Abstract

Spices and herbs are important parts of human daily food consumption and play an essential role in seasoning and/or preserving food, curing illness, and enhancing cosmetics. Proper processing is necessary because the fresh produce has high moisture content and often high load of microorganisms. Dehydration is the most common method used to lower moisture content and hence the water activity to a safe limit which prolongs shelf life. However, consumers’ demand on processed products with most of the original characteristics of the fresh plants has increased. Consequently, drying must be executed carefully in the interest of retaining the taste, aroma, color, appearance, as well as nutritional value of the plants to maximum possible extent. In addition to quality considerations, drying efficiency is another key aspect for evaluating drying performance. This article reviews recent developments in the production of high dried spices and herbs. It attempts to detail the relative merits of selected recently developed drying techniques with focus on solar-assisted and microwave-assisted hybrid drying techniques which offer high-quality drying with excellent efficiency. Outlook for future research trends and challenges for dehydration of spices and herbs is also discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Spices and herbs are mostly botanical origin plants that are especially valued by virtue of their taste, aroma, color, medicinal functionality, and preservative action [1,2,3]. Normally, such produce should be handled properly before being utilized to season and/or preserve food, cure illness, and enhance cosmetics [4,5,6]. Fresh harvested spices and herbs contain a high mount of moisture and numerous microorganisms; immediate preservation should be carried out to prevent biological deterioration after harvesting due to their perishable characteristics. Thermal drying is the most commonly used cost-effective means of post-harvest processing to avoid losses of these raw materials [7]. It is also necessary to avoid potential safety hazard due to formation of toxins [8, 9].

Drying is one of the oldest techniques for food preservation and it is an indispensable process in the food industry. It aims at lowering moisture content and water activity to safe limits that prolong shelf life, minimize packaging demand, as well as reduce shipping weights [10,11,12]. Therefore, this technique is widely used for dehydrating foodstuff such as vegetables, fruits, spices, herbs, and other products [13,14,15,16].

Nowadays, consumers’ demand on processed products with most of the original characteristics of the fresh plants has increased. Consequently, drying must be executed carefully in the interest of retaining the flavor, aroma, color, appearance, and nutritional value of the plants as much as possible [17]. In addition to quality considerations, drying efficiency is another key aspect for evaluating drying performance, which involves energy consumption, drying time, drying rate, and so forth.

Drying can be roughly described as a mass and heat transfer process consisting of the removal of water or another solvent by evaporation from a solid, semi-solid, or liquid [18]. However, the drying mechanism is quite complex to be accurately described and modeled because it involves concurrent heat, mass, and momentum transfer through a porous or nonporous substance with phase transition and with or without chemical reactions [19]. It is recognized as an energy intensive unit operation for most industrial processes [20,21,22], and certain evidences revealed that industrial drying consumes around 10–15% of national industrial energy in some developed countries [23,24,25], whereas around 30–40% of total energy consumption in several developing countries [26].

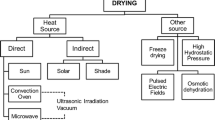

Various conventional drying techniques have been applied for spices and herbs including solar drying [27], hot air-drying [28], freeze-drying [29], and microwave drying [30]. However, most of these drying methods require long drying time and excessive energy consumption, thus causing the dehydrated products with undesirable quality [31, 32]. Since spices and herbs are heat-sensitive raw materials, it is desirable to process them under gentle drying conditions. Solo drying technique is generally incapable of providing both excellent product quality and high drying efficiency, and numerous innovative drying techniques have been established and adopt to improve drying efficiency (e.g., drying time, drying rate, and energy consumption) as well as to obtain premium quality products.

The objective of this review is to present an overview of the recent developments in the high quality and efficient drying of spices and herbs. The relative merits of selected novel techniques (mainly hybrid drying techniques) in offering the high quality drying with high efficiency and outlook for future research trends and challenges for spices and herbs dehydration are discussed.

Novel Hybrid Drying Techniques

Conventional “solo” drying techniques (e.g., solar drying, hot air-drying, freeze-drying) can rarely achieve high drying efficiency with least effect on quality of dried spices and herbs [33,34,35]. The combination of two or more different drying methods can provide a synergistic effect, resulting in diminished energy requirement and drying time while maintaining most quality attributes [36, 37].

Researchers have made considerable effort to devise novel hybrid drying techniques to further promote the drying performance, with respect to product quality (e.g., aroma, taste, nutrients, color, texture, etc.). Here, novel hybrid techniques are summarized, classified, and discussed.

Solar-Assisted Hybrid Drying Techniques

Solar energy is one of the most widely used renewable energy sources for drying of fruits [38], vegetable [39], spices and herbs [40, 41], etc. Solar drying is an economical and sustainable eco-friendly process for agricultural products [42]. However, this technology has its limitations such as poor quality and hygienic issues in the products, slow drying process, losses of product due to insects and birds, large space requirement, as well as high labor cost [43,44,45].

Based on solar energy utilization, solar drying can be sorted into three main groups: (a) direct or open-air sun drying where the product is directly exposed to the sun, (b) indirect solar drying or convective solar drying, and (c) mixed-mode or hybrid solar drying. Meanwhile, solar dryers are divided into two major categories: natural and forced convection solar dryers. From the structural aspects, solar dryers were also allocated to three major types: the greenhouse type, the collector type, and the heat pump-assisted type. Table 1 lists spices and herbs that are subjected to solar-assisted hybrid drying and what methods are used, and details are addressed in the following section.

