Abstract

The use of energy and carbon-intensive inputs in agriculture is unsustainable as it contributes to climate change, adversely affecting crop productivity and human life. Barley, the fourth most important cereal crop, has been restricted to areas with limited resources. Maintaining a balance between productivity, profitability, and sustainability by identifying viable genotypes that adapt well to resource-restricted settings and assessing them under low energy-carbon intensive management is critical. A field experiment was conducted during 2016-17 to 2018-19 to assess the energy-carbon footprint, productivity and profitability of five barley cultivars under two contrasting tillage-residue management systems in semi-arid plains of North-West India. The zero-till + residue retention (ZT+RR) system, among the tillage-residue management options, and RD-2552 followed by BH-946, among the cultivars, provided significantly higher crop productivity and profitability. Although cultivars' responses to the tillage-residue management method were not statistically significant in terms of grain yield, they were in terms of net returns. Therefore, RD-2552 and BH-946 cultivars could provide higher profitability with the ZT+RR system as compared to those with the conventional-till + residue incorporation (CT+RI) system. Although cultivars did not affect the energy-carbon footprints of barley production, tillage-residue management methods did. The ZT+RR system enhanced the energy and carbon use efficiencies of the barley cultivation with lower energy-carbon footprints. The cultivar RD-2552 followed by BH-946 under the ZT+RR system could provide higher productivity and profitability with lower energy-carbon footprints. Adoption of conservation agriculture-based tillage-residue management practices could improve productivity and profitability of barley crop with reduced energy-carbon footprints in the semi-arid ecologies of India.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The energy consumption pattern of the agricultural sector has grown extensively, particularly during the past three to four decades, due to excessive use of fossil fuels in crop production (Parihar et al. 2018). However, the use of energy and carbon-intensive inputs in agriculture is not sustainable due to its contribution to climate change that adversely affects crop productivity and human life (Ghorbani et al. 2011). Agriculture accounts for 10–12 percent of total yearly anthropogenic greenhouse gas (GHG) emissions (Tjandra et al. 2016; Ashoka et al. 2017), hence compounding the situation of global warming and climate change (Lobell and Gourdji 2012). Improving agricultural production's energy use efficiency (EUE) minimizes carbon dioxide emissions, limits energy dependence, and effectively offsets rising oil prices (Vourdoubas 2016). Crop management practices that sequester carbon and require low energy inputs should be prioritized due to their notable significance in environmental sustainability (Meena et al. 2022). Therefore, identifying and promoting crop management strategies with low carbon footprint (CF) values is critical to make present agriculture more cost-effective and eco-friendly, with low GHG emissions (Liu et al. 2016). In this regard, energy and carbon auditing studies that provide a basis for identifying energy and carbon-efficient management practices are helpful (Xue et al. 2016; Chaudhary et al. 2017).

Crop production involves various energy and carbon-consuming operations (tillage, planting, manuring, weed and water management, harvesting and threshing, etc.) that emit a significant quantity of GHGs, affecting the environmental quality (Ntinas et al. 2017; Yadav et al. 2017). Tillage is one of the most energy-intensive agricultural operations that accounts for approximately 30 percent of the total energy used in crop production (Singh et al. 2008; Lal 2015), thus directly contributing to GHG emissions (Soni et al. 2013; Yadav et al. 2017). Therefore, emulation of efficient tillage practices can minimize environmental concerns and improve agricultural sustainability by improving EUE and reducing CFs (Ozkan et al. 2004; Pandey and Agrawal 2014). In this context, conservation agriculture (CA) based crop production technologies like zero or minimum tillage and crop residue mulch on the soil surface can potentially improve the EUE by eliminating energy-intensive operations (Lal 2015; Parihar et al. 2017). Several studies have confirmed that long-term adoption of CA-based zero tillage (ZT) with crop residue mulch on the soil surface enhances crop yield, reduces production cost, and improves soil and environment quality (Yadav et al. 2017; Meena et al. 2018). Adoption of CA technologies reduces fossil fuel consumption and the dependencies on human labour, which may decrease energy input requirements, GHG emissions, and the cost of cultivation (Yadav et al. 2016; Mrunalini et al. 2020; Das 2021). The GHG emission has been reported to be reduced by adopting ZT practice owing to less fossil fuel use and higher C sequestration (Lal et al. 2019; Chaudhary et al. 2021). Rahman et al. (2021) estimated the GHG emission to be lower in ZT (1987.2 kg CO2-eq ha-1) as compared to conventional tillage (CT) (2028.3 kg CO2-eq ha-1) under wheat cultivation using the farm efficiency analysis tool (FEAT). Zero-till with crop residue retention showed 40% lower GHG emission than CT under barley cultivation (Chaudhary et al. 2021). Zero tillage reduced the energy consumption by 56% and CF by 39% as against CT under the rice-maize cropping system (Lal et al. 2019). In addition, residue retention under ZT led to a notable improvement in crop productivity and soil health. Considering the aforementioned case studies, ZT has the potential to help in replenishing soil organic carbon (SOC) levels through residue retention, hence reducing overall GHG emissions. Although the overall impact of CA-based technologies on soil health, energy consumption, carbon footprints, and GHG emissions is somewhat encouraging, crop production under ZT has been significantly unpredictable. Previous studies have shown an increase (Faiz et al. 2022), decrease (Lal et al. 2019) or no effect (Roohi et al. 2022) on crop productivity under the ZT system as compared to CT. It is evident that crop yield has a significant effect on GHG emissions. Therefore, it is essential to comprehend the impact of tillage on energy-carbon footprint and crop productivity-profitability.

Barley is the fourth most important cereal in the world, accounting for around 15% of total coarse grains in use (Dhillon et al. 2019). It is preferably grown in rainfed areas with limited irrigation facilities and poor soil fertility in India. It is an important source of dietary fibres, protein, vitamins and minerals source for humans and livestock. Over the past several decades, the area under barley production has been steadily decreasing, owing to a gradual shift towards wheat production due to its higher yield potential (Kumar et al. 2014). It has restricted barley to marginal and problematic soils, further adding to its low production. Adopting varieties better adapted to resource-limited conditions and evaluating them under various crop management technologies (optimization for tillage options, time of sowing, fertilizer, irrigation etc.) could enhance barley production. Tillage methods have a major influence on the soil physical environment, which in turn affects the yield of the crop. Singh et al. (2013) evaluated malt barley under different tillage options and observed a higher yield and malt recovery under ZT compared to CT. Furthermore, the varietal selection is undoubtedly a prime component of crop production. Plant genotypes in breeding programs are mostly evaluated under CT systems. Therefore, little is known about the varietal performance of barley under the ZT system. Apart from higher productivity, the genotypes should also impart yield stability under aberrant environmental conditions, ensuring profitable production for farmers. Therefore, studies evaluating alternative tillage options and residue management practices for optimizing carbon and energy budget and enhancing crop productivity-profitability under the semi-arid ecologies are essentially required to understand and promote effective technologies for reducing GHG emissions and preventing global warming. Thus, keeping this in view, the present study was undertaken with two broad objectives: (1) to assess the crop productivity and profitability of barley cultivars under contrastitillage-residue management options; (2) to evaluate energy-carbon use efficiencies and footprints for different treatment combinations, thus identifying a suitable barley cultivar and tillage-residue management system that could be sustainable in the long run.

