Abstract

Quantification of antioxidant compounds in fruits is important in many studies of food chemistry, including those regarding the investigation of biological activities and recovery of bioactive compounds from by-products. In this chapter, we describe a protocol for quantitatively determining antioxidant compounds in fruits using LC-MS/MS. Demonstration of the method is shown for different classes of compounds, including phenolic acids (hydroxybenzoic and hydroxycinnamic acids) and flavonoids (flavonols, flavanones, flavan-3-ols, and flavones). The protocol details sample preparation, instrumental analysis, data interpretation, and quantification. Sample preparation involves extraction that is assisted by ultrasound or microwaves followed by a purification step using solid phase extraction. Analyses are carried out using selected reaction monitoring with two transitions for each compound. Two methods of quantification are described: internal standard method and standard addition method. They are both discussed based on the availability of standards, sample number, and matrix effects.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Key words

1 Introduction

Fruits are rich in various bioactive compounds and represent a valuable component of a healthy diet [1,2,3]. They are consumed in natura and used in ice-creams, candies, desserts, jams, marmalades, and other fruit preserves. In addition, there has been an increased interest in using by-products from fruit processing as natural additives to improve the quality of food products. In this sense, their use as a functional food and as carriers for nutrients has attracted the attention of food scientists [4]. This interest is due to the biological activities that compounds in fruits have in the human body, such as decreases in total cholesterol, high-density lipoprotein cholesterol, low-density lipoprotein cholesterol, tumor initiation/promotion, platelet aggregation, and eicosanoid synthesis. Antioxidant and antimutagenic activities are also related to the bioactive compounds contained in fruits; although they occur in small quantities and vary widely in chemical structure and function [1,2,3, 5,6,7,8]. In fruits, phenolic molecules are reported as the main bioactive compounds responsible for providing a number of health benefits [3].

Phenolic compounds are characterized by the presence of at least one aromatic ring with one or more hydroxyl functional groups attached. As a result, they can vary from simple phenolic acids to complex oligomers such as procyanidins and condensed tannins. Phenolic compounds can be classified regarding their water solubility or in two main groups, flavonoids and non-flavonoids, which are then divided into subgroups. In the group containing the non-flavonoids, phenolic acid is the most important subgroup of phytochemicals in fruits. Phenolic acids are essentially derivatives of benzoic and cinnamic acids. Flavonoids can be classified into seven subgroups: flavonols, flavones, isoflavones, flavanones, anthocyanidins, flavanonols, and flavanol [3, 9]. The phenolic composition in fruits varies considerably, with a special contribution of flavonols, flavan-3-ols, anthocyanins, and hydroxycinnamic and hydroxybenzoic acids [3]. Additionally, phenolic compounds can exist in their glycosylated forms or esterified with gallic acid, as epigallocatechin [3, 9]. The structural diversity of phenolic compounds associated with their low concentrations and complexity of food matrices are reasons for requiring sensitive and selective techniques for both qualitative and quantitative analyses [10].

Most analytical methods for determining phenolic compounds are based on liquid chromatography with detection based on spectrophotometric and/or mass spectrometric techniques. Several configurations are reported for liquid chromatography coupled to mass spectrometry, including the most recent developments in both techniques [3, 10]. Regarding the separation technique, the conventional high performance liquid chromatography (usually with columns with particle size of 5 μm) has been enhanced to become ultra-high performance liquid chromatography (columns with particle size lower than 2 μm). Improved resolution, higher peak efficiency, shorter retention times, narrower peaks, lower detection/quantification limits, and reduced solvent consumption are considered the main advantages of using sub-2 µm columns. Regarding mass spectrometry, single low-resolution analyzers have been replaced to tandem and/or high-resolution instruments. Tandem mass spectrometry using a triple quadrupole is mostly used for quantitative purposes. Improved selectivity and signal-to-noise ratio, lower detection/quantification limits, and the variety of experiments are considered the main advantages of triple quadrupole tandem mass spectrometry [10].

