Abstract

A new method for the analysis of α-tocopherol in tropical fruits by ultra performance convergence chromatography (UPC2) was developed for the first time. Five varieties of tropical fruit samples were separately saponified under classical heating and extracted with ether. The extracted α-tocopherol was separated on a BEH column, with a mobile phase consisting of CO2 and methanol, with a gradient elution (99:1 to 90:10), and detected with diode array detector at 293 nm. The limit of detection (LOD) and limit of quantification (LOQ) were about 60.0 and 103.3 ng, respectively. This method was considered to be simple, fast and reliable, and successfully applied to analysis of α-tocopherol in tropical fruits. The values of α-tocopherol in pitaya, jackfruit, durians, mango, and papaya ranged from 0.16 to 0.45 mg/100 g dry weight in edible portion. Recovery rates obtained by the standard addition method on these tropical fruit samples ranged from 95.4 to 101.4 % with high repeatability (RSD, 1.2–2.6 %).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

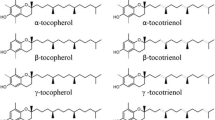

Vitamin E, composed by α-, β-, γ-, and δ-tocopherols and tocotrienols, is widespread in plant tissues including herbs, green leafy vegetables, leguminous plants, oilseeds, grains, wheat, and to a lesser extent in animal foods such as fish, eggs, milk, and liver (Boschin and Arnoldi 2011; Chung et al. 2013; Hussain et al. 2012; 2013; Iglesias et al. 2012; Kraujalis and Venskutonis 2013; Monge-Rojas and Campos 2011; Pinheiro-Sant’Ana et al. 2011). As one of the major antioxidants, vitamin E is an essential micronutrient for humans and animals since it can protect cell membranes from oxidation and low-density lipoproteins against lipid peroxidation by scavenging free radicals, therefore, reducing the risk of pathophysiology of cardiovascular disease (Pekmezci 2011; Wade et al. 2013). What is more important is that α-tocopherol is the most biologically active member of the vitamin E family (Salinthone et al. 2013). However, the Chinese Food Composition Table contains few data on the α-tocopherol content of tropical fruits, and information on the nutritional values of fresh and processed Chinese fruits is needed for the benefit of consumers.

So far, various methods are developed for the analysis and quantification of α-tocopherol in food and supplement matrices. A spectrophotometric method has been applied to specific determination of α-tocopherol in a variety of grains and seeds (Prieto et al. 1999). Non-aqueous capillary electrophoresis (NACE) method is applied to assay of α-tocopherol in vegetable oils. And the methods based on liquid chromatography (LC) both with normal and reversed chromatographic phases (RPLC) for the α-tocopherol analysis have been found in the literature (Grebenstein and Frank 2012; Nagata et al. 2011; Santos et al. 2012). Among these technologies, high-performance liquid chromatography (HPLC) equipped with MS or NMR has been used successfully in the analysis of α-tocopherol present in many food matrices (Annunziata et al. 2012; Chen et al. 2011; Darnet et al. 2011; Jadoon et al. 2010; Plozza et al. 2012; Slavin and Yu 2012; Strohschein et al. 1999; Tangolar et al. 2011). α-Tocopherol has also been analyzed by gas chromatography flame ionization detector (GC/FID) and gas chromatograph mass spectrometry (GC/MS) method (Hussain et al. 2013; Jokić et al. 2012). As a latest chromatography technology, ultra performance convergence chromatography (UPC2), which integrate the advantages of supercritical fluid chromatography (SFC) and ultra performance liquid chromatography (UPLC) technologies and allow a rapid, reliable, and cost-effective separation and quantification analysis, is regarded as the substituent of normal HPLC, the orthogonality and complementary to RPLC and GC.

In this work, a new analytical method of α-tocopherol based on UPC2 has been described for the first time, which shows a good linear correlation for low levels of concentration and an adequate resolution for a short runtime. Moreover, the method has also been efficiently validated and applied to characterize α-tocopherol in five tropical fruit samples.