Forced convection solar dryers are convenient to dry large amounts of raw materials [46]. Rabha et al. [47] conducted the comparative experiments to investigate the drying characteristic in the indirect-type forced convection solar tunnel dryer and open-air sun drying of thin layer ghost chili pepper. The indirect-type solar dryer consists of a semi-continuous-type tunnel dryer, two double-pass solar air heaters (SAH), a shell and tube heat exchanger, and a blower. Figure 1a shows a schematic layout of the dryer, and the cross-sectional profile of a solar air heater is presented in Fig. 1b. Their study showed that the drying time required to reduce the moisture ratio of ghost chili pepper from 589.6% (db) to 12% (db) was 123 h in solar tunnel dryer, while 193 h in open-air sun drying. In addition to its longer drying time process, open-air sun drying had undesirable effects on the color, texture, and quality of dried ghost chili pepper. El-Sebaii et al. [48] investigated the mathematical models of thin layer drying to specify the suitable model for depicting the drying behavior of thymus and mint in an indirect-mode forced convection solar dryer. Midilli and Kucuk model (MR = 0.9891 exp. (−0.0568t3.0459) + 0.029 t) was suitable for describing the thin layer solar drying of mint. However, the Page (MR = exp. (−6.2032 × 10−8 t4.9107)) and modified Page models (MR = exp. (−(0.0341 t)4.9107)) gave the best model fit for dehydration of thymus. The cost of drying mint and thymus in the indirect-mode forced convection solar dryer was found to be 0.025 €/kg and 0.087 €/kg, respectively.

a Schematic layout of a solar tunnel dryer and b cross-sectional profile of a solar air heater. a 1 Tunnel dryer, 2 shell and tube heat exchanger for energy storage, 3 solar air heater, 4 air blower, 5 ball valve, 6 pyranometer, 7 thermocouple, 8 flow meter, 9 energy meter, 10 data acquisition system [47]

Solar dryer with greenhouse unit is used to store solar energy inside the greenhouse during the daytime or to transfer excess thermal energy from inside the greenhouse to a heat storage area [49]. Normally, this type of solar dryer utilizes transparent plastic tunnels as air heaters. Morad et al. [49] constructed three identical solar tunnel greenhouse dryers with a forced convection dryer for peppermint plants and leaves. Two suction air fans were installed to increase the air flow rates of the drying system. Drying rate, drying efficiency, product quality, and drying cost under different operational conditions were evaluated, and the experimental results showed that the drying rate was increased by 22.78% for whole plants with continuous fan operating system, while 24.8% for leaves with periodical fan operating system. The operational costs were reduced by 6.95% with periodical operating system for peppermint plants. Tham et al. [50] evaluated the drying characteristics of herbs using an industrial scale solar greenhouse dryer (SGD) with an integrated heat pump (HP) system. Results revealed that SGD integrated with HP system has successfully reduced the room relative humidity by 10–15%. Also, heat pump has mitigated the product rehydration issue by maintaining room relative humidity at a maximum value of 65% throughout the drying period. The drying rate of Java tea was improved three- to fourfolds, i.e., from 0.004–0.008 g H2O/g dry matter (DM) min to 0.018–0.025 g H2O/g DM min, whereas 10% drying time was saved for both Java tea leaf and Sabah snake grass leaf with the assistance of heat pump system. Meanwhile, the supply of dry air from the heat pump system with a magnitude of 0.25–0.50 m/s helps to enhance the drying rate of the herbs as well as minimize the non-uniformity of drying temperature and relative humidity inside the solar greenhouse dryer.

Solar air collectors are classified as single-pass, double-pass, or multi-pass collectors. A hybrid solar-assisted fluidized bed dryer with a low temperature solar collector was proposed by Rodríguez et al. [51], the drying process conducted in two ensued systems: (1) an open sun dryer and (2) a pilot fluidized bed dryer coupled with a low temperature solar collector for air heating. The Habanero chili’s moisture content was removed to 5% from 90% in 10.3 h, with good product quality. The mean drying time achieved a 50% reduction, also an energy reduction of 2.6 kW for every dried chili. Ceylan et al. [52] fabricated a mixed-mode, fluidized bed dryer with a solar air collector and investigated the drying kinetics of mint leaves. Their experimental system consists of a combination of a solar air collector, a parabolic trough collector, and a heat pump system. The solar air collector provided the required heat energy for the drying process during the daytime. Heated water in the parabolic trough collector was stored in the depot which would be used in the drying process during the night. The temperatures of the drying air for the solar air collector, the parabolic trough collector, and the heat pump operating modes were controlled with accuracies of ±0.35, ±0.444, and ±0.478 °C, respectively. Experimental results showed that a solar energy system can be used with temperature control for different applications, such as heating greenhouses and preheating in air conditioning systems. A new dryer with solar air collector was constructed by Şevik et al. [53], which consists of double-pass solar air collector (DPSAC) unit, heat pump (HP) unit, photovoltaic (PV) unit, measuring devices, and automatic control system (Fig. 2). In order to keep a constant drying air temperature during the drying process, a PID control unit is integrated. The coefficient performance of the systems for drying mint and parsley were calculated as 2.28 and 2.17, respectively. Energy utilization ratios of the dryer for drying mint and parsley were calculated as 0.18–0.25 and 0.2–0.26, respectively. On the other hand, experimental results indicated that the DPSAC, HP, PV unit, and PID control unit could work in coordination with each unit and the dried products with good physical properties such as color, shrinkage, and taste. Kareem et al. [54] evaluated the performance of a forced convective multi-pass solar air heating collector (MPSAHC) system assisted with granite for drying of Roselle. The experiments were conducted under the daily average relative humidity, solar irradiance, ambient temperature, and wind speed of 64.5%, 635.49 Wm−2, 32.24 °C, and 0.81 m/s, respectively. An average drying rate of 33.57 g(kgm2h)−1 was achieved, while the system optical efficiency, collector efficiency, drying efficiency, and moisture pickup efficiency of 70.53, 64.08, 36.22, and 66.95% were obtained, respectively. MPSAHC dryer was 21 h faster with fair color retention comparing to open sun drying approach which was conducted under the same weather condition. The techno economic analysis reflected the system as a worthy investment with a payback period of 2.14 years. Mghazli et al. [55] studied the drying kinetics of rosemary in an indirect active solar dryer with a separate solar collector and a drying unit. The experiments were carried out at four different air temperatures (50, 60, 70, and 80 °C) and two air flow rates (300 and 150 m3/h) for an ambient temperature in the range of 26–37 °C. Results showed that the increase of temperature could reduce drying duration. Midilli and Kucuk model (MR = 0.9969 exp. (−0.0381t1.2702) − 0.0022 t, under air temperature: 80 °C and air flow rate: 150 m3/h) was found as best fit for thin layer drying when simulation was done for all the drying data. In the covered ranges, the effective moisture diffusivity values (Deff) were obtained between 9.74 × 10−11 and 1.48 × 10−10 m2/s from the Fick’s diffusion model. The Arrhenius relation with an activation energy value of 54.37 kJ/mol expressed the temperature effect on the diffusion coefficient.

