Abstract

The objectives of this research were to solve the problem that the existing sugarcane seed metering device had high per cent of damaged seeds and omission rate. An electromagnetic vibration-type single-bud sugarcane seed metering device was designed. It made use of the characteristic of vibrating automatic metering to avoid damaging buds. And it could be adjusted to different sowing speeds by setting the controller. The migratory mechanism was analysed. The helix angle and working parameters of the metering device were obtained by the experiment. The results of the experiment showed that the order of factors affecting the qualification rate was amplitude > frequency > helix angle. The best qualification rate of the metering device was achieved when the helix angle was 6°, the amplitude was 0.4 mm and the frequency was 53.2 Hz, and the results of verification experiments showed that the qualification rate of metering was over 80% and the per cent of damaged buds was 0 with the best parameter combination. This metering device met the standard requirements of sugarcane seeds metering.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The perennial planting area of sugarcane in China is 1.5 million ha, accounting for over 90% of Chinese sugar crop. At present, single-bud sugarcane planting is the least seeding rate planting technology, when the seeding rate is about 2000 kg/ha and the germination rate is up to 70%. Compared with multiple buds sugarcane planting, the seeding amount is reduced by 83.3%, which is convenient for the seed selection, disinfection and mechanization (Liang et al. 2014). However, sugarcane planting mainly depends on artificial cultivation and the mechanization level is low in China (Wang and Jianlin 2012). Thus, the planter suitable for single-bud sugarcane planting is urgently needed.

The seed metering device is the core part of sugarcane planter, whose working performance directly influences sugarcane planting quality. The study of other countries for sugarcane metering devices focuses on the pre-cut type metering device, in which the belt or chain is adopted for sugarcane sowing. The sugarcane metering devices are highly automatic and efficient, but reseeding, leakage and injury are very serious (Pessoa Jr 2005; Kumar and Singh 2012; Taghinezhad et al. 2013; Naik et al. 2013; Namjoo and Razavi 2014; Singh and Singh 2016; Thienyaem et al. 2014, 2016). A Chinese study for sugarcane metering devices mainly focuses on the cutting-type metering devices, in which the roller clamping and cutting method is adopted to achieve planting. However, there is serious injury to the buds and the method relies on manual assistance feeding and sowing, which leads to high leakage rate and low qualification rate and evenness (Yang et al. 2007; Wang et al. 2013; Huang et al. 2014, 2015a, b; Zeng et al. 2015; Liu et al. 2018). The existing single-bud sugarcane seed metering devices are composed of sorting mechanism and planting mechanism, which can sow single-bud sugarcane orderly and reduce the leakage rate, but the buds are damaged seriously by planting mechanism (Liu et al. 2013a, b; Huang et al. 2015a, b).

Therefore, in order to reduce the injury rate and leakage rate and improve the qualification rate and evenness of the sugarcane metering device, a single-bud sugarcane seed metering device was designed on the basis of the electromagnetic vibration without any damage characteristic (Zhang et al. 1992, 1996; Li and Zhao 2000; He et al. 2003; Wang et al. 2015). The influence factors of planting quality were determined by analysing the migratory mechanism of single-bud sugarcane. The influence factors on the rate of planting quality were analysed through experiments. This study aims to provide theoretical reference basis for optimizing the single-bud sugarcane seed metering device.

Materials and Methods

Main Frame

Electromagnetic vibration is a new seed sowing technology, which has the advantages of simple transmission, accurate control, no damage to seeds, high precision and good evenness (Yang et al. 2012). The electromagnetic vibration-type single-bud sugarcane seed metering device (Fig. 1) is mainly composed of spiral groove, disc, seed-cleaning plate, substructure, spring, controller (Fig. 2) and coil.