Materials and Methods

Chemicals and Reagents

The standard of dl-all-rac-α-tocopherol (purity ≥ 96 %) was purchased from Sigma Aldrich (St. Louis, MO) and stored at 4 °C until use. Carbon dioxide (99.999 %) was purchased from Foshan Kedi Gas Chemical Industry Co., Ltd, Guangdong. HPLC grade methanol was obtained from Fisher Scientific Co. (Pittsburgh, PA). Deionized water (<18 MΩ cm−1 resistivity) was obtained using a Milli-Q SP® reagent water system (Millipore, Bedford, MA). Other chemicals (analytical grade) were purchased from Sinopharm Chemical Reagent Co., Ltd (Beijing, China). All solvents were filtered through 0.45-μm filters (Millipore, Bedford, MA) before use.

Raw Materials

Five varieties of fresh tropical fruits including pitaya, jackfruit, durians, mango, and papaya were purchased at the local supermarket in Zhanjiang, Guangdong, China. They were stored at 4 °C prior to use.

Sample Preparation

The edible portion of the same fruit was cut into small pieces and homogenized in a commercial homogenizer and freeze-vacuum dried for 12 h in a dark room, and then quickly ground into powder with a mortar and pestle. The extraction was completed according to the method of AOAC (2000) with some modifications. In brief, saponification of α-tocopherol was achieved by placing 6–12 g of the freeze-dried powder in a brown glass saponification flask, followed by adding 45 ml of anhydrous ethanol containing 5 ml of 10 % vitamin C and 10 ml of 50 % potassium hydroxide solution. The resulting mixture was refluxed in a boiling water bath for 30 min, and then cooled down in ice water; after adding 85 ml of ether, the contents were mixed by continuous shaking for 2 min. After separation of the two layers, the upper layer was transferred into a brown glass separatory funnel, and the sample was twice extracted with 25 ml of ether. The combined ether extract was washed with about 100 ml of deionized water until alkali-free. The ether solution was dried over anhydrous sodium sulfate and evaporated in a rotary evaporator (Buchi, Switzerland) under vacuum in a 50 °C water bath. The residue was dissolved in 2.0 ml of methanol for analysis.

Standard Preparation and Calibration

Approximately 0.2 g α-tocopherol was weighed into a 100-ml volumetric flask and diluted to volume with ethanol (HPLC grade), and then shaken well to dissolve. The stock standard solution was stored at 4 °C in an explosion-proof freezer and diluted before use. α-Tocopherol was quantified by calibration curve ranging from 0.1 to 2.0 mg/ml. An analytical curve was constructed using five increasing concentrations. A linear correlation between peak areas and concentrations was determined. The linear regression equation obtained was used to calculate the content of α-tocopherol in fruit samples.

Apparatus and Optimization of Chromatographic Conditions for Analysis

Analysis of α-tocopherol was performed using the ACQUITY UPC 2™ system (Waters, USA) with a diode array detector. The system was controlled using Empower 3 software. We used the UPC2 and an ACQUITY UPC2 BEH column (3.0 × 100 mm, 1.7 μm) at 50 °C with greater efficiency for the separation of α-tocopherol with a mobile phase consisting of carbon dioxide (CO2, 99.999 %) and methanol. The efficiency of chromatographic separation of α-tocopherol was evaluated from tests with different proportions of mobile phases, flow rate, and back pressure (data not shown). And appropriate injection volumes (0.2–10 μl) based on the samples with variable α-tocopherol contents was also investigated. Identification and quantification of α-tocopherol was respectively performed by comparing retention times and peak areas obtained for standard and samples, analyzed under the same conditions.

Method Validation

The linearity range was obtained on the previously optimized chromatographic conditions from the injection of five increasing concentrations of the standard solution of α-tocopherol. The data of peak areas of α-tocopherol were used for linear regression analysis. The correlation coefficient (R 2) obtained was used to assess linearity (Pinheiro-Sant’Ana et al. 2011).

