Abstract

A work has been done to study the effects of material properties and compression speed on microbial survival and tensile strength in diclofenac tablet formulations. Tablets were produced from three formulations containing diclofenac and different excipients (DC, DL and DDCP). Two types of machines (Hydraulic hand press and single punch press), which compress the tablets at different speeds, were used. The compression properties of the tablets were analyzed using Heckel and Kawakita equations. A 3-dimensional plot was produced to determine the relationship between the tensile strength, compression speed and percentage survival of Bacillus subtilis in the diclofenac tablets. The mode of consolidation of diclofenac was found to depends on the excipient used in the formulation. DC deformed mainly by plastic flow with the lowest Py and Pk values. DL deformed plastically at the initial stage, followed by fragmentation at the later stage of compression, whereas DDCP deformed mainly by fragmentation with the highest Py and Pk values. The ranking of the percentage survival of B. subtilis in the formulations was DDCP > DL > DC, whereas the ranking of the tensile strength of the tablets was DDCP > DL > DC. Tablets produced on a hydraulic hand press with a lower compression speed had a lower percentage survival of microbial contaminants than those produced on a single punch press, which compressed the tablets at a much higher speed. The mode of consolidation of the materials and the speed at which tablet compression is carried out have effects on both the tensile strength of the tablets and the extent of destruction of microbial contaminants in diclofenac tablet formulations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Compaction of pharmaceutical powdered solids is the simultaneous processes of compression and consolidation of a two-phase (particulate solid–gas) system, which arises from the application of a force. Compression is a decrease in the bulk volume of materials as a result of the displacement of a gaseous phase, while consolidation is an increase in the mechanical strength of the materials due to particle–particle interactions (Marshal 1986). The processes of compaction involve the application of external forces which result in closer repacking of the powder particles. This results in volume reduction. As the load increases, rearrangement becomes more difficult and further compression involves some type of particle deformation. If on the removal of a load, the deformation is to a large extent spontaneously reversible, i.e. it behaves like rubber, then the deformation is said to be elastic.

With several pharmaceutical materials, such as acetylsalicylic acid and microcrystalline cellulose, elastic deformation is the dominant mechanism of compression within the range of maximum force normally encountered in practice.

However, in other groups, the elastic limit or yield point is reached and loads above this level result in deformation not immediately reversible upon removal of the applied force. Bulk volume reduction in these cases results in plastic deformation and/or viscous flow of the particles, which are squeezed into the remaining void spaces resembling the behavior of modeling clay. The mechanism of plastic deformation predominates in materials, in which the shear strength is less than the tensile or breaking strength. On the other hand, when the shear is greater, particles may be preferentially fractured and the smaller fragments then help fill up any adjacent air spaces. This most likely occurs with hard brittle materials, and is known as brittle fracture e.g. sucrose behaves in this manner. The predisposition of a material to deform in a particular manner depends on the lattice structure, in particular whether weakly bonded, lattice planes are inherently present. It was reported that the dominating compression mechanism depends on the mechanical properties of the materials (Sun and Grant 2001).

The shear stress manifested during compression has an effect on the survival of microorganisms in the formulations. This shear stress depends largely on the principal mode of consolidation of the materials. It is therefore essential to establish a relationship between the compressional characteristics and survival of microorganisms in the formed tablets.

Certain parameters for materials are derivable from density measurement, Heckel (1961a, b) and Kawakita (Kawakita and Ludde Kawakita et al. 1997) equations. These parameters were used to analyze the compressional characteristics of diclofenac formulations and a relationship between the mode of consolidation and microbial survival in diclofenac formulations was established. This work also examined the effect of the compression speed on the compressional properties of materials, tensile strength and survival of microbial contaminant in diclofenac tablet formulations.

Diclofenac was used in this study due to its poor compressibility when compressed on its own without an excipient. Works have been done to demonstrate satisfactory release profiles for diclofenac sodium when xanthan gum and Khaya gum were used in the formulation. Diclofenac requires excipients to overcome the capping problem encountered in the formulation. Lactose, dicalcium phosphate and microcrystalline cellulose (Avicel) at a drug: excipient ratio of 1:1 have been used (Sujja-areevath et al. 1996). Bacillus subtilis, a spore forming bacterium was chosen as the microbial contaminant due to its resistance to destruction by both physical and chemical attack.

