Abstract

Most studies on frozen foods’ deterioration focus on measurements of selected quality determining indices at the reference frozen storage conditions at limited time points (e.g., 6 and 12 months). This information is not sufficient to predict the frozen system behavior under a different storage temperature, or under the real, dynamic conditions of the actual cold chain. For this purpose, a systematic kinetic study is essential; additionally, the real uncertainty of model parameters needs to be taken into account, in order to proceed to realistic shelf life estimations. In this review work, published findings on kinetic data of deterioration of frozen food of plant origin were analyzed. Kinetic parameters (e.g., activation energy, shelf life, etc.) were extracted and some of them incorporated to a further investigation. The scope is to provide a critical assessment and a comprehensive meta-analysis of the literature information on quality loss modeling of frozen foods. Therefore, common quality indices for specific systems are reviewed, fundamental methodologies used to build kinetic models are assessed, and alternative approaches to improve practical applications of these models are proposed. Alternative methodologies are described in order to take into account the calculated uncertainty of models’ parameters when assessing the remaining shelf life of the product at any point within the cold chain. This was implemented in a FORTRAN code through a Monte Carlo scheme, on literature data of vitamin C loss in different frozen matrices, as well as for other quality indices (e.g., color). Results demonstrated the improved predictions obtained, with broader and more realistic confidence intervals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Freezing, one of the most important unit operations for the food industry, involves the removal of latent heat from a food system, resulting in a substantial decrease of its temperature and water activity via crystallization of a major part of the water. Freezing slows down microbial activity, nutritional loss, and sensory degradation prolonging significantly shelf life and allowing the transportation of perishable and seasonal products to otherwise inaccessible remote markets [1]. However, the literature is not always clear regarding the actual effect of freezing temperatures and storage conditions on some important attributes of frozen foods and this part needs further clarification. Food quality, and especially its mathematical description through appropriate models, is in the center of current food science research.

Most studies on frozen food deterioration are based on measurements of few selected parameters (e.g., vitamin C, phenolic compounds, anthocyanins, carotenoids) at a reference temperature (e.g., − 18 °C) and a few time points (e.g., 6 and 12 months). Bonat Celli et al. [1] published a thorough review of the effect of frozen storage on the quality of fruits, presenting data for several tissues. Although this approach allows for a comparative assessment (especially when a different freezing process is applied), it cannot be further exploited to predict the frozen system behavior under a different storage temperature, or most importantly under the real, non-isothermal conditions of the actual cold chain. For this purpose, a systematic kinetic study, based on quality measurements for an extended time period, at constant temperatures in the range of interest, is essential to be able to obtain accurate predictions on dynamic systems [2,3,4,5], e.g., at any point within the cold chain. It is also necessary to have the prevailing values for dynamic temperatures in a given cold distribution chain.

Temperature is not the only quality-determining factor. Ice formation causes severe textural changes, such as tissue disruption. Moreover, the separation of solid water produces a concentrated unfrozen phase which can be in a liquid, rubbery, or glassy state depending on the storage temperature of the frozen foods. Chemical reaction rates decrease as the temperature is lowered due to the slow movement of molecules having the necessary activation energy for the reaction; however, in a frozen matrix, the increasing solute concentration further affects the mobility properties of the system [6]. One cannot overlook this complexity that influences the kinetics of quality loss during storage.

There are only few studies investigating and describing mathematically the effect of phase transitions and temperature fluctuations at low temperatures (during distribution and storage of frozen foods) on the quality of real food matrices [7], and not merely on model systems simulating food product behavior. In food models, several workers have tested the applicability of the Arrhenius, WLF, and other equations to assess glass transition effect on the rates of different chemical reactions [8,9,10,11]. Focusing on real food systems, an alternative to the Arrhenius approach for expressing quality loss kinetics is by relating the reaction rate to Tstorage − Tg. Syamaladevi et al. [12], Syamaladevi et al. [13], and Zhang et al. [14] evaluated the stability of several frozen food matrices in glassy and rubbery states during long-term storage and concluded that significant degradation occurred even in the glassy state. An important observation from the literature review concerning WLF kinetics applicability is that this equation is mostly used as an empirical model, without aiming at elucidating the real mechanism behind frozen food quality loss. This can be attributed to two main reasons: on one hand, temperature conditions of the experimental procedure are, in most cases, far from the glass transition zone, and secondly, the real mechanisms that include glass transition and other freeze-concentration phenomena are too complex to describe mathematically. In this context, in the majority of the published works, in-depth modeling of quality degradation mechanisms in a broad temperature zone, aiming to account for the high complexity of the combined effect of all contributing factors, is not available.

Based on these considerations and observations, despite the importance of Tg’ theory and its practical implication, in the majority of published works regarding quality degradation modeling, the “apparent kinetics” methodological approach is used. According to this approach, a kinetic model comprises two parts, namely, a primary model that empirically describes the selected index change as a function of time and a secondary model that characterizes parameters employed in primary models as a function of processing factors and/or environmental conditions. The combination of primary and secondary models is then capable of predicting the index change as a function of time, processing factors, and environmental conditions [15].

An overview of all methodologies concerning frozen food kinetic studies taking into account only the effect of temperature (apparent kinetics) shows that there are weak points, mainly with regards the determination of the confidence intervals, and consequently the uncertainty of the model parameters. The necessity to account for the real uncertainty of model parameters is to be able to predict in a more accurate way deteriorative changes, at any selected temperature and time, and thus proceed to realistic and reliable shelf life estimations. Several statistical tools are available to assess the variability (through the estimated confidence intervals) of each kinetic parameter and appropriately incorporate it to the initial quality function. As a next step, Monte Carlo simulation techniques are currently often applied in the literature for the probabilistic assessment of stochastic variability and uncertainty, as it will be discussed in detail in a following section.

When reviewing reported values for kinetic parameters, in most cases, a significant variability among shelf life studies of frozen foods occurs, even among researches investigating similar or even the same type of food systems. Based on these kinetic results and a meta-analysis approach, it would be interesting to go a step further and predict product shelf life, assessing at the same time the uncertainty of this prediction in each case. Meta-analysis, defined as a “statistical analysis of a collection of analytic results for the purpose of integrating the findings from a large amount of primary studies” [16] is used in this study in order to (i) compile the differences in kinetic results by identifying and reporting all important parameters (i.e., food matrix, temperature range tested, parameters’ values) and (ii) use the available data to provide estimates with increased statistical power and broader applicability [17]. The primary aim of this meta-analysis is to produce a more accurate estimate of the effect of kinetic parameters’ uncertainty on product shelf life than is possible using only the single-parameter value often provided in published literature. In this study, therefore, the main targets were to review available results on frozen food kinetics and further analyze them, with a methodology aiming to uncertainty calculations of shelf life, through a Monte Carlo approach (as detailed in the ‘Case study’ section), in order to obtain more realistic shelf life predictions.

