Abstract

Extracting the contiguous coal seams under the lowermost aquifer in the unconsolidated Cenozoic alluvium is apt to water and quicksand inrush. By using a series of investigation methods including empirical formulas, numerical simulation, theoretical analysis, etc., the study focused on the fracture and the excess pore water pressure in the overlying strata in the process of extracting no. 8 coal seam firstly and no. 9 coal seam (under no. 8 coal seam) subsequently in no. 8102 working face of Luling coal mine in the north of Anhui Province of China. When no. 8 coal seam was extracted, the water-conducting fractured zone penetrated into the lowermost aquifer and rapid dissipation of excess pore water pressure above the gob occurred, accompanied by relatively high seepage hydraulic gradient over the headgate and the tailgate. When no. 9 coal seam was extracted, failure did not obviously extend upwards and the excess pore water pressure decreased slowly and a relatively high seepage hydraulic gradient transferred downwards from the headgate to the tailgate in the inclined profile. The safe water head (H s) in the lowermost aquifer was confirmed to 15.6 m. Therefore, water and quicksand inrush was avoided effectively in the process of extracting the contiguous coal seams by dewatering, controlling mining height, and laying double resistance nets in the working face.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In China, a considerable number of coal seams are covered by the unconsolidated Cenozoic alluvium, which is comprised of clay, sand, and gravel, in the Yellow River and the Huai River alluvial plain areas (Zhang and Peng 2005). Usually, the lowermost aquifer in the alluvium, with water-bearing sands mixed with gravels, is a potential threat to safe mining due to water and quicksand inrush. The statistics shows that about 285 coal mines (with estimated reserves exceeding 100 billion tons) of 600 in China suffer from water and quicksand inrush during extracting the coal seams covered by the unconsolidated Cenozoic alluvium (Liu 1981).

Such water and quicksand inrush presents many concerns for miners and researchers (Hill and Price 1983; Booth 1986; Kim et al. 1997; Islam et al. 2009). In order not to destroy the groundwater environment in the alluvium, an aquifer protection extracting technique is applied in the western mine areas in China, which will enable the mining-induced dropdown of the groundwater to be restored to its original level (Zhang et al. 2011). Practical experience has proven that under suitable geological conditions, the dropdown can recover within a certain time period, although the aquifer may have been disturbed by mining (Booth and Spande 1992; Booth and Bertsch 1999; Booth et al. 2000). However, the technique will consume much coal resource, especially in the eastern mine areas in China where the coal resource is almost exhausted and the residual resource is commonly covered by the unconsolidated Cenozoic alluvium. To enhance recovery and decrease resource loss, it is often necessary to extract the coal seams by maintaining rock and coal pillar as long as the mining does not suffer from water and quicksand inrush.

The height of rock and coal pillar is defined as the shortest vertical distance between the lowermost aquifer in the alluvium and the working face (Zhang and Peng 2005; Miao et al. 2011). If the height is too small, water and quicksand inrush will cause serious consequences such as mine inundation, endangering the lives of miners, and surface collapse. If the height is too large, it will lead to a loss of coal resource. Therefore, the optimal design for rock and coal pillar is of crucial importance for safety in mining, especially extracting contiuous seams under the lowemost aquifer in the alluvium.

Recently, further studies on the optimal design have been conducted (Singh and Singh 1999; Yavuz 2004; Gandhe et al. 2005; Singh et al. 2011). Due to the complex behaviors of mechanics and hydromechanics in the process of mining, empirical formulas on the basis of field observations are, generally, adopted for assessing the failure of overlying strata and for determining the reasonable height of rock and coal pillar (Liu 1981; Singh et al. 1996). Still, the empirical formulas are only suited for extracting a single coal seam under aquifers in the alluvium by longwall mining method and not for extracting contiguous coal seams. In order to predict and prevent water and quicksand inrush, during extracting the contiguous seams, it is of vital importance to study the mining-induced failure and the deformation-induced excess pore water pressure in the overlying strata.

Furthermore, if the geological and hydrogeological condition permitted, the failure and excess pore water pressure made certain, and some prevention measures adopted, these coal seams, even contiguous seams, can be extracted without water and quicksand inrush. The paper takes no. 8102 working face of no. 810 mining panel in Luling coal mine for example to analyze the feasibility of extracting contiguous coal seams under the unconsolidated Cenozoic alluvium by longwall mining method.