Materials and methods

Materials

The materials used were Diclofenac (Unique Chemicals, Gujarat, India.), Cornstarch, Dicalcium phosphate (DCP) and Lactose (Sam Pharmaceuticals, Ilorin, Nigeria), Gelatin BP(Hopkins and Williams, Chadwell Health, Essex, UK.), Bacillus subtilis spores (Laboratory stock culture, Department of Veterinary Microbiology and Parasitology, University of Ibadan), Nutrient agar pH 6.0, Nutrient broth pH 6.8, Saboraud dextrose agar pH 5.6, and MacConkey broth (Department of Pharmaceutical Microbiology, University of Ibadan.).

Methods

Preparation of diclofenac formulations

Diclofenac formulations were made from binary mixtures of Diclofenac and Corn starch, Diclofenac and Lactose, and Diclofenac and dicalcium phosphate (DCP). The formulations were prepared by mixing the powders in the proportions listed in Table 1. Each batch was mixed for 5 min in a Kenwood planetary mixer (Erweka, Heusentamm, Germany). The powder mixtures were then stored in air tight containers and labeled appropriately.

Preparation of inoculum

An overnight culture of 18 h was prepared from Bacillus subtilis spores (Laboratory stock culture obtained from Department of Veterinary Microbiology and Parasitology, University of Ibadan). 1 ml of the overnight culture was placed in 9 ml of sterile distilled water and 2 ml of the culture was placed in sterile glass mortars and allowed to dry at 37 °C for 48 h.

Contamination of the materials

Quantities (10 g) of the Diclofenac formulations were gently mixed in the contaminated glass mortars using the method of increasing quantities to give an even dispersion of the contaminating organism within the individual samples. Viable counts of microbial contaminants were carried out on the contaminated and uncontaminated materials.

Preparation of granules

Batches (250 g) of Diclofenac formulations were used. Each formulation was dry-mixed for 5 min in a Kenwood planetary mixer and moistened with 30 ml of distilled water. Massing was continued for 5 min and the wet masses were granulated by passing them manually through a number 12 mesh sieve (1,400 μm). The granules produced were dried in a hot air oven for 18 h at 50 °C and therreafter re-sieved through a number 16 mesh sieve (1,000 μm). The granules were stored in air tight containers. The granule size (500–1,000 μm) was collected separately from each batch and stored in air-tight containers and used for the rest of the studies.

Bulk and tap densities

Loose bulk density

The loose bulk density, Do, of each diclofenac formulation granules was determined at zero pressure by pouring 20 g each of the materials through a funnel at an angle of 45° into a 50 ml measuring cylinder with a diameter of 2.3 cm. The bulk volume (Vo) and loose bulk densities (Do) of the formulations were determined.

Tapped density

The tapped volume of each of the diclofenac formulation granules was determined by pouring 20 g of each powder into a 50 ml measuring cylinder. The materials were then subjected to various numbers of taps in the cylinder according to British Standard 1,460 (38 taps per minute). Values of tapped volume (VN) for the materials were determined at intervals of 25 taps. Tapped density Db values were determined from the tapped volume. The determinations were carried out in quadruplicate.

Particle density

The particle densities of corn starch, lactose, dicalcium phosphate (DCP) and Diclofenac formulation granules were determined using the pycnometer method with xylene (a non-solvent) as the displacement fluid. A 50 ml pycnometer bottle was first weighed empty (W), and then filled with xylene until it began to overflow. The excess was wiped off. The bottle with the xylene was weighed (W1). The difference between the two weights was calculated (W2). Two grams of the powders (W3) was transferred to the bottle. The xylene over flowed and the excess was wiped off the bottle. The bottle with the content was weighed (W4). The particle density (ρs) of the powder was calculated using the following equation:

Preparation of Tablets

Quantities (500 mg) of the 500–1,000 μm fractions of the contaminated and uncontaminated diclofenac formulations were compressed for 1 min into tablets with pre-determined loads using two types of machines that compress the tablets at different speeds: a Single punch press (Erweka GMBH Heusentamm AR 400), which compresses at a relatively faster speed and a Carver hydraulic Hand press (Model C, Carver Inc, Menomonee falls, Wisconsin, USA), which compresses at a much slower speed. Compression on the single punch press was performed at different speeds of 20, 40, 80 and 120 mm per second. Before each compression, the dies (12.5 mm diameter) and flat-faced punches were lubricated with a 2 % w/v dispersion of magnesium stearate in ether. After compression, the tablets were stored in air tight containers for 24 h to allow for elastic recovery and hardening and to prevent falsely low yield values. The weights and dimensions of the tablets were determined to within ± 1 mg and 0.01 mm respectively. The relative densities (D) of the tablets were calculated using the following equation:

where D = relative density of the tablet, Vt = volume of the tablet and ρs = Particle density of the material.

