Abstract

A simple and efficient multiple pesticide residue analytical method using quick, easy, cheap, effective, rugged, and safe (QuEChERS) extraction and liquid chromatography triple quadrupole-mass spectrometry was developed and validated for the determination of ten insecticides and three fungicides in eggplant. The method was validated by evaluating the accuracy, precision, linearity, limit of detection, and limit of quantification. The average recoveries of the selected pesticides ranged from 71.8 to 112 % with precision in case of repeatability (RSDr) ≤16.2 % in four fortification levels of 0.01, 0.05, 0.1, and 0.5 mg/kg. The linearity was ≥0.997 for all of the selected pesticides with matrix-matched calibration standards. The limit of detection (LOD) ranged from 0.001 to 0.003 mg/kg and the limit of quantification (LOQ) was 0.01 mg/kg, which was lower than the Maximum residue levels set by European Union (EU-MRLs). Matrix effect was also evaluated, and it was found that thiamethoxam, cypermethrin, and deltamethrin had pronounced matrix effect (−69, +57, and +93 %, respectively). This method was applied for the residue analysis of 72 fresh eggplant fruit samples collected from different market places in Thessaloniki, Greece. Among the 72 analyzed samples, 34 (47 % of the total no. of samples) had pesticide residues, of which, 5 had multiple pesticide residues and 29 had single pesticide residue. Only one sample contained residue above the EU-MRLs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Vegetables are commonly used to fulfill the balance diet requirement as they are a vital source of vitamins and fiber (Bemph and Augustine 2011). Eggplant is one of the most common and popular vegetable throughout the entire tropical and subtropical regions of the world. It is grown extensively in China, India, Bangladesh, Pakistan, Philippines, Japan, Indonesia, Turkey, Greece, Italy, France, USA, and Mediterranean and Balkan countries (Bose and Som 1986). The benefits of eggplant are well known. It helps to prevent colon cancer, reduces cholesterol level, helps in the type 2 diabetes management, is very rich in antioxidant, and also helps to control weight (Dome 2013).

Eggplant is very much susceptible to insect attack and disease infestation from seedling to fruiting stage. It is undoubtedly true that a negative economic impact on the production of vegetables occurs by the insect pests and diseases. Due to plant pests and diseases, 20 to 40 % crop yields are reduced globally, besides the fact that the world will need to produce 60 % more food for the over increasing world population by 2050 (FAO 2012). To ensure this demand, control of insect pests and diseases plays a key role. Until today, pesticides play a vital role for the control of insect pests and diseases, but pesticides create several adverse effects on human health, agroecosystem, and the environment resulting from indiscriminateness, overuse, and misuse of pesticides (McIntyre et al. 1989). So, it is necessary to use pesticides following good agricultural practice (GAP). Monitoring of pesticide residues is the essential tool to ensure GAP. To monitor pesticide residues nationally in the commercial produce, development of multiresidue methods incorporating the commonly used and registered pesticides is required. Besides, multiresidue methods are the essential tools for the analysts in order to determine pesticide residues quickly and easily.

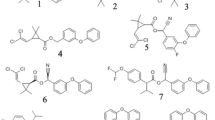

Up to now, only few multiresidue analytical methods for eggplant were developed using Liquid chromatography-tandem mass spectrometry (LC-MS/MS) (Frenich et al. 2004; Dasika et al. 2012; Caboni et al. 2008; Obana et al. 2003). However, the developed methods did not incorporate the most important pesticides used by the farmers in different countries, especially in Europe. In this study, 13 of the most commonly used and also registered pesticides for the control of insect pests and diseases of eggplant in Greece were selected. Among them, ten insecticides contain three organophosphorus (chlorpyrifos, chlorpyrifos-methyl, dimethoate), two pyrethroids (cypermethrin, deltamethrin), three neonicotinoids (acetamiprid, thiamethoxam, thiacloprid), one oxadiazine (indoxacarb), and one dimethylcarbamate (pirimicarb) and three fungicides belonging to the classes of strobilurin (azoxystrobin), triazole (difenoconazole), and carbamate fungicides (propamocarb hydrochloride). To the best of our knowledge, this is the first developed multiresidue method for eggplant using LC-MS/MS incorporating the aforementioned pesticides with the exception of acetamiprid, thiamethoxam, thiacloprid, and chlorpyrifos. With this view, the present study was conducted in order to develop and validate a multiresidue analytical method for eggplant using LC-MS/MS and also to monitor the pesticide residues in eggplant in Greece.