2 Material and Methods

2.1 Soil and Climate of Study Site

The present experiment was carried out during three successive winter seasons (2016-17 to 2018-19) at Rajasthan Agricultural Research Institute, Jaipur, Rajasthan, India (26° 51' N, 75° 47' E, and 390 m above mean sea level). The experimental site belongs to a semi-arid climate characterized by cold winters and hot summers. The occurrence of frost during December/January is a pretty common phenomenon in the area. The region receives an average annual precipitation of 563 millimetres, of which approximately 90 percent falls irregularly between the second part of June and the end of September. The average annual evaporation (850 mm) continues to be more than the average annual precipitation, resulting in frequent soil moisture deficits. During the experimental period (November to April), the total precipitation at the experimental site ranged from 107.2 mm to 173.4 mm (2016-17 to 2018-19). During the trial period (November to April), the average weekly maximum and minimum temperatures ranged from 19.8 to 40.7 °C and 5.7 to 26.8 °C, respectively. At the experimental site, the soil was sandy loam in texture (with 82% sand, 7% silt, and 11% clay) and slightly alkaline (pH 8.1) with low organic carbon content (0.23 g kg-1) (Walkley and Black 1934). The surface soil (0-15 cm) was low in available N (172.0 kg N ha-1) (Subbiah and Asija 1956), medium in NaHCO3 extractable P (18.1 kg P ha-1) (Olsen et al. 1954) and NH4OAc extractable K (237.0 kg K ha-1) (Hanway and Heidel 1952).

2.2 Experimental Details and Crop Management

The experiment was laid out in a split-plot design with three replications. The main plot consisted of two contrasting tillage and residue management practices, i.e., conventional tillage (CT) with residue incorporation (RI) and zero tillage (ZT) with residue retention (RR). In sub-plots, five promising cultivars of barley viz. BH-946, BH-902, RD-2552, DWRB 101, and DWRUB 52 were grown. The CT system involved one deep ploughing followed by two harrowing and planking to prepare a seedbed with desired tilth. Whereas, under the ZT system, no preparatory tillage was performed and crop seeds were drilled directly using a zero-till seed-cum-fertilizer drill. In CT plots, pearl millet crop residues equivalent to 6 Mg ha-1 were incorporated by chopping and spreading uniformly on the field before primary tillage. The same quantity of pearl millet residues was also retained on the soil surface in ZT plots. The barley cultivars were sown at a seed rate of 100 kg ha-1 during the first fortnight of November. The crop was harvested during the first fortnight of April. The recommended dose of fertilizers (60-30-20 kg N-P2O5-K2O ha-1) was supplied to the crop. Half of the recommended fertilizer dose of N and the total P and K were applied as basal at the sowing time. The rest half quantity of nitrogen was supplied through top dressing at the first irrigation, i.e., 25-30 days after sowing (DAS). In ZT plots, glyphosate at 1.2 kg a.i. ha-1 was sprayed about 7-10 days before sowing the crop to kill the existing weeds. Besides, a pre-emergence application of pendimethalin at 1.0 kg a.i. ha-1 was made on the same day of sowing to check the initial flush of weeds in both CT and ZT plots. In CT plots, one manual weeding was done at 25-35 DAS to manage the late-season weeds effectively. However, in ZT plots, 2, 4 D was sprayed at 0.75 kg a.i. ha-1 post-emergence (30-35 DAS) to control the late-season broadleaved weeds effectively. In all treatments, one pre-sowing irrigation (6 cm) followed by four post-sowing irrigations (4.5 cm each) at 25–30, 50–55, 80–85, and 100–105 DAS were applied.

2.3 Assessment of Crop Productivity, Profitability, and Crude Protein Content of Barley

The crop was harvested, and the harvested produce of each plot was tied in bundles and left in the field for sun drying, after which the biological yield was recorded by weighing them using a spring balance. After threshing the bundles from each plot using a plot thresher, the grains were cleaned, dried, and weighted. The final grain yield was expressed in dry weight at 12% moisture content. Straw yield for individual plots was calculated by subtracting the grain yield from the total biomass yield.

The revenue of production, including the cost incurred during cultivation and a cost-benefit analysis, was estimated for each treatment combination. The variable costs incurred through major inputs used for different operations such as residue management, seedbed preparation and sowing, weed management, fertilizer and plant protection chemicals, irrigation management, harvesting and threshing, etc., were considered in estimating the total cost of cultivation. The gross returns from each treatment combination were calculated by multiplying the economic biomass (grain and straw) with respective prevailing market prices. Likewise, deducting the cost of cultivation from the gross returns gave a net returns from each treatment combination. Finally, the benefit-to-cost ratio was calculated by dividing the net returns by the total cost of cultivation.

The crude protein content of barley grain was estimated indirectly by multiplying the nitrogen (N) concentration of grain with the standard factor of 6.25 (AOAC 1990). For this purpose, the N content of grain samples was estimated using modified Kjeldahl's method (Lindner 1944). Biomass protein equivalent yield (BPEY) was calculated by multiplying the crude protein content of grain with grain yield. Finally, adult protein equivalent (APE) was determined using a standard demand of 60 g protein person-1 day-1 (ICMR 1981).

2.4 Calculation of Energy Relations

The stored energy in all inputs and outputs (total biological yield) of the production system was used to determine the energy relations. The energy equivalent coefficients used in the study were collected from various sources and are presented in table 1 (Mittal and Dhawan 1988; Singh et al. 1997). The energy requirement (MJ ha-1) under different treatment combinations was determined using the following equations.

ERi = energy requirement of ith input (MJ ha-1); Qi = quantity of ith input used (unit ha-1); Eeqi = energy equivalent coefficient of ith input (MJ unit-1); EI = total energy footprint or requirement of a treatment combination (MJ ha-1)

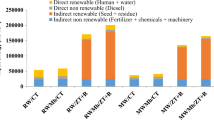

The energy sources used in crop production can be categorized into direct and indirect sources, considering their energy release pattern (Devasenapathy et al. 2009). Direct energy sources (animate power, diesel, and irrigation) release energy upon use, whereas indirect energy sources do not release energy directly but involve a significant amount of energy in production and storage. The present study considers agricultural inputs such as fertilizers, plant protection chemicals, farm machinery, seeds, and crop residues under indirect energy sources. The energy sources are further categorized as non-renewable and renewable based on their exhaustibility (Devasenapathy et al. 2009). The animate power (human and animal) and irrigation are classified as direct renewable energy, while diesel is considered direct non-renewable energy. Likewise, indirect renewable energy source includes crop seeds and residues, whereas fertilizers, plant protection chemicals, and machinery are indirect non-renewable energy. The energy input was computed based on the amount of energy that was utilized in several agricultural operations ranging from field preparation and sowing of the crop to harvesting and threshing. Figures 1–3 illustrate the usage pattern of input energy for the various treatment combinations that were employed in the study. These treatment combinations were examined. The energy outputs from different treatment combinations were estimated by multiplying the energy equivalent coefficient (Table 1) with the quantity of crop biomass (grains and straw) produced. The energy use under different tillage and residue management options was analyzed using indices proposed by (Mittal and Dhawan 1988; Singh et al. 1997). The energy efficiency indicators were calculated using equation (3) to (7).