Metering Mechanism

When the metering device works, alternating current is loaded on the coils after half-wave rectification of alternating current of certain frequency. The disc is the downward movement and rotary motion under the influence of suction, which is generated when the coils are energized, and spring. The disc returns to the original position under the reaction force of spring when the suction is zero. The spiral groove and disc occur in harmonic vibration during a period of the suction (Fig. 3). The single-bud sugarcane, which acceleration meets certain conditions, is motion and adjustment under the influence of the gravity, friction and inertial force. The vertical single-bud sugarcane is in the lying state when it passes the ladder of the spiral groove. The redundant single-bud sugarcane returns to the disc automatically by the seed-cleaning plate so that only one sugarcane seed is planted. The sowing speeds are adjusted for tractor speed by setting the controller.

Analysis of Migratory Mechanism

Only the forward motion and throwing motion meet the requirements of metering for the device. So it is necessary to study the critical condition of the throwing motion of sugarcane seeds by analysing its state. The mechanical model of sugarcane seed (Fig. 4) is built by making the spiral groove become to straight groove.

When the disc and the spiral groove are downward and rotate, the sugarcane seed is in the upward movement if the inertial force is higher than the friction force; if not the sugarcane seed is stationary. When the disc and the spiral groove are upward and rotate, the sugarcane seed is in the downward movement if the inertial force is higher than the friction force; if not the sugarcane seed is stationary. The sugarcane seed is in the skidding state when the inertial force is less than the gravity (Fig. 5); otherwise, the sugarcane seed is in the throwing state. The displacement of sugarcane seed under throwing state depends on the time. The displacement is maximum when the time of throwing is equal to the downward movement time of spiral groove (Fig. 6). The displacement is smaller when the sugarcane seed returns to the spiral groove in advance or delay (Fig. 7).

The displacement of sugarcane seed at the direction of inertial force is given by the formula as follows:

where S is the displacement of sugarcane seed, mm, A is the amplitude of disc, mm, and ω is the angular frequency of suction, Hz.

The conditions of sugarcane seed under skidding state (Liu 2007; Yang et al. 2007) are given by the formula as follows:

where α is the angle between the direction of the vibration and the spiral groove, °, β is the helix angle of spiral groove, °, and μ is the friction coefficient between sugarcane seed and spiral groove.

The conditions of sugarcane seed under throwing state (Liu 2007; Yang et al. 2007) are given by the formula as follows:

The skidding state of sugarcane seed is selected when the metering device is designed since the skidding state is more stable than the throwing state. So the conditions of sugarcane seed under skidding state are given by the formula as follows:

The skidding speed of sugarcane seed is given by the formula as follows:

where \( \varphi_{k} \) is the hypothetical slipping angle of forward direction, °, \( \varphi_{k}^{{\prime }} \) is the true slipping angle of forward direction, °, and \( \varphi \) is the phase angle, °.

The hypothetical slipping angle of forward direction is given by the formula as follows:

where K is the stiffness of all springs, N/m.

The true slipping angle of forward direction is given by the formula as follows:

where \( \theta_{k} \) is the slide angle of forward direction, °.

So the average skidding speed of sugarcane seed is given by the formula as follows:

where \( \varphi_{m}^{{\prime }} \) is the true stopping angle of forward direction, °.

According to the above results, the skidding speed of sugarcane seed is mainly determined by amplitude of disc, angular frequency of suction, angle between the direction of the vibration and the spiral groove, helix angle of spiral groove, the friction coefficient between sugarcane seed and spiral groove and the stiffness of all spring.

Design of Planter Plate

The disc is designed as ladder-type spiral in order to avoid discontinuous metering and improve the quality and efficiency of planting. Diameter, which is determined by the length and number of sugarcane seed, is an important structural parameter for disc (Fig. 8).

The diameter of disc is given by the formula as follows:

where L is the length of sugarcane seed, mm, and N is the number of sugarcane seed.

The length of single-bud sugarcane seed is about 50 mm. So the diameter of the disc is determined by the number of sugarcane seed. The number of sugarcane seed should be as large as possible in order to reduce the motion resistance of sugarcane seed. According to the frame size of sugarcane planter, the diameter of the disc is designed to be 600 mm (Fig. 9).

