Abstract

This study presents a method validation procedure for the determination of aflatoxin B1, B2, G1, and G2 in hazelnut, hazelnut paste, walnut, peanut, pistachio, corn, and wheat. The method consisting of clean-up with immunoaffinity column, high performance liquid chromatography with postcolumn derivatization and fluorescence detection was validated in accordance with Commission Regulation 2004/882/EC. The selectivity, linearity, decision limit, detection capability, detection and quantification limits, precision, recovery, ruggedness, and measurement uncertainty of the method were determined. The limit of detection and limit of quantification values (μg/kg) were: aflatoxin B1, 0.02, 0.07; aflatoxin B2, 0.01, 0.02; aflatoxin G1, 0.02, 0.07; and aflatoxin G2, 0.01, 0.03. The relative standard deviation values for the repeatability and within-laboratory reproducibility were below 4 and 5 %, respectively. The recovery values of the spiked samples ranged from 80 to 105 %. These results complied with minimum performance criteria established by regulation 2006/401/EC. Therefore, the procedure can be implemented for the routine analysis of aflatoxins in the studied matrices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Aflatoxins (AFs), difuranocoumarin derivatives, are produced by fungi, Aspergillus flavus, Aspergillus parasiticus, and the rare Aspergillus nomius (Juan et al. 2008). Twenty aflatoxins have been identified, and the most of them are metabolites formed endogenously in animals. Aflatoxin B1, B2, G1, and G2 (AFB1, AFB2, AFG1,and AFG2) are the main AFs occurring naturally in foods and feeds, and AFB1 is the most common and most toxic form. Aflatoxin B1, B2, G1, and G2 are named for their fluorescence characteristics. Aflatoxin B1 and B2 show strong blue fluorescence under UV light, whereas aflatoxin G1 and G2 exhibit greenish yellow fluorescence (Wogan and Busby 1980). AFB2 and AFG2, the dihydroxy derivatives of AFB1 and AFG1, respectively, are biologically inactive until they are oxidized to AFB1 and AFG1 in vivo.

Aflatoxins have been classified as carcinogenic compounds to human. AFB1 has been classified as group 1 of human carcinogens (IARC 1993). Highly toxic, immunosuppressive, mutagenic, and teratogenic effects of aflatoxins have been identified as well (Castells et al. 2008; Hussein and Jeffrey 2001). Moreover, malabsorption syndrome and decrease in bone strength may occur owing to AFs consumption (Nelson et al. 1982). Aflatoxins not only have adverse effects on human health but also cause serious economic losses.

The level of aflatoxins in corn, cereals, sorghum, peanut, hazelnut, walnut, pistachio, corn, and other oil seed crops contaminated by aflatoxins varies with respect to region. Tropical and subtropical region are more convenient for mold growth and toxin production. From previous surveys, about 19 % of peanut samples (n = 1416) were found to be contaminated with an average value of 1 μg/kg AFB1 (Stoloff 1977) in North America, whereas in Thailand, about 49 % of peanut samples (n = 216) were contaminated with an average value of 424 μg/kg AFB1 (Shank et al. 1972).

To ensure food safety, the maximum level of aflatoxin in foods has been set by international organizations. European Commission Regulation 2010/165/EC established limits for AFB1 and total AFs of 8 and 15 μg/kg, respectively, in hazelnuts, Brazil nuts, groundnuts and other oilseeds, to be subjected to sorting or other physical treatment before human consumption or use as ingredient in foodstuffs. The legal limit of AFB1 and total AFs in groundnuts and other oilseeds intended for human consumption are 2 and 4 μg/kg, while in hazelnut and Brazil nuts are 5 and 10 μg/kg, respectively (Codex 2006 & EC 165/2010). In Turkey, the maximum level of AFB1 and total AFs in dried fruit, hazelnut, pistachio, peanut, oil seeds and processed foods were 5 and 10 μg/kg, respectively (TFC 2002). Each country has established its legal limits.

Several methods have been developed to determine AFs in foods; immunoassays techniques (Lee et al. 2004; Li et al. 2001), capillary electrophoresis (Pena et al. 2002), thin layer chromatography (Braicu et al. 2008; Abbas 2005), and high performance liquid chromatography (HPLC) with fluorescence detection (Bacaloni, et al. 2008). Recently, analytical methods based on clean-up with immunoaffinity column and HPLC with postcolumn derivatization and fluorescence detection have gained much attention for the determination of AFs in food matrices. Although several studies have been reported to determine AFs in foods by using these methods (Asis et al. 2002; Daradimos et al. 2000; Stroka et al. 2000), only few validation studies are available which comply with regulation 2004/882/EC and 2006/401/EC (Muscarella et al. 2007; Tavcar-Kalcher et al. 2007).

