Abstract

The Cerchar abrasivity index (CAI) is one of the most widely known index method for identification of rock abrasivity. It is a simple and fast testing method providing reliable information on rock abrasiveness. In this study, the relationships between the CAI and some rock properties such as uniaxial compressive strength (UCS), point load strength, Brazilian tensile strength and Schmidt rebound hardness, and equivalent quartz content (EQC) are examined. The relationships between the CAI and drill bit lifetime is also investigated and the type of drill bit wear observed is mentioned. Additionally, the CAI is modeled using simple and multiple linear regression analysis based on the rock properties. Drill bit lifetime is also modeled based on the CAI. The results show that the CAI increases with the increase of the UCS, point load strength, Brazilian tensile strength, L-type and N-type Schmidt rebound hardness, and the EQC. It is concluded that the higher and the lower bit lifetime are obtained for marl and andesitic-basaltic formation, respectively. Moreover, flushing holes, inserted button, button removal, and failures of button on the bits are determined as the type of drill bit wear. The modeling results show that the models based on the UCS and the EQC give the better forecasting performances for the CAI.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Drilling machines are commonly used in the rock excavations. Tools are the most important materials of this equipment. Various types of cutting bits or tools are used to penetrate or drill and break the rock (Rostami 2011; Hamzaban et al. 2014a). Their lifetime is mainly related to the rock abrasiveness depending on rock types and presence of abrasive minerals in the rock. Therefore, many tests have been developed and used in order to identify the rock abrasivity (Verhoef 1997; Ghasemi 2010). These tests include Cerchar abrasivity test, Taber abrasion, the Laboratoire Central des Ponts et Chaussees (LCPC) abrasivity test, abrasion value or abrasion value cutter steel test, and Schimazek’s wear index (Dahl et al. 2012; Hamzaban et al. 2014b; Rostami et al. 2014).

Cerchar abrasivity test is one of the most widely used rock abrasion tests suggested by the International Society of Rock Mechanics (ISRM). It can be effectively used for the estimation of bit life in various mining, drilling and tunneling applications (Singh et al. 1983; Al-Ameen and Waller 1994; Hamzaban et al. 2014a; Alber et al. 2014; Ulusay 2015). Many studies investigating the effect of various factors on Cerchar abrasivity index (CAI) have been documented in relevant literature.

West (1989) indicated that CAI shows good correlation with the abrasive mineral content of a rock. The researcher determined a high degree of correlation with CAI and Mohs’ hardness. Yarali et al. (2008) found that rock abrasiveness is a function of the amount of abrasive minerals, average grain size of quartz, cement type, and cementation. Yarali (2005) showed that quartz content is the most dominant rock property affecting CAI. Al-Ameen and Waller (1994) indicated that CAI is largely influenced by rock strength. Suana and Peters (1982) concluded that CAI increases with the equivalent quartz content. Plinninger et al. (2003) concluded that Young’s modulus and equivalent quartz content are two important factors for evaluating CAI.

In this study, relationships between CAI and some rock properties were investigated. Based on the rock properties, new prediction models for CAI are developed using simple and multiple regression analysis. The relationships between CAI and drill bit lifetime are also investigated and drill bit lifetime is modeled based on CAI. Additionally, the types of drill bit wear were also mentioned. The developed models were verified using some statistical approaches including the F and t tests.

Field studies

This study was carried out at Cankurtaran and Salmankas tunnels in Turkey. The Cankurtaran tunnel is a highway tunnel under construction which is located in the Artvin province, Turkey. It will be one of the longest highway tunnels of Turkey (5228.00 m) when the construction is finished. The tunnel is built in two tubes and each tube is containing two lanes of traffic in each direction. The Salmankas tunnel is also a highway tunnel under construction which is located on the border of Trabzon and Bayburt provinces, Turkey. The tunnel is built with two tubes each 4150.00 m in length. The locations of the tunnels are shown in Fig. 1.

The Salmankas tunnel is connecting the provincial roads on the route from Araklı, Trabzon via Dagbasi. The rocks of the Dagbasi platform cover an area of approximately 25 km2. The platform belonging to the northern zone of the eastern pontides is located about 75 km south of Trabzon. This area comprises late cretaceous volcanic and pyroclastic rocks at the top and lower Jurassic volcanic and pyroclastic rocks at the bottom. Cretaceous sediments are intercalated into the volcanic series. Late cretaceous volcanisms are dacite and rhyolite in composition. Phenocrysts comprise plagioclase, quartz, alkaline feldspar, biotite, and hornblende (Aydınçakır 2006; Kaygusuz and Aydınçakır 2009). A detailed description of the composite stratigraphic sections of the study areas is presented in Fig. 2.

