Abstract

Sugarcane leaves straw (SLS) consists of 30.79% hemicelluloses, 40.84% cellulose and 25.80% lignin on dry solid basis and has the potential to serve as a lost cost feedstock for production of value-added products such as ethanol, xylitol, organic acids etc. by microbial fermentation based processes. This work evaluated the hydrolysis of SLS under different conditions using dilute sulfuric acid in order to obtain a xylose-rich hydrolyzate. Acid hydrolysis experiments were performed according to an experimental design considering the following factors: time, temperature, concentration of the acid solution and solid: liquid ratio. The optimum conditions found were 130°C and concentration of sulfuric acid solution of 2.9% w/v, solid: liquid ratio (1:4) and 30 min of residence time. These optimal conditions allowed obtaining a hydrolysate with xylose concentration of 56.5 g/l, corresponding to the recovery of 85.1% from the hemicellulosic fraction of SLS. Analysis of variance was performed for screening of the design experimental matrix. It was observed that only the factors of the acid solution concentration and temperature were significant at 95% confidence.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sugarcane is the principal crop cultivated in tropical countries of the world. Brazil is the largest producer of sugarcane in the world, followed by India and China. The estimated Brazilian production for the 2010/2011 harvest is of approximately 651 million tons of sugarcane (CONAB 2011). Almost 250 kg dry weight of post harvesting sugarcane leaves (SL) is generated from one ton of raw sugarcane (Krishnan et al. 2010). In the world, 5.4 × 108 dry tons of sugarcane is processed annually (Cerqueira-Leite et al. 2009) thus generating a considerable amount of lignocellulosic biomass feasible for the production of motor fuel ethanol, xylitol or other important products of economic importance. Generally, SL is left in agricultural fields during sugarcane processing (Krishna et al. 1998, Krishnan et al. 2010; Ferreira-Leitão et al. 2010) and are openly burnt on fields causing the environmental pollution. The judicious application of such huge amount of biomass into commercial value based products will offer an economic advantage, employment and better environmental protection (Kim and Dale 2004; Chandel and Singh 2011). SL contains an appreciable amount of cellulose and hemicellulose (71.13% wt.) which can be de-polymerised by chemical or enzyme formulations into simple sugar monomers (glucose, xylose, arabinose, mannose, galactose etc.) (Singh et al. 2008; Ferreira-Leitão et al. 2010; Krishnan et al. 2010). Such sugar streams can be converted into several compounds of economic importance by biotechnological routes (Krishna et al. 1998; Krishnan et al. 2010).

Dilute acid hydrolysis is a fast and specific method to break-down hemicellulosic fraction of cell wall into their monomeric constituents. This method is easy to perform but it is hampered by non-selectivity and byproduct formation (Gray et al. 2006). During acid catalyzed process at high temperature, hemicelluloses fraction of cell wall is depolymerised into simple sugars mainly xylose and other sugars such as arabinose, galactose, mannose and glucose (Chandel et al. 2007, 2011). A number of other undesired compounds are also released or formed during this process such as lignin derived phenolics, sugar derived furans and hemicellulose structure derived compounds (weak acids, extractives, resins). These compounds are required to be eliminated from the sugar solution prior to the fermentation to get the satisfactory yields and productivities of metabolites (Chandel et al. 2007).

Production of these compounds could be minimized if appropriate sets of pretreatments conditions are employed in the process. Acid load, temperature and solid to liquid ratio used in the hydrolysis process are critical parameters for the maximum hemicelluloses break-down and less production of inhibitory compounds (Kumar et al. 2009a; Lee and Jeffries 2011). Therefore, a detail study of such parameters is essential prior to design the acid hydrolysis process for any kind of lignocellulosic material.

Design of experiments and statistical tools provide more information about the optimization of conditions in a few trials. They provide a systematic and efficient plan for lignocellulosic biomass hydrolysis considering the interactive effects among the control factors (Scordia et al. 2010). Many control factors can be simultaneously studied and optimized by statistical experimental designs.

In the present work, we have studied the statistical optimization of dilute sulfuric acid mediated hydrolysis of sugarcane leaves straw (SLS) for the maximum hemicellulose degradation into simpler sugars by fractional experimental and central composite design of experiments.

Materials and Methods

Raw Material

SLS used in this study was provided by San Francisco power plant located at Sertãozinho, Brazil. After sun drying the straw was milled to 20 mesh (0.85 mm) by knife mill and stored in the storage room at room temperature for hydrolysis experiments.

Chemical Characterization of the SLS

Characterization of SLS was performed in accordance with the methodology suggested by Rocha (2000) and Gouveia et al. (2009).

