Abstract

Several European countries have expanded the traditional use of anaerobic digestion, i.e. waste treatment, to energy generation through attractive incentives. In some countries, it is further promoted by additional payments to generate biogas from biomass. This review aims to summarise agronomic aspects of methane production from maize, to address resulting abiotic environmental effects and to highlight challenges and prospects. The opportunities of biogas production are manifold, including the mitigation of climate change, decreasing reliance on fossil fuels and diversification of farm income. Although the anaerobic digestion of animal manure is regarded as the most beneficial for reducing greenhouse gas (GHG) emission from manure storage, the energy output can be substantially enhanced by co-digesting manure and maize, which is the most efficient crop for substrate provision in many regions. Although first regarded as beneficial, the rush into biogas production strongly based on maize (Zea mays ssp. mays) is being questioned in view of its environmental soundness. Main areas of concern comprise the spatial concentration of biogas plant together with the high amount of digestate and resulting pollution of surface and ground water, emission of climate-relevant gases and detrimental effects of maize cultivation on soil organic matter degradation. Key challenges that have been identified to enhance the sustainability of maize-based biogas production include (1) the design of regionally adapted maize rotations, (2) an improved management of biogas residues (BR), (3) the establishment of a more comprehensive data base for evaluating soil C fluxes in maize production as well as GHG emissions at the biogas plant and during BR storage and (4) the consideration of direct and indirect land use change impact of maize-based biogas production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The use of renewable energies is being promoted as an efficient means of contributing to a reduction of GHG emissions, and thus, it represents a major pillar of climate protection measures [39]. Within the portfolio of renewable energies, biomass is a key element for developing sustainable energy systems. Traditionally, the combustion of biomass for heat, light and power generation has been used in many parts of the world, and fuel wood is still the most important bioenergy source worldwide [72]. Presently, biomass contributes 12.7 % of the global final energy consumption. Advanced biomass-to-energy conversion technologies, including thermochemical and biochemical processes, provide more convenient energy carriers that are better adapted to the needs at the household, smallholder and industrial scale.

Biogas, although belonging to the first generation biofuels, has the advantage that a wide variety of biomass sources, including organic waste, can be converted to methane via anaerobic digestion. In developing countries with warmer climates, such as India and China, biogas has contributed to domestic energy supplies for decades [71]. In more developed countries, biogas was formerly used mainly for wastewater treatment, and more recently, it has gained importance as a contribution to the efforts in climate protection of several European member states, notably Germany, Austria and Italy [49, 70, 113]. Compared to other biomass-based fuels, biogas is characterised by higher energy and resource-use efficiency than, for instance, biodiesel or bioethanol [20, 123]. In particular, the anaerobic digestion of animal slurry is regarded as having an important climate protection role, since the GHG emissions arising during slurry storage and application are substantially reduced [90, 107]. Animal slurry has a relatively low volatile solids (VS)-specific methane yield, which, however, can be substantially improved when co-digesting with feedstocks such as silage maize (Zea mays ssp. mays), various grass species or sugar beet (Beta vulgaris ssp. vulgaris) [7]. Since only carbon is extracted during the fermentation, and the plant nutrients that largely remain in the biogas residues (BR) can later be used to replace fossil fuel-based mineral fertiliser, biogas production systems often are considered to have almost closed nutrient cycles [6].

The rush into bioenergy production, however, may cause some serious environmental concerns, as in the case of bioethanol production in the USA [89] or in Germany with respect to biogas production [118]. In Germany, the implementation of the Kyoto Protocol and the European directive on the promotion of electricity production from renewable energy sources (2001/77/EG) [50] has led to an expansion of biogas production on agricultural farms, on a scale not previously seen, due to an attractive feed-in tariff system. Today, Germany is the largest biogas producer in the European Union, with around 7,100 biogas plants in 2011 (landfill gas and sewage gas plants not included) corresponding to a total installed electric output of 2,780 MW and providing 3.1 % of the country’s electricity consumption [51]. Most of the biogas plants (91 %) use wet biomass streams, co-digesting slurry and crop substrate [37]. While a well-considered expansion of bioenergy production is assumed to reduce greenhouse gas emissions and to contribute to securing energy supplies, the expansion of biogas production that has occurred during recent years in Germany, with its substrate supply strongly based on maize (Fig. 1), is a cause of growing concern about potential damage to the environment.

Substrate use in biogas plants in Germany 2010, as based on fresh matter [37]

The aim of this review is (1) to compile and summarise the research activities and current discussions on agronomic aspects of methane production from maize and (2) to synthesise abiotic environmental effects resulting from biogas maize production, including the emission of climate-relevant gases, N leaching and soil organic carbon balance.

Agronomic Aspects of Biogas Maize Production

Productivity of Maize and Alternative Crops

The macroeconomic sustainability of current bioenergy cropping systems is best quantified in terms of their energy efficiency, especially in view of scarce land. With net energy yield up to 170 GJ ha-1 achieved in biogas production via combined heat and electricity generation, it is clear that this bioenergy path is one of the most efficient bioenergy production lines [52]. Current results obtained in a Germany-wide joint project focussing on the agronomic, ecologic and economic performance of various biogas cropping systems clearly show that, at most sites throughout Germany, maize has the highest potential of dry matter and methane yield potential [153] due to its low nutrient demand, high water-use efficiency and high digestibility. Only at marginal production sites, which are characterised by either low temperatures and high precipitation or, at the other extreme, by very low water availability, maize may be outcompeted by other crops. For the coastal marsh region of northern Germany, which is characterised by low temperature, high precipitation and clay-rich soils, for instance, Quakernack et al. [117] found forage grasses and cereals grown for whole crop silage to achieve yields similar to that of maize, but at a higher yield security. In parts of eastern and southern Germany where low precipitation limits maize growth, sorghum (Sorghum bicolor × bicolor) and sudan grass (Sorghum sudanense × bicolor) might provide alternative substrates [153], yet breeding approaches are still in their infancy. Sugar beet has the potential to achieve a high methane yield on soils with sufficient water supply [141], but technical challenges with respect to storage and cleaning still hamper large-scale use [37]. Perennial crops such as Miscanthus (Miscanthus × giganteus, Miscanthus sachariflorus and Miscanthus sinensis) or willow (Salix sp.) seems not suitable for anaerobic digestion due to a substantially lower specific methane yield caused by their lignocellulosic structure [82, 147].

Consequently, the loss in diversification of crop rotation observed over the last decades due to agricultural policy and the pressure for cost-effectiveness and specialisation has been reinforced by the expansion of biogas production in many regions, where maize dominates crop substrate supply and is often grown in monoculture [48]. This applies, for instance, to the sandy soil regions of northern Germany, where dairy farming has traditionally been the prevailing farming activity and the share of maize on arable land was high already before the biogas boom took hold. It is frequently stated that permanent grassland might represent a cost-efficient alternative to maize. Intensive management, however, is required to ensure high grass yield, which results in a lower net energy yield and a lower competitive ability [30, 47, 61]. In regions where cash-crop farming has been dominating, the proportion of maize in crop rotations was usually lower than in dairy farming regions. Crop rotation diversity therefore might benefit from maize expansion.

Productivity of Maize Cropping Systems

The introduction of catch crops, double-cropping and maize rotations is currently being intensively discussed in terms of alternatives to maize monoculture for reducing the potential negative impact of monoculture and for enhancing yield [80, 153]. Maize can achieve very high net assimilation rates, but the canopy duration usually is often limited and therefore does not allow it to fully absorb radiation in early summer, especially in northwestern Europe. Peak photosynthetic rates, however, do not necessarily result in the highest productivity, since leaf area duration appears at least as important for the productivity of a cropping system as leaf photosynthetic efficiency [13, 68]. Hence, a major aim should be year-round soil coverage with crops suitable for biomethanisation.