Cankurtaran tunnel formation passes through four lithologic units. These formations are Subasi Sırti formation, Cankurtaran formation, Şenkaya formation, and the Kabaköy formation. The Kabaköy formation, which rests on Late Cretaceous units, consists of andesitic and basaltic lavas and pyroclastics with lesser amounts of sandstones, sandy limestones, marl, and tuffs (Yılmaz et al. 1996; Kırmacı and Akdag 2005). The Cankurtaran formation is represented by reddish pelagic limestone. The unit includes terrigenous clastics, rarely olistostromal levels, and slump structures. The unit does not contain any volcanic interbeds. But, it is cut by basalt, diabase dykes, and sills. Lithologic features of the unit contain yellowish, in places greenish or reddish, greenish-gray, and gray-beige limestones—thick-bedded-type limestones. The hanging wall and footwall of the Cankurtaran formation contain medium- to thin-bedded marls (Yılmaz et al. 1996; Kaya 2012). The Şenkaya formation is composed of mainly thin-bedded marls. The unit contains dark-gray claystone and red and gray marls with thin layers. The unit is cut by dikes of basalt, diabase dyke and sill. The formation is covered by the Kabaköy formation. The Subasi formation mainly consists of volcanic-sedimentary rocks. The unit is made up of volcanic breccia, massive agglomerated tuff, and andesitic pyroclastic at the lower and upper levels. The unit covers the Cankurtaran tunnel portal. The basal conglomerate of the Subasi formation consists of sandstone, tuff, marl, limestone, and claystone (see Fig. 2) (Kaya 2012).

Rock samples

Rock samples from 43 different areas of the tunnels were taken for the laboratory tests. Table 1 shows the names of the rocks samples and tunnel lengths (m), specifying the locations for block sampling.

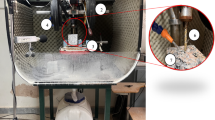

On the tunnel faces, Schmidt rebound hardness measurements were taken using two kinds of test devices (N-type and L-type impact energy of 2.207 and 0.735 Nm, respectively). The tests were performed in accordance with ASTM’s (2005) suggested methods. The tunnel area on which the measurements were taken is shown in Fig. 3.

In order to determine the lifetime of drill bit in the tunnels, measurements were taken from three jumbo machines in the tunnel face. The jumbo machines are Atlas Copco Rocket Boomer 282, Sandvik DD320, and Tamrock Axera6. The properties of the machines are presented in Table 2. The bits having the same number of buttons (9) and a diameter of 45 mm are selected in order to provide similar drilling conditions. The bit lifetime is calculated from the equation (Eq. 1) proposed by Thuro (1997):

Laboratory studies

For the laboratory tests, core samples were prepared (see Fig. 4). Mechanical properties, the EQC, and the CAI of the rocks were determined.

Uniaxial compressive strength

The uniaxial compressive strength (UCS) tests were performed on the prepared core samples having a length to diameter ratio of 2:2.5. The stress rate was applied within the limits of 0.5–1 MPa/s and five core samples from each rock were subjected to the UCS test. The tests were carried out using an electronic-hydraulic Servo-controlled stiff press testing machine. The tests were carried out according to the method suggested by ISRM (1979) and ASTM (2010).

Brazilian tensile strength

The Brazilian tensile strength test method consists of loading a disk of the rock until failure occurs across the diametrical axis. The disk was prepared from 54.7 mm (NX) core diameter samples with a length to diameter ratio of 1:2. A loading rate of 200 N/s was applied. The tests were carried out using an electronic-hydraulic Servo-controlled stiff press testing machine. The test was conducted on ten samples from each rock type and the results were averaged. The tests were performed in accordance with the method suggested by ISRM (1981) and ASTM (2010).

Point load strength

The point load strength test is intended as an index test for the strength classification of rock materials. The test was performed on core samples having a length to diameter ratio of 1:2. The load was steadily increased such that failure occurs within 10–60 s. The test is invalidated if the fracture surface passes through only one lading point. The point load strength test was repeated at least ten times for each rock type, and the average value was recorded as the point load strength. The tests were carried out according to the methods suggested by ISRM (1985).