The aim of this study was to develop a fast, economical, precise, and reliable method for aflatoxin analysis in hazelnut, hazelnut paste, walnut, peanut, pistachio, corn, and wheat. The proposed method consisting of clean-up with immunoaffinity column and HPLC with postcolumn derivatization and fluorescence detection was validated according to the Commission Regulation 2004/882/EC in terms of selectivity, linearity, decision limit, detection capability, detection and quantification limits, precision, recovery, ruggedness, and measurement uncertainty.

Experimental

Samples

Representative samples of hazelnut, hazelnut paste, walnut, peanut, pistachio, corn, and wheat were collected from importer and exporter companies in Trabzon, and sampling was performed according to the sampling method in Turkish food codex (TFC 2007). Each sample was from 10 to 30 kg transferred into polyethylene bags and stored at 20 ± 5 °C. The samples were grounded by using a laboratory grinder (Robout Coupe, R23 grinder) and subsamples were transferred in plastic bags and stored at −5 °C until analysis. To prove homogeneous samples, a homogeneity test was applied (Baltacı et al. 2009).

Chemicals and Reagents

All reagents used were analytical or HPLC grade. Supelco aflatoxin standard solution consisting of 1.0 μg/mL AFB1, 0.3 μg/mL AFB2, 1.0 μg/mL AFG1, and 0.3 μg/mL AFG2 were obtained from Sigma–Aldrich (St. Louis, MO, USA, catalog number : 46304-U). Stock standard solutions (1 μg/mL AFB1, 0.3 μg/mL AFB2, 1 μg/mL AFG1, and 0.3 μg/mL AFG2) and working standard solutions (0.726, 1.450, 2.180, 2.910, 3.630 μg/L for AFB1, 0.216, 0.432, 0.648, 0.864, and 1.080 μg/L, for AFB2; 0,720, 1.440, 2.160, 2.880, and 3.600 μg/L for AFG1; 0.223, 0.446, 0.670, 0.893, and 1.112 μg/L for AFG2) of AFs were prepared in methanol and stored at −20 °C in amber glass vials. HPLC-grade methanol and acetonitrile were supplied from JT Baker (JT. Baker BV, Netherlands). Analytical grade potassium bromide, nitric acid, and sodium chloride were supplied from Sigma–Aldrich (St. Louis, MO, USA). Immunoaffinity columns were obtained from Romer Labs (Romer Labs Diagnostic, Tulln, Austria). Calibrated equipments were used for analysis.

Apparatus

Robot Coupe laboratory grinder (Robot Coupe, R23, USA) and Waring laboratory blender (Waring, Torrington, USA) were used for the extraction. Quantitative analysis was performed on a HPLC system (Shimadzu, Japan) equipped with a system controller CBM-20A, a solvent delivery unit LC-20 AD, a gradient system LC-20AB, an on-line degasser DGU-20A3, an autosampler SIL-20A, a column oven SPD-20A, a scanning fluorescence detector RF-10 AXL, a symmetry ACE C18 column (150 × 4 mm, 5 μm, Advanced Chromatography Technologies, Aberdeen, Scotland), and a Kobra cell (R-Biopharm, Glasgow, Scotland) for postcolumn derivatization. OQ-PV test of the HPLC system was performed by Shimadzu technical service.

Sample Extraction and Cleanup

First, 25 g representative subsamples were weighed into a blender chamber and 5 g NaCl and 125 ml of 70 % methanol (AOAC 991.31) were added to the chamber. After the mixture was blended for 2 min at high speed, the extract was filtered through a filter paper (Schleicher&Schwel, ∅240 mm, Dassel, Germany). An aliquot of 5 ml of the filtrate was applied onto immunoaffinity column by using a syringe containing 10 ml of deionized water, and the filtrate was passed through column at a flow rate of 3 ml/min. The column was washed with 20 ml of deionized water at a flow rate of 5 ml/min, and then air was passed through a syringe at least three times. The aflatoxin bound to the column was eluted with 1 ml of methanol at a flow rate of 0.5 ml/min. Aflatoxins were collected into a flask (2.5 ml) and transferred in an amber glass vial.