Catch Crops and Double-Cropping

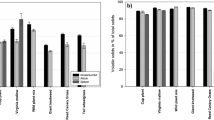

The use of catch crops or double-cropping thus would provide the opportunity to exploit the high photosynthetic capacity of the C4 maize crop in summer and to use the potential of C3 crops in spring and autumn [12]. Environmental performance is improved by an almost year-round soil cover, which reduces the risk of soil erosion and facilitates weed control. Double-cropping systems, in addition, provide the possibility of diversifying risks in terms of yield security resulting from extreme weather events. Although catch and double crops are mostly regarded favourably, their negative impacts on the main crop must be considered, when, for instance, affecting ecophysiological characteristics of maize, such as leaf area and leaf carbon exchange, and thus decreasing maize dry matter and N yield under nutrient-limited conditions [96]. In addition, maize yield may be reduced due to a shortening of the length of the vegetation period, since maize sowing is usually delayed when following a catch crop that is harvested in late spring/early summer. Earlier cultivars are required for exploiting the remaining vegetation period, which are known to have a lower yielding potential [23]. Vetter [153], investigating the biomass accumulation of various catch-cropping and double-cropping systems throughout Germany, found an average yield reduction of 15% when growing maize after a winter rye (Secale cereale) catch crop compared to main crop maize (Fig. 2). In agreement, Grignani et al. [64] and Herrmann et al. [69] reported a difference of 4–5 t DM ha−1 between maize main crop and maize following a ryegrass (Lolium multiflorum) catch crop, which was mainly attributed to later sowing and the use of an earlier variety, but N immobilisation after destruction of the grass sward may have also contributed to yield depression. Apart from nutrient supply and vegetation period, water availability is another key factor for successful catch- or double-cropping. In regions that are prone to spring and summer drought, catch- or double-cropping systems bear a risk of maize yield loss compared to sole-cropping due to competition for water resources. Results by Vetter [153] may exemplify that the yield reduction of maize observed after winter catch crops could only be overcompensated at sites Werlte and Dornburg, where water availability was sufficient (Fig. 2). Whether the moderate yield gain of catch cropping covers the cost for additional soil cultivation, harvest, ensiling and transport remains questionable [153]. In addition, the authors tested a number of double-cropping systems at various sites with annual precipitation above 550 mm and reported a yield gain of only 2–3 t DM ha−1 for the highest yielding combination [rye–maize or rye/pea (Pisum sativum)–maize] compared to maize following a mustard (Sinapis alba) catch crop. Intercropping maize with other crops such as sunflower (Helianthus annuus) might promote the acceptance of biogas cropping, but did not result in any yield gain compared to sole-cropped maize [36, 153].

Dry matter yield of winter rye (cover crop) and maize (main crop) as influenced by environmental conditions (Werlte: low soil quality, high precipitation; Dornburg: high soil quality, low-moderate precipitation; Güterfelde: low soil quality, low precipitation). Yields represent means of experimental years 2006 and 2007 [153]

Maize Crop Rotations

Rotations designed for forage use or energy recovery, including maize as one of several main crops, have not been exhaustively investigated so far in northwestern Europe. Systematic studies conducted in Belgium, France and northern Italy consistently show a maize yield benefit when growing maize in maize–ley rotations compared with monoculture [64, 105, 152]. The experimental data, as well as a meta-analysis of internationally published results conducted by Nevens and Reheul [104], clearly indicate that N availability is a key factor determining the rotation effect, with the rotation benefit on maize yield decreasing with increasing N supply, or in other words, maize grown in rotation is less responsive to N fertilisation than maize grown in monoculture. Moreover, non-N effects, as for instance due to soil water availability, soil structure, disease and weed pressure may contribute to positive rotation effects [104]. The studies furthermore revealed that the total rotation yield benefit is strongly determined by the maize share and the difference in yielding potential between maize and the remaining rotation elements, with maize–ley rotations often being less competitive than maize monoculture [64, 152].

Slightly different results were obtained by a 3-year experiment conducted on a sandy soil site in northern Germany, aiming to analyse the yielding potential and environmental effects of a crop rotation comprising white clover (Trifolium repens)/grass (Lolium perenne) ley, maize and triticale (×Triticosecale) compared with maize monoculture [155]. Clover–grass was managed as a mixed system with two cuts followed by two grazings. The last cut, which was not harvested, served as catch crop and was ploughed in the following spring before maize sowing. In agreement with the previously mentioned studies, maize in rotation achieved on average 10–15% higher net energy for lactation (NEL) yield than maize monoculture and considerably higher N yield, which was also reflected in a low N balance for the entire rotation (Fig. 3). Energy yield of the entire rotation was similar to, or slightly higher than, that of maize monoculture (not shown). The implementation of maize rotations, however, is restricted by cross compliance obligations with respect to the maintenance of permanent grassland. This is especially challenging for farms located on light sandy soils, as in northern Germany, where ploughing of potentially available grassland would allow the generation of higher yields [146, 156]. Maize production on peaty soils, however, should be banned to avoid excessive GHG emission [128, 148].

Performance of silage maize grown in monoculture and rotation, quantified in terms of energy yield (GJ NEL ha−1), nitrogen yield (kg N ha−1) and N surplus (kg N ha−1). Monoculture I, without grass understorey; monoculture II, with grass understorey; rotation, silage maize–triticale–white clover grass; nitrogen input includes N fertiliser and atmospheric N deposition; N surplus is obtained as difference of N output and total N input [155]

Environmental Aspects of Biogas Maize Production

The biogas residue or digestate, which remains following anaerobic digestion, represents a valuable source of plant-available nutrients, which should be recycled in a sustainable manner to supply nutrient inputs that might otherwise come from fossil fuel-based mineral fertilisers. Challenges with respect to nutrient management may arise from the high density of biogas plants observed in several regions with existing high livestock densities, where biogas production may cause an oversupply of organic fertiliser. A recent German farm survey revealed that N surplus, which represents an appropriate indicator of N loss, tends to increase with the share of maize on arable land, since a high maize share usually is accompanied by a high proportion of nutrients from organic fertiliser [21]. The situation becomes more problematic when large amounts of substrates are purchased. For instance, it is estimated that one tenth of the maize substrate fermented in the federal state of Schleswig-Holstein, northern Germany, originates from Denmark.

In addition to challenges related to BR volume, specific digestate properties might lead to conflicts with environmental protection goals. This applies in particular to (1) the EU Water Framework Directive [43] aiming to achieve ‘good ecological and chemical status’ for all community waters by 2015; (2) the EU NEC (National Emission Ceilings) Directive [44], setting upper limits for each member state for total emissions of ammonia, sulphur dioxide, nitrogen oxides and volatile organic compounds; and (3) the ambitious aims with respect to reduction of GHG emission set by European and national policies.

Implication of Biogas Residue Properties for Nutrient Flows and Dynamics

Nitrogen Dynamics

Information on the short- and long-term effects of BR application on carbon and nutrient flows is a prerequisite for optimising biogas production systems in view of the need for environmental sustainability. During the process of anaerobic digestion, the fermentation substrate is subject to transformations, bringing about substantial changes in physical and chemical properties of the BR when compared to that of liquid animal manure, which may modify biochemical processes taking place at soil surface or in the soil. The concentrations of C and N are key drivers of N availability, with the C/N ratio being regarded a reliable indicator of N release from organic fertiliser. For C/N ratios below 6–7, intensive N mineralisation during the year of application may be expected, while for low N content of the digestate, N availability in the soil is assumed to be limited due to N immobilisation [67]. Since a large part of the energy content of the fermentation substrate is converted and exported in terms of methane, the C/N ratios of BR are substantially lower than values reported for animal slurry, with a large variation depending on the digestion procedure. For cofermentation, Gutser et al. [67] reported the C/N ratio to range between 2 and 5, while monofermented crop substrate would result in a C/N ratio of 5–8. In contrast to the C/N ratio, the NH4–N share of the total N content and the pH value may substantially increase during fermentation [67, 136, 143]. Furthermore, the higher stability of organic matter is hypothesised to support humus accumulation [9, 67]. A higher recalcitrance of organic matter might also prevent N immobilisation of mineral N [66, 93]. Finally, BR is characterised by a lower viscosity which facilitates its infiltration after application [116].

