Abstract

In 2010, a water inrush accident through a fault with a high flow rate occurred at Tianzhuang coal mine in Jining, Shandong Province, China, which was subject to the fault excavation. Grouting is an important treatment method before and after water inrush accidents. In this paper, the evolution of this water inrush accident is studied, and the effective treatment method is presented. The obtained results indicate that groundwater from Ordovician limestone aquifer 28.5 m below the floor flowed into the roadway through the fault zone. Results also show that this water inrush through the fault zone can be divided into a flow rate steady increase phase, a rapidly increase phase, a decrease phase, and a steady phase. The first two phases resulted from permeability increase of the fault, which was caused by seepage failure, and water level of the aquifer led to last two phases. Additionally, grouting using the ground borehole successfully controlled this water inrush accident, and it is proven to be a valid method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water inrush caused by the complex geological conditions, after gas explosion, is the most serious disaster in mining work accidents in China (Sui et al. 2011; Wu et al. 2011). Although since 2005 with increasing application of groundwater inrush prevention systems, the number of related coal mine accidents has shown a clear descending trend (Huang et al. 2014; Ma et al. 2017). Water inrush accidents still occur in China coal mines every year and result in the death of miners (Ma et al. 2017), e.g., on March 2010, a water inrush incident occurred at Luotuoshan coal mine, 32 miners died, and on September 2015, a water inrush accident in Jiangjiawang coal mine killed 21 miners, and 11 miners died at Zhaojin coal mine in 2016. Thus, on no account can we ignore the immense danger of mine water accident (Huang et al. 2014).

According to the statistics (Qiao et al. 2013; Huang et al. 2014), more than 80% of the water inrush accidents in China were related with the faults around the working face or the roadway. Numerous researchers have studied the reaction of faults (e.g., Caine et al. 1996; Babiker and Gudmundsson 2004; Mukai and Fujimori 2007) and the mechanism of water inrush through faults (e.g., Johnsen et al. 2008; Niebling et al. 2012; Huang et al. 2016). On August 17, 2010, a water inrush accident occurred at Tianzhuang coal mine in Jining City, Shandong Province, China. Near 8 years have passed since this water inrush incident, and this paper aims to study the process of the water inrush accident, in order to better understand the mechanism of this accident. Furthermore, the corresponding treatment measures used in this coal mine were discussed.

Accident details

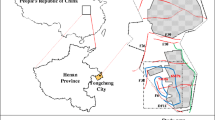

Tianzhuang coal mine is situated in Yanzhou coalfield, Eastern China (Fig. 1) and was formally put on production on November 18, 2002, and its production capacity is 0.9 million tons. Nowadays, Tianzhuang coal mine is mining the Permo-Carboniferous coal seams, i.e., the No. 16 coal seam whose thickness varies from 0.9 to 1.3 m. On August 17, 2010, at 23:23, the water inrush accident occurred at No. 8602 heading face of Tianzhuang coal mine. A round outlet was observed in the fault zone. Fortunately, nobody was injured or dead in this accident.

Water source and inrush channel

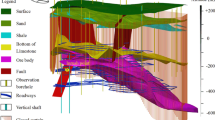

The key questions, such as the water source and its mechanism, are important to understand the water inrush accident (Li et al. 2013). As shown in Fig. 2, there is no doubt that this water inrush accident must be associated with the fault, namely the fault zone is the flow channel. Thus, it was evident that groundwater from the aquifer underlying the floor inrush through the fault into the gateway induced the accident. According to the geological data, the fault is a normal fault with an inclination of 85°, and its breaking distance and thickness of the fault zone are 16 and 1 m, respectively. Then, the second question to be asked is that where did the water come from. Figure 3 is the top view of geological section map and the location of water inrush point. It can be seen that several faults (i.e., No. 1, No. 2, No. 3, and No. 4 fault) have been exposed in the construction section of the channel with about 80 m distance from the water inrush point, and all the faults are normal faults, which all tend to be consistent. Rock formations under the floor were gradually uplifted induced by the fault, resulting in only about 28.5 m distance between the water point from strong rich water in Ordovician limestone and the gateway. Ordovician limestone is one of the most abundant water bearing stratas in Tianzhuang coal mine and even in North China. The Ordovician limestone is a confined karst aquifer containing an abundant supply of water and with a very high water pressure (Zhang 2005). According to the hydrologic observation wells, the water level in an Ordovician hydrologic observation well which was about 1 km apart from the water inrush point dropped 8 m during the water inrush accident (as shown in Fig. 4), while the water levels in No. 13 and No. 14 limestone observation wells did not change. Under these conditions mentioned above, the water inrush accident occurred owing to that water from Ordovician limestone aquifer gushed to the gateway through the fault.

Top view of geological section map and the location of water inrush point (after Huang et al. 2014)

Based on the above information, it can be concluded that the water inrush source comes from the Ordovician limestone aquifer, the water inrush channel is the fault zone, and the determination of water source and channel is the basis of the design governance scheme.

