Abstract

Now that Finite Element springback prediction has become possible, springback compensation can also be carried out in the context of a forming simulation, before actual production tools are made. The Displacement Adjustment (DA) and Springforward (SF) methods were applied to an analytical bar stretch-bending model, in order to gain insight about the influence of material, process and geometrical parameters on springback and compensation. The DA method was investigated in both a one-step and iterative variant. In one-step DA, a compensation factor is required. This factor can be directly calculated for the analytical model. The results can be used as a guideline for industrial processes, where such a calculation is not possible. Finally, it was shown that iterative DA leads to better tool shapes than SF, and that practical and computational problems make the use of SF impossible in an industrial context.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Many sheet metal parts, especially in the automotive industry, are produced with the deep drawing process. An initially flat blank is deformed plastically, using a set of tools, generally a die, punch and blankholder. When the tools are opened after forming, the product will spring back due to internal stresses in the blank. Finite Element (FE) forming codes have been improved significantly in the last decade and the prediction of springback has become more accurate (Cao et al. 2005). At the same time, high strength steels and aluminium are used more frequently. These materials are known to show large springback deformations and the forming process becomes harder to set up correctly. Therefore, it has become essential to predict springback correctly in the FE simulations, not only to identify and quantify problems, but also to solve them. This decreases the process planning effort and costs to produce geometrically accurate products.

The objective of springback compensation algorithms is to adjust the geometry of the forming tools so that after springback, the product will achieve the desired shape. To avoid many practical issues, the goal of the algorithms presented in this paper is to find the optimal forming shape, instead of the tool surfaces. This is the shape of the product when the tools are still closed (see Fig. 1). The shape of the forming tools can be directly derived from the forming shape. This will not be demonstrated here, instead the authors refer to the industrial examples in Lingbeek (2003), Lingbeek et al. (2005a, 2006).

Two methods for springback compensation are proposed in literature, the Displacement Adjustment (DA) method (Gan and Wagoner 2004; Gan et al. 2004; Wagoner et al. 2003) and the Springforward (SF) method (Karafillis and Boyce 1992a, b, 1996). The DA method is a strictly geometrical method, based on the intuitive idea to displace the geometry of the forming shape in the direction opposite to the geometrical error. In “Principle of the DA method”, the method will be described in a more exact way. During tests with industrial problems (Lingbeek et al. 2005b, 2006) some basic questions arose: the effectiveness of the method depends on various parameters including the part geometry, material and process settings. In this paper, relationships between these parameters and the effectiveness of the compensation process are established.

The SF method has a more physical approach, based on the internal stresses that cause springback. Therefore, it has the potential for faster and more effective compensation. However, the method turned out to be problematic (Gan and Wagoner 2004). In “Principal problems of the SF method” the algorithm will be explained in detail. It will be shown that the basic assumption of the SF method is not suitable for iterative application, and that the results of the one-step variant depend on material and process parameters.

The main focus for springback compensation is the use in combination with FE simulations. However, these simulations have some practical issues and comprise several complex physical and numerical phenomena. Therefore, a simple analytical model for a stretch-bending process is used to analyze compensation methods in this paper. In the following section, the model is introduced.

An analytical model for forming and springback prediction

The simulation of forming processes is applied in the automotive industry on daily basis, but it is not without problems:

-

The uncertainty of convergence of implicit FE calculations or the corresponding inaccuracies of explicit calculations are still subject to discussion (He and Wagoner 1996).

-

Physically and numerically complex phenomena such as contact and friction make interpretation of FE results difficult.

-

The numerical cost is high

Therefore, an analytical model of a forming process was used to investigate the compensation methods. Besides the fast and reliable calculation, this has another advantage: since the model is straightforward and because it only has few parameters, it can also provide principal insights in the compensation process.

The analytical springback model (Wagoner and Li 2005, 2007) represents a stretch-bending process that was developed to assess the accuracy of FE springback calculations. An initially straight bar is bent to a forming shape with radius R due to a bending moment M and a tension force T. When the loading moment is removed, the bar springs back to a radius r (Fig. 2). For each parameter, SI units are used in this paper.