Nitrogen Use Efficiency

A lower viscosity, together with a higher NH4–N share, as well as a reduced C/N ratio and N immobilisation, will enhance short-term N availability [66, 94, 140]. In agreement, Gutser et al. [67] reviewed the short-term N-use efficiency of BR, i.e. in the year of application, to range between 40 and 60 % mineral fertiliser equivalent (MFE) for monodigested crop substrate and between 50 and 70 % for co-digested slurry when applied to various crops, which was considerably higher compared to undigested cattle slurry (35–45 % MFE). Year-after-year application of animal slurry is known to increase the residual N effect. Likewise, Gutser et al. [67] estimated long-term MFE to vary between 60 and 70 %, provided a 40–60 % short-term MFE. A higher short-term N-use efficiency, however, will probably result in a lower residual N effect, as found in a simulation study for undigested and digested cattle slurry applied to grassland [129]. The abovementioned values are considerably lower than the nutrient value found in own studies, where co-digested residue was applied to maize monoculture in a 2-year field experiment [69]. Nutrient value, quantified as relative N fertiliser value as means over 2 years, amounted to 0.75 for BR and 0.57 for cattle slurry on a humus sandy site, while on a sandy loam site, values were even higher (BR, 0.98; pig slurry, 0.75). When interpreting results on N-use efficiency, the application technique should be taken into consideration, since interactions may occur with fertiliser type [140].

Phosphorus and Potassium

Literature on the effect of anaerobic digestion on P mobility is scarce. Güngör and Karthikeyan [65] reported a reduction in soluble P content, which was attributed to partitioning of orthophosphates into particle-bound form subsequently after digestion of dissolved unreactive P. It is mainly Ca and Mg that seem to be responsible for this interaction [138, 157]. Gooch et al. [63] found an increased concentration of orthophosphate in the digestate. Field and pot experiments by Möller and Vogt [100], Loria and Sawyer [87] and Möller and Stinner [99] indicate similar plant P availability after application of undigested and digested slurry.

It is often postulated that biogas production would allow for closed nutrient cycles, which seems reasonable in the case of P and K, since gaseous emissions during fermentation as well as during storage and spreading of the BR can be excluded. However, P and K may partially be retained in the fermenter due to absorption to small particles [91]. Schievano et al. [127] documented losses to range from 6 to 9 % and 2 to 5 % for P and K, respectively.

Implications for Sustainable Nutrient Management

Another challenge with respect to nutrient cycling refers to the nutrient composition of BR. As is already known from forage production, the ratio of nutrients (N/P/K) of slurry does not necessarily meet the crop requirements, and thus requires mineral fertiliser supplementation, or it causes nutrient oversupply. The same applies to BR, as shown in recent work by Möller et al. [97], in which the BR had a concentration of K that was too low, compared to N and P, for silage maize fertilisation. An optimised substrate management was suggested for remedying nutrient imbalances, including (1) the separation of BR and (2) a seasonally adapted substrate input schedule, with fermentation of N-rich substrates in autumn and winter for spring application and of substrates low in N during summer for autumn fertilisation [98].

A future challenge with respect to nutrient cycling might arise in Germany if the Fertiliser Ordinance, which implements the EU Nitrate Directive into German legislation, were to treat BR equally to animal manure in terms of maximum application limits. Currently, the maximum amount of animal manure is limited to 170 kg N ha−1 year−1 (230 kg N with exemption), while for BR, only the N share originating from animals (minus animal species-specific losses in the barn and during storage) has to be taken into account. Compliance with respect to N and P surplus limits (60 kg N ha−1, 20 kg P2O5 ha−1), however, is required for any type of fertilisation. Biogas farms with a high proportion of their acreage devoted to substrate production and cultivating crops with a high N demand per hectare, as for instance grassland or anticipated high yielding biogas maize varieties, thus will face problems with respect to nutrient surpluses as severe as on dairy farms.

Nitrogen Leaching

With respect to the N-leaching potential of BR application, it might be argued that the higher plant N availability and lower residual N effect [129] would facilitate fertiliser management, promote N uptake and thus reduce the N-loss risk. Organic fertiliser, however, usually is applied before or at maize sowing, and BR fertilisation therefore might entail a higher risk of N leaching if low maize N uptake during early growth and high precipitation events coincide. This hypothesis is supported by recent findings from an incubation trial, indicating a high mineralisation and nitrification potential of BR during the first weeks after application [125].

Results from a 5-year field trial conducted on grassland in Austria did not show any difference in leachate nitrate load between anaerobically digested and raw cattle slurry, which most likely was due to a low N level and very high annual precipitation [116]. Similarly, Merz and Trösch [92] reported no impact of anaerobic digestion on nitrate loss of a cocksfoot (Dactylis glomerata) sward investigated in a lysimeter trial. Another lysimeter study found lower nitrate loss in wheat for digested cattle slurry than for raw slurry [122]. Slightly higher nitrate leaching was found in a simulation study only when applying digested slurry without reducing the total fertiliser amount due to the higher N availability of the digestate [76].

This is in agreement with our own research, where the N leaching potential of BR from co-digestion (maize/pig slurry), animal slurry and mineral N fertiliser was investigated in a 2-year field experiment conducted at two sites in northern Germany, including different substrate production systems and fertilisation intensities [142]. At both sites and for all crops tested, BR application resulted in a similar nitrate leaching potential to that of liquid animal manure despite differences in NH4–N share (pig slurry, 71 %; cattle slurry, 55 %; BR, 53 %). As expected from previous research [120, 155], nitrate leaching per hectare was much lower for cut grassland than for maize monoculture. The differences, however, were partly offset when relating nitrate loss to the unit of methane produced. A comparison of maize monoculture with maize rotations (maize–whole crop wheat–grass catch crop; maize–grain wheat–mustard catch crop) showed similar nitrate leaching per hectare (20–25 kg NO3–N ha−1) at N input required for maximum DM yield, and marginally lower nitrate loss per unit methane produced for the monoculture [3.1 kg NO3–N (1,000 m3 CH4)−1] caused by a higher methane hectare yield. In the case of overfertilisation, however, the increase in nitrate leaching was substantially larger for maize monoculture. The introduction of catch crops may increase C and N storage, even when aboveground biomass is harvested [34, 101]. Depending on the C/N ratio of the catch crop species, a positive or negative net N mineralisation can be observed after its incorporation, which affects main crop N uptake and nitrate leaching [33, 130, 145].

Emission of Climate-Relevant Gases

Since biogas production is substantially promoted to mitigate climate change, it has to be ensured that climate-relevant gases emitted during substrate production and processing, fermentation as well as during storage and application of BR do not counteract the efforts to reduce CO2 emission. Major GHGs evolving from crop husbandry and plant operation are nitrous oxide (N2O), methane (CH4) and carbon dioxide (CO2). In addition, ammonia volatilisation may indirectly contribute to N2O when organic or mineral fertiliser volatilises as ammonia and is re-deposited onto the soil [103]. The assessment of GHG emissions resulting from BR application is somewhat hampered since most studies on emissions from BR are based on digested animal slurry, while only few studies provide co-digestion or maize specific data.

Emissions at the Biogas Plant

Systematic and comprehensive measurements of emissions related to the operation of biogas plants are still scarce. Liebetrau et al. [86] took punctual measurements at different plant components for two periods of each of 5 days at 10 biogas plants, which enabled the identification of relevant emission sources, but did not provide enough data for emission balancing. Emissions during silage storage, feeding and processing of the fermentation substrate appeared to be of minor importance. Average emission factors for feeding and processing were estimated at 100 g CH4, 12 g N2O and 5.6 g NH3 t−1 substrate [35]. Fermenters usually are supposed to be gastight, which seems valid if equipped with a concrete top, but not for foil roof coverage. Liebetrau et al. [86] found foil roofs to emit on average 0.004 % of methane produced. A gastight cover provides an efficient measure to reduce GHG emission from storage [15]. A recent Germany-wide monitoring revealed, however, that only 37 % of biogas plants are equipped with a gastight BR storage, 27 % have a closed, not gastight BR storage, while 36 % stored their BR uncovered [37]. Methane may also become lost with exhaust gases when not completely combusted, since it is not degraded in conventional waste air treatment facilities. These losses were found to range between 0.5 and 3.1 % of produced methane or 10–40 g CO2eq kWh −1el [8, 11, 53, 86, 119]. Other sources of losses include gas leakages (average: 1 % of methane produced) and biogas that is flared when biogas plants are partly switched off due to an overload of the electric grid. [86, 119].

