Abstract

This paper presents new attempts to explore the dependency of some key geotechnical properties of soils such as compaction characteristics, hydraulic conductivity, and soil shear strength to their index properties and performance of developed models to predict these properties. To do this, a database of 580 data sets was compiled including the results of grain size distribution, Atterberg limits, compaction, and permeability, measured at different levels of compaction degree (90 to 100 %) as well as consolidated-drained triaxial compression tests. Dependency of each geotechnical property to their index parameters was investigated using an Evolutionary polynomial regression method, to develop prediction models based on the collected database. Investigation of the performance of the developed models indicates that these models are capable of predicting these soil properties with a confidence interval of 95 %. Parametric analyses were also performed on the developed models.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In geotechnical engineering practice, soils are rarely used in their natural compaction state, and to meet different geotechnical criteria, they should often be compacted. Compacted soil is widely used in landfills liners and waste impoundments, to cap new waste disposal units and to close old waste disposal sites because of its relatively low cost, accessibility, durability, high resistance to heat, and other factors (Wang and Huang 1984).

Almost all the regulatory agencies in the world require that compacted soil liners and covers be designed to have a hydraulic conductivity of less than or equal to a specified maximum value. According to the US Environmental Protection Agency Regulation, Brazilian Standard (NBR 13896-1997), and German Standards, compacted clay liners are required to have conductivity of 10−7 cm/s or less; however, the Chinese Ministry of Construction has specified a permeability of 10−8 cm/s or less for this purpose (Du et al. 2009).

For a successful design and construction of compacted soil liners and covers, not only the hydraulic conductivity but also factors including chemical compatibility, construction method, slope stability and bearing capacity, and subsidence phenomenon should be taken into consideration as well as environmental factors such as desiccation, and the development and execution of a construction quality assurance plan (Daniel 1984; Oakley 1987; EPA 1988; Elsbury et al. 1990; Daniel and Benson 1990). In Fig. 1, different instabilities in compacted soil liners in landfills can be observed (Dixon and Jones 2005).In practice, design engineers traditionally require that soil liners be compacted within a specified range of water content and to a minimum dry unit weight. According to Hermann and Elsbury (1987), this minimum value is 95 % of γ dmax from standard Proctor compaction (ASTM D-698) or 90 % of γ dmax from modified Proctor compaction (ASTM D-1557). The range of acceptable water content for soil liners and covers might typically be about zero to four percentage points wet of standard or modified Proctor optimum (Fig. 2).

Potential failures modes occurred in soil liners, after Dixon and Jones (2005)

The shape of the acceptable evolved empirically from construction practices applied to roadway bases, structural fills, embankments, and earth dams. The specification is based primarily upon the need to achieve a minimum γ d for adequate strength and limited compressibility. Soil liners are compacted wet of optimum because wet-side compaction minimizes hydraulic conductivity due to the change in the texture of soil (Bjerrum and Huder 1957; Lambe 1951; Mitchell et al. 1965; Boynton and Daniel 1985).

Daniel and Benson (1990) analyzed the results of Mitchell et al. (1965) and Boutwell and Hedges (1989) to investigate this traditional approach for the design of compacted soils liners. They concluded that the traditional approach did not address the geotechnical requirements of compacted soil liners, properly.

In Fig. 3a which is drawn based on the results of Mitchell et al. (1965), the significant portion of the superimposed acceptable zone on the contours of hydraulic conductivity yielded a hydraulic conductivity of more than 10−7 cm/s which is stated as a criterion for the design and construction of compacted soil liners. In Fig. 3b, the contours of hydraulic conductivity and shear strength are superimposed on the acceptable zone for 95 % of γ dmax and water content 0–4 % wet of optimum (Boutwell and Hedges 1989). However all w–γ d points contained within the acceptable zone correspond to test specimens with a hydraulic conductivity of less than 10−7 cm/s, but the shape and boundaries of the acceptable zone in this figure correlate with neither the hydraulic conductivity nor the shear strength. Besides this, as can be observed, the variation in shear strength in the acceptable zone is dramatic which could cause considerable deficiencies in the performance of compacted soil liners.