Schematic of PID-controlled double-pass solar air collector-heat pump drying system [53]

By recovering waste heat in heat pump systems, they reduce energy consumption and thereby provide efficient and environmentally friendly technologies [56]. Hence, solar dryers with heat pump system have been widely developed. Mortezapour et al. [56] developed a hybrid photovoltaic–thermal solar dryer equipped with a heat pump system for drying of saffron (Fig. 3). The effect of air flow rate at three levels (0.008, 0.012, and 0.016 kg/s), drying air temperature at three levels (40, 50, and 60 °C), and two different drying modes (with and without the heat pump system) on the operating parameters of the dryer was investigated. The results showed that energy consumption and total drying time decreased as air flow rate and drying air temperature increased. Applying the heat pump unit increased the electrical efficiency of the solar collector, whereas decreasing the total energy consumption and drying time. The highest values for thermal and electrical efficiency of the solar collector were 28 and 10.8%, respectively. The maximum dryer efficiency of 72% and highest specific moisture extraction rate of 1.16 were gained at an air flow rate of 0.016 kg/s and air temperature of 60 °C with deployment of the heat pump system. Gan et al. [57] evaluated the effect of different drying conditions by solar-assisted heat pump drying on drying kinetics and product quality of Misai Kucing. Experimental results showed that the drying rates by solar-assisted heat pump drying in all drying trials were higher than solar drying. The result shows that the effect of relative humidity and air velocity on drying rate is significant during the initial and later stage of drying. In addition to its long time process, solar dried samples had the greatest total color change as compared to solar-assisted heat pump dried samples. Besides, there is a significant difference (p < 0.05) between the content of sinensetin (SEN) in fresh samples and solar dried samples. SEN and rosmarinic acid (RA) retention among the dehydrated samples were maximum 83.07% in leaves and 92.54% in flowers, respectively, by solar-assisted heat pump drying method. For solar-assisted heat pump dried samples, there are no significant differences (p > 0.05) in the retention of SEN and RA as compared to fresh samples.

Schematic of solar dryer equipped with a heat pump system [56]

Microwave-Assisted Hybrid Drying Techniques

Microwaves are a form of electromagnetic energy generated by magnetrons under the combined force of perpendicular electric and magnetic fields, with frequencies between 300 MHz and 300 GHz while wavelengths range from 100 cm (300 MHz) to 0.1 cm (300 GHz) [58, 59]. The most common frequency of microwave used is 915 and 2450 MHz in the industrial food drying applications. The mechanism of microwave drying is that water molecules are bipolar and repeatedly rotate as a result of the rapidly alternating electromagnetic field, and heat is created throughout the material due to friction between the water molecules so the moisture will intensively evaporate and transfer to the surface [60].

Microwave drying has many advantages compared to conventional drying methods, such as rapid dehydration rate [61], short processing time [62], fast and accurate control [63], and clean process without bringing secondary waste [64]. However, single microwave drying method has some shortcomings that include non-uniform heating, possible textural damage, and limited penetration depth of the microwave field into the products [65]. Therefore, microwave is often combined with other drying methods to overcome the limitations of solo microwave drying. Table 2 displays the applications of microwave-assisted hybrid drying for spices and herbs, and it is discussed in detail in the following section.

Szadzińska et al. [66] studied the drying rate, the energy consumption, and the quality aspect of green pepper with combined convective-microwave-ultrasound (CVMU) dryer and convective (CV) dryer. The schematic of the experimental setup of the MUCV dryer is shown in Fig. 4, and this hybrid dryer allows convective drying with microwave and ultrasound enhancement independently as well as in different combinations. Experimental results have shown that reduction in drying time reached the highest level in microwave-enhanced convective drying up to 88%, and only 39% by ultrasound enhancement. The lowest energy consumption value (1.26 kWh) was obtained from microwave-enhanced convective drying process, and approximately 84% energy was saved compared to the energy usage of convective drying process that amounted to 7.97 kWh. For the nutritional aspect, it was demonstrated that convective-ultrasound drying allows remaining most of the vitamin C and up to 70%. For color, the best dried biological materials were obtained by implementing convection, microwave, and ultrasound simultaneously. Moreover, the CVMU drying process resulted in a low water activity and better rehydration ability for the dried green pepper.

Scheme of a hybrid dryer: 1 fan, 2 airborne ultrasound system (AUS), 3 ultrasound feeder, 4 electric heater, 5 air outlet, 6 ultrasound transducer AUS, 7 pyrometer, 8 rotating sample pan, 9 drive sample pan, 10 balance, 11 microwave generator, 12 control cupboard [66]

Łechtańska et al. [67] investigated the effects of five different drying methods with different application of microwave and infrared radiation on drying kinetics, energy consumption, and quality of green pepper (Table 3). The results proved that enhancement of convective (CV) drying by both microwave and infrared radiation (CVMW + IRper or CV + MWper + IRper) significantly reduced the drying time up to 76% as compared to pure CV drying. The highest degree of vitamin C retention that amounted to 63.91% was attained by CVMW drying as compared to CV drying (46.54%). Meanwhile, the CVMW drying resulted also in the lowest energy consumption of 3.3 ± 0.1 kWh. CV + IRper drying presented the highest energy consumption (6.9 ± 0.1 kWh), the lowest vitamin C retention (16.86%), and the worst dried samples from the visual appearance and color. The experiments proved that convective drying assisted with both microwave and/or infrared radiation significantly reduced the drying time and energy consumption, improved the color of the dried product, as well as enabled better vitamin C retention compared to pure convective drying.

