Abstract

Groundwater outburst has an impartible relationship with geological structures such as water-conducting faults, which are widely distributed in north China. In order to study the seepage property and mechanism of water outburst from the faults above a confined aquifer in the coal mining, the simulation model of ground water inrush for fault was designed. The water outburst parameters, such as water inflow, permeability, seepage velocity, porosity and other variables under different material combination and water pressures, were obtained; the research results indicate as follows: (1) The changes of the water inflow can be divided into three stages, i.e., the water inflow slowly increases at the early stage, rapidly increases at the middle stage and keeps unchanged at the late stage. (2) The seepage process can be represented by the seepage combination types, which are composed of pore flow, fissure flow and pipe flow, and the seepage changes not only with time but also with different conditions. (3) Mining would lead to the reactivation of faults and further enhance the permeability of fault zone potentially. The tiny granules in fault would be eroded and moved to exterior as the time under the high water pressure and lead to the change of porosity parameters. In this case, the seepage velocity would increase ceaselessly, and then the seepage would convert into pipe flow and finally lead to water inrush accidents.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Many coal mines are threatened by various kinds of groundwater during coal extractions in China (e.g., Wang and Liu 1989; Li 1996; Wang and Park 2003; Wu et al. 2004; Zhang 2005). The most serious three main types of possible disasters affecting the safe operation of coal mines are water inrushes from the Ordovician limestone under the Permo-Carboniferous coal seams in northern China. The Ordovician limestone is a confined karst aquifer containing an abundant supply of water and with a very high water pressure (e.g., Bieniawski 1982; Zhang and Shen 2004; Zhang and Peng 2005; Zhang and Qu 2008). Recent laboratory and field investigations show that high-pressure groundwater can break through seam floors and burst into mining workings due to the characteristics of aquifer, plus mining-induced strata failure and inherent geological structures (such as water-conducting faults) (e.g., Li and Zhou 2006; Wu and Zhou 2008; Li et al. 2011; Zhu and Wei 2011; Zhang et al. 2013; Zhu et al. 2013). Besides, with the coal mining extending to deeper ground, there are an increasing number of water outburst accidents during coal extractions. In these accidents, water outburst caused by fault often results in serious damage, involving both the loss of lives and significant economic loss.

According to the incomplete official statistics, more than 80 % of mine water outburst accidents in underground coal mines are related to the fault zones (e.g., Li 1996; Wang and Miao 2006). The fault fracture zones as an important water outburst channel, it can be concluded that the configuration of existing faults is the key factor determining the safety of coal mining with underlying aquifers. At present, the research on water outburst mechanism is mainly concentrated on either reaction of fault or damage of floor strata (Babiker and Gudmundsson 2004; Caine et al. 1995; Zhu and Wei 2011). They did not involve the configuration structure of broken zone and the change process of seepage law in the water inrushes of faults.

In this paper, the seepage property and mechanism of water outburst from the faults above a confined aquifer have been studied. The study establishes a similar material simulation model of ground water inrush to describe the behavior of water seepage flow in coal-seam-floor-containing fault and summarizes the relationship between the mass of the fault and water seepage instability.

2 Experimental

2.1 Equipment and method

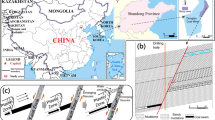

The paper focuses on the investigation of mechanism and modeling of groundwater bursting along fault zones, which is performed through a case of the working face NO. 32071 in Peigou Coal Mine. The Peigou Coal Mine is located in Zhengzhou City, Henan Province, north China. In the working face NO. 32071, there was a fault F32-9 cut through the beneath layers (Fig. 1). The fault displacement varied from 5 to 10 m, and it was a normal fault with a dip angle of 70°. A cross section of engineering geological model is shown in Fig. 2. According to the geometric ratio of the simulation model, the similarity model of groundwater inrush for fault was designed (Fig. 3). The main part of the model measured 600 mm in height and 250 mm in diameter. The channel, which was the most critical criterion to design for simulating water outburst above a confined aquifer, was built by using the plank and cement mortars (Fig. 4). Besides, the cement mortars served as the nearly impermeable material were obtained using the water–cement ratio at 0.30 and cement–sand ratio at 0.4. The uniaxial compressive strength for 7 day was about 46 MPa.