Based on the results of these analyses, Daniel and Benson (1990) proposed a new approach for design and construction compacted soil liners. According to this method, the compaction curve of the soil based on the compactive effort used in the field or a range of compactive efforts should be developed. Permeability tests are carried out to determine the hydraulic conductivity of each compacted specimen. The w–γ d relationship should be re-plotted with different symbols used to represent compacted specimens that had hydraulic conductivities meeting the design criteria. However, the acceptable zone is modified based on other considerations, e.g., shear strength, interfacial friction with an overlying geomembrane, shrink/swell considerations, concern over cracking when settlement occurs, concern for constructability, or local practices (Fig. 4).

Developing acceptable zone for design of compacted soil liners based on hydraulic conductivity and shear strength (Daniel and Benson 1990)

This method was further developed by Daniel and Wu (1993) to design and construct compacted soil liners in arid regions considering the shrinkage to have minimum desiccation cracks in liners. Although the proposed method by Daniel and Benson (1990) and Daniel and Wu (1993) is very precise and efficient, developing an acceptable zone is not an easy task, especially in the early stages of earthworks when the correct source of soil should be chosen among several different sources.

Performing laboratory tests to develop an accepted zone for design and construction of compacted soil liners is very time consuming especially in the case of permeability tests on samples with high portions of clay content. Because of these difficulties, using models which are capable of reasonable prediction of geotechnical properties of soils based on their index properties is of interest to geotechnical engineers. Correlation between compaction characteristics of soils and their index properties has been the subject of many investigations based on these properties of soils; some judgments could be made for the hydraulic conductivity and shear strength of soils.

Rowan and Graham (1948), Davidson and Gardiner (1949), Turnbull (1948), Jumikis (1946), Ring et al. (1962), Ramiah et al. (1970), Nagaraj (1994), etc. are among the researchers who tried to relate compaction characteristics of soils to index properties such as specific gravity and Atterberg limits (liquid limit, plastic limit, shrinkage limit, and plasticity index) and some factors related to their grain size distribution.

Similar models have been developed to estimate hydraulic conductivity of soils based on some of their basic properties. Researchers including Hazen (1911), Zunker (1930), Carman (1937), Burmister (1954), Michaels and Lin (1954), Olsen (1962), Mitchell et al. (1965), Wang and Huang (1983), Koltermann and Gorelick (1995), Boadu (2000), Chapuis (2004), Sinha and Wang (2008), and Cote et al. (2011) among others have tried to predict the hydraulic conductivity of soils from some factors related to the grain size distribution of the soil, Atterberg limits, and density of soils; however, the impact of soil’s structure and texture and definitely the type of permeant can increase the uncertainty in the prediction of hydraulic conductivity.

As opposed to the latter two geotechnical properties, several studies have been carried out to predict the shear strength of soils based on their basic properties. Kayadelen et al. (2009) used artificial neural network (ANN), Genetic Programming (GP), and Adaptive Neuro Fuzzy (ANFIS) methods to predict the φ′ value of soils from their index properties and Mousavi et al. (2011) used GP and orthogonal least squares algorithm (OLS) to present a correlation between the internal friction angle and the physical properties of soils such as fine and coarse content, density, and liquid limit. Sezer (2013) used nonlinear multiple regression (NMR), neurofuzziness (NF), and ANN methods to predict the shear strength of soil (Tizpa et al. 2014).

Database

A database with 595 data sets was compiled, in which 155 data sets were used for modeling the permeability, 320 data sets for modeling maximum dry density (MDD) and optimum moisture content (OMC), and 120 cases for modeling effective friction angle of shearing. The database includes test results performed on different types of soils; therefore, the results of this research should be valid for all types of soils.