As for emission data referring to the fermenter and feeding device, there is still lack of data on emissions during storage, which may be modified by many environmental factors, such as temperature, air pressure, wind speed, fill level and digestion processes during fermentation. Although carbon is largely converted and exported, a certain amount of methane remains dissolved in the BR, which may be emitted later. Moreover, carbon remaining undegraded in the digester provides potential for residual gas production occurring in the post-digester or in the BR storage [62]. In order to keep the residual gas production low, a high substrate degradation rate is thus required during fermentation. Weissbach et al. [159] found a residual gas potential of 5.5–8.1 % (determined in batch trial at 38 °C) and of 1.5–3.0 % (24 °C) of the potential substrate methane yield. A similar range was reported for data collected in a monitoring study across Germany, where residual gas potential averaged 9.7 % (37 °C) and 5.1 % (20–22 °C) of methane yield for single-stage plants and 3.5 and 1.5 % for multi-stage plants, respectively [55]. Under unfavourable conditions (low hydraulic retention time, incomplete digestion), however, it may be as high as 21.8 % (37 °C, multi-stage). The estimates for the average residual gas potential are in good agreement with the experimental data of Liebetrau et al. [86], which revealed that emissions from BR storage may reach a considerable order of magnitude, as indicated by values varying between 0 and 500 g CO2eq kWh −1el for two measurement periods each of 5 days. Nevertheless, mono- or co-digestion of animal slurry substantially reduces methane emissions, as demonstrated by a pilot-scale study conducted in a winter and a summer experiment by Clemens et al. [31].

The higher pH value and NH4–N content of biogas residues from mono- or co-digestion are assumed to entail a higher risk of ammonia emission during storage, compared with that of liquid animal manure. In addition, the lower solid content of BR may reduce crust formation at the storage, which would abate extensive ammonia loss [135]. Crusts, first of all, may act as physical barrier, but recent research indicates that methane as well as ammonia-oxidising bacteria located in the crust may contribute to a reduction of emissions [106, 109]. Clemens et al. [31] found similar ammonia emissions for undigested slurry and BR in winter, but twice as high for BR in summer, which was attributed an interaction of higher temperature and higher pH value of BR.

Apart from ammonia and methane, nitrous oxide can be emitted from stored BR, resulting from either nitrification or denitrification at the boundary layer between aerobic and anaerobic conditions [139]; this could easily be prevented by a gastight cover, which eliminates oxygen in the headspace and hence N2O formation. Experimental data by Clemens et al. [31] revealed slightly lower N2O emissions for BR than for undigested slurry in winter, whereas it was the reverse in summer, probably due to differences in NH4–N share or structure. Total GHG emissions of BR amounted to 14.8 kg CO2eq m−3 BR for the 100-day winter experiment and 46.7 kg CO2eq m−3 for the 140-day summer period and, in total, were lower for BR than for undigested slurry. Similarly, Amon et al. [2] reported 37.03 kg CO2eq m−3 over an 80-day period for digested cattle slurry covered with a wooden lid, which was dominated by methane and was considerably lower than for untreated slurry (91 kg CO2eq m−3). Estimates by Cuhls et al. [35] provide average emission factors for production and storage of 2,500 g CH4 (62.5 kg CO2eq) t−1 substrate, 15 g N20 (4.5 kg CO2eq) and 90 g NH3 (0.27 kg CO2eq). Recent research findings indicate that methane emissions during storage might be cost-effectively mitigated by acidification of liquid manure before storage [110].

Emissions during Application

With pH values of BR increasing up to one unit, compared to undigested substrate [137], a higher ammonia emission potential can be expected after field application. However, a higher ammonia volatilisation potential must not necessarily result in higher emissions since the lower solid content and reduced viscosity cause better infiltration characteristics. Results in the literature on the effect of anaerobic digestion on ammonia volatilisation after field application therefore are inconsistent. While Rubaek et al. [121] reported reduced emissions, others found no significant differences [27, 160] or increased ammonia loss [2, 140]. A 2-year field study conducted at two sites in northern Germany consistently revealed higher ammonia volatilisation of mono- and co-digested BR, compared to undigested pig slurry, amounting to 12, 16 and 9 %, respectively, of total ammonia nitrogen (TAN), while it was in the same range as undigested cattle slurry (13 %) [59]. The discrepancies observed in the literature probably can be attributed to differences in pH increase during fermentation and temperature [26, 160], which are key drivers of ammonia volatilisation. A unit increase of 0.1 in pH, for instance, may enhance ammonia emissions by 1.6 % of TAN [60]. A simulation study analysing crop species and rotation effects on ammonia emission gave lowest relative ammonia loss for maize monoculture, while BR application into a maize–wheat–cover crop rotation or grassland showed higher loss [59], since part of the BR had to be applied during unfavourable environmental conditions, e.g. during summer. If we presume a total of 7,100 biogas plants in Germany at the end of 2011, an average BR production of 10,000 t per year and per plant [158], an average NH4–N content of 2.2 kg m−3, an 80 % share of plant-derived BR and an ammonia–N loss of 15 % of TAN, then approximately 18,740 t ammonia–N is additionally volatilised from biogas production. Ammonia emission could easily be reduced, and plant N-use efficiency be enhanced if BR were to be injected or immediately incorporated after application [27, 160].

With respect to N2O emission following BR application, it might be hypothesised that the reduced content of degradable organic matter would reduce the potential for denitrification and result in lower N2O loss, compared to undigested slurry [140]. Furthermore, lower viscosity and faster infiltration could support C and N dispersion in soil, which, depending on soil nitrate status, could promote or reduce N2O fluxes [111]. During the initial period after application of BR and liquid manure, denitrification appears to be the dominant process producing N2O [132]. Apart from the contents of soil nitrate and easily degradable C, however, many other factors such as soil texture, soil moisture, oxygen availability, temperature, crop and application technique [74, 77, 126, 134, 161] affect denitrification; it is not surprising therefore that literature results on the effect of anaerobic digestion on N2O emission vary widely. Lower N2O loss after application of digested compared to raw slurry was found by some studies [26, 32, 108], while others could not detect any difference among fertiliser types [16, 31, 150]. Systematic studies on the impact of crop on N2O emission after BR application are scarce. Wulf et al. [161] reported an interaction of slurry treatment with crop during the first 2 weeks after application, where on arable land higher N2O emission was detected for raw slurry compared to BR, while on grassland it was vice versa. These effects were mainly attributed to the availability of easily degradable C, which seemed more limiting on arable land than on grassland. In the same study, the authors found a substantial increase in N2O fluxes when injecting, instead of trail hose applying BR. Injection may have enhanced the development of anaerobic microsites with high availability of N and easily degradable C and promoted denitrification. Dittert et al. [40], analysing N2O emission of mineral N, animal slurry and BR applied to various crops in three levels, found higher N2O fluxes for maize compared to grass and wheat. This was attributed to a later onset of water consumption and N uptake of maize. The crop effect was blurred or even reversed when relating N2O loss to crop yield. The importance of soil properties for denitrification was reflected in a soil texture effect, where N2O–N emission at a sandy site was three times lower than at a site characterised by a sandy loam. Fertiliser type had only a moderate effect on N2O emission under field conditions: On average, 0.5 % of the fertiliser N applied was emitted as N2O–N on the sandy soil and 1.7 % on the sandy loam soil, which is in the range reported for animal manure [38]. A supplementary lab experiment [132], however, revealed a significant interaction of fertiliser type and soil water content, with substantially higher emissions for BR than mineral N application only occurring at high soil moisture content. Low soil moisture after BR application was most likely also responsible for a low level of N2O loss and missing crop effects in a field trial conducted on a clay marsh soil [144]. Results from field trials conducted in Denmark showed substantially higher N2O fluxes in maize compared to winter rye, both for raw slurry and BR, which was attributed to the timing (maize, before sowing; rye, into crop), application technique (maize, injection; rye, trailing hose) and differences in soil temperature [24].