This review paper aims to provide a critical assessment of the literature on modeling of quality changes during storage and distribution of frozen foods, focusing on frozen fruits and vegetables. To accomplish this goal, it presents a necessary overview on fundamental methodologies used to build quality kinetic models, common quality indices selected for specific frozen food systems and kinetic models, and considerations to improve practical applications of quality kinetic models of frozen foods, by taking into account the uncertainty of kinetic parameters.

Frozen Food Quality Indices and Modeling

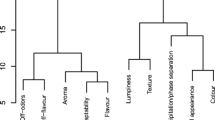

The quality degradation of frozen fruits and vegetables is mostly described by nutritional content loss and sensory attribute deterioration (e.g., color/overall appearance, texture, flavor/aroma, taste, etc). The main physical changes that occur during frozen storage are moisture migration and ice recrystallization, both related to the stability of products’ frozen water, which affects the vegetable texture, loss of nutrients, and drip loss. On the other hand, chemical changes in frozen vegetables and fruits cause off-flavor development, pigment and color degradation [1], oxidative deterioration, and vitamin loss. In this work, several indices’ change is reported after a certain storage at discrete temperatures, for a number of matrices; however, no kinetic modeling is presented.

When addressing food quality kinetics, in the established and more frequently employed two-step approach, the most representative quality indices are selected, and their changes are measured as a function of processing or storage time at constant temperature conditions using a primary model. The second step is to select an appropriate secondary model that best describes the effect of temperature or any other appropriate kinetic parameter on the rate of changes.

Alternatively, the model parameters can be determined in a single step considering the same dataset, obtained at different temperature conditions, as a whole and performing a non-linear regression through appropriate mathematical equations which are developed by incorporating the secondary into the primary model. Initial guesses for this non-linear procedure may be obtained from the two-step approach. The advantage of one-step analysis modeling is not only the increased number of degrees of freedom, but rather the use of more precise parameter estimates and the development of more realistic models due to the knowledge of various responses [18]. Several studies in the area of frozen foods have been published in recent literature that use one-step kinetic analysis [19, 20]. However, an important issue that needs to be addressed in this case is the selection of the fitting algorithm and the respective fit criterion that is not always well described and sustained [18]. It is advisable that the developed primary and secondary models are validated by challenging the calculated quality values to measured ones via additional independent experiments. Validated, mathematical models can be a useful tool to quantitatively predict quality at any stage and set of conditions in the food chain.

Another approach currently introduced involves the simultaneous determination of kinetic parameters of primary and secondary models based on experiments at dynamic conditions instead of isothermal data; such a procedure is rarely reported in frozen food kinetics, whereas frequently adopted in other areas of food science [5, 21,23,23]. Another issue of major importance, which may be the source of errors, is the selection of the most suitable non-isothermal profile, as well as the most appropriate primary and secondary models for the system under study.

Primary models describe the change of chemical concentration, enzyme activity, microbial population, etc. as a function of time; in the case of frozen foods, this is mostly attributed either to the decrease of one or more quality attributes, such as a nutrient or a desirable flavor or to the production of an undesirable substance, such as an off-flavor or discoloration (Eq. 1):

where the quality index (A) is a measurable chemical, physical, microbiological, or sensory attribute, chosen to describe the quality degradation of the food system in question. The constant k is the apparent reaction rate constant and n is the apparent order of the respective reactions. The term “apparent” used indicates that Eq. 1 does not necessarily describe the actual mechanism of the phenomenon studied.

The values of k and n of Eq. 1 are determined by appropriately fitting the change with time of the experimentally measured values of (A) to Eq. 1. In this context, integrating Eq. 1 leads to an expression for quality quantification, which actually demonstrates its dependency on time and numerous intrinsic and extrinsic factors:

where Q can be defined as the quality function of the food and k, the apparent reaction rate constant is a function of composition factors Ci [24], and of environmental factors, Ej. Moisture content, water activity, pH, NaCl, gas composition (mostly in the case of modified atmosphere packaged products), pressure (when high hydrostatic pressure is applied) etc. are among the most popular influencing parameters, and their effect may be appropriately included in secondary models. The most simplified approach is to describe this parameter’s effect on reaction rate in a way similar to the temperature effect, using the most popular secondary models (e.g., Arrhenius etc.), by substituting temperature parameter with the factor in question. When the effect of more than one parameter is studied, then more complicated equations are developed usually applying the same models in a consecutive way [25]. The analytical form of Q(A) depends on the reaction order. The rate of change of A can be in general represented by a nth order equation [26]. For example, microbial death, thermal denaturation of proteins, and vitamin loss are often described as first-order phenomena, whereas other food quality-related actions, such as non enzymatic browning, texture loss, and overall sensory deterioration, are better described as apparent zero-order phenomena. However, for specific phenomena, such microbial population inactivation/growth and enzyme activity, alternative primary models, other than the nth order, are used, such as the Bigelow, the Logistic (especially in the field of predictive microbiology), or the Weibull models [27, 28]. The main primary models used in the area of frozen food kinetics, their mathematical equation, and the explanations of the symbols used are briefly presented in Table 1.

In order to describe the effect of external parameters, such as temperature, aw, pH etc., on the apparent reaction rate constant k of eq. (2), appropriate mathematical equations, in the form of k = f(T, aw, pH, etc.), are developed (secondary models). The effect of temperature on the rate of frozen food reaction rates has been in the center of research, since it significantly affects product’s overall quality and shelf life. The classical Arrhenius model is the most frequently applied in order to describe quality changes of frozen foods and its equation is shown in Table 1, where the main secondary models used for frozen food quality loss indices are briefly presented.

In the case of frozen matrices that may be subject to glass transition, the effect of temperature is not adequately described by a single Arrhenius equation due to a drastic acceleration of the observed rates of the diffusion-controlled reactions above Tg. In the rubbery state, the activation energy is not constant, but can be better described as a function of temperature. To describe this kind of behavior, an alternative equation, namely the Williams-Landel-Ferry (WLF) expression (Eq. 4) that empirically models the temperature dependence of mechanical and dielectric relaxations in the range Tg < T < Tg + 100, is often used (Table 1).

According to Peleg et al. [34], the “glass transition temperature, “Tg,” has frequently served as the reference temperature, and it has been assumed that the rate of both physical and chemical processes in foods primarily depends on how far the temperature is above or below their “Tg.”. Williams et al. [36], assuming Tref = Tg and applying WLF equation for data available for various polymers, estimated mean values of the coefficients C1 = − 17.44 and C2 = 51.6. However, the uniform application of these constants is often problematic [10, 37] and the calculation of system-specific values, whenever possible, should be preferred. Additionally, WLF model is based on the assumption that the temperature effect is qualitatively the same at every temperature range and hence that it can be used for extrapolation to both low and high temperatures [38]. In any case, this modeling approach of temperature effect is significantly constrained by its empirical nature.