According to the field investigation of engineering geological conditions for fault, the rock mass of fault fracture zone is composed of rock skeleton and fine filling granules (Fig. 5). Combined with the laboratory testing results, the fillings, such as the clay minerals, account for 50~70 % of the total volume in the fault. Therefore, the filling materials, which were selected to simulate the process of water outburst from fracture zone, were configured using the fractured limestone as skeletons and the fractured mudstone as the fillings. The fractured limestone contained the granule size of 10~20 mm, and the fractured mudstone contained the granule size of 0~2 mm and 2~5 mm in the proportion of 1–1. Thus, the mixture of materials could simulate the water outburst of fault fracture zone in different conditions (Table 1).

2.2 Data processing

The data such as water pressure, seepage length, water inflow, granule flow ratio, porosity, seepage velocity, permeability and other variables are collected in the course of the seepage test. The granule flow ratio is calculated by

where Δm n is the granule flow mass which is collected in the seepage test, and Δt is the time which is 10 s in the seepage test. The porosity is calculated as follows:

where ρ is the density of coal gangue. Then increase in porosity in each time period is calculated by

where ϕ 0 is the initial porosity, a and b are the length and width of section of water inrush channel, and h is the height of water inrush channel. The seepage velocity is expressed as

where Q is the water inflow, k is the permeability, η is the dynamic viscosity of the fluid, and p is the water pressure.

For the Darcy flow, we have

according to Eq. (4) to Eq. (5), the permeability of fracture zone is calculated by

2.3 Results and discussion

2.3.1 Changes of water inflow

Based on the observations from the physical modeling, the changes of the water inflow can be divided into three stages, i.e., the water inflow slowly increases at the early stage, rapidly increases at the middle stage and keeps unchanged at the late stage (Fig. 6). Comparing Figs. 6 and 7, the permeability could also be classified as three stages, i.e., the initial seepage stage, seepage mutation stage and stable seepage stage (Fig. 7). At the first stage, the water inflow of fault increased slowly, and the increases slow down. This is due to the fact that the permeability and porosity increase gradually with migration of a small amount of granules. At the second stage, the water inflow increased rapidly in a very short time. The reason is that a large amount of granules in fracture zone is eroded and transported under the effect of fluid as the time, the porosity, permeability and granule migration velocity increase rapidly, and eventually, a main seepage channel is formed. At the third stage, the water inflow in the fault maintained steady values with the quick decrease in granule migration velocity after the seepage mutation, and both the permeability and porosity tended to be stable.

2.3.2 Changes in loss of quantity of fillings

The relationship between granules’ flow ratio and time is shown in Fig. 8; all the loss of quantity of fillings reached maximum in a short time, and then it decreased quickly in the water seepage of fault. The microfissures or voids in the fracture zones appeared extending under the erosion of water flow, as shown in Fig. 9. In the initial stage, the filling granules, which increased slowly with the less amount of granules’ erosion, could cause the changes of porosity slightly. As the water inrush time went on, the fine particulates’ migration velocity, loss of quantity, permeability and water inflow increased rapidly, which results in the change of porosity quickly. As a large number of filling granules were eroded and carried away by water as the time, only the rock skeleton and larger granules, which did not were eroded and transported, were left. Then, there were no mass changes in the fracture zones, and the porosity maintains steady values after a period of time.

2.4 Discussion on the influence factors of groundwater inrush

2.4.1 Material combination

Comparing Fig. 10a, b with the proportion of fine particulates becoming higher in fault, the permeability of fault increased with time gradually, and the water inflow also increased. As to the seepage time, when the ratios of rock skeleton and fillings were 1–1, 1–2 and 1–4, the steady seepage times were 90, 70 and 50 s, respectively. In addition, it was observed that with the proportion of fine particulates becoming higher, the stable seepage time decreased gradually, and the stable water inrush time also decreased. This is due to the fact that the higher the proportion of fine filling particulates in fault are, the more quantity of fillings are soured away by water under the effect of water erosion and led to great changes of porosity for fracture zone. Figure 10c gives the relationship curves between granule flow ratio and time under different material combinations. For the different types of faults, with the fillings increased gradually, the loss of quantity of filling granules increased gradually. Meanwhile, the steady seepage time would be shortened gradually. This phenomenon can be explained as follows: The more the proportion of fillings in fault are, not only the more the fine filling granules that could be eroded and transported are under the high-pressure water, but also the fine fillings could cause the smaller initial porosity and poor permeability in fault. And then at the bottom of the fault could be quickly gathered large energy and made a lot of filling granules be separated from the fault in a short time. The relationship curves between porosity and time under different material combinations are shown in Fig. 10d. For the different types of faults, within 0~20 s, with the fillings increased, the initial porosity increased considerably in the water seepage of fault. After 20 s, the porosity that was caused by the increasing fillings increased rapidly, making the porosity becoming larger for fault that contained higher proportion of fillings after the seepage mutations.