Under the environmental conditions of northwestern Europe, agriculturally used upland soils usually are assumed to act as methane sinks since methane consumption by methanotrophic bacteria under oxic conditions outweighs methane production by methanogenic bacteria under anoxic conditions [41]. Methane emission after BR application may result from either volatilisation of dissolved methane produced during anaerobic digestion and BR storage or by methanogenesis in the soil/surface slurry band when anaerobic conditions prevail [161]. The first pathway is supported by many field studies showing only short emission events directly after application of liquid manure (e.g. [25, 32, 40]). Clemens et al. [31], for instance, found 90 % of total methane to be emitted within 4 h after application by trailing shoe, without significant differences between BR and raw slurry. Injection of BR was shown to delay methane release [161]. Support for the second pathway comes from Wulf et al. [161], who attributed longer continuing methane emission from BR injection into grassland to soil methanogenesis. In contrast, Sänger et al. [125] reported net methane consumption after BR application investigated in an incubation trial. On the whole, the contribution of methane emissions after BR application to total methane emission of biogas production is negligible compared to emissions occurring at the fermenter and BR storage [2, 31].

Soil Organic Carbon

Impact of Maize Cultivation

The impact of biogas production from maize on changes of soil organic C (SOC) has been intensively discussed, and it is suspected that SOC stock depletion will not be compensated by a reallocation of BR when aboveground biomass is nearly completely harvested and extensively degraded during anaerobic digestion. Maize C input via roots and rhizodeposition at physiological maturity is estimated at 29 % of shoot C [3]. Up to 30 % of the C added to the soil in terms of maize roots and stubble may reside in the soil [17, 54, 64]. Carbon loss is mainly driven by degradation of soil organic matter via respiration and by leaching of organic or inorganic C compounds. In addition, wind and water erosion may contribute to a depletion of C stocks.

According to the C balancing approach [149] applied in the German Cross Compliance commitments for EU subsidisation, forage maize cultivation causes a loss of 560–800 kg humus C/ha and year (soil organic matter C). When assuming a typical slurry application of 30 m³ ha−1, the negative balance decreases to 290–530 kg humus C. An optimal humus C balance is assumed to lie between −75 and 100. These values, however, are questioned, since the impact of soil and climatic conditions is not taken into consideration. Furthermore, the approach is based on older work, and it may be assumed that current maize varieties provide higher above- and belowground biomass [75]. Long-term experimental data on C stock changes in temperate forage maize production are limited. A 27-year field study on forage production systems, including permanent grassland, maize monoculture and several grass/maize rotations), showed a 30 % decline in SOC for maize, but only a 3 % decrease for grassland [151]. A close relationship was detected between the grass proportion of rotations and SOC decline. In agreement, Ludwig et al. [88], studying changes of SOC stocks in a field trial after 39 years of continuous maize, found the sequestration of C derived from maize to be lower than the loss of C originating from C3 crops grown before the onset of the experiment. For a humus sandy soil located in northern Germany, our own simulations showed annual SOC losses of 660 and 270 kg C ha−1 for treatments highly supplied with mineral N or cattle slurry [18]. A typical fertilisation of 20 t slurry plus 75 kg mineral N ha−1 gave an annual depletion of 370 kg C ha−1. This is below the C loss value of 1,002 kg ha−1 that was found by Jans et al. [73] for maize fertilised with 510 kg C ha−1 as slurry. Moors et al. [102] reported C budgets (net ecosystem exchange minus harvested C) to vary between −4,800 and 1,500 kg C ha−1 for maize grown at several sites throughout Europe. An 11-year continuous maize experiment conducted in Denmark revealed an increase in SOC [84]. Depending on the amount of organic fertilisation (with/without maize residue application) 90–940 kg C ha−1 were accumulated annually. More previous works also found negative and positive effects of maize cultivation on SOC [4, 14, 85].

Carbon Dynamics After BR Application

The C balance approach according to the German Cross Compliance commitments assumes BR application to accumulate 6–12 kg humus C t−1 (for BR with 4–10 % DM content), which equals cattle slurry, but is lower than farmyard manure or compost. The composition of BR in terms of their contents of N, P and K, however, often does not comply with crop demand. When, for instance, applying the amount of BR required to achieve a balanced C budget in maize the P balance limit (20 kg P2O5 ha−1) set by the fertiliser ordinance may be exceeded, and it was concluded that crop rotations have to be adapted [42, 97]. Recent research, however, indicates that BR might have a considerably higher stability against microbial degradation than previously assumed. Incubation studies by Sensel et al. [133] found that only 25 % of C in BR was mineralised when amended to soil (100 days, 22 °C), which was a much lower proportion than for cattle slurry (75 %) or fresh farmyard manure (66 %). This coincides with findings by Alburquerque et al. [1] reporting 30 % C mineralisation for co-digested cattle slurry after 56 days incubation at 26 °C and by Kirchmann and Lundvall [81] who found a 20 % lower CO2 release of anaerobically digested compared to fresh pig slurry. High CO2 emission (54 % of added C) following maize digestate incubation detected by Sänger et al. [124] was probably due to incomplete substrate degradation in the fermenter.

Substrate composition and the degree of degradation during anaerobic digestion, which can vary substantially, have a large impact on microbial decomposition of OM and consequently on C sequestration. Biochemical oxygen demand, content of dissolved organic C (DOC) and the ratio of DOC to total N were identified as reliable parameters for characterising BR stability and estimating soil C and N turnover [1]. Apart from mineralisation of organic C, it should be taken into consideration that dissolved inorganic C (carbonate, bicarbonate) can contribute to CO2 emission after BR application to acid soils [28].

Life Cycle Carbon Footprint

Greenhouse Gas Balance

Environmental benefits of biogas production are largely due to the mitigation of GHG emission when substituting fossil fuel and/or digesting slurry. However, high GHG emission during crop cultivation, plant operation and BR storage, the energy consumption for plant operation, as well as poor heat utilisation may reduce or even outweigh the CO2 savings. A larger number of studies on GHG balances of biogas production have been published in recent years (e.g. [57, 61, 95, 115]). The findings are not easily comparable, since different system boundaries, databases, methodologies and functional units were applied, and assumptions underlying the calculations often are not adequately documented. Moreover, calculations often are based on average crop yields and on emission factors for GHG instead of measurements, which do not reflect the variation caused by climate, soil and management. The fermentation of organic waste, e.g. cattle slurry or crop residues, is regarded as most beneficial in view of GHG savings over fossil energy use [57, 78]. However, with the potential of agricultural residues and biowaste being restricted and agricultural land being limited, co-digestion may provide a compromise between GHG mitigation efficiency and land-use efficiency.

Much of the environmental pollution resulting from biogas production is attributable to the production of substrate [162], mainly due to emissions resulting from fertiliser production and N2O loss following fertilisation, whereas fuel consumption for crop cultivation and processing contributes less [95, 114, 154]. Arnold [5] found a range between 40.2 and 46 g CO2eq kWh−1 for maize, while double cropping, e.g. rye/maize, rye/sorghum, cereal whole crop silage/maize, clover–grass/maize, caused higher emissions from 54.0 to 77.4 g CO2eq kWh−1. Substantially higher values for maize (about 100 g CO2eq kWh−1) obtained by Plöchl and Heiermann [112] were probably due to a lower yield level.

As for substrate production, a large variation may be expected when comparing GHG balances calculated for the complete biogas process chain. The share of animal slurry in substrate is a main determinant of GHG balance. Negative balances, i.e. net GHG savings, are commonly reported for biogas plants digesting slurry only, or digesting a high proportion of slurry [10, 78], whereas GHG emissions of sub-optimal systems may exceed those of fossil-based electricity and heat production [95, 115]. A scenario study by Meyer-Aurich et al. [95], including the impact of substrate feedstock, heat use, BR storage cover and land-use change (LUC) found the GHG balance to range between 110 (co-digestion cattle slurry/maize, no additional heat use, gas tight storage) and 400 g CO2eq kWh−1 (maize monodigestion, no additional heat use, LUC, i.e. 25 % of maize on former grassland). Compared to fossil fuel-based energy systems, GHG savings up to 75 % seem achievable [29, 95]. Maize-based biogas production thus can comply with the current (35 % GHG reduction) or future (50 % GHG reduction by 2017) target set by the EU Renewable Energy Directive 2009/28/EC [45], which so far applies only to biofuels and electricity produced from liquid biomass, but an extension to biogas is discussed [83]. The large range in GHG savings reported in literature may at first appear contradictory, but is partly due to different reference energy systems used. The choice of the reference energy system has substantial impact on the CO2 saving potential [19, 57, 78], which highlights the need for a standard reference as already provided for biofuels and electricity from liquid biomass.