When comparing the use of the Arrhenius vs. WLF equation in frozen systems, it can be observed in some cases that neither a single Arrhenius nor the WLF equation can describe the temperature dependence in the whole temperature range. There are only few studies focusing on this behavior, demonstrating a shift in the slope of the respective Arrhenius plot, especially in the case of specific enzymatic reactions, which may indicate either a change in the activation energy or a different controlling mechanism [10, 11]. Due to the significant modification of mechanical and mobility properties between glassy and rubbery systems, a break in the Arrhenius plot at or near the glass transition temperature of the system may be expected [39, 40]. According to Peleg et al. [38] and Peleg et al. [41], this break of the Arrhenius plot can be attributed to the equal weight given to the reaction rate constants over the whole temperature range investigated, which does not necessarily applies. In order to observe the curvature expected in the Arrhenius plot within the rubbery state, data over a broader temperature range below the system Tg may be required, a prerequisite rather difficult to meet in the common frozen food matrices. However, it should be underlined that, although being a measurement of high importance, in some cases, accounting for the glass transition temperature may not be adequate per se for explaining the break or the curvature observed in an Arrhenius plot [9, 42] in frozen systems. In those matrices, the importance of other factors such as the nature of the glass-forming matrix, the role of freeze concentration, water activity changes, enzyme-catalyzed reactions in noncellular systems, etc. should be also taken into consideration [10] when attempting to explain a curvilinear Arrhenius plot. In view of these observations, further investigation on the kinetics of diffusion-limited processes in frozen systems is required.

Most of the equations proposed, including the Arrhenius and the WLF, although developed based on principles of chemical kinetics and thermodynamics, are empirically applied for complex food systems and do not imply a true mechanism. Hence, the value of Ea is not really an “activation energy”, as defined in thermodynamics, but rather a “universal” comparative measure of temperature dependence of the studied reaction or phenomenon in general. For frozen food quality-related reactions, values of Ea are in the range of 50 to 120 kJ/mol.

In Peleg et al. [38] and Peleg et al. [34], the limitations of both secondary models (Arrhenius and WLF) are discussed in depth, focusing on their cautious applicability at the lower end of the examined temperature range, since their logarithmic relationships make them particularly sensitive to rates. Instead, Peleg et al. [41] and Peleg et al. [26] proposed an exponential model, based on the Arrhenius equation, as shown in Table 1. The use of this form of the alternative model, where applicable, will eliminate the unnecessary compression and inversion of the temperature scale that the Arrhenius model requires. This approach is mathematically equivalent to the Q10 approach extensively used in the earlier literature [43, 44]. When using this model, one can convert published Ea values into c values of the proposed mathematical equation, and vice versa, as shown in Table 1.

In Table 2, a list of recent research papers focusing on kinetic modeling of foods of plant origin is compiled, reporting the matrix in question, the quality indices measured and the values of the kinetic parameters estimated, applying the Arrhenius law to describe the effect of temperature on reaction rate change. WLF equation was applied in a few cases, e.g., in Giannakourou and Taoukis [46] for frozen green peas. In all cases, the kinetic study is based on isothermal experiments; however, in a few among these studies, results were further validated at dynamic conditions [19, 20, 45, 46, 54], aiming at being exploited as prediction tools for product shelf life in a real cold chain. In addition to the studies in Table 2, several other references can be found in the field of frozen food quality evaluation [26, 55]. However, the majority provide a single or very limited data point analysis (e.g., measurements at two or three preselected storage times) compared to the quoted ones that applied a more systematic kinetic analysis in a wide range of storage temperatures.

Prediction of the Remaining Shelf Life of Frozen Foods

Based on numerous field surveys concerning handling practices for frozen foods [56,57,58,59], frozen foods are due to be exposed to a variable temperature environment, which not infrequently includes stages of abusive storage or transport/transfer conditions. Given the fluctuations occurring in the real cold, post-processing chain, it is crucial to fully account for the effect of temperature history on the loss of quality parameters.

Often in practice, the two-step kinetic approach is applied via the accelerated shelf life testing (ASLT) methodology, to shorten the extremely lengthy experimental process [51, 55, 60]. Extrapolation of the kinetic results to normal, non-abusive storage conditions should take into account the limitations of the secondary model applicability. The value Q(At) of the quality function at time t, defined by eq. (2) in the case of isothermal conditions, is calculated by the following integral, where T(t) describes the change of temperature as a function of time:

where keff is the value of the rate of the quality loss reaction at the effective temperature Teff. Teff is defined as the constant temperature that results in the same quality value as the variable temperature distribution over the same time period, which equals ttot.

If the T(t) function can be described by a step sequence, or, equivalently, can be discretized in small time increments ti of constant temperature Ti (with Σti = ttot), then Eq. 3 can be expressed by Eq. 4, assuming the applicability of Arrhenius equation, as the secondary model:

From Eq. 4, the value of keff can be estimated and subsequently, from the Arrhenius model, the effective temperature Teff can be calculated.

With an effective use of ASLT, shelf life modeling and determination that normally takes a year could be completed in 3 to 6 months, if the testing temperature range is from − 5 to − 12 °C. The duration of the shelf life determination by ASLT depends on the temperature dependence of the quality deterioration phenomena (as expressed by the Ea value).

Estimation of Parameter Uncertainty and Its Effect on Reliable Predictions

In kinetic studies, apart from the calculation of estimates for models’ kinetic parameters, the estimation of their confidence intervals, representing the range of their uncertainty, is equally important. As stated by Van Boekel [30], a challenge in this scientific area is to investigate in-depth the statistical quality of parameter estimates, in order to describe and take into account models’ parameter uncertainty; this would allow for more reliable and safe predictions.

Concerning the conventional method of two-step procedure, usually followed in the case of frozen foods, besides being time-consuming, it lacks reliability concerning the expression of parameters’ variability [18]. Following the standard procedure of this methodology, the confidence intervals of the primary model parameters at each temperature are not taken into account when calculating the secondary model parameters, which, consequently, can be falsely narrower than the actual ones. On the other hand, in the case of nonlinear models and a one-step process, an important issue is that the confidence intervals of the parameters involved are not symmetric and thus their estimation is not straightforward.

These remarks reveal that there are weak points both in the two-step as well as in the one-step approach, mainly at the determination of the uncertainty of the secondary model parameters. Therefore, a reliable alternative is deemed necessary to account for the real uncertainty of model parameters, in order to be able to predict in a more accurate way quality changes, at any selected temperature and time during processing and product shelf life (at storage or distribution).

The use of techniques such as Monte Carlo simulation has been recently employed in literature for the probabilistic assessment of stochastic variability and uncertainty associated with microbiological quality and safety [61,62,63] or chemical/sensory [56, 64,65,66,67,68] attributes of several food matrices. Furthermore, the Monte Carlo technique is also in the bootstrap methodology described by Efron and Tibshiraniin [69], first applied in scientific fields other than food science. Using this technique, the variation of the primary model’s parameters is estimated based on the propagation of error, artificially introduced to the experimental data (concentration vs. time data); for this, it was assumed that the experimental data was normally distributed and the error introduced at each measurement was based on its standard deviation [70,71,72]. In another case, a bootstrap Monte Carlo analysis has been proposed to compute the confidence intervals (CI) of the parameters of the Arrhenius equation in Mishra et al. [73] in order to estimate the bootstrap confidence and prediction bands (CB and PB, respectively) of the factor (here anthocyanin retention) measured.