Determination of the Initial Acid Hydrolysis Conditions of the SLS

SL was subjected to chemical hydrolysis with the different concentrations of diluted sulfuric acid at various residence times. Acid hydrolysis of SLS was carried out in 500 ml Erlenmeyer flasks containing 10 g of dry SLS. The reaction was conducted in an autoclave under various conditions determined by a fractional experimental design 24−1. The levels of the factors investigated in the experimental design, with their real values and coded, are presented in Table 1. At this stage, influence of the factors and their relationship was studied aiming the recovery of xylose (response variable).

The parameters (independent variables) were analyzed within a range (−1, 0, +1) where −1 corresponds to the value encoded on the lower level of the parameters, 0 corresponds to the intermediate level and +1 at the top level. The extraction efficiency of xylose was calculated from the Eq. 1:

where C is xylose concentration in the hydrolyzate (g/l), V volume of acid solution used in solid: liquid ratio and M is xylose mass obtained in the sugar cane straw characterization. The relationship between the coded values and real values was calculated using the Eq. 2:

where, x i is coded value of the independent variable, X i real value of the independent variable, X 0 real value of the independent variable on the central point and ΔX is mean distance between the lower and upper.

Optimization of Acid Hydrolysis

At this stage, the results (xylose concentration and extraction efficiency) obtained from the fractional factorial design, according to item 2.1.3, was selected the responsive variables to be considered in the optimization step of hydrolysis. This optimization was performed using response surface methodology, according to Neto and Scarminio (2001). Experiments were performed in 500 ml Erlenmeyer flasks containing 10 g of dry straw and the reaction carried out in an autoclave according to a central composite design face-centered, considering temperature and concentration of the sulfuric acid solution as independent parameters. The reaction time (30 min) and S: L ratio (1:4) was fixed during the experiments. The experimental design and the investigated levels of each parameter are presented in Table 2. The parameters were analyzed within a range (−1, 0, +1) where −1 corresponds to the value encoded on the lower level of the parameters, 0 corresponds to the intermediate level and +1 at the top level. The hydrolyzates were filtered and stored at 4°C for further analysis.

Results and Discussion

Chemical Characterization of SLS

SLS was subjected to experimental assays using methods described in “Chemical Characterization of the SLS” section from 2 g of sample on dry basis for their characterization and the results are presented as the basic constituents (Table 3) and on the macromolecules fractions (Table 4).

Toward quantification of sugar monomers, it was found that 26.57% of the straw corresponds to xylose, representing 86.27% of its hemicellulose fraction. Hemicellulose fraction of SLS was characterized as an arabinoxylan containing arabinose monomer after every six xylose units. The hemicellulose of SLS is usually characterized as arabinoxylan, with a glucose content insignificant (Fengel and Wegener 1989). The presence of glucose in the hemicellulose hydrolysate was obtained from the amorphous regions of cellulosic fraction. Substituent such as acetyl glucouranosil and xylan groups are still characterized in proportions of about 0.06 and 0.10 respectively (Table 3).

The hemicellulose fraction represented 30.79% of the straw, whereas the cellulose accounted for most of the material, representing 40.84%. This value for the content of hemicellulose is higher than the values found for other lignocellulosic residues such as Eucalyptus globulus with 17.1% (Cruz et al. 2000), sugarcane bagasse with 26.2% (Neureiter et al. 2002) and rice straw with 22% (Mussato and Roberto 2002).

Determination of the Initial Conditions of Acid Hydrolysis of SLS

Hydrolysis conditions for each investigated parameter in the fractionated experimental design assays by acid hydrolysis of SLS are presented in Table 5 together with the responses obtained from xylose concentration in g/l.

The hemicellulose is considered more susceptible to degradation than cellulose (Fengel and Wegener 1989). Thus, it is possible to obtain a hydrolyzate rich in pentoses (mainly xylose). The concentration of xylose presented a range of 0.33 g/l (assay 1) to 33.05 g/l (assay 12), reaching xylose extraction yield up to 74.6%. The best responses to xylose concentration were found in the conditions of the central point (assays 9–12), around 31.70 g/l (Table 5), followed by assay 7 (22.99 g/l) where the parameters temperature and acid concentration are at their highest levels. The assays 8, with all parameters in its upper levels presented response of 20.26 g/l xylose. This value was slightly lower than assay 7 results, can be explained by degradation of xylose as a function of higher reaction time. Since the best responses to the concentration of xylose were obtained under the conditions of the central point (Table 5), it is estimated that the region investigated, based on four parameters involved and their levels is modeled by a quadratic function.