Input-wise energy requirement (MJ ha-1) under contrasting tillage-residue management options and barley cultivars (mean of 3 years). The height of a bar (difference between upper value and lower value on y-axis) indicates the energy contribution of an input towards cumulative energy requirement (cumulative value on y-axis) under a treatment. CT+RI: conventional tillage with residue incorporation; ZT+RR: zero tillage with residue retention.

Operation-wise energy requirement (MJ ha-1) under contrasting tillage-residue management options and barley cultivars (mean of 3 years). The height of a bar (difference between upper value and lower value on y-axis) indicates the energy contribution of an operation towards cumulative energy requirement (cumulative value on y-axis) under a treatment. CT+RI: conventional tillage with residue incorporation; ZT+RR: zero tillage with residue retention.

NE = net energy (MJ ha-1); EO = gross energy output (MJ ha-1); EUE = energy use efficiency; EP = energy productivity (kg MJ-1); BY = biological yield of barley (kg ha-1), ER = energy requirement of a treatment combination (MJ ha-1); EPF = energy profitability; ES = specific energy (MJ kg-1); GY = grain yield (kg ha-1)

2.5 Calculation of Carbon Relations

The carbon footprint of different treatment combinations was estimated at both spatial and yield scales to study the environmental impact during the cropping period. The spatial CF was calculated by considering the GHGs emission (in terms of CO2-eq) per unit area. In the present study, only CO2 and N2O emissions have been considered, as soil redox potential in each treatment was higher than that required for methane emission, and no on-farm burning of crop residue was done. According to equation (8), the GHGs emission per unit area (spatial CF) is equal to the total CO2 emission from utilized inputs and N2O emission from nitrogen (N) application (Pandey and Agrawal 2014). The inputs' GHG emissions were evaluated using consumed inputs' quantity and CO2-eq coefficients (Table 1) according to the following equation (9). The N2O emission was calculated by multiplying the quantity of nitrogen (N) supplied through fertilizer, emission coefficient (0.01) (Tubiello et al. 2015), the conversion factor for N to N2O (1.571) and global warming potential of N2O (298) (Kirschbaum 2014) as per equation (10). The CF per unit yield (yield scale CF) was estimated by using equation (11) (Pandey and Agrawal 2014).

CFS = carbon footprint per unit area (kg CO2-eq ha-1); CFI = carbon footprint of inputs (kg CO2-eq ha-1); CFN = carbon footprint of N2O emission from N application (kg CO2-eq ha-1); Qi = quantity of ith input consumed (unit ha-1); CEci = CO2-eq coefficient of ith input (kg CO2-eq unit-1); QN = quantity of external N applied (kg ha-1); 0.01 is the emission factor; 1.571 is the conversion factor for N to N2O; 298 is global warming potential of N2O (kg CO2-eq per kg N2O); CFy = carbon footprint per unit yield (kg CO2-eq per kg yield); GY = grain yield of barley (kg ha-1)

The carbon output represented the total crop biomass produced in each treatment combination. The total biological yield of barley under each treatment was multiplied by 0.44 (assuming that plant dry matter contains 44% carbon) to estimate the carbon output. The carbon efficiency (CE), carbon efficiency ratio (CER) and carbon sustainability index (CSI) are calculated using the following equations (Chaudhary et al. 2017).

CI = carbon input (kg C-eq ha-1); CFS = carbon footprint per unit area (kg CO2-eq ha-1); 0.27 is the conversion factor for CO2 to C; CE = carbon efficiency; CO = total carbon output (kg C-eq ha-1); CER = carbon efficiency ratio; COG = carbon output in grain (kg C-eq ha-1); CSI = carbon sustainability index

2.6 Statistical Analyses

The recorded data during individual years, as well as their pooled means, were analyzed statistically using analysis of variance (ANOVA) for split-plot design (SPD) under SAS 9.3 software (SAS Institute, Cary, NC). The F-test and least significant difference (LSD) (P<0.05) were used to decipher the significance of the means of tillage and residue management practices, cultivars and their interactions.

3 Results

3.1 Crop Productivity and Profitability

The contrasting tillage and residue management options considerably affected the crop's productive tiller numbers and yields (Table 2). The number of productive tillers and yields of barley were significantly higher under ZT+RR compared to CT+RI. The ZT+RR increased the grain, straw, and biomass yield by 6.45, 6.55 and 6.50% over CT+RI, respectively. The biomass protein equivalent yield (BPEY) and adult protein equivalent (APE) under ZT+RR were 5.8% higher than that of CT+RI (Table 2). The productive tiller numbers and crop productivity varied significantly across the cultivars. Among cultivars, DWRUB-52 produced the highest number of productive tillers (402 m-2), which was at par with DWRB-101 and significantly higher than that of BH-946, BH-902, and RD-2552 (Table 2). However, the RD-2552 cultivar gave the highest grain, straw and biomass yields (5890, 7093 and 12984 kg ha-1, respectively).

The box and whisker plot showed the variability in the crop productivity of treatment combinations over three years (Fig. 4). The inner quartile range (a measure of variability based on dividing a dataset into quartiles) of the box and whisker plot was the lowest for BH-946 cultivar with ZT+RR system (174 kg ha-1) and highest for RD-2552 cultivar with CT+RI system (448 kg ha-1) (Fig. 4). It implies a minimum variability in crop productivity of the BH-946 cultivar under ZT+RR system, while a maximum variability was observed in RD-2552 cultivar under CT+RI system over three cropping seasons. The ZT+RR improved the mean grain yield of a particular cultivar by 5-8% over the CT+RI. The improvement ranged from at least 299 kg ha-1 in RD-2552 to a maximum of 420 kg ha-1 in DWRUB-52 (Fig. 4). However, the improvement in grain yield of a particular cultivar due to ZT+RR over CT+RI was not statistically significant.

The box and whisker graphic illustrates the variance and average grain yield over three years. Whiskers (lines extending from the box) represent variability outside the inner quartiles. The upper and lower limits of the box reflect the range of inner quartiles. The horizontal line within a box indicates the median value, whereas the "x" inside a box indicates the mean value. CT+RI: conventional tillage with residue incorporation; ZT+RR: zero tillage with residue retention.