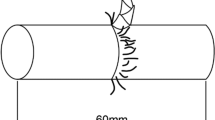

Design of Spiral Groove

The spiral groove is composed of the welding between the plate and disc. The width of spiral groove is determined by the diameter of sugarcane seed. The diameter of sugarcane seed is about 30 mm. So the width of spiral groove is designed to be 50 mm. In order to avoid congestion and seed clearing, a ladder, which is a height of 10 mm, is designed on the spiral groove. The number of the spiral is designed to be 2.5. The helix angle of spiral groove is designed to 4°–10° (Zhang et al. 1996; Liu 2007). The final helix angle depends on the experiment results.

Design of Vibration System

The vibration system, which is composed by spring and vibrator (Fig. 10), is the power source of the metering device.

The stiffness of all springs is given by the formula as follows (Dong et al. 2005, Dong and Yang 2006; Liu and Zhao 2008; Yang et al. 2009).

where i is the number of all springs, E is the elasticity modulus, MPa, b is the width of spring, mm, h is the thickness of spring, mm, α is the compression coefficient and l is the length of spring, mm.

The field parameters of spring are presented in Table 1.

The stiffness of all springs is designed to be 700,983.14 N/m. The angle between the direction of the vibration and the spiral groove is equal to the installation angle of spring. The installation angle of spring is designed to be 25°, so the angle between the direction of the vibration and the spiral groove is 23° (Liu et al. 2005). The voltage of vibrator is designed to use alternating current which voltage is 220 V.

Materials and Equipment

The experiments are carried out in order to obtain the helix angle and working parameters of the electromagnetic vibration-type single-bud sugarcane seed metering device (Fig. 11). The experiment is conducted at the Research Institute of Agricultural Machinery, Chinese Academy of Tropical Agricultural, Zhanjiang City, Chinese Guangdong Province (Fig. 12). The materials and equipment are presented in Table 2.

Single factor experiments and orthogonal experimental design of regression method are used to study the relationship between the factors (helix angle, amplitude of disc, angular frequency of suction) and the qualification rate of metering. The travelling speed of s test bench is set to 2 km/h. The sample data are collected at 20 m in the interior of the test bench displacement. To reduce experiment error, each group of the experiment is repeated three times.

In accordance with agronomic of single-bud sugarcane planting, 5–7 segments of sugarcane seeds should be guaranteed every meter, so the theoretical spacing of single-bud sugarcane seed is about 200 mm. When the seed spacing is less than half of the theoretical spacing, this refers to repetition. When the seed spacing is greater than 1.5 times of the theoretical spacing, this refers to omission (Yang et al. 2005). Thus, the qualified seed spacing of single-bud sugarcane is 100–300 mm. The evaluation index of metering performance is presented in Table 3 (Liu et al. 2013a, b). The qualification rate of metering is given by the formula as follows:

where n is the qualification sample size and N is the total sample size.

Results and Discussion

Single Factor Experiments

The programme and results of single factor experiments are presented in Table 4.

The relation between factors and qualification rate of metering is given by the formulas as follows:

The results of the significant test of each formula and coefficient show that the P value of the helix angle and qualification rate of metering is 0.01103, the P value of the amplitude and qualification rate of metering is 0.00101, and the P value of the frequency and qualification rate of metering is 0.00115. So helix angle, amplitude and frequency have a strong impact on the qualification rate of metering. The fitting degrees of each formula, which is well fitted, are more than 0.9. The regression curve of each factor and qualification rate is built (Figs. 13, 14, 15).

It is seen from the regression curve of helix angle and qualification rate that the qualification rate gets lower with the increase in helix angle. The speed of sugarcane seed becomes lower with the increase in helix angle. Thus, the omission is so serious that the qualification rate gets lower.

It is seen from the regression curve of amplitude and qualification rate that the qualification rate first increases and then decreases with the increase in amplitude. The speed of sugarcane seed is higher with the increase in amplitude, thus leading to higher qualification rate. When the speed of sugarcane seed is too high, the over-sowing is so serious that the qualification rate gets lower.