In the acid hydrolysis of lignocellulosics, parameters such as time, temperature, concentration of the acid solution and solid: liquid ratio has been considered the most influential parameters on hemicellulose break down (Chandel et al. 2011; Scordia et al. 2010). Kumar et al. (2009b) carried out acid hydrolysis of water-hyacinth with 2% H2SO4 (v/v) and S: L ratio of 1:10 for 7 h at room temperature in shake flasks. Canettieri et al. (2004) used an experimental design for acid hydrolysis of Eucalyptus grandis and obtained the maximum hemicellulosic break down under the following conditions (H2SO4 0.65% w/v, 157°C for 20 min and S: L ratio of 1:8.6 g/ml). Pessoa et al. (1997), determined the best conditions (100 mg of H2SO4 per gram of dry matter and S: L ratio of 1:10 g/ml for 10 min and 121°C) for acid hydrolysis of sugarcane bagasse. Chandel et al. (2007) used 2.5% (v/v) HCL for hydrolysis of sugarcane bagasse at 140°C for 30 min at S: L ratio of 1:10. Under these conditions, a total of reducing sugars (30.29 g/l) was achieved along with furnans (1.89 g/l), total phenolics (2.75 g/l) and acetic acid (5.45 g/l).

Table 6 presents the estimated quantitative effect of each parameter on the xylose recovery with statistical significance at 95% confidence. The values of the effects obtained by the t- test verify that the concentration parameter of the acid solution has more influence on the response, followed by the temperature. Two parameters (time and S: L ratio) showed no statistically significant effect on xylose recovery.

Optimization of the Conditions of Acid Hydrolysis of SLS

After verification of the significant impact of temperature and acid concentration, other important parameters (hydrolysis time and S: L ratio) were chosen to study their impact on hemicellulose break down.

A central composite experimental design was conducted face-centered in order to optimize the conditions of acid hydrolysis of SLS and the experiments are shown in Table 7, along with the responses obtained in each test. The tests were performed to extract xylose. Xylose extraction efficiency was expressed as a percentage of xylose extracted in relation to the fraction of xylose present in the straw. Considering the influence of each factor on the response, it is observed that when the concentration of the acid solution was set at its lowest level, we found a concentration of xylose in the hydrolyzate very low (experiments 1 and 2). However, when the temperature is set at its lowest level led to changes in the concentration of the acid solution, the concentration of xylose in the hydrolyzate increased significantly, from 0.88 to 14.47 g/l.

The higher extraction of xylose was obtained with the temperature at its upper level (130°C), with the concentration of the acid solution ranging from 2.0 to 3.5%. These values correspond to tests 4 and 6, for which there was no statistical difference found between them. In these tests, it was possible to obtain a concentration of around 47.5 g/l xylose, with an extraction of around 71.5% of xylose from hemicellulose fraction of cell wall.

The analysis of variance (ANOVA) was performed considering the response of xylose concentration (Table 8) and observed that both temperature and concentration of the acid solution were significant at 95% confidence and that the interaction between these two factors was also significant.

The generated model presented a determination coefficient of 0.94, meaning that 94% of the total variations around the average, caused by experimental conditions employed were explained by the regression. This fact indicates that this mathematical model generated fits properly. ANOVA model shows no lack of fit (P > 0.05), indicating that it can be used for predictive purposes. The synergy effect of two factors can be seen in Fig. 1. With the concentration of the acid solution on the lower level, temperature variation virtually showed no effect on xylose extraction from SL, whereas at high acid concentration, xylose extraction process showed great sensitivity to temperature variation.

To get a more clear view, the influence of factors on the extraction of xylose, a response surface was generated representing the responses within the region investigated (Fig. 2). The figure shows a curvature ranging from lower levels to higher levels of the factors, indicating a maximum point that corresponds to the xylose extraction (71.77%).

An analysis of the behavior of the xylose concentration as a function of temperature and concentration of the acid solution can be accomplished using the predictive model generated from the regression coefficients, obtained by response surface methodology, where C is the answer in g/l, A is the concentration of the acid solution in% w/v and T is temperature in °C:

From the empirical model generated by statistical analysis (Eq. 3), conditions can be predicted that allow maximum extraction of xylose (g/l) in the hydrolyzate, within the region investigated as a function of temperature and concentration of acid solution factors. These conditions, with the maximum concentration of xylose obtained are presented in Table 9, where there is a prediction of 51.27 g/l xylose (77.2% extraction) in the temperature exceeding 130°C (value coded equal to 1) and concentration of the acid solution equal to 2.93% w/v (coded value equal to 0.62).