Methods for determining phenolic compounds in fruits usually require steps such as lyophilization, extraction, purification, analysis, and quantification. Usually, the freeze-dried powder is subjected to solid–liquid extraction, which can be assisted by ultrasound or microwaves [9, 11, 12]. The extraction of phenolic compounds has been performed using different solvents, with a mixture of ethanol: water (80:20, v/v) being considered a good composition for obtaining phenolic acids and flavonoids. Depending on the matrix, a purification step is carried out via solid phase extraction (SPE) using a variety of adsorbents and sizes [9, 13, 14]. In general, C18 adsorbents present good recoveries for flavonoids, whereas the polymeric ones give good results for both flavonoids and phenolic acids. Chromatographic separation is predominantly carried out in reversed-phase mode (C18 columns) using acidified water and organic solvent (methanol or acetonitrile) as phases A and B, respectively [3, 10]. Electrospray ionization (ESI) in the negative ion mode is the most common choice for both flavonoids and phenolic acids. For quantitative purposes, using triple quadrupole, selected reaction monitoring (SRM) is preferable [10, 15]. Quantification of phenolic compounds in fruits has been performed using different strategies. Like for other complex matrices, standard addition and internal standard methods are preferable to the external calibration method [10].

In this chapter, we describe a protocol for determining phenolic compounds in fruits using LC-MS /MS. In detail, we present the steps of sample preparation, optimization of spectrometric parameters, analysis and quantification.

2 Materials

2.1 Equipment

-

1.

Analytical balance.

-

2.

Centrifuge.

-

3.

Lyophilizer.

-

4.

Vortex mixer.

-

5.

Water purification system.

-

6.

Ultrasonic bath or microwave system.

-

7.

Nitrogen gas evaporator (see Note 1).

-

8.

Liquid chromatograph coupled to a tandem mass spectrometer with its own pump and gas supply (see Note 2).

-

9.

Single syringe infusion pump.

2.2 Supplies and Chromatography Accessories

-

1.

Glass centrifuge tube (see Note 3).

-

2.

Glass syringe (see Note 3).

-

3.

Glass vials (2.0 mL) with Teflon cap for chromatographic analysis.

-

4.

Volumetric glass flasks (see Note 3).

-

5.

Glass Pasteur pipettes (see Note 3).

-

6.

Vacuum filtration system (47 mm, 300 mL funnel, 1000 mL receiving flask).

-

7.

Vacuum manifold for SPE .

-

8.

Micropipettes and tips.

-

9.

Membrane filters of 0.2 μm (see Note 4).

-

10.

Syringe filters of 0.22 or 0.45 μm (see Note 4).

-

11.

C18 column (see Note 5).

-

12.

SPE cartridges (see Note 6).

2.3 Chemicals, Solvents, and Gases

-

1.

Standards of antioxidant compounds, such as phenolic acids (hydroxycinnamic and hydroxybenzoic acids) and flavonoids (flavonols, flavanones, flavan-3-ols, and flavones) (see Table 1 and Note 7).

-

2.

Isotope-labeled internal standards, at least one for the phenolic acids and another for the flavonoids (see Note 7).

-

3.

Acetonitrile (ACN, LC-MS grade), methanol (MeOH, LC-MS grade), ethanol (EtOH, LC-MS grade), and formic acid (FA, LC-MS grade).

-

4.

Ultrapure water with resistivity of 18.2 MΩ.cm.

-

5.

Nitrogen gas for drying extracts.

2.4 Standard Solutions and Mobile Phase

-

1.

Individual stock solutions: Each standard (analytes and internal standards) is individually dissolved in EtOH to prepare stock solutions at 1.0 mg/mL (see Note 8).

-

2.

Individual intermediate solutions: Each stock solution is diluted to yield an intermediate solution at 5.0 μg/mL (see Note 9).

-

3.

Working solutions: Individual solutions of 0.5 μg/mL (500 ng/mL) for optimization of instrumental parameters are prepared from intermediate solutions by diluting them ten times (see Note 10).

-

4.

Mixed solution A: Prepare one mixed solution at 5.0 μg/mL from all individual analyte solutions (see Note 9).

-

5.

Mixed solution B: Prepare one mixed solution at 5.0 μg/mL from all individual isotope-labeled standard solutions (see Note 9).

