Abstract

Use of microwaves has increased largely in the domestic household in the last few decades due to the convenience of using microwave ovens. In the industrial sector, microwave processing is used in some of the unit operations, while it is yet to capture a major place in the industrial applications. The major drawback associated with microwave heating is the non-uniform temperature distribution, resulting in hot and cold spots in the heated product. The non-uniform temperature distribution not only affects the quality of the food but also raises the issue of food safety when the microorganisms may not be destroyed in the cold spots. The temperature distribution during microwave heating has been studied in a wide variety of products by several researchers. This paper summarizes their results and the solutions offered by them to lessen the non-uniformity of heating. The current applications of microwave energy in the industrial sector are also highlighted.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microwave heating has gained acceptance in domestic usage and is gaining popularity in industrial applications. The ease and convenience of using microwave ovens has resulted in a permanent place for microwave ovens in every household in the industrialized nations and is increasing at a fast rate in developing economies. The changing attitude of the consumers and their fast life style has resulted in “ready-to-eat” meals for which microwaves are of great use. Microwave heating is faster compared to conventional cooking. The microwave heating is expected to deliver more homogeneous heat treatment at a faster rate than conventional heating. Furthermore, microwave ovens are easy to operate and requires less maintenance.

Conventional heating relies on the processes of conduction and convection to transport heat from the heating sources to the product, which requires relatively longer period of time, whereas microwave heating has the potential to deliver heat instantly throughput the product due to volumetric heat generation (Mullin 1995). Thermal damage incurred to a product during heating is directly proportional to the temperature and time involved. In conventional heating, higher temperature and longer heating time may cause serious damage to the quality attributes, such as color, flavor, and nutrient of the product (Lin et al. 1998). The effect of frying procedure on temperature profile of bacon was studied by Lee et al. (1983). The temperature was measured in the conventional electric skillet while frying bacon, and a temperature spread of 17 ± 4 °C was observed over the entire cooking surface of the skillet, showing that the temperature was not uniform in conventional frying.

Although microwave ovens have occupied an irreplaceable position in the household, microwave energy has not yet been exploited to its fullest potential in the industrial applications. One of the major drawbacks of microwave heating is the existence of hot spots in several zones depending on product geometry (Ho and Yam 1992; Campanone and Zaritzky 2005). Major problems in microwave heating, such as poor end quality, microbial safety concerns, and overheating, are related to non-uniform heating during microwave processing (Ho and Yam 1992; Lin et al. 1995; Zhou et al. 1995; Buffler 1992). Several researchers have studied the temperature distribution during microwave heating in food materials and suggested some measures to reduce the non-uniform temperature distribution. The objectives of this paper are (a) to present a thorough review of the temperature distribution studies conducted by various researchers in different food materials and to synthesize their results and their suggestions to minimize the non-uniformity during microwave heating and (b) highlight the areas where the microwave processing is carried out in industries.

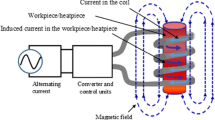

Principle of Microwave Heating

Microwaves are electromagnetic waves with frequencies ranging from about 300 MHz to 300 GHz and corresponding wavelengths from 1 to 0.001 m (Decareau 1985). Microwave heating is based on the transformation of alternating electromagnetic field energy into thermal energy by affecting the polar molecules of a material. The most important characteristic of microwave heating is volumetric heat generation (Mullin 1995). Conventional heating occurs by convection followed by conduction where heat must diffuse in from the surface of the material. Volumetric heat generation means that materials can absorb microwave energy internally and convert it into heat. In microwave heating, heat is generated throughout the material, leading to faster heating rates (Gowen et al. 2006). Microwave and radio frequency heating are both dielectric heating. When a dielectric (poor electrical conductors) material is brought into a rapidly alternating electric field, heat is generated inside the material, which is known as dielectric heating. Microwaves are reflected by metals, transmitted by electrically neutral materials, such as glass, plastics, paper, and ceramics, and absorbed by electrically charged materials (Mullin 1995).

Maxwell’s Equation and Lambert’s Law

The heat generation during microwave heating has been modeled by many researchers using Maxwell’s equation (Ayappa et al. 1991, 1992; Oliveira and Franca 2002) or Lambert’s law (Lin et al. 1995; Zhou et al. 1995) to evaluate the effect of the electromagnetic field distribution (Romano et al. 2005).

The electromagnetic field distribution inside microwave cavity is governed by Maxwell’s equations. The solution for Maxwell’s equation could be obtained using different numerical methods, and the Maxwell’s equation for constant permittivity and permeability was given as (Geedipalli et al. 2007).

Where E is the electric field intensity (V/m), ω is the angular frequency (rad/s), μ is the permeability of free space (H/m), H is the magnetic field intensity (A/m), ε o is the permittivity of free space (F/m), and ε is the complex relative permittivity.

The complex relative permittivity, ε is defined as: ε = ε′ + j· ε″ where ε′ is the dielectric constant and ε″ is the relative dielectric loss factor (Geedipalli et al. 2007).

The amount of power that can be absorbed by a substance or the conversion of microwave energy to heat is expressed by the following equation (Decareau 1992)

where P = power absorbed (W/m3), σ = dielectric conductivity and E = electric field strength (V/m)

The dielectric conductivity σ = 2πε o ε″f, where f is the frequency of energy source (Hz), ε o is the dielectric constant of vacuum or permittivity of free space (F/m), and ε″ is the relative dielectric loss factor of the substance.

The relationship between the dielectric properties and uniformity of heating is characterized by penetration depth, which is the distance from the surface of the product before the intensity decays to 1/e (approximately 37%) of the original value.

λ is the wavelength (cm), ε′ is the relative dielectric constant and tan δ is the loss tangent, which is the ratio between the dielectric loss factor (ε″) and the dielectric constant (ε′). Dielectric data are necessary to model microwave heating and develop new microwave foods (Boyaci et al. 2008).