HPLC Conditions

The isocratic mobile phase consisted of water, methanol, and acetonitrile (6:3:2) and 350 μl of 4 M HNO3 and 0.120 g of KBr were added to 1 L of the mobile phase. Flow rate was set at 1 ml/min and column temperature was 22 °C. Sample volume of 100 μl was injected in triplicate. The fluorescence detection was set to an excitation wavelength of 360 nm and an emission wavelength of 430 nm. Postcolumn derivatization with electrochemically generated bromine method was used to enhance fluorescence intensity of aflatoxin derivatives. Electrochemical cell supplying 100 μA electrical current was positioned between the column and fluorescence detector by using PTFE tube (30 cm).

Validation Procedure

Method validation procedure was carried out according to Commission Regulation 2004/882/EC. Twenty-one independent blank samples were analyzed to check the sensitivity of the method. Linearity was checked by analyzing standard solutions of aflatoxin B1, B2, G1, and G2 at five different concentrations. Calibration curves were constructed by plotting the peak area of each standard solution versus the concentration of standard solution. For the determination of LOD and LOQ, ten independent blank samples spiked with standard solutions of aflatoxins were analyzed. To determine detection limit (CCα) and detection capability (CCβ), twenty-one independent blank samples fortified with aflatoxins were prepared. Recovery and precision were determined by analyzing spiked samples at three different concentrations (2.5, 5, and 7.5 μg/kg) and 20.8, 41.6, and 62.4 μl of aflatoxin B1, B2, G1, and G2 (3 μg/ml) dissolved in benzene:acetonitrile (98:2) were added to 25 g of the samples, respectively. The homogenized samples were stored in the dark for 2 h, and the solvent was evaporated via nitrogen. Finally, the ruggedness of the method was tested. The spiked samples consisted of hazelnut (n:3), hazelnut paste (n:3), walnut (n:3), peanut (n:3), pistachio (n:3), corn (n:3) and wheat (n:3).

Statistical Analysis

Microsoft Excel statistical software (Microsoft Office Excel 2003, Microsoft Corp., Redmond, WA USA) was used for data processing. The Cochran test and the Grubbs test were performed to eliminate results with too high difference between triplicate measurements and outliers. The equation of calibration curve was determined by using least square regression analysis.

Results and Discussion

Method Performance Characteristics

Method validation was performed by conducting a single-laboratory study in accordance with the European Union Commission Regulation 2004/882/EC. Method performance characteristics determined were selectivity, linearity, detection and quantification limits, decision limit, detection capability, precision, recovery, ruggedness, and measurement uncertainty.

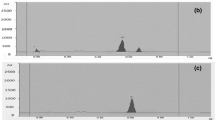

Selectivity

Selectivity is the degree to which a method can determine particular analyte without interferences from other components. Selectivity of an analytical method towards naturally present substances (metabolites, endogenous substances and matrix constituents, etc) has to be checked before proceeding with the validation procedure. To check the selectivity of the proposed method, the chromatograms of independent blank samples (n = 21) were compared with the chromatograms of blank samples fortified with aflatoxin B1, B2, G1, and G2 and naturally contaminated samples. The chromatograms obtained for spiked samples, blank samples, and standard mixture were presented in Fig. 1. No interferences at the retention time of each aflatoxin were observed in the studied matrices. From the chromatograms of a blank sample and a naturally contaminated sample, it is evident that the proposed method has the power of discrimination between the analyte and other matrix components.

Linearity

Calibration curves were constructed by plotting the peak areas of three series of standard solutions at five different concentrations (0.726, 1.450, 2.180, 2.910, and 3.630 μg/L for AFB1; 0.216, 0.432, 0.648, 0.864, and 1.080 μg/L, for AFB2; 0,720, 1.440, 2.160, 2.880, and 3.600 μg/L for AFG1; 0.223, 0.446, 0.670, 0.893, and 1.112 μg/L for AFG2). Least square regression analysis was applied to determine equation of each calibration graph. The equation describing the calibration curve was y = A(x) + B, where y is the peak area of standard solution expressed in fluorescence unit and x is the concentration of standard solution expressed in μg/L. The regression coefficient of each calibration graph was found to be higher than 0.999. The regression was tested by performing the F test at 95 % confidence level, and the linearity was obtained in the following ranges: 0.07–9.08 μg/kg for AFB1 in the samples, 0.02–2.70 μg/kg for AFB2 in the samples, 0.07–9.0 μg/kg for AFG1 in the samples, and 0.03–2.79 μg/kg for AFG2 in the samples, respectively. The retention time values (min) were 6.87, 8.35, 9.32, and 11.47 for AFG2, AFG1, AFB2, and AFB1, respectively, with relative standard deviation values of 0.5 % (repeatability) and 3.5 % (within-laboratory reproducibility).