It is seen from the regression curve of frequency and qualification rate that the qualification rate first increases and then decreases with the increase in frequency. The speed of sugarcane seed is faster and faster with the increase in frequency, thus leading to higher qualification rate. When the speed of sugarcane seed is too high, the over-sowing is so serious that the qualification rate gets lower.

Orthogonal Experimental Design of Regression Method

The level range of each influencing factor is determined according to the results of single factor experiments. The levels of factors are presented in Table 5. The results of orthogonal experimental design of regression method are presented in Table 6.

The relation between factors and qualification rate of metering is given by the formula as follows according to the results of the experiments.

The results of the significant test of the formula and coefficients are presented in Table 7.

It is seen from the table that the formula shows a significant lack of fit, but the formula is fitted well to most of the experiment results. The significance of formula is very obvious. The influence of helix angle on qualification rate is significant. The influence of amplitude on qualification rate is very significant. The influence of frequency on qualification rate is very significant. The influence of the product of helix angle and amplitude on qualification rate is not significant. The influence of the product of helix angle and frequency on qualification rate is significant. The influence of the product of amplitude and frequency on qualification rate is significant. The influence of the square of helix angle on qualification rate is not significant. The influence of the square of amplitude on qualification rate is very significant. The influence of the square of frequency on qualification rate is very significant. The order of factors affecting the qualification rate is amplitude > frequency > helix angle. The formula is given by gradual analysis as follows:

The level codes are substituted in the formula, and thus, the final relation between factors and qualification rate of metering is given by the formula as follows:

The best qualification rate and parameter combination are obtained by optimizing the formula. The best qualification rate of theory is 85.6%, and the best parameter combination is 6°, 0.4 mm and 53.2 Hz. The best qualification rate of theory with 95% confidence intervals is 84.2–87.4%.

Verification Experiment

The verification experiments were conducted under the condition of the best parameter combination. The verification experiment includes the laboratory experiment and field experiment (Fig. 16). While the tractor is moving in the forward direction, the furrow opener opens up the seed channel, and then, the sugarcane seeds planted (Fig. 17). The results of the laboratory experiments are presented in Table 8, and the results of the field experiments are presented in Table 9.

It is seen from the table that the average of qualification rate of the laboratory experiment is 85.5%. The average of qualification rate of the field experiment is 80.4%. All qualification rates are more than 80%, so this metering device meets the standard requirements. There is a certain difference between the qualification rate of the laboratory experiment and that of field experiment. The reasons for the decline in the qualification rate of the field experiment are the forward velocity of tractor instability and the unevenness of the ground. There is no damage to the buds as compared to conventional sugarcane metering devices.

Conclusions

An electromagnetic vibration-type single-bud sugarcane seed metering device was designed. The metering device has the characteristics of automatic sowing and without any damage. The factors influencing the skidding speed of sugarcane seed were determined by migratory mechanism analysis. The order of factors affecting the qualification rate was amplitude > frequency > helix angle. The laboratory experiments proved that the best qualification rate was achieved when the helix angle was 6°, the amplitude was 0.4 mm and the frequency was 53.2 Hz. The verification experiments proved that the qualification rate of metering was more than 80% and the per cent of damaged buds was 0 under the condition of the best parameter combination, and this metering device met the standard requirements.

References

Dong, Yan, and Jian Yang. 2006. The theory analysis on vibrated characteristic of electromagnetic vibrated seeding apparatus. Journal of Agricultural Mechanization Research (12): 76–77.

Dong, Yan, Jian Yang, Xiaoli Yang, and Zhaoxin Liang. 2005. The simulation study on electromagnetic vibrated seeding apparatus by virtual prototype technology. Journal of Agricultural Mechanization Research (6): 97–99, 103.

He, Peixiang, Mingjin Yang, and Zhonghui Chen. 2003. Study on photoelectric controlled precision seeder. Transactions of the Chinese Society for Agricultural Machinery 34(1): 47–49.