The limit of detection (LOD) of the method was determined considering a signal-to-baseline noise ratio of three with reference to the background noise obtained from blank sample. The limit of quantification (LOQ) was determined considering a signal to the detection limit ratio of nine.

The accuracy and precision of the method were tested with recovery test by adding known concentrations of α-tocopherol in five tropical fruit samples. To evaluate recovery, triplicate samples of each fruit (approximately 6.0 g) were carefully weighted in volumetric flasks, and then standard solutions at low, medium, and high concentrations (50 %, 80 %, and 120 % of the original α-tocopherol contents, respectively) were added respectively for the procedure of extraction and analysis. The recovery values were obtained from the percent difference between the contents added and analyzed.

Results and Discussion

Optimization of Chromatographic Conditions

Analysis of the α-tocopherol was conducted using the chromatographic condition that presented the best results. According to the previous study, the optimized conditions were mobile phase consisting of (A) CO2 and (B) methanol, a linear gradient elution (0 min, 99:1; 0.5 min, 90:10; 2 min, 99:1), and a flow rate of 1.8 ml/min; the injection volume was 1 μl. Unless stated otherwise, the ABPR is 1,880 psi and the detector wavelength was set at 293 nm with compensation from 400 nm to 500 nm. The qualitative and quantitative measures of α-tocopherol in samples were based on retention times and peak areas.

Method Validation

The linearity range varied between 0.05 and 2.0 mg/ml for α-tocopherol, using the conditions optimized in this study. It can be observed that the linearity range for α-tocopherol was wide, which ensures acquisition of reliable data for fruits with low and high contents of α-tocopherol. The correlation coefficient (R 2) was 0.9995.

Recoveries of α-tocopherol in the five samples of tropical fruits ranged from 95.4 (durians) to 101.4 % (papaya). And the respectabilities of the measurements were high (RSD, 1.4–2.6 %) (Table 1). In general, good recovery percentages were found for α-tocopherol, which decrease the chances of losses during extraction and analysis, and guarantee reliability of the optimized method.

The LOD and LOQ were approximately 60.0 and 103.3 ng/ml. It can be noticed from the values obtained that LOD and LOQ were low, suggesting that the standard method allows detection of small quantities of α-tocopherol.

Analysis of α-Tocopherol in Tropical Fruits

Figure 1a illustrates the typical chromatographic profile obtained from the standard solutions of α-tocopherol. The typical chromatographic profile of the tropical fruit samples analyzed in this work is shown in Fig. 1b. It is observed that α-tocopherol occurred in all samples. And it is verified that the extraction method of the samples allowed perfect identification and quantification of α-tocopherol.

The contents of α-tocopherol of five tropical fruits are presented in Table 1. It is observed that the α-tocopherol content varied widely according to the type of fruits evaluated. The highest α-tocopherol content in the edible portion was found in pitaya (0.45 mg/100 g DW), followed by durian (0.36 mg/100 g DW), papaya (0.26 mg/100 g DW), jackfruit (0.20 mg/100 g DW), and mango with the lowest one (0.16 mg/100 g DW). It was also noted that the method used in this study was effective in extracting α-tocopherol present in the samples, including those in lower concentrations, which may be suitable for analysis of α-tocopherol in various food matrices. The values of α-tocopherol contents in selected fruit samples of this study agree with previous publications (data not shown; Charoensiri et al. 2009; Corral-Aguayo et al. 2008; Hadi and Hayati 2006) when taking fruit varieties and maturity, sample preparation, and determination method into consideration.