Case Study

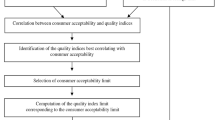

To study the shelf life of frozen spinach leaves, a literature review can assist in selecting the most representative quality indices. A systematic kinetic study conducted at several constant temperatures, using as main index vitamin C loss, is listed in Table 2. A first-order reaction order (primary model) was found to describe the above chemical reaction (Fig. 1a, Eq. 5) and Arrhenius equation to describe the temperature effect (secondary model) (Eq. 6):

a Vitamin C loss of frozen spinach [46], applying first-order kinetics and b joint confidence intervals for Arrhenius parameters when a global one-step procedure is used

where C0 is the initial vitamin C concentration (mg/100 g of food), kref is the reaction rate of the vitamin C oxidation at a reference temperature Tref (here equals to − 18 °C), Ea is the activation energy of the chemical reaction, and R is the universal gas constant.

Based on 50% vitamin C loss, spinach shelf life can be predicted at any arbitrary reference temperature, using Eqs. 5 and 6. Considering the single value estimates of the parameters (as calculated out of linear regression analysis), the frozen spinach shelf life is estimated at − 20 °C, either at 385 days (data from [45]) (and 241 days at − 18 °C) or at 190 days (data from [46]) (and 121 days at − 18 °C).

If a global-one step approach, based on non-linear regression is applied (SYSTAT 8.0) using a single equation (eq. 7) that integrates both primary and secondary models (Eqs. 5 and 6):

then, results concerning the estimation of parameters and their 95% CI namely Ea (in kJ/mol) = 115.3 ± 7.06 and kref (at − 18 °C, in day−1) = 0.00462 ± 0.00066, are slightly different from those depicted in Table 2 [46]. When applying the two-step approach, the 95% CI are calculated via regression analysis and are usually much wider than those calculated with a global one-step approach. At this point, it is worthy pointing out that, in addition to the traditional Arrhenius equation, in Peleg et al. [26] data on vitamin C loss for frozen spinach and frozen peas [46] have been successfully fitted to the exponential model (as an alternative secondary model, already presented in Table 1). It was also demonstrated that the isothermal version of the endpoints method provided accurate predictions of the concentration ratios of vitamin C in the two frozen vegetables investigated.

Potential correlation between the kinetic parameters implies that the confidence interval of one parameter depends on the value of the other parameter. Therefore, joint confidence regions should be used [74] and they are depicted in Fig. 1b (SYSTAT 8.0) for this particular case study. However, in the case of nonlinear models, an important issue underlined by Van Boekel [18] is that the confidence intervals of the parameters involved are not symmetric, and thus, their estimation is not straightforward; therefore, caution is needed when interpreting them in order to make safe predictions.

Attempting a further analysis of available kinetic data, it is possible to include the 95% confidence intervals of the Arrhenius parameters (Ea and kref) in the relative plot, instead of using only their single estimates (represented by the linear regression thin line of Fig. 2a, b); this is achieved by estimating and plotting the respective 95% confidence bands (CB) and prediction bands (PB), in order to have a more realistic perspective of the uncertainty of predictions [67]. For y = ln(kT) and x = (1/Tref-1/T), the expected value of y for a given xo (± 95% CB) is given by Eq. (8):

Effect of kT data uncertainty on secondary model predictions. Circles depict mean values of kT data. Black straight line is the linear regression line of the mean values; red lines represent the ± 95% confidence band (CB) and blue lines represent the ± 95% prediction band (PB) a data from Giannakourou and Taoukis [46], b data from Dermesonluoglu et al. [45]

while predicted value of y for a given xo (± 95% PB) is given by Eq. (9):

where σy is the standard deviation of the residuals, σxx is the sum of squared error, N is the number of variables, \( {\overset{\frown }{y}}_o \)is the estimated value of y based on linear regression, \( \overline{x} \)the mean value of all x’s and ta/2 is the value of Student’s distribution for N-2 degrees of freedom. Using the two sets available for vitamin C loss in frozen spinach, the plots of Fig 2a, b are generated, showing the experimental data points, the linear regression lines, and the estimated 95% CB and PB, respectively.

The selection of a confidence level (here 95%) actually demonstrates the probability that the confidence interval produced will contain the true parameter value. The % confidence level corresponds to percentages of the area of the normal density curve. For example, a 95% confidence interval covers 95% of the normal curve and the probability of observing a value outside of this area is less than 5%. Given that the normal curve is symmetric, half of the area is in the left tail of the curve, and the other half of the area is in the right tail of the curve. Therefore, assuming that Arrhenius parameters follow such a pattern, Ea and kref at a constant, ‘reference’ temperature can be described by a normal distribution curve, rather than a single value. The benefit of the proposed approach is that it incorporates the variability calculated by the secondary model (based on the linear regression of the Arrhenius equation) and thus the variability of its parameters [67] to the estimation of the shelf life. To demonstrate the implementation of this methodology, the aforementioned published data on vitamin C loss in frozen spinach and estimations of Ea and kref already shown in Fig. 3 are used. Then, a Monte Carlo simulation can be applied, assuming that Ea and kref variability are described by a normal distribution. A similar approach was used by Sui and Zhou [75] when assessing the confidence intervals of Ea and kref parameters of the Arrhenius equation for non-isothermal degradation of cyanidins, by generating artificial data on the initial concentration, using the experimental error, an approach that could be also applied in the case of frozen foods, under non-isothermal conditions. At this point, it should be noted that there are many types of data variability, which cannot always be mathematically described [76]. Furthermore, there are specific situations presented where a single probability distribution is unable to account for the scarcity or imprecision present in the available data [77]; however, data variability, in a form of randomness as represented by a Gaussian distribution, is commonly formulated and encountered in food engineering.

An example of such a normal distribution, which is constructed based on the estimate of the mean value, Ea, of 120.0 kJ/mol and its standard deviation, (σ = 7.0 kJ/mol) is demonstrated in Fig. 3, based on linear regression and confidence interval estimation, using data shown on the previous Fig. 2a for data from Giannakourou and Taoukis [46]. The same procedure was followed to construct the corresponding distribution curve for kref.

The next step involves the use of the Monte Carlo technique [67, 78] through a FORTRAN algorithm. The application of Monte Carlo techniques has recently been described in several food safety applications [79, 80]. At each iteration, a random number was generated and a value was assigned to Ea and kref (independently the one from the other) based on the discretization of the corresponding normal distribution curve. The correlation between the random numbers and the respective values of Ea and kref was based on the frequency determined by the corresponding distribution. In this case study, Monte Carlo algorithm was repeated for 10,000 iterations, a number suggested in Singh and Markeset [81] and Barreto and Howland [82], who state that ‘although one thousand repetitions will usually generate a fairly good approximation, 10000 would be even closer to the truth’. This observation is important, as Monte Carlo simulation aims to be an approximation to the actual truth in a sampling context, based on an infinite number of repetitions. The purpose of Monte Carlo implementation in this work was to assign specific values to the Ea and kref parameters, allowing for Ea-kref pairs of values to be estimated; subsequently, based on the Arrhenius equation, the rate constant k was estimated at an arbitrarily chosen temperature of − 18 °C, and the corresponding shelf life was calculated (including its uncertainty) at that temperature (based on 50% vitamin C loss as the acceptability limit). Results for shelf life (SL) calculation, as well as its uncertainty, are shown in Fig. 4 (red line), representing a frequency curve with a mean value (SL estimate) equal to 125.0 ± 23.9 (95%CI) days, giving a more realistic prediction than the sole estimation of 121 days, based merely on Arrhenius parameters’ mean estimated values.