Huang, Chang, Jiangping Liu, Xuehu Dong, Ming Li, Lijiao Wei, and Yiguo Deng. 2014. Design of key components of a new-type sugarcane planter. Guangdong Agricultural Sciences 41(22): 151–154, 237.

Huang, Yiqi, Xiaobo Wang, Kai Yun, and Meizhang Huang. 2015a. Design and experiments of buds-injury-prevention system based on induction-counting in sugarcane-seeds cutting. Transactions of the Chinese Society of Agricultural Engineering 31(18): 41–47.

Huang, Yiqi, Kai Yin, Meizhang Huang, and Xiaobo Wang. 2015b. Seed meter of single-bud segment sugarcane seeds. CN Patent 104798517.

Kumar, Sanjay, and B.R. Singh. 2012. Performance Feasibility and Economic Viability of Sugarcane Planter in Western Plane Zone of Uttar Pradesh, India. Sugar Tech 14(2): 101–108.

Li, Zhiwei, and Yaojian Zhao. 2000. Study and test of electromagnetic vibrating type rice seeder for hill seedling nursery box. Transactions of the Chinese Society for Agricultural Machinery 31(5): 32–34.

Liang, Yongjian, Xiaoqiu Zhang, Liu Yang, Litao Yang, and Yangrui Li. 2014. Research progress in breeding technique of sugarcane healthy seeding or seedcanes. Biotechnology Bulletin (11): 91–96.

Liu, Cunrui, Haoran Cheng, Qiao Zhou, Zhao Chen, Yang Luo, Yuqing Zhao, and Qing Shi. 2018. Design to key parts of a new type of ground wheel driving sugarcane planter. Journal of Agricultural Mechanization Research 40(1): 120–123, 134.

Liu, Lipin, Genfa Han, Ke Ma, and Yingzhi Han. 2013a. Specifications for Single Seed Drills (Precision Drills). Beijing: China Machine Press.

Liu, Qingting, Dantong Yang, Yinggang Ou, and Xiaoping Zhou. 2013b. Seeding apparatus for planting single-bud sugarcanes. CN Patent 103141196.

Liu, Yonghong. 2007. Experimental analysis on electromagnetic vibration cotton precision seeding device. Journal of Agricultural Mechanization Research (6): 137–138.

Liu, Yonghong, Jianwen Zha, and Shanru Cai. 2005. Mechanics analysis of electromagnetic vibration cotton precision feed. Journal of Agricultural Mechanization Research (4): 105–107.

Liu, Yonghong, and Hongguang Zhao. 2008. Study on diffluence electromagnetic vibration cotton precision seeding device. Journal of Agricultural Mechanization Research (8): 112–113, 116.

Naik, Ravindra, S.J.K. Annmalai, and N. Vijayan Nair. 2013. Studies on mechanisation of planting of sugarcane bud chip settings raked in Protrays. Sugar Tech 15(1): 27–35.

Namjoo, Moslem, and Jalil Razavi. 2014. Development and evaluation of a new double-row sugarcane billet planter with overlap planting pattern. Agricultural Mechanization in Asia, Africa and Latin America: AMA 45(2): 57–64.

Pessoa Jr., Adalberto. 2005. Perspectives on Bioenergy and biotechnology in Brazil. Applied Biochemistry and Biotechnology 121(1): 59–70.

Singh, A.K., and P.R. Singh. 2016. Development of a tractor operated sugarcane cutter planter for mechanisation of sugarcane planting in deep furrows. Sugar Tech 19(4): 1–8.

Taghinezhad, Javad, Reza Alimardani, and Ali Jafari. 2013. Design a capacitive sensor for rapid monitoring of seed rate of sugarcane Planter. Agricultural Engineering International: CIGR Journal 15(4): 23–29.

Thienyaem, Titinai, Khwantri Saengprachatanarug, Masami Ueno, and Taira Eizo. 2016. Analysis of discharge consistency and performance of a sugarcane billet planter with side-conveyer concept. KKU Engineering Journal 43(1): 9–12.