Determination of Compressional properties of Diclofenac Formulations

The compressional properties of the formulations were determined using the Heckel and Kawakita plots.

Heckel Plots

The Heckel equation is used widely for determining the relative density, D, of a powder bed during compression to the applied pressure, P (Alebiowu and Itiola 2001). Heckel plots of ln [1/(1 − D)] against the applied pressure, P, in MN m−2 were plotted for the different powders. The values of K and A were obtained from the slopes and intercepts of the plots, respectively. The equation is written as follows:

The slope of the straight line portion, K, is the reciprocal of the mean yield pressure, Py of the material. From the value of the intercept, A, the relative density, Da can be calculated using the equation,

The relative density of the powder bed at the point when the applied pressure equals zero, D0, was used to describe the initial rearrangement phase of densification as a result of die filling. The relative density, Db, describes the phase of rearrangement at low pressure and is the difference between Da and D0:

Kawakita Plots

The Kawakita equation was used to evaluate powder compression using the degree of volume reduction, C (Alebiowu and Itiola 2001). The volume of each sample at zero pressure, Vo was determined. The volume of the tablets at different compression pressures (Vp) and the degree of volume reduction (C) were also calculated. Kawakita plots of P/C as a function of the applied pressure (P) were made for the different formulations. The values of a and b were obtained from the slope and intercept respectively. The reciprocal of b yields a pressure term Pk, which is the pressure needed to reduce the volume of the powder bed by 50 % (Shivanand and Sprockel 1991) and is related to the plasticity of the material. The equation is written as follows:

The equation in practice can be rearranged to give

Determination of Microbial Survival

Viable counts were carried out on the compressed tablets of both contaminated and uncontaminated formulations. These were compared with the number of viable cells of uncompressed contaminated formulations.

Approximately 1 g of contaminated (or uncontaminated) tablets was disintegrated in 9 ml of sterile distilled water. The resultant suspension was serially diluted and 1 ml volume of a 1 in 100 dilution was transferred immediately into 10 ml melted (but cooled) nutrient agar. Using the pour-plate method, the content of the nutrient agar bottle was transferred to a sterile Petri dish. The agar was allowed to set and was incubated at 37 °C for 24 h. Survival, estimated as the mean of quadruplicate determinations, was expressed for the contaminated tablets as a percentage relative to the uncompressed control contaminated materials.

Tensile Strength Tests

The tensile strength of the tablets was determined at room temperature by diametrical compression (Fell and Newton 1970; Ayorinde and Itiola 2005) using a tablet hardness tester (DBK INSTRUMENT, MUMBAI-400060, Model:EH01). The tablet was placed between the platen of the tester and the adjustable knob was screwed until contact was made with the tablet. Sufficient pressure was applied to cause tablet breakage. The crushing strength was read on the tester. The results were taken only from tablets that split cleanly into two halves without any signs of lamination. All measurements were performed in quadruplicate. The radial tensile strength, T (MN m−2) of the tablets was calculated using the equation:

Results

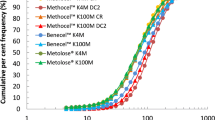

The results in Table 2, Figs. 1 and 2 show the change in relative density (D) of the tablets as a function of the compression pressure. The relative density increased with increasing compression pressure in the diclofenac formulations. The inverse plasticity parameters (Py and Pk) were highest in DDCP with the ranking DDCP > DL > DCS. The percentage survival of the Bacillus subtilis spores in the tablets was lowest in DCS; the ranking was DDCP > DL > DCS.

In Table 3, the tensile strength of the tablets decreased with increasing compression speed in all formulations. The percentage survival of the microbial contaminants in the tablets increased with increasing compression speed.

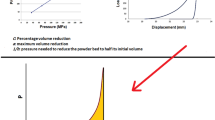

Figure 3 shows the effect of the tensile strength and compression speed on the survival of Bacillus subtilis in a diclofenac tablet in a 3-D plot.