Modeling the heat generation due to microwaves by considering that the microwave power decreases exponentially as a function of penetration into the sample is termed as Lambert’s law. In this approach, since all reflections are neglected, it is valid only for semi-infinite samples and can be obtained through a series of simplifications applied to Maxwell’s equation (Barringer et al. 1995). Lambert’s law can be evaluated according to the following expression (Datta et al. 1992)

where Q L is the microwave power, Q 0 is the transmitted power flux at the surface of the material, ℓ is the sample characteristics length in centimeter and d is the microwave penetration depth in centimeter.

Major Problems in Microwave Heating

One of the major problems associated with microwave heating is the non-uniform temperature distribution. The non-uniform temperature distribution has been studied by several researchers (Fakhouri and Ramaswamy 1993; Mullin and Bows 1993; Goksoy et al. 1999; Ryynanen and Ohlsson 1996; Ryynanen et al. 2001; Lee et al. 2002; Sakai and Wang 2004; Manickavasagan et al. 2006; Gunasekaran and Yang 2007; Geedipalli et al. 2007). Researchers have tried to develop a model for the microwave heating to predict temperature distribution in the microwave heated food (Chen et al. 1993; Barringer et al. 1995; Lin et al. 1995; Zhou et al. 1995; Mallikarjunan et al. 1996; Ni and Datta 1999; Vilayannur et al. 1998; Raaholt and Ohlsson 2000; Yang and Gunasekaran 2004; Campanone and Zaritzky 2005). Microwave heating or drying sometimes results in poor quality of the end product (Gunasekaran 1990; Adu and Otten 1996; Warchalewski et al. 1998; Funebo and Ohlsson 1998; Krokida et al. 2001; Blaszczak et al. 2002). One of the serious concerns from heating food in a microwave oven is the incomplete kill of microbes due to uneven temperature distribution (Fung and Cunningham 1980; Carlin et al. 1982; Aleixo et al. 1985; Rosenberg and Bogl 1987). Moisture accumulation at the surface of food during microwave heating was studied by Datta and Ni (2002). Ohlsson and Thorsell (1984) observed a couple of problems in microwave reheating of chilled foods, such as uneven heat distribution between different meal components, dehydration of thin meat and fish slices, and skin formation on boiled white potatoes.

Another issue with the microwave heating is the large number of factors that affect the microwave heat transfer behavior such as the thickness, the geometry, and the dielectric properties of the food. The heat capacity and the dielectric properties (dielectric constant ε′, loss factor ε″) change with the moisture content and temperature, which also complicates the microwave drying process (Funebo and Ohlsson 1998). In addition, several factors influence the uniformity of electromagnetic field. These factors can be divided into two groups: cavity effects and workload or product interaction. Cavity effects are due to design limitation, location of the microwave inlet point, shape of the cavity, and hanging parts such as mixer, which are sometimes used for stirring the product to ensure more uniform electromagnetic field distribution. Workload interactions include loss factor, penetration depth, thickness, shape, and size of the product that are different from product to product (Kelen et al. 2006).

Temperature Distribution Studies

The temperature distribution studies have been conducted by several researchers in various types of food materials, such as ready-to-eat meals, different kinds of meat, grains, and food models. The non-uniform temperature distribution pattern and the results of the various studies are summarized in this section.

Ready-to-Eat Meals

Changing life style of the people has increased the need and demand for the ready-to-eat meals, which is one of the fastest growing sectors in developed countries (Gehlar and Regmi 2005). Many researchers have studied the temperature distribution during microwave heating of ready-to-eat meals, which consists of several components.

The heating uniformity and temperature distribution of ready-to-eat meals during microwave heating was studied by Ryynanen and Ohlsson (1996). The food samples tested were four-component chilled ready-to-eat meal containing meat patties, sauce, mashed potato, and carrot. Temperature measurements during microwave heating were made using two fiber optic measuring systems with seven probes. The temperature distribution after microwave heating was measured with 35 copper-constantan thermocouples, 30 s after microwave heating and after a cooling period of 5 min. The temperature difference between the hottest and the coldest spot in mashed potatoes was greater than 70 °C, after 30 s of microwave heating. Mean component temperatures, 30 s after heating, were 62.7–79.9 °C for mashed potatoes, 78.8–87.2 °C for meat patties, 82.1–90.0 °C for sauce, and 61.3–94.3 °C for carrots. After cooling period of 5 min, mean temperatures decreased, and the range became smaller as temperature distribution became more even due to heat conduction.

Microwave pasteurization of ready-to-eat meals was studied by Burfoot et al. (1988) using a domestic multi-mode microwave oven (2,450 MHz) with a rotating turntable, a pilot-scale tunnel (2,450 MHz, multimode, four magnetron and power rating of each magnetron was 1.5 kW) and another pilot scale tunnel of 896 MHz (single-mode, single microwave generator operating at an output of 7 kW). The ready-to-eat meal consisted of spaghetti in the base of the tray with a bolognaise meat sauce on top. Temperatures were measured using thermocouples. The probes were inserted near the four corners of the product, at the center, and mid-way along each edge. Temperature differences measured in the sample heated for same duration using a domestic microwave oven and pilot-scale tunnel at 2,450 MHz were 66 and 36 °C, respectively. In experiments with domestic oven, the temperatures at the corners were higher than at the edges, while the temperature at the center was substantially lower. When heated using the multimode tunnel, the mean temperatures were higher than 77.5 °C, but the minimum temperature was as low as 50 °C, which is insufficient for pasteurization. In the 896-MHz tunnel, maximum temperature difference of 17 °C was observed. Temperature distributions were different in the multimode and the single-mode tunnels. In the multimode tunnel, product temperatures were cooler at their center than the edges and the corners, whereas in the single-mode tunnel, a more uniform temperature distribution was obtained with corners cooler than the edges.

The temperature distribution in microwave-heated laboratory-formulated food products (spaghetti with meat sauce, rice with salmon, and white sauce) similar to commercial products in small trays was studied by Ramaswamy and Pillet-Will (1992). The experiments were conducted in domestic microwave oven (2,450 MHz) with cavity dimensions of 34 × 33 × 27 cm and without a turntable. Temperatures were recorded using needle-type copper-constantan thermocouples after completing the microwave heating and during the holding period (not when the microwave was switched on). The difference in the temperature between the hottest and the coldest spot was as high as 65 °C for spaghetti and rice. Temperatures of prepared meals at various locations are given in Table 1. Based on the temperature distribution, it was concluded that reheating of food in a microwave oven may lead to some spots far from hot, while certain parts may be close to the boiling point giving an illusion that the whole food may be steaming hot.