Materials and Methods

Chemicals and Reagents

Reference standards of acetamiprid, azoxystrobin, chlorpyrifos, deltamethrin, difenoconazol, indoxacarb, propamocarb, thiacloprid, and thiamethoxam were obtained from Sigma-Aldrich (St. Louis, MO, USA), dimethoate and pirimicarb were from Neochema (Bodenheim, Germany), and chlorpyrifos-methyl and cypermethrin were from LGC (Middlesex, UK).

Liquid chromatography-mass spectrometry (LC-MS) grade methanol, gradient grade acetonitrile, and chromatography grade water were from Merck (Darmstadt, Germany). Sodium chloride (NaCl) was purchased from Chem-Lab (Zedelgem, Belgium), anhydrous magnesium sulfate (MgSO4) was from Panreac (Barcelona, Spain), and primary secondary amine (PSA) was from Agilent (Santa Clara, CA, USA). Ammonium acetate of mass spectrometry grade was purchased from Fluka (Buchs, Switzerland).

Preparation of Pesticide Standard Solution

Pesticide standard stock solutions (1,000 mg/L) of chlorpyrifos, chlorpyrifos-methyl, dimethoate, deltamethrin, cypermethrin, acetamiprid, thiamethoxam, thiacloprid, indoxacarb, pirimicarb, propamocarb hydrochloride, azoxystrobin, and difenoconazole were prepared separately with methanol and stored at −20 °C until use. A mixed pesticide standard solution of 50 mg/L was prepared by adding the proper volume of each individual stock solution and diluted to volume. Intermediate mixed pesticide standard solution of 10 mg/L was prepared from the mixed pesticide standard solution of 50 mg/L. Then, mixed pesticide standard working solutions of 0.05, 0.1, 0.2, 0.5, 1.0, 1.5, and 5.0 mg/L were prepared by transferring the proper amount from 10-mg/L intermediate mixed pesticide standard solution into seven separate 10-mL volumetric flasks. Matrix-matched calibration standards were prepared by adding mixed pesticide standard working solutions in the blank extract to reach the final concentrations of 0.005, 0.01, 0.02, 0.05, 0.10, and 0.15 mg/L. Calibration standards in methanol were also prepared at the same concentration levels. All of the standards were kept in a freezer at −20 °C until use.

Sampling and Sample Preparation

Eggplant fruit samples were collected from different market places in Thessaloniki, Greece, such as supermarkets, open markets, and retail vegetable shops. Eggplant fruits were collected in a clean polyethylene bag to reduce cross-contamination and labeled properly of the collected samples. All collected samples were carried out to the pesticide Science Laboratory, Aristotle University of Thessaloniki (AUTH), Greece, on the same sampling day. Unit weight of each individual fruit was recorded. The whole unit was cut into small pieces and stored at −20 °C until homogenization.