Conclusions

Tropical fruits are rich natural sources of antioxidants such as α-tocopherol for humans and animals; so, a rapid analytical method to evaluate its content and level is needed. After saponification and extraction with ether, α-tocopherol in five varieties of tropical fruits was satisfactorily determined by using a UPC2 system with a diode array detector. The result shows a rapid (retention time of about 0.4 min), sensitive, and highly reproducible separation and quantification, which have also been described for the first time in food matrix. This method is considered as a potential substituent of normal HPLC, the orthogonality and complementary to RPLC and GC in the analysis of α-tocopherol in different types of food matrix. Moreover, the information of this study will be useful for selection of high-quality raw materials for the exploitation of healthier fruit product processing.

References

Annunziata M, Attico A, Woodrow P, Oliva M, Fuggi A, Carillo P (2012) An improved fluorimetric HPLC method for quantifying tocopherols in Brassica rapa L. subsp. sylvestris after harvest. J Food Compos Anal 27:145–150

AOAC (2000) Vitamin E activity (all-rac-α-tocopherol) in milk-based infant formula. In: Phifer E (ed) AOAC Official Method 992.03 (17th ed.) Official methods of analysis of AOAC international, Gaithersburg, 2000

Boschin G, Arnoldi A (2011) Legumes are valuable sources of tocopherols. Food Chem 127:1199–1203

Charoensiri R, Kongkachuichai R, Suknicom S, Sungpuag P (2009) Beta-carotene, lycopene, and alpha-tocopherol contents of selected Thai fruits. Food Chem 113:202–207

Chen H, Angiuli M, Ferrari C, Tombari E, Salvetti G, Bramanti E (2011) Tocopherol speciation as first screening for the assessment of extra virgin olive oil quality by reversed-phase high-performance liquid chromatography/fluorescence detector. Food Chem 125:1423–1429

Chung I, Yong S, Lee J, Kim S (2013) Effect of genotype and cultivation location on β-sitosterol and α-, β-, γ-, and δ-tocopherols in sorghum. Food Res Int 51:971–976

Corral-Aguayo R, Yahia E, Carrillo-Lopez A, González-Aguilar G (2008) Correlation between some nutritional components and the total antioxidant capacity measured with six different assays in eight horticultural crops. J Agric Food Chem 56:10498–10504

Darnet S, Serra J, da Cruz RA, Meller da Silva L (2011) A high-performance liquid chromatography method to measure tocopherols in assai pulp (Euterpe oleracea). Food Res Int 44:2107–2111

Grebenstein N, Frank J (2012) Rapid baseline-separation of all eight tocopherols and tocotrienols by reversed-phase liquid-chromatography with a solid-core pentafluorophenyl column and their sensitive quantification in plasma and liver. J Chromatogr A 1243:39–46

Hadi A, Hayati N (2006) Chemical composition and activities of antioxidant compounds in red pitaya fruit (Hylocereus sp.), and effects on glucose and lipid profile level of induced hyperglycemia rats. Thesis, Universiti Putra Malaysia

Hussain A, Larsson H, Olsson M, Kuktaite R, Grausgruber H, Johansson E (2012) Is organically produced wheat a source of tocopherols and tocotrienols for health food. Food Chem 132:1789–1795

Hussain N, Jabeen Z, Li Y, Chen M, Li Z, Guo W, Shamsi I, Chen X, Jiang L (2013) Detection of tocopherol in oilseed rape (Brassica napus L.) using gas chromatography with flame ionization detector. J Integ Agr 12:803–814

Iglesias J, Pazos M, Torres J, Medina I (2012) Antioxidant mechanism of grape procyanidins in muscle tissues: redox interactions with endogenous ascorbic acid and α-tocopherol. Food Chem 134:1767–1774

Jadoon S, Waseem A, Yaqoob M, Nabi A (2010) Flow injection spectrophotometric determination of vitamin E in pharmaceuticals, milk powder and blood serum using potassium ferricyanide–Fe(III) detection system. Chin Chem Lett 21:712–715

Jokić S, Vidović S, Zeković Z, Kuzmanović S, Jevrić L, Marić B (2012) Chemometric analysis of tocopherols content in soybean oil obtained by supercritical CO2. J Supercrit Fluid 72:305–311