An et al. [68] investigated the air-drying (AD), freeze-drying (FD), infrared drying (IR), microwave drying (MD), and intermittent microwave combined with convective drying (IM&CD) of ginger rhizome slices. Quality attributes of the dried samples were compared with respect to total phenolic content (TPC), total flavonoid contents (TFC), and pharmacologically active components (6-, 8-, 10-gingerols and 6-shogaol). Investigation results (Table 4 and Fig. 5) showed that FD, IR, and IM&CD had higher retention of TPC and TFC compared to AD and MD process. However, FD and IR had relative high energy consumption and drying time, especially freeze-drying. Therefore, considering both the quality aspects and energy consumption, IM&CD would be very promising for thermos-sensitive material due to its higher efficiency, good quality retention, and lower cost, which had a broad market prospect for commercial-scale application.

Changes of 6-, 8-, 10-gingerol, and 6-shogaol content of ginger extract during AD, IR, FD, CM, and IM&CD drying processes. AD hot air-drying, IR infrared drying, FD freeze-drying, MD microwave drying, IM&CD intermittent microwave-convection drying. For each column, values followed by the same letter (a–c) are not statistically different at P < 0.05 as measured by Duncan’s test [68]

Lv et al. [69] introduced a new microwave fluidized bed drying (MFBD) method for ginger slices. The schematic diagram of this MFBD equipment is shown in Fig. 6. Material tray and vibration frame are fixed together in the dryer and connected with vibration motor through damping spring, and the raw materials in the tray start rolling and are in a suspended state while the vibration motor works. Six magnetrons are evenly arranged at the top of the drying chamber independently. The problems of local overheating could be solved through even arrangement of magnetrons and fluidization system of materials. Good drying quality and high drying speed are obtained for MFBD at microwave power 2.0 to 0.4 W/g in different drying stages. Meanwhile, in order to understand the water flow characteristics of ginger slices in MFBD, low nuclear magnetic resonance was used to detect the materials in different drying stages. The state of water could be categorized as free water (FW), immobilized water (IW), and bonded water (BW). FW is the main water state in fresh ginger slices and converts to the IW quickly in the beginning stage, and then both FW and IW decreased until the final stage is reached.

Schematic diagram of a MFBD equipment: 1 damping spring, 2 vibration motor, 3 vibration frame, 4 frequency converter, 5 touch screen, 6 material tray, 7 MFD chamber, 8 monitor, 9 magnetron, 10 induced draft fan [69]

Meetha et al. [70] conducted a study on application of novel combined microwave drying technology for better color retention of nutmeg mace. Pulsed microwave-assisted hot air-drying (PMHAD) was investigated at three different power levels (0.5, 1, and 1.445 kW) with 30-s pulsation at a hot air temperature of 45 °C, and the color values of nutmeg mace were compared with the market and fresh sample using colorimeter. For the dried nutmeg mace, the desired color is usually darker, more reddish, and less yellowish. Among the PMHAD-treated samples, power level of 1.445 kW was darker, 1 kW was more reddish, and 0.5 kW was less yellowish, while the market sample were lighter and yellowish. It is clear that PMHAD method has more color retention compared to market samples.

Microwave-vacuum (MV) drying combines the advantages of both microwave drying and vacuum drying and improves energy efficiency and product quality [71, 72]. Sánchez et al. [73] investigated the influence of the vacuum level and the microwave power on aroma compounds and sensory quality of rosemary dried by MV method. The time needed to dry rosemary was shortened with higher values of microwave power and vacuum intensity. Experimental data showed that the higher the vacuum intensity in the drying system at a specific microwave power and/or the higher the microwave power, the lower the total quantity of volatiles. However, the higher vacuum intensity and microwave power lead to the shorter drying time. The optimum conditions were 72–74 kPa and 360 W for 39 min to get the dried samples and 240 W and 0 kPa (56 min were required) compared to almost 180 min are required for drying of rosemary using pure CV drying. This study also revealed that MVD could be applied in drying of very sensitive materials, such as rosemary, and for this purpose, very high vacuum levels with low microwave powers should be applied. Sánchez et al. [74] evaluated the influences of drying method on the quality of marjoram. Convective drying (CVD), microwave-vacuum drying (MVD), as well as a combination of convective pre-drying and MV finish-drying (CVPD + MVFD) were carried out for dehydrating of marjoram. Volatile compounds from marjoram samples were extracted by hydro distillation and analyzed by gas chromatography. Thirty three compounds were tentatively identified and quantified, and among them cis-sabinene hydrate (229 mg/100 g dry basis, db) and terpinen-4-ol (169 mg/100 g, db) are the major components. Results showed significant differences in the aroma quality of marjoram dried by different methods. The total quantity of volatiles of fresh marjoram (825 mg/100 g, db) was considerably reduced by most of the drying methods, except for the MVD at 240 and 360 W. The MVD method at 240 W was the optimized option for drying marjoram followed by the combined method with 50 °C and 240 or 360 W: the drying time was relatively short (≈162 and 158 min, respectively) and has good aroma quality as observed by sensory analysis (high scores of fresh and vegetable odor). The same authors also studied the influence of drying methods on aroma compounds of sweet basil within the same drying methods mentioned before [75]. The total quantity of volatiles was considerably reduced from 32.1 g/kg of fresh sweet basil to 14.4 g/kg of dried sweet basil by employing both CVD and MVD. The CVPD at 40 °C and then MVFD at 360 W was the optimized process for drying sweet basil; the time required was relatively short (≈250 min), with a relative high quantity of volatile compounds (16.7 g/kg) and good aroma quality.

Other Drying Sources-Assisted Hybrid Drying Techniques

Apart from drying source of solar and microwave combined drying techniques, several conventional drying techniques combined with other methods have been developed and adopt for drying of spices and herbs.

Mihindukulasuriya et al. [76] established a laboratory-scale rotary dryer prototype (Fig. 7) that can operate in three different modes: hot air (HA), infrared (IR), and IR combined with hot air (IRHA) for drying of chili. The hot air mode consumed 60.4% more power than the IR mode as well as 33.5% more power than the combined mode at 70 °C. On the other hand, the redness of the chili was decreased by 30% in the IR mode compared to the hot air and IRHA modes at 70 °C. In the IR mode, at 70 °C, the loss in capsaicin content was 2 and 22% greater than hot air mode or combined mode, respectively. The quality characteristics in terms of capsaicin content and color were similar with IRHA mode and HA mode for temperatures ranging from 65 to 70 °C. A positive correlation was observed between retention time and power consumption with HA and IRHA modes, while a negative correlation was identified in IR mode. Based on color, capsaicin content, power consumption, and retention time in each mode, the best overall performance with respect to drying chili was obtained at 70, 65, and 50 °C in HA, IRHA, and IR mode, respectively.