In order to validate the predictive model obtained and verify the prediction of 51.27 g/l for the extraction of xylose by acid hydrolysis, we carried out further hydrolysis experiments under optimum conditions, where the temperature employed was 130°C and concentration the acid solution was 2.9% w/v. The experiments were performed in triplicate and it was able to obtain a hydrolyzate medium with xylose concentration of 56.52 g/l, corresponding to extraction yield of 85.09% of xylose.

Acid hydrolysis has been used to different lignocellulosic materials for extraction of fermentable sugars. Table 10 presents a comparative data on acid hydrolysis employed for different lignocellulosic materials. It can be observed from Table 10 that the present results are fairly compared with other studies.

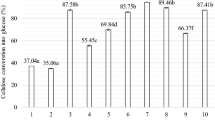

Characterization of Hemicellulosic Hydrolyzate

Upon completion of the acid hydrolysis under optimum conditions, the hydrolyzate medium was characterized for the presence of different sugar monomers and inhibitory compounds (Fig. 3). It was observed that the optimum conditions of acid hydrolysis allowed reaching an extraction of xylose corresponding to 56.52 g/l. However, inhibitors also generate in significant amount in acid catalysed saccharification process of lignocellulosics which directly affect the fermentation efficiency of microorganisms used in the reaction. Therefore, the removal of these inhibitors should be considered in future work like a stage of detoxification.

Conclusion

In conclusion, acid hydrolysis of the sugarcane leaves allowed obtaining the hydrolyzate rich in fermentable sugars, with concentration up to 56.52 g/l of xylose corresponding to the extraction of 85.1% xylose. The parameters with statistical significance in the acid hydrolysis process to extract xylose of cane sugar straw were the temperature and concentration of the acid solution, while the time and solid: liquid ratio was not significant. This study demonstrates the potential of sugarcane leaves for the production of simpler sugars under the optimized set of parameters. This sugar solution can be converted into many value-added products such as fuel ethanol, xylitol, organic acids, single cell protein and others by microbial conversion process.

References

Canettieri E.V., J. B. Almeida E Silva, J. A. Carvalho JR. 2004. Hidrolisis acida de biomasa: Optimizacion de la extraccion de xilosa a partir de residuos de Eucalyptus grandis. Congreso Internacional Sobre Azucar Y Derivados de la Cana—Diversificacion.

Canilha, L., W. Carvalho, J. Batista, and A. Silva. 2006. Xylitol bioproduction from wheat straw: Hemicellulose hydrolysis and hydrolyzate fermentation. Journal of the Science of Food and Agriculture 86: 1371–1376.

Cerqueira-Leite, R.C., M.R.L.V.L. Leal, L.A.B. Cortez, W.M. Griffin, and M.I.G. Scandiffio. 2009. Can Brazil replace 5% of the 2025 gasoline world demand with ethanol? Energy 34: 655–661.

Chandel, A.K., and O.V. Singh. 2011. Weedy lignocellulosic feedstock and microbial metabolic engineering: Advancing the generation of ‘Biofuel’. Applied Microbiology and Biotechnology 89: 1289–1303.

Chandel, A.K., R.K. Kapoor, A.K. Singh, and R.C. Kuhad. 2007. Detoxification of sugarcane bagasse hydrolysate improves ethanol production by Candida shehatae NCIM 3501. Bioresource Technology 98: 1947–1950.

Chandel, A.K., O.V. Singh, G. Chandrasekhar, L.V. Rao, and M.L. Narasu. 2011. Bioconversion of novel substrate, Saccharum spontaneum, a weedy material into ethanol by Pichia stipitis NCIM3498. Bioresource Technology 102: 1709–1714.

CONAB. 2011. <http://www.conab.gov.br>. August 2011.

Cruz, J.M., J.M. Domínguez, H. Domínguez, and J.C. Parajó. 2000. Preparation of fermentation media from agricultural wastes and their bioconversion to xylitol. Food Biotechnology 14: 79–97.

Felipe M.G.A., M.C.O. Hauly, E.V. Canettieri, E.J. Cândido, C.Tamanini. 2003. Avaliação da casca de aveia para obtenção de hidrolisado hemicelulósico e produção de xilitol por processo fermentativo. In Simpósio Nacional de Fermentações, 14, 2003, Florianópolis. Florianópolis: Anai. CDROM.

Fengel, D., and G. Wegener. 1989. Wood chemistry, ultra structure, reactions, 613. Berlin: Walter de Gruyter.