Discussions

Compressional Properties of Materials

Heckel Plots

The changes in relative density of materials with compression pressure for the diclofenac formulations are presented in Table 2. The values of K and A were respectively obtained from the slopes and intercepts of the plots of ln(1/1 – D) against applied pressure (Fig. 1). The relative densities DA and DB were obtained using the following equations.

Thus,

and

The curve experienced at low compression pressures (initial phase of compression cycle) indicates rearrangement and particle fragmentation (Duncan-Hewitt and Weatherly 1990). As compression increases, the higher linearity obtained indicates plastic deformation (Georget et al. 1994, Ayorinde et al. 2005).

High linearity with correlation coefficients > 0.95 were obtained at the second phase of the plots, which generally commenced at applied pressure of 113.230 MN m−2 for diclofenac formulations. Such high linearity is often experienced with comparatively soft materials that undergo plastic deformation while retaining different porosities depending on the initial packing arrangement in the die.

Previous studies by Ayorinde et al. (2005) had shown the mode of consolidation of the excipients (dicalcium phosphate, lactose and Corn starch). The Heckel plots for dicalcium phosphate and lactose showed initial curves followed by linear regions. The initial curve suggests that fragmentation and particle rearrangement were occurring during the initial stages of compression. Lactose, is a brittle crystalline material, whose compacts are consolidated by both plastic deformation and fragmentation; it consolidates by fragmentation at the initial stages of the compression cycle and then by plastic deformation at the latter stages (Armstrong and Palfery 1989). Dicalcium phosphate consolidates almost entirely by fragmentation (Zhang et al. 2003). Corn starch was shown to deform mainly by plastic flow (Paronen and Juslin 1983; Ayorinde et al. 2005,), which is shown by the absence of an initial curve in its Heckel plots.

Representative Heckel plots for diclofenac formulations are shown in Fig. 2. The mode of consolidation of the diclofenac formulations was found to be dependent on the nature of the excipient present in the formulation. Formulations containing corn starch (DCS) deformed mainly by plastic flow, whereas DDCP, which contained the fracturing dicalcium phosphate, consolidated mainly by fragmentation. DL showed an initial curve at the early stages of compression, followed by plastic deformation at the latter stage, which is similar to what was obtained with lactose. These results show that the mode of consolidation of the drug, diclofenac, is largely dependent on the nature of the excipient used in the formulation.

The plastic deformation of particles can be attributed to glide (or slip), twinning and kinking, all in simple shear (Bandyopadhyay and Grant 2002). Plastic deformation by slip occurs along specific planes known as slip planes and along specific directions. Mechanical twinning involves the bending of the crystal lattice by shearing parallel to a crystallographic plane, whereas kinking is the bending of the crystal lattice in platy minerals e.g. micas. Fracture in brittle materials is associated with crystal lattice defects and imperfections.

Parameters Derived from Heckel Plots

(Mean Yield Pressure Py and Pressure term, Pk)

The yield pressure is defined as the stress at which plastic deformation of the particles is initiated and can be derived from the linear part of the Heckel plot. As far as the non-linear part of the plot is concerned, the initial curvature at low pressure reflects particle fragmentation and rearrangement, whereas the deviation from a straight line at high pressure may be caused by capping and lamination of the powder. The Heckel plots and the parameters derived are quite sensitive to variations in the experimental conditions, such as the maximum compression pressure applied (Sonnergaard 1999). The mean yield pressure, Py, is inversely proportional to the ability of a material to deform plastically, and indicates the rate of onset of plastic deformation occurring in a material. The values of Py were calculated from the slope of the second compression region of the Heckel plots for the materials. The ranking of Py values among diclofenac formulations was DDCP > DL > DCS, indicating that the onset of plastic deformation occurred at the lowest pressure in DCS. Moreover, corn starch as an excipient will induce a faster onset of plastic flow in diclofenac formulations than either lactose or dicalcium phosphate. Furthermore, the formulation containing dicalcium phosphate generally exhibits high Py values. This is expected because dicalcium phosphate has been shown to be the least plastic compared to lactose and corn starch.