The temperature distribution in frozen and refrigerated foods during microwave heating was studied by Fakhouri and Ramaswamy (1993). The household microwave oven (2,450 MHz) with cavity dimensions of 34 × 33 × 27 cm and without turntable was used, and the temperatures were measured after microwave heating using copper constantan thermocouples. The frozen and the refrigerated food studied were lasagna and shepherd’s pie. The frozen food was heated as per the instructions, i.e., the frozen lasagna was heated for 4 min at full power, 4 min at 70% power level, and held for 5 min before serving. This heating resulted in a center temperature of over 90 °C with a maximum variability of 10 °C. The frozen shepherd’s pie was heated for 9 min at 50% power level, and the temperature in the central region was only about 20 °C, whereas the corners were nearly boiling and the temperatures around the edges were close to 90 °C, thereby resulting in a temperature variation of 70 °C. The instruction for both the refrigerated lasagna and shepherd’s pie was to heat for 5 min at full power. When heated as instructed, the center temperature of shepherd’s pie reached 62 °C, while the edges and corners reached boiling temperature and the maximum variation was 42 °C. The variation in the temperature after a holding time of 5 min was 18 °C. The refrigerated lasagna, when heated for 5 min, resulted in a center temperature of 56.7 °C and even after holding it for 5 min, increased to 67.5 °C, which was still not the safe temperature. They concluded that precooked frozen and refrigerated foods showed non-uniformity in temperature even when the manufacturer’s instructions were followed.

A methodology was developed for assessing the heating performance of domestic microwave ovens with glass turntables by James et al. (2002) using three important reheating characteristics: its true power, heating variability, and repeatability. The materials used for testing were liquid (water, sauce), solid (mashed potatoes), and multicomponent food (mashed potato and sauce), and the temperatures were measured after microwave heating using T-type (copper-constantan) thermocouples. For the multicomponent food, the tray was divided into 12 compartments, the minimum and maximum temperatures were measured, and the mean and the range of temperatures were calculated. The most uniform temperature distribution was found in trays containing water corresponding to 61.7 and 83.9°C for mean temperatures at cold and hot spot, respectively. The least uniform temperatures were found in the multicomponent trays, with mean temperatures of 36.7 and 91.8 °C at cold and hot spot, respectively. Since all the trials are quantifiable, the results could be analyzed to provide a numerical value for an individual oven’s performance.

Meats

Many of the incidences of food poisoning are associated with meat and meat products. Outbreaks associated with salmonella resulting from the consumption of undercooked meat products are of major concern to the health of the humans. Non-uniform temperature distribution resulting in cold spot has serious concerns in meat products because of the survival of the bacteria resulting in health hazards.

The non-uniformity of surface temperatures of poultry meat after microwave heating was studied by Goksoy et al. (1999). Whole-chilled chicken carcasses, ranging in mass from 1,063 to 1,820 g, and chicken breast portions, 126 to 189 g, were used in the study. The fiber optic probes were used to monitor the temperatures of chicken carcass heated in a 2,450-MHz oven with turntable and stirrer. Different trials were conducted by keeping the carcass breast up, breast down, and breast portion alone. In carcass breast-up position, the highest temperatures were measured on the vent, wing, and lower leg areas and the lowest on the upper leg, upper back, and breast. Placing the carcass breast down during heating changed the temperature distribution but did not improve it. The vent, wing, lower leg, and lower back parts of the carcasses reached high average temperatures of 88, 97, 90, and 96 °C, respectively. However, the average temperature on the upper leg and breast muscle were 48 and 29 °C, which are far below that required to kill the pathogens. Their study revealed that an average temperature difference of up to 61 °C was found between different parts on the carcass, and a variability of up to 30 °C in surface temperatures at defined positions on replicates was seen. They concluded that substantial cooking was achieved at some parts of the chicken, whereas some other surfaces had only reached a temperature that would support pathogenic growth rather than eliminate any pathogens present. The mean temperature and standard deviation of the chicken carcass heated by microwave is given in Table 2.

The variability in temperature distribution of ground pork patties with and without salt cooked by microwave energy was studied by Jeong et al. (2007). Pork patties of 90 g each were made with and without salt and at two fat levels of 10% and 20%. Patties were cooked in a domestic microwave oven (2,450 MHz) with a turntable, until the center of the patty reached the designated testing temperature (76.7 °C). The temperatures were measured using fiber optic sensor (Optical Slip Ring Systems, Fiso Technologies, Quebec, Canada) and measured at three locations, at the center, edge, and at mid-way between center and the edge position. The results of the experiments showed that the temperatures at the edges of the patties increased more rapidly to above 90 °C than those at the center position or the mid-way where the temperatures were only around 75 °C. Patties without salt had similar range of temperatures at the center and mid-way, whereas for patties with salt, temperature non-uniformity was found between the center and the mid-way positions, too.

The extent of destruction of food-borne pathogenic bacteria in turkeys cooked in microwave ovens (2,450 MHz) was evaluated by Aleixo et al. (1985). The turkeys were inoculated with Salmonella typhimurium, Staphylococcus aureus, or Clostridium perfringens. The turkeys were cooked until the temperature reached 76.6 °C, the necessary temperature for the development of desirable sensory attributes and tested for the presence of bacteria. The temperature was monitored by thermometers inserted on each side of the breast almost touching the breast bone. The results showed that, although there was a reduction in the number of cells containing bacteria (1 to 2 log reduction in the number of cells for C. perfringens, 3 to 4 log reduction of S. aureus, and 4 to 7 log reduction of S. typhimurium), the cooking procedure did not completely eliminate any of the three pathogenic bacteria from the turkeys. The extent of survival was proportional to the number of spores in the initial inoculums. They concluded that any recommendations made to consumers on microwave roasting of turkeys should take into account the possibility of survival of pathogenic microorganisms in the product after cooking.