Schematic illustration of a combined IR and hot air rotary dryer [76]

Different drying methods such as hot air (HA) drying (50 °C) with 58–63% relative humidity (RH), low humidity hot air (LHA) drying (50 °C and 28–30% RH), and radiofrequency (RF) drying (50 °C, 56–60% RH) were investigated for efficient dehydration of dill (Anethum graveolens) greens with optimal retention of color and constituents (Naidu et al. [77]). Results showed that the drying time of HA and RF was marginally higher (around 22%) compared to HA. Lightness, greenness, and yellowness of LHA dried sample were higher than those of the RF and HA dried dill greens. Extracts from dill greens dehydrated by LHA exhibited good free radical scavenging activities from 5 to 88%. Further, methanolic extracts of dill greens dehydrated by LHA drying had a noticeable effect on scavenging free radicals. Results of the consumer acceptance study have shown that up to 70 and 80% of the panelists gave the “Like Very Much” rating to a snack food “Vada” which made with fresh and dried dill greens, respectively.

Antal et al. [78] compared two drying methods, hot air-drying (HAD), high (150–250 Pa) and low pressure (10–30 Pa) of vacuum freeze-drying (VFD), used for the dehydration of spearmint leaves in terms of essential oil composition and rehydration ability of the final dried product. It was observed that drying time and essential oil content were strongly influenced by vacuum pressure. Higher chamber pressure increased the drying time but preserved the major volatile compounds of dried product. Comparing the quality of dried product, freeze-dried product is better than hot air-dried ones. Meanwhile, freeze-dried mint leaves also had higher rehydration rates (0.5 min) than hot air-dried ones (5 min) at water temperatures of 75 °C. It is recommended that the drying of spearmint leaves by VFD and the pressure in the drying chamber should not be too low.

Other Latest Novel Drying Techniques

Recently, some alternative novel technologies, such as nonthermal techniques, CO2 drying and pretreatment of pulsed electric field (PEF), and osmotic dehydration (OD), can improve both product quality and drying efficiency.

The nonthermal technologies such as ultrasounds have shown promise for inactivating microorganisms at near-ambient temperatures, improving energy efficiency and reducing thermal degradation of food components, therefore consequently preserving the sensory and nutritional quality of food products [79, 80]. Rodríguez et al. [81] assessed the influence of high-intensity ultrasound (US) on transfer phenomena during the convective drying in a high-void bed of thyme leaves. Drying kinetics of thyme leaves were carried out at air velocity of 1, 2, and 3 m/s with different air temperatures (40, 50, 60, 70, and 80 ± 1.2 °C) and different levels of acoustic power density (0, 6.2, 12.3, and 18.5 kW/m3). The drying time reduction obtained at an air velocity of 1 m/s at 40 or 50 °C was around 30% when US was applied. The obtained results also showed that the influence of the US power density applied on the internal resistance to the mass transfer was significantly lower than its influence of the external resistance; therefore, process intensification is mainly linked to external resistance. Nevertheless, the influence of the application of US on transport phenomena was only observed at air temperatures and air velocities below 70 °C and 3 m/s, respectively.

Bušić et al. [82] examined the effects of CO2 drying, hot air-drying, and freeze-drying on the bioactive qualities and sensory properties of basil. The obtained results showed freeze-drying was recognized as the most suitable technique for preservation of color, essential oil content, bioactive compounds, and antioxidant capacity of basil. The essential oil content of basil ranged from 0.21 to 0.96% and decreased upon prolongation of CO2 drying time. Among four identified phenolic acids (rosmarinic, chicoric, caftaric, and caffeic), rosmarinic acid was the most abundant in all samples. Longer CO2 drying duration (4 h) also exhibited the most detrimental effect on the polyphenolic compound content and antioxidant capacity of dried basil. The taste and appearance of CO2 dried basil were scored higher in comparison to air-dried basil, but further optimization of CO2 drying is needed to improve its aroma properties. Optimized conditions for employing shorter CO2 drying time (2 or 3 h) and pressures of 80–100 bar at 40 °C might be a good alternative to freeze-drying of basil.

Drying can be also combined with pretreatments to obtain some beneficially physical or chemical changes as well as application of various energy fields that enhance heat-mass transport and product quality [83]. Won et al. [84] identified the effects of PEF pretreatment on the drying characteristics of red pepper. The PEF treatment was conducted with electric field strength of 1.0–2.5 kV/cm using a fixed pulse width of 30 μs and at a pulse frequency of 100 Hz. The PEF treatment time was 1, 2, and 4 s. Drying of control and PEF-pretreated samples was conducted at 45 °C. The untreated control reached the target moisture ratio of 15% after 4.9 h of drying, whereas the PEF-pretreated sample (2.5 kV/cm, 100 Hz, 4 s) required only 3.2 h for the same moisture ratio, indicating a 34.7% reduction in drying time. Even the shortest PEF pretreatment (2.5 kV/cm, 100 Hz, 1 s) required 3.9 h to reach the target moisture ratio, which corresponded to a 20.4% reduction in drying time. A reduced drying time can be explained by PEF treatment-induced membrane disruptions, which might positively affect the drying properties by increasing the mass transfer of water. Moreover, the shorter drying time in the PEF-pretreated sample might lead to greater retention of carotenoid pigments. The results proved that a short PEF pretreatment can accelerate the drying efficiency of red pepper and benefit the quality of dried red pepper. The potential of osmotic dehydration (OD) as a pretreatment has been proven useful not only in a number of studies, assuring a high effectiveness of dehydration, but also in many cases a taste of improvement [85, 86]. Boggia et al. [87] optimized of both process variables and mixture composition for the OD process of PDO Genovese basil leaves allowed to enhance the quality of the dried products and to limit their changes in appearance, texture, flavor, and color. The experimental results ascertained that the appearance and the aroma of dried leaves were as much similar as possible to those of fresh PDO Genovese basil. As a sequence, this experimental approach could be successfully used, also on industrial scale, for the optimization of similar OD processes.