Cerchar abrasivity index

The CAI was carried out using the original Cerchar apparatus. The original layout features a vice holding the rock specimen and a testing lever that is directly connected to a steel stylus. The steel stylus has a 90° conical tip and Rockwell hardness of HRC 54–56. The steel stylus is applied to the surface of a rock specimen under a static force of 70 N and scratched over the rock surface by moving the lever at a velocity of 10 mm/s. After the test, the wear surface of the steel stylus is measured under a microscope to an accuracy of 0.01 mm. The Cerchar test was applied to sawn specimens. Five scratches were made for every specimen and the mean of these readings were recorded as the CAI (Plinninger et al. 2003; Alber et al. 2014). Measurement was executed by side view settings as shown in Fig. 5.

Equivalent quartz content

The quartz content and other mineral contents of the 43 rock samples were obtained by microscopic examination. The equivalent quartz content of the rock samples was calculated as proposed by Thuro and Plinninger (2003) (Eq. 2):

where EQC is equivalent quartz content (%), A is mineral amount (%), R is Rosiwal abrasiveness (%), and n is number of minerals.

Results and discussion

Relationships between Cerchar abrasivity index, rock properties, and drill bit life time

The experimental results of the study are summarized in Table 3. The relationships between CAI and the mechanical rock properties are depicted in Fig. 6. The linear correlations were found between CAI and the mechanical properties. It can be seen that CAI increased with the increase of UCS, point load strength, Brazilian tensile strength, and L- and N-type Schmidt rebound hardness. It can be noted that the result is in agreement with the previous studies. The literature reviews clearly showed that CAI is highly influenced by the strength properties of the rock (Al-Ameen and Waller 1994; Plinninger et al. 2003; Kahraman et al. 2010; Deliormanlı 2012).

The relations between the CAI and the EQC are depicted in Fig. 7. The linear correlations were found between the CAI and the EQC. It can be seen that CAI increased with the increase of EQC. This result is in agreement with earlier investigations. Suana and Peters (1982), West (1989), and Yarali et al. (2008) found a good correlation between CAI and the quartz content of the rock. They stated that quartz content and equivalent quartz content are the important factors governing CAI. Similar results were found by Fowell and Abu Bakar (2007), Ghasemi (2010), and Moradizadeh et al. (2016). Plinninger et al. (2003) stated that the combination of Young’s modulus and the EQC of rock have a good correlation with CAI.

Figure 8 shows the relationships between drill bit lifetime and CAI for different rock types during conventional drill and blast tunneling. As can be seen from the related figure, there is an exponential relation between bit lifetime and the CAI. The correlation coefficient of r = 0.72 indicates moderate relations between two variables. The higher bit lifetime were obtained for the marl formation while the lower values were obtained for the andesitic and basaltic formation. Fowell et al. (1987) presented that the amount of bit lifetime depends on rock properties, abrasive minerals, and bit material, as well as discontinuities of rock mass and operational conditions. Natau et al. (1993) found that the material strength and the quartz content are important for estimating the bit wear. Persson et al. (1994) mentioned that bit wear increases with the content of quartz or other hard minerals in the rock. However, Plinninger et al. (2002a, 2002b) showed a bad relationship between Cerchar abrasivity index and drill bit lifetime. The researchers revealed that this model may be used for a quick and cheap estimation of a rock’s abrasivity but appears to be not suitable for a more precise calculation of drill bit lifetime.

Apart from rock strength, mineral shape and grain size are much affected on abrasive rock. The grain sizes of crystalline rocks with sharp edges are especially abrasive. Rounded quartz grains are usually showed to be less abrasive than are irregularly shaped ones (Feniak 1944; Persson et al. 1994; Oksogoev 2005).

The drill bit wear type observed on the bits was also investigated. The drill bit wear types determined are shown in Fig. 9. It can be said that flushing holes, inserted button, button removal, and failures of button on the bits were the types of wear observed. Thuro (1997) Schormair et al. (2006) demonstrated that the shape of the button and the design of the bit geometry and flush holes have a strong influence on the bit lifetime.

Modeling of the CAI and the bit lifetime

Based on the relationships between CAI and the mechanical rock properties, as well as the EQC, the following models (Eq. 3–9) were developed for the estimation of CAI using simple linear regression analysis (SLRA). The determination coefficients (R 2) of the models range from 0.67 to 0.75. The model based on UCS showed the better forecasting performance over the models including other rock properties.

where σ c is the uniaxial compressive strength (MPa), Is 50 is the point load strength (MPa), σt is the Brazilian tensile strength (MPa), and R L and R N are L- and N-type Schmidt rebound hardness, respectively. EQC is equivalent quartz content.