The destruction of Trichina larvae in beef–pork loaves cooked in microwave ovens without turntables was studied by Carlin et al. (1982). Ground chuck was purchased from supermarket and infected with Trichina spiralis. Meat loaves were made in three different shapes: (1) ring, (R), (2) oval (O), and (3) oblong (L) shapes. The meat loaves were then cooked for various times at different power settings, and the final temperatures were measured at five locations. The results of this study showed that infective Trichinae were found in beef–pork loaves after cooking in microwave ovens. They recommended not to cook pork in microwave ovens. The temperature of beef–pork loaves at various cooking times are given in Table 3.

Food Models

The temperature distribution in microwave heated food models was studied by Ramaswamy and Pillet-Will (1992). The experiments were conducted in domestic microwave oven (2,450 MHz) without a turntable, and the material tested was 10% starch gel. Temperatures were recorded using needle-type copper-constantan thermocouples. The difference in the temperature between the hottest and the coldest spot for the starch gel was 63.9 °C. Temperature distribution in starch gel decreased from the corners (68.8 °C) to the edges (63.6 °C), then near the center (45.0 °C), and finally at the center (37.7 °C). It was concluded that uneven temperature distribution was found in all samples with corners being close to boiling temperatures while interior locations being below 50 °C.

The temperature distribution during microwave heating (2,450 MHz) of food products having different dielectric properties was studied by Sakai and Wang (2004). One percent agar gel (sample A) and 1% agar gel containing 1% NaCl (sample B) were prepared as pseudofoods having different dielectric properties. Temperatures were measured using infrared thermometers, and from the results, it was observed that the sample A was heated at the center and at the edges, while sample B was heated at the edges. Their results confirmed that variation in dielectric properties influence the temperature distribution during microwave heating.

The effect of experimental parameters, such as sample size, pulsing ratio, and microwave processing time, on sample temperature distribution was studied by Gunasekaran and Yang (2007). Two percent agar gel samples were prepared and poured into glass beakers and stored at 4 °C for 16 h for uniform initial sample temperature. The samples were then heated individually in a laboratory microwave oven (2,450 MHz), and the temperatures were measured. The samples were removed from the microwave oven after every minute of microwave heating, and the temperatures were measured using a T-type thermocouple. When heated by continuous microwave power, the temperature distribution in 3.5-cm radius sample was more uneven compared to the 4.0-cm radius sample. Since the depth of penetration and microwave power was the same in both cylinders, the absorbed power along the radial axis in 3.5-cm radius agar gel cylinder was greater than in 4.0-cm agar gel cylinder. They concluded that pulsed microwave heating resulted in more uniform temperature distribution in the samples than the continuous microwave heating.

Grain

The non-uniformity of surface temperatures of grains (barley, wheat, and canola) after heating in a pilot-scale microwave dryer (2,450 MHz) was studied by Manickavasagan et al. (2006). Fifty grams of grain samples were heated in the pilot-scale microwave dryer at five power levels and two exposure times. The average surface temperatures after microwave treatment were between 72.5 and 117.5 °C, 65.9 and 97.5 °C, and 73.4 and 108.8°C for barley, canola, and wheat, respectively. They reported that non-uniform heating patterns were observed for all three grain types, and the difference between maximum and minimum temperatures (ΔT) were in the range of 7.2–78.9 °C, 3.4–59.2 °C, and 9.7–72.8 °C for barley, canola, and wheat, respectively.

Wheat class identification using thermal imaging was studied by Manickavasagan et al. (2008). During their preliminary study, capability of microwave heating was tested to identify wheat classes. But non-uniform heating pattern within a sample was identified as a major problem, and hence, a simple plate heater with temperature control mechanism was used for the further experiments.

Modeling of Temperature Distribution during Microwave Heating

The temperature distribution in a product during microwave heating is governed by the interaction and absorption of radiation, and the modeling of microwave heating involves microwave power absorption and temperature distribution inside the product (Oliveira and Franca 2002). The process of microwave heating has been numerically modeled by two methods such as finite difference domain method and finite element method (FEM).

Ho and Yam (1992) studied the effectiveness of using metal bands to improve the heating uniformity of a model food. The food model used was 3% agar gel in cylindrical Pyrex glass beakers and heated in a 2,450-MHz microwave oven. Aluminum bands of 0.002-cm thickness were shielded in various patterns in the cylindrical beakers with different spacing and orientation. Fiber optic temperature probes were placed on the sample, and the probes were connected to the fiber optic temperature acquisition systems to measure the temperature of the sample. Temperatures were also measured in unshielded cylinders containing food model. Since the temperature profile in a cylindrical sample was a function of both time and position, they defined two parameters to compare the heating uniformity in shielded and unshielded samples. The first one is relative uniformity (RU) defined as

where SD and SD (open) are standard deviations of heating rates of shielded and unshielded samples, respectively. The second parameter is relative power absorption (RP) defined as

where P and P (open) are power absorption of shielded and unshielded samples, respectively. Their results indicated that the unshielded samples had the largest heating rate variation, and the shielded samples had more uniform heating. The metal foils for shielding are used as reflectors to protect microwave-sensitive food areas from over heating. By providing shielding in the sensitive areas, overheating could be avoided, which results in more uniform heating.

A three-dimensional finite element model of heat and mass transfer in food material during microwave heating was developed by Zhou et al. (1995). Experiments were conducted using potato in two geometries: slab (64 × 48 × 30 mm) and cylinder (50-mm diameter and 40-mm height) as test material. The temperature distribution pattern was similar to those reported by Ramaswamy et al. (1991). In slab geometry, the temperature decreased away from the corners to the edges with a further decrease at the center. The temperature at the top surface was lower than the middle layer because of a large evaporation at the top surface. The moisture distribution pattern showed that moisture dropped rapidly at the corners and edges while relatively flat in the center portion. The temperature distribution in cylindrical geometry was different from that of slab geometry. In cylinder, hot spots were along the central axis of the cylinder and the lowest temperature was at the region between the center and the surface. Moisture distribution was flat in the central region with a rapid drop near the surface because of evaporation. They concluded that, for cylindrical-shaped food materials, during microwave heating, hot spots occurred along the central axis, and for slab-shaped materials, cold spot was located near the geometric center and hot spots occurred along the corners.