For each data set, the permeability, OMC, MDD, compaction degree, friction angle, and soil index properties (grain size curve, Atterberg limits, and specific density) were available. However, a soil type index (STI) was introduced to take into account the classification of the soil (USCS) in modeling the compaction characteristics. The STI values were specified according to the following sequence: GW(1), GP(2), SW(3), SP(4), GM(5), SM(6), GC(7), SC(8), ML(9), CL(10), MH(11), and CH(12). In the cases of mixed classifications (e.g., CL-ML), STI was calculated as the average value of the individual classifications. Table 1 gives the descriptive statistics of the input variables used for the model developments. Also, the variation ranges of the output parameters are summarized in Table 2. Note that the gravel content (G c) was a coarse aggregate with a particle size coarser than 4.75 mm and the grain size of sand content (S c) ranged from 4.75 to 0.075 mm. Sand content includes coarse sand (S 1) ranging from 4.75 to 0.6 mm, medium sand (S 2) ranging from 0.6 to 0.2 mm, and fine sand (S 3) ranging from 0.2 to 0.075 mm. Particles that ranged from 0.075 to 0.002 mm were classified as silt and particles smaller than 0.002 were clay.

As presented in Table 3, the database was obtained from different sources but mainly from the geotechnical engineering laboratory at the Federal University of Bahia (UFBA), Brazil. Some other cases from Wang and Huang (1984), Kayadelen et al. (2009), and Mousavi et al. (2011) were also added.

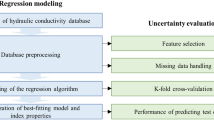

Evolutionary polynomial regression

Evolutionary polynomial regression (EPR) is a data-driven regression method that was developed by Giustolisi and Savic (2006) based on evolutionary computing. To avoid the problem of mathematical expressions growing rapidly in length with time, in EPR the evolutionary procedure searches for the exponents of a polynomial function with a fixed maximum number of terms. During one execution, it returns a number of expressions with increasing numbers of terms up to a limit set by the user to allow the optimum number of terms to be selected (Ahangar-Asr et al. 2011). In general, EPR is a two-stage method to construct symbolic models using polynomial structures. In the first stage, EPR searches for exponents of polynomial expressions by employing a genetic algorithm (GA). In the second stage, numerical regression is used to compute the constant values of the previously selected terms by solving a least squares (LS) problem. The general expression in EPR can be formulated as:

Where y is the computed vector of output and F is an n-dimensional function. X is the matrix of inputs and n is the number of input terms in the expression. Also, f is a function defined by the user and a i is a constant.

To apply the EPR procedure, the evolutionary process starts from a constant mean of output values. By increasing the number of evolutions, it gradually picks up different participating parameters in order to form equations describing the relationship between the parameters of the system. The EPR procedure stops when the termination criterion (the maximum number of terms in the mathematical expression, the maximum number of generations, or a particular allowable error) is satisfied. Figure 5 shows a typical flow diagram of the EPR procedure.

Typical flow diagram for EPR procedure (Rezania et al. 2008)

Performance analysis

Fitting parameters analysis

Different statistical approaches have been used to evaluate the performance of the prediction models. These parameters are the coefficient of determination (COD), root mean squared error (RMSE), and coefficient of residual mass (CRM). Following equations are the mathematical expressions of these parameters:

Where M i and P i are the measured and predicted values, respectively, \( \overline{M} \) is the mean of the measured values, and n is the number of samples. The RMSE is the variance of the residual error and should be minimized when the outputs fit a set of data. The case of a perfect fitting RMSE is zero. The lower the RMSE is, the higher the accuracy of the model predictions. The CRM represents the difference between the measured and predicted values. The optimum value of CRM is zero. Positive values of CRM indicate under estimation and vice versa.

Parametric analysis

For further verification of the EPR prediction models, parametric analyses have been performed. The method of parametric analysis is based on changing one predictor variable at a time while the other predictor variables are kept constant at the average values of their entire data sets.

Parametric analysis investigates the response of the predicted values from the EPR models to a set of input data generated over the training ranges of the minimum and maximum data. These variables are presented to the prediction model and the output is calculated. This procedure is repeated using another variable until the model response is tested for all input variables.