Geological settings

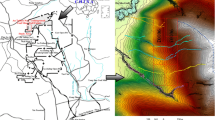

Luling coal mine is located in the east of Sulin mine area in Anhui Province in China (Fig. 1), whose strata consist of, in ascending order, Archean, Sinian, Cambrian, Ordovician, Carboniferous, Permian, Triassic, Jurassic, Cretaceous, Paleogene, Neogene, and Quaternary (Zheng et al. 2008; Jiang et al. 2010; Tan et al. 2009). In the mine area, the main coal-bearing sequences occur in the lower Permian Shanxi and Shihezi formations.

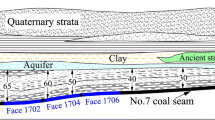

No. 810 mining panel in Luling coal mine, being an isolated basin, is located in the west part of the mine (Fig. 2). The primary minable coal seams in the mining panel are no. 8 and no. 9 coal seams in the lower Permian Shihezi formation. The thickness of no. 8 coal seam is 1.5 to 10.0 m with an average of 7.0 m. The thickness of no. 9 coal seam is 0.5 to 4.8 m with an average of 3.0 m. Rock thickness between no. 8 and no. 9 coal seams is averagely 4.0 m and the dip angle of the two coal seams ranges from 6° to 8°, so they can be considered as contiguous gently inclined seams. The thickness of overlying unconsolidated Cenozoic alluvium ranges from 183 to 256 m with an average of 242 m. The physical and mechanical parameters (Table 1) of selected typical rock and soil samples from the KY-1 drill hole (Fig. 3) were tested in the laboratory.

Stratigraphic columns obtained from boreholes and the division of aquifers and aquifuges in no. 810 mining panel of Luling coal mine. a The first aquifer; b the first aquifuge; c the second aquifer; d the second aquifuge; e the third aquifer; f the third aquifuge; g the fourth or lowermost aquifer; h bedrock

There are four aquifers and three aquifuges in the unconsolidated Cenozoic alluvium from up to down, which are the first aquifer, the first aquifuge, the second aquifer, the second aquifuge, the third aquifer, the third aquifuge, and the fourth or lowermost aquifer, respectively (Fig. 3). Among these formations, the unit flow rate (q) in the third aquifer is approximately from 0.226 to 0.689 l/m s and thus can be characterized as a medium to strong water-bearing aquifer. The third aquifuge ranges from 40.0 to 70.0 m in thickness and consists of sandy clay, clay, and calcareous clay, which contributes to good impermeability and bad hydraulic connection between the third aquifer and the underlying lowermost aquifer even if the coal seams are extracted without rock and coal pillar.

The unit flow rate (q) of the lowermost aquifer varies from 0.00036 to 0.00405 l/m s and thus can be characterized as a weak water-bearing aquifer. The aquifer varies from 5.0 to 23.0 m with an average of 12.0 m in thickness, its water-bearing zones taking on fragmentary distribution (Fig. 2). The aquifer consists primarily of sand, sandy gravel, interbedded gravel, and breccia. Although the lowermost aquifer is poor in the water abundance, it acts as a direct discharge aquifer during extracting no. 8 and no. 9 coal seams because it lies directly above the coal seams and the deformation-induced excess pore water pressure (2.0 ∼ 3.0 MPa) in the overlying strata is very high.

The failure and excess pore water pressure in the overlying strata

Empirical formulas predicting during extracting no. 8 coal seam

The fractured overlying strata induced by longwall mining can be divided into some zones, such as the caved zone and the water-conducting fractured zone. Though there is no general agreement on the exact shape of these fractured zones, most studies show that it is in the form of a dome, a horse saddle, or a flat arch (Liu 1981; Miao et al. 2011). The observations have shown that the failure of overlying strata is considerably different depending upon the inclination of the coal seams (Liu 1981). For flat or slightly inclined coal seams (inclination angle α < 30°), the water-conducting fractured zone displays broadly in the profiles with extended lobes over the headgate and the tailgate (Miao et al. 2011), which is shown in Fig. 4. Liu (1981) has developed empirical formulas for predicting the heights of caved zones and water-conducting fractured zones for four rock types, i.e., hard and strong; medium hard; soft and weak; and weathered soft and weak bedrock.