Limit of Detection and Limit of Quantification

Ten blank samples fortified with AFB1 (0.074 μg/kg), AFB2 (0.023 μg/kg), AFG1 (0.070 μg/kg), and AFG2 (0.032 μg/kg) were analyzed to calculate the LOD and LOQ values of the method. The LOD and LOQ values were determined according to Analytical Detection Limit Guidance (ADLG 1996). For the estimation of LOD, the standard deviation of the response (s) was multiplied by the Student’s t test value for ten replicates and nine degrees of freedom. The estimated LOD values were verified in accordance with the guidance (ADLG 1996) as well. The LOQ values were calculated by ten times the standard deviation of the response.

The LOD values obtained for AFB1, AFB2, AFG12, and AFG2 were 0.02, 0.01, 0.02, and 0.01 μg/kg, respectively. The LOQ values were 0.07, 0.02, 0.07, and 0.03 μg/kg for AFB1, AFB2, AFG1, and AFG2, respectively.

Detection Limit and Detection Capability

Two new performance characteristics, CCα and CCβ, are introduced by Regulation 2002/657/EC (2002). While CCα refers to the limit above which samples are concluded to be non-compliant (α = 5 %), CCβ refers to the smallest content of the substances that may detected, identified and/or quantified in a sample (β = 5 %). The CCα and CCβ values were determined to analyze 21 blank samples fortified with aflatoxins at the maximum permitted limit (MRL) regulated by Turkish food codex. The CCα and CCβ values of the method estimated according to the following equations are presented in Table 1.

Precision and Accuracy

Precision was tested by analyzing ten blank samples fortified with aflatoxin B1, B2, G1, and G2 at the concentrations of 0.5, 1, and 1.5 times MRL. For the repeatability test, samples were prepared in six replicates and analyses were performed by the same operator in 1 day. To determine within-laboratory reproducibility, samples (six replicates) were analyzed by three different operators in 3 days over a month. The results for the repeatability expressed with the standard deviation (Sr) and the relative standard deviation (RSDr) and the results for the within-laboratory reproducibility expressed with the standard deviation (SR) and the relative standard deviation (RSDR) are presented in Table 2. Regulation 2006/401/EC declared that RSD values shall not exceed the values derived from the Horwitz equation. Both RSD values at the three concentration levels were found to be lower than the reference values (Table 2) calculated from the Horwitz equation. These results revealed that the developed method meets minimum performance criteria established by Regulation 2006/401/EC. Therefore, the precision of the method is acceptable.

Recovery

Samples spiked with aflatoxins at three different concentrations (0.5, 1, and 1.5 times MRL) were prepared to perform the recovery study. The spiked samples (six replicates) were analyzed with the developed method. The recovery values obtained were in the range of 80–105 % (Table 3), complying with the values (70–110 %) recommended by Regulation 2006/401/EC. The recovery of the method was determined by analyzing FAPAS test material (T0474) as well. Recovery was estimated by dividing the detected mean value by the certified value. The estimated recovery values varied from 81.4 to 95.7 %, confirming acceptable values for the accuracy of the method. Therefore, it can be interpreted that satisfactory results are achieved by using the proposed method for the determination of aflatoxin in hazelnut, hazelnut paste, walnut, peanut, pistachio, corn, and wheat.