Potential for Optimisation

When exploiting the GHG mitigation potential of biogas production, the reduction of N2O emissions seems to be most critical for the GHG balance—a gastight BR storage cover provided—due to its high global warming potential and the high degree of uncertainty related to its estimation [95, 154]. If a gastight cover is not available, variation of GHG balance is dominated by storage emissions [95]. Depending on the substrate degradation in the digester and the residual methane potential of the BR, GHG emission of uncovered biogas production systems may even exceed those of reference energy systems [57, 95]. A 5–7 % CH4 emission of total CH4 production was determined as a critical threshold by Plöchl et al. [114]. The GHG balance can be improved when credits for thermal use can be accounted for [22, 57]. A decrease of 60 g CO2eq kWh−1, for instance, was reported for a co-digestion system after introducing heat use [95]. Carbon debt due to LUC represents another factor having a large impact on GHG balance, which is often not included in GHG balances, but this is intensively discussed in Germany because it is presumed that a considerable proportion of the permanent grassland destruction observed in recent years has been due to the expansion of biogas maize. Estimates by Meyer-Aurich et al. [95] showed an increase of 60 g CO2eq kWh−1 for a typical biogas farm when assuming a 25 % share of maize grown on ploughed grassland. While direct effects of LUC are hardly substantiated by data, the situation is even more difficult for indirect LUC effects caused by outsourcing of food and forage production, which can only be overcome by a global balance [56].

Other Impact Categories

Although the CO2 saving potential represents a key indicator of sustainability, a comprehensive assessment of biogas production requires additional indicators [58], the net energy yield and energy efficiency being very important in the case of high competition for land. Net useful energy yields reported for maize or maize rotations are up to 174 GJ ha−1 [30, 131], while energy output/input ratio ranges between 2 and 16, depending on biogas yield, utilisation efficiency and reference system [30, 46, 61, 115, 131]. Transport distance consistently was found to have a substantial impact on energy efficiency [30, 115], which together with low biogas yields explains the low energy efficiency of slurry-only fermentation [115]. In contrast to energy efficiency, the impact of transportation distance on GHG balance is regarded as moderate [57, 154]. Literature data on the influence of biogas production on acidification and eutrophication unanimously underline a higher environmental impact compared to fossil fuel-based energy systems [22, 79, 131].

Conclusions

Biogas is one option within the portfolio of renewable energy technologies, which are supported in many countries by climate protection and energy policies. Anaerobic digestion of animal manure is generally considered an efficient option to reduce GHG emission from manure storage. Its limited energy output can be enhanced substantially through co-digestion with crop substrate, where maize shows superior performance to many other crops in northwestern Europe. Such farm-scale production systems may open additional sources of income alongside traditional farming and may contribute to rural development. Hasty decisions to promote co-digestion systems when global and local implications are still uncertain, however, could result in unintended side-effects on agricultural structure and the environment. In Germany, for instance, nearly 7 % of the arable land was used for biogas substrate production in 2011 (thereof 80 % biogas maize), but provided only 3 % of the national electricity consumption. Due to its relatively high land requirements and high CO2 avoidance costs, maize-based co-digestion probably will not play a major role in future energy supply, but rather may serve as a temporary bridging technology in the transition towards an resource-efficient energy supply. In the meanwhile, sustainability of existing maize-based co-digestion systems has to be enhanced, not only with regard to the climate change mitigation potential but also in view of other environmental objectives. The following major research challenges have been identified:

-

Design of regionally adapted maize cropping systems as an alternative to maize monoculture for optimising substrate provision while minimising environmental impact.

-

Enhanced management of biogas residues, which represent a valuable source of nutrients and organic fertilisation, but may pose challenges especially in regions with a high livestock density and biogas operations, and on soils prone to leaching.

-

Establishment of a more comprehensive data base on the carbon fluxes in maize cultivation to allow a reliable assessment of the carbon budget of biogas maize production.

-

Similarly, a more extensive data base is required with respect to climate relevant trace gas fluxes occurring at the biogas plant and during BR storage, in order to ensure a reliable life cycle assessment of maize-based biogas production.

-

Consideration of direct and indirect land use change in GHG balance calculation, which could thwart potential carbon benefits for long time, e.g. maize cultivation on ploughed grassland or peaty soils and leakage effects through the displacement of agricultural production resulting in land use change elsewhere.

Any science-based climate and energy policy aiming to promote resource-efficient bioenergy sources needs to be preceded and monitored by a thorough impact analysis, in which aside from the effects on the abiotics, which were discussed in this review, also the effects on the biotic environment will have to be considered.

Abbreviations

- BR:

-

Biogas residues

- GHG:

-

Greenhouse gas

- OM:

-

Organic matter

- SOC:

-

Soil organic carbon

- TAN:

-

Total ammonia nitrogen

References

Alburquerque JA, de la Fuente C, Bernal MP (2011) Chemical properties of anaerobic digestates affecting C and N dynamics in amended soils. Agric Ecosyst Environ. doi:10.1016/j.agee.2011.03.007

Amon B, Kryvoruchko V, Amon T, Zechmeister-Boltenstern S (2006) Methane, nitrous oxide and ammonia emissions during storage and after application of dairy cattle slurry and influence of slurry treatment. Agric Ecosyst Environ 112:153–162

Amos B, Walters WT (2006) Maize root biomass and net rhizodeposited carbon: an analysis of the literature. Soil Sci Soc Am J 70:1489–1503

Angers DA, Voroney RP, Cote D (1995) Dynamics of soil organic matter and corn residues affected by tillage practices. Soil Sci Soc Am J 59:1311–1315

Arnold K (2011) Greenhouse gas balance of biomethane—which substrates are suitable? Energy Sci Technol 1:67–75

Arthurson V (2009) Closing the global energy and nutrient cycles through application of biogas residue to agricultural land—potential benefits and drawbacks. Energies 2:226–242

Asam Z, Poulsen TG, Nizami A-S, Rafique R, Kiely G, Murphy JD (2011) How can we improve biomethane production per unit of feedstock in biogas plants? Appl Energ 88:2013–2018

Aschmann V, Jin W, Effenberger M, Gronauer A (2009) Emissionsproblematik und Energieeffizienz biogasbetriebener BHKW im Verlauf der Standzeit. In: Bayerische Landesanstalt für Landwirtschaft (ed) Internationale Wissenschaftstagung Biogas Science 2009, Band 1, pp 193–200. http://www.lfl.bayern.de/publikationen/daten/schriftenreihe/p_37628.pdf. Accessed 16 Mar 2012

Asmus F, Linke B (1987) Zur pflanzenbaulichen verwertung von Gülle-Faulschlamm aus der biogasgewinnung. Feldwirtschaft 28:354–355

Bachmeier J, Effenberger M, Gronauer A (2010) Greenhouse gas balance and resource demand of biogas plants in agriculture. Eng Life Sci 10:560–569

Bachmeier J, Gronauer A (2007) Klimabilanz von Biogasstrom. http://www.lfl.bayern.de/publikationen/daten/informationen/p_27453.pdf. Accessed 30 Oct 2011

Baker JM, Griffis TJ (2011) Evaluating the potential use of winter cover crops in corn-soybean systems for sustainable co-productioin of food and fuel. Agric Forest Meteorol 149:2120–2132

Baldocchi D (2008) Breathing of the terrestrial biosphere: lessons learned from a global network of carbon dioxide flux measurement systems. Aust J Bot 56:1–26

Balesdent J, Mariotti A, Boisgontier D (1990) Effect of tillage on soil organic carbon mineralization estimated from 13C abundance in maize fields. J Soil Sci 41:587–596

Berg W, Brunsch R, Pazsiczki I (2006) Greenhouse gas emissions from covered slurry compared with uncovered during storage. Agric Ecosyst Environ 112:129–134