Extraction and Cleanup

Ten grams of properly homogenized eggplant sample was taken in a 50-mL screw-capped polypropylene centrifuge tube, and 10 mL acetonitrile (MeCN) was added into the centrifuge tube. The centrifuge tube was closed properly and shaken vigorously for 30 s by vortex mixer. Then, 4 g anhydrous MgSO4 and 1 g NaCl were added into the centrifuge tube, and it was shaken by vortex mixer for 1 min. Afterward, the extract was centrifuged for 5 min at 5,000 rpm. An aliquot of 3 mL of the MeCN layer was transferred into a 15-mL microcentrifuge tube containing 600 mg anhydrous MgSO4 and 120 mg PSA. The content of the centrifuge tube was thoroughly mixed by vortex for 30 s and centrifuged for 5 min at 4,000 rpm. A 1-mL supernatant was taken into a clean test tube, and one drop of toluene was added into the test tube. Then, it was concentrated to dryness under a gentle stream of nitrogen (15 psi) by using the Turbovap LV (Caliper Life Sciences, Germany) evaporator at 30 °C. The test tube containing the extract was stored at −20 °C until analysis. The extract was reconstructed by adding 100-μL LC-MS grade methanol and 900 μL of the mobile phase mixture (80 % mobile phase A and 20 % mobile phase B) used for LC-MS/MS analysis. The amount of the sample in the final extract was equivalent to 1 g/mL.

Preparation of Matrix-Matched Calibration Standards

A blank eggplant sample was prepared through the extraction and cleanup procedures as described above. Then, the extract was reconstructed by adding 100 μL of mixed pesticide standard working solutions of 0.05, 0.1, 0.2, 0.5, 1.0, 1.5 mg/L and 900 μL of the mobile phase mixture (80 % mobile phase A and 20 % mobile phase B) used for LC-MS/MS analysis to reach the final concentrations of 0.005, 0.01, 0.02, 0.05, 0.10, and 0.15 mg/L.

Liquid Chromatography Triple Quadrupole Mass Spectrometry

An LC-MS system, consisting of a Surveyor LC pump and autosampler, and a TSQ Quantum Discovery Max triple quadrupole mass spectrometer (Thermo Electron Corporation, Waltham, MA, USA) were used for the identification and quantification of the selected pesticides. The LC pump gradient program was 0–5 min, 20 % mobile phase B; 5–16 min, 100 % mobile phase B; and 16–27.5 min, 20 % mobile phase B. The mobile phase flow rate was 0–18.5 min, 0.2 mL/min; 18.5–25.5 min, 0.5 mL/min; and 25.5–27.5 min, 0.2 mL/min. Mobile phase A consisted of a 90:10, water/methanol mixture containing 5 mM of ammonium acetate, whereas mobile phase B was a 10:90, water/methanol mixture containing 5 mM of ammonium acetate. A HyPurity C18 analytical column (50 mm × 2.1 mm i.d., 3-μm particle size) was used for the chromatographic separation (Thermo Scientific). The column oven temperature was 40 °C, the injection volume was 20 μL, and the total run time was 27.50 min.

The mass spectrometry system was a triple quadruple which was equipped with an electrospray ionization (ESI) source operated at the positive ion mode. The operating conditions of ESI were as follows: sheath gas (nitrogen) pressure was 30 arbitrary units; auxiliary gas (nitrogen) pressure was 10 arbitrary units; spray voltage was 4,000 V; Capillary temperature was 325 °C. The collision gas pressure was 1.5 mTorr. The acquisition was made in the selected reaction monitoring (SRM) mode. The parent ion and quantification and confirmation ions are presented in Table 1. All of the data were acquired and processed by the TraceFinder software (Thermo Scientific).

Method Validation

The analytical method was validated by evaluating the linearity, accuracy, precision, limit of detection, and limit of quantification.

Accuracy and Precision

The accuracy of the method was calculated as percent recovery of pesticides from spiked samples. Pesticide-free eggplants were collected from a retail market of fresh products of organic farming. The collected samples were cut into small pieces and stored at −20 °C until homogenization. Homogenization was done by fruit blender. A 10-g homogenized sample was spiked prior to the determination procedure by the addition of a mixed pesticide standard working solution to reach the final fortification levels of 0.01, 0.05, 0.10, and 0.50 mg/kg. For each level, five replicates were analyzed. After the addition of each concentration in the matrix, the mixture was equilibrated by shaking, and the samples were allowed to settle for 30 min prior to extraction in order to ensure the sufficient contact of the analytes with the whole matrix. Then, the samples were prepared according to the method which was described earlier.