-

6.

Mixed solution C: Prepare one mixed solution at 0.5 μg/mL from the mixed solution A by diluting it ten times (see Note 11).

-

7.

Calibration curve using the internal standard method: Prepare solutions of different concentrations of analytes and equal concentrations of internal standards. Suggested concentrations for analytes: 10, 25, 50, 75, 100, 250, 500, 750, and 1000 ng/mL. Suggested concentration for internal standards: 500 ng/mL. Table 2 shows mixing volumes for calibration curve solutions (see Note 12). Calibration curve using the standard addition method is discussed below.

-

8.

Mobile phase A: Water acidified with FA (0.1%, v/v) (see Note 13).

-

9.

Mobile phase B: MeOH.

-

10.

Wash solvent: MeOH.

-

11.

Seal wash solvent: MeOH.

2.5 Samples

-

1.

Fruits of interest may be purchased in supermarkets, open air markets, from street vendors, or may be collected directly from a tree that grows naturally or in orchards. This protocol can also be applied to fruit juices though with slight modifications.

3 Methods

3.1 LC-MS/MS Analysis

-

1.

Each individual solution at 500 ng/mL is injected into a mass spectrometer using a syringe pump at a flow rate of 5.0 μL/min (see Note 14).

-

2.

First, identify the m/z value for the precursor ion [M − H]− in the full scan spectrum obtained in the negative ion mode (see Note 15). Table 1 lists such values for common antioxidant compounds.

-

3.

Once the precursor ion has been visualized, change the operation mode to product ion scan experiment and identify the major fragments for each compound (see Note 15). Table 1 lists the values for common antioxidant compounds.

-

4.

Change the operation mode to SRM (MRM, multiple reaction monitoring, in some software), set at least two transitions (precursor ion > product ion) for each compound and optimize them regarding CE and other voltages (see Note 16). Table 1 lists two possible transitions for common antioxidant compounds.

-

5.

Once the previous steps have been done for all compounds, the transitions and their respective parameters are put together in a single method file. Additionally, the syringe pump is disconnected from the mass spectrometer, and an LC system is coupled to it.

-

6.

Set the ESI parameters as suggested by the user’s manual for the flow rate used (see Note 17).

-

7.

Connect a C18 column and use water acidified with FA (0.1%, v/v) as mobile phase A and MeOH as mobile phase B (see Note 13).

-

8.

Set the LC gradient profile as follows: 0–1 min (5% B), 1–4 min (5–60% B), 4–7 min (60–70% B), 7–10 min (70–100% B), 10–12 min (100% B), 12–13 min (100–5% B), 13–15 min (5% B) (see Note 18).

-

9.

Other LC parameters, such as flow rate (0.45 mL/min) and injection volume (5.0 μL), need to be set.

-

10.

Put vials containing the blank and individual standard solutions into the autosampler chamber, and run them to verify retention time, peak shape, and purity of compounds (see Note 19).

-

11.

Put vials containing the blank, mixed standard solutions and samples into the autosampler chamber and run them to construct calibration curves and quantify the analytes in the fruits.

3.2 Sample Preparation

3.2.1 Extraction

-

1.

Wash fruits with water to eliminate contaminants and dust.

-

2.

Weigh the fruits before removing any parts or before lyophilization.

-

3.

Seed and peel may be removed depending on the species and the study objectives. Cut the fruits or use a food processor/blender to obtain small pieces. Then, freeze the material in a proper recipient to lyophilizing it at a later time.

-

4.

Lyophilize the pieces of fruits (whole or pulp) while protecting them from light using aluminum foil.

-

5.

Weigh the freeze-dried fruits and calculate the percentage of water.

-

6.

Macerate the freeze-dried powder in a pistil and mortar.

-

7.

Place about 1.0 g of freeze-dried fruit in a glass tube (see Note 20).

-

8.

For quantification purposes using the internal standard method, they are added into fruit samples before the extraction procedure. Surrogate solution (mixed solution B with internal standards at 5.0 μg/mL; 100 μL) is added to the freeze-dried fruit before extraction. Alternatively, the analyst may choose the method of standard addition for quantification purposes. In this case, several extractions are done using fruit samples spiked with different quantities of analytes, as shown in Table 3 (see Notes 7 and 21).