Using the relationships between CAI and the bit lifetime, the model (Eq. 9) presented below was developed for the estimation of the bit lifetime. The R 2 value for the model is determined as 0.52:

where BL is the bit lifetime (m/bit) and CAI is the Cerchar abrasivity index.

Validation of the proposed models was checked by the F and t tests. The F and t tests are carried out for the confirmation of the correctness of the whole model and independent variable involved in the model, respectively (Aydin et al. 2014). If the t value calculated by the SPSS is greater than the tabulated t value (obtained from t distribution table), the independent variable in the model is considered to be significant. In case of the whole model significance, the F test is used. If the F calculated by SPSS is greater than the tabulated F value (obtained from F distribution table), the model is accepted as valid (Berman and Wang 2011; Aydin et al. 2013). Validation test results of the simple regression models (SRMs) can be seen from Table 4; at the 95% confidence level, the computed t values are greater than the tabulated t values, suggesting that the developed models are statistically valid. At the confidence level of 95%, the computed F values are greater than the tabulated F values, indicating the correctness of the models.

To be able to develop a model with higher determination coefficient, multiple linear regression analysis (MLRA) is also employed for the data using a statistical package SPSS 20. However, the MLRA could not produce a powerful model for the prediction of CAI. The determination coefficient of the best model obtained with MLRA was 0.76 which is slightly higher than the model based on UCS. The developed model is presented (Eq. 10). The MLRA is applied for predictable CAI using UCS and EQC and the analysis results are showed in Table 5.

where σ c is the uniaxial compressive strength (MPa), and EQC is equivalent quartz content (%).

In the current study, modeling studies were carried out for the rocks having CAI between 0.43 and 3.15. It can be noted that this is the first half of the CAI range in the Cerchar classification. Therefore, the models could provide better forecasting performances for the rocks having similar ranges of CAI.

Conclusions

The CAI is usually used to show rock abrasivity for prediction of drill bit lifetime and tool cost in excavation and drill applications. The following conclusions could be drawn from the present study:

-

It was concluded that CAI increased with increasing UCS, point load strength, Brazilian tensile strength, L-type and N-type Schmidt rebound hardness, and the EQC. The result of the study has confirmed that CAI is influenced by both rock strength and total abrasive mineral content.

-

An exponential relation between the bit lifetime and the CAI was determined. The higher and the lower bit lifetime were obtained from marl and andesitic-basaltic formation, respectively. It can be mentioned that the material strength parameters and abrasive mineral content of the rock is important for estimating the bit lifetime.

-

The modeling results of the simple regression analysis showed that the models based on the UCS give the better forecasting performances for the CAI.

-

It was revealed that a powerful model for the prediction of CAI could not be produced using the MLRA. The determination coefficient of the best model (see Eq. 10) obtaining with MLRA was 0.76 which is slightly higher than the model based on UCS.

In this study, experimental and modeling studies were carried out for the rocks having CAI below 3.15. Therefore, the models could provide better forecasting performances for the rocks having similar ranges of CAI. For further studies, it is recommended carrying out studies on rocks having relatively higher CAI. Additionally, the estimation of CAI can also be investigated with neural networks or another metaheuristic search. The results of the different methods could be compared with the simple and multiple linear regression analysis to see the performance of the proposed models.

References

Al-Ameen SI, Waller MD (1994) The influence of rock strength and abrasive mineral content on the Cerchar abrasive index. Eng Geol 36:293–301

Alber M, Yarali O, Dahl F, Bruland A, Kasling H, Michalakopoulos TN, Cardu M, Hagan PC, Aydin H, Ozarslan A (2014) ISRM suggested method for determining the abrasivity of rock by the Cerchar abrasivity test. Rock Mech Rock Eng 47:261–266

ASTM (2010) Standard test method for compressive strength and elastic moduli of intact rock Core specimens under varying states of stress and temperatures. American Standarts for Testing and Materials, D7012–10, United States

ASTM (2005) Standard D 5873–05: standard test method for determination of rock hardness by rebound hammers method. Vol. 04.09. ASTM International, West Conshohocken

Aydin G, Karakurt I, Aydiner K (2013) Wear performance of saw blades in processing of granitic rocks and development of models for wear estimation. Rock Mech Rock Eng 46(6):1559–1575

Aydin G, Karakurt I, Hamzacebi C (2014) Artificial neural network and regression models for performance prediction of abrasive waterjet in rock cutting. Int J Adv Manuf Technol 75:1321–1330