If data from the two different published sources are compared using the same stochastic approach, one can observe the significant differences in the SL prediction, reflected not only on the mean SL predicted value, but also on its uncertainty (Fig. 4), an observation that confirms the risk in applying results of one study to another, even if the matrix in question is almost the same. From data out of Dermesonluoglu et al. [45], results for SL calculation give a mean value (SL estimate) equal to 249.0 ± 47.6 (95%CI) days, compared to the one value estimation of 241 days, based merely on Arrhenius parameters’ mean values. Comparing the two literature sources, in Giannakourou and Taoukis [46], vitamin C loss was measured in cubes of frozen spinach, whereas in Dermesonluoglu et al. [45], the food product in study was frozen spinach leaves. In any case, the important differences observed rise questions about the generalized applicability of shelf life models in different tissues and make the need for incorporating parameters uncertainty into SL prediction more crucial. In order to further sustain this observation, the same stochastic approach was also applied for vitamin C loss in other matrices, for which appropriate kinetic data are available (Table 2). Results, presented in Table 3, demonstrate the different behavior and the different temperature sensitivity of vitamin C degradation, when different cellular environments are concerned.

This methodology is neither limited to a specific quality index nor to first-order kinetics. As an example, the study could be extended for color degradation, which in Giannakourou and Taoukis [56], for frozen green peas, was described by parameter (ΔC) change as a pseudo-zero-order reaction. Using comparatively the kinetic data out of this study for the two alternative modes of deterioration, namely vitamin C loss and color change (Table 2), applying the shelf life criteria set (ΔC = 10) and following the steps of the proposed methodology via Monte Carlo technique, the shelf life can be calculated at any temperature of interest. Figure 6a, b illustrates the predicted shelf life at two temperatures, namely at − 8 °C and − 18 °C, based on the two quality factors, demonstrating that the shelf life can be decided either on the basis of nutritional declaration (vitamin C content) or sensory criteria (color) depending on the actual temperature history of the product.

In all the discussion up to now, it is worthy noticing that the variation of the primary model (Eq. 5) parameters (vitamin C loss rate, kVitC) has not been taken into account in determining the uncertainty of the parameters of the secondary model (Eq. 6, kref and Ea). Considering the divergence of estimates of kinetic parameters in different studies, as already shown for the case of frozen spinach, it would be a challenge to assess how the propagation of the primary model parameter variability into the secondary model kinetic parameters would change and improve shelf life predictions in the area of frozen foods.

In such an attempt, a different approach was followed using the published data from Giannakourou and Taoukis [46] for vitamin C loss in frozen spinach (Table 2). The proposed procedure was based on the assumption that the estimate of the main parameter kVitC of Eq. (6), which is determined by linear regression of lnC vs. t data for each temperature, can be described by a distribution of values rather than by a single value. The benefit of this approach is that it incorporates the error in kVitC calculated by the linear regression of the primary model, and thus the variability of the parameter [83, 84]. This time in applying the Monte Carlo simulation, a normal distribution was assumed to describe kVitC variability, for each of the five temperatures studied. At each iteration, a random number was generated and a value was assigned to kVitC based on the discretization of the corresponding normal distribution curve, for each of the five temperatures studied. The purpose was to create a set of 5-kVitC values for the studied temperatures, so as, by using Eq. 6, each iteration provides an estimate for Arrhenius parameters, namely kref and Ea. In a similar way to the previously described case study, Monte Carlo simulation was repeated 10,000 times, assigning values to each set of kVitC values.

The ultimate goal was to determine the values and the corresponding errors (or confidence intervals) of kref and Ea (Eq. 6) based on the kVitC datasets that have been produced out of the previous step of Monte Carlo application. For each specific, random, set of the 5kVitC values, a pair of estimates for kref and Ea and their corresponding variations was assessed based on linear regression of lnkVitC vs. (1/T-1/Tref) data.

The application of the proposed methodology using the experimental data of vitamin C loss in frozen spinach led to significant changes of the 95% CI of the parameters kref and Ea compared to their initial estimates (without altering at all the mean value, as expected). The 95% CI on the kref and Ea found through the proposed analysis were ± 0.001766 day−1 and ± 17.36 kJ/mol, respectively, comparable to the initial estimates of ± 0.001015 day−1 and ± 11.85 kJ/mol, respectively, that were calculated without taking into account the uncertainty at the determination of each kVitC value (at each temperature). This also affects shelf life predictions at − 18 °C, if we use the approach already discussed, using the Monte Carlo iteration algorithm. As shown in Fig. 5, with the latter technique 95% CI of shelf life are broader when variability of primary model’s parameters is integrated, leading to more realistic assessments.

Distribution of the 10,000 values of shelf life at − 18 °C, generated by the Monte Carlo simulation based on available, published kinetic data of vitamin C loss in spinach [46] with and without integrating primary models’ uncertainty

One can notice, however, that differences in this case are not that big, possibly due to the narrow 95% CI of primary model’s parameter kVitC (Fig. 6). As demonstrated in Giannakourou and Stoforos [67], in case of a broader uncertainty of primary model’s parameter, the aforementioned differences would be significant enough to justify completely the application of this more complicated computational tool.

Distribution of shelf life, based on kinetic data of vitamin C loss and color degradation for frozen green peas [52] at a − 8 °C and b − 18 °C

In any case, this set of data served as a case study to demonstrate the structure and the rationale of the different approaches to kinetically model a quality index change in frozen foods, when temperature is assumed as the crucial factor. Main steps would be identical—possibly with slight computational modifications—if the primary model does not follow a pseudo-first-order degradation (as in vitamin C loss case) or if another secondary model (e.g., the WLF equation) is chosen over the traditional Arrhenius equation.

Conclusions

As demonstrated by a thorough review of current literature, few publications provide a systematic and profound kinetic study when addressing frozen tissue quality degradation and most models published do not really specify the possible application and one can interpret results in his/her own judgment. Additionally, another important observation is that there has been little attention in the food science literature, so far, for the statistical quality of kinetic parameters, and especially for the effect of their uncertainty. Therefore, next to the well-known biological variability of foods, it is important to study the significance of parameter uncertainty (as expressed by their 95% Confidence Intervals) in more detail, certainly if the scope is to make real model predictions. Reporting of parameter uncertainty is paramount when kinetic results are presented. The use of techniques such as Monte Carlo simulations is very promising and should be used much more often [30].