2.4.2 Water inrush pressure

Figure 11 presents the relationship between the seepage parameters and time under different pressures. It could be observed that the water inflow, permeability, granule flow ratio and porosity increased more slowly and that growth is very smaller under low pressures. With the increasing water pressure, the water inflow and permeability increased more rapidly, and the growth is very larger, when the water inrush pressures were 0.2, 0.4 and 0.6 MPa and the time for steady seepage were 80, 70 and 60 s, respectively, as shown in Fig. 11a, b. It can be seen from Fig. 11c that with the increasing water pressure, the fine granules’ flow ratios increased to the peak rapidly, and the time for the peak were 50, 40 and 30 s, respectively, and then the increase slows down. In addition, for the porosity, as shown in Fig. 11d, it could be observed that the porosity changed slowly under the low pressures, but with the water pressure increasing rapidly, not only the porosity increased, but also the time for the peak would be shortened gradually.

Thus, it is reasonable to conclude that the mass flow of fillings is the key factor determining the steady seepage of fault with underlying aquifers under the different pressures. This is due to the fact that when the water pressures increase gradually in fault, the water erosion ability and migration velocity become more stronger, which leads to more quantity of fillings that are soured away by water.

3 Analysis of the seepage mutation mechanism

Based on the test results that were described above and combined with the characteristic of a large number of water inrush cases for fault, the research results indicate that the filling granules are not eroded and transported at the beginning of water bursting in fault fracture zones. The type of void is mainly pore, and the water inflow increases slowly; then the seepage, which will be approximately regarded as pore flow, obeys the Darcy law. The tiny granules in fault would be eroded and moved to exterior as the time under the high water pressure and lead to the changes of the porosity and permeability parameters. In this case, the seepage would convert into the fissure flow, resulting in a greater permeability and an increasing amount of water constantly. In addition, the increasing permeability may in turn cause a greater seepage velocity and carrying capacity of water, which may result in more granules being eroded and moved with the water flow. The penetration ability, porosity and water inflow constantly increase by such a variable mass interaction process until the tiny fillings remain unchanged. Then, the porosity and permeability and water inflow tend to be stable. Meanwhile, the water inrush channel of fault can be regarded as the karst pipe. And then the seepage converts into the pipe flow, which may result in a very large water inrush. The process can be represented by the seepage combination types, which are composed of the pore flow, fissure flow and pipe flow. In addition, the water inrushes are not the same under different material combination and water pressures. Therefore, the seepage changes not only with time but also with different conditions.

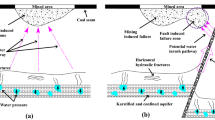

When mining excavations are made, the redistribution of the stress field leads to the reactivation of faults and potentially further enhances the permeability of fault zone. Hence, a potential pathway for groundwater outburst is created between fault and the damage zone in floor strata. In addition, the tiny filling granules in fault zones are eroded and moved as the time under the high water pressure and result in the seepage conversion, which contain the seepage types of pore flow, fissure flow and pipe flow. And finally, the water inrush accidents would be brought about. It can be said that the mining fracture characteristics, high confined water and migration of tiny filling granules have a complicated nonlinear coupling relationship, and the water seepage is a nonlinear dynamic system that is unstable and evolves into water inrush in rock strata. According to the theory of nonlinear dynamics, when the control parameters in the nonlinear system satisfy a certain condition, the structure instability contains bifurcation and mutation in the fault system will take place. Thus, the loss of quantity of filling granules is a key factor to lead to seepage conversion of fault. The schematic diagram of water inrush is shown in Fig. 12.