Bertora C, Alluvione F, Zavattaro L, van Groenigen JW, Velthof G, Grignani C (2008) Pig slurry treatment modifies slurry composition, N2O, and CO2 emissions after soil incorporation. Soil Biol Biochem 40:1999–2006

Bertora C, Zavattaro L, Sacco D, Monaco S, Grignani C (2009) Soil organic matter dynamics and losses in manured maize-based forage systems. Eur J Agron 30:177–186

Bleken MA, Herrmann A, Haugen LE, Taube F, Bakken L (2009) SPN: a model for the study of soil–plant nitrogen fluxes in silage maize cultivation. Eur J Agron 30:283–295

Börjesson P, Berglund M (2007) Environmental system analysis of biogas systems—Part II: the environmental impact of replacing various reference systems. Biomass Bioenerg 31:326–344

Börjesson P, Mattiasson B (2008) Biogas as a resource-efficient vehicle fuel. Trends Biotechnol 26:7–13

Breitschuh G, Gernand U (2010) Nachhaltigkeit im Maisanbau. Mais 1(2010):4–7

Bühle L, Stülpnagel R, Wachendorf M (2011) Comparative life cycle assessment of the integrated generation of solid fuel and biogas from biomass (IFBB) and whole crop digestion (WCD) in Germany. Biomass Bioenerg 35:363–373

Capristo PR, Rizzalli RH, Andrade FH (2007) Ecophysiological yield components of maize hybrids with contrasting maturity. Agron J 99:1111–1118

Carter MS, Ambus P (2009) Greenhouse gas emissions from cultivation of energy crops—is it important? ICROFS news 4(2009):2–3

Chadwick DR, Pain BF (1997) Methane fluxes following slurry applications to grassland soils: laboratory experiments. Agric Ecosyst Environ 63:51–60

Chantigny MH, Angers DA, Rochette P, Bélanger G, Massé D (2007) Gaseous nitrogen emissions and forage nitrogen uptake on soils fertilized with raw and treated swine manure. J Environ Qual 36:1864–1872

Chantigny MH, Rochette P, Angers DA, Massé D, Côté D (2004) Ammonia volatilization and selected soil characteristics following application of anaerobically digested pig slurry. Soil Sci Soc Am J 68:306–312

Chen R, Senbayram M, Lin X, Dittert K (2011) Origin of positive δ13C of emitted CO2 from soils after application of biogas residues. Soil Biol Biochem 43:2194–2199

Claus S, Wienforth B, Sieling K, Kage H, Senbayram M, Dittert K et al (2012) Greenhouse gas balance of bioenergy cropping systems under the environmental conditions of Schleswig–Holstein. Grassland Sci Eur 17:601–603

Claus S, Wienforth B, Sieling K, Kage H, Taube F, Herrmann A (2011) Energy balance of bioenergy cropping systems under the environmental conditions of Schleswig–Holstein. Grassl Sci Europe 16:365–367

Clemens J, Trimborn M, Weiland P, Amon B (2006) Mitigation of greenhouse gas emissions by anaerobic digestion of cattle slurry. Agric Ecosyst Environ 112:171–177

Collins HP, Alva AK, Streubel JD, Fransen SF, Frear C, Chen S et al (2011) Greenhouse gas emissions from an irrigated silt loam soil amended with anaerobically digested dairy manure. Soil Sci Soc Am J 75:2206–2216

Constantin J, Beaudoin N, Laurent F, Cohan J-P, Duyme F, Mary B (2011) Cumulative effects of catch crops on nitrogen uptake, leaching and net mineralization. Plant Soil 341:137–154

Constantin J, Mary B, Laurent F, Aubrion G, Fontaine A, Kerveillant P et al (2010) Effects of catch crops, no till and reduced nitrogen fertilization on nitrogen leaching and balance in three long-term experiments. Agric Ecosyst Environ 135:268–278

Cuhls C, Mähl B, Clemens J (2011) Treibhausgas-emissionen aus biogasanlagen. UmweltMagazin 1(2):44–45

Dabbagh Mohammadi Nassab A, Amon T, Kaul H-P (2011) Competition and yield in intercrops of maize and sunflower for biogas. Ind Crop Prod 34:1203–1211

DBFZ - Deutsches BiomasseForschungsZentrum (2011) Monitoring zur Wirkung des Erneuerbare-Energien-Gesetzes (EEG) auf die Entwicklung der Stromerzeugung aus Biomasse. http://www.erneuerbare-energien.de/inhalt/36204/4593/. Accessed 16 Mar 2012

De Klein CAM, Sherlock RR, Cameron KC, van der Weerden TJ (2001) Nitrous oxide emissions from agricultural soils in New Zealand—a review of current knowledge and directions for future research. J Roy Soc New Zeal 31:543–574

Demirbas AH, Demirbas I (2007) Importance of rural bioenergy for developing countries. Energy Convers Manage 48:2386–2398

Dittert K, Senbayram M, Wienforth B, Kage H, Muehling KH (2009). Greenhouse gas emissions in biogas production systems. The Proceedings of the International Plant Nutrition Colloquium XVI, UC Davis. http://www.escholarship.org/uc/item/18p5q83f. Accessed 16 Mar 2012

Dunfield PF (2007) The soil methane sink. In: Reay D, Hewitt CN, Smith K, Grace J (eds) Greenhouse gas sinks. CABI, Wallingford, pp 152–170

Ebertseder T, Groß J (2008) Ausweitung des energiepflanzenanbaus aus sicht des pflanzenbaus und des nährstoffmanagements. In: Bundesarbeitskreis Düngung (BAD) (ed) Klimawandel und bioenergie—pflanzenproduktion im spannungsfeld zwischen politischen vorgaben und ökonomischen rahmenbedingungen. BAD, Frankfurt, pp 131–147

EC—European Commission (2000) Directive 2000/60/EC of the European Parliament and of the Council of 23 October 2000 establishing a framework for community action in the field of water policy. OJL 327, 22 Dec 2000, pp 1–73

EC—European Commission (2001) Directive 2001/81/EC of the European Parliament and of the Council of 23 Oct 2001 on national emission ceilings for certain atmospheric pollutants. LJL 309, 27 Nov 2001, pp 22–30

EC—European Commission (2009) Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC

Eder B (2010) Pflanzenbauliche Untersuchungen zum Einfluss von Genotyp und Anbauverfahren auf die Ertragsbildung und das Methanbildungspotenzial von Mais (Zea mays L.). Doctoral thesis, Technische Universität München

Eder B, Papst C, Darnhofer B, Eder J, Schmid H, Hülsbergen KJ (2009b) Energie- und CO2-Bilanz für Silomais zur Biogaserzeugung vom Anbau bis zur Stromeinspeisung. In: Bayerische Landesanstalt für Landwirtschaft (ed) Internationale Wissenschaftstagung Biogas Science 2009, Band 3, pp 717–719. http://www.lfl.bayern.de/publikationen/daten/schriftenreihe/p_37630.pdf. Accessed 16 Mar 2012

European Environment Agency (EEA) (2007) Estimating the environmentally compatible bioenergy potential from agriculture. EEA Technical report no. 12/2007

EurObserv’ER (2010) Biogas barometer. http://www.eurobserv-er.org/pdf/baro200b.asp. Accessed 16 Mar 2012

European Parliament and Council (2001) Directive 2001/77/EC of the European Parliament and of the Council of 27 Sept 2001 on the promotion of electricity produced from renewable energy sources in the internal electricity market. Off J Eur Comm L 283/33–40

Fachverband Biogas (2011) Biogas segment statistics 2011. http://www.biogas.org/edcom/webfvb.nsf/id/DE_Branchenzahlen. Accessed 16 Mar 2012

Faulstich M (2008) Energie aus Biomasse. Energiekongress der Bayerischen Staatsregierung ‘Sichere Energie bezahlbar und klimafreundlich’, 4 June 2008, Munich, Germany. http://www.energiekongress-bayern.de/vortraege.htm. Accessed 16 Mar 2012

Flesh TK, Desjardins RL, Worth D (2011) Fugitive methane emissions from an agricultural biodigester. Biomass Bioenerg 35:3927–3935