-

9.

Add 5.0 mL of an EtOH/water solution (80:20, v/v) to the freeze-dried extract, and then the mixture is mixed in a vortexer (see Note 22).

-

10.

The mixture is subjected to extraction of the antioxidant compounds, which may be assisted by microwaves or ultrasound (see Note 23).

-

11.

After releasing the phenolic compounds from the solid matrix, the mixture is centrifuged at 2264 × g for 5 min.

-

12.

Collect the supernatant with a glass Pasteur pipette and transfer it to a glass tube. Repeat extraction following the procedure previously described.

-

13.

Supernatants are pooled and the solvent evaporated with a gentle stream of nitrogen gas to eliminate EtOH, and then lyophilized (see Note 24). Weigh the dried extract.

-

14.

The raw extract without purification may be analyzed. In addition, a clean-up step using SPE cartridges (C18 or polymeric adsorbents) may improve quantitative results (see Note 25).

-

15.

For instrumental analysis, redissolve the dried extract with 200 µL of MeOH, add 800 µL de water and, then filter it through a 0.22 or 0.45 μm filter to remove particles before injection.

-

16.

Transfer the filtered sample solution to glass vials (2.0 mL) and proceed to LC-MS/MS analysis. Occasionally, the concentrations of some compounds in the extract solution may be too high (outside of calibration curve range), thus dilution needs to be carried out.

3.3 Data Processing

Figure 1 shows the total ion chromatogram (TIC) and the extracted ion chromatogram (XIC) for an antioxidant compound (bergenin).

-

1.

For standard solutions, identify each analyte and internal standard by referring to the transitions and retention times of the standards (see Fig. 1 and Table 1).

-

2.

For samples, identify each analyte by comparing its retention time and transitions to those of the standards (see Note 26).

-

3.

Follow instructions 4–6 and 7–8 for internal standard and standard addition methods, respectively.

-

4.

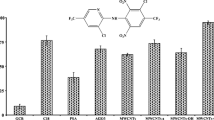

Internal standard method: Integrate the peak for each analyte and internal standard in the solutions with different concentrations in order to construct calibration curve (see Fig. 2 and Table 2).

-

5.

Internal standard method: Construct the calibration curve by plotting the ratio of the analyte signal to the internal standard signal as a function of the analyte standard concentration. The curve equation is used to calculate the analyte concentration in unknown samples (see Note 27, see Fig. 2 and Table 2).

-

6.

Internal standard method: Integrate the peak for each analyte and internal standard in the sample solutions and calculate the ratio of the analyte signal to the internal standard signal. This ratio is considered the y of the curve equation to find the analyte concentration (see Fig. 2 and Table 2).

-

7.

Standard addition method: Integrate the peak for each analyte in the solutions from extractions with different additions of the standards (see Fig. 3 and Table 3).

-

8.

Standard addition method: Construct the calibration curve by plotting the analyte signal as a function of the concentration added to the sample. The x-intercept gives the concentration of the analyte in the sample without spiking the standards (see Note 28, see Fig. 3 and Table 3).

-

9.

Consider the appropriate calculations and/or dilutions to express concentration of the analyte as I) mass/mass of extract, II) mass/mass of dried fruit, III) mass/mass of fresh fruit (see Note 29).

4 Notes

-

1.

A nitrogen gas evaporator may be a homemade one made with a glass Pasteur pipette coupled to a hose and a support to fix tubes containing samples.

-

2.

Herein, demonstrations were based on results obtained using an 1200 Series HPLC system with a quaternary pump (Agilent Technologies, Santa Clara, USA) coupled to a 4000 Q-Trap system (Applied Biosystems Sciex, Foster City, USA) with an ESI source. Data acquisition and processing were executed using Analyst 1.6.3 (Applied Biosystems Sciex, Foster City, USA).

-

3.

Solvent may leach compounds out of ordinary plastic tubes, thus contaminating samples and resulting in high noise baseline. Therefore, glass tubes or plastic of high quality should be used.

