow in post-failure rock. Acta Mech Sinica 35(6):660–667

Miao XX, Liu WQ, Chen ZQ (2004) Seepage theory of mining rock mass. The Science Publishing Company, Beijing

Miao XX, Li SC, Chen ZQ (2009) Bifurcation and catastrophe of seepage flow system in broken rock. Min Sci Technol 19:1–7

Miao XX, Li SC, Chen ZQ, Liu WQ (2011) Experimental study of seepage properties of broken sandstone under different porosities. Transp Porous Media 86:805–814

Pradeep Kumar GN, Venkataraman P (1995) Non-Darcy converging flow through coarse granular media. Journal of the Institution of Engineers (India): Civil Engineering Division 76:6–11

Qiao W, Hu G, Li WP (2013) Experimental study on the conversion from seepage to flow of water inrush aroused by fault activation in fully mechanized top-coal caving. J Min & Saf Eng 30(1):30–37

Qiu XD, Yan ZL, Liu L, Wang H (2004) Effect of particle-size characteristics on seepage property of rockfill. Rock and Soil Mechanics 25(6):950–954

Song YQ, Wang XY, Cheng P, Peng CJ, Xu S (2011) The mechanical criterion and numerical simulation of thick-walled elliptical cylinder collapse column model under water inrush. J China Coal Soc 36(3):452–455

Stephson D (1984) Hydraulic calculation in rock-fill engineering. Ocean Publishing Company, Beijing

Sun MG, Li TZ, Huang XW, Chen RH (2003) Penetrating properties of non-Darcy flow in fragmentized rocks. J Anhui Univ Sci Technol (Nat Sci) 23(2):11–13

Tang JH, Bai HB, Yao BH, Wu Y (2011) Theoretical analysis on water-inrush mechanism of concealed collapse pillars in floor. Min Sci Technol 21(1):57–60

Wang LZ (2014) Accelerated experimental study on permeability for broken mudstone with mass loss. China University of Mining & Technology, Xuzhou

Wang LZ and Kong HL (2015) An axial loading permeation test device. China Patent, 201520830304.0

Wang LZ, Kong HL (2017) Accelerated experimental study on permeability for fractured rock accompanying with mass loss. The Science Publishing Company, Beijing

Wang LZ, Kong HL (2018) Variation characteristics of mass-loss rate in dynamic seepage system of the broken rocks. Geofluids 2018(7137601):1–17

Wang JC, Li JB (2010) Physical model and theoretic criterion of the forecast of water inrush caused by collapse columns. J Univ Sci Technol Beijing 32(10):1243–1247

Wang JC, Yang SL (2009) Numerical simulation of mining effect on collapse column activated water conducting mechanism. J Min & Saf Eng 26(2):140–144

Wang JC, Li JB, Xu GM (2010) Development and application of simulation test system for water inrush from the water-conducting collapse column. J Min & Saf Eng 27(3):305–309

Wang LZ, Chen RH, Chen ZQ (2013a) Permeability rule of round slice red sandstone with different seepage pressure during its whole shear deformation. Electron J Geotech Eng 18:2165–2175

Wang LZ, Chen ZQ, Shen HD (2013b) Experimental study on the type change of liquid flow in broken coal samples. J Coal Sci & Eng(Chin) 19(1):19–25

Wang LZ, Chen ZQ, Kong HL, Shen HD (2013c) Experimental study of impact of loading history on permeability characteristics of broken coal with different grain size gradations. Rock Soil Mech 34(5):1325–1330

Wang LZ, Chen ZQ, Kong HL, Shen HD (2014a) Effects of pore pressure on permeability of sandstone during bending deformation. Int J Rock Mech Min Sci 70(9):26–32

Wang LZ, Kong HL, Chen ZQ et al (2014b) A sustainable pressurized osmosis device for seepage test of rock mass, China Patent, 201410031033.2

Wang LZ, Chen ZQ, Kong HL, Xu H (2014c) Numerical simulation on penetration laws of broken rock with mass loss under different pressure gradients. Electron J Geotech Eng 19:2491–2502

Wang LZ, Chen ZQ, Kong HL (2014d) Influences on penetration laws of broken mudstone with mass loss from Talbol power exponents. Electron J Geotech Eng 19:3681–3692

Wang LZ, Chen ZQ, Kong HL, Ni XY (2014e) An experimental study of the influence of seepage pressure and initial porosity on variable mass seepage for broken mudstone. J Min & Saf Eng 31(3):462–468

Wang LZ, Lan Y, FengMM et al (2014f) Two section lengthened osmotic, China Patent, 201420614509.0

Wang LZ, Kong HL, Wang W, Hui WR, Wang ZY (2015a) Experimental study on the fractal feature of confined broken gangues. Electron J Geotech Eng 20(21):12047–12056

Wang LZ, Kong HL, Chen ZQ et al (2015b) A compatible penetration test device for syringe type and pump station, China Patent, 201520827913.0

Wang LZ, Kong HL, Xu B, Yin Y (2016a) Nonlinear seepage property of broken mudstone considering particle migration. Electron J Geotech Eng 21(20):7033–7044 21(20):7033–7044, 2016

Wang LZ, Kong HL, Qin Y et al (2016b) A hydraulic seepage pressure loading device for rock permeability test, China Patent, 201621444385.1