The size and shape effect on non-uniformity of temperature distribution in microwave-heated food materials using a three-dimensional FEM was studied by Vilayannur et al. (1998). The key factors that influence the uniformity of temperature distribution are the dielectric and thermophysical properties of the product, frequency, and power of the incident microwave energy and the shape and size of the product (Datta 1990). Hence, they tried to predict the most desirable size and shape combination for a product of any given volume using finite element analysis. The model food selected was potato in three different shapes, namely, brick, cylinder, and hexagonal prism, with three different volumes 75, 90, and 105 cm3. Their results showed that, for the brick shaped products, hot spots were at the corners, while the cold spot was at the geometric center. For the cylinder, the hot spot was at the center, confirming the focusing effect observed by the earlier researchers. In hexagonal-prism-shaped product, center was cold, whereas hot spot was found along the boundary. The results of the study suggest that non-uniformity in temperature distribution was lower in hexagonal-shaped products than the cylinder- and brick-shaped products. The lower non-uniformity in hexagonal-shaped products was explained by calculating the standard deviation of temperature distribution within the product. The standard deviation of temperature ranged from 4.9–6.4 °C in case of hexagonal-prism-shaped products, whereas it was 7.0–7.5 °C and 5.2–8.2 °C for brick- and cylinder-shaped products.

A numerical analysis of electromagnetic and temperature fields in a microwave cavity and the characteristics of microwave heating was studied by Funawatashi and Suzuki (2003). Their analysis showed that electric field and the heating rate depends greatly on the position of the dielectric. They suggested that uneven heating in a microwave field is of two types. One is due to the standing wave, and another is due to rapid decay of microwave. In case of uneven heating due to standing waves, the non-uniformity could be reduced by metallic stirrers and turn tables in domestic ovens.

A finite difference mathematical model to predict temperature profiles for different geometries during microwave heating process was developed by Campanone and Zaritzky (2005). They also verified the numerical predictions with the experimental data obtained in the lab. According to their model, in case of spheres, hot spot occurred at the center of the sphere. In cylinders, non-uniform radial distribution was observed with the highest temperatures at the surface and the center. In cubes and brick-shaped products, microwave energy concentrated in the corners, resulting in hot spots in the corners.

Theoretical and experimental investigations were carried out by Rattanadecho (2004) using frozen layered samples in a microwave oven. The major challenge in the microwave thawing process of layered sample is the presence of moving boundary condition, which leads to complex interaction of thawing front, temperature profiles, and absorbed microwave energy within the sample. The sample was two layered with unfrozen layer (water) and the frozen (ice) layer. The effect of layered configuration, layer thickness, and electric field intensity input on thawing rate were discussed, when a 2.45-GHz microwave energy was applied to the two-layered sample. The results showed that changing of layered configuration changes the heating pattern within the layer. When the unfrozen layer was on top, major part of incident waves were absorbed within a thickness of 20 mm due to the absorption of microwave energy, and the temperature distribution within the unfrozen layer decayed slowly along the propagation direction. When the frozen layer was on top, the incident microwave was further penetrated to the unfrozen layer, since ice in the frozen layer was highly transparent to microwave. There was a hot spot at the leading edge of the unfrozen layer, which resulted in the conduction of heat from hotter region in unfrozen layer to the cooler region in the frozen layer. There was an upward movement of thawing front at the interface between frozen and unfrozen layer. At an exposure time of 120 s, there was a difference of about 50 °C between the maximum and minimum temperatures. The thawing rate decreased with increasing unfrozen layer thickness. An increase in electric filed intensity resulted in an increase in the heating and thawing rates.

Solutions Proposed to Reduce Non-uniform Temperature Distribution

Non-uniform heating is prevalent in microwave heating irrespective of the food product. Wide temperature variations were observed within heated samples during microwave heating of different kinds of meat, ready-to-eat meals, grains, vegetables, and model foods. Researchers have suggested some ways to reduce the intensity of uneven heating. Fung and Cunningham (1980) suggested that microwave heating in combination with conventional heating would result in more uniform heating of foods and destruction of bacteria. Ohlsson and Thorsell (1984) recommended that large food components of more than 25-mm thickness should not be placed on top of each other but should be placed side by side, whereas thin slices should be stacked edge to edge and uniform thickness should be maintained whenever possible. By controlling the food geometry, heating uniformity could be improved substantially. The effectiveness of using metal bands to improve the microwave heating uniformity was studied by Ho and Yam (1992), and they concluded that shielding using metal bands was an effective way to improve the heating uniformity of the cylindrical samples under restricted conditions and more experimental works are needed to describe the effect of metal shielding under conditions of food materials with various dielectric properties, sizes, and geometries. Buffler (1992), Ryynanen and Ohlsson (1996), and Vilayannur et al. (1998) suggested some means for controlling the uneven heating such as design of the microwave oven, manipulation of the heat cycle, ingredient formulation, design of the package, and a combination of the above.

Boyes et al. (1997) studied microwave and water blanching of corn kernels and suggested that non-uniformity could be overcome by over-blanching, but the product viability may be commercially less compared to a water or steam-blanched product. Goksoy et al. (1999) suggested that heating on reduced power for longer times and shielding the overheated portion with aluminum foil resulted in improved surface temperature distributions. A device and method for uniform heating of food in microwaves was designed by Zhang et al. (2004) (US patent no. 6,777,655 B2) to reduce the problems of cold spot, uneven heating, and splattering of food. Datta et al. (2005) suggested that microwave heating in combination with air-jet impingement or infrared heating decreases the non-uniformity of temperature distribution. It was suggested by Gunasekaran and Yang (2007) that pulsed microwave heating resulted in more uniform temperature distribution in the samples than the continuous microwave heating. Although researchers have given some solutions based on their study, the results are confined to specific conditions and cannot be generalized.