4 Conclusions

The process of water inrush from the water-conducting faults above a confined aquifer was simulated, which included the parameters, such as porosity, seepage, permeability and water inflow. The research results can be drawn as follows:

-

1.

The changes in the water inflow can be divided into three stages, i.e., the water inflow slowly increases at the early stage, rapidly increases at the middle stage and keeps unchanged at the late stage.

-

2.

The seepage process can be represented by the seepage combination types, which are composed of pore flow, fissure flow and pipe flow, and the seepage changes not only with time but also with different conditions.

-

3.

Mining would lead to the reactivation of faults and further enhances the permeability of fault zone potentially. The tiny granules in fault would be eroded and moved to exterior as the time under the high water pressure and lead to the change of porosity parameters. In this case, the seepage velocity would increase ceaselessly, and then the seepage would convert into pipe flow and finally lead to water inrush accidents.

References

Babiker M, Gudmundsson A (2004) The effects of dykes and faults on groundwater flow in an arid land: the Red Sea Hills, Sudan. J Hydrol 297:256–273

Bieniawski ZT (1982) Improved design of coal pillars for US mining conditions. In: Proceedings of the first international conference on stability in underground mining, Vancouver, Canada, pp 8–16

Caine JS, Evans JP, Foster CB (1995) Fault zone architecture and permeability structure. Geology 24:1025–1028

Li LJ (1996) Study of water in-rush mechanism, Ph.D. thesis, China University of Mining and Geology, Xuzhou, People’s Republic of China

Li GY, Zhou WF (2006) Impact of karst water on coal mining in North China. Eng Geol 49:449–457

Li LC, Yang TH, Liang ZZ et al (2011) Numerical investigation of groundwater outbursts near faults in underground coal mines. Int J Coal Geol 85:276–288

Wang ZY, Liu TQ (1989) Study of water in-rush mechanism of coal seam floor strata. Coalf Geol Surv 1:9–36 (in Chinese and abstract in English)

Wang LG, Miao XX (2006) Numerical simulation of coal floor fault activation influenced by mining. J Chin Univ Min Technol 16:385–388

Wang JA, Park HD (2003) Coal mining above a confined aquifer. Int J Rock Mech Min Sci 40:537–555

Wu Q, Wang M, Wu X (2004) Investigations of groundwater bursting into coal mine seam floors from fault zones. Int J Rock Mech Min Sci 41:557–571

Wu Q, Zhou WF (2008) Prediction of groundwater inrush into coal mines from aquifers underlying the coal seams in China: vulnerability index method and its construction. Eng Geol 56:245–254

Zhang JC (2005) Investigations of water inrushes from aquifers under coal seams. Int J Rock Mech Min Sci 42:350–360

Zhang JC, Peng SP (2005) Water inrush and environmental impact of shallow seam mining. Eng Geol 48:1068–1076

Zhang YS, Qu YX (2008) Some problems of karstic collapse posts in North China type coalfields. J Eng Geol 8:35–39 (in Chinese and abstract in English)

Zhang JC, Shen BH (2004) Coal mining under aquifers in China: a case study. Int J Rock Mech Min Sci 41:629–639

Zhang R, Jiang ZQ, Sun Q et al (2013) The relationship between the deformation mechanism and permeability on brittle rock. Nat Hazard 66:1179–1187

Zhu WC, Wei CH (2011) Numerical simulation on mining-induced water inrushes related to geologic structures using a damage-based hydro mechanical model. Eng Earth Sci 62:43–54

Zhu SY, Jiang ZQ, Cao DT et al (2013) Restriction function of lithology and its composite structure to deformation and failure of mining coal seam floor. Nat Hazard 68:483–495

Acknowledgments

The authors wish to acknowledge the following funding for the supporting of this study: the State Basic Research and Development Program of China (No. 2013CB036003), the PAPD (A Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions) and the outstanding innovation PhD student scholarship of China University of Mining and Technology(2013–2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, R., Jiang, Z., Zhou, H. et al. Groundwater outbursts from faults above a confined aquifer in the coal mining. Nat Hazards 71, 1861–1872 (2014). https://doi.org/10.1007/s11069-013-0981-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11069-013-0981-7