Final Remarks

Spices and herbs have been world-widely consumed not only for flavoring and preserving foods but also for coloring, medicinal, and cosmetic purposes. Novel technologies of food dehydration are a response to the latest consumer demands for dried products with superior quality while becoming more environmentally and economically sustainable. The recent application of solar-assisted, microwave-assisted, and other drying source-assisted hybrid drying methods as well as other latest novel drying techniques in regard to dehydrating of spices and herbs are presented in this article.

Some trends and future challenges for the dehydration of spices and herbs are the following:

-

Develop cost-effective drying techniques, especially for heat-sensitive herbs and spices.

-

Integrate other techniques (such as nano-technology, high hydrostatic pressure, and microencapsulation) with existing drying methods.

-

Deploy on-line measurement tools to monitor the drying process and dynamically control of critical process parameters.

-

Establish reliable mathematical models (especially in hybrid drying system) via computational fluid dynamic simulation, advanced analytical techniques as well as hybrid neuro-fuzzy approach.

-

Develop environmental friendly drying systems, using sustainable or pollution-free resources.

-

Fabricate automatic and continuous dryers to simplify operations and lower costs.

References

Srinivasan K (2005) Spices as influencers of body metabolism: an overview of three decades of research. Food Res Int 38(1):77–86

Parveen S, Das S, Begum A, Sultana N, Hoque M, Ahmad I (2014) Microbiological quality assessment of three selected spices in Bangladesh. Int Food Res J 21(4):1327–1330

Kivilompolo M, Hyötyläinen T (2007) Comprehensive two-dimensional liquid chromatography in analysis of Lamiaceae herbs: characterisation and quantification of antioxidant phenolic acids. J Chromatogr A 1145(1–2):155–164

Iriti M, Vitalini S, Fico G, Faoro F (2010) Neuroprotective herbs and foods from different traditional medicines and diets. Molecules 15(5):3517–3555

Chanchal D, Swarnlata S (2008) Novel approaches in herbal cosmetics. J Cosmet Dermatol 7(2):89–95

Kaefer CM, Milner JA (2008) The role of herbs and spices in cancer prevention. J Nutr Biochem 19(6):347–361

Muller J, Reisinger G, Muhlbauer W (1989) Drying of medicinal and aromatic plants in a greenhouse solar dryer. Landtechnik 2:58–65

Xie L, Mujumdar AS, Xiao HW, Gao ZJ (2015) Recent technologies and trends in medicinal herb drying. http://www.Academia.Edu/download/41682412/Chapter_4 _Recent_technologies_andtrends_in_medicinal_herb_drying-revised_5_December_2015.Pdf

Parto N (2015) Case study: pathogens and spices. Queen’s Printer for Ontario, Toronto

Hamrouni-Sellami I, Rahali FZ, Rebey IB, Bourgou S, Limam F, Marzouk B (2013) Total phenolics, flavonoids, and antioxidant activity of sage (Salvia officinalis L.) plants as affected by different drying methods. Food Bioprocess Technol 6(3):806–817

Hamrouni-Sellami I, Wannes WA, Bettaieb I, Berrima S, Chahed T, Marzouk B, Limam F (2011) Qualitative and quantitative changes in the essential oil of Laurus nobilis L. leaves as affected by different drying methods. Food Chem 126(2):691–769

Doymaz I (2005) Drying characteristics and kinetics of okra. J Food Eng 69(3):275–279

Wang Y, Zhang M, Mujumdar AS, Mothibe KJ (2013) Microwave-assisted pulse-spouted bed freeze-drying of stem lettuce slices—effect on product quality. Food Bioprocess Technol 6(12):3530–3543

Nathakaranakule A, Jaiboon P, Soponronnarit S (2010) Far-infrared radiation assisted drying of longan fruit. J Food Eng 100(4):662–668

Balasubramanian S, Roselin P, Singh KK, Zachariah J, Saxena SN (2016) Postharvest processing and benefits of black pepper, coriander, cinnamon, fenugreek, and turmeric. Crit Rev Food Sci 56(10):1585–1607

Sa-adchom P, Swasdisevi T, Nathakaranakule A, Soponronnarit S (2011) Drying kinetics using superheated steam and quality attributes of dried pork slices for different thickness, seasoning and fibers distribution. J Food Eng 104(1):105–113

Crivelli G, Nani RC, Di Cesare LF (2002) Influence of processing on the quality of dried herbs. Atti VI Giornate Scientifiche SOI 2:463–464

Mujumdar AS (2007) Handbook of industrial drying. Taylor & Francis, Philadelphia

Mujumdar AS, Huang LX (2007) Global R&D needs in drying. Dry Technol 25(4):647–658

Onwude DI, Hashim N, Janius RB, Nawi NM, Abdan K (2016) Modeling the thin-layer drying of fruits and vegetables: a review. Compr Rev Food Sci 15(3):599–618

Raghavan GSV, Rennie TJ, Sunjka PS, Orsat V, Phaphuangwittayakul W, Terdtoon P (2005) Overview of new techniques for drying biological materials with emphasis on energy aspects. Braz J Chem Eng 22(2):195–201

Zhang M, Jiang H (2014) Recent food drying R&D at Jiangnan University: an overview. Dry Technol 32(15):1743–1750

Satimehin AA (2014) A mathematical model for deep bed drying of gelatinized white yam (Dioscorea rotundata, Poir). Int J Energy Eng 4(2A):33–39

Onwude DI, Hashim N, Chen G (2016) Recent advances of novel thermal combined hot air drying of agricultural crops. Trends Food Sci Technol 57(part A):132–145

Klemeš J, Smith R, Kim JK (2008) Handbook of water and energy management in food processing. Woodhead Publishing, Cambridge

Karim MA, Hawlader MNA (2005) Drying characteristics of banana: theoretical modelling and experimental validation. J Food Eng 70(1):35–45

Özcan M, Arslan D, Ünver A (2005) Effect of drying methods on the mineral content of basil (Ocimum basilicum L.) J Food Eng 69(3):375–379

