Abstract

Microalgae are considered promising feedstocks for biofuel and bio-product generation. The algal carbohydrates can be hydrolyzed into sugars before their fermentation into ethanol. In this study, nutrient limitation strategy was employed to evaluate the biochemical composition of Chlorella sorokiniana. Limiting nitrate (1.0 g/L KNO3) in the culture medium increased the total carbohydrate and starch content of microalga by 50.28 and 34.06%, respectively. However, this significantly lowered their yield due to low microalgal biomass production. Cultivation of C. sorokiniana cells with 4.0 g/L KNO3 as nitrogen source for 8 days was optimum for bioethanol production as the highest total carbohydrate yield of 422.44 mg/L was obtained under these conditions. Nitrate limitation (1.0 g/L KNO3) favored the increased production of high-value carotenoids in C. sorokiniana that could further contribute to improving the economics of the bioethanol production process. Feasibility studies for ethanol production from C. sorokiniana revealed that a maximum of 13.86 mg/mL of reducing sugars was extracted in the hydrolysate by treating the microalgal biomass with 2.8% sulfuric acid at 121 °C for 30 min. Fermentation of acid hydrolysate produced ethanol at a concentration of 2.91 mg/mL in 96 h with 41.16% of theoretical yield.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microalgae are unicellular microscale (cell size ranging from 2 to 200 μm) photosynthetic microorganisms which possess high carbon dioxide fixation abilities during photosynthesis in the presence of sunlight and other essential nutrients [1]. Microalgae are capable of producing abundant biomass comprising carbohydrates, lipids, and proteins. Cellulose is the predominant constituent of the microalgal cell wall besides pectin and sulfated polysaccharides [2]. The majority of the starch (20 to 50%) is located intracellularly in the plastids. Other components such as lipids (20 to 60%) and proteins (20 to 50%) are also found in microalgal cells [1]. Some microalgal strains such as C. sorokiniana, Nannochloropsis sp., Desmodesmus sp., Nannochloropsis sp., Scenedesmus SDEC-8, and Botryococcus braunii have been documented to possess lipids as high as 45 to 64% of dry weight content [3]. The microalgae produce substantial amounts of proteins (42 to over 70%) in certain species of cyanobacteria and up to 58% in Chlorella vulgaris [4]. The metabolic products and their relative proportions are closely associated with the environmental conditions and nutrient availability including the quantity, abundance and magnitude of CO2 levels, temperature, pH, sunlight, nutrients, and the existence (or non-existence) of other organisms [5].

Microalgae are essential raw materials for bioethanol production since they possess (i) high photosynthetic capability, (ii) fast rate of growth, (iii) high proportion of carbohydrates, and (iv) lack of lignin in their cell wall [6]. Carbohydrates are produced in diverse forms which may vary depending upon the type or species of the microalgae. Cyanophytes are well recognized to store glycogen, although some species produce semi-amylopectin. Chlorophyta are known to possess starch as semi-crystalline granules composed of both amylose and highly branched amylopectin polymers while Floridean starch is the main carbohydrate polymer produced by Rhodophyta [7]. In certain species of microalgae, an increased accumulation of carbohydrates and starch takes place under environmental/nutritional stress conditions, viz. phosphorus limitation, nitrogen starvation, elevated light intensity, and high carbon dioxide concentration [8]. The carbohydrate content of microalgae can be increased by various cultivation strategies which include nitrogen depletion, CO2 supplementation, pH shift, and variation in temperature. It is well known that due to nitrogen-deficient conditions, various strains of microalgae convert peptides or proteins to lipids or carbohydrate reserves [2]. The nitrogen starvation results in inhibition of microalgal cell growth along with an increase in carbohydrate and starch content of the microalgae. High carbohydrate and starch content of 66.9 and 43.4% was observed in microalga C. zofingiensis after only 1 day of nitrogen starvation [9]. Under autotrophic conditions, C. vulgaris P12 accumulated starch up to 41% of cell dry weight [10] while another strain of C. vulgaris accumulated up to 55% of starch under nitrogen-limiting growth conditions [11].

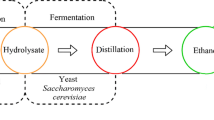

Microalgae possessing a high content of various carbohydrates, viz. starch, cellulose, agar, and glycogen can be easily transformed into fermentable sugars for their subsequent conversion into ethanol [12]. The process of bioethanol production from algae is a multi-step process including harvesting, biomass pre-treatment, hydrolysis, and fermentation. Of the total cost linked to the microalgae processing and production, harvesting constitutes 20–30% due to the small size and growth of microalgae in very dilute cultures [13]. The harvested biomass is further subjected to pre-treatment which is essential to disintegrate the hard cell wall and liberate the fermentable sugars for ensuing their fermentation into ethanol. Production cost, energy efficiency, ease of application, hydrolytic capability, and its feasibility for commercialization are the most essential features of an efficient pre-treatment process [14]. Among different pre-treatments, chemical pre-treatment has been identified as the most viable option, as it is capable of performing both the pre-treatment and hydrolysis of microalgal biomass together. Most widely employed chemicals in the pre-treatment process are usually different acids and alkali as they are considered to be the most inexpensive chemicals possessing high hydrolytic capabilities and least levels of toxicity at their commonly applied concentrations [15]. Acid pre-treatment is the most preferred method as it provides higher hydrolytic efficiency for conversion of complex carbohydrates into sugars and ethanol. Various species of microalgal biomass, viz. Dunaliella sp. and Scenedesmus abundans, have been subjected to sulfuric acid pre-treatment by several researchers [16, 17]. Acid concentration, temperature, and time are the primary factors affecting the conversion of polysaccharides into fermentable sugars during the pre-treatment process. The use of acid at high concentration can lead to the corrosion of equipment and generation of various fermentation inhibitors [18]. Nevertheless, these disadvantages could be overcome by using dilute acids for the pre-treatment.

In the current study, the strategy of nitrogen limitation was employed to enhance carbohydrate/starch accumulation in indigenous microalga Chlorella sorokiniana by varying the concentrations of potassium nitrate in the culture medium. Ethanol production potential of C. sorokiniana was evaluated by studying the effect of varying acid concentrations on the hydrolysis of microalgal polysaccharides into sugars and subsequent fermentation of the hydrolysate by Saccharomyces cerevisiae into ethanol.

Materials and Methods

Microalgal Strain and Culture Conditions

Microalgal strain, Chlorella sorokiniana, was procured from the stock culture collection of Biodiesel Laboratory, Department of Renewable Energy Engineering, P.A.U., Ludhiana. Starter cultures were initiated from pure single colonies by inoculating them into 250 mL of synthetic medium. The chemical composition of complete synthetic medium with some modifications was as follows: K2HPO4 0.20 g/L, KH2PO4 0.50 g/L, FeSO4·7H2O 0.03 g/L, MgSO4·7H2O 0.20 g/L, KNO3 4.0 g/L, and trace mineral solution 1.0 mL/L: H3BO3 2.86 g/L, Na2MoO4·2H2O 0.04 g/L, MnCl2·2H2O 1.81 g/L, ZnSO4·7H2O 0.02 g/L, CuSO4·5H2O 0.07 g/L [19]. Cultures were grown at 28 ± 2 °C with an uninterrupted supply of light using white fluorescent bulbs at an irradiance level of 6000 lx. Carbon dioxide–enriched air (1% v/v) was sparged into the culture medium at a constant flow rate of 0.3 vvm (volume gas per volume liquid culture per min) [20].

Experimental Setup

The cells of C. sorokiniana were grown initially to the logarithmic phase. The pre-cultured cells were collected by centrifugation at 10,000 rpm for 10 min. The cell pellets were washed twice with the distilled water and then resuspended in 500 mL of fresh synthetic medium as control and the modified synthetic medium containing 2.0 g/L and 1.0 g/L potassium nitrate. The starting inoculum size of 1.0 × 107 cells/mL was kept the same in all the experiments. The samples were collected immediately after resuspension and at regular intervals. Each experiment was replicated thrice.

Growth and Biomass Concentration

The growth of C. sorokiniana was determined daily by recording the absorbance (λ = 600 nm) of the triplicate culture samples using UV–visible spectrophotometer (SL 159, ELICO, Hyderabad, India) after suitable dilution with deionized water for achieving 0.05–0.6 absorbance range. For biomass determination, cells were harvested by centrifugation of the culture suspension at 10,000 rpm for 10 min, followed by washing with distilled water and drying at 60 °C until the weight was invariant [9].

Determination of Total Carbohydrate Content

The carbohydrates were extracted from the dried biomass of C. sorokiniana [21] in triplicates. To the dried algal biomass, 25 mL of HCl (1.5 N) was added followed by autoclaving the algal suspension at 121 °C, 15 psi for 15 min. The resulting mixture was allowed to cool at room temperature, followed by neutralization with sodium hydroxide solution (400 g/L) and the final volume was made to 50 mL with distilled water. One milliliter each of zinc acetate (300 g/L) and potassium ferrocyanide (150 g/L) was added to it. The solution was allowed to stand for 30 min with the subsequent addition of 0.2 mL of sodium tungstate (120 g/L). The final solution was, then, eventually filtered using Whatman no. 1 filter paper for the estimation of total sugars from the filtrate [22]. The total carbohydrate content and yield were expressed as dry weight percentage and milligram per liter, respectively.

Determination of Starch

Starch was extracted from C. sorokiniana biomass by vortexing the microalgal cells (30 mg) in 1 mL distilled water for 5 min using 0.5-mL glass beads [8]. Ethanol (80%) was used for the extraction of pigments from the biomass thrice at 65 °C for 15 min. To the pellet, 3 mL perchloric acid (30%) was added for hydrolysis of the starch and the mixture was continuously stirred at room temperature for 15 min. The process was repeated thrice. The extracts were pooled and the final volume was made to 10 mL. Total sugars present in the extract were determined [22], and the values obtained were multiplied by 0.9 for determination of starch. Starch content and yield were expressed as dry weight percentage and milligram per liter, respectively. Determinations were carried out in triplicates.

Determination of Total Soluble Protein

Total proteins were determined by extracting the dried microalgal biomass in triplicate (30 mg) using 90% ethanol (20 mL) for 1 h followed by centrifugation at 10,000 rpm for 10 min [23]. The pellet obtained after centrifugation was allowed to mix with 20% trichloroacetic acid (10 mL) followed by incubation at 95 °C for 15 min in a water bath. Ethanol (95%) was used for repeated washing of the pellet. The pellet was, then, dissolved in 10 mL of sodium hydroxide solution (4.0 g/L) and extracted twice at 60 °C for 1 h in a water bath. The soluble protein content was quantified by using Folin-Ciocâlteu reagent with bovine serum albumin as protein standard and expressed in dry weight percentage [24].

Determination of Chlorophyll and Carotenoid Content

The extraction of chlorophyll was performed as described with some modifications [25]. The fresh algal biomass in triplicate (30 mg) was immersed in 15 mL of 80% acetone and placed in water bath at 65 °C for 2 h. During the 2-h incubation period, the algal suspension was subjected to vigorous shaking after every 15 min and then allowed to rest in the dark for 24 h. Acetone was added to compensate for the evaporation that occurred during the extraction of pigments from algal biomass. The suspension was subjected to centrifugation at 10,000 rpm for 5 min and absorbance of the cell-free extract was recorded at 663, 647, and 470 nm with UV–visible spectrophotometer. For calculating the concentration of chl a, chl b, and carotenoids, the below mentioned equations were used [25]:

where Ca, chlorophyll a; Cb, chlorophyll b; C(x+c): x, xanthophyll; c, carotene.

Acid Hydrolysis of Microalgal Biomass

Dried algal pellets, in triplicate, slurred at a solid to liquid ratio of 1:10 (w/v) were mixed with five concentrations of sulfuric acid, viz. 0.7, 1.4, 2.8, 5.6, and 8.3% and pre-treated in an autoclave at 121 °C and 15 psi for 30 min. The hydrolysates were collected, allowed to cool at room temperature, and then filtered using Whatman no. 1 filter paper. The clear supernatant was used for the estimation of total sugars [22] and reducing sugars by the method of Nelson [26].

Fermentation of Microalgal Hydrolysate

Fermentation of microalgal hydrolysate was carried out as per method of Markou et al. [27]. Microalgal hydrolysate was neutralized with NaOH (4.0 g/L) and pH of hydrolysate was adjusted to 5.0. The following nutrients (g/L) were supplemented with the microalgal hydrolysate: NH2SO4 2; K2HPO4 1.0; KH2PO4 1.0; ZnSO4 0.2; MgSO4 0.2; yeast extract 2.0. After the addition of nutrients, the hydrolysate was pasteurized at 80 °C for 15–20 min. The solution was, then, agitated at 250 rpm for 5–10 min and kept in UV light for 30 min to sterilize the hydrolysate. The yeast S. cerevisiae (MTCC11815) was cultured in glucose yeast extract broth (GYE) maintained at pH 5.5. The hydrolysate was inoculated with 10% yeast inoculum and fermentation was carried out at 28 ± 2 °C using an orbital-shaking incubator at 100 rpm for 96 h. The concentrations of ethanol [28] and residual reducing sugars [26] in the fermented sample were determined spectrophotometrically at 48, 72, and 96 h.

Statistical Analysis

The experiments were conducted in three replicates and the values were expressed as mean values ± standard error (SE). Data were analyzed using ANOVA followed by Tukey’s HSD test. SPSS Statistics 20.0 version was used for the statistical analyses and p < 0.05 was considered to be significant.

Result and Discussion

Microalgal Growth and Biomass in Relation to Potassium Nitrate Levels

The growth of C. sorokiniana increased with subsequent increase in the nitrate level in the medium (Supplementary Fig. S1). The growth curve depicted 1 day of lag phase and of logarithmic phase up to day 7 followed by stationary phase with 4.0 g/L potassium nitrate in the culture medium. However, limiting potassium nitrate to 2.0 and 1.0 g/L in the culture medium caused alga to take 10 days to reach the stationary phase. The highest fresh and dry biomass concentrations of 8053.33 mg/L and 1556.67 mg/L, respectively, were observed on day 8 with 4.0 g/L nitrate level (Supplementary Fig. S2). High nitrate concentration in the culture medium substantially increases the synthesis of chlorophyll pigments, thereby increasing the rate of photosynthesis. Most of the carbohydrates produced are utilized as an energy source through respiration reaction for the rapid division of cells, thereby resulting in increased cell biomass and growth [29]. However, the fresh and dry biomass concentrations of 2266.67 mg/L and 323.33 mg/L, respectively, were recorded on day 2 upon limiting the nitrate level in the medium to 1.0 g/L, though C. sorokiniana maintained the ability to grow under nitrate limitation with reduced biomass as compared to the high nitrate level in the culture medium. This might be due to the utilization of nitrogen harvested from salvage pathways related to the turnover of the proteins [30].

Carbohydrate/Starch Accumulation in C. sorokiniana in Relation to Nitrate Levels

Lipids and starch are the predominant storage compounds of carbon and energy in the majority of the microalgal cells and plants, especially synthesized in response to stress conditions. Carbohydrate content of algae is an important constituent that determines the efficacy of bioethanol production from the algae. The results of total carbohydrates obtained by the cultivation of C. sorokiniana under varying nitrate levels in the medium are shown in Fig. 1. C. sorokiniana was able to accumulate the carbohydrates under all the tested potassium nitrate levels in the culture medium; however, the total carbohydrate content varied significantly (p < 0.05) at different days. At 4.0 g/L KNO3, the total carbohydrate content of microalga declined from 22.16 to 17.14% by day 2 and then increased up to 29.50% on day 6 and then declined thereafter. However, by limiting the potassium nitrate levels up to 2.0 g/L and 1.0 g/L in the culture medium, the total carbohydrate content increased drastically from 21.56 to 31.40% and 22.80 to 50.28% by days 4 and 2, respectively (Fig. 1a). The decrease in the potassium nitrate level in the culture medium quickly induced carbohydrate accumulation in the microalga. These results agree with the previous findings that inferred an increased accumulation of carbohydrate in C. vulgaris P12 up to 41% under nitrogen limiting situations [10]. Similarly, the total carbohydrate contents of 60 and 32.75% were observed in the microalgae, Synechococcus and C. vulgaris, respectively with the limitation of sodium nitrate in the culture medium [31]. Nitrogen starvation resulted in an intensive production of carbohydrates in Haematococcus pluvialis that accumulated carbohydrates up to 63% by day 1 and then subsequently decreased along with accumulation of fatty acids up to 35% [32]. The possible explanation for this could be that during nitrogen-limiting conditions, the nitrogen available to the microalgae is utilized for the production of essential cell structures and enzymes. The carbon dioxide fixed by the microalga under these conditions is thereby converted into either carbohydrates or lipids rather than proteins, depending upon the species [10]. In the present study, the total carbohydrate yield of microalga increased from 5.61 to 422.44 mg/L by day 8 and then decreased to 300.89 mg/L by day 10 with 4.0 g/L KNO3 in the culture medium (Fig. 1b). Limiting potassium nitrate levels up to 2.0 g/L and 1.0 g/L in the culture medium resulted in the highest total carbohydrate yield of 371.78 and 240.86 mg/L by days 8 and 6, respectively. Though the potassium nitrate limitation induced the accumulation of carbohydrate in the cells of C. sorokiniana, the yield of carbohydrate was observed to be comparatively low. The decline in the carbohydrate yield from 422.44 to 240.86 mg/L by limiting potassium nitrate in the culture medium might be due to severe inhibition of cell division under these conditions [9].

a Total carbohydrate content (% dw basis) of C. sorokiniana grown in a medium containing different potassium nitrate levels. Different letters indicate statistically significant difference between different potassium nitrate levels at each cultivation time. Values are mean ± standard error of three replicates. b Total carbohydrate yield (mg/L) of C. sorokiniana grown in a medium containing different potassium nitrate levels. Different letters indicate statistically significant differences between different potassium nitrate levels at each cultivation time. Values are mean ± standard error of three replicates

Carbohydrates in the microalgae are species specific. Eukaryotic microalgae typically contain either starch as in red and green algae or β-glucans as in diatoms and brown algae as their chief storage carbohydrate [33]. The kind of storage carbohydrates is of immense significance if the biomass is to be considered as substrate for fermentation and production of ethanol. Hence, it is paramount to study the principal carbohydrate in the microalgae for its subsequent conversion into ethanol. Starch accumulation in C. sorokiniana in relation to different potassium nitrate levels in the culture medium is shown in Fig. 2. At 4.0 g/L potassium nitrate level in the culture medium, the highest starch content of 24.59% was recorded by day 6, while limiting the nitrate level to 2.0 g/L and 1.0 g/L in the medium significantly (p < 0.05) enhanced starch content to 25.06% and 34.06% by days 4 and 2, respectively (Fig. 2a). However, the highest total starch yield of 246.15 mg/L was found by day 8 with 4.0 g/L potassium nitrate in the culture medium (Fig. 2b). High starch content of C. sorokiniana with nitrate limitation might be due to the excessive photosynthetic carbon flux within the cell. The increased accumulation of metabolic intermediate, i.e., 3-phosphoglycerate, might cause an activation of ADP-glucose pyro phosphorylase that is primarily involved in starch synthesis [9]. The increase in the starch content of another microalgal strain C. vulgaris P12 up to 40% with the deprivation of urea in the culture medium was reported in another study [10].

a Total starch content (% dw basis) of C. sorokiniana grown in a medium containing different potassium nitrate levels. Different letters indicate statistically significant differences between different potassium nitrate levels at each cultivation time. Values are mean ± standard error of three replicates. b Total starch yield (mg/L) of C. sorokiniana grown in a medium containing different potassium nitrate levels. Different letters indicate statistically significant differences between different potassium nitrate levels at each cultivation time. Values are mean ± standard error of three replicates

The total soluble protein content of C. sorokiniana at different potassium nitrate levels is shown in Fig. 3. At 4.0 and 2.0 g/L potassium nitrate levels, the total soluble protein content increased from 12.36 to 27.38% and 10.78 to 20.91%, respectively, by day 8 and declined thereafter. However, the total soluble protein content declined up to day 10, when the nitrate level in the culture medium was 1.0 g/L. Significant differences (p < 0.05) in the total soluble protein content were observed at different potassium nitrate levels with the lowest protein content observed at 1.0 g/L potassium nitrate level. The microalgae trigger their metabolism by the accumulation of carbohydrates/lipids as energy reservoir to prevail over the periods of nitrogen stress. For this, peptides/proteins are transformed into energy reserves and protein synthesis also gets slowed down as nitrogen is one of the major elements required for this purpose. This increase in the carbohydrates/lipids was also associated with concomitant decline in the content of protein in another study [34]. The total carbohydrates increased from 25.2 to 35.3%, whereas the total proteins declined from 58.9 to 52.3%. Thus, depletion of nitrogen in the culture medium stimulated the production of carbohydrates at the cost of the proteins.

Total soluble protein content (% dw basis) of C. sorokiniana grown in a medium containing different potassium nitrate levels. Different letters indicate statistically significant differences between different potassium nitrate levels at each cultivation time. Values are mean ± standard error of three replicates

The chlorophyll and carotenoid content of C. sorokiniana in relation to different potassium nitrate levels in the culture medium is shown in Table 1. Chlorophyll a, b, and total chlorophyll content continued to increase to 403.22, 346.66, and 749.88 µg/g, respectively, by day 8 with 4.0 g/L KNO3 in the culture medium. However, chlorophyll a, b, and total chlorophyll contents were found to be relatively low with 2.0 and 1.0 g/L nitrate levels with maximum increase up to days 8 and 4, respectively. Chlorophyll a, b, and total chlorophyll contents decreased by 3.0- to 3.2-fold by day 4 with 1.0 g/L nitrate level relative to its maximum content at a high nitrate level (4.0 g/L KNO3) in culture medium. In a similar study, both the pigments (chlorophyll a and b) decreased progressively in the nitrogen-limiting medium from day 4 onwards, whereas these pigments were relatively unchanged in the nitrogen-repleted cultures until day 8 [35]. The green alga, Neochloris oleoabundans, assembled a substantial amount of chlorophyll under abundantly available nitrogen in the medium. However, upon the exhaustion of nitrogen in the medium, the microalgal cells started utilizing their own nitrogen by the degradation of chlorophyll molecules [36].

Total carotenoid content continued to increase at all potassium nitrate levels in the culture medium, although content was found to be relatively low, i.e., 221.41 µg/g on day 10 at the 1.0 g/L nitrate level. The total carotenoid to chlorophyll content of C. sorokiniana was higher on day 10 at all the potassium nitrate levels. However, significantly (p < 0.05) high total carotenoid to chlorophyll content of 2.51 was observed by day 10 in the culture medium containing 1.0 g/L potassium nitrate. Certain species of microalgae are known to assemble high levels of carotenoids such as β-carotene and xanthophylls under elevated light intensity and nitrogen deficiency conditions. The induction of carotenoid synthesis might serve as intracellular light traps, thereby protecting the photosynthetic piments from excessive irradiation. This mechanism is of great importance, especially under nitrogen deficiency conditions when the efficiency of other protective mechanisms depending on protein synthesis (particularly, the antioxidant enzymes) is thought to be restricted [37]. Versatility of C. sorokiniana metabolism under different nitrate regimes might favor the production of high-value non-fuel products such as carotenoids which could play a pivotal role in making energy and economic balance of microalgal bioethanol production more favorable. Similar types of biorefinery concepts that involve the extraction of fatty acids and carotenoids from microalgae for feed and food industry along with the production of biohydrogen and biodiesel have been studied by several researchers [38].

The results revealed that though limiting nitrate in the culture strongly induced the accumulation of starch and carbohydrates in C. sorokiniana cells, the total carbohydrate and starch yield were observed to be low. The nitrate limitation led to higher carbohydrate/starch content in C. sorokiniana at the expense of low biomass and yield. Limitation of nitrate in the culture medium also decreased the total soluble protein and chlorophyll content, though the carotenoid to chlorophyll ratio increased significantly. On the basis of the highest total carbohydrate yield of 422.44 mg/L achieved on day 8 with the supplementation of 4.0 g/L KNO3 in the culture medium, harvesting of the microalgal cells was carried out under these conditions for acid hydrolysis and fermentation of microalgal hydrolysate for ethanol production.

Effect of Acid Concentration on Hydrolysis of Microalgal Biomass

Acid hydrolysis is a common method and sulfuric acid is recognized as the principal catalyst for hydrolysis of biomass. It is capable of hydrolyzing the complex polysaccharides into simple sugars. Figure 4 shows the effect of sulfuric acid concentration on hydrolysis of complex carbohydrates of microalgal biomass. The total sugars and reducing sugars of the algal hydrolysate increased considerably from 446.16 to 487.41 and 158.02 to 277.56 mg/g dried algal biomass, respectively with an increase in concentration of acid from 0.7 to 2.8%. Further increase in the acid concentration up to 8.3% decreased both the total and reducing sugar contents of the hydrolysate. The decrease in the sugar level at the higher acid concentration might be due to the conversion of sugars into furfurals, thereby decreasing the yield of fermentable sugars [39]. For hydrolysis, a lower concentration of the acid is desirable owing to smaller amounts of the neutralizing agent required in the subsequent steps of fermentation and less corrosion of experimental equipment [14]. Hence, for subsequent experimental studies, 2.8% concentration of acid was used for the hydrolysis of microalgal biomass. Several studies have revealed that the efficacy of the acid hydrolysis depends upon cell wall rigidity of different microalgal species. The hydrolysis of Chlorella sp. with 2.8% sulfuric acid induced a gradual increase in the concentration of sugar up to 17.0 g/L and this level was maintained for 5 h in another study [40]. Similarly, dilute acidic hydrolysis of C. vulgaris FSP-E biomass with 1% sulfuric acid resulted in glucose yield of 93.6% from the microalgal carbohydrates [41].

Total sugar and reducing sugar content (mg/g) of hydrolysate produced by treating microalgal biomass with different acid concentrations. Different letters indicate statistically significant differences in total and reducing sugars at different acid concentrations. Values are mean ± standard error of three replicates

Fermentation of Microalgal Hydrolysate for Ethanol Production

The acid-hydrolyzed biomass was utilized for the production of ethanol via separate hydrolysis and fermentation process using optimal acid hydrolysis conditions (2.8% sulfuric acid at 121 °C, 30 min). After acid hydrolysis of C. sorokiniana, the acid hydrolysate with reducing sugar concentration of 13.86 mg/mL was obtained (Fig. 5). Saccharomyces cerevisiae cells were inoculated into the microalgal hydrolysate to accomplish the fermentation of ethanol at 28 ± 2 °C. After the inoculation of yeast, the reducing sugar content declined quickly along with rapid increase in the concentration of ethanol. Maximum ethanol concentration of 2.91 mg/mL and ethanol yield of 41.16% (relative to theoretical yield of ethanol based on the quantity of reducing sugars liberated from the microalga following acid hydrolysis) were achieved within 96 h of fermentation. The ethanol concentration and yield reported in this study were found to be comparable with the studies carried out by several other researchers (Table 2). Acid hydrolysis is recommended as the most feasible hydrolysis method for the production of ethanol from the sugar-abundant microalgal biomass, as it is an economical and faster method with comparatively fivefold shorter operation time (60–120 min) as compared to enzymatic hydrolysis. Further optimization of hydrolysis of C. sorokiniana biomass for the production of fermentable sugars and their fermentation into ethanol by efficient yeast might help improve the yield of ethanol.

Conclusion

Chlorella sorokiniana culture, when grown under nitrate-limiting conditions, showed a significant increase in the carbohydrate and starch content. However, their yield was relatively low under these conditions due to the inhibition of the microalgal cell growth. The carotenoid content also showed a considerable increase when nitrate was limited in the culture medium. In the biorefinery concept, nitrate limitation is considered to be a good strategy for co-producing carbohydrates for ethanol as well as value-added pigments such as carotenoids. The carbohydrate yield and ethanol production efficiency of this strain can be enhanced by employing a two-stage cultivation strategy involving nitrate-sufficient conditions during the first stage and subsequently limiting nitrate in the culture medium.

References

Velazquez-Lucio J, Rodríguez-Jasso RM, Colla LM, Saenz-Galindo A, Cervantes-Cisneros DE, Aguilar CN, Fernandes BD, Ruiz HA (2018) Microalgal biomass pretreatment for bioethanol production: a review. Biofuel Res J 5:780–791. https://doi.org/10.18331/BRJ2018.5.1.5

Chen CY, Zhao XQ, Yen HW, Ho SH, Chang CL, Lee DJ, Bai FW, Chang JS (2013) Microalgae- based carbohydrates for biofuel production. Biochem Eng J 78:1–10. https://doi.org/10.1016/j.bej.2013.03.006

Garcia LM, Adjalle K, Barnabe S, Ragha GSV (2017) Microalgae biomass production for a biorefinery system: recent advances and the way towards sustainability. Renew Sust Energ Rev 76:493–506. https://doi.org/10.1016/j.rser.2017.03.024

Becker EW (2007) Micro-algae as a source of protein. Biotechnol Adv 25(2):207–210

Juneja A, Ceballos RM, Murthy GS (2013) Effects of environmental factors and nutrient availability on the biochemical composition of algae for biofuels production: a review. Energies 6(9):4607–4638

Agwa OK, Nwosu IG, Abu GO (2017) Bioethanol production from Chlorella vulgaris biomass cultivated with Plantain (Musa paradisiaca) pells abstract. Adv Biosci Biotechnol 8:478–490. https://doi.org/10.4236/abb.2017.812035

Barkia I, Saar N, Manning SR (2019) Microalgae for high-value products towards human health and nutrition. Mar Drugs 17(5):1–29

Branyikova I, Marsalkova B, Doucha J, Branyik T, Bisova K, Zachleder V (2011) Microalgae - novel highly efficient starch producers. Biotechnol Bioeng 108:766–776. https://doi.org/10.1002/bit.23016

Zhu S, Wang Y, Huang W, Xu J, Wang Z, Xu J, Yuan Z (2014) Enhanced accumulation of carbohydrate and starch in Chlorella zofingiensis induced by starvation. Appl Biochem Biotechnol 174:2435–2445. https://doi.org/10.1007/s12010-014-1183-9

Dragone G, Fernandes BD, Abreu AP, Vicente AA, Teixeira JA (2011) Nutrient limitation as a strategy for increasing starch accumulation in microalgae. Appl Energy 88:3331–3335. https://doi.org/10.1016/j.apenergy.2011.03.012

Behrens PW, Bingham SE, Hoeksema SD, Cohoon DL, Cox JC (1989) Studies on the incorporation of CO2 into starch by Chlorella vulgaris. J Appl Phycol 1:123–130. https://doi.org/10.1007/BF00003874

Ueda R, Hirayama S, Sugata K, Nakayama H (1996) Process for the production of ethanol from microalgae. US Patent 5,578,472

Barros AI, Goncalves AL, Simoes M, Pires JCM (2015) Harvesting techniques applied to microalgae: a review. Renew Sust Energ Rev 41:1489–1500. https://doi.org/10.1016/j.rser.2014.09.037

Phwan CK, Chew KW, Sebayang AH, Ong HC, Ling TC, Malek MA, Show PL (2019) Effects of acids pre-treatment on the microbial fermentation process for bioethanol production from microalgae. Biotechnol Biofuels 12:191. https://doi.org/10.1186/s13068-019-1533-5

Harun R, Danquah MK (2011) Influence of acid pre-treatment on microalgal biomass for bioethanol production. Process Biochem 46(1):304–309. https://doi.org/10.1016/j.procbio.2010.08.027

Bojórquez NV, Rocha RV, Escalante MAA, Barajas JAS (2016) Production of bioethanol from biomass of microalgae Dunaliella tertiolecta. Int J Env Agri Res 2(2):110–116

Agustini NWS, Hidhayati N, Wibisono SA (2019) Effect of hydrolysis time and acid concentration on bioethanol production of microalgae Scenedesmus sp. IOP Conf Series Earth Environ Sci 308:1–11

Duarte LC, Fernandes TS, Carvalheiro F, Girio FM (2009) Dilute acid hydrolysis of wheat straw oligosaccharides. Appl Biochem Biotechnol 153(1):116–126

Xiong W, Li X, Xiang J, Wu Q (2008) High-density fermentation of microalga Chlorella protothecoides in bioreactor for microbio-diesel production. Appl Microbiol Biotechnol 78(1):29–36. https://doi.org/10.1007/s00253-007-1285-1

Yao CH, Ai JN, Cao XP, Xue S (2013) Salinity manipulation as an effective method for enhanced starch production in the marine microalga Tetraselmis subcordiformis. Bioresour Technol 146(6):663–671. https://doi.org/10.1016/j.biortech.2013.07.134

Margarites ACF, Costa JAV (2014) Increment of carbohydrate concentration of Chlorella minutissina microalgae for bioethanol production. Int J Res Appl 4(3):80–86

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28(3):350–356. https://doi.org/10.1021/ac60111a017

Kong WB, Yang H, Cao YT, Song H, Hua SF, Xia CG (2013) Effect of glycerol and glucose on the enhancement of biomass, lipid and soluble carbohydrate production by Chlorella vulgaris in mixotropic culture. Food Technol Biotechnol 51(1):62–69

Lowry OH, Rosenbrough NL, Farr AL, Radall RJ (1951) Protein measurement with folin phenol reagent. J Biol Chem 193(1):265–275

Lichtenthaler HK, Buschmann C (2001) Chlorophylls and carotenoids: measurement and characterization by UV-VIS spectroscopy. Curr Protocols Food Anal Chem 1:F4.3.1-F4.3.8. https://doi.org/10.1002/0471142913.faf0403s01

Nelson N (1994) A photometric adaptation of the Somogyi method for the determination of glucose. J Biol Chem 153:375–380

Markou G, Angelidaki I, Nerantis E, Georgakakis D (2013) Bioethanol production by carbohydrate-enriched biomass Arthrospira (Spirulina) platensis. Energy 6:3937–3950. https://doi.org/10.3390/en6083937

Caputi AJ, Ueda M, Brown T (1968) Spectrophotometric determination of ethanol in wine. Am J Enol Viticult 19(3):160–165

Suyono EA, Muavatun U, Husna F, Khotimah H, Pratiwi I, Husna R, Cahyani F, Purwanti Y, Samudra TT (2016) The effect of nitrogen stress in medium for increasing carbohydrate as a bioethanol source and carotenoid as an antioxidant from Chlorella zofingiensis culture. ARPN J Eng Appl Sci 11:2698–2701

Negi S, Barry AN, Friedland N, Sudasinghe N, Subramanian S, Pieris S, Holguin FO, Dungan B, Schaub T, Sayre R (2015) Impact of nitrogen limitation on biomass, photosynthesis, and lipid accumulation in Chlorella sorokiniana. J Appl Phycol 28:803–812. https://doi.org/10.1007/s10811-015-0652-z

Mollers KB, Cannella D, Jorgensen H, Frigaard NU (2014) Cyanobacterial biomass as carbohydrate and nutrient feedstock for bioethanol production by yeast fermentation. Biotechnol Biofuels 7(1):64. https://doi.org/10.1186/1754-6834-7-64

Recht L, Zarka A, Boussiba S (2012) Patterns of carbohydrate and fatty acid changes under nitrogen starvation in the microalgae Haematococcus pluvialis and Nannochloropsis sp. Appl Microbiol Biotechnol 94:1495–1503. https://doi.org/10.1007/s00253-012-3940-4

Ball SG, Morell MK (2003) From bacterial glycogen to starch: understanding the biogenesis of the plant starch granule. Ann Rev Plant Biol 54:207–233

Michelon W, Da Silva ML, Mezzari MP, Pirolli M, Prandini JM, Soares HM (2016) Effects of nitrogen and phosphorus on biochemical composition of microalgae polyculture harvested from phycoremediation of piggery wastewater digestate. Applied Biochem Biotechnol 178(7):1407–1419. https://doi.org/10.1007/s12010-015-1955-x

Vello V, Chu WL, Lim PE, Majid NA, Phang SM (2018) Metabolomic profiles of tropical Chlorella species in response to physiological changes during nitrogen deprivation. J Appl Phycol 30:3131–3151. https://doi.org/10.1007/s10811-018-1504-4

Li Y, Horsman M, Wang B, Wu N, Lan CQ (2008) Effects of nitrogen sources on cell growth and lipid accumulation of green alga Neochloris oleoabundans. Appl Microbiol Biotechnol 81(4):629–636. https://doi.org/10.1007/s00253-008-1681-1

Solovchenko AE, Khozin-Goldberg I, Didi-Cohen S, Cohen Z, Merzlyak MN (2008) Effects of light and nitrogen starvation on the content and composition of carotenoids of the green microalga Parietochloris incisa. Russ J Plant Physiol 55(4):455–462. https://doi.org/10.1134/S1021443708040043

Gouveia L (2014) From tiny microalgae to huge biorefineries. Oceanography 2(1):1–8. https://doi.org/10.4172/2332-2632.1000120

Khan MI, Lee MG, Shin JH, Kim JD (2017) Pretreatment optimization of the biomass of Microcystis aeruginosa for efficient bioethanol production. AMB Express 7:19. https://doi.org/10.1186/s13568-016-0320-y

Seon G, Kim HS, Cho JM, Kim M, Park WK, Chang YK (2020) Effect of post-treatment process of microalgal hydrolysate on bioethanol production. Sci Rep 10(1):1–2. https://doi.org/10.1038/s41598-020-73816-4

Ho SH, Huang SW, Chen CY, Hasunuma T, Kondo A, Chang JS (2013) Bioethanol production using carbohydrate-rich microalgae biomass as feedstock. Bioresour Technol 135:191–198

Kim KH, Choi IS, Kim HM, Wi SG, Bae HJ (2014) Bioethanol production from the nutrient stress-induced microalga Chlorella vulgaris by enzymatic hydrolysis and immobilized yeast fermentation. Bioresour Technol 153:47–54

Nguyen MT, Choi SP, Lee JW, Lee JH, Sim SJ (2009) Hydrothermal acid pretreatment of Chlamydomonas reinhardtii biomass for ethanol production. J Microbiol Biotechnol 19(2):161–166

Wang X, Liu X, Wang G (2011) Two-stage hydrolysis of invasive algal feedstock for ethanol fermentation. J Integr Plant Biol 53(3):246–252

Acknowledgements

Authors are thankful to the Head, Department of Renewable Energy Engineering, Punjab Agricultural University, Ludhiana, for providing the necessary facilities to carry out this study.

Author information

Authors and Affiliations

Contributions

MST and AK conceived and designed the experimental study. MS was involved in the experimental setup. APK performed the experiments and collected data. The manuscript was written and edited by APK, MST, and AK.

Corresponding author

Ethics declarations

Ethics Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Authorship Consent

All the authors read, approved the final manuscript, and agreed for this submission.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Fig. S1

Growth (a.u.) of C. sorokiniana grown in a medium containing different potassium nitrate levels. Values are mean ± standard error of three replicates (DOCX 18 KB)

Fig. S2

Fresh biomass and dry biomass (mg/L) of C. sorokiniana grown in a medium containing different potassium nitrate levels. Values are mean ± standard error of three replicates (DOCX 21 KB)

Rights and permissions

About this article

Cite this article

Kaur, A., Taggar, M.S., Kalia, A. et al. Nitrate-Induced Carbohydrate Accumulation in Chlorella sorokiniana and its Potential for Ethanol Production. Bioenerg. Res. 15, 253–263 (2022). https://doi.org/10.1007/s12155-021-10292-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-021-10292-2