Aydınçakır E (2006) Dağbaşı (Araklı-Trabzon) Granitoyidi ve Çevre Kayaçların Petrografik, Jeokimyasal ve Petrolojik Özelliklerinin İncelenmesi, M.Sc. Thesis, Karadeniz Technical University Trabzon, pp 121. Unpublished

Berman ME, Wang J (2011) Essential statistics for public managers and policy analysts, 3rd edn. CQ Press, Washington, p 321

Cerchar (1986) Centre d’Études et des Recherches des Charbonages de France. The Cerchar abrasiveness index, Verneuil

Dahl F, Bruland A, Jakobsen PD, Nilsen B, Grøv E (2012) Classifications of properties influencing the drillability of rocks, based on the NTNU/SINTEF test method. Tunn Undergr Space Technol 28:150–158

Deliormanlı AH (2012) Cerchar abrasivity index (CAI) and its relation to strength and abrasion test methods for marble stones. Constr Build Mater 30:16–21

Feniak MW (1944) Grain sizes and shapes of various minerals in igneous rocks. Geological Survey, Ottawa, pp 415–421

Fowell RJ, Hekimoğlu OZ, Altınoluk S (1987) Drag tools employed on shearer drums and Roadheaders. Turkey Mining Congress Ankara pp. 529–550

Fowell RJ, Abu Bakar MZ (2007) A review of the Cerchar and LCPC rock abrasivity measurement methods. In Proc. of the 11th Congress of the International Society for Rock Mechanics, Lisbon, Portugal, pp. 155–160

Ghasemi A (2010) Study of Cerchar abrasivity index and potential modifications for more consistent measurement of rock abrasion. Dissertation study, Pennsylvania State University

Hamzaban MT, Memarian H, Rostami J, Ghasemi-Monfared H (2014a) Study of rock–pin interaction in Cerchar abrasivity test. Int J Rock Mech Min Sci 72:100–108

Hamzaban MT, Memarian H, Rostami J (2014b) Continuous monitoring of pin tip wear and penetration into rock surface using a new Cerchar abrasivity testing device. Rock Mech Rock Eng 47:689–701

ISRM (1979) Suggested method for determining the uniaxial compressive strength and deformability of rock materials. Int J Rock Mech Min Sci Geomech Abstr 16:135–140

ISRM (1981) Rock characterization testing and monitoring ISRM suggested methods, suggested methods for determining hardness and abrasiveness of rocks. Part 3, pp 101–3

ISRM (1985) Suggested method for determining point load strength. Int J Rock Mech Min Sci Geomech Abstr 22:51–60

Kahraman S, Alber M, Fener M, Gunaydin O (2010) The usability of Cerchar abrasivity index for the prediction of UCS and E of misis fault breccia: regression and artificial neural networks analysis. Expert Syst Appl 37:8750–8756

Kaya A (2012) Cankurtaran (Hopa-Artvin) Tünel Güzergahının ve Çevresinin Jeoteknik Açıdan İncelenmesi, PhD Thesis, Karadeniz Technical University Trabzon, pp 218. Unpublished

Kaygusuz A, Aydınçakır E (2009) Mineralogy, whole-rock and Sr–Nd isotope geochemistry of mafic microgranular enclaves in Cretaceous Dagbasi granitoids, eastern pontides, NE Turkey: evidence of magma mixing, mingling and chemical equilibration. Chemie der Erde – Geochemistry 69(3):247–277

Kırmacı MZ, Akdag M (2005) Origin of dolomite in the Late Cretaceous–Paleocene limestone turbidites, eastern pontides, Turkey. Sediment Geol 181:39–57

Moradizadeh M, Cheshomi A, Ghafoori M, TarighAzali S (2016) Correlation of equivalent quartz content, slake durability index and Is50 with Cerchar abrasiveness index for different types of rock. Int J Rock Mech Min Sci 86:42–47

Natau O, Mutschler TH, Lempp CH (1993) Estimation of the cutting rate and the bit wear of partial- face tunnelling machines. Int Soc Rock Mech 3:1591–1596

Oksogoev AA (2005) Regimes with peaking in self-organized processes of the highly intensive materials processing. Chapter 9. In: İvanova VS, Novikov VU, Oksogoev AA (eds) Fractals, applied Synergetics and structure design, pp 125–158

Persson Per-A, Holmberg R, Lee J (1994) Mechanical drilling and boring in rock. Chapter 2. In: Rock Blasting and Explosives Engineering pp 25–54