Results and discussions

EPR model for maximum dry density

Eight input parameters have been used in the EPR model for maximum dry density (kN/m3) including gravel content (G c); coarse, medium, and fine sand content (S 1, S 2, and S 3); silt and clay content (S c and C c); plastic limit (PL); and STI. The following EPR model is obtained for predicting MDD:

Figure 6 shows the predicted values of MDD versus measured values for training and testing data sets. Among 320 measured data sets, 290 sets (90 %) have been used for training and 30 sets (10 %) have been used for testing the model. Table 4 also presents the performance of the EPR prediction model.

Figure 7 presents the results of the parametric study on the EPR MDD model. As is obvious from graphs, increasing coarse content (gravel content and coarse, medium, and fine sand content) increases the maximum dry density of the soil. It is also coherent that the gravel content has the greatest effect on the prediction of MDD values. It can be seen that increasing fine content (silt and clay) causes the MDD to decrease. Moreover, MDD decreases as the plastic limit increases which could imply greater fine content in the soil.

EPR model for optimum moisture content

Five input parameters have been used in the EPR model for OMC including specific gravity (Gs), clay content (C), PL, MDD, and STI. The obtained model from EPR for prediction of OMC is:

Figure 8 shows a comparison between the results of the EPR model and experimental data for both the training and testing sets. Among the 320 measured data sets, 290 sets (90 %) were used for training and 30 sets (10 %) were used for testing the model. Table 5 also presents the performance of the EPR prediction model.

Figure 9 presents the results of the parametric study of the developed EPR model for OMC. As is clear from graphs, increasing clay content which implies higher plastic limits leads to higher values of OMC. However, it can be seen that MDD and OMC are clearly dependent. By increasing the maximum dry density, the OMC values decrease. Furthermore, G s seems to have a minor effect on OMC values.

EPR model for permeability coefficient (K)

Four input parameters have been used in the EPR model for the permeability coefficient (cm/s) including effective grain size (D 10), mean grain size (D 50), plasticity index (PI), and compaction degree (Cd) expressed in percent. D is referred to effective grain size to mean grain size of soil. The following EPR model is obtained for predicting the permeability:

Figure 10 shows a comparison between the results of the EPR model and experimental data for both training and testing sets. Among the 155 measured data sets, 140 sets (90 %) were used for training and 15 sets (10 %) were used for testing the model. Table 6 illustrates the performance of the developed EPR model for training and testing datasets.

Figure 11 presents the results of the parametric study of the EPR permeability model. Figure 11a shows that by increasing the dimensionless parameter of D 10/D 50, the permeability of the soil increases. It is obvious that increasing the ratio of D 10 to D 50 implies uniform particle size distribution which causes the permeability to increase. Figure 11b indicates that increasing the compaction degree decreases the permeability of soil due the reduction in the void ratio. As expected, increasing the plasticity index also causes the permeability of the soil to decline (Fig. 8c). Another aspect that is coherent from results is that the plasticity index has the greatest effect on the permeability of soils.

EPR model for angle of shearing resistance

Four input parameters were used to build the EPR model for predicting the effective angle of shearing resistance. These parameters are as follows: coarse-grained content (Cc), fine-grained content (Fc), soil bulk density (γ), and shearing rate (Sr). These important factors, representing the φ′ behavior, were selected based on the literature review (Kayadelen et al. 2009; Mousavi et al. 2011). As expected, the main parameters affecting the soil strength parameters should be the soil type and soil density as well as the shearing rate at which the shear tests are performed. The obtained model for the effective angle of shearing resistance is:

A comparison between the measured and predicted values of φ' illustrates that the model described here provides highly accurate prediction of the effective angle of shearing resistance (Fig. 12). Table 7 illustrates the performance of the developed EPR model for the training and testing datasets. Note that among the 120 data sets, 105 sets were used for training and 15 sets were used for testing the model.

Figure 13 shows the results of the parametric study on the EPR effective angle of shearing resistance model. As expected, the results of the parametric study indicate that φ′ increases as the coarse content increases and decreases with increasing fine content. As can be seen, the effective friction angle will increase by increasing the soil bulk density.