-

4.

Membrane and syringe filters of nylon, PTFE (hydrophobic and hydrophilic) or PVDF. For columns with a particle size lower than 3 μm, 0.22 μm filters are preferable.

-

5.

Herein, a Kinetex C18 column (particle size of 2.6 μm, length of 50 mm, and internal diameter of 2.1 mm) (Phenomenex, Aschaffenburg, Germany) was used. If possible, choose a C18 end-capped column with particle size lower than 3 μm.

-

6.

SPE cartridges (C18 or polymeric adsorbents) may be used in a clean-up step. Usually, C18 provides good recoveries for flavonoid aglycones, whereas adsorbents based on polystyrene-divinylbenzene-N-vinylpyrrolidone copolymers yield good recoveries for both phenolic acids and flavonoids. Cartridges of 200 mg are typically used.

-

7.

Other similar compounds (phenolic acids, flavonoids—aglycones, and glycosylated and esterified derivatives) may be included in the method. Ideally, an isotope-labeled internal standard should be used for each analyte, which is often impossible. Instead, one isotope-labeled internal standard may be used for each compound class for evaluating recovery. Another possibility is using one of the available compounds as internal standard. Its absence in the sample is indispensable. Thus, a preliminary analysis of the sample without any addition is done. The compounds that were not detected in that previous analysis may be chosen as internal standards for the following ones. In addition, the analyst may choose not to use any internal standard and quantify compounds using the standard addition method (see Note 21).

-

8.

For instance, a mass of 10 mg of the standard is weighed and transferred to a 10 mL volumetric glass flask, which is then completed with solvent up to the volumetric mark to obtain a concentration of 1.0 mg/mL. For the isotope-labeled internal standards, a quantity of 1.0 mg is usually available for purchase. Some flavonoid aglycone standards are difficult to dissolve in EtOH. Therefore, a minimum amount of a less polar solvent is required to dissolve the solid before the addition of EtOH. Store all solutions at −20 °C to avoid photolysis, oxidation, and solvent evaporation.

-

9.

Use the dilution equation (C1V1 = C2V2), where C1 is the initial concentration, V1 is the initial volume, C2 is the final concentration, and V2 is the final volume. For instance, an aliquot of 25 μL of the stock solution is transferred to a 5.0 mL volumetric flask, then it is completed with MeOH up to the volumetric mark to yield a concentration of 5.0 μg/mL.

-

10.

Use the dilution equation again. For instance, an aliquot of 100 μL of the intermediate solution is transferred to a 2.0 mL glass vial. Add 900 μL of MeOH to yield a concentration of 0.5 μg/mL. This solution volume is usually enough to optimize instrumental parameters. Depending on equipment sensitivity and molecule ionization efficiency, a more diluted solution may be required.

-

11.

Transfer an aliquot of 500 μL of the mixed solution A to a 5.0 mL volumetric flask, and then complete it with MeOH up to the volumetric mark to yield a concentration of 0.5 μg/mL.

-

12.

Considering C1 as the concentration of the mixed solution A or C and V2 of 1.0 mL, use the dilution equation to calculate V1, which is the aliquot needed to prepare solutions with C2 of 10, 25, 50, 75, 100, 250, 500, 750, and 1000 ng/mL. Table 2 shows the mixing volumes of the calibration curve solutions. Such a wide range of concentration is due to the high variability of the concentrations found for phenolic compounds in fruits.

-

13.

Preparation of the mobile phase A: Measure out 999 mL of ultrapure water and transfer it to a glass bottle. Add 1 mL of FA to it. Prepare a fresh mobile phase before use. Filter it through 0.2 or 0.45 μm membrane filter using a vacuum system and, then degas it in ultrasonic bath for 10 min. Use inline filters in HPLC solvent bottles.

-

14.

MS/MS optimization is individually carried out for each compound from the working solution of 500 ng/mL. Depending on equipment sensitivity and molecule ionization efficiency, a more diluted solution may be required. Optimization from the individual standard is recommended because there are analytes that have the same molecular mass. In addition, the fragmentation of phenolic compounds is very similar, and this may occur in the source, creating several possibilities of interferences. Before starting the optimization, make sure the mass analyzers are calibrated.