Precision in case of repeatability (RSDr) was determined at four fortification levels of 0.01, 0.05, 0.10, and 0.50 mg/kg with five replicates on the same day. Precision in case of reproducibility (RSDR) was determined at two fortification levels of 0.01 and 0.10 mg/kg with five replicates at 3 weeks of interval.

Limit of Detection and Limit of Quantification

The limit of detection (LOD) was calculated according to EURACHEM guidelines (EURACHEM 1998). In order to determine the LOD of each analyte, ten independent sample blanks fortified at the lowest acceptable concentration of 0.01 mg/kg were injected, and the LOD was expressed as the analyte concentration corresponding to three times the standard deviation. Limit of quantification (LOQ) was determined according to the European Commission (EC) document no. SANCO/12495/2011 (European commission 2011). LOQ was set as the lowest fortification level for each pesticide that was achieved in the acceptable accuracy (mean recoveries for individual pesticides in the range of 70–120 %) and precision (RSDr ≤ 20 %).

Results and Discussion

Optimization of Cleanup

Nowadays, quick, easy, cheap, effective, rugged, and safe (QuEChERS) method is widely used for extraction and cleanup of the samples, especially for fruits and vegetables which was first introduced by Anastassiades et al. in 2003 (Anastassiades et al. 2003). This method is gaining popularity day by day compared to the other existing methods as it has a lot of advantages. The important ones are high recoveries of analytes with a wide range of polarity and volatility, the low organic solvent consumption, and the low cost per sample. Sample cleanup is one of the important steps to reduce the matrix effect. The QuEChERS cleanup method used for eggplant with the selected pesticides was slightly modified which is described below:

For the cleanup of the samples, a series of trial were conducted to determine the appropriate amount of anhydrous MgSO4 and PSA. At first, the appropriate amount of anhydrous MgSO4 was determined by performing recovery experiments employing 450 and 600 mg of the reagent per 3-mL extract. The results revealed that for most of the pesticides, there was not a significant difference between 450 and 600 mg of MgSO4, except in the case of chlorpyrifos-methyl (85 and 96 %, respectively), difenoconazole (70 and 76 %, respectively), and deltamethrin (106 and 95 %, respectively). The percent relative standard deviation (RSD%) was also better when 600 mg of MgSO4 was used (≤6 %) compared to 450 mg of MgSO4 (≤15 %). Thus, 600 mg of MgSO4 was selected for further use.

In a second series of experiments, different amounts of PSA were used (75, 120, 150 mg PSA per 3-mL extract). Recoveries were within the acceptance limits (70–120 %) for all pesticides except in the case of thiamethoxam when 150 mg of PSA was used (122 %). Thus, 120 mg of PSA was selected since for all pesticides, recoveries were in the range of 81–94 %, and higher recoveries compared to the 75-mg treatment for propamocarb hydrochloride (81 and 71 %, respectively), thiacloprid (94 and 84 %, respectively), and difenoconazole (88 and 76 %, respectively) were recorded. At the end of these trials, 600 mg anhydrous MgSO4 and 120 mg PSA for 3-mL extract were set for the proper cleanup of eggplant matrix.

Method Validation

Accuracy and Precision

A very good accuracy and precision were found for all of the analytes at four fortification levels of 0.01, 0.05, 0.10, and 0.50 mg/kg. The average recoveries ranged from 71.8 to 112 % with RSDr ≤16.2 % for all of the analytes (Table 2). Reproducibility (interday accuracy and precision) was done after 3-week interval at two fortification levels of 0.01 and 0.10 mg/kg, and it was also found very good. Average recoveries ranged from 74.6 to 106 %, and RSDR were below 15 % for all of the analytes (Table 3). Relative percent difference (RPD) was also calculated at two fortification levels of 0.01 and 0.10 mg/kg. RPD was below 10 % for all of the analytes (Table 3).