Kraujalis P, Venskutonis P (2013) Supercritical carbon dioxide extraction of squalene and tocopherols from amaranth and assessment of extracts antioxidant activity. J Supercrit Fluid 80:78–85

Monge-Rojas R, Campos H (2011) Tocopherol and carotenoid content of foods commonly consumed in Costa Rica. J Food Compos Anal 24:202–216

Nagata Y, Nishio T, Kanazawa H (2011) Reaction monitoring of tocopherols with active nitrogen oxides by ultra high-speed liquid chromatography. J Pharmaceut Biomed 55:241–246

Pekmezci D (2011) Vitamin E and immunity. In: Gerald L (ed) Vitamins and hormones. Elsevier, Waltham, pp 179–215

Pinheiro-Sant’Ana H, Guinazi M, Oliveira D, Della Lucia C, Reis B, Brandão S (2011) Method for simultaneous analysis of eight vitamin E isomers in various foods by high performance liquid chromatography and fluorescence detection. J Chromatogr A 1218:8496–8502

Plozza T, Craige Trenerry V, Caridi D (2012) The simultaneous determination of vitamins A, E and β-carotene in bovine milk by high performance liquid chromatography–ion trap mass spectrometry (HPLC-MSn). Food Chem 134:559–563

Prieto P, Pineda M, Aguilar M (1999) Spectrophotometric quantitation of antioxidant capacity through the formation of a phosphomolybdenum complex: specific application to the determination of vitamin E. Anal Biochem 269:337–341

Salinthone S, Kerns A, Tsang V, Carr D (2013) α-Tocopherol (vitamin E) stimulates cyclic AMP production in human peripheral mononuclear cells and alters immune function. Mol Immunol 53:173–178

Santos J, Mendiola J, Oliveira M, Ibáñez E, Herrero M (2012) Sequential determination of fat- and water-soluble vitamins in green leafy vegetables during storage. J Chromatogr A 1261:179–188

Slavin M, Yu L (2012) A single extraction and HPLC procedure for simultaneous analysis of phytosterols, tocopherols and lutein in soybeans. Food Chem 135:2789–2795

Strohschein S, Rentel C, Lacker T, Bayer E, Albert K (1999) Separation and identification of tocotrienol isomers by HPLC-MS and HPLC-NMR coupling. Anal Chem 71:1780–1785

Tangolar S, Özogul F, Tangolar S, Yağmur C (2011) Tocopherol content in fifteen grape varieties obtained using a rapid HPLC method. J Food Compos Anal 24:481–486

Wade L, Nadeem N, Young I, Woodside J, McGinty A, McMaster C, McEneny J (2013) α-Tocopherol induces proatherogenic changes to HDL2 and HDL3: an in vitro and ex vivo investigation. Atherosclerosis 226:392–397

Acknowledgments

This work was supported by the Special Fund for Agro-scientific Research in the Public Interest (201303077).

Compliance with Ethics Requirements

This is an original research article that has neither been published previously, nor considered presently for publication elsewhere. And all authors named in the manuscript are entitled to the authorship and have approved the final version of the submitted manuscript.

Conflict of Interest

Xiao Gong declares that he has no conflict of interest. Ningli Qi declares that she has no conflict of interest. Xiaoxi Wang declares that she has no conflict of interest. Jihua Li has received research grants (Special Fund for Agro-scientific Research in the Public Interest (201303077)) from the Ministry of Agriculture of the People’s Republic of China. Lijing Lin declares that he has no conflict of interest. This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gong, X., Qi, N., Wang, X. et al. A New Method for Determination of α-Tocopherol in Tropical Fruits by Ultra Performance Convergence Chromatography with Diode Array Detector. Food Anal. Methods 7, 1572–1576 (2014). https://doi.org/10.1007/s12161-014-9789-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-014-9789-7