Ruggedness

Ruggedness was investigated by means of the Youden ruggedness trial, in which seven factors were explored in an experiment requiring eight determinations (Table 4). The factors evaluated for samples were extraction solvent, sample matrix, column temperature, analyst, type of extract for cleanup, reversed phase HPLC column, and mobile phase. The standard deviation for the effects can then be calculated:

where E i is each of the calculated effects and n is the total number of parameters. To assess if the method is robust compared to each variation, the influence of each variable on the method performance has to be assessed by applying the t test (Bratinova et al. 2009). The experimental t values for each of the effects were calculated using the following formula:

The calculated t values presented in Table 4 are lower than the t critical value for ν = n − 1 degrees of freedom (t crit = 2.45, ν = 6, 97.5 % confidence level), that is why the method is robust with respect to the changes in the procedure. The results obtained in the ruggedness study reveal that analytical results are not affected by the slight variations in the selected factors. Consequently, the proposed method is applicable for the determination of AFs in hazelnut, hazelnut paste, walnut, peanut, pistachio, corn, and wheat.

Proficiency Test

The technical competence of the laboratory was tested by participating in the FAPAS (Food and Environment Research Agency) proficiency test 04145 in October 2009. The FAPAS test material (hazelnut) was analyzed in triplicate. The Z score calculated by the FAPAS was used to evaluate the results. The Z scores obtained in the FAPAS ring test were 0.9, −1.1, −0.8, −0.8, and −0.9 for AFB1, AFB2, AFG1, AFG2, and total AFs, respectively. These values were below the reference value of 2 (absolute), indicating the technical competence of the laboratory.

Measurement Uncertainty

Evaluation of uncertainty of the analytical results is compulsory for laboratories accredited according to ISO 17025/2005, and there are several proposed methods of uncertainty calculations (EURACHEM Guide 1995; EURACHEM/CITAC GUIDE CG 4 2000; and Nordic Committee on Food Analysis, NMKL 2003). In this study, we used the analytical validation parameters obtained from each step of the process. The determination of relative uncertainty (u) has been performed by considering eight sources of uncertainty: (a) volume; (b) mass; (c) calibration curve; (d) method reproducibility and repeatability; (e) preparation of standard; (f) accuracy; and (g) reproducibility of device.

A relative expanded measurement uncertainty was calculated using a coverage factor k of 2, corresponding approximately to a 95 % confidence level (EURACHEM/CITAC GUIDE CG 4 2000) giving values of 9.5, 11.0, 10.5, and 13.5 % for aflatoxins B1, B2, G1, and G2 in foodstuffs.

Conclusions

An analytical method based on clean-up with immunoaffinity column and HPLC with fluorescence detector was validated according to Regulation 2004/882/EC for the determination AFs in food matrices. The method performance characteristics were found to be conformed to minimum performance criteria established by Regulation 2006/401/EC. The validated method provides accurate and precise results and presents rapid and economic procedure. The excellent results achieved in a proficiency test round confirmed laboratory technical competence. The proposed method is well suited to satisfy the demands for accurate and sensitive detection of aflatoxins with sample preparation and cleanup steps. The developed procedure is rapid and allows the simultaneous determination of aflatoxins in different food matrices with high sensitivity. [2, 3, 4, 9, 12, 13, 14, 15, 16, 18, 19, 20, 21, 25, 26, 27, 28, 31, 34, 36, 37, 40, 42, 44, 48]

References

Abbas HK (2005) Aflatoxin and food safety. International Standard Book Number 10: 0-8247-2303-1 (Hardcover) pp 253–254

Analytical Detection Limit Guidance & Laboratory Guide for Determining Method Detection Limits, Wisconsin Department of Natural Resources Laboratory Certification Program, April 1996

Asis R, Di Paola RD, Aldao MAJ (2002) Determination aflatoxin B1 in highly contaminated peanut sample using HPLC and ELISA. Food Agric Immunol 14:201–208

Baltacı C, Kara M, Aliyazıcıoğlu R, Kolaylı S, Karaman M, Yıldız O (2009) Determination of homogenization of grinder used for aflatoxin analysis of Turkish hazelnuts. J Biol Inorg Chem 37(1):33–39

Bacaloni A, Cavaliere C, Cucci F, Foglia P, Samperi R, Lagan A (2008) Determination of aflatoxins in hazelnuts by various sample preparation methods and liquid chromatography–tandem mass spectrometry. J Chrom 1179:182–189

Braicu C, Puia C, Bodoki E, Socaciu C (2008) Screening and quantification of aflatoxins and ochratoxin in different cereals cultivated in Romania using thin layer chromatography-densitometry. J Food Qual 31:108–120

Bratinova S, Raffael B, Simoneau C (2009) Guidelines for performance criteria and validation procedures of analytical methods used in controls of food contact materials. JRC Scientific and Tecnichal Report, EUR 24105 EN - 1st edn