Plinninger R, Kasling H, Thuro K, Spaun G (2003) Testing conditions and geomechanical properties influencing the Cerchar abrasiveness index (CAI) value. Technical note. Int J Rock Mech Min Sci 40:259–263

Plinninger RJ, Spaun G, Thuro K (2002a) Prediction and classification of tool wear in drill and blast tunneling. In Van.Roy & Jermy (eds), Proceedings 9th Int. IAEG Congress, Durban, South Africa 2226–2236

Plinninger RJ, Spaun G, Thuro K (2002b) Predicting tool wear in drill and blast. Tunnels Tunnelling Int Mag, p. 1–5

Rostami J (2011) Mechanical rock breaking. SME Mining Engineering Handbook, 3rd Edition, Chapter 7.1, Darling Peter (ed). Society for Mining, Metallurgy and Exploration Inc. p. 417–434

Rostami J, Ghasemi A, Gharahbagh EA, Dogruoz C, Dahl F (2014) Study of dominant factors affecting Cerchar abrasivity index. Rock Mech Rock Eng 47:1905–1919

Schormair N, Thuro K, Plinninger R (2006) The influence of anisotropy on hard rock drilling and cutting. In: Proceedings of the IAEG, Geological Society of London

Singh RN, Hassani FP, Elkington PJ (1983) The application of strength and deformation index testing to the stability assessment of coal measures excavation. 24th US Symp. Rock Mechanics, pp. 599–609

Suana M, Peters TJ (1982) The Cerchar abrasivity index and its relation to rock mineralogy and petrography. Rock Mech 15(1):1–8

Thuro K (1996) Bohrbarkeit beim konventionellen Sprengvortrieb. Geologisch-felsmechanische Untersuchungen anhand sieben ausgewahlter Tunnelprojekte. Münchner Geologische Hefte Reihe B: Angewandte Geologie 1:1–145

Thuro K (1997) Drillability prediction—geological influences in hard rock drill and blast tunnelling. Geol Rundsch 86:426–438

Thuro K, Plinninger RJ (2003) Hard rock tunnel boring, cutting, drilling and blasting: rock parameters for excavatability. ISRM, 2003 Technology roadmap for rock mechanics, South African Institute of Mining and Metallurgy, 1227–1234

Ulusay R (ed.) (2015) The ISRM suggested methods for rock characterization, testing and monitoring: 2007–2014. doi: 10.1007/978–3–319-07713-0. Springer International Publishing Switzerland

URL.1.www.miningandconstruction.sandvik.com. February 2015

URL.2.www.atlascopco.com.tr. February 2015

Verhoef PNW (1997) Wear of rock cutting tools. Balkema, Rotterdam, Brookfield

West G (1989) Rock abrasiveness testing for tunnelling. Int J Rock Mech Min Sci Geomech Abstr 26:151–160

Yaralı O (2005) Zonguldak taşkömür havzası kömür çevre kayaçlarının aşındırıcılık özelliklerinin araştırılması. Turkey 19th International Mining Congress and Fair, İzmir, pp 243–253

Yaralı O, Yaşar E, Bacak G, Ranjith PG (2008) A study of rock abrasivity and tool wear in coal measures rocks. Coal Geology 74(1):53–66

Yılmaz A, Adamia S, Lordkipanidze M, Yılmaz T, Kurt I, Abesadze G, Lazarashvili T, Beradze R, Nadareishvili R, Kuloshvili S, Salukvadze N, Özkan M (1996) A study of tectonic units of the area along the Turkish-Georgian border: 2nd International Symposium on the Petroleum Geology and Hydrocarbon Potential of the Black Sea Area, Procedings, Şile-İstanbul, Turkey, s. 119–132

Acknowledgements

The authors would like to thank Karadeniz Technical University, Scientific Research Projects Units for the financial support (Project Number: 8683). Furthermore, the authors greatly appreciate NAS-YSE and AS-YOL Construction Company for the permission of collecting data in the tunnels. The thin section tests were carried out in Istanbul Technical University with the generous helps of Assoc. Prof. Gultekin Topuz. Additionally, the authors are thankful to Assoc. Prof. Gokhan Aydin for his suggestions to improve the manuscript quality. Finally, the authors gratefully acknowledge Assoc. Prof. Olgay Yarali (Zonguldak, Turkey).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Capik, M., Yilmaz, A.O. Correlation between Cerchar abrasivity index, rock properties, and drill bit lifetime. Arab J Geosci 10, 15 (2017). https://doi.org/10.1007/s12517-016-2798-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-016-2798-7