Industrial Applications of Microwave Energy

Microwave and radio-frequency heating are both dielectric heating, but microwave heating occurs at higher frequency (915 and 2,450 MHz) and the wavelength is small, whereas the radio-frequency heating occurs at lower frequency (13.56, 27.12, and 40.68 MHz) and the wavelength is large compared to the dimensions of the sample being heated (Zhao et al. 2000; Tewari 2007). Microwave heating is employed in industries for certain unit operations. Some commercially proven applications of microwave processing include dehydration of low moisture solids, pre-cooking of meat products, and tempering of frozen foods (Tewari 2007). The largest industrial application of microwave processing is the tempering of meat for further processing (Ahmed and Ramaswamy 2007). Conventional tempering results in large temperature gradient and takes several days. Whereas microwaves can easily penetrate the frozen product, thus reaching the inner regions in a short time of 5–10 min for 20–40 kg of frozen meat (Ahmed and Ramaswamy 2007). There are at least 400 microwave tempering systems operating in the USA alone, and in UK, there are several large systems, up to 200 kW utilized for tempering frozen beef and butter (Fu 2004). Microwave energy at 915 MHz has three times the penetration depth of 2,450 MHz, thereby allowing for better penetration depth and processing of products of large geometries (Fu 2004).

Pasta drying using a combination of conventional hot air drying followed by a microwave and hot air drying and microwave vacuum drying of fruit juice concentrates have been used for a long time in the industries (Tewari 2007). Precooking of bacon is another largest application of microwave heating in the food industry. During grilling, bacon loses fat component and the desirable quality characteristics. Microwave heating of bacon produces better structure with less shrinkage (Schiffmann 2001). A complete microwave system has also been used for bacon cooking, where a series of magnetrons are used to cook the bacon and the placement of the magnetron varies among the manufacturers (Ahmed and Ramaswamy 2007). The finish drying of potato chips was one of the first large scale application of microwave energy in the food processing industry. Conventional drying cannot rapidly achieve the desired low moisture levels of potato chips, whereas conventional drying of potato chips up to 6–8% followed by finish drying by microwave energy overcomes the difficulty in the potato chips manufacturing process (Ahmed and Ramaswamy 2007).

Conclusions

Temperature distribution studies during microwave heating have been conducted by several researchers in different food products. The results of the studies have proven that there is a wide variation in the temperature distribution during microwave heating, and the non-uniform temperature distribution occurs irrespective of the material heated. The major limitation for using microwave heating in industrial application is the existence of non-uniform temperature distribution. Although a couple of solutions has been given so far, these are restricted to certain conditions, and non-uniformity could only be reduced but not eliminated. A major improvement in the temperature distribution during microwave heating will result in the maximum utilization of microwave heating in industrial processes.

References

Adu, B., & Otten, L. (1996). Microwave heating and mass transfer characteristics of white beans. Journal of Agricultural Engineering Research, 64(1), 71–78. doi:10.1006/jaer.1996.0047.

Ahmed, J., & Ramaswamy, H. S. (2007). Microwave pasteurization and sterilization of foods. In M. S. Rahman (Ed.), Handbook of food preservation (2nd ed., pp. 691–711). Florida, USA: CRC Press.

Aleixo, J. A. G., Swaminathan, B., Jamesen, K. S., & Pratt, D. E. (1985). Destruction of pathogenic bacteria in turkeys roasted in microwave ovens. Journal of Food Science, 50(4), 873–875. doi:10.1111/j.1365-2621.1985.tb12969.x.

Ayappa, K. G., Davis, H. T., Davis, E. A., & Gordon, J. (1991). Analysis of microwave heating of materials with temperature dependent properties. AlChe Journal, 37(3), 313–322.

Ayappa, K. G., Davis, H. T., Davis, E. A., & Gordon, J. (1992). Two dimensional finite element analysis of microwave heating. AlChe Journal, 38(10), 1577–1592.

Barringer, S. A., Davis, E. A., Gordon, J., Ayappa, K. G., & Davis, H. T. (1995). Microwave heating temperature profiles for thin slabs compared to Maxwell and Lambert law predictions. Journal of Food Science, 60(5), 1137–1142. doi:10.1111/j.1365-2621.1995.tb06309.x.

Blaszczak, W., Gralik, J., Klockiewicz-kaminska, E., Fornal, J., & Warchalewski, J. R. (2002). Effect of γ-radiation and microwave heating on endosperm microstructure in relation to some technological properties of wheat grain. Nahrung/Food, 46(2), 122–129.

Boyaci, I. H., Sumnu, G., & Sakiyan, O. (2008). Estimation of dielectric properties of cakes based on porosity, moisture content and formulations using statistical methods and artificial neural networks. Food and Bioprocess Technology, in press.

Boyes, S., Chevis, P., Holden, J., & Perera, C. (1997). Microwave and water blanching of corn kernels: Control of uniformity of heating during microwave heating. Journal of Food Processing and Preservation, 21(6), 461–484. doi:10.1111/j.1745-4549.1997.tb00796.x.

Buffler, C. R. (1992). Microwave cooking and processing (pp. 14–83). New York, USA: Van Nostrand Reinhold.

Burfoot, D., Griffin, W. J., & James, S. J. (1988). Microwave pasteurization of prepared meals. Journal of Food Engineering, 8(3), 145–156. doi:10.1016/0260-8774(88)90050-7.

Campanone, L. A., & Zaritzky, N. E. (2005). Mathematical analysis of microwave heating process. Journal of Food Engineering, 69(3), 359–368. doi:10.1016/j.jfoodeng.2004.08.027.

Carlin, F., Zimmermann, W., & Sundberg, A. (1982). Destruction of Trichina larvae in beef-pork loaves cooked in microwave ovens. Journal of Food Science, 47(4), 1096–1099. doi:10.1111/j.1365-2621.1982.tb07626.x.

Chen, D. D., Singh, R. K., Haghighi, K., & Nelson, P. E. (1993). Finite element analysis of temperature distribution in microwaved cylindrical potato tissue. Journal of Food Engineering, 18(4), 351–368. doi:10.1016/0260-8774(93)90052-L.