The expenditure incurred on the cultivation of barley under CT+RI was substantially higher than that of ZT+RR (Table 2). In contrast, the gross and net returns under the ZT+RR system were significantly higher than those under the CT+RI system. The ZT+RR system reduced the cost of cultivation by 27% but enhanced the gross and net returns by 6.5 and 30.3%, respectively, over the CT+RI system. A benefit-to-cost ratio of 2.49 was obtained under the ZT+RR system, which was 79% higher than the CT+RI. In sub-plots, the cost of cultivation remained the same for all barley cultivars as the type and quantity of inputs used for each cultivar were similar. The RD-2552 cultivar resulted in the highest gross and net returns (1511 and 1014 USD ha-1, respectively) and benefit-cost ratio (2.13), which were significantly higher than other cultivars. The DWRB-101 cultivar resulted in the lowest gross and net returns (1552 and 855 USD ha-1, respectively) and benefit-cost ratio (1.80). The gross and net returns from the RD-2552 cultivar were 5-12% and 7-19%, respectively, higher than the other cultivars.

The contrasting tillage-residue management options significantly interacted with the type of cultivars with respect to the net returns. The ZT+RR enhanced the net returns of cultivars by 28-32% over the CT+RI system. The improvement ranged from at least 236 USD ha-1 (in BH-946 and DWRB-101) to a maximum of 253 USD ha-1 in BH-902 (Fig. 5). The lower limit of net returns from the treatment combinations was computed using descending cumulative distribution functions (CDFs). The CDFs describe the probability (y-axis) of obtaining net returns greater than or equal to the values on the x-axis (Fig. 5). A vertically slanting line having a high slope that shifts as far to the y-axis as possible depicts a low-risk and high-profit scenario (Krupnik et al. 2012). Results showed that the RD-2552 cultivar with the ZT+RR system could provide minimum net returns ranging from 1067 USD ha−1 to 1193 USD ha−1 with 0% to 100% probability. This treatment combination gave net returns of 1076 USD ha−1 with 89% probability. It means a grower could achieve 1076 USD ha−1 net returns with 89% certainty from the RD-2552 cultivar in the ZT+RR system, while an 11% risk is associated with not achieving it. The minimum assured net returns with 100% probability was the highest in RD-2552 with the ZT+RR, followed by BH-946 with ZT+RR (1006 USD ha−1) and the lowest in DWRB-101 with CT+RI (648 USD ha−1). The RD-2552 with the ZT+RR and BH-946 with ZT+RR combinations reduced the economic risk at all probability levels more consistently as compared to other combinations. Within the ZT+RR system, the minimum assured net returns with 100% probability ranged from 902 USD ha−1 in DWRUB-52 to 1067 USD ha−1 in RD-2552. Similarly, within the CT+RI system, the minimum assured net returns with 100% probability ranged from 648 USD ha−1 in DWRB-101 to 793 USD ha−1 in RD-2552.

Descending cumulative distribution functions describing the potential (y-axis) of obtaining net returns (USD ha-1) greater than values on the x-axis over three cycles of 2-year crop rotations. A vertical leaning line (with a higher slope) shifted as far to the y-axis as possible depicts a low-risk and high-profit scenario. The figure listed indicates the mean net returns over three years of experimentation. The CD values (p<0.05) for interaction between tillage-residue management options and cultivars is 80.8 USD ha-1.

3.2 Energy Use Pattern and Energy Relations

The energy use patterns of barley cultivation under different tillage-residue management options and cultivars have been studied by computing source, input and operation-wise energy requirements (Fig 1-3). The total energy requirement for cultivation of all barley cultivars remained the same as the type and quantity of inputs used for each cultivar were similar. However, among tillage-residue management options, the total energy requirement under the ZT+RR system was 3% lower than that of the CT+RI system (Fig.1). The contribution of indirect renewable energy was the highest (83.0-85.6%), followed by indirect non-renewable (8.0-8.8%), direct renewable (4.3-4.7%), and direct non-renewable energies (2.8-4.3%) towards the total energy requirements irrespective of treatments. The input-wise energy use analysis showed that crop residue followed by fertilizers (81.3-83.8% and 4.8-4.9%, respectively) contributed the maximum to the total energy requirements irrespective of treatments. Among the used inputs, diesel, herbicide, machinery and labour (with a range of 2534, 1273, 815 and 470 MJ ha-1, respectively) were responsible for the variability in total energy requirements across ZT+RR and CT+RI (Fig. 2). The ZT+RR system resulted in 69, 65 and 30% savings in energy consumed by diesel, machinery and labour, respectively, over the CT+RI system. However, the ZT+RR system consumed 167% more energy through herbicide use than the CT+RI system. The operation-wise energy use analysis showed that field preparation-sowing and weed management (with a range of 3349 and 1265 MJ ha-1, respectively) were responsible for the variability in total energy requirements across ZT+RR and CT+RI (Fig. 3). The ZT+RR system resulted in a 60% saving in energy consumed by field preparation-sowing over the CT+RI system. However, the ZT+RR system consumed 63% more energy for weed management than the CT+RI system (Fig. 3).

Total energy inputs, outputs, and crop productivity were used to compute various energy relations for all treatments (Table 3). Both tillage-residue management options and cultivars significantly affected different energy indices. Among tillage-residue management options, ZT+RR resulted in 7.5% higher energy outputs as compared to the CT+RI. The lower energy inputs and higher energy outputs in the ZT+RR system led to 21% more net energy (NE) production than in the CT+RI system (Table 3). Similarly, lower energy inputs and higher grain and biomass yields in the ZT+RR system resulted in 11.8% more energy productivity (EP) and 8.9% less specific energy (SE) than that of the CT+RI system. Besides, the energy use efficiency (EUE) and energy profitability (EPF) under the ZT+RR system were 11.2 and 25.6%, respectively, higher than that of the CT+RI. In sub-plots, the total energy outputs varied from 151500 MJ ha-1 with DWRUB-52 cultivar to 168539 MJ ha-1 with RD-2552 cultivar (Table 3). The total energy output from the RD-2552 cultivar was significantly higher than other cultivars except for BH-946. The RD-2552 resulted in the highest NE, EUE, EP and EPF, which were 8.8-25.4, 4.2-11.3, 3.8-11.4 and 8.9-25.4%, respectively, higher than that of other cultivars. However, the SE was the highest and lowest in the RD-2552 and the DWRB-101 cultivar, respectively. The SE in the RD-2552 cultivar was 4.1-10.3% lower than in other cultivars.

3.3 Carbon Footprint and Use Efficiency

The CFS of barley cultivation under different tillage-residue management options and cultivars has been studied by estimating input and operation-wise GHG emissions (kg CO2-eq ha-1) (Fig 6-7). The CFs for the cultivation of all barley cultivars remained the same as the type and quantity of inputs used for each cultivar were similar. However, the tillage-residue management options significantly affected the CFs of barley cultivation. The total CFS of the ZT+RR system was 5% lower as compared to the CT+RI system (Fig. 6). The analysis of input-wise GHG emissions showed that crop residue followed by fertilizers (69.4-71.2% and 9.2-9.7%, respectively) contributed the maximum to the total CFS irrespective of treatments. Among the used inputs, diesel, herbicide, machinery and labour (with a range of 150, 31, 43 and 26 kg CO2-eq ha-1, respectively) were responsible for the variability in total CFS across ZT+RR and CT+RI systems (Fig. 6). The ZT+RR system resulted in 69.4, 65.2 and 30.2% lower CFS due to diesel, machinery and labour, respectively, over the CT+RI system. However, the CFS due to herbicide use was 163.1% higher in the ZT+RR system as compared to the CT+RI system. The analysis of operation-wise GHG emissions showed that field preparation-sowing and weed management (with a range of 193 and 6 kg CO2-eq ha-1, respectively) were responsible for the variability in total CFS across ZT+RR and CT+RI systems (Fig. 6). The CFS for the field preparation-sowing in the ZT+RR system was 53.9% lower than that of the CT+RI system. However, CFS for management in the ZT+RR system was 13.0% higher than that of the CT+RI system (Fig. 7).