In Eqs. 1 and 2, h c and h f are the heights of the caved zone and the water-conducting fractured zone evaluated from the immediate roof of coal seams (Fig. 4), ΣM is the accumulative thickness of the extracted coal seams, a and b are the coefficients depending upon the lithology, and σ is the mean square deviation, as shown in Table 2.

According to the soft and weak rock type in the overlying strata of no. 8102 working face in no. 810 mining panel in Luling coal mine (Fig. 3 and Table 1) and the average extracted height of 7 m, the heights of the caved zone and water-conducting fractured zone were predicted as follows (The equations were adopted to “+”), h c = 100 ∑ M/(6.2 ∑ M + 32) + 1.5 = 10.8 m h f = 100 ∑ M/(3.1 ∑ M + 5.0) + 4 = 30.2 m, as shown in Fig. 5. From Fig. 5, the caved zone above the headgate should approach to the lowermost aquifer in the alluvium and the water-conducting fractured zone should penetrate through the aquifer, so water and quicksand inrush can occur more easily during mining. To extract as much coal resource as possible, the subsequent working face was placed toward the shallow level of coal seams in the inclined profile, which raised more concerns that the caved zone and the water-conducting fractured zone would all penetrate into the lowermost aquifer, especially above the headgates in working faces. Consequently, it was essential to prevent water and quicksand inrush from the lowermost aquifer to the gob during extracting no. 8 coal seam.

Numerical simulation during extracting no. 9 coal seam

Numerical model

It is difficult to accurately estimate the heights of the caved zone and the water-conducting fractured zone on the basis of Eqs. 1 and 2 during extracting no. 9 coal seam subsequently in no. 8102 working face. In order to illuminate the failure of overlying strata, the explicit three-dimensional finite difference program FLAC3D version 3.0 (Sarkar et al. 2012) was used for the analysis. Following the Mohr–Coulomb constitutive relation and considering the fluid–solid coupling and the large deformation, a numerical model was established by FLAC3D. The length, width, and height of the model were 350, 960, and 177.6 m, respectively, which were meshed into 43,680 zones and 47,628 grid points (Fig. 6). In the middle of the model and near no. 8 and 9 coal seam, there was a group with 320 m in length and 110 m in width simulating the working face. The surrounding surfaces of the model were set horizontal constraints, the bottom surface was set three-dimensional constraint, and the top surface was set free, with a vertical load for simulating the weight of overlying strata. All the model boundaries were impermeable. The extracted space was set to be a draining boundary, the excess pore water pressure of the third aquifer in the alluvium was initialized 1 MPa, and that of the lowermost aquifer was initialized 2 MPa. Due to not considering the influence of the structure of overlying strata, the physical and mechanical parameters of the numerical model had the same values as the testing results in the laboratory, as shown in Table 1. In the inclined direction of the working face, full-seam mining was simulated firstly in no. 8 coal seam and subsequently in no. 9 coal seam. In advancing direction of the working face, every 10 m was regarded as a mining step, including 11 mining steps in the process.

The failure of overlying strata

The plastic zones in the overlying strata in the inclined profile during extracting no. 8 coal seam firstly and no. 9 coal seam subsequently in no. 8102 working face were obtained, as shown in Fig. 7. From Fig. 7, the plastic zone during extracting no. 8 coal seam broadly displayed a profile with extended lobes over the headgate and tailgate, like a horse saddle or a flat arch. Similarly, the plastic zone during extracting no. 9 coal seam also took on a horse saddle or a flat arch, propagating upwards slightly and concentrating mainly above the headgate and tailgate of the working face. Compared to extracting no. 8 coal seam, the failure of overlying strata showed no significant change in the process of extracting no. 9 coal seam.

The excess pore water pressure in the overlying strata

When no. 8 coal seam of the working face was extracted in no. 8102 working face, the dissipation of excess pore water pressure in the lowermost aquifer above the gob occurred rapidly in the inclined profile, and the high value of excess pore water pressure concentrated mainly above the headgate and the tailgate like the failure of overlying strata, where relatively high seepage hydraulic gradient was produced (Fig. 8). While no. 9 coal seam extracted subsequently, the excess pore water pressure dissipated slowly above the gob (Fig. 8). A relatively high seepage hydraulic gradient transferred downwards from the headgate to the tailgate in the inclined profile.

Calculating of the safe water head

Obviously, in an aquifer, the lower the initial water head is, the lower the seepage hydraulic gradient is. The seepage hydraulic gradient can induce the fracture to be water conductive in the overlying strata. So, water and quicksand inrush can be avoided effectively as long as the seepage hydraulic gradient is kept below the allowable value.