-

15.

Using a syringe pump with a flow rate of 5.0 μL/min, source parameters may be set as suggested by the equipment user manual. Herein, the following ESI parameters were set in the negative ion mode: ion spray voltage at 4.0 kV, nebulizer gas at 20 psi, and curtain gas at 10 psi. For full scan experiments, set a scan range of mass at m/z 100 to 700 (or according to analyte mass). For product ion scan experiments, set the m/z of the precursor ion in the first mass analyzer and set a scan range of mass in the third one—from m/z 50 to a value that ensures that you see [M − H]− in the spectrum. Additionally, vary collision energy (CE) automatically or manually to ensure a proper spectrum—low intensity for the precursor ion and high intensity for the product ions.

-

16.

It is strongly recommended that more than one precursor ion > product ion transition is monitored to demonstrate the specificity of the quantitative analysis. If it is possible, choose product ions that are not derived from common losses, such as CO2 and H2O. At the same time, choose the most abundant product ions. If in doubt, set more than two transitions in order to decide afterwards which one will be discharged. Automatically or manually optimize the MS voltages as CE, CXP, DP, and EP. The election of the quantifier and qualifier transitions is based on their intensity. Usually, the highest one is elected as the quantifier transition.

-

17.

When the MS is connected to the LC, source parameters need to be adjusted for the new flow rate. Because the optimum values differ for each equipment, optimization of the source parameters must be done. At first, preliminary analyses can be done using values suggested in the equipment user manual. Herein, the following MS parameters were set in the negative ion mode: ion spray voltage at 4.0 kV, heater gas at 40 psi, nebulizer gas at 45 psi, curtain gas at 12 psi, and ion spray temperature at 550 °C.

-

18.

Some adjustment in the elution gradient may be required depending on the column used. The chromatographic method should contain washing and equilibration steps to ensure reproducibility of the next runs in the same sequence. When working on the reversed-phase mode, the phenolic compounds are eluted according to molecule polarity and size. Thus, phenolic acids commonly elute before flavonoid aglycones. Table 1 shows the retention times of analytes under the chromatographic conditions described herein. It is not necessary that all compounds be completely separated, except those with the same precursor and product ions such as the protocatechuic/gentisic acids, (+)-catechin/(−)-epicatechin, kaempferol/luteolin, and hesperidin/quercetin pairs.

-

19.

Purge each device to ensure air bubbles have been removed from the pipeline before analysis. Then, download the method parameters and ensure the column is well equilibrated before analysis of the standard solutions or samples. Run some blank injections to ensure a stable baseline and reproducible retention times.

-

20.

Ideally, the phenolic compounds should be immediately extracted after lyophilization. Similarly, the chromatographic analyses should be done immediately after extraction. If this is not possible, the freeze-dried extract must be stored at −20 °C to avoid photolysis and oxidation.

-

21.

The choice between internal standard and standard addition methods is based on the availability of isotope-labeled standards, sample matrix, and the number of samples. For studies with one or few samples, the standard addition method is an attractive option to correct matrix effects and for obtaining proper quantification. If this quantification method is chosen, extractions are done from fruit samples spiked with different quantities of analytes. Furthermore, it is necessary to analyze the non-spiked sample to determine the original concentrations of analytes. Thus, 0, 20, 50, 75, 100, 125, 150, and 200 μL of mixed solution C with analytes at 0.5 μg/mL are added to the freeze-dried fruit before extraction.

-

22.

The analyst may choose other values for fruit mass and solvent volume. Consider the proportion of 5 mL/g of freeze-dried fruit.

-

23.

For ultrasound-assisted extraction, use a frequency of 20–40 kHz at 40 °C for 15 min, protect the mixture from the light with aluminum foil. For microwave-assisted extraction, use a power level of 100 W at 40 °C for 15 min.

-

24.

Regulate the pressure of the gas cylinder to avoid losses of compounds caused by solution splashing.

-

25.