Calibration Curve and Linearity

Six-point calibration curves were prepared by matrix-matched standards and also standards in methanol and analyzed in triplicate. Calibration curves were made by plotting the mean peak area of the selected pesticides versus concentration. Linearity was evaluated by calculating the correlation coefficient, intercept, and slope of the regression line. Linearity was very good, and coefficients of determination were ≥0.997 for all of the selected pesticides with matrix-matched calibration standards. The slopes, intercepts, and correlation coefficients for all of the selected pesticides are summarized in Table 4.

Limit of Detection and Limit of Quantification

The LOD of each analyte is presented in Table 4. The LOD ranged from 0.001 to 0.003 mg/kg. The LOQ for all of the selected pesticides was set to 0.01 mg/kg which was achieved in the acceptable accuracy (mean recoveries for individual pesticides in the range of 84 to 112 %) and precision (RSDr ≤ 12.8 %).

Matrix Effects

Effect of matrix is one of the major challenges for the determination of pesticides by LC-MS/MS with ESI source. Matrix effect, which is caused by the ion enhancement or suppression, depended on the type of sample analyzed and significantly influences the quantification of the analytes by LC-MS (Wang et al. 2010). Due to the presence of coeluting species, the matrix resulting from the improper cleanup can interfere in the ionization of the target analytes. Thus, the response of the target analytes may be enhanced or suppressed compared to the solvent-based standards. So, sample extraction and cleanup play a significant role for the reduction of matrix effect. In this study, matrix effects were estimated as the ratio of the slopes of the calibration curves prepared with matrix-matched standards to those of solvent-based standards (Gilbert-Lopez et al. 2010). Matrix effects of eggplant fruits for the selected pesticides are presented in Table 5. Results revealed that the effect of matrix was prominent for thiamethoxam, cypermethrin, and deltamethrin. To overcome this effect, use of matrix-matched standards is the best way for quantification.

Application of the Method for Real Sample Analysis

The proposed method was used for the analysis of eggplant fruits collected from different market places in Greece. A total of 72 samples were analyzed. Analytical results are shown in Table 6. Among the analyzed samples, 38 (53 % of the total no. of samples) contained no detectable residues of the pesticides sought, and 34 (47 % of the total no. of samples) had pesticide residues, of which 5 had multiple pesticide residues and 29 had a single pesticide residue. Only one sample was found contaminated with dimethoate at a level above the EU-MRLs (European commission 2005). The detected pesticides were chlorpyrifos, dimethoate, thiamethoxam, thiacloprid, acetamiprid, cypermethrin, and deltamethrin. Thiamethoxam was found frequently in most of the contaminated samples which indicates that this pesticide is widely used to control the insect pests of eggplant in Greece. The ranges of the detected residues were 0.010–0.139 mg/kg.

Conclusions

The described method in this study is an efficient and easy multiresidue analytical method for eggplant using LC/ESI-MS/MS. In this method, a very good accuracy and precision were found for all analytes. The average recoveries ranged from 71.8 to 112 % with RSDr ≤ 16.2 % and RSDR ≤ 15 %. RPD was below 10 % for all analytes, thus fulfilling the requirement set by SANCO document no. SANCO/12495/2011 for accuracy and precision (European commission 2011). Moreover, the amount of QuEChERS cleanup materials were optimized in this method. Anhydrous MgSO4 of 600 mg and 120 mg PSA for 3-mL extract performed better than the other combinations suggested by QuEChERS original method (Anastassiades et al. 2003) and buffered QuEChERS method (Lehotay 2007).

Thirteen most important pesticides used by the farmers in different countries, especially in Europe, were incorporated in this method that helps the scientist/analysts for quick determination of multiple pesticide residues in eggplant. In addition, this analytical method was applied successfully to monitor the pesticide residues in eggplant in Greece. Last but not least, matrix effect was also evaluated in this method, and it was found that thiamethoxam, cypermethrin, and deltamethrin had pronounced matrix effect (−69, +57, and +93 %, respectively). Thus, the proposed method can be used successfully to monitor multiple pesticide residues in eggplant.