The strain in the direction along the beam ε is calculated in the following formula. The tension strain is ε t .

By entering ε = 0 into the previous equation the neutral line z 0 can be found:

An elasto-plastic material model was chosen, using the Hollomon law:

In this model, σ is the stress, t the thickness of the beam, E is Young’s modulus, σ 0 is the yield stress, K and n are parameters for the hardening behavior. At the end of the deformation stage, the bar is held in equilibrium by the tension force T and the moment M. These can be calculated analytically as follows:

Here, w is the width of the bar. Details of the assumptions of the model and the calculation of the previous integrals can be found in Wagoner and Li (2005). It is important to notice that only the springback caused by the unbending moment, not the release of the tension force, is considered in this model. It can be calculated with the following formula (Wagoner et al. 2008):

Here, I is the area moment of inertia. For a given desired radius after springback r target , the required forming radius \(\bar{R}\) can be directly calculated from Eq. 6:

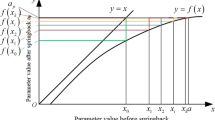

Since M = M(R), this is a nonlinear equation. The function is well-behaved so that a bisection algorithm was used to find \(\bar{R}\) numerically. In Fig. 3 the results are visualized for various values of the normalized tension force \(\bar{T}\). Here, the tension force is divided by the force, required to achieve plastic deformation under tension only:

The desired radius was set at r target = 1.0m and r target /t = 100. The material is IF-steel (see Table 1). SI units (m, Pa, N) are used in the paper. This is a shallow curvature, which can be found in many automotive body panels. When the stretching force is increased, \(\bar{R}\) converges to r target .

The explanation for this phenomenon is that, like in more complex forming processes, springback decreases with increasing in-plane tension (Kuwabara 2005). The stress-state over the thickness of the bar is assessed in two situations: with no additional tension load and with a heavy tension load. The stress profile over the thickness of the bar is visualized schematically in Fig. 4. When the elastic zone is drawn out of the bar, the stress state gets a gentle slope and the unbending moment , and therefore springback, diminishes. When springback becomes minimal, the bar can be bent to the desired shape directly and no compensation is required, as Fig. 3 shows.

Principle of the DA method

For most industrial forming processes, an analytical model is not available and therefore an optimal forming shape (in this case represented by \(\bar{R}\)) cannot be calculated directly. For simple 2D geometries with a limited set of geometrical parameters, general optimization strategies can be applied to these parameters, as was demonstrated in Ghouati et al. (1998). For complex shaped products the number of parameters is too large for such approaches and more general springback compensation methods, such as DA, must be used (Fig. 5).

Geometric springback compensation is based on the following principle: the shape error between the sprung-back product S and desired geometry D is measured, where S and D are topologically identical sets of points on each geometry. Generally the forming geometry, the shape of the product before the tools are released, will represent D.

When FE meshes are used, these points can be represented by the nodes, but in for a general description of geometry, it the one-to-one relationship from a point \(\vec{s}_n\) on the springback geometry to a point \(\vec{d}_n\) on the desired geometry suffices. Points of the tool-surface are displaced in the direction opposite to the shape error to provide the compensated forming geometry C. This is described in the following equation:

The idea is that a product that is formed to the compensated forming geometry C will spring back to the desired geometry D. Due to nonlinearities in the deep drawing process this aim is never achieved fully: from practical experience it is well-known that the compensation has to be slightly larger than the springback in order to obtain the optimal product geometry. Therefore the compensation factor a , ranging from 0.7 to 2.5 in practise (Lingbeek et al. 2006), is included in Eq. 12. The value of a is different for each forming process and cannot be predicted effectively. In fact, it is not possible to calculate one parameter a which will result in a compensated forming geometry that is satisfactory at each point.

Therefore the DA method, as proposed in Gan and Wagoner (2004), Gan et al. (2004), Wagoner et al. (2003), is an iterative procedure, avoiding the use of the compensation factor.

Again, the desired geometry is the vector D. The forming shape of the j + 1-th iteration is calculated by compensating the j-th forming shape with the actual shape deviation S j − D. In this way an acceptable product is usually achieved in less than 10 iterations. Note also that each point in C is adjusted individually so that it becomes theoretically possible to achieve a fully optimal forming shape.

The non-iterative variant, called one-step DA, should not be dismissed. Even though the single overbending factor makes the results less accurate (Lingbeek et al. 2006), it is sometimes the only way to carry out springback compensation, for example when geometrical measurements of prototype products (Ohnimus et al. 2005) instead of FE simulations provide the shape deviation field.

One-step DA

Firstly, the focus is on the one-step application of the DA method. More specifically, the influence of various process and material parameters on the compensation factor will be shown.

The general DA method relies on displacement data, whereas only bending radii R and r are calculated in the analytical model. However, the springback displacement u at the end of the bar can be derived directly from these variables, as shown in Fig. 2.

With the springback displacement and the optimal forming displacement, the optimal compensation factor \(\bar{a}\) can be directly calculated using Eq. 14.

The results are shown in Fig. 6. In the graph the compensation factor is drawn for varying tension force T, and for two materials, interstitial free (IF) steel and DP-600 (see Table 1 and Fig. 7). It can be concluded that for higher strength materials, a higher compensation factor needs to be applied. When there is an elastic band present inside the bar (for IF steel \(\bar{T} < 1.32\)) the compensation factor rises with increasing tension. When the force is so large that the bar is deformed plastically in the entire cross section, the compensation factor becomes 1.0.

In one-step application of DA the compensation factor needs to be applied because the forming process is nonlinear: after springback compensation, the forming process has changed and springback has become different as well.

For this analytical process the only parameter that is changed during compensation is the forming radius. Changing the forming radius will change the amount of springback, and the behavior of the stretch-bending process is different in three cases:

-

ε t = 0, pure bending

-

\(0<\varepsilon_t\leq\frac{t}{2R}\), elastic band inside the bar

-

\(\varepsilon_t>\frac{t}{2R}\), fully plastic deformation

Therefore, different compensation factors are required, which explains the complex shape of Fig. 6. The stress profiles in thickness (z −)direction of the bar are shown for all three situations in Fig. 8 (left). The grey lines represent bending to a radius of 1.0, the black lines show the stress profiles when the bar is bent further, to a radius of 0.8. The thickness t equals 0.01, and the material is IF-steel. In the case of pure bending, the elastic band becomes slightly narrower with increased bending. In case of fully plastic deformation, only a very small change occurs (due to the hardening in the material). However, in the intermediate case, the stress profile becomes quite different because the neutral line shifts.

The unbending moment, causing springback, is calculated by integrating the function σ(z)z over the thickness, as shown in Eq. 5. This function σ(z)z is shown in the figures on the right, again for bending radii of 1.0 (grey) and 0.8 (black). The unbending moment, and therefore springback, only changes significantly in the intermediate case, due to the shifting of the neutral axis. The unbending moment becomes larger by bending further, so springback becomes larger as well and a compensation factor higher than 1.0 can be profitably used. The location of the neutral axis is dependent of the tension strain in the following way (see Eq. 2):

This means that the shift of the neutral axis increases with increasing tension strain, so the change in springback increases with increasing tension strain as well. This explains the increasing compensation factor in Fig. 6 in the intermediate case. When the tension strain is so large that the neutral axis is not present anymore, only plastic deformation takes place and the optimal compensation factor becomes 1.0.

The relationship between the tool geometry and the compensation factor \(\bar{a}\) has been investigated. In Fig. 9, \(\bar{a}\) is shown with varying values of r target /t. In industrial parts, the curvature differs strongly over the geometry. The model shows that the shallower the geometry is, the lower the compensation factor.

Iterative application of DA on the model

Figure 10 shows the shape error during the subsequent iterations with the iterative DA process for various tension forces. The shape error is defined here as the displacement error at the free end of the bar. Note that the shape error was normalized by dividing it with the shape error using the original tools (hence the value of 1.0 at the first iteration). This is done because springback is different for different tension loads. It can be concluded that the iterative implementation of DA will converge to the correct forming-radius, irrespective of the tension force T, but T does influence the convergence rate of the method.

With increasing tension force T the convergence becomes slower, until the load is so high that the bar is fully plastically deformed (for IF-steel: \(\bar{T} > 1.32\)), then convergence is very fast again. This is shown more clearly in Fig. 11, which shows the rate of convergence μ:

For the DA process in combination with the analytical model μ is approximately constant for each iteration. For large values of T, μ approaches zero, which means that the speed of convergence is very high. Note that the graph is similar to graph Fig. 6. In the iterative DA process, the tools are compensated with a factor of 1.0 in each iteration, so when the optimal ‘one-step’ compensation factor is close to one, very fast convergence is obtained. When an elastic band is present in the bar the compensation becomes slower as the process is more non-linear.

The conclusion is that when the bar is fully plastically deformed, not only the compensation becomes very fast, also springback is reduced drastically. From an industrial standpoint, this is important for shallowly curved objects such as a car roof, where there is relatively little plastic deformation in the product area. Not only will springback become larger, it also becomes harder to compensate effectively.

Principal problems of the SF method

Instead of simply compensating springback based on geometric deformation, the SF method uses the cause of springback, the internal stresses. The procedure is presented in the block-diagram of Fig. 12, taken from (Karafillis and Boyce 1996). Note that C n is the forming shape in the n-th iteration and D is the desired shape.

The SF algorithm (Karafillis and Boyce 1996)

In the analytical model, springback is caused by the unbending moment only, therefore, the method can be easily adapted:

-

1.

Forming: The bar is stretch bent to the desired radius R ref

-

2.

The reaction moment M 0 is calculated

-

3.

SF: Moment M 0 is reversed and applied to an unstressed bar with radius R ref . The radius R 1 of the spring forward geometry is calculated.

-

4.

Forming after compensation: The bar is stretch bent to radius R 1

-

5.

Repeat steps 2-4 until R i is stable

In combination with the analytical model, the results of SF are very good: after compensation the remaining shape error is an order of magnitude lower than with the DA method in case of pure bending, and twice as low for larger tension forces.

However, in realistic, three dimensional forming processes, serious problems arise. As there is no single unbending moment anymore across the blank, the unbending moment needs to be generalized to the difference in the internal stress state after forming and after springback. This stress state is extracted from the forming simulation, reversed and applied to a virgin blank in the desired shape. Generally, springback happens under the action of large tensile stresses, so, during the SF calculation, these stresses become compressive. This makes the compensated geometry very sensitive to small changes or errors (Gan and Wagoner 2004), buckling can occur and in some cases the FE calculation will even fail to converge (Lingbeek et al. 2005b).

In the DA method, a desired geometry D is specified (Eq. 12), and this desired geometry is approached iteratively. A target geometry is not specified in the SF method, but the SF method is also applied iteratively until a stable solution is obtained. However, this does not necessarily lead to the best obtainable tool shape. This was demonstrated for an elasto-plastic bar stretching problem (Lingbeek 2003). A straight, rectangular bar is stretched (into the plastic region) to the desired length l, using a stretching force F. After release of the force, the bar springs back and obtains its final length. A simple elastic-linear plastic material model was used. The same procedure was followed as for the stretch-bending model, but instead of the unbending moment, the reaction force − F was used.

When the ideal plastic behavior is used in the model, and the bar is stretched beyond the yield point it shall be clear that the process force does not change when the bar is stretched to a different (larger) length: the force is determined by the yield stress only. Hence, the reaction force − F in step two will always be identical, F 1 = F 2 = F 3 = ..., the SF shape also remains identical l 1 = l 2 = l 3 = .... and consequently in each iteration the same shape is produced.

When a hardening material model (Fig. 13) is used, the process will converge but a shape error will remain, unlike the DA method (Fig. 14).

Conclusion

The analytical stretch-bending model provides insight in springback behavior and in how to compensate it most effectively. It has been shown that the compensation depends on geometry, material and process parameters:

-

The compensation factor is higher for strongly curved geometries

-

The compensation factor depends strongly on the in-plane tension in the bar

-

The compensation factor is higher for higher strength steels

-

No single correct global compensation factor can be provided for complex blank geometries

-

The convergence speed of the DA method also depends on material, process and geometrical parameters

-

The iterative DA method leads to better tool shapes than the SF method

-

The SF method is sensitive to the position of fixation points due to high compressive stresses in the blank, and due to buckling effects, calculation of the compensated geometry is not possible in most cases.