Ferreira-Leitão, V., C. Cruz Perrone, J. Rodrigues, A.P.M. Franke, S. Macrelli, and G. Zacchi. 2010. An approach to the utilization of CO2 as impregnating agent in steam pretreatment of sugarcane bagasse and leaves for ethanol production. Biotechnology for Biofuels 3: 1–8.

Gouveia E.R., R.T. Nascimento, A.M. Souto-Maior, G.J.M. Rocha. 2009. Validação de metodologia para a caracterização química de bagaço de cana-de-açúcar. Quimica Nova 32:1500–1503.

Gray, K.A., L. Zhao, and M. Emptage. 2006. Bioethanol. Current Opinion in Chemical Biology 10: 1–6.

Kim, S., and B.E. Dale. 2004. Global potential bioethanol production from wasted crops and crops residues. Biomass and Bioenergy 26: 361–375.

Krishna, S.H., K. Prasanthi, G.V. Chowdary, and C. Ayyanna. 1998. Simultaneous saccharification and fermentation of pretreated sugarcane leaves to ethanol. Process Biochemistry 33: 825–830.

Krishnan, C., L. da Costa Sousa, M. Jin, L. Chang, B. Dale, and V. Balan. 2010. Alkali-based AFEX pretreatment for the conversion of sugarcane bagasse and cane leaf residues to ethanol. Biotechnology and Bioengineering 107: 441–450.

Kumar, P., D.M. Barrett, M.J. Delwiche, and P. Stroeve. 2009a. Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Industrial and Engineering Chemistry Research 48: 3713–3729.

Kumar, A., L.K. Singh, and S. Ghosh. 2009b. Bioconversion of lignocellulosic fraction of water-hyacinth (Eichhornia crassipes) hemicellulose acid hydrolysate to ethanol by Pichia stipitis. Bioresource Technology 100: 3293–3297.

Lee, J.W., and T.W. Jeffries. 2011. Efficiencies of acid catalysts in the hydrolysis of lignocellulosic biomass over a range of combined severity factors. Bioresource Technology 102(10): 5884–5890.

Mussato, S.I., and I.C. Roberto. 2002. Produção biotecnológica de xilitol a partir da palha de arroz. Biotecnologia Ciência e Desenvolvimento 28: 34–39.

Mussatto, S.I., and I.C. Roberto. 2005. Acid hydrolysis and fermentation of brewer’s spent grain to produce xylitol. Journal of the Science of Food and Agriculture 85: 2453–2460.

Neto B.B., I.S. Scarminio IS, R.E Bruns. 2001. In: Como fazer experimentos: Pesquisa e desenvolvimento na ciência e indústria. Campinas: Editora da Unicamp.

Neureiter, M., H. Danner, C. Thomasser, B. Saidi, and R. Braun. 2002. Dilute-acid hydrolysis of sugarcane bagasse at varying conditions. Applied Biochemistry and Biotechnology 98–100: 49–58.

Pessoa, J.R., I.M. Mancilha, and S. Sato. 1997. Acid hydrolysis of hemicellulose from sugarcane bagasse. Brazilian Journal of Chemical Engineering 14: 291–297.

Rocha, G.J.M. 2000. Deslignificação de bagaço de cana de açúcar assistida por oxigênio. 2000. Tese (Doutorado em biotecnologia industrial), Universidade de São Paulo. São Carlos: Instituto de Química de São Carlos.

Scordia, D., S.L. Cosentino, and T.W. Jeffries. 2010. Second generation bioethanol production from Saccharum spontaneum L. spp. aegyptiacum (Wild.) Hack. Bioresource Technology 101: 5358–5365.

Singh, P., A. Suman, P. Tiwari, N. Arya, A. Gaur, and A.K. Shrivastava. 2008. Biological pretreatment of sugarcane trash for its conversion to fermentable sugars. World Journal of Microbiology and Biotechnology 24: 5667–5673.

Stoutenburg, R.M., J.A. Perrotta, T.E. Amidon, and J.P. Nakas. 2008. Ethanol production from a membrane purified hemicellulosic hydrolysate derived from sugar maple by Pichia stipitis NRRL Y-7124. BioResources 3: 1349–1358.

Acknowledgments

Financial support from FAPESP to carry out this study is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moutta, R.O., Chandel, A.K., Rodrigues, R.C.L.B. et al. Statistical Optimization of Sugarcane Leaves Hydrolysis into Simple Sugars by Dilute Sulfuric Acid Catalyzed Process. Sugar Tech 14, 53–60 (2012). https://doi.org/10.1007/s12355-011-0116-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-011-0116-y