Input-wise spatial carbon footprint/GHG emission (kg CO2-eq ha-1) under contrasting tillage-residue management options and barley cultivars (mean of 3 years). The height of a bar (difference between upper value and lower value on y-axis) indicates the spatial carbon footprint of an input towards cumulative spatial carbon footprint (cumulative value on y-axis) under a treatment. CT+RI: conventional tillage with residue incorporation; ZT+RR: zero tillage with residue retention.

Operation-wise spatial carbon footprint/GHG emission (kg CO2-eq ha-1) under contrasting tillage-residue management options and barley cultivars (mean of 3 years). The height of a bar (difference between upper value and lower value on y-axis) indicates the spatial carbon footprint of an operation towards cumulative spatial carbon footprint (cumulative value on y-axis) under a treatment. CT+RI: conventional tillage with residue incorporation; ZT+RR: zero tillage with residue retention.

The carbon use efficiency indicators were computed by using total carbon inputs (CI), total carbon outputs (CO) and crop productivity (Table 4). The CI varied significantly across tillage-residue management options, whereas it remained the same for all cultivars. Among tillage-residue management options, the ZT+RR system required a 4.9% lower CI but produced 8.5% higher CO compared to the CT+RI system (Table 4). The CE, CSI and CER of the ZT+RR system were significantly higher than that of the CT-RI. The ZT+RR system enhanced the CE, CSI and CER by 14.2, 45.7 and 11.9%, respectively, over the CT+RI system. The CFY of the ZT-RR system was significantly lower than that of the CT-RI. The ZT+RR system reduced the CFY by 11.2% over the CT+RI. In sub-plots, cultivars significantly affected CO, CE, CSI, CER and CFY (Table 4). The CO varied from 5134 kg C-eq ha-1 for DWRUB-52 to 5654 kg C-eq ha-1 for RD-2552. The CO of the RD-2552 cultivar was 3.5-10.1% higher as compared to other cultivars. The RD-2552 cultivar resulted in a significantly higher CE, CSI and CER than others. The CE, CSI and CER of the RD-2552 cultivar were 3.5-10.2, 4.3-12.7 and 4.7-12.0% higher than that of others. The CFY varied from 0.63 kg-1 CO2-eq kg-1 grain for RD-2552 to 0.71 kg-1 CO2-eq kg-1 grain for DWRB-101. The CFY of RD-2552 was 4.5, 6.0, 8.7 and 11.2% lower than that of BH-946, BH-902, DWRUB-52 and DWRB-101, respectively.

4 Discussion

Selection of an appropriate tillage system along with residue management option for crops is crucial for reducing energy consumption and plays a noteworthy role in energy-carbon budgeting. In the present study, minimum soil disturbance and crop residue retention could be the reason for the high and consistent productivity of barley in the ZT+RR system which could be attributed to improved soil quality (Busari et al. 2015; Yadav et al. 2016) and crop residue mulch effects (Patil et al. 2015; Hosseini et al. 2016). Minimum soil disturbance by tillage activities benefits in improving soil microbial diversity while enhancing the quantity and quality of soil organic matter (Kushwaha and Singh 2005). The favourable growing environment created due to high input of organic matter into soil in the ZT+RR system led to a higher number of productive tillers, which later translated into higher crop yields. A higher and stable yield in ZT and residue incorporation system is an indication of good management practices. Similar, trend was also observed in total biological yield where ZT with residue retention performed better against CT with residue incorporation. The estimation of total biological yield provides an insight into the overall impact of management practices not only on grain production but also on the total dry matter accumulation in the plant system which is directly influenced by the soil fertility. The observed variability in crop productivity across the cultivars could be due to their genetic constituents. The RD-2552, BH-946, and BH-902 cultivars have six rows in the spike, whereas DWRUB-52 and DWRB-101 cultivars have two rows in the spike. The genetic nature and higher number of grain spike-1 could be the reason for the higher productivity of the RD-2552 cultivar as compared to others. However, the grain yield obtained from DWRUB-52 was comparable to that obtained from BH-902 (six rowed cultivar). In an earlier study by Sharma and Verma (2010), reports of test weight (1000 grain weight) was recorded to be considerably higher in two-rowed varieties as opposed to six-rowed in the spike of barley. This might explain the yield compensation of BH-902 as compared to DWRUB-52 cultivar. It is evidently observed in this study that the genetic effect significantly contributes to the performance of crop cultivars under various tillage and residue management options, which is crucial information while devising strategies for meeting environmental sustainability goals and ensuring food security.

The total variable cost of cultivation of barley with the CT+RI system was 27% higher than the ZT+RR system. The higher cost of cultivation under the CT+RI system was due to more use of machinery and diesel during field preparation and extra-human power required for manual weeding. Similar results of higher production cost due to adoption of CT over ZT was also reported by Ozpinar and Ozpinar (2011) and Choudhary et al. (2016). The low cost of cultivation and higher crop productivity led to higher net returns and benefit-cost ratio in the ZT+RR system. Thus, the ZT+RR system is a feasible option for higher crop productivity and profitability of barley in semi-arid agro-ecologies. The combined financial implication brought about by higher productivity and net returns (better cost-saving effect) is compelling enough to warrant widespread adoption of ZT+RR technology under barley cultivation in resource-scarce regions of Rajasthan. Besides, it provided the higher minimum assured net returns due to more consistent and higher crop yields than the CT+RI system. Among cultivars, the RD-2552 resulted in higher net revenue and benefit-cost ratio due to the higher biomass production compared to other genotypes at the same cost of cultivation.

The total energy requirement of the CT+RI system was higher than that of the ZT+RR system due to more use of inputs such as machinery, diesel and labour in the CT+RI system. The saving in the use of machinery and fossil fuel due to omission of primary and secondary tillage practices and labour due to chemical weed management resulted in lower energy requirements in the conservation agriculture system. However, irrespective of tillage practices, adding residue involved a considerable amount of energy (81.4-83.9%), thus increasing the system's total input energy requirement. Our result confirms that residue management contributes maximum to the total energy requirement of tillage-residue management systems (Parihar et al. 2017; Choudhary et al. 2017). The higher biomass energy production and lower input energy consumption in the ZT+RR system resulted in higher energy output, NE, EUE, EP, and EPF compared to the CT+RI system. Efficient use of energy is definitive and necessary to ensure cleaner crop production. Cultivation practices involving no-tillage and proper residue management have the potential for increasing the decarbonization rate and energy use efficiency, thus bringing a reduction in the pace of global warming. There are several reports showing higher energy use efficiency and low GHG emissions under ZT based CA system compared to CT system (Barut et al. 2011; Pratibha et al. 2015). Among cultivars, RD-2552 resulted in higher EO, NE, EUE, EP and EPF at the same level of input energy consumption, which could be due to higher biomass accumulation as compared to other cultivars. Crop residue, either applied as mulch (in ZT+RR) or incorporated (in CT+RI), enhanced the carbon input of barley cultivation considerably due to its higher carbon content (44% carbon). Similar findings of an increase in carbon input with the increase in crop residue quantity under contrasting tillage managements were also reported by Gan et al. (2009) and Goglio et al. (2014). However, the CT+RI system emitted 187% and 227% more GHGs through machinery and fossil fuel use, respectively, compared to ZT+RR. The observed difference in GHG emission was due to less use of machinery and fossil fuel through the omission of primary and secondary tillage under ZT+RR (Mohammadi et al. 2014; Pratibha et al. 2015). The higher carbon output in the ZT+RR system was due to higher crop biomass production than in the CT+RI system. The lower carbon input and higher carbon output led to higher CE, CER and CSI in the ZT+RR system as compared to CT+RI. The CY of the ZT+RR system was lower due to higher grain yield and reduced GHG emissions as compared to the CT+RI system. Similar findings on higher values of carbon use indices (CE, CER and CSI) and lower carbon footprint (CY) for conservation agriculture-based systems have also been reported (Lal 2004; Dubey and Lal 2009; Pratibha et al. 2015). Among cultivars, RD-2552 resulted in higher CE, CER and CSI and lower carbon footprints compared to all other cultivars at the same level of carbon consumption. The higher carbon output in terms of biomass with RD-2552 cultivar was a reason for observed differences in carbon use indices.

5 Conclusions

The enhanced energy and carbon use efficiency in crops and cropping systems have a significant role in reducing carbon footprint and promoting environmental sustainability. The present study involving two contrasting tillage-residue management options and five cultivars reveals that the zero tillage with residue retention (among the tillage-residue management options) and RD-2552 followed by BH-946 (among the cultivars) provided higher crop productivity and profitability. When compared to the conventional tillage with residue incorporation system, the RD-2552 and BH-946 cultivars could deliver higher productivity with reduced variability and higher minimum assured net returns under the zero tillage with residue retention system. Although the cultivars did not influence the energy-carbon footprints of the barley cultivation, the tillage-residue management options did. The zero tillage with residue retention technique improved energy and carbon use efficiency in barley production, resulting in reduced energy-carbon footprints. Therefore, the cultivation of RD-2552 followed by BH-946 cultivars under the zero tillage with residue retention system could provide higher productivity and profitability with lower energy-carbon footprints. The adoption of conservation agriculture-based tillage-residue management practice could provide higher productivity and profitability in barley crop with a lower carbon footprint and higher energy use efficiency in semi-arid ecologies of India which could be sustainable in the long run. This study helps to quantify the integral effect of tillage practices, residue management and performance of different cultivars of barley on energy use and carbon footprint which is crucial for the mitigation of carbon released into the atmosphere, energy consumption, and economic parameters. The present study will lead the way in assisting policymakers which will enable them to design clean agricultural production systems to ensure food security and improve environmental quality.

Glossary

APE: Adult protein equivalent

BPEY: Biomass protein equivalent yield

BY: Biological yield

CA: Conservation agriculture

CE: Carbon efficiency

\(CE_{\mathrm{c}i}\): CO2-eq coefficient of ith input

CER: Carbon efficiency ratio

CF: Carbon footprint

\(CF_{\mathrm{I}}\): Carbon footprint of inputs

CFN: Carbon footprint of N2O emission from N application

CFS: Carbon footprint per unit area

CFS: Carbon footprint per unit area

CFy: Carbon footprint per unit yield

CI: Carbon input

CO: Total carbon output

COG: Carbon output in grain

CSI: Carbon sustainability index

CT: Conventional tillage

Eeqi: Energy equivalent coefficient of ith input

EPF: Energy profitability

EI: Total energy footprint or requirement of a treatment combination

EO: Gross energy output

EP: Energy productivity

ER: Energy requirement of a treatment combination

ERi: Energy requirement of ith input

ES: Specific energy

EUE: Energy use efficiency

GHG: Greenhouse gas

GY: Grain yield

NE: Net energy

Qi: Quantity of ith input consumed

Qi: Quantity of ith input used

QN: Quantity of external N applied

RI: Residue incorporation

RR: Residue retention

ZT: Zero tillage

Data availability

All data generated or analyzed during this study are included in this published article.

Code availability

Not applicable.

References

AOAC (1990) In K Helrich (ed) Official methods of analysis, 15th edn. Association of Official Analytical Chemists, Inc., Arlington

Ashoka P, Meena RS, Kumar S, Yadav GS, Layek J (2017) Green nanotechnology is a key for eco-friendly agriculture. J Clean Prod 142:4440–4441. https://doi.org/10.1016/j.jclepro.2016.11.117

Barut ZB, Ertekin C, Karaaga HA (2011) Tillage effects on energy use for corn silage in Mediterranean Coastal of Turkey. Energy 36:5466–5475. https://doi.org/10.1016/j.energy.2011.07.035

Busari MA, Kukal SS, Kaur A, Bhatt R, Dulazi AA (2015) Conservation tillage impacts on soil, crop and the environment. Int Soil Water Conserv Res 3:119–129. https://doi.org/10.1016/j.iswcr.2015.05.002

Chaudhary VP, Singh KK, Pratibha G, Bhattacharyya R, Shamim M, Srinivas I, Patel A (2017) Energy conservation and greenhouse gas mitigation under different production systems in rice cultivation. Energy 130:307–317. https://doi.org/10.1016/j.energy.2017.04.131

Chaudhary VP, Chandra R, Chaudhary R, Bhattacharyya R (2021) Global warming potential and energy dynamics of conservation tillage practices for different rabi crops in the Indo-Gangetic Plains. J Environ Manage 296:113–182. https://doi.org/10.1016/j.jenvman.2021.113182

Choudhary M, Rana KS, Rana DS, Bana RS (2016) Tillage and crop residue effects in rainfed pearl millet (Pennisetum glaucum) in conjunction with sulphur fertilization under pearl millet - Indian mustard (Brassica juncea) cropping system. Indian J Agron 61:15–19

Choudhary M, Rana KS, Bana RS, Ghasal PC, Choudhary GL, Jakhar P, Verma RK (2017) Energy budgeting and carbon footprint of pearl millet–mustard cropping system under conventional and conservation agriculture in rainfed semi-arid agroecosystem. Energy 141:1052–1058. https://doi.org/10.1016/j.energy.2017.09.136

Das TK, Ghosh S, Das A, Sen S, Datta D, Ghosh S, Raj R, Behera B, Roy A, Vyas AK (2021) Conservation Agriculture impacts on productivity, resource-use efficiency, and environmental sustainability: A holistic review. Indian J Agron 66:111–127

Deng JL (1985) Grey control system. Hua Zhong Institute of Technology Press, China

Devasenapathy P, Senthilkumar G, Shanmugam PM (2009) Energy management in crop production. Indian J Agron 54:80–90

Dhillon JS, Eickhoff EM, Mullen RW, Raun WR (2019) World potassium use efficiency in cereal crops. Agron J 111:889–896. https://doi.org/10.2134/agronj2018.07.0462

Dubey A, Lal R (2009) GWP and sustainability of agricultural production systems in Punjab, India, and Ohio, USA. J Crop Improv 23:332–350. https://doi.org/10.1080/15427520902969906

Faiz MA, Bana RS, Choudhary AK, Laing AM, Bansal R, Bhatia A, Bana RC, Singh YV, Kumar V, Bamboriya SD, Padaria RN, Khaswan SL, Dabas JPS (2022) Zero tillage, residue retention and system-intensification with legumes for enhanced pearl millet productivity and mineral biofortification. Sustainability 14:543. https://doi.org/10.3390/su14010543

Gan YT, Campbell CA, Jansen HH, Lemke R, Liu LP, Basnyat P, McDonald CL (2009) Carbon input to the soil by oilseed and pulse crops in a semiarid environment. Agric Ecosyst Environ 132:290–297. https://doi.org/10.1016/j.agee.2009.04.014

Ghorbani R, Mondani F, Amirmoradi S, Feizi H, Khorramdel S, Teimouri M, Sanjani S, Anvarkhah S, Aghel H (2011) A case study of energy use and economical analysis of irrigated and dryland wheat production systems. Appl Energy 88:283–288. https://doi.org/10.1016/j.apenergy.2010.04.028

Goglio P, Grant BB, Smith WN, Desjardins RL, Worth DE, Zentner R, Malhi SS (2014) Impact of management strategies on the global warming potential at the cropping system level. Sci Total Environ 490:921–933. https://doi.org/10.1016/j.scitotenv.2014.05.070

Hanway JJ, Heidel H (1952) Soil analysis methods as used in Iowa state college soil testing laboratory. Iowa Agric 57:1–31

Hosseini SZ, Firouzi S, Aminpanah H, Sadeghnejhad HR (2016) Effect of tillage system on yield and weed populations of soybean (Glycine max L.). An Acad Bras Ciênc 88:377–384. https://doi.org/10.1590/00013765201620140590

Indian Council of Medical Research (1981) Recommended dietary intakes for Indians. National Institute of Nutrition, ICMR, Hyderabad, p 87

Kirschbaum MU (2014) Climate-change impact potentials as an alternative to global warming potentials. Environ Res Lett 9:1–11. https://doi.org/10.1088/17489326/9/3/034014

Krupnik TJ, Shennan C, Rodenburg J (2012) Yield, water productivity and nutrient balances under the system of rice intensification and recommended management practices in the Sahel. Field Crops Res 130:155–167. https://doi.org/10.1016/j.fcr.2012.02.003

Kumar V, Khippal A, Singh J, Selvakumar R, Malik R et al (2014) Barley research in India: Retrospect & prospects. J Wheat Res 6:1–20

Kushwaha CP, Singh KP (2005) Crop productivity and soil fertility in a tropical dryland agro-ecosystem: impact of residue and tillage management. Exp Agric 41:39–50. https://doi.org/10.1017/S0014479704002303Liu

Lal R (2004) Carbon emission from farm operations. Environ Inter 30:981–990. https://doi.org/10.1016/j.envint.2004.03.005

Lal R (2015) Sequestering carbon and increasing productivity by conservation agriculture. J Soil Water Conserv 70:55A–62A. https://doi.org/10.2489/jswc.70.3.55A

Lal B, Gautam P, Nayak AK, Panda BB, Bihari P, Tripathi R et al (2019) Energy and carbon budgeting of tillage for environmentally clean and resilient soil health of rice-maize cropping system. J Clean Prod 226:815–830. https://doi.org/10.1016/j.jclepro.2019.04.041

Lindner RC (1944) Rapid analytical methods for some of the more common inorganic constituents of the plant tissues. Plant Physiol 19:76–89. https://doi.org/10.1104/pp.19.1.76

Liu Q, Liu B, Ambus P, Zhang Y, Hansen V, Lin Z, Shen D, Liu G, Bei Q, Zhu J, Wang X (2016) Carbon footprint of rice production under biochar amendment–a case study in a Chinese rice cropping system. GCB Bioenergy 8:148–159. https://doi.org/10.1111/gcbb.12248

Lobell DB, Gourdji SM (2012) The influence of climate change on global crop productivity. Plant Physiol 160:1686–1697. https://doi.org/10.1104/pp.112.208298

Meena RS, Kumar V, Yadav GS, Mitran T (2018) Response and interaction of Bradyrhizobium japonicum and Arbuscular mycorrhizal fungi in the soybean rhizosphere: A review. Plant Growth Regul 84:207–223. https://doi.org/10.1007/s1072501703348

Meena OP, Sammauria R, Gupta AK, Gupta KC, Behera B et al (2022) Energy-carbon footprint vis-à-vis system productivity and profitability of diversified crop rotations in semi-arid plains of North-West India. J Plant Nutr Soil Sci 22:2026–2041. https://doi.org/10.1007/s42729-022-00791-2

Mittal JP, Dhawan KC (1988) Research manual on energy requirements in agricultural sector. ICAR, New Delhi, pp 20–23

Mohammadi A, Rafiee S, Jafari A, Keyhani A, Mousavi-Avval SH, Nonhebel S (2014) Energy use efficiency and greenhouse gas emissions of farming systems in north Iran. Renew Sustain Energy Rev 30:724–733. https://doi.org/10.1016/j.rser.2013.11.012

Mrunalini K, Rolaniya LK, Datta D, Kumar S, Behera B, Makarana G, Singh A, Prasad JVNS, Pratibha GS, Naik MR, Swamy GN, Rao CS (2020) Resource conservation technologies for climate change adaptation and mitigation. In: Rao CS (ed) Climate Change and Indian Agriculture: Challenges and Adaptation Strategies. ICAR-National Academy of Agricultural Research Management, Hyderabad, Telangana, India, pp 1–22

Ntinas GK, Neumair M, Tsadilas CD, Meyer J (2017) Carbon footprint and cumulative energy demand of greenhouse and open-field tomato cultivation systems under Southern and Central European climatic conditions. J Clean Prod 142:3617–3626. https://doi.org/10.1016/j.jclepro.2016.10.106

Olsen BC, Cole CV, Watenabe FS, Dean LA (1954) Estimation of available phosphorus by extraction with sodium carbonate. USDA, Circular No. 939:19

Ozkan B, Akcaoz H, Fert C (2004) Energy input-output analysis in Turkish agriculture. Renew Energy 29:39–51. https://doi.org/10.1016/S09601481(03)00135-6

Ozpinar S, Ozpinar A (2011) Influence of tillage and crop rotation systems on economy and weed density in a semi-arid region. J Agric Sci Technol 13:769–784

Pandey D, Agrawal M (2014) Carbon footprint estimation in the agriculture sector. In: Assessment of carbon footprint in different industrial sectors, vol 1. Springer, Singapore, pp 25–47. https://doi.org/10.1007/9789814560412_2

Parihar CM, Jat SL, Singh AK, Majumdar K, Jat ML, Saharawat YS, Pradhan S, Kuri BR (2017) Bio-energy, water-use efficiency and economics of maize-wheat mungbean system under precision-conservation agriculture in semi-arid agroecosystem. Energy 119:245–256. https://doi.org/10.1016/j.energy.2016.12.068

Parihar CM, Jat SL, Singh AK, Kumar B, Rathore NS, Jat ML, Saharawat YS, Kuri BR (2018) Energy auditing of long-term conservation agriculture based irrigated intensive maize systems in semi-arid tropics of India. Energy 142:289–302. https://doi.org/10.1016/j.energy.2017.10.015

Patil SB, Balakrishna Reddy BC, Chitgupekar SC, Patil BB (2015) Modern tillage and integrated nutrient management practices for improving soil fertility and productivity of groundnut (Arachis hypogaea L.) under the rainfed farming system. Int Lett Nat Sci 29:1–12. https://doi.org/10.18052/www.scipress.com/ILNS.29.1

Pratibha G, Srinivas I, Rao KV, Raju BMK, Thyagaraj CR, Korwar GR, Venkateswarlu B, Shanker AK, Choudhary DK, Rao KS, Srinivasarao C (2015) Impact of conservation agriculture practices on energy use efficiency and global warming potential in rainfed pigeon pea-castor systems. Eur J Agron 66:30–40. https://doi.org/10.1016/j.eja.2015.02.001

Rahman MM, Aravindakshan S, Hoque MA, Rahman MA, Gulandaz MA, Rahman J, Islam MT (2021) Conservation tillage (CT) for climate-smart sustainable intensification: Assessing the impact of CT on soil organic carbon accumulation, greenhouse gas emission and water footprint of wheat cultivation in Bangladesh. Environ Sustain Indic 10:100–106. https://doi.org/10.1016/j.indic.2021.100106

Roohi E, Mohammadi R, Niane AA, Niazian M, Niedbała G (2022) Agronomic performance of rainfed barley cultivars under different tillage systems in highland areas of dryland conditions. Agronomy 12:1070. https://doi.org/10.3390/agronomy12051070

Sharma R, Verma R (2010) Effect of irrigation, nitrogen and varieties on the productivity and grain malting quality in barley. Cereal Res Commun 38:419–428. https://doi.org/10.1556/crc.38.2010.3.12

Singh MK, Pal SK, Thakur R, Verma UN (1997) Energy input-output relationship of cropping systems. Indian J Agric Sci 67:262–264

Singh KP, Prakash V, Srinivas K, Srivastava AK (2008) Effect of tillage management on energy-use efficiency and economics of soybean (Glycine max) based cropping systems under the rainfed conditions in North-West Himalayan region. Soil Tillage Res 100:78–82. https://doi.org/10.1016/j.still.2008.04.011

Singh B, Sharma A, Joshi N, Mittal P, Singh S (2013) Combining ability analysis for grain yield and its components in malt barley (Hordeum vulgare). Indian J Agric Sci 83:96–98

Soni P, Taewichit C, Salokhe VM (2013) Energy consumption and CO2 emissions in rainfed agricultural production systems of Northeast Thailand. Agric Syst 116:25–36. https://doi.org/10.1016/j.agsy.2012.12.006

Subbiah BV, Asija GL (1956) A rapid procedure for the estimation of available nitrogen in soils. Curr Sci 25:259–260

Tjandra TB, Ng R, Yeo Z, Song B (2016) Framework and methods to quantify carbon footprint based on an office environment in Singapore. J Clean Prod 112:4183–4195. https://doi.org/10.1016/j.jclepro.2015.06.067

Tubiello FN, Cóndor-Golec RD, Salvatore M, Piersante A, Federici S, Ferrara A, Rossi S, Flammini A, Cardenas P, Biancalani R, Jacobs H, Prasula P, Prosperi P (2015) Estimating greenhouse gas emissions in agriculture: a manual to address data requirements for developing countries. Food and Agriculture Organization of the United Nation, Rome, Italy

Vourdoubas J (2016) Energy and agri-food systems: production and consumption. In: Zero waste in the Mediterranean. Natural resources, food and knowledge/International Centre for Advanced Mediterranean Agronomic Studies (CIHEAM) and Food and Agriculture Organization of the United Nations (FAO). Presses de Sciences Po, Paris, p 155

Walkley A, Black IA (1934) An examination of the Degtjareff method for determining soil organic matter, and a proposed modification of the chromic acid titration method. Soil Sci 37:29–38. https://doi.org/10.1097/0001069419340100000003

Xue JF, Pu C, Liu SL, Zhao X, Zhang R et al (2016) Carbon and nitrogen footprint of double rice production in Southern China. Ecol Indic 64:249–257. https://doi.org/10.1016/j.ecolind.2016.01.001

Yadav MR, Parihar CM, Jat SL, Singh AK, Kumar D, Pooniya V, Parihar MD, Saveipune D, Parmar H, Jat ML (2016) Effect of long-term tillage and diversified crop rotations on nutrient uptake, profitability and energetics of maize (Zea mays) in North-Western India. Indian J Agri Sci 86:743–749

Yadav GS, Lal R, Meena RS, Datta M, Babu S, Das A, Layek J, Saha P (2017) Energy budgeting for designing sustainable and environmentally clean/safer cropping systems for rainfed rice fallow lands in India. J Clean Prod 158:29–37. https://doi.org/10.1016/j.jclepro.2017.04.170

Acknowledgments

The authors are thankful to the Director, ICAR-Indian Institute of Wheat and Barley Research (ICAR-IIWBR) Karnal, Haryana, India, and the Director, Rajasthan Agricultural Research Institute (RARI), Jaipur, Rajasthan, India, for providing the necessary facilities and financial support to conduct the study.

Author information

Authors and Affiliations

Contributions

MR Yadav and S Kumar: Conceptualization, Field study, Investigation, Resource allocation, Data curation; B. Behera: Data curation, Formal analysis, Data validation, Writing of original draft; VP Yadav, AS Khrub, LR Yadav, KC Gupta, OP Meena and AS Baloda: Data analysis, Writing of original draft, Supervision; MB Raza, RK Panda, MK Lal: Review and Editing, Supervision, Graphical representation.

Corresponding author

Ethics declarations

Ethics approval

Ethical approval is not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yadav, M.R., Kumar, S., Behera, B. et al. Energy-Carbon Footprint, Productivity and Profitability of Barley Cultivars under Contrasting Tillage-Residue Managements in Semi-Arid Plains of North-West India. J Soil Sci Plant Nutr 23, 1109–1124 (2023). https://doi.org/10.1007/s42729-022-01107-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42729-022-01107-0