In this work, the practical aspects of modeling frozen food quality were reviewed. Two alternative techniques were proposed for exploiting and further analyzing available published kinetic data. A methodology that takes into account the calculated uncertainty of the secondary model parameters (Arrhenius equation) and, going a step further, an approach that introduces the variability of the primary model’s parameters into the secondary model. Both schemes allow for the estimation of the remaining shelf life of the product in question at any point within the chill chain, in a more reliable and realistic way, compared to the traditional two-step kinetic study. The Monte Carlo simulation approach applied on published literature data of vitamin C loss in several food matrices demonstrated the improved predictions that can be obtained. The same procedure was implemented for zero-order kinetics, in the case of another quality index, color degradation, frequently measured during frozen food storage. In this latter case, shelf life of frozen green peas was predicted either on nutritional criteria (vitamin C loss) or on color degradation. Comparative results at two different temperatures showed that the quality factor that determines the end of shelf life may vary, depending on the actual temperature history of the product.

It should be pointed out that, although the preceding analysis referred mainly to first-order vitamin C loss/zero-order color degradation and temperature dependence modeled by the Arrhenius equation, the same methodology can be employed when a different primary or secondary model is used to describe kinetic data.

References

Bonat Celli G, Ghanem A, Su-Ling Brooks M (2016) Influence of freezing process and frozen storage on the quality of fruits and fruit products. Food Rev Int 32:280–304. https://doi.org/10.1080/87559129.2015.1075212

Corradini MG, Peleg M (2006b) Prediction of vitamins loss during non-isothermal heat processes and storage with non-linear kinetic models. Trends Food Sci Technol 17(1):24–34

Mattick KL, Legan JD, Humphrey TJ, Peleg M (2001) Calculating Salmonella inactivation in nonisothermal heat treatments from isothermal nonlinear survival curves. J Food Prot 64(5):606–613

Periago PM, van Zuijlen A, Fernandez PS, Klapwijk PM, ter Steeg PF, Corradini MG, Peleg M (2004) Estimation of the non-isothermal inactivation patterns of Bacillus sporothermodurans IC4 spores in soups from their isothermal survival data. Int J Food Microbiol 95(2):205–218

Valdramidis VP, Geeraerd AH, Bernaerts K, Van Impe JF (2006) Microbial dynamics versus mathematical model dynamics: the case of microbial heat resistance induction. Innov Food Sci Emerg 7:80–87. https://doi.org/10.1016/j.ifset.2005.09.005

Charoenrein S, Harnkarnsujarit N (2016) Food Freezing and Non-Equilibrium States. In: Non-Equilibrium States and Glass Transitions in Foods: Processing Effects and Product-Specific Implications. pp 39–62. doi:https://doi.org/10.1016/b978-0-08-100309-1.00004-3

Reid DS, Sajjaanantakul T, Lillford PJ, Charoenrein S (2010) Water Properties in Food, Health, Pharmaceutical and Biological Systems: ISOPOW 10. Water properties in food, health, pharmaceutical and biological systems: ISOPOW 10. doi:https://doi.org/10.1002/9780470958193

Biliaderis CG, Swan RS, Arvanitoyannis I (1999) Physicochemical properties of commercial starch hydrolyzates in the frozen state. Food Chem 64:537–546. https://doi.org/10.1016/S0308-8146(98)00165-4

Manzocco L, Nicoli MC, Anese M, Pitotti A, Maltini E (1998) Polyphenoloxidase and peroxidase activity in partially frozen systems with different physical properties. Food Res Int 31:363–370. https://doi.org/10.1016/S0963-9969(98)00095-7

Terefe NS, Hendrickx M (2002) Kinetics of the pectin Methylesterase catalyzed De-esterification of pectin in frozen food model systems. Biotechnol Prog 18:221–228. https://doi.org/10.1021/bp010162e

Terefe NS, Van Loey A, Hendrickx M (2004) Modelling the kinetics of enzyme-catalysed reactions in frozen systems: the alkaline phosphatase catalysed hydrolysis of di-sodium-p-nitrophenyl phosphate. Innov Food Sci Emerg 5:335–344. https://doi.org/10.1016/j.ifset.2004.05.004

Syamaladevi RM, Sablani SS, Tang J, Powers J, Swanson BG (2011) Stability of anthocyanins in frozen and freeze-dried raspberries during long-term storage: in relation to glass transition. J Food Sci 76:E414–E421. https://doi.org/10.1111/j.1750-3841.2011.02249.x

Syamaladevi RM, Manahiloh KN, Muhunthan B, Sablani SS (2012) Understanding the influence of state/phase transitions on ice recrystallization in Atlantic Salmon (Salmo salar) during frozen storage. Food Biophys 7:57–71. https://doi.org/10.1007/s11483-011-9243-y

Zhang Y, Zhao J-H, Ding Y, Nie Y, Xiao H-W, Zhu Z, Tang X-M (2017) Effects of state/phase transitions on the quality attributes of mango (Mangifera indica L.) during frozen storage. Int J Food Sci Technol 52:239–246. https://doi.org/10.1111/ijfs.13275

Huang K, Tian H, Gai L, Wang J (2012) A review of kinetic models for inactivating microorganisms and enzymes by pulsed electric field processing. J Food Eng 111:191–207. https://doi.org/10.1016/j.jfoodeng.2012.02.007

DerSimonian R, Laird N (1986) Meta-analysis in clinical trials. Control Clin Trials 7:177–188. https://doi.org/10.1016/0197-2456(86)90046-2

Sutton AJ, Abrams KR, Jones DR (2001) An illustrated guide to the methods of meta-analysis. J Eval Clin Pract 7:135–148. https://doi.org/10.1046/j.1365-2753.2001.00281.x

Van Boekel MAJS (1996) Statistical aspects of kinetic modeling for food science problems. J Food Sci 61:477–486. https://doi.org/10.1111/j.1365-2621.1996.tb13138.x

Gonçalves EM, Abreu M, Brandão TRS, Silva CLM (2011a) Degradation kinetics of colour, vitamin C and drip loss in frozen broccoli (Brassica oleracea L. ssp. Italica) during storage at isothermal and non-isothermal conditions. Int J Refrig 34:2136–2144. https://doi.org/10.1016/j.ijrefrig.2011.06.006

Gonçalves EM, Pinheiro J, Abreu M, Brandão TRS, Silva CLM (2011b) Kinetics of quality changes of pumpkin (Curcurbita maxima L.) stored under isothermal and non-isothermal frozen conditions. J Food Eng 106:40–47. https://doi.org/10.1016/j.jfoodeng.2011.04.004

Huang L (2015a) Direct construction of predictive models for describing growth of Salmonella Enteritidis in liquid eggs - a one-step approach. Food Control 57:76–81. https://doi.org/10.1016/j.foodcont.2015.03.051

Valdramidis VP, Geeraerd AH, Bernaerts K, Van Impe JFM (2008) Identification of non-linear microbial inactivation kinetics under dynamic conditions. Int J Food Microbiol 128:146–152. https://doi.org/10.1016/j.ijfoodmicro.2008.06.036