The inverse of constant b gives another pressure term, Pk, which has an inverse relationship with the plasticity of materials. The value of Pk, which represents the pressure required to reduce the powder bed by 50 % and is related to the yield stress of the individual powder or granule particle (Adam et al. 1994; Georget et al. 1994), are also presented in Table 2. Low Pk values indicate that the material is soft and readily deforms plastically under pressure. The ranking of Pk among the diclofenac formulations was DDCP > DL > DCS. The difference was significant (P < 0.01). This shows that cornstarch imparted the highest level of plasticity to diclofenac, as evidenced by the lowest Pk value in the formulation containing cornstarch. This also suggests that corn starch can increase the softness of the formulation as well as its ability to deform plastically under pressure more than lactose and dicalcium phosphate.

Material Properties and Microbial Survival

It was generally observed that percent survival of Bacillus subtilis spores was least in the formulation containing corn starch (Table 2). The ranking of the reduction of viability of the microorganism was DCS > DL > DDCP. DCS, DL and DDCP showed a 94 %, 90 % and 88 % decrease in viability, respectively, at the highest compression pressure of 226.46 MN m−2.

DCS, which has the highest degree of plastic deformation among the diclofenac formulations, as evidenced by low Py and Pk values, had the lowest level of microbial survival in the formed tablets. This suggests that plastically deforming cornstarch exhibits the highest decrease in viability of the microbial contaminants, whereas dicalcium phosphate exhibits the least. Previous studies showed that shearing forces and localization heat are the main mechanisms of microbial death during compaction (Plumpton et al. 1986; Ayorinde et al. 2005). The main mechanism of consolidation for corn starch is by plastic deformation, which causes a high localized shear flow. Under compression pressure, this would lead to greater interparticulate contact, which would enhance the mechanical disruption of the microorganisms to a greater level. Therefore, the formulation containing corn starch exhibited greater surface disruption and destroyed more microorganisms that were bonded to or in the formulations than the brittle materials.

DL and DDCP, through a fracturing mechanism, can rearrange and fill the available void spaces, thereby decreasing the area of interparticle contact in the materials. This fragmentation produces a lower level of shear flow in the materials compared to plastic deformation. Therefore, in this case, microorganisms would probably be inactivated to a smaller extent by shearing.

These results suggest that the compression of plastically deforming materials would cause a higher level of bacterial inactivation in the formed tablets than fracturing materials. A supportive mechanism involved in the destruction of microorganisms is the heat generated by friction during tabletting, which should be higher for plastically deforming materials (Fassihi and Parker 1977; Ayorinde et al. 2005). Therefore, the compressional characteristics of the materials, as described by the parameters obtained from the Heckel and Kawakita plots, may provide some indication of the likelihood of survival of microorganisms in pharmaceutical materials during tabletting.

Material Properties and Tensile Strength

Tensile strength indicates how a material will react to forces being applied in tension. A tensile test is a fundamental mechanical test that determines the modulus of elasticity, elastic limit, plasticity and other tensile properties. Composite particles of powders intended for tablet processing need to be of sufficient compressibility and be strong enough to prevent unwanted breakage during handling. The bond strength can be obtained from the tensile strength (T) of the tablets (Itiola and Pilpel 1986a, 1991). Tensile strength has been used in this present study to assess the mechanical properties of diclofenac tablets. The most common way of determining the crushing strength of a particle is to apply a load diametrically and measure the force needed to cause fracture (Alander et al. 2003).

Table 3 lists the results of the tensile tests on the tablets. Correlation coefficients > 0.970 were obtained. DDCP generally exhibited the highest T values among the diclofenac formulations; the ranking was DDCP > DL > DCS. This result shows that fracturing materials produced tablets with higher tensile strength. Correlations have been found between the fracture strength and the compression behavior of the particles (Fichtner 2007). Deformability of pellets made from microcrystalline cellulose could be related to their tensile and shear strength, and was found to be reduce for stronger pellets (Basshaiwoldu et al. 2004).

Compression Speed and Microbial Survival

There was a general inverse relationship between the log % survival of Bacillus subtilis spores and the relative density of the tablets with correlation coefficient of 0.926 to 0.999 (P < 0.001) for the formulations compressed on a hydraulic hand press with a compression speed of less than 20 mm/s and on a single punch press on which a higher compression speed was used.

The survival of the microorganisms was significantly lower (P < 0.01) for the materials compressed on the hydraulic hand press than those compressed on a single punch press. Compressing the tablets at slower speeds subjects the organisms to greater mechanical disruption and frictional heat. A longer dwell time was also achieved at a slower compression speed, which in turn leads to more plastic deformation that further inactivates the microbial contaminants. As the speed of compression increases from 20 to 120 mm/s on the single punch press, the survival of the organisms generally increased (P > 0.05).