Castells M, Marin S, Scanchis V, Ramos AJ (2008) Distribution of fumonisins and aflatoxins in corn fractions during industrial cornflake processing. Int J Food Microbiol 123:81–87

Commission Regulation (EU) No 165/2010 of 26 February 2010 amending Regulation (EC) No 1881/2006 setting maximum levels for certain contaminants in foodstuffs as regards aflatoxins

Commision Decision 2002/657/EC (2002). Commision Decision of 12 August 2002 implementing Council Directive 96/23/EC concerning the performance of analytical methods and the interpretation of results

Daradimos E, Marcaki P, Koupparis M (2000) Evaluation and validation of two fluorometric HPLC methods for the determination of aflatoxin B1 in olive oil. Food Addit Contam 17:65–73

Hussein SH, Jeffrey MB (2001) Toxicity, metabolism, and impact of mycotoxins on humans and animals. Toxicology 167:101–134

International Agency for Research on Cancer (IARC). (1993). IARC monograph on the Evaluation of Carcinogenic Risk to Humans, vol. 56. Lyon, France

Juan C, Zinedine A, Molto JC, Idrissi L, Mañes J (2008) Aflatoxins levels in dried fruits and nuts from Rabat-Sale´ area, Morocco. Food Control 19:849–853

Lee NA, Wang S, Allan RD, Kennedy IR (2004) A rapid aflatoxin B1 ELISA: development and validation with reduced matrix effects for peanuts, corn, pistachio and soyabeans. J Agric Food Chem 52:2746–2755

Li F, Yoshizawa T, Kawamura O, Luo X, Li Y (2001) Aflatoxins and fumonisins in corn from the high-incidence area for human hepatocellular carcinoma in Guangxi, China. J Agric Food Chem 49:4122–4126

Muscarella M, Lo Magro S, Palermo C, Centonze D (2007) Validation according to European Commission Decision 2002/657/EC of a confirmatory method for aflatoxin M1 in milk based on immunoaffinity columns and high performance liquid chromatography with fluorescence detection. Anal Chim Acta 594:257–264

Nelson TS, Jhonson ZB, Kirby LK, Beasly JN (1982) Digestion of dry matter, amino acids and energy utilization by chicks fed molded corn containing mycotoxins. J Poult Sci 35:584

Pena R, Alcaraz MC, Arce L, Rıos A, Valcarcel M (2002) Screening of aflatoxins in feed samples using a flow system coupled to capillary electrophoresis. J Chrom 967:303–314

Stoloff L (1977) Aflatoxin—an overview. In: Mycotoxins in human and animal health. JC

Shank RC, Wogan GN, Gibson JB (1972) Dietary aflatoxins and human liver cancer. I. Toxigenic molds in foods and food stuffs of tropical Southeast Asia. Food Cosmet Toxicol 10:51

Stroka J, Anklam E, Jorissen U, Gilbert J (2000) Immunoaffinity column cleanup with liquid chromatography using post-column bromination for determination aflatoxins in peanut butter, pistachio paste, fig paste, and paprika powder: collabrative study. J AOAC Int 83:30–340

Tavcar-Kalcher G, Vrtac K, Pestevsek U, Vengust A (2007) Validation of the procedure for the determination of aflatoxin B1 in animal liver using immunoaffinity columns and liquid chromatography with post column derivatisation and fluorescence detection. Food Control 18:333–337

Turksih Food Codex. (2002). Certain contaminants in foodstuff level of sampling for official control of the notification, notification no:2002/25, Ankara

Turkish Food Codex (2007) Mycotoxins in foodstuffs the official level control for getting sample, notification of sample preparation and analysis method criteria, notification no:2007/21, Ankara

Wogan GN, Busby WF Jr (1980) Naturally occurring carcinogens. In: Liener IE (ed) Toxic constituents of plant feedstuffs. Academic Press Inc, New York

Acknowledgments

The authors would like to express thanks to Trabzon Provincial Laboratory for technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baltacı, C., İlyasoğlu, H. & Yüksel, F. Single-Laboratory Validation for the Determination of Aflatoxin B1, B2, G1, and G2 in Foods Based on Immunoaffinity Column and Liquid Chromatography with Postcolumn Derivatization and Fluorescence Detection. Food Anal. Methods 6, 36–44 (2013). https://doi.org/10.1007/s12161-012-9417-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-012-9417-3