The interface between the fractured zone in the overlying strata and the lowermost aquifer in the alluvium can be simplified to be a pumping well; the equation is given for a confined well flow as follows (Bear 1972):

In which s is the dropdown of water head, in meter; Q is the discharge flow rate of the borehole, in cubic meter per day; T = KM, is the coefficient of transmissibility in the confined aquifer, in square meter per day; K is the hydraulic conductivity, in meter per day; M is the thickness of the confined aquifer, in meter; a = K/μ e is the pressure transitivity coefficient, in square meter per day; t is the pumping time, in day; μ e is the elastic specific yield; r is the distance from the studied site to the center of the well, in meter. According to Eq. 3, when s = 0, r is R, and R is the influence radius as follows:

When failure in the overlying strata propagates upwards the lowermost aquifer without water and quicksand inrush, the water head in the aquifer can be determined as the safe water head (H s). Combined with the data of the coefficient of transmissibility (T = 15.8 m2/day) and the elastic specific yield (μ e = 0.6 × 10−3) obtained by pumping test in the aquifer, the relation curve between the influence radius (R) and the pumping time (t) can be drawn by Eq. 4. From the curve (Fig. 9), it can be seen that the influence radius (R) extends fast in the first 10 min and then relatively slow later. Consequently, the influence radius (R) at the tenth minute (R 10 = 20.3 m) was taken as the basis of calculating the safe water head (H s). The calculated safe water heads (H s) are listed in Table 3 according to the test results of the soil samples from the lowermost aquifer. Taking safe factor into account, the safe water head (H s) for the sand and clay of the lowermost aquifer can be adopted to 15.6 m. That is, if the water head was kept below the safe water head (H s = 15.6 m) before extracting the coal seams, there would be no water and quicksand inrush even if fracture propagated upwards the lowermost aquifer in the alluvium.

Key prevention measures

In order to keep the water head in the lowermost aquifer below the safe water head (H s = 15.6 m), numerous drill nests were arranged along the headgate and the tailgate of no. 8102 and 8101 working face (Fig. 10) and not less than three draining holes in each drill nest were drilled to reach the aquifer. These holes had been drained for at least 10 months until there was little water in the majority of draining holes, which would make the water head below the safe water head (H s = 15.6 m). Because of poor water abundance in the aquifer, the dropdown water heads were recovered with so much difficulty that extracting the contiguous coal seams in the working face became possible.

According to the numerical simulation, the relatively intensive failure occurred and the relatively high seepage hydraulic gradient appeared above the headgate of the working face during extracting the contiguous coal seams, so that water and quicksand would rush easily into the gob from above. Therefore, the extracted height adjacent to the headgate was controlled, and half of the coal seam thickness was usually extracted.

In addition, to reduce failure and seepage hydraulic gradient above headgate, double resistance nets, which consisted of polypropylene grids by the tensile technology in double plane directions, were placed on the roof of the headgate during extracting the contiguous coal seams (Fig. 11) and groundwater in the bottom aquifer discharged slowly into the gob, and the high seepage hydraulic gradient in the aquifer cannot be easily produced. As a result, the possibility of water and quicksand inrush from the aquifer decreased greatly.

Conclusions

In no. 8102 working face, the caved zone approached the lowermost aquifer above the tailgate when no. 8 coal seam was extracted, and the water-conducting fractured zone penetrated into the lowermost aquifer. When no. 9 coal seam was extracted subsequently, failure did not obviously extend upwards.

When no. 8 coal seam was extracted firstly, rapid dissipation of excess pore water pressure in the lowermost aquifer above the gob occurred, accompanied by relatively high seepage hydraulic gradient over the headgate and the tailgate. When no. 9 coal seam was extracted subsequently, the excess pore water pressure decreased slowly and a relatively high seepage hydraulic gradient transferred downwards from the headgate to the tailgate in the inclined direction. During extracting the contiguous coal seams in the working face, the safe water head (H s) in the lowermost aquifer was calculated to be 15.6 m.

Water and quicksand inrush was avoided effectively by dewatering, controlling mining height, and laying double resistance nets in the working face, which will produce demonstrative value in the eastern mine areas in China where the coal resource is almost exhausted and the residual resource is commonly covered by the unconsolidated Cenozoic alluvium.