Water inrush process indicated by flow rate

Figure 5 shows the variation curve of the water flow rate (q) during the water inrush accident. Water inrush through the fault is also a process of the washout of an existing in-fill in the fault. Laboratory tests are the common methods to investigate the granular loss of fillings (e.g., Zhang et al. 2014; Ma et al. 2017). However, it is difficult to obtain the granule flow rate in an actual water inrush accident, resulting in extremely rare data of the granule flow rate. According to the data, the variation of the granule flow rate (qg) in the fault can be studied. The water flow through the fault can be simplified as a pipe flow. Weisbach firstly proposed the equation that we now know as Darcy-Weisbach Formula, which can be used to calculate head loss (hf) (Miller et al. 1945)

where is λ friction factor, l is the length of pipe work, d is the inner diameter of pipe work, v is the velocity of fluid, and g is the acceleration due to gravity.

And, the average velocity of fluid is

When \( {R}_e>4160{\left(\frac{d}{2\Delta}\right)}^{0.85} \), the friction factor can be calculated as follows:

where Δ is the roughness of the internal surface and Re is the Reynolds number.

Based on Eqs. (1–3), the inner diameter of pipe work can be estimated as

where h is the head of aquifer.

Then, granule flow rate (qg) can be estimated as

According to the Nikuradse experiment curve (Nikuradse 1932), we chose the d/Δ = 30, then the granule flow rate (qg) can be calculated using Eq. (5), and the calculated result is shown in Fig. 5. Combining the results of the water flow rate (q) and the granule flow rate (qg) provides information on the water inrush process, which can be divided into four phases:

-

1.

Phase I (flow rate steady increase phase). This phase occurs in the early regime of the water inrush accident. The duration of this period is 40.5 h, the flow rate (q) increased from 3 to 335 m3/h, and the rate of increase of flow rate was increasing as well. The content of solid matter in water was also increasing, and finally a diameter of 204 mm rough tubular water inrush channel was formed. The water inrush from the fault in this phase was turbid with fine sediment and a small amount of gravel. In this phase, the tiny granules in the fault would be eroded and moved to exterior as the time induced by water seepage and lead to the changes of the porosity and permeability parameters (Zhang et al. 2014).

-

2.

Phase II (rapidly increase phase). In this phase (just about 3 h), water flow rate rapid increased from 335 to 1255 m3/h. The increasing water flow rate may cause a greater seepage velocity and carrying capacity of water, which may result in more granules being eroded and moved with the water flow. Thus, solid material content in the second phase was significantly higher than the previous phase, where the largest amount of solid material reaches 1.04 m3/h, a diameter of 346 mm rough tubular water inrush channel was formed. The water inrush from the fault in this phase was turbid with a lot of fine sediment and gravel, and a round outlet was observed in the fault zone. In this phase, the materials within the fault zone were quickly washed out, resulting in the structure damage of the fractured zone and rapid increase of its permeability.

-

3.

Phase III (decrease phase). As the water inrushes from the fault, the water flow rate gradually reduced from 1255 to 860 m3/h. According to the situation of 8602 working face, the inrush water was clear and the water inrush channel has not changed. The decrease of the effluent flow mainly resulted from the continuous large flow of the effluent and the decrease of the water level of the effluent water source (as shown in Fig. 4). In this phase, as a large number of filling granules were eroded and carried away by water as the time, only the rock skeleton and larger granules, which were not eroded and transported, were left. Thus, the granule flow rate (qg) decreased quickly in this phase.

-

4.

Phase IV (steady phase). The water flow rate in this phase was gradually stabilized at a larger value, the inrush water was clear, and the water inrush channel was constant. The water level of the effluent water was kept gradually steady after the continuous large flow of water (Fig. 4). The water level of the Ordovician limestone aquifer was kept at about 1 m in this phase. The effluent flow rate was balanced with the water level of the aquifer, forming a stable aquifer landing funnel.

Furthermore, the fitting results show that exponential relationship, linear relationship, quadratic polynomial relationship, and linear relationship exist between the water flow rate and the time with high regression coefficients for four phases, respectively (Table 1).

Treatment measures and discussions

Two proposals were chosen in the initial stage (Fig. 6). One is grouting from gateway, the other is grouting from the surface. The second proposal was chosen in order to keep safe.

First, a cut-off wall was built in the gateway which was 50.0 m apart from the water inrush point (Fig. 7). Then, grouting boreholes were drilled from the ground surface, drilling through the gateway, and throwing aggregate and grouting. The cut-off wall with the thickness of 15.0 m was constructed in the crossheading, 50 m away from the water inrush point. And, at the bottom of the wall, three large diameter pipelines were buried for catchments, with high-pressure valves set outside. In order to speed up the progress, the method of rapid reinforcement of loose stone with polyurethane is adopted. Moreover, reinforcements were laid in the wall to enhance its overall strength (Fig. 8). Meanwhile, four grouting boreholes were designed and drilled, and each borehole was drilled vertically (as shown in Fig. 7), where borehole 1 and borehole 2 were drilled through the gateway to throw aggregate and grouting, and borehole 3 and borehole 4 both were drilled into the Ordovician limestone aquifer to plug the water source.