Datta, A. K. (1990). Heat and mass transfer in the microwave processing of food. Chemical Engineering Progress, 86(6), 47–53.

Datta, A. K., Geedipalli, S. S. R., & Almeida, M. F. (2005). Microwave combination heating. Food Technologist, 59(1), 36–40.

Datta, A. K., & Ni, H. (2002). Infrared and hot-air assisted microwave heating of foods for control of surface moisture. Journal of Food Engineering, 51(4), 355–364. doi:10.1016/S0260-8774(01)00079-6.

Datta, A. K., Prosetya, H., & Hu, W. (1992). Mathematical modeling of batch heating of liquids in a microwave cavity. Journal of Microwave Power and Electromagnetic Energy, 27(1), 101–110.

Decareau, R. V. (1985). Microwaves in the food processing Industry. Natick, MA: Academic.

Decareau, R. V. (1992). Microwave foods: New product development. Connecticut, USA: Food and Nutrition Press.

Fakhouri, M. O., & Ramaswamy, H. S. (1993). Temperature uniformity of microwave heated foods as influenced by product type and composition. Food Research International, 26(2), 89–95. doi:10.1016/0963-9969(93)90062-N.

Fu, Y. C. (2004). Fundamentals and Industrial applications of microwave and radio frequency in food processing. In J. S. Smith, & Y. H. Hui (Eds.), Food processing: Principles and applications (pp. 79–100). Iowa, USA: Blackwell.

Funawatashi, Y., & Suzuki, T. (2003). Numerical analysis of microwave heating of a dielectric. Heat Transfer-Asian Research, 32(3), 227–236. doi:10.1002/htj.10087.

Funebo, T., & Ohlsson, T. (1998). Microwave assisted air dehydration of apple and mushroom. Journal of Food Engineering, 38(3), 353–367. doi:10.1016/S0260-8774(98)00131-9.

Fung, D. Y. C., & Cunningham, F. E. (1980). Effect of microwaves on microorganisms in foods. Journal of Food Protection, 43(8), 641–650.

Gehlar, M., & Regmi, A. (2005). New directions in global food Markets: Factors shaping global food markets. Economics Research Service, USDA. Retrieves 2 April 2006 from http://www.ers.usda.gov/publications/aib794/aib794.pdf.

Goksoy, E. O., James, C., & James, S. J. (1999). Non-uniformity of surface temperatures after microwave heating of poultry meat. Journal of Microwave Power and Electromagnetic Energy, 34(3), 149–160.

Gowen, A., Abu-Ghannam, N., Frias, J., & Oliveira, J. (2006). Optimisation of dehydration and rehydration properties of cooked chickpeas (Cicer arietinum L.) undergoing microwave-hot air combination drying. Trends in Food Science & Technology, 17(4), 177–183. doi:10.1016/j.tifs.2005.11.013.

Gunasekaran, S. (1990). Grain drying using continuous and pulsed microwave energy. Drying Technology, 8(5), 1039–1047. doi:10.1080/07373939008959934.

Gunasekaran, S., & Yang, H. (2007). Effect of experimental parameters on temperature distribution during continuous and pulsed microwave heating. Journal of Food Engineering, 78(4), 1452–1456. doi:10.1016/j.jfoodeng.2006.01.017.

Geedipalli, S. S. R., Rakesh, V., & Datta, A. K. (2007). Modeling the heating uniformity contributed by a rotating turntable in microwave ovens. Journal of Food Engineering, 82(3), 359–368. doi:10.1016/j.jfoodeng.2007.02.050.

Ho, Y. C., & Yam, K. L. (1992). Effect of metal shielding on microwave heating uniformity of a cylindrical food model. Journal of Food Processing and Preservation, 16(5), 337–359. doi:10.1111/j.1745-4549.1992.tb00214.x.

James, C., Swain, M. V., James, S. J., & Swain, M. J. (2002). Development of methodology for assessing the heating performance of domestic microwave ovens. International Journal of Food Science & Technology, 37(8), 879–892. doi:10.1046/j.1365-2621.2002.00636.x.

Jeong, J. Y., Lee, E. S., Choi, J. H., Lee, J. Y., Kim, J. M., Min, S. G., et al. (2007). Variability in temperature distribution and cooking properties of ground pork patties containing different fat level and with/without salt cooked by microwave energy. Meat Science, 75(3), 415–422. doi:10.1016/j.meatsci.2006.08.010.

Kelen, A., Ress, S., Nagy, T., Pallai, E., & Pintye-Hodi, K. (2006). Mapping of temperature distribution in pharmaceutical microwave vacuum drying. Powder Technology, 162(2), 133–137. doi:10.1016/j.powtec.2005.12.001.

Krokida, M. K., Maroulis, Z. B., & Saravacos, G. D. (2001). The effect of the method of drying on the color of dehydrated products. International Journal of Food Science & Technology, 36(1), 53–59. doi:10.1046/j.1365-2621.2001.00426.x.

Lee, M. L., Gray, I., & Pearson, A. M. (1983). Effects of frying procedures and compositional factors on the temperature profile of bacon. Journal of Food Science, 48(3), 817–819. doi:10.1111/j.1365-2621.1983.tb14907.x.

Lee, D. S., Shin, D., & Yam, K. L. (2002). Improvement of temperature uniformity in microwave-reheated rice by optimizing heat/cold cycle. Food Service Technology, 2(2), 87–93. doi:10.1046/j.1471-5740.2002.00035.x.

Lin, Y. E., Anantheswaran, R. C., & Puri, V. M. (1995). Finite element analysis of microwave heating of solid foods. Journal of Food Engineering, 25(1), 85–112. doi:10.1016/0260-8774(94)00008-W.

Lin, T. M., Durance, T. D., & Scaman, C. H. (1998). Characterization of vacuum microwave, air and freeze dried carrot slices. Food Research International, 31(2), 111–117. doi:10.1016/S0963-9969(98)00070-2.