Similar concentrations of phenolic compounds are found for raw and purified extracts in some fruits. However, raw extracts for some fruits show a relevant matrix effect. In this case, a clean-up using SPE cartridges may help to eliminate interferences. Usually, C18 provides good recoveries for flavonoid aglycones, whereas polymeric adsorbents yield good recoveries for both phenolic acids and flavonoids. It is important to check the general instructions provided by the supplier for the conditioning and equilibration steps. Herein, we described a protocol for a clean-up using a 200 mg cartridge with a sorbent based on polystyrene-divinylbenzene-N-vinylpyrrolidone copolymers. The cartridge is first conditioned by rinsing it with 3 mL of methanol and is equilibrated with 3 mL of water acidified with FA (0.1%, v/v). The extract (redissolved in a minimum amount of MeOH (≈250 μL) and diluted in 5 mL of water acidified with FA) is loaded in the cartridge. Then, it is washed with 3 mL of water acidified with FA to remove sugars and other polar interferences. The retained phenolic compounds are eluted with 5 mL of MeOH. The extract is evaporated to dryness with a gentle stream of nitrogen gas until dry.

-

26.

It is important to verify the ratio for the transitions monitored for confirming the identity of phenolic compounds. Thus, compare the peak area ratio between the transitions (Aqualifier transition/Aquantifier transition) found in sample with that observed in the standard solution. Considering that fragmentation in tandem instruments is highly reproducible, a substantial change in this ratio indicates chemical interference in at least one of the transitions.

-

27.

The calibration curve based on the internal standard method yields a model described by the following mathematical equation: y = a + bx, where y is the instrument response (peak area), b represents the slope (sensitivity), a is the intercept (background), and x represents the corresponding concentration (see Fig. 1).

-

28.

The calibration curve based on standard addition method yields a model described by the following mathematical equation: y = a + bx. The point at x = 0 is the reading of the sample without the addition of standards (original concentration), whereas the other points are the reading after spiking increasing quantities of standards. Thus, the value on the x-axis at which y = 0, x-intercept, is the concentration of analyte in the sample without spiking (see Fig. 2).

-

29.

The x-value found using the curve equation is the concentration of analyte in the vial (analyzed solution). If any dilution was done, use the following equation: \( {C}_{\mathrm{concentrated}\ \mathrm{extract}}={C}_{\mathrm{diluted}\ \mathrm{extract}}\times \frac{V_f}{V_i} \), where volume ratio is the dilution factor used. If no dilution was done, the concentration obtained using calibration curve is equal to the concentration of extract solution. For expressing concentration in analyte mass/extract mass, use the following equation: \( {C}_{\mathrm{analyte}/\mathrm{extract}\ \mathrm{mass}}={C}_{\mathrm{extract}\ \mathrm{solution}}\times \frac{V_{\mathrm{solution}}}{m_{\mathrm{extract}}} \), where mextract is the mass of extract and Vsolution is the volume of solvent used for redissolving it. For expressing the concentration in analyte mass/dried fruit mass, use the following equation: \( {C}_{\mathrm{analyte}/\mathrm{dried}\ \mathrm{fruit}\ \mathrm{mass}}={C}_{\mathrm{analyte}/\mathrm{extract}\ \mathrm{mass}}\times \frac{m_{\mathrm{extract}}}{m_{\mathrm{dried}\ \mathrm{fruit}}} \), where mextract is the mass of extract obtained after extraction from a certain mass of dried fruit (mdried fruit). For expressing the concentration in analyte mass/fresh fruit mass, use the following equation: \( {C}_{\mathrm{analyte}/\mathrm{fresh}\ \mathrm{fruit}\ \mathrm{mass}}={C}_{\mathrm{analyte}/\mathrm{dried}\ \mathrm{fruit}\ \mathrm{mass}}\times \frac{m_{\mathrm{dried}\ \mathrm{fruit}}}{m_{\mathrm{fresh}\ \mathrm{fruit}}}, \) where mdried fruit is the mass of material obtained after lyophilization of a certain mass of fresh fruit (mfresh fruit).