Valdramidis VP, Taoukis PS, Stoforos NG, Van Impe JFM (2012) In: Cullen PJ, Tiwari BK, Valdramidis VP (eds) novel thermal and non-thermal technologies for fluid foods. Academic Press, London, UK doi:https://doi.org/10.1016/b978-0-12-381470-8.00014-1

Taoukis PS, Giannakourou MC (2018) Modelling food quality. Food Sci Technol (London) 32:38–43

Giannakourou MC, Stoforos NG (2016) In: Carvajal-Millan E, Mohan CO, Ravishankar CN (eds) food process engineering and quality assurance, apple academic press Inc., NJ, USA

Peleg M, Normand MD, Dixon WR, Goulette TR (2018) Modeling the degradation kinetics of ascorbic acid. Crit Rev Food Sci 58:1478–1494. https://doi.org/10.1080/10408398.2016.1264360

Peleg M (2003) Microbial survival curves: interpretation, mathematical modeling, and utilization. Comments on Theoretical Biology 8:357–387

Peleg M, Normand MD, Corradini MG (2005) Generating microbial survival curves during thermal processing in real time. J Appl Microbiol 98:406–417

Taoukis PS, Labuza TP, Saguy S (1997) In: Valentas KJ, Rotstein E,Singh RP (Eds) Handbook of food engineering practice. New York: CRC Press

Van Boekel MAJS (2008) Kinetic modeling of food quality: a critical review. Compr Rev Food Sci Food 7:144–158. https://doi.org/10.1111/j.1541-4337.2007.00036.x

Fu B, Labuza TP (1993) Shelf life prediction: theory and applications. Food Prot 4(3):125–133

Corradini MG, Peleg M (2006a) On modeling and simulating transitions between microbial growth and inactivation or vice versa. Int J Food Microbiol 108:22–35

Arrhenius SA (1889) Über die Dissociationswärme und den Einfluß der Temperatur auf den Dissociationsgrad der Elektrolyte. Z Phys Chem 4:96–116. https://doi.org/10.1515/zpch-1889-0408

Peleg M, Normand MD, Corradini MG (2012a) The Arrhenius equation revisited. Crit Rev Food Sci 52(9):830–851

Peleg M, Normand MD, Corradini MG (2017) A new look at kinetics in relation to food storage. Annu Rev Food Sci Technol 8:135–153

Williams ML, Landel RF, Ferry JD (1955) The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J Chem Eng 77:3701–3707

Peleg M (1992) On the use of the WLF model in polymers and foods. Crit Rev Food Sci Nutr 32:59–66. https://doi.org/10.1080/10408399209527580

Peleg M, Engel R, Gonzalez-Martinez C, Corradini MG (2002) Non-Arrhenius and non-WLF kinetics in food systems. J Sci Food Agric 82(12):1346–1355

Nelson KA, Labuza TP (1994) Water activity and food polymer science: implications of state on Arrhenius and WLF models in predicting shelf life. J Food Eng 22:271–289. https://doi.org/10.1016/0260-8774(94)90035-3

Taoukis PS, Tsironi TS, Giannakourou MC (2015) handbook of food processing and engineering. In: Tzia K, Varzakas T (eds) food engineering fundamentals, vol I. CRC press, Boca Raton, Florida, USA

Peleg M, Normand MD, Corradini MG (2012b) On Quantifying Nonthermal Effects on the Lethality of Pressure-Assisted Heat Preservation Processes. J Food Sci 77:R47–R56. https://doi.org/10.1111/j.1750-3841.2011.02444.x

Giannakourou MC, Taoukis PS (2003c) Stability of dehydrofrozen green peas pretreated with nonconventional osmotic agents. J Food Sci 68:2002–2010

Labuza TP (1982) Shelf-Life Dating of Foods. Food & Nutrition Press, Inc., Westport

Taoukis PS (2011) In: Heldman DR, Moraru CI (eds) Encyclopedia of Agricultural, Food and Biological Engineering, Vol. II, 2nd edn. CRC Press, Taylor & Francis Group, New York

Dermesonluoglu E, Katsaros G, Tsevdou M, Giannakourou M, Taoukis P (2015) Kinetic study of quality indices and shelf life modelling of frozen spinach under dynamic conditions of the cold chain. J Food Eng 148:13–23. https://doi.org/10.1016/j.jfoodeng.2014.07.007

Giannakourou MC, Taoukis PS (2003b) Kinetic modelling of vitamin C loss in frozen green vegetables under variable storage conditions. Food Chem 83:33–41. https://doi.org/10.1016/S0308-8146(03)00033-5

Martins RC, Silva CLM (2004) Frozen green beans (Phaseolus vulgaris, L.) quality profile evaluation during home storage. J Food Eng 64:481–488. https://doi.org/10.1016/j.jfoodeng.2003.11.015

Gonçalves EM, Cruz RMS, Abreu M, Brandão TRS, Silva CLM (2009) Biochemical and colour changes of watercress (Nasturtium officinale R. Br.) during freezing and frozen storage. J Food Eng 93:32–39. https://doi.org/10.1016/j.jfoodeng.2008.12.027

Dermesonlouoglou EK, Giannakourou M, Taoukis PS (2016) Kinetic study of the effect of the osmotic dehydration pre-treatment with alternative osmotic solutes to the shelf life of frozen strawberry. Food Bioprod Process 99:212–221. https://doi.org/10.1016/j.fbp.2016.05.006

Dermesonlouoglou E, Zachariou I, Andreou V, Taoukis PS (2018) Quality assessment and shelf life modeling of pulsed electric field pretreated osmodehydrofrozen kiwifruit slices. Int J Food Stud 7:34–51. https://doi.org/10.7455/ijfs/7.1.2018.a4

Martins RC, Lopes IC, Silva CLM (2005) Accelerated life testing of frozen green beans (Phaseolus vulgaris, L.) quality loss kinetics: colour and starch. J Food Eng 67:339–346. https://doi.org/10.1016/j.jfoodeng.2004.04.037

Giannakourou MC, Taoukis PS (2002) Systematic application of time temperature integrators as tools for control of frozen vegetable quality. J Food Sci 67(6):2221–2228

Dermesonlouoglou E, Giannakourou M, Taoukis P (2007) Kinetic modelling of the quality degradation of frozen watermelon tissue: effect of the osmotic dehydration as a pre-treatment. Int J Food Sci Technol 42:790–798. https://doi.org/10.1111/j.1365-2621.2006.01280.x

Cruz RMS, Vieira MC, Silva CLM (2009) Effect of cold chain temperature abuses on the quality of frozen watercress (Nasturtium officinale R. Br.). J Food Eng 94:90–97. https://doi.org/10.1016/j.jfoodeng.2009.03.006

Corradini MG, Peleg M (2007) Shelf-life estimation from accelerated storage data. Trends Food Sci Technol 18:37–47

Giannakourou MC, Taoukis PS (2003a) Application of a TTI-based distribution management system for quality optimization of frozen vegetables at the consumer end. J Food Sci 68:201–209