References

Bear J (1972) Dynamics of fluids in porous media. Elsevier, Amsterdam

Booth CJ (1986) Strata-movement concepts and the hydrogeological impact of underground coal mining. Ground Water 24:507–515

Booth CJ, Bertsch L (1999) Groundwater geochemistry in shallow aquifers above longwall mines in Illinois, USA. Hydrogeology Journal 7:561–575

Booth CJ, Spande ED (1992) Potentiometric and aquifer property changes above subsiding longwall mine panels, Illinois basin coalfield. Ground Water 30:362–368

Booth CJ, Curtiss AM, Demaris PJ, Bauer RA (2000) Site-specific variation in the potentiometric response to subsidence above active longwall mining. Environmental & Engineering Geoscience 6:383–394

Gandhe A, Venkateswarlu V, Gupta RN (2005) Extraction of coal under surface water body—a strata control investigation. Rock Mechanics and Rock Engineering 38(5):399–410

Hill JG, Price DR (1983) The impact of deep mining on an overlying aquifer in western Pennsylvania. Ground Water Monitoring Review 3:138–143

Islam MR, Hayashi D, Kamruzzaman AB (2009) Finite element modeling of stress distributions and problems for multi-slice longwall mining in Bangladesh, with special reference to the Barapukuria coal mine. International Journal of Coal Geology 78:91–109

Jiang B, Qu ZH, Geoff GX, Wang ML (2010) Effects of structural deformation on formation of coalbed methane reservoirs in Huaibei coalfield, China. International Journal of Coal Geology 82:175–183

Kim JM, Parizek RR, Elsworth D (1997) Evaluation of fully-coupled strata deformation and groundwater flow in response to longwall mining. International Journal of Rock Mechanics & Mining Sciences 34:1187–1199

Liu TQ (1981) Surface movements, overburden failure and its application. Coal Industry Press, Beijing

Miao XX, Cui XM, Wang JA, Xu JL (2011) The height of fractured water-conducting zone in undermined rock strata. Engineering Geology 120:32–39

Sarkar TN, Singh TN, Verma AK (2012) A numerical simulation of landslide-prone slope in Himalayan region—a case study. Arabian Journal of Geosciences 5:73–81

Singh R, Singh TN (1999) Wide stall mining for optimal recovery of coal from a thick seam under surface features. International Journal of Rock Mechanics & Mining Sciences 36:155–1688

Singh R, Singh TN, Dhar BB (1996) Coal pillar loading for shallow mining conditions. International Journal of Rock Mechanics & Mining Sciences 33:757–68

Singh AK, Singh R, Maiti J, Kumar R, Mandal PK (2011) Assessment of mining induced stress development over coal pillars during depillaring. International Journal of Rock Mechanics & Mining Sciences 48(2):805–818

Tan JQ, Ju YW, Hou QL, Zhang WY, Tan YJ (2009) Distribution characteristics and influence factors of present geo-temperature field in Su-Lin mine area, Huaibei coalfield. Chinese Journal of Geophysics 52(3):732–739

Yavuz H (2004) An estimation method for cover pressure re-establishment distance and pressure distribution in the goaf of longwall mines. International Journal of Rock Mechanics & Mining Sciences 41(2):193–205

Zhang JC, Peng SP (2005) Water inrush and environmental impact of shallow seam mining. Engineering Geology 48:1068–1076

Zhang DS, Fan GW, Ma LQ, Wang XF (2011) Aquifer protection during longwall mining of shallow coal seams: a case study in the Shendong Coalfield of China. International Journal of Coal Geology 86:90–196

Zheng LG, Liu GJ, Qi CC, Zhang Y, Wong MH (2008) The use of sequential extraction to determine the distribution and modes of occurrence of mercury in Permian Huaibei coal, Anhui Province, China. International Journal of Coal Geology 73:139–155

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (no. 41173106) and the Science and Technology Project of Anhui Province, China (no. 12010402150). We also gratefully acknowledge the numerical analysis carried out by our research group.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, L., Zhang, S. & Gui, H. Prevention of water and quicksand inrush during extracting contiguous coal seams under the lowermost aquifer in the unconsolidated Cenozoic alluvium—a case study. Arab J Geosci 7, 2139–2149 (2014). https://doi.org/10.1007/s12517-013-1029-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12517-013-1029-8