Demiray E, Tulek Y (2014) Drying characteristics of garlic (Allium sativum L) slices in a convective hot air dryer. Heat Mass Transf 50(6):779–786

Gümüşay ÖA, Borazan AA, Ercal N, Demirkol O (2015) Drying effects on the antioxidant properties of tomatoes and ginger. Food Chem 173:156–162

Arslan D, Özcan MM, Mengeş HO (2010) Evaluation of drying methods with respect to drying parameters, some nutritional and colour characteristics of peppermint (Mentha × piperita L.). Energ Convers Manag 51(12):2769–2775

Moses JA, Norton T, Alagusundaram K, Tiwari BK (2014) Novel drying techniques for the food industry. Food Eng Rev 6(3):43–55

Karam MC, Petit J, Zimmer D, Baudelaire Djantou E, Scher J (2016) Effects of drying and grinding in production of fruit and vegetable powders: a review. J Food Eng 188:32–49

Mohamed HAR, Sallam YI, El-Leithy AS, Aly SE (2012) Lemongrass (Cymbopogon citratus) essential oil as affected by drying methods. Ann Agric Sci 57(2):113–116

Buchaillot A, Caffin N, Bhandari B (2009) Drying of lemon myrtle (Backhousia citriodora) leaves: retention of volatiles and color. Dry Technol 27(3):445–450

Argyropoulos D, Müller J (2014) Changes of essential oil content and composition during convective drying of lemon balm (Melissa officinalis L.) Ind Crop Prod 52:118–124

Raso J, Barbosa-Cánovas GV (2003) Nonthermal preservation of foods using combined processing techniques. Crit Rev Food Sci 43(3):265–285

Huang L, Zhang M, Wang L, Mujumdar AS, Sun D (2012) Influence of combination drying methods on composition, texture, aroma and microstructure of apple slices. LWT Food Sci Technol 47(1):183–188

Kaveh M, Chayjan AR, Esna-Ashari M (2015) Thermal and physical properties modelling of terebinth fruit (Pistacia atlantica L.) under solar drying. Res Agric Eng 61(4):150–161

Yaldız O, Ertekin C (2001) Thin layer solar drying of some different vegetables. Dry Technol 19(3):583–596

Janjai S, Srisittipokakun N, Bala BK (2008) Experimental and modelling performances of a roof-integrated solar drying system for drying herbs and spices. Energy 33(1):91–103

Orphanides A, Goulas V, Gekas V (2016) Drying technologies: vehicle to high-quality herbs. Food Eng Rev 8(2):164–180

Mustayen AGMB, Mekhilef S, Saidur R (2014) Performance study of different solar dryers: a review. Renew Sust Energ Rev 34:463–470

Deshmukh W, Varma MN, Chang KY, Wasewarm KL (2014) Investigation of solar drying of ginger (zingiberofficinale): emprical modelling, drying characteristics, and quality study. Chin J Eng. doi:10.1155/2014/305823

Rabha DK, Muthukumar P, Somayaji C (2017) Energy and exergy analyses of the solar drying processes of ghost chilli pepper and ginger. Renew Energy 105:764–773

Yahya M, Fudholi A, Sopian K (2017) Energy and exergy analyses of solar-assisted fluidized bed drying integrated with biomass furnace. Renew Energy 105:22–29

Belessiotis V, Delyannis E (2011) Solar drying. Sol Energy 85(8):1665–1691

Rabha DK, Muthukumar P, Somayaji C (2017b) Experimental investigation of thin layer drying kinetics of ghost chilli pepper (Capsicum chinense Jacq.) dried in a forced convection solar tunnel dryer. Renew Energy 105:583–589

El-Sebaii AA, Shalaby SM (2013) Experimental investigation of an indirect-mode forced convection solar dryer for drying thymus and mint. Energy Convers Manag 74:109–116

Morad MM, El-Shazly MA, Wasfy KI, El-Maghawry HAM (2017) Thermal analysis and performance evaluation of a solar tunnel greenhouse dryer for drying peppermint plant. Renew Energy 101:992–1004

Tham TC, Ng MX, Gan SH, Chua LS, Aziz R, Chuah LA, Hii CL, Ong SP, Chin NL, Law CL (2017) Effect of ambient conditions on drying of herbs in solar greenhouse dryer with integrated heat pump. Dry Technol. doi:10.1080/07373937.2016.1271984

Rodríguez EC, Fiueroa IP, Mercado CAR (2013) Feasibility analysis of drying process habanero chili using a hybrid-solar-fluidized bed dryer in Yucatan Mexico. J Energy Power Eng 7:1898–1908

Ceylan İ, Gürel AE (2016) Solar-assisted fluidized bed dryer integrated with a heat pump for mint leaves. Appl Therm Eng 106:899–905

Şevik S (2014) Experimental investigation of a new design solar-heat pump dryer under the different climatic conditions and drying behavior of selected products. Sol Energy 105:190–205

Kareem MW, Habib K, Ruslan MH, Saha BB (2017) Thermal performance study of a multi-pass solar air heating collector system for drying of roselle (Hibiscus sabdariffa). Renew Energy. doi:10.1016/j.renene.2016.12.099

Mghazli S, Ouhammou M, Hidar N, Lahnine L, Idlimam A, Mahrouz M (2017) Drying characteristics and kinetics solar drying of Moroccan rosemary leaves. Renew Energy 108:303–310

Mortezapour H, Ghobadian B, Minaei S, Khoshtaghaza MH (2012) Saffron drying with a heat pump-assisted hybrid photovoltaic–thermal solar dryer. Dry Technol 30(6):560–566

Gan SH, Chua LS, Aziz R, Baba MR, Abdullah LC, Ong SP, Law CL (2017) Drying characteristics of Orthosiphon stamineus Benth by solar assisted heat pump drying. Dry Technol. doi:10.1080/07373937.2016.1275673

Pozar DM (2005) Microwave engineering. Wiley, Hoboken

Sorrentino R, Bianchi G (2010) Microwave and RF engineering. Wiley, New York

Vadivambal R, Jayas DS (2010) Non-uniform temperature distribution during microwave heating of food materials–a review. Food Bioprocess Technol 3(2):161–171