Gogou E, Derens E, Alvarez G, Taoukis P (2014) Field test monitoring of the food cold chain in European markets. Refr Sci Technol 548–554

Gogou E, Katsaros G, Derens E, Alvarez G, Taoukis PS (2015) Cold chain database development and application as a tool for the cold chain management and food quality evaluation. Int J Refrig 52:109–121. https://doi.org/10.1016/j.ijrefrig.2015.01.019

Gwanpua SG, Verboven P, Leducq D, Brown T, Verlinden BE, Bekele E, Aregawi W, Evans J, Foster A, Duret S, Hoang HM, Van Der Sluis S, Wissink E, Hendriksen LJAM, Taoukis P, Gogou E, Stahl V, El Jabri M, Le Page JF, Claussen I, Indergård E, Nicolai BM, Alvarez G, Geeraerd AH (2015) The FRISBEE tool, a software for optimising the trade-off between food quality, energy use, and global warming impact of cold chains. J Food Eng 148:2–12. https://doi.org/10.1016/j.jfoodeng.2014.06.021

Labuza TP (1985) In: Fennema OR (ed) food chemistry, 2nd edn. Marcel Dekker, New York

Aspridou Z, Koutsoumanis KP (2015) Individual cell heterogeneity as variability source in population dynamics of microbial inactivation. Food Microbiol 45(Part B):216–221. https://doi.org/10.1016/j.fm.2014.04.008

Huang L (2015b) Dynamic determination of kinetic parameters, computer simulation, and probabilistic analysis of growth of Clostridium perfringens in cooked beef during cooling. Int J Food Microbiol 195:20–29. https://doi.org/10.1016/j.ijfoodmicro.2014.11.025

Lianou A, Koutsoumanis KP (2011) A stochastic approach for integrating strain variability in modeling Salmonella enterica growth as a function of pH and water activity. Int J Food Microbiol 149:254–261. https://doi.org/10.1016/j.ijfoodmicro.2011.07.001

Channon HA, Hamilton AJ, D'Souza DN, Dunshea FR (2016) Estimating the impact of various pathway parameters on tenderness, flavour and juiciness of pork using Monte Carlo simulation methods. Meat Sci 116:58–66. https://doi.org/10.1016/j.meatsci.2016.01.004

Evrendilek GA, Avsar YK, Evrendilek F (2016) Modelling stochastic variability and uncertainty in aroma active compounds of PEF-treated peach nectar as a function of physical and sensory properties, and treatment time. Food Chem 190:634–642. https://doi.org/10.1016/j.foodchem.2015.06.010

Giannakourou MC, Koutsoumanis K, Dermesonlouoglou E, Taoukis PS (2001) Applicability of the shelf life decision system (SLDS) for control of nutritional quality of frozen vegetables. Acta Hortic 566:275–280

Giannakourou MC, Stoforos NG (2017) A theoretical analysis for assessing the variability of secondary model thermal inactivation kinetic parameters. Foods 6:7

Wesolek N, Roudot AC (2016) Assessing aflatoxin B1 distribution and variability in pistachios: validation of a Monte Carlo modeling method and comparison to the codex method. Food Control 59:553–560. https://doi.org/10.1016/j.foodcont.2015.06.034

Efron B, Tibshirani RJ (1993) An introduction to the bootstrap, 1st edn. Chapman & Hall/CRC Monographs on Statistics & Applied Probability, Boca Raton, FL, USA

Poschet F, Bernaerts K, Geeraerd AH, Scheerlinck N, Nicolaı̈ BM, Van Impe JF (2004) Sensitivity analysis of microbial growth parameter distributions with respect to data quality and quantity by using Monte Carlo analysis. Math Comput Simul 65:231–243. https://doi.org/10.1016/j.matcom.2003.12.002

Poschet F et al (2003) Monte Carlo analysis as a tool to incorporate variation on experimental data in predictive microbiology. Food Microbiol 20:285–295. https://doi.org/10.1016/S0740-0020(02)00156-9

Poschet F, Geeraerd AH, Van Loey AM, Hendrickx ME, Van Impe JF (2005) Assessing the optimal experiment setup for first order kinetic studies by Monte Carlo analysis. Food Control 16:873–882. https://doi.org/10.1016/j.foodcont.2004.07.009

Mishra DK, Dolan KD, Yang L (2011) Bootstrap confidence intervals for the kinetic parameters of degradation of anthocyanins in grape pomace. J Food Process Eng 34:1220–1233. https://doi.org/10.1111/j.1745-4530.2009.00425.x

Dolan KD, Yang L, Trampel CP (2007) Nonlinear regression technique to estimate kinetic parameters and confidence intervals in unsteady-state conduction-heated foods. J Food Eng 80:581–593

Sui X, Zhou W (2014) Monte Carlo modelling of non-isothermal degradation of two cyanidin-based anthocyanins in aqueous system at high temperatures and its impact on antioxidant capacities. Food Chem 148:342–350. https://doi.org/10.1016/j.foodchem.2013.10.060

Rodríguez-Martínez V, Velázquez G, Welti-Chanes J, Torres, JA (2018) In: Barbosa-Cánovas GV, Fontana AJ, Schmidt SJ, Labuza TP (eds.), water activity in foods, Fundamental and applications. Wiley-Blackwell, New York

Destercke S, Chojnacki E (2009) Safety, reliability and risk analysis: theory. In: Martorell S, Soares CG, Barnett J (eds) Methods and applications. Taylor & Francis Group, London

Smid JH, Verloo D, Barker GC, Havelaar AH (2010) Strengths and weaknesses of Monte Carlo simulation models and Bayesian belief networks in microbial risk assessment. Int J Food Microbiol 139:S57–S63. https://doi.org/10.1016/j.ijfoodmicro.2009.12.015

Cassin MH, Paoli GM, Lammerding AM (1998) Simulation modeling for microbial risk assessment. J Food Prot 61(11):1560–1566

Jaykus LA (1996) The Application of Quantitative Risk Assessment to Microbial Food Safety Risks. Crit Rev Microbiol 22(4):279–293. https://doi.org/10.3109/10408419609105483

Singh M, Markeset T (2009) In: Martorell S, Soares CG, Barnett J (eds) Safety, reliability and risk analysis: theory, methods and applications, Taylor & Francis Group, London

Barreto H, Howland FM (2006) Introductory econometrics: using Monte Carlo simulation with Microsoft excel®. Cambridge University Press, New York

Lammerding AM, Fazil A (2000) Hazard identification and exposure assessment for microbial food safety risk assessment. Int J Food Microbiol 58:147–157. https://doi.org/10.1016/s0168-1605(00)00269-5

Taoukis PS (2001). In: Tijkskens LMM, Hertog MLATM, Nicolai BM (Eds) Food process modeling. New York: CRC Press

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Giannakourou, M.C., Taoukis, P.S. Meta-analysis of Kinetic Parameter Uncertainty on Shelf Life Prediction in the Frozen Fruits and Vegetable Chain. Food Eng Rev 11, 14–28 (2019). https://doi.org/10.1007/s12393-018-9183-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-018-9183-0