Thienyaem, Titinai, Khwantri Saengprachatanarug, Saree Wongpichet, Taira Eizo, and Prakarn Thongrak. 2014. The influence of the metering device arrangement to the discharging consistency of the sugarcane billet planter. Advanced Materials Research 931–932: 1561–1567.

Wang, Meimei, Liancheng Chen, Qingting Liu, Yinggang Ou, and Zhi He. 2013. Sowing leakage monitoring and marking system for sugarcane planter. Transactions of the Chinese Society for Agricultural Machinery 44(6): 50–55.

Wang, Xiaoming, and Jianlin Mo. 2012. Current situation of sugarcane production mechanization in China and thinking on correlative problems. Journal of Agricultural Mechanization Research 10: 6–11.

Wang, Yingbiao, Xueguan Zhao, Mingli Xu, Chao Li, Xin Lu, and Shijun Li. 2015. Experiment and directional movement technology of corn seed based on electromagnetic vibration. Transactions of the Chinese Society for Agricultural Machinery 46(1): 79–88.

Yang, Jian, Yang Wang, Wang Gaofeng, and Li Junlin. 2012. Optimization experiments on electromagnetic vibrated seeder of rice bud-seed for field seedling raising. Transactions of the Chinese Society of Agricultural Engineering 28(6): 32–38.

Yang, Mingjin, Yang Ling, and Li Qingdong. 2007. Development and experimental research on electromagnetic vibrated feeding device of twisting type. Journal of Agricultural Mechanization Research (11): 109–111.

Yang, Wang, Jian Yang, Xiaorong Zhou, and Yong Zhou. 2009. Parameters study on the vibrant system electromagnetic vibrated seeding apparatus. Journal of Agricultural Mechanization Research 31(2): 47–50, 54.

Yang, Zhaowen, Xingfu Liu, and Wenying Li. 2005. Testing Methods of Single Seed Drills (Precision Drills). Beijing: Standards Press of China.

Zeng, Zhiqiang, Yinggang Ou, Qingting Liu, Dantong Yang, Qiao Hu, and Qingyan Liu. 2015. Test and analysis of the sugarcane mechanization plant system. Modern Agricultural Equipments (3): 30–32, 54.

Zhang, Xueyi, Jinghao Hou, and Yuan Zang. 1992. An experimental research of the electromagnetic vibrated feeding device. Transactions of the Chinese Society for Agricultural Machinery (1): 22–27.

Zhang, Xueyi, Yaojian Zhao, Li Zhou, Cunshan Zhang, and Mingling Gao. 1996. Theoretical analysis and experiment on the kinematics of feeding device under electromagnetic vibration. Transactions of the Chinese Society of Agricultural Engineering (1): 81–86.

Acknowledgements

This research was funded by the Basic Business Expenses Items of the Central Level Public Welfare Research Institutes No. 1630132018001 from the People’s Republic of China Ministry of Science and Technology, National Key R&D Project No. 2017YFD0700805 from Ministry of Agriculture and Rural Affairs of the People’s Republic of China, Zhanjiang Science and Technology Planning Project No. 2017A02017 from Zhanjiang Science and Technology Bureau of China, and Natural Science Foundation of Hainan Province No. 518MS121 from Hainan Provincial Department of Science and Technology of China. Finally, the authors are also thankful to editor and anymore reviewers for guidance and support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Fengguang He, Ganran Deng and Zhaojun Niu have received research Grants from Tropical Agricultural Machinery Research Institute, Chinese Academy of Tropical Agricultural Sciences. Xiao You, from Hainan Provincial Institute of Agricultural Machinery, participated in manuscript modification. Ming Li is a member of Tropical Agricultural Machinery Research Institute, Chinese Academy of Tropical Agricultural Sciences. The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, F., Deng, G., Li, M. et al. Design of Electromagnetic Vibration-Type Single-Bud Sugarcane Seed Metering Device. Sugar Tech 21, 815–824 (2019). https://doi.org/10.1007/s12355-019-00715-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-019-00715-y