Conclusion

The accurate determination of the geotechnical properties of soil from their index parameters is of paramount importance in the design of geotechnical structures. Because laboratory tests to determine the MDD, OMC, permeability, and effective friction angle are time consuming and expensive, it is desirable to develop models which are capable of predicting these parameters. This paper presents prediction models which use evolutionary polynomial regression. A database of 533 data sets was compiled. The database contains classification, Atterbeg limits, compaction, permeability, direct shear, and consolidated-drained triaxial compression test results which were performed on different types of soils (SC, SM, SP, CL, CH, ML, and MH). The database is obtained from tests carried out in the geotechnical laboratory at the UFBA, Brazil, as well as some experimental data from the literature.

The results of the prediction models have been compared with the experimental data. Comparisons of the results demonstrate that the developed EPR models provide highly accurate predictions. In the EPR approach, there is no need to preprocess, normalize, or scale the data. An intriguing feature of EPR is its ability to present more than one model for a complex phenomenon. The best models are chosen based on their performance on a set of data. For further verification of the EPR prediction models, parametric analyses were performed.

References

Ahangar-Asr A, Faramarzi A, Mottaghifard N, Javadi AA (2011) Modeling of permeability and compaction characteristics of soils using evolutionary polynomial regression. Comput Geosci 37(11):1860–1869

ASTM D-1557. (2012). Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort.

ASTM D-698. (2012). Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort.

Bjerrum L, Huder J (1957) Measurement of the permeability of compacted clays. In: Proceedings, Fourth International Conference on Soil Mechanics and Foundation Engineering, Vol. 1, London, England., pp 6–10

Boadu, F. K. (2000). Hydraulic conductivity of soils from grain-size distribution. Journal of Geotechnical and Geoenvironmental Engineering, Vol. 126, No. 8.

Boutwell, G., and C. Hedges. (1989). Evaluation of waste retention liners by multivariate statistics. Proceeding 12th International Conference on Soil Mechanics and Foundation Engineering. Rio de Janeiro. 815–818

Boynton SS, Daniel ED (1985) Hydraulic conductivity of compacted clay. J Geotech Eng 111(4):465–478

Burmister, D. M. (1954). Principles of permeability testing of soils. ASTM Symposium on Permeability of Soils, ASTM Special Technical Publication No. 163

Carman PC (1937) Fluid flow through granular beds. Trans Inst Chem Eng 15:150

Chapuis RP (2004) Predicting the saturated hydraulic conductivity of sand and gravel using effective diameter and void ratio. Can Geotech J 41(5):787–795

Cote J, Fillion MH, Konrad JM (2011) Estimating hydraulic and thermal conductivity of crushed granite using porosity and equivalent particle size. J Geotech Geoenviron Eng ASCE 137(9):834–842

Daniel, D. E. (1984). Predicting the hydraulic conductivity of compacted clay liners. Journal of Geotechnical Engineering, ASCE, Vol. 110, No. 2, 1984, pp. 285–300.

Daniel DE, Benson CH (1990) Water content-density criteria for compacted soil liners. J Geotech Eng 116(12):1811–1830

Daniel DE, Wu YK (1993) Compacted clay liners and covers for arid sites. J Geotech Eng 119(2):223–237

Davidson, D.T., and Gardiner, W.F. (1949). Calculation of standard proctor density andnoptimum moisture content from mechanical analysis, shrinkage factors, and plasticity index. In: Proceedings of the HRB29, pp.447–481.

Dixon ND, Jones RV (2005) Engineering properties of municipal solid waste. Original Research Article Geotextiles and Geomembranes 23(3):205–233

Du YJ, Shen SL, Liu SY, Hayashi S (2009) Contaminant mitigating performance of Chinese standard municipal solid waste landfill liner systems. Geotext Geomembr 27(3):232–239

Elsbury B, Daniel D, Sraders G, Anderson D, ASCE (1990) Lessons learned from compacted clay liner. J Geotech Engrg 116(11):1641–1660

Giustolisi, O., and Savic, D.A. (2006). A symbolic data-driven technique based on evolutionary polynomial regression. Journal of Hydroinformatics, IWA-IAHR Publishing, UK 8 (3), 207–222

Hazen A, ASCE (1911) Discussion of ‘Dams on Sand Foundations’ by A. C. Koenig. Transactions 73:199–203

Hermann, J. G., and Elsbury, B. R. (1987). Influential factors in soil liner construction for waste disposal facilities. In Geotechnical Practice for waste disposal’87, ASCE press, 522–536. R. D.Woods, Ed. ASCE.