Flessa H, Ludwig B, Heil B, Merbach W (2000) The origin of soil organic C, dissolved organic C and respiration in a long-term maize experiment in Halle, Germany, determined by 13C natural abundance. J Plant Nutr Soil Sci 163:157–163

FNR—Fachagentur für nachwachsende Rohstoffe (2009) Biogas-Messprogramm II. http://www.fnr-server.de/ftp/pdf/literatur/pdf_385-messprogramm_ii.html. Accessed 16 Mar 2012

Fritsche UR, Sims REH, Monti A (2010) Direct and indirect land-use competition issues for energy crops and their sustainable production—an overview. Biofuel Bioprod Bior 4:692–704

Gärtner S, Münch J, Reinhardt G, Vogt R (2008) Ökobilanzen. Materialband E. In: R Vogt et al (eds) Optimierungen für einen nachhaltigen Ausbau der Biogaserzeugung und -nutzung in Deutschland, pp 86–143. http://www.erneuerbare-energien.de/inhalt/43280/40870/. Accessed 16 Mar 2012

Global Bioenergy Partnership (GBEP) (2011) 24 Sustainability indicators for bioenergy. http://www.globalbioenergy.org/programmeofwork/sustainability/gbep-report-on-sustainability-indicators-for-bioenergy/en/. Accessed 16 Mar 2012

Gericke D (2009) Measurement and modelling of ammonia emissions after field application of biogas slurries. Doctoral thesis, Christian-Albrechts-Universität Kiel, Germany

Gericke D, Bornemann L, Kage H, Pacholski A (2012) Modelling ammonia losses after field application of biogas slurry in energy crop rotations. Water Air Soil Poll 223:29–47. doi:10.1007/s11270-011-0835-4

Gerin PA, Vliegen F, Jossart J-M (2008) Energy and CO2 balance of maize and grass as energy crops for anaerobic digestion. Biores Technol 99:2620–2627

Gioelli F, Dinuccio E, Balsari P (2011) Residual biogas potential from the storage tanks of non-separated digestate and digested liquid fraction. Biores Technol 102:10248–10251

Gooch CA, Inglis SF, Wright PE (2007) Biogas distributed generation systems evaluation and technology transfer. NYSERDA Project No. 6597 Interim Report. http://www.manuremanagement.cornell.edu/Pages/General_Docs/Reports/NYSERDA_Interim_Report_Final_2007.pdf. Accessed 30 Oct 2011

Grignani C, Zavattaro L, Sacco D, Monaco S (2007) Production, nitrogen and carbon balance of maize-based forage systems. Eur J Agron 26:442–453

Güngör K, Karthikeyan KG (2008) Phosphorus forms and extractability in dairy manure: a case study for Wisconsin on-farm anaerobic digesters. Biores Technol 99:425–436

Gutser R, Dosch P (1996) Cattle-slurry-15N turnover in a long-term lysimeter trial. Proceedings of the International Symposium on Fertilizers and Environment, 26–29 Sept, Salamanca

Gutser R, Ebertseder T, Weber A, Schraml M, Schmidhalter U (2005) Short-term and residual availability of nitrogen after long-term application of organic fertilizers on arable land. J Plant Nutr Soil Sci 168:439–446

Heggenstaller AH, Liebman M, Anex RP (2009) Growth analysis of biomass production in sole-crop and double-crop corn systems. Crop Sci 49:2215–2224

Herrmann A, Sieling K, Wienforth B, Taube F, Kage H (2012) Short-term effects of biogas residue application on yield performance and N balance parameters of maize in different cropping systems. J Agric Sci 49(6):2215--2224

Holm-Nielsen JB, Al Seadi T, Oleskowicz-Popiel P (2009) The future of anaerobic digestion and biogas utilization. Biores Technol 100:5478–5484

IEA - International Energy Agency (2005). Biogas production and utilisation. IECD/IEA, Paris. http://www.ieabioenergy.com/MediaItem.aspx?id=56. Accessed 16 Mar 2012

IEA – International Energy Agency (2011) Renewables information 2011. OECD/IEA, Paris

Jans WWP, Jacobs CMJ, Kruijt B, Elbers JA, Barendse S, Moors EJ (2010) Carbon exchange of maize (Zea mays L.) crop: influence of phenology. Agric Ecosyst Environ 139:316–324

Jarecki MK, Parkin TB, Chan AS, Hatfield JL, Meek DW, Jones R (2008) Greenhouse gases emission from two soils under N fertilizer and swine slurry. J Environ Qual 37:1432–1438

Johnson JM-F, Allmaras RR, Reicosky DC (2006) Estimating source carbon from crop residues, roots and rhizodeposits using the national grain-yield database. Agron J 98:622–636

Jorgensen U, Petersen BM (2006) Interactions between biomass energy technologies and nutrient and carbon balances at the farm level. In: Technology for recycling of manure and organic residues in a whole-farm perspective, vol I. DIAS report plant production no. 122, pp 49–55

Jungkunst HF, Freibauer A, Neufeldt H, Bareth G (2006) Nitrous oxide emissions from agricultural land use in Germany—a synthesis of available annual field data. J Plant Nutr Soil Sci 169:341–351

Jungmeier G, Spitzer J (2001) Greenhouse gas emissions of bioenergy from agriculture compared to fossil energy heat and electricity supply. Nutr Cycl Agroecosyst 60:267–273

Jury C, Benetto E, Koster D, Schmitt B, Welfring J (2010) Life cycle assessment of biogas production by monofermentation of energy crops and injection into the natural grid gas. Biomass Bioenerg 34:54–66

Karpenstein-Machan M (2001) Sustainable cultivation concepts for domestic energy production from biomass. Cr Rev Plant Sci 20:1–14

Kirchmann H, Lundvall A (1993) Relationship between N immobilization and volatile fatty acids in soil after application of pig and cattle slurry. Biol Fertil Soils 15:161–164

Klimiuk E, Pokoj T, Budzynski W, Dubis B (2010) Theoretical and observed biogas production from plant biomass of different fibre contents. Biores Technol 101:9527–9535

Klinski S (2008) Eignung der Biomassenachhaltigkeitsverordnung (BioNachV) zur Anbindung an das Erneuerbare-Energien-Gesetz (EEG). Materialband N. In: R Vogt et al (eds) Optimierungen für einen nachhaltigen Ausbau der Biogaserzeugung und -nutzung in Deutschland, pp 86–143. http://www.erneuerbare-energien.de/inhalt/43280/40870/. Accessed 16 Mar 2012

Kristiansen SM, Hansen EM, Jensen LS, Christensen BT (2005) Natural 13C abundance and carbon storage in Danish soils under continuous silage maize. Eur J Agron 22:107–117

Liang BC, Gregorich EG, Schnitzer M, Monreal CM, MacKenzie AF, Voroney RP et al (1998) Retention and turnover of corn residue carbon in some eastern Canadian soils. Soil Sci Soc Am J 62:1361–1366

Liebetrau J, Daniel-Gromke J, Reuschel C, Oehmichen K, Clemens J, Hafermann C et al (2011) Bewertung klimarelevanter Gase aus landwirtschaftlichen Biogasanlagen auf der Basis von Emissionsmessungen. In: KTBL (ed) Biogas in der Landwirtschaft – Stand und Perspektiven. KTBL-Schrift 488, pp 185-195

Loria ER, Sawyer JE (2005) Extractable soil phosphorus and inorganic nitrogen following application of raw and anaerobically digested swine manure. Agron J 97:879–885

Ludwig B, John B, Ellerbrock R, Kaiser M, Flessa H (2003) Stabilization of carbon from maize in a sandy soil in a long-term experiment. Eur J Soil Sci 54:117–126

Malcolm SA, Aillery M, Weinberg M (2009) Ethanol and a changing agricultural landscape. Economic research report no. 86. US Department of Agriculture, Economic Research Service

Maranon E, Salter AM, Castrillon L, Heaven S, Fernandez-Nava Y (2011) Reducing the environmental impact of methane emissions from dairy farms by anaerobic digestion of cattle waste. Waste Mange 31:1745–1751

Massé DI, Croteau F, Masse L (2007) The fate of crop nutrients during digestion of swine manure in psychrophilic anaerