Abstract

Camelina (Camelina sativa L. Crantz), as a bioenergy and bio-product feedstock, may be grown as a rotation crop in the wheat-based cropping system to increase land use efficiency in the Northern Great Plains (NGP). In this study, which was conducted from 2008 to 2011 in central Montana, we evaluated the energy balance of three 2-year cop rotational sequences that included camelina-winter wheat (Triticum aestivum L.) (CAM-WW) and barley (Hordeum vulgare L.)-winter wheat (BAR-WW) compared with a traditional fallow-winter wheat (FAL-WW) rotation. Results indicated that 52 and 57 % more energy input was invested in CAM-WW and BAR-WW compared to FAL-WW system (9182 MJ ha−1), respectively. In all rotations, nitrogen fertilizer was the most energy-consuming input and accounted for 76, 68, and 69 % of the total energy used in wheat, barley, and camelina production, respectively. Averaged over 3 years, CAM-WW and BAR-WW systems yielded 34 and 29 % greater gross energy output compared with FAL-WW. The CAM-WW and BAR-WW also outperformed FAL-WW by 30 and 6 % in terms of net energy output. No significant differences in energy efficiency were found between the FAL-WW and CAM-WW systems. Taking into account of the greater net energy as well as similar values of energy use efficiency, the CAM-WW system performed better than the traditional FAL-WW system under rainfed conditions in central Montana. There is a good potential to improve the energy efficiency of the CAM-WW cropping system (by more than 26 %) through refinement of agronomic practices, mainly nitrogen fertilization and herbicide application, which can further enhance the sustainability of camelina feedstock production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Camelina (Camelina sativa L. Crantz) is an annual oilseed crop belonging to the Brassicaceae family [10]. Oil of this crop has been recognized as an outstanding feedstock for bioenergy purposes and recent studies have confirmed its superiority as a biodiesel and aviation fuel [10, 14, 31, 33]. In recent years, extensive efforts have been made to characterize camelina’s agronomic potential for the western and northern regions of the US Great Plains and Canada [10, 11, 20]. Results of these studies confirmed that camelina can suitably fit with the environmental conditions and boundaries of the Northern Great Plains and, thus, has potential to fill the fallow period of the wheat-based cropping systems to increase land use efficiency [6, 20]. Chen et al. [6] reported that total biomass and grain yield are greater in camelina-wheat annual cropping system than that in traditional fallow-wheat systems of Central Montana. Nevertheless, the sustainability of a camelina-winter wheat rotation (CAM-WW) compared to the traditional fallow-winter wheat (FAL-WW) system needs to be investigated. Effective use of non-renewable energy sources is considered as a major component of sustainability in the agricultural activity, especially bio-feedstock productions; thus, energy analysis is one useful indicator of environmental and long-term sustainability of cropping systems [2, 24]. Moreover, energy analysis provides opportunities toward optimization of non-renewable energy consumption, thereby contributing positively to reducing greenhouse gas emissions and to enhancing the long-term environmental sustainability of cropping systems [4, 27].

Energy production of primary bioenergy feedstocks such as corn (Zea mays L.) [15, 23, 26], soybean (Glycine max L. Merr.) [9, 19, 26, 28], and rapeseed (Brassica napus L.) [22, 29, 32] has been extensively investigated. Energy from biomass crops (second-generation feedstock) such as cardoon (Cynara cardunculus L.), giant reed (Arundo donax L.), and Miscanthus spp. also has received considerable attention from researchers [3, 7, 16]. It has been argued that suitable bioenergy crops must yield significantly more energy than what is used for producing these crops [17]. Despite the great potential of camelina for production as a climate-friendly biofuel feedstock, the energy efficiency or energy balance in this crop is not well documented.

Individual crops vary in their energy input and output. Therefore, crop rotation can impact the energetics of an entire cropping system. Zentner et al. [34] reported that non-renewable energy consumption for entire cropping systems differed significantly with crop rotations in the Canadian Prairies. Since nitrogen fertilizer is the most energy-demanding input in most cropping systems [12, 21], Zentner et al. [34] reported that the inclusion of pulse crops such as peas (Pisum sativum L.) into cropping systems can significantly reduce total energy input to the systems due to their role in minimizing external nitrogen input. Burgess et al. [5] evaluated the energy balance of 14 various wheat-pulse combinations in comparison with a continuous wheat-wheat system in Montana. They concluded that diversification of cropping systems in Montana with pulse crops will have positive impacts on energy balance of the system.

In order to make camelina a viable bioenergy crop and to be able to produce the feedstock efficiently and sustainably, the energetic performance of this crop should be evaluated. In the present study, energy balance indicators, including energy efficiency and net energy, were used to evaluate energy performance of CAM-WW and barley-winter wheat rotations compared with a traditional FAL-WW rotation in a rainfed environment of the NGP. The potential to improve the energy efficiency of these rotations through optimization of agronomic practices is also discussed.

Materials and Methods

Site Description and Experimental Details

The study was conducted at the Central Agricultural Research Center (47° 03′ N, 109° 57′ W; 1400 m elevation) of Montana State University near Moccasin, MT. The soil at this site is classified as a Judith clay loam (fine–loamy, carbonatic, frigid Typic Calciustolls) with the water-holding capacity being limited by gravel content and a shallow soil profile (60 cm). Long-term (l909–2013) average crop-growing season (September to August) precipitation in this area is about 390 mm with mean air temperature of about 5.8 °C. In Table 1, the monthly precipitation and average temperature during the study as well as the 20-year long-term averages are presented.

The experiment was conducted from 2008 to 2011 on soil that was fallowed in the year prior to initiating the study (2007). Experimental plots were laid out in a randomized complete block design with four replicates. The rotation plots were 3.7 m wide and 18.3 m long. To avoid the confounding effect of varying weather conditions on crop rotation effects, the experiment was designed so that each crop in rotation was presented in each year of the study. The details of operation practices for each crop are shown in Table 2.

Energy Balance

Energy balance was evaluated using the process analysis methodology described by Fluck and Baird [8], accounting for energy used for manufacture and operation of farm machinery, fuel, lubricants, fertilizer, and pesticides. Inputs were converted to energy equivalents using standard coefficients (Table 3). Among the available coefficients, we selected the most up-to-date values that have been used for energy analysis in similar environments. The primary source of energy coefficients of machineries was Burgess et al. [5], which accounted for fuel and lubrication consumption as well as energy to manufacture machinery and amortized over its useful life. Energy coefficients for herbicides are derived from Krohn and Fripp [14]. Grain used as seed was not included as energy input; instead, it was subtracted from the harvested grain [13]. Neither environmental inputs (solar radiation, precipitation water, wind, nutrient dry and wet deposition, and so forth) nor labor inputs were considered in the energy input calculation since labor usually has an insignificant share in total energy inputs of the mechanized farming systems [34]. Energy costs for delivering the products to off-farm location, storage, and drying were also not considered. The total energy input (MJ ha−1) of each crop was calculated by summing all inputs used in the production procedure. Energy input used in whole rotation was also calculated by summing the energy used for each crop in the rotation.

Energy output was determined as a function of grain yield and grain higher heating values (HHV). A random sample of each plot was taken, and HHV was determined based on the bomb calorimeter combustion method. Average HHV of winter wheat, barley, and camelina were 18.5, 18.2, and 26.5 MJ kg−1, respectively. Crop residue did not get an allowance in energy analysis since they remained on the field and returned to the soil [34]. The energy balance of each cropping system was evaluated using two energy performance indicators as follows:

-

Energy efficiency = Energy Output (MJ ha−1)/Energy Input (MJ ha−1)

-

Net energy (MJ ha−1) = Energy Output (MJ ha−1) − Energy Input (MJ ha−1)

In this paper, the term energy efficiency will be used in the common general sense of efficiency (greater efficiency being desirable). We first focused on energy analysis of the cropping systems based on the current agricultural practices used in this study. Thereafter, we evaluated the possible options to improve energy balance over the current systems/practices.

Data Analysis

Data from the first year of the experiment (2008) was not included in the statistical analysis, because we considered the first year as background year without rotational effects. Data of energy output and energy balance indices were subject to ANOVA using PROC GLM of SAS software. Fisher’s least significant difference test (LSD) at P < 0.05 was employed to separate the means when F test indicated significant differences. Since there were great variations among years, the data were analyzed in each year.

Results and Discussion

Energy Input

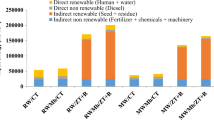

In comparing energy inputs used for the production of individual crops, winter wheat was the most energy-demanding crop requiring 8284 MJ ha−1 of non-renewable energy for agricultural inputs (Fig. 1). This value of energy input is quite similar to the average energy input of 9053 MJ ha−1 reported for winter wheat in the Canadian Prairies [34]. Barley and camelina were ranked following winter wheat with the total energy input of 6156 and 5968 MJ ha−1. Energy input used during the fallow period was considerably lower (898 MJ ha−1) than those used for crop production (Fig. 1).

Very limited information exists in literature regarding energy input of camelina. Petre et al. [25] reported 31,404 MJ ha−1 energy input for camelina in Romania which is considerably higher than that used in the current study. The discrepancy between energy requirements for camelina in these studies are due to differences in system boundaries and management practices, especially high levels of chemical fertilizer, high rate of herbicide, and intensive soil preparation in Petre et al. [25] work. Compared to similar biofuel crops such as canola, camelina in the current study required lower energy inputs. Fore et al. [9] reported 9506 MJ ha−1 and Smith et al. [30] reported 7651 MJ ha−1 of energy input required for canola production in Minnesota and western Canada. For other biofuel crops such as soybean, energy inputs can vary from 4588 [9] to 15,506 MJ ha−1 [26].

The energy expenditure for the fallow period in the current study is also lower than that reported by Zentner et al. [34] in the Canadian Prairies (ranged from 1332 to 1581 MJ ha−1 depending on the management practice), which could be related to no-till practices implemented in the current study.

Except in the fallow period, in which herbicide was the only energy-consuming input, nitrogen fertilizer was the most energy-demanding input accounting for 76, 68, and 69 % of the total energy input used in wheat, barley, and camelina, respectively. Our results agreed with reports by other researchers [5, 34] who reported a share of more than 70 % for nitrogen in the total energy input of cropping systems in the Northern Great Plains. Similar values have been reported by others in other regions [12, 21, 29]. The US average for the proportion of nitrogen in the total energy expenditure for producing a winter wheat crop is about 47 % [27]. The higher proportion of nitrogen in current study is because farmers usually apply higher N rate for higher grain protein concentration to receive protein premium or avoid penalty due to low grain protein concentration.

Considering the total energy expenditure in the complete rotation, the lowest energy input was used in the traditional FAL-WW (9182 MJ ha−1) whereas 57 and 55 % more energy input was invested in BAR-WW and CAM-WW compared to FAL-WW, respectively (Fig. 1).

Energy Output

The energy output of individual crops in the studied cropping systems varied considerably across years (Table 4). When comparing energy yield of winter wheat in different rotations, greater energy was always obtained from wheat rotated with fallow. Lower grain yield thus energy output of wheat in rotation with camelina and barley is attributed to lower content of stored water in the soil, which limited moisture availability for wheat in the intensified cropping systems compared to that in FAL-WW rotation (for details see Chen et al. [6]) (Table 4).

Camelina gross energy output in this study ranged from 31,740 to 11,690 MJ ha−1 (Table 4). Limited data are available reporting energy output of camelina especially in rainfed farming systems. However, compared to irrigated canola [22, 32], energy output of camelina was lower, which was due to low grain yield harvested in this rainfed system. As shown in Table 4, camelina energy yield was extremely low in 2011. Excessive rainfall received during May and June (when camelina was blooming) adversely influenced camelina pollination and grain formation in that year. Consistently, the Montana Agricultural Statistics reported considerably lower yield for camelina and mustard across the state in 2011 compared to 2010 (http://www.nass.usda.gov/Statistics_by_State/Montana/Publications/Annual_Statistical_Bulletin/2012/2012_Bulletin.pdf).

Total energy output of the cropping systems also varied across the experimental years (Table 4). In 2009 and 2010, BAR-WW and CAM-WW rotations produced 49 and 44 % (averaged over 2 years) greater gross energy output compared to FAL-WW. However, in 2011, due to a considerably low yield of all crops, energy output of intensified cropping systems declined; no significant differences were observed between the cropping systems in this regard (Table 4). Averaged over 3 years of the experiment, the highest energy output was attributed to the CAM-WW rotation, although it was not significantly greater than the BAR-WW sequence. Both of the alternative rotations produced significantly greater energy output than the traditional FAL-WW rotation.

Energy Indices

Except in 2011, the lowest net energy was attributed to the FAL-WW rotation (Table 4). Averaged over 3 years, CAM-WW produced the greatest net energy which was 30 and 6 % greater than that obtained from FAL-WW and BAR-WW rotations. Liska and Cassman [18] proposed net energy as a standard metric for energy productivity of biofuel production systems. This indicator can be suitably used to compare different cropping systems in terms of energy productivity [12, 22, 29, 34]. In rainfed farming systems, crop performance is greatly influenced by environmental conditions, which can also impact the energy performance of the cropping systems. In this study, under favorable environmental conditions such as in 2010, intensified cropping systems yielded greater net energy than the FAL-WW rotation (Table 4). It shows that higher energy invested in the alternative systems was completely offset by greater energy output of these alternative cropping systems.

Averaged over three years of the study, camelina’s net energy yield was 18,283 MJ ha−1 (Table 4). As mentioned previously, one necessary criterion for a biofuel to be a sustainable alternative to petroleum fuels is a positive net energy balance [9]. Camelina net energy yield in the current study is considerably greater than that reported for generic biofuel crops such as soybean and canola [9], but lower than biomass crops [1, 3, 7, 16]. This clearly shows the potential of camelina as a biofuel feedstock because considerably less fossil energy inputs are required for its production than the energy contained in its seed. It should be noticed that energy analyses presented in this paper considered only the in-farm energy flow (from planting to harvesting) and does not include energy of transportation and processing into other fuel products.

Energy efficiency of the cropping systems is shown in Table 4. Values of energy efficiency of the cropping systems were relatively high, especially in 2010, showing that non-renewable energy sources were efficiently consumed in these cropping systems. No significant differences were found between energy efficiency of the three rotations in 2009 and 2010 whereas FAL-WW outperformed alternative rotations in 2011 (Table 3). No statistically significant difference was found between the energy efficiency of the FAL-WW and the CAM-WW rotations averaged over 3 years of the experiment. With respect to energetics, the CAM-WW system outperformed the traditional FAL-WW rotation, as it tended to produce greater net energy and had a similar energy efficiency as compared with the FAL-WW system.

Potentials to Improve Energy Efficiency

The sustainability of the alternative cropping systems could be further improved through enhancing the energy efficiency, by either increasing energy output (yield) or reducing energy inputs. The former can be achieved through the selection of high-yielding cultivars. Recently, several newly developed camelina cultivars have been tested and some of them have shown considerable yield advantages over existing cultivars (Chen unpublished data). The latter (reducing energy input) can also be achieved through the optimization of the agronomic practices.

For example, our ongoing experiments showed that the application of starter fertilizer is not necessary for camelina after winter wheat as N, P, and S carried over from the previous crop is sufficient for camelina’s requirements. Also, camelina in-crop herbicide application may be reduced through good weed management in previous crop and weed management prior to planting. It is expected, through the optimization of fertilizer and herbicide consumption, almost 29 % of total energy input of camelina can be saved which in turn will greatly influence energy use efficiency in CAM-WW rotation.

Conclusion

According to the results of the present study, intensified cropping systems required more energy input than a traditional FAL-WW rotation. However, the greater amount of energy used in the intensified cropping systems was completely offset by the greater amount of energy output generated by the alternative cropping systems (i.e., CAM-WW and BAR-WW). Net energy obtained from the intensified cropping systems was considerably greater than the control (depending on the environmental conditions) despite that these systems did not differ in energy efficiency. It can be concluded that the CAM-WW and BAR-WW cropping systems outperformed the traditional FAL-WW system with respect to energy balance. In all rotations, nitrogen fertilizer was the largest energy input, accounting for nearly 70 % of the total energy input into the cropping systems studied. There is considerable potential to improve the energy performance of the alternative cropping systems, especially the CAM-WW system in this region. Refinement of management practices will greatly improve the energy balance sustainability of the alternative cropping systems.

Abbreviations

- CAM-WW:

-

Camelina-winter wheat

- BAR-WW:

-

Barley-winter wheat

- FAL-WW:

-

Fallow-winter wheat

- NGP:

-

Northern Great Plains

References

Afshar RK, Chaichi MR, Alipour A, Ansari M, Dashtaki M, Hashemi M (2015) Potential of milk thistle for biomass production in semi-arid regions. Crop Sci (Accepted)

Alluvione F, Moretti B, Sacco D, Grignani C (2011) EUE (energy use efficiency) of cropping systems for a sustainable agriculture. Energy 36:4468–4481

Angelini LG, Ceccarini L, Di Nasso NN, Bonari E (2009) Long-term evaluation of biomass production and quality of two cardoon (Cynara cardunculus L.) cultivars for energy use. Biomass Bioenerg 33:810–816

Bailey AP, Basford WD, Penlington N, Park JR, Keatinge JDH, Rehman T et al (2003) A comparison of energy use in conventional and integrated arable farming systems in the UK. Agric Ecosyst Environ 97:241–253

Burgess MH, Miller PR, Jones CA (2012) Pulse crops improve energy intensity and productivity of cereal production in Montana, USA. J Sustain Agric 36:699–718

Chen C, Bekkerman A, Keshavarz Afshar R, Neill K (2015) Intensification of dryland cropping systems for bio-feedstock production: evaluation of agronomic and economic benefits of Camelina sativa. Ind Crops Prod (accepted)

Cosentino SL, Copani V, D’Agosta GM, Sanzone E, Mantineo M (2005) First results on evaluation of Arundo donax L. clones collected in Southern Italy. Ind Crop Prod 23:212–222

Fluck RC, Baird CD (1980) Agricultural energetics. Westport: CT: AVI

Fore SR, Porter P, Lazarus W (2011) Net energy balance of small-scale on-farm biodiesel production from canola and soybean. Biomass Bioenerg 35:2234–2244

Gesch RW (2014) Influence of genotype and sowing date on camelina growth and yield in the north central US. Ind Crop Prod 54:209–215

Gugel RK, Falk KC (2006) Agronomic and seed quality evaluation of Camelina sativa in western Canada. Can J Plant Sci 86:1047–1058

Hülsbergen K, Feil B, Diepenbrock W (2002) Rates of nitrogen application required to achieve maximum energy efficiency for various crops: results of a long-term experiment. Field Crop Res 77:61–76

Khakbazan M, Mohr RM, Derksen DA, Monreal MA, Grant CA, Zentner RP, Moulin AP, McLaren DL et al (2009) Effects of alternative management practices on the economics, energy and GHG emissions of a wheat-pea cropping system in the Canadian Prairies. Soil Till Res 104:30–38

Krohn BJ, Fripp M (2012) A life cycle assessment of biodiesel derived from the “niche filling” energy crop camelina in the USA. Appl Energy 92:92–98

Lavigne A, Powers SE (2007) Evaluating fuel ethanol feedstocks from energy policy perspectives: a comparative energy assessment of corn and corn stover. Energ Policy 35:5918–5930

Ledda L, Deligios PA, Farci R, Sulas L (2013) Biomass supply for energetic purposes from some Cardueae species grown in Mediterranean farming systems. Ind Crop Prod 47:218–226

Lewandowski I, Schmidt U (2006) Nitrogen, energy and land use efficiencies of miscanthus, reed canary grass and triticale as determined by the boundary line approach. Agric Ecosyst Environ 112:335–346

Liska AJ, Cassman KG (2008) Towards standardization of life-cycle metrics for biofuels: greenhouse gas emissions mitigation and net energy yield. J Biobased Mater Bio 2:187–203