References

Heleno SA, Martins A, Queiroz MJRP, Ferreira ICFR (2015) Bioactivity of phenolic acids: metabolites versus parent compounds: a review. Food Chem 173:501–513. https://doi.org/10.1016/j.foodchem.2014.10.057

Sun C et al (2020) Anti-diabetic effects of natural antioxidants from fruits. Trends Food Sci Technol. https://doi.org/10.1016/j.tifs.2020.07.024

Haminiuk CWI, Maciel GM, Plata-Oviedo MSV, Peralta RM (2012) Phenolic compounds in fruits—an overview. Int J Food Sci Technol 47:2023–2044. https://doi.org/10.1111/j.1365-2621.2012.03067.x

Majerska J, Michalska A, Figiel A (2019) A review of new directions in managing fruit and vegetable processing by-products. Trends Food Sci Technol 88:207–219. https://doi.org/10.1016/j.tifs.2019.03.021

Kris-Etherton PM et al (2002) Bioactive compounds in foods: their role in the prevention of cardiovascular disease and cancer. Am J Med 113:71–88. https://doi.org/10.1016/S0002-9343(01)00995-0

Ahangarpour A, Sayahi M, Sayahi M (2019) The antidiabetic and antioxidant properties of some phenolic phytochemicals: a review study. Diabetes Metab Syndr Clin Res Rev 13:854–857. https://doi.org/10.1016/j.dsx.2018.11.051

Pap N et al (2021) Berry polyphenols and human health: evidence of antioxidant, anti-inflammatory, microbiota modulation, and cell-protecting effects. Curr Opin Food Sci. https://doi.org/10.1016/j.cofs.2021.06.003

Roleira FMF et al (2015) Plant derived and dietary phenolic antioxidants: anticancer properties. Food Chem 183:235–258. https://doi.org/10.1016/j.foodchem.2015.03.039

Alara OR, Abdurahman NH, Ukaegbu CI (2021) Extraction of phenolic compounds: a review. Curr Res Food Sci 4:200–214. https://doi.org/10.1016/j.crfs.2021.03.011

Motilva MJ, Serra A, Macià A (2013) Analysis of food polyphenols by ultra high-performance liquid chromatography coupled to mass spectrometry: an overview. J Chromatogr A 1292:66–82. https://doi.org/10.1016/j.chroma.2013.01.012

Kumar K, Srivastav S, Sharanagat VS (2021) Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing by-products: a review. Ultrason Sonochem 70:105325. https://doi.org/10.1016/j.ultsonch.2020.105325

Dzah CS et al (2020) The effects of ultrasound assisted extraction on yield, antioxidant, anticancer and antimicrobial activity of polyphenol extracts: a review. Food Biosci 35:100547. https://doi.org/10.1016/j.fbio.2020.100547

Antolovich M, Prenzler P, Robards K, Ryan D (2000) Sample preparation in the determination of phenolic compounds in fruits. Analyst 125:989–1009. https://doi.org/10.1039/B000080I

Ćirić A, Prosen H, Jelikić-Stankov M, Durević P (2012) Evaluation of matrix effect in determination of some bioflavonoids in food samples by LC-MS/MS method. Talanta 99:780–790. https://doi.org/10.1016/j.talanta.2012.07.025

Bataglion GA, Da Silva FMA, Eberlin MN, Koolen HHF (2015) Determination of the phenolic composition from Brazilian tropical fruits by UHPLC-MS/MS. Food Chem 180:280–287. https://doi.org/10.1016/j.foodchem.2015.02.059

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Science+Business Media, LLC, part of Springer Nature

About this chapter

Cite this chapter

Bataglion, G.A. (2022). Quantitative Determination of Antioxidant Compounds in Fruits Using Liquid Chromatography Tandem Mass Spectrometry. In: Koolen, H. (eds) Mass Spectrometry for Food Analysis. Methods and Protocols in Food Science . Humana, New York, NY. https://doi.org/10.1007/978-1-0716-2107-3_5

Download citation

DOI: https://doi.org/10.1007/978-1-0716-2107-3_5

Published:

Publisher Name: Humana, New York, NY

Print ISBN: 978-1-0716-2106-6

Online ISBN: 978-1-0716-2107-3

eBook Packages: Springer Protocols