Borehole 1 and borehole 2 were drilled firstly until drilling through the gateway. Then, close the valve of the pipe in the cut-off wall, and to throw aggregate from the boreholes. Aggregate consisted of the stone with diameter lower than 0.5 mm, coarse sand composition. Then, grouting was carried out from the boreholes using the slurry, which made up of water and cement-based material, fly ash, and sawdust as well. After that, Borehole 3 and borehole 4 were drilled, the main grouting materials were water and cement. Table 2 lists the statistics of the grouting materials.

Figure 9 shows the variation of the water level of Ordovician limestone aquifer after grouting; the water level rose to 6 m since the treatment completed and rose to 9 m 15 days after that, indicating that the water level of the water source increased continuously after treatment. After that, no water inrush incident happens at the gateway or working face.

The phenomenon also shows that this water inrush through fault delayed in time, which agreement with other researchers (Qiao et al. 2013; Huang et al. 2014). Thus, it is necessary to realize that it may evolve into a water inrush disaster when turbid water was observed in the fault. And then, observations should be timely carried out and evacuate miners.

Conclusions

This paper presents an investigation on a water inrush accident through a fault in Tianzhuang coal mine, Shandong Province, China. According to the water flow and phenomenon information obtained at mine site, four phases can be proposed, i.e., flow rate steady increase phase, rapidly increase phase, decrease phase, and steady phase, representing permeability and fracture changing characteristics and variation of water level of the source aquifer. We successfully control the water-rush accident using grouting from surface. In addition, it is suggested to pay attention to the phenomenon of early water inrush from fault, because many water inrush through faults delay in time.

References

Babiker M, Gudmundsson A (2004) The effects of dykes and faults on groundwater flow in an arid land: the red sea hills, Sudan. J Hydrol 297:256–273

Caine JS, Evans JP, Foster CB (1996) Fault zone architecture and permeability structure. Geology 24(11):1025–1028

Huang Z, Jiang ZQ, Qian ZW et al (2014) Analytical and experimental study of water seepage propagation behavior in the fault. Acta Geodyn Geomater 11:361–370

Huang Z, Jiang ZQ, Tang X, Wu XS et al (2016) In situ measurement of hydraulic properties of the fractured zone of coal mines. Rock Mech Rock Eng 49:1–7

Johnsen Ø, Chevalier C, Lindner A et al (2008) Decompaction and fluidization of a saturated and confined granular medium by injection of a viscous liquid or a gas. Physical Rev E Stat Nonlinear Soft Matter Phys 78:051302

Li T, Mei T, Sun X, Lv Y et al (2013) A study on a water-inrush incident at Laohutai coalmine. Int J Rock Mech Min 59:151–159

Ma D, Rezania M, Yu HS et al (2017) Variations of hydraulic properties of granular sandstones during water inrush: effect of small particle migration. Eng Geol 217:61–70

Miller FP, Vandome AF, Mcbrewster J (1945) Darcy–Weisbach equation. Alphascript Publishing

Mukai A, Fujimori K (2007) Secular change of permeability in the fracture zone near the Nojima fault estimated using strain changes due to water injection experiments. Tectonophysics 443:193–199

Niebling M, Toussaint R, Flekkøy EG et al (2012) Dynamic aero fracture of dense granular packings. Phys Rev E Am Phys Soc 86:061315

Nikuradse J (1932) Laws of turbulent flow in smooth pipes. Regularity of Turbulent Flow in Smooth Pipes

Qiao W, Hu G, Li WP (2013) Experimental study on the conversion from seepage to flow of water inrush aroused by fault activation. J Min Saf Eng 30:30–37

Sui W, Liu J, Yang S, Chen Z et al (2011) Hydrogeological analysis and salvage of a deep coalmine after a groundwater inrush. Environ Earth Sci 62:735–749

Wu Q, Zhu B, Liu S (2011) Flow-solid coupling simulation method analysis and time identification of lagging water-inrush near mine fault belt. Chin J Rock Mech Eng 30(1):93–104

Zhang J (2005) Investigations of water inrushes from aquifers under coal seams. Int J Rock Mech Min 42:350–360

Zhang R, Jiang Z, Zhou H, Yang C, Xiao S (2014) Groundwater outbursts from faults above a confined aquifer in the coal mining. Nat Hazards 71:1861–1872

Acknowledgements

This study was supported through funding from the National Natural Science Foundation of China (Grant No. 41602299 and 41702326) and the State Basic Research and Development Program of China (Grant No. 2013CB036003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

• An underground water inrush accident at Tianzhuang coal mine was studied.

• We observed flow data during the water inrush accident.

• Flow evolution course during water inrush accident was proposed.

• This water inrush accident was successfully controlled by the proposed treatments.

Rights and permissions

About this article

Cite this article

Qian, Z., Huang, Z. & Song, J. A case study of water inrush incident through fault zone in China and the corresponding treatment measures. Arab J Geosci 11, 381 (2018). https://doi.org/10.1007/s12517-018-3727-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-018-3727-8