Wang LZ, Kong HL, Qin Y et al (2016c) An electromagnetic induction type seepage pressure loading device for rock permeability test, China Patent, 201621444383.2

Wang LZ, Chen ZQ, Kong HL (2017) An experimental investigation for seepage-induced instability of confined broken mudstones with consideration of mass loss. Geofluids 4:1–12

Xiang YF (1993) A mechanical model using in the process of water inrush from Karst column. Coal Geol & Explor 21(5):36–39

Xie HP, Gao F, Ju Y (2015) Research and development of rock mechanics in deep ground engineering. Chin J Rock Mech Eng 34(11):2161–2178

Xu TY, Zhang XH, Meng XY (1998) Analysis on seepage property of rockfill mass. Journal of Hydraulic Engineering 29(S1):81–84

Xu JP, Song Y, Cheng YH, Qiu ZQ (2005) Distributing of ground stress in and around Karst collapse column. J Min & Saf Eng 22(4):118–120

Xu JP, Kong YF, Tong HS (2006) The mechanism and criterion of Karst collapse column activating to conduct water under weak runoff state. Carsologica Sin 25(1):35–39

Yang D, Zhao YS (1998) Numerical simulation of solid-fluid coupling function of fracture media. J China Coal Soc 23(1):37–41

Yang TH, Chen SK, Zhu WC, Meng ZP, Gao YF (2008) Water inrush mechanism in mines and nonlinear flow model for fractured rocks. Chin J Rock Mech Eng 27(7):1411–1416

Yao BH (2012) Research on variable mass fluid-solid coupling dynamic theory of broken rock mass application. China University of Mining & Technology, Xuzhou

Yao BH, Wei JP, Wang DK, Ma D, Chen ZQ (2013) Numerical study on seepage property of karst collapse columns under particle migration. Comput Model Eng Sci 91(2):81–100

Yao BH, Mao XB, Wei JP, Wang DK (2014) Study on coupled fluid-solid model for collapse columns considering the effect of particle transport. J China Univ Min Technol 43(1):30–35

Yao BH, Chen ZQ, Wei JP, Bai TH, Liu SM (2018) Predicting erosion-induced water inrush of karst collapse pillars using inverse velocity theory. Geofluids 2018(2090584):1–18

Yin SX, Wang SX (2003) A numerical simulation analysis of influence of karstic collapse columns on rock yield and water inrush from coal floor. J China Coal Soc 28(3):264–269

Yin SX, Wu WJ, Li YJ, Liu GL, Yang WM (2008) Water inrush in Karst collapse columns in North China coalfields. China Coal Industry Publishing House, Beijing

Yu BY, Chen ZQ, Wu Y, Zhang SB, Yu LL (2015) Experimental study on the seepage characteristics of cemented broken mudstone. J Min & Saf Eng 32(5):853–858

Yu BY, Chen ZQ, Ding QL, Wang LZ (2016) Non-Darcy flow seepage characteristics of saturated broken rocks under compression with lateral constraint. Int J Min Sci Technol 26(6):1145–1151

Zeng Y, Ning ZF, Wang Q, Sun HL, Huang L, Ye HT (2018) Gas transport in self-affine rough microchannels of shale gas reservoir. J Pet Sci Eng 167:716–728

Zhang BY (2016) Test research on seepage evolution law of collapse column under mining. China University of Mining & Technology, Xuzhou

Zhang JF, Zhang HL, Meng D, Cao J (2009) Numerical simulation of rock deformation and seepage field with a fully-water Karstic collapse column under mining influence. Chin J Rock Mech Eng 28(S1):2824–2829

Zhang K, Yao BH, Wu SG, Zhang HT (2013) Study on the characteristics of variable mass seepage and water inrush mechanism of collapse column. J Min & Saf Eng 30(6):892–896

Zhang BY, Bai HB, Zhang K (2016a) Research on permeability characteristics of Karst collapse column fillings in complete stress-strain process. J Min & Saf Eng 33(4):734–740

Zhang BY, Bai HB, Zhang K (2016b) Experimental research on seepage mutation mechanism of collapse column medium. Rock and Soil Mechanics 37(3):745–752

Zhu WC, Wei CH, Zhang FZ, Yang TH (2009) Investigation of water inrush from Karst subsidence column by using a coupled hydro-mechanical model. Chin J Undergr Space Eng 5(5):928–933

Acknowledgments

The authors thank the authors of all the references, and also the referees for their careful reading of this paper and valuable suggestions.

Funding

This work is supported by the Natural Science Foundation of Jiangsu Province of China (BK20160433), the National Natural Science Fund of China (11502229), the Joint Open Fund of Jiangsu Collaborative Innovation Center for Ecological Building Material and Environmental Protection Equipments and Key Laboratory for Advanced Technology in Environmental Protection of Jiangsu Province, the Outstanding Young Backbone Teacher of QingLan Project in Jiangsu Province, Jiangsu Government Scholarship for Overseas Studies, Scholarship for Overseas Studies in Yancheng Institute of Technology, and the Program of Outstanding Young Scholars in Yancheng Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Kong, H., Wang, L. Seepage problems on fractured rock accompanying with mass loss during excavation in coal mines with karst collapse columns. Arab J Geosci 11, 585 (2018). https://doi.org/10.1007/s12517-018-3881-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-018-3881-z