References

Anastassiades M, Lehotay SJ, Stajnbaher D, Schenck FJ (2003) Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “Dispersive Solid-Phase Extraction” for the determination of pesticide residues in produce. J AOAC Int 86:412–431

Bemph CK, Augustine KD (2011) Pesticide residues in fruits at the market level in Accra Metropolis, Ghana, a preliminary study. Environ Monit Assess 175:551–561

Bose TK, Som MG (1986) Vegetables crops in India. B. Mitra, Naya Prokash, 206, Bidhan Sarani, Calcutta 700006, India, pp 4–293

Caboni P, Sarais G, Angioni A, Vargiu S, Pagnozzi D, Cabras P, Casida JE (2008) Liquid chromatography tandem mass spectrometric ion switching determination of chlorantraniliprole and flubendiamide in fruits and vegetables. J Agric Food Chem 56:7696–7699

Dasika R, Tangirala S, Naishadham P (2012) Pesticide residue analysis of fruits and vegetables. J Environ Chem Ecotoxicol 4(2):19–28

Dome Health (2013) Eggplant health benefits-5 important benefits for your health of eggplants.www.domehealth.com/2013/05/eggplant-health-benefits-5-important.html

EURACHEM (1998) The fitness for purpose of analytical methods.www.eurachem.com

European commission (2005) EU pesticide residue MRLs. Regulation no. 396/2005. http://ec.europa.eu/sanco_pesticides/public/index.cfm

European commission (2011) Method validation and quality control procedures for pesticide residues analysis in food and feed. Document no. SANCO/12495/2011

FAO (2012) Global pact against plant pests marks 60 years in action. FAO celebrates anniversary of creation of the international plant protection convention in 3 April 2012, Rome. http://www.fao.org/news/story/en/item/131114/icode/

Frenich AG, Vidal JL, Lopez TL, Aquado SC, Salvador IM (2004) Monitoring multiclass pesticide residues in fresh fruits and vegetables by liquid chromatography with tandem mass spectrometry. J Chromatogr A 1048:199–206

Gilbert-Lopez B, Garcia-Reyes JF, Lozano A, Fernandez-Alba AR, Molina-Diaz A (2010) Large-scale pesticide testing in olives by liquid chromatography electrospray tandem mass spectrometry using two sample preparation methods based on matrix solid-phase dispersion and QuEChERS. J Chromatogr A 121:6022–6035

Lehotay SJ (2007) Pesticide residues in food by acetonitrile extraction and partitioning with magnesium sulfate. J AOAC Int 90:485

McIntyre AN, Allision N, Penman DR (1989) Pesticides: issues and options for New Zealand. Ministry for the Environment, Wellington, New Zealand

Obana H, Okihashi M, Akutsu K, Kitagawa Y, Hori S (2003) Determination of neonicotinoid pesticide residues in vegetables and fruits with solid phase extraction and liquid chromatography mass spectrometry. J Agric Food Chem 51:2501–2505

Wang J, Chow W, Leung D (2010) Application of LC/ESI-MS/MS and UHPLC QqTOFMS for the determination of 148 pesticides in fruits and vegetables. Anal Bioanal Chem 396:1513–1538

Acknowledgments

The principal author is grateful to the State Scholarship Foundation (IKY), Greece, for their financial support to pursue his PhD. The authors are thankful to Kotopoulou Athina, kintzikoglou Katherina, and Tsampoula Aggeliki in the Pesticide Science Laboratory of AUTH for their cooperation during the present study.

Conflict of Interest

M. D. H. Prodhan declares that he has no conflict of interest. Emmanouil-N. Papadakis declares that he has no conflict of interest. Euphemia Papadopoulou-Mourkidou declares that she has no conflict of interest. This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prodhan, M.D.H., Papadakis, E.N. & Papadopoulou-Mourkidou, E. Determination of Multiple Pesticide Residues in Eggplant with Liquid Chromatography-Mass Spectrometry. Food Anal. Methods 8, 229–235 (2015). https://doi.org/10.1007/s12161-014-9898-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-014-9898-3