In practice, the compression speeds are increased significantly during the scale up of tablet production and technology transfer. Therefore, the results suggest that microorganisms in raw materials might exhibit a significant level of survival on tablet machines, which operate at very high compression speeds, normally in excess of 200 mm/s. Therefore, the use of an excessive compression speed should be avoided because the likelihood of survival of the microbial contaminants increases with increasing compression speed.

Compression Speed and Tensile Strength

Tablets compressed on a hydraulic hand press generally had higher T values than those compressed on a single punch press and as the compression speed increased on the single punch press, the values of T decreased. This suggests that the lower the dwell time, the lower the tensile strength of the tablets. Therefore, when a high speed tabletting machine with short dwell time is to be employed in tablet production, the use of a binder at an appropriate concentration should be considered in order to produce tablets with satisfactory mechanical strength. This assertion is supported by the fact that tablets of the same formulation, produced by wet granulation process (in which binders were used) had higher T values than those produced by wet granulation method (in which no binder was used).

Relating the Effects of Compression speed, Tensile strength and Microbial Survival in Tablets

A 3-D plot was made to relate the effects of the compression speed, tensile strength and log percent survival of Bacillus subtilis spores in diclofenac tablets (Fig. 3). An inverse linear relationship between the compression speed and log percent survival of Bacillus subtilis spores was obtained. The correlation was significant (P < 0.05) in all formulations. As the compression speed increases, the dwell time decreases; hence, the extent of mechanical disruption to which microbial contaminant is subjected is reduced. Shorter dwell time also reduces the extent of plastic deformation in materials, which also in turn reduces the inactivation of the microbial contaminant.

In practice, compression speeds are increased significantly during tablet production scale up and technology transfer. Thus the results suggest that microorganisms in raw materials might exhibit a significant level of survival on tablet machines that operate at very high compression speeds, usually in excess of 200 mm/s. Hence, the use of an excessive compression speed should be avoided as it has been shown that the higher the compression speed, the higher the survival chance for the microbial contaminants. Also, expectation of microbial destruction during compression in tablet production should not be taken as a guarantee that all the microbial contaminants present in raw materials will be eliminated. Therefore, manufacturers must implement microbial control on the tablet ingredients for direct compression by ensuring the approval and validation of the active and excipient raw materials in the pilot plant. Raw materials must also meet standards for microbial specifications.

Conclusion

This study showed that the mode of consolidation of materials and the speed at which tablet compression is carried out have effect on both the tensile strength of the formed tablets and the extent of destruction of the microbial contaminant in diclofenac tablet formulations. Hence, in production scale up, an excessive compression speed above 200 mm/s should be avoided to ensure minimum microbial survival and tablets with satisfactory mechanical strength.

References

Adams, M.J., M.A. Mullier, and J.P.K. Seville. 1994. Agglomerate strength measurement using a uniaxial confined compression test. Powder Technology 78: 5–13.

Alander, E.M., M.S. Uusi-Penttila, and A.C. Rasmuson. 2003. Characterization of paracetamol agglomerates by image analysis and strength measurement. Powder Technology 130: 298–306.

Alebiowu, G., and O.A. Itiola. 2001. Effects of natural and pregelatinized sorghum, plantain and corn starch binders on the compressional characteristics of a paracetamol tablet formulation. Pharmaceutical Technology (Suppl. Ed: Drug Delivery): 26–30.

Armstrong, N.A., and I.P. Palfery. 1989. The effect of machine speed on the consolidation of four directly compressible diluents. Journal of Pharmacy and Pharmacology 41: 149–151.

Ayorinde, J.O., O.A. Odeku, and O.A. Itiola. 2005. The survival of Bacillus subtilis spores in dicalcium phosphate, lactose and corn starch, and their binary mixtures during tabletting. Pharmaceutical Technology 29(12): 56–64.

Bandyopadhyay, R., and J.W. Grant. 2002. Plasticity and slip system of plate-shaped crystals of l- lysine monohydrochloride dihydrate. Pharmaceutical Research 19: 491–496.