Mandal KG, Hati KM, Misra AK (2009) Biomass yield and energy analysis of soybean production in relation to fertilizer-NPK and organic manure. Biomass Bioenerg 33:1670–1679

McVay KA, Khan QA (2011) Camelina yield response to different plant populations under dryland conditions. Agron J 103:1265–1269

McLaughlin NB, Hiba A, Wall GJ, King DJ (2000) Comparison of energy inputs for inorganic fertilizer and manure based corn production. Can Agric Eng 42:9–18

Mousavi-Avval SH, Rafiee S, Jafari A, Mohammadi A (2011) Improving energy use efficiency of canola production using data envelopment analysis (DEA) approach. Energy 36:2765–2772

Patzek TW (2004) Thermodynamics of the corn-ethanol biofuel cycle. Crit Rev Plant Sci 23:519–567

Pervanchon F, Bockstaller C, Girardin P (2002) Assessment of energy use in arable farming systems by means of an agro-ecological indicator: the energy indicator. Agric Syst 72:149–172

Petre SM, Jurcoane S, Dobre P, Petcu R, Dimitriu D (2012) Life cycle assessment: by-products in biofuels production battle; rapeseed vs. Camelina sativa L. AgroLife Sci J 2:58–65

Pimentel D, Patzek TW (2005) Ethanol production using corn, switchgrass and wood; biodiesel production using soybean and sunflower. Nat Resour Res 14:65–76

Piringer G, Steinberg LJ (2006) Reevaluation of energy use in wheat production in the United States. J Ind Ecol 10:149–167

Pradhan A, Shrestha DS, Van Gerpen J, Duffield J (2008) The energy balance of soybean oil biodiesel production: a review of past studies. Am Soc Agric Biol Eng 5:185–194

Rathke G, Diepenbrock W (2006) Energy balance of winter oilseed rape (Brassica napus L.) cropping as related to nitrogen supply and preceding crop. Eur J Agron 24:35–44

Smith EG, Janzen HH, Newlands NK (2007) Energy balances of biodiesel production from soybean and canola in Canada. Can J Plant Sci 87:793–801

Shonnard DR, Williams L, Kalnes TN (2010) Camelina‐derived jet fuel and diesel: sustainable advanced biofuels. Environ Prog Sustain Energy 29:382–392

Unakitan G, Hurma H, Yilmaz F (2010) An analysis of energy use efficiency of canola production in Turkey. Energy 35:3623–3627

Vollmann J, Moritz T, Kargl C, Baumgartner S, Wagentristl H (2007) Agronomic evaluation of C. sativa genotypes selected for seed quality characteristics. Ind Crop Prod 26:270–277

Zentner RP, Lafond GP, Derksen DA, Nagy CN, Wall DD, May WE (2004) Effects of tillage method and crop rotation on non-renewable energy use efficiency for a thin Black Chernozem in the Canadian prairies. Soil Tillage Res 77:125–136

Acknowledgments

The authors like to thank Karnes Neill, Johnna Heser, and Kelly Arnold for the technical support in the field and laboratory. The funding support of this project came from USDA Western Sustainable Research and Education grant, No. 080019002; Montana Agricultural Experiment Station; and USDA-NIFA BRDI grant, No. 2012-10006-20230.

Compliance with Ethical Standards

We declare that:

- The data presented in this paper is original and have not been manipulated

- The manuscript has not been submitted to more than one journal for simultaneous consideration

- The manuscript has not been published previously (partly or in full)

- Proper acknowledgments and citations to other works are given

- The manuscript has been approved by all the authors and consent to submit has been received explicitly from all co-authors, as well as from the responsible authorities

- Authors whose names appear on the submission have contributed sufficiently to the scientific work

- Chengci Chen, and Reza Keshavarz-Afshar declare that they have no conflict of interest (financial or non-financial).

- This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Keshavarz-Afshar, R., Chen, C. Intensification of Dryland Cropping Systems for Bio-feedstock Production: Energy Analysis of Camelina. Bioenerg. Res. 8, 1877–1884 (2015). https://doi.org/10.1007/s12155-015-9644-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-015-9644-8