Mallikarjunan, P., Hung, Y. C., & Gundavarapu, S. (1996). Modeling microwave cooking of cocktail shrimp. Journal of Food Process Engineering, 19(1), 97–111. doi:10.1111/j.1745-4530.1996.tb00383.x.

Manickavasagan, A., Jayas, D. S., & White, N. D. G. (2006). Non-uniformity of surface temperatures of grain after microwave treatment in an industrial microwave dryer. Drying Technology, 24(12), 1559–1567. doi:10.1080/07373930601030796.

Manickavasagan, A., Jayas, D. S., White, N. D. G., & Paliwal, J. (2008). Wheat class identification using thermal imaging. Food and Bioprocess Technology, in press.

Mullin, J. (1995). Microwave processing. In G. W. Gould (Ed.), New methods of food preservation (pp. 112–134). Bishopbriggs, UK: Blackie Academic and Professional.

Mullin, J., & Bows, J. (1993). Temperature measurements during microwave cooking. Food Additives and Contaminants, 10(6), 663–672.

Ni, H., & Datta, A. K. (1999). Moisture loss as related to heating uniformity in microwave processing of solid foods. Journal of Food Process Engineering, 22(5), 367–382. doi:10.1111/j.1745-4530.1999.tb00492.x.

Ohlsson, T., & Thorsell, U. (1984). Problems in microwave reheating of chilled foods. Journal of Foodservice Systems, 3, 9–16.

Oliveira, M. E. C., & Franca, A. S. (2002). Microwave heating of foodstuffs. Journal of Food Engineering, 53(4), 347–359. doi:10.1016/S0260-8774(01)00176-5.

Raaholt, B. W., & Ohlsson, T. (2000). Tools for improving the heating uniformity of foods heated in a microwave oven. Microwave World, 21(1), 24–28.

Ramaswamy, H. S., Pillet, T., & Fakhouri, M. (1991). Distribution and equalization of temperature in a microwave heated food model. ASAE Paper No. 913518. St. Joseph, MI.

Ramaswamy, H. S., & Pillet-Will, T. (1992). Temperature distribution in microwave heated food models. Journal of Food Quality, 15(6), 435–448. doi:10.1111/j.1745-4557.1992.tb00969.x.

Rattanadecho, P. (2004). Theoretical and experimental investigation of microwave thawing of frozen layer using a microwave oven (effects of layered configurations and layer thickness). International Journal of Heat and Mass Transfer, 47(5), 937–945. doi:10.1016/j.ijheatmasstransfer.2003.08.019.

Romano, V. R., Marra, F., & Tammaro, U. (2005). Modelling of microwave heating of foodstuff: Study on the influence of sample dimensions with a FEM approach. Journal of Food Engineering, 71(3), 233–241. doi:10.1016/j.jfoodeng.2004.11.036.

Rosenberg, U., & Bogl, W. (1987). Microwave pasteurization, sterilization, blanching, and pest control in the food industry. Food Technologist, 41(6), 92–97.

Ryynanen, S., & Ohlsson, T. (1996). Microwave heating uniformity of ready meals as affected by placement, composition, and geometry. Journal of Food Sciences, 61(3), 620–624. doi:10.1111/j.1365-2621.1996.tb13171.x.

Ryynanen, S., Tuorila, H., & Hyvonen, L. (2001). Perceived temperature effects on microwave heated meals and meal components. Food Service Technology, 1(3), 141–148. doi:10.1046/j.1471-5740.2001.d01-4.x.

Sakai, N., & Wang, C. (2004). An analysis of temperature distribution in microwave heating of foods with non-uniform dielectric properties. Journal of Chemical Engineering of Japan, 37(7), 858–862. doi:10.1252/jcej.37.858.

Schiffmann, R. F. (2001). Microwave processes for the food industry. In A. K. Datta & R. C. Anantheswaran (Eds.), Handbook of microwave technology for food applications (pp. 229–335). New York, USA: Marcel Dekker.

Tewari, G. (2007). Microwave and radio-frequency heating. In G. Tewari & V. K. Juneja (Eds.), Advances in thermal and non-thermal food preservation (pp. 91–98 & 131–143). Iowa, USA: Blackwell.

Vilayannur, R. S., Puri, V. M., & Anantheswaran, R. C. (1998). Size and shape effect on non-uniformity of temperature and moisture distributions in microwave heated food materials: Part 1 Simulation. Journal of Food Process Engineering, 21(3), 209–233. doi:10.1111/j.1745-4530.1998.tb00448.x.

Warchalewski, J. R., Gralik, J., Wojtasiak, R. Z., Zabielski, J., & Kusnnierz, R. (1998). The evaluation of wheat grain odour and colour after gamma and microwave irradiation. Electronic Journal of Polish Agricultural Universities, 1(1), 1–11.

Yang, H. W., & Gunasekaran, S. (2004). Comparison of temperature distribution in model food cylinders based on Maxwell’s equations and Lambert’s law during pulsed microwave heating. Journal of Food Engineering, 64(4), 445–453. doi:10.1016/j.jfoodeng.2003.08.016.

Zhang, H., Bonneveau, L. H., Yout, W., Helstern, G. C., & Loizeau, G. (2004). Uniform microwave heating of food in a container. US Patent 6,777,655.

Zhao, Y., Flugstad, B., Kolbe, E., Park, J. W., & Wells, J. H. (2000). Using capacitive (radio frequency) dielectric heating in food processing and preservation- a review. Journal of Food Process Engineering, 23(1), 25–55. doi:10.1111/j.1745-4530.2000.tb00502.x.

Zhou, L., Puri, V. M., & Anantheswaran, R. C. (1995). Finite element modeling of heat and mass transfer in food materials during microwave heating- Model development and validation. Journal of Food Engineering, 25(4), 509–529. doi:10.1016/0260-8774(94)00032–5.

Acknowledgments

We thank the Canada Research Chairs program and the Natural Sciences and Engineering Research Council of Canada for providing financial support for this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vadivambal, R., Jayas, D.S. Non-uniform Temperature Distribution During Microwave Heating of Food Materials—A Review. Food Bioprocess Technol 3, 161–171 (2010). https://doi.org/10.1007/s11947-008-0136-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-008-0136-0