Banker, G.S., and N.R. Anderson. 1986. Tablets. In The theory and practice of industrial pharmacy, 3rd ed, ed. L. Lachman, H.A. Lieberman, and J.L. Kanig, 301–303. Philadelphia: Lea and Febiger.

Bashaiwoldu, A.B.B., F. Podczeck, and M. Newton. 2004. A study on the effect of drying techniques on the mechanical properties of pellets and compacted pellets. European Journal of Pharmaceutical Sciences 21: 119–129.

Cook, G.D., and M.P. Summer. 1990. Effects of compression speed on the tensile strength of tablets of binary mixtures containing Aspirin. Journal of Pharmacy and Pharmacology 42: 462–467.

Duncan-Hewitt, W.C., and G.C. Weatherly. 1990. Modelling the uniaxial compaction of pharmaceutical powders using the mechanical properties of single crystals. I: ductile materials. Journal of Pharmaceutical Sciences 79: 147–152.

Fassihi, A.R., and M.S. Parker. 1977. The effects of processing factors upon the microbial content of tablets. Journal of Applied Bacteriology 43: XVII.

Fell, J.T., and J.M. Newton. 1970. Determination of tablet strength by diametral compression test. Journal of Pharmaceutical Sciences 59: 688–691.

Fichtner. F. 2007. Identification and variation of some functionality related characteristics of pharmaceutically relevant solid materials and their effects on product performance. Ph.D dissertation, Faculty of Pharmacy, Uppsala University.

Georget, D.M.R., R. Parker, and A.C. Smith. 1994. A study of the effect of water content on the compaction behaviour of breakfast cereal flakes. Powder Technology 81: 189–195.

Heckel, R.W. 1961a. An analysis of powder compaction behaviour. Transactions of the Metallurgical Society of AIME 221: 1001–1008.

Heckel, R.W. 1961b. Density-pressure relationships in powder compaction. Transactions of the Metallurgical Society of AIME 221: 671–675.

Hersey, J.A., and J.E. Rees. 1971. Deformation of particles during Briquetting. Nature 230: 96.

Itiola, O.A., and N. Pilpel. 1986. Studies on metronidazole tablet formulations. Journal of Pharmacy and Pharmacology 38: 81–86.

Itiola, O.A., and N. Pilpel. 1991. Formulation effects on the mechanical properties of metronidazole tablets. Journal of Pharmacy and Pharmacology 43: 145–147.

Kawakita, K., I. Hattori, and M. Kishigami. 1997. Characteristics constants in Kawakita’s compression equations. Journal of Powder and Bulk Solids Technology 1: 3–8.

Marshal, K. 1986. Compression and consolidation of powdered solids. In The theory and practice of industrial pharmacy, 3rd ed, ed. H.A. Lachman, and J.L. Kanig, 66–100. Philadelphia: Lea and Febiger.

Paronen, P., and M. Juslin. 1983. Compressional characteristics of four starches. Journal of Pharmacy and Pharmacology 35: 627–635.

Plumpton, E.J., P. Gilbert, and J.T. Fell. 1986. Effects of spatial distribution of contaminating microorganisms within tablet formulation on subsequent inactivation through compaction. International Journal of Pharmaceutics 30: 237–240.

Shivanand, P., and O.L. Sprockel. 1991. Compaction behaviour of cellulose polymers. Powder Technology 69: 177–184.

Sonnergaard, J.M. 1999. A critical evaluation of the Heckel equation. International Journal of Pharmaceutics 193: 63–71.

Sujja-areevath, J., D.L. Munday, P.J. Cox, and K.A. Khan. 1996. Release characteristics of diclofenac sodium from encapsulated natural gum mini-matrix formulations. International Journal of Pharmaceutics 139: 53–62.

Sun, C., and D.J.W. Grant. 2001. Effects of initial particle size on the tableting properties of lysine monohydrochloride dihydrate powder. International Journal of Pharmaceutics 215: 221–228.

Zhang, Y., Y. Law, and S. Physical. 2003. Properties and compact analysis of commonly used direct compression binders. http://www.aapspharmscitech.org/view.asp?art=pt040462. Accessed on 10/07/08.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ayorinde, J.O., Itiola, O.A. & Odeniyi, M.A. Effects of material properties and speed of compression on microbial survival and tensile strength in diclofenac tablet formulations. Arch. Pharm. Res. 36, 273–281 (2013). https://doi.org/10.1007/s12272-013-0027-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12272-013-0027-4