Jumikis, A.R. (1946). Geology and soils of the Newark metropolitan area. Journal of the Soil Mechanics and Foundations Division, ASCE 93(SM2), 71–95.

Kayadelen C, Gu¨naydın O, Fener M, Demir A, Zvan O A (2009) A modeling of the angle of shearing resistance of soils using soft computing systems. Expert Syst Appl 36:11814–11826

Koltermann CE, Gorelick SM (1995) Fractional packing model for hydraulic conductivity derived from sediment mixtures. Water Resour Res 31:3283–3297

Lambe, T.W. (1951) Soil testing for engineers. Wiley, New York, pp. 151–158.

Michaell, A.S., Lin, C.S. (1954). The permeability of kaolinite. Industrial and Engineering Chemistry, Vol.46.

Mitchell, J.K., Hopper, D.R., and Campanella, R. C. (1965). Permeability of compacted clay. Journal of the Soil Mechanics and Foundations Division, ASCE, Vol. 91, No. SM4.

Mousavi SM, Alavi AH, Mollahasani A, Gandomi AH, Arab Esmaeili M (2011) Formulation of soil angle of shearing resistance using a hybrid GP and OLS method. Eng Comput. doi:10.1007/s00366-011-0242-x

Nagaraj, T.S. (1994). Analysis and prediction of compaction characteristics of soils, Unpublished

Oakley, R. E. (1987). Design and performance of earth-lined containment systems. In Goetechnical Practice for waste disposal’87, Gotechnical Special Publication 13, R. D.Woods, Ed. ASCE.

Olsen HW (1962) Hydraulic flow through saturated clays. Clay Clay Miner 9:131–161

Ramiah BK, Viswanath V, Krishnamurthy HV (1970) Interrelationship of compaction and index properties. Proceedings of the Second South East Asian Conference on Soil Engineering, Singapore, In, pp 577–587

Rezania M, Javadi AA, Giustolisi O (2008) An evolutionary-based data mining technique for assessment of civil engineering systems. Journal of Engineering Computations 25(6):500–517

Ring GW, Sallgerb JR, Collins WH (1962) Correlation of compaction and classification test data. HRB Bulletin 325:55–75

Rowan HW, Graham WW (1948) Proper compaction eliminates curing period in construction fills. Civ Eng 18:450–451

Sezer A (2013) Simple models for the estimation of shearing resistance angle of uniform sands. Neural Comput & Applic 22(1):111–123

Sinha SK, Wang MC (2008) Artificial neural network prediction models for soil compaction and permeability. Geotech Eng 26(1):47–64

Tizpa P, Jamshidi CR, Karimpour Fard M, Machado LS (2014) ANN prediction of some geotechnical properties of soil from their index parameters. Arab J Geosci. doi:10.1007/s12517-014-1304-3

Turnbull JM (1948) Computation of the optimum moisture content in the moisture density relationship of soils. In: In: Proceedings of the Second International Conference on Soil Mechanics and Foundation Engineering, Rotterdam, Holland., pp 256–262

United State Environmental Protection Agency (EPA). (1988). Seminars-Requirements for Hazardous Waste Landfill Design, Construction and Closure, CERI-88-33

Wang MC, Huang CC (1984) Soil compaction and permeability prediction models. J Environ Eng 110(6):1063–1083, ASCE

Zunker, F. (1930). Das verhalten des bodens zum wasser. Handbuch der bodenlehre, Vol. 6

Acknowledgments

The database used in this research has been mainly obtained from the geotechnical engineering laboratory at the Federal University of Bahia (UFBA), which is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jamshidi Chenari, R., Tizpa, P., Ghorbani Rad, M. et al. The use of index parameters to predict soil geotechnical properties. Arab J Geosci 8, 4907–4919 (2015). https://doi.org/10.1007/s12517-014-1538-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12517-014-1538-0