Finally, the analytical model has potential for further exploration. If a relationship between the stress state, material and geometry and a local compensation factor could be established for FE (shell-)elements, a better one-step compensation method could be developed. As in industry springback compensation procedures are mostly based on one trial tool-geometry only and iterative methods are too time-consuming and costly, this would mean a significant improvement.

References

Cao J et al (eds) (2005) Benchmark study report. Proceedings 6th int. NUMISHEET conference, part B, Detroit, 15–19 August 2005

Gan W, Wagoner RH (2004) Die design method for sheet springback. Int J Mech Sci 46:1097–1113

Gan W, Wagoner RH, Mao K, Price S, Rasouli F (2004) Practical methods for the design of sheet formed components. J Eng Mater Technol 126(4):360–367

Ghouati O, Joannic D, Gelin J (1998) Optimisation of process parameters for the control of springback in deep drawing. In: Huétink J, Baaijens FPT (eds) Proceedings 6th NUMIFORM conference, Enschede, June 1998

He N, Wagoner RH (1996) Springback simulation in sheet metal forming. In: Lee J-K, Kinzel GL, Wagoner RH (eds) Proceedings NUMISHEET ’96. The Ohio State University, Ohio, p 308

Lingbeek RA (2003) Aspects of a designtool for springback compensation. Masters thesis, University of Twente

Lingbeek RA, Huétink H, Ohnimus S, Petzoldt M, Weiher J (2005a) The development of a finite elements based springback compensation tool for sheet metal products. J Mater Process Technol 169(1):115–125

Lingbeek RA, Huétink J, Ohnimus S, Weiher J (2005b) Iterative springback compensation of numisheet benchmark #1. In: Smith L et al (eds) Proceedings 6th NUMISHEET conference, vol A, Detroit, 15–19 August 2005, pp 328–333

Lingbeek RA, Meinders T, Ohnimus S, Petzoldt M, Weiher J (2006) Springback compensation: fundamental topics and practical application. In: Juster N, Rosochowski A (eds) Proceedings 9th ESAFORM conference, Glasgow, 26–28 April 2006, p 403–406

Karafillis AP, Boyce MC (1992a) Tooling design in sheet metal forming using springback calculations. Int J Mech Sci 34:113–131

Karafillis AP, Boyce MC (1992b) Tooling design accommodating springback errors. J Mater Process Technol 32:499-508

Karafillis AP, Boyce MC (1996) Tooling and binder for sheet metal forming processes compensating springback error. Int J Mach Tools Manuf 36:503

Kuwabara T (2005) Advances of plasticity experiments on metal sheets and tubes and their applications to constitutive modelling. In: Smith L et al (eds) Proceedings 6th NUMISHEET conference, vol A, Detroit, 15–19 August 2005, pp 20–37

Ohnimus S, Petzoldt M, Rietman B, Weiher J (2005) Compensating springback in the automotive practice using MASHAL. In: Smith L et al (eds) Proceedings 6th NUMISHEET conference, vol A, Detroit, 15–19 August 2005, pp 322–327

Wagoner RH, Gan W, Mao K, Price S, Rasouli F (2003) Design of sheet forming dies for springback compensation. In: 6th Int. ESAFORM conference. University of Salerno, Salerno, pp 7–12

Wagoner RH, Li M (2005) Advances in springback. In: Smith L et al (eds) Proceedings 6th NUMISHEET, vol A, Detroit, 15–19 August 2005, pp 209–214

Wagoner RH, Li M (2007) Simulation of springback: through thickness integration. Int J Plast 23(3):345–360

Wagoner RH, Wang JF, Li M (2008) Springback. In: ASM metals handbook on forming and forging, vol 14. ASM, Metals Park (in press)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lingbeek, R.A., Gan, W., Wagoner, R.H. et al. Theoretical verification of the displacement adjustment and springforward algorithms for springback compensation. Int J Mater Form 1, 159–168 (2008). https://doi.org/10.1007/s12289-008-0369-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-008-0369-5