Wray D, Ramaswamy HS (2015) Novel concepts in microwave drying of foods. Dry Technol 33(7):769–783

Wang J, Xi YS, Yu Y (2004) Microwave drying characteristics of potato and the effect of different microwave powers on the dried quality of potato. Eur Food Res Technol 219(5):500–506

Li Z, Wang N, Raghavan GSV, Cheng W (2006) A microcontroller-based, feedback power control system for microwave drying processes. Appl Eng Agric 22(2):309–314

Rattanadecho P, Makul N (2016) Microwave-assisted drying: a review of the state-of-the-art. Dry Technol 34(1):1–38

Zhang M, Tang J, Mujumdar AS, Wang S (2006) Trends in microwave-related drying of fruits and vegetables. Trends Food Sci Technol 17(10):524–534

Szadzińska J, Łechtańska J, Kowalski SJ, Stasiak M (2017) The effect of high power airborne ultrasound and microwaves on convective drying effectiveness and quality of green pepper. Ultrason Sonochem 34:531–539

Łechtańska JM, Szadzińska J, Kowalski SJ (2015) Microwave- and infrared-assisted convective drying of green pepper: quality and energy considerations. Chem Eng Process Process Intensif 98:155–164

An K, Zhao D, Wang Z, Wu J, Xu Y, Xiao G (2016) Comparison of different drying methods on Chinese ginger (Zingiber officinale Roscoe): changes in volatiles, chemical profile, antioxidant properties, and microstructure. Food Chem 197(part B):1292–1300

Lv WQ, Li S, Han Q, Zhao Y, Wu H (2016) Study of the drying process of ginger (Zingiber officinale Roscoe) slices in microwave fluidized bed dryer. Dry Technol 34(14):1690–1699

Meetha JN, Muhammadali P, Joy MI, Mahendran R, Santhakumaran A (2016) Pulsed microwave assisted hot air drying of nutmeg mace for better colour retention. J Spices and Aromat Crops 25(1):84–87

Cui ZW, Xu SY, Sun DW (2004) Effect of microwave-vacuum drying on the carotenoids retention of carrot slices and chlorophyll retention of Chinese chive leaves. Dry Technol 22(3):563–575

Giri SK, Prasad S (2007) Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng 78(2):512–521

Calín-Sánchez Á, Szumny A, Figiel A, Jałoszyński K, Adamski M, Carbonell-Barrachina ÁA (2011) Effects of vacuum level and microwave power on rosemary volatile composition during vacuum–microwave drying. J Food Eng 103(2):219–227

Calín-Sánchez Á, Figiel A, Lech K, Szumny A, Martínez-Tomé J, Carbonell-Barrachina ÁA (2015) Dying methods affect the aroma of Origanum majorana L. analyzed by GC-MS and descriptive sensory analysis. Ind Crop Prod 74(15):218–227

Calín-Sánchez Á, Lech K, Szumny A, Figiel A, Carbonell-Barrachina ÁA (2012) Volatile composition of sweet basil essential oil (Ocimum basilicum L.) as affected by drying method. Food Res Int 48(1):217–225

Mihindukulasuriya SDF, Jayasuriya HPW (2015) Drying of chilli in a combined infrared and hot air rotary dryer. J Food Sci Technol 52(8):4895–4904

Naidu MM, Vedhashree M, Satapathy P, Khanum H, Ramsamy R, Hebbar HU (2015) Effect of drying methods on the quality characteristics of dill (Anethum graveolens) greens. Food Chem 192:849–856

Antal T, Figiel A, Kerekes B, Sikolya L (2011) Effect of drying methods on the quality of the essential oil of spearmint leaves (Mentha spicata L.) Dry Technol 29(15):1836–1844

Martynenko A, Kudra T (2015) Non-isothermal drying of medicinal plants. Dry Technol 33(13):1550–1559

Pereira RN, Vicente AA (2010) Environmental impact of novel thermal and non-thermal technologies in food processing. Food Res Int 43(7):1936–1943

Rodríguez J, Mulet A, Bon J (2014) Influence of high-intensity ultrasound on drying kinetics in fixed beds of high porosity. J Food Eng 127:93–102

Bušić A, Vojvodić A, Komes D, Akkermans C, Belščak-Cvitanović A, Stolk M, Hofland G (2014) Comparative evaluation of CO2 drying as an alternative drying technique of basil (Ocimum basilicum L.)— the effect on bioactive and sensory properties. Food Res Int 64:34–42

Mard ND, Boudhrioua N, Kechaou N, Courtois F, Bonazzi C (2012) Influence of air drying temperature on kinetics, physicochemical properties, total phenolic content and ascorbic acid of pears. Food Bioprod Process 90(3):433–441

Won YC, Min SC, Lee DU (2015) Accelerated drying and improved color properties of red pepper by pretreatment of pulsed electric fields. Dry Technol 33(8):926–932

Figiel A, Michalska A (2017) Overall quality of fruits and vegetables products affected by the drying processes with the assistance of vacuum-microwaves. Int J Mol Sci 18(1):71

Changrue V, Orsat V, Raghavan GSV (2008) Osmotically dehydrated microwave vacuum drying of strawberries. J Food Process Preserv 32(5):798–816

Boggia R, Leardi R, Zunin P, Bottino A, Capannelli G (2013) Dehydration of pdo genovese basil leaves (Ocimum basilicum maximum L. cv genovese gigante) by direct osmosis. J Food Process Preserv 37(5):621–629

Acknowledgments

We acknowledge the financial support from National Key R&D Program of China (Contract No. 2017YFD0400501), National Natural Science Foundation Program of China (Contract No. 31671864), Jiangsu Province (China) “Collaborative Innovation Center for Food Safety and Quality Control” Industry Development Program, and Jiangsu Province (China) Infrastructure Project (Contract No. BM2014051), all of which enabled us to carry out this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, W., Mujumdar, A.S., Zhang, M. et al. Novel Drying Techniques for Spices and Herbs: a Review. Food Eng Rev 10, 34–45 (2018). https://doi.org/10.1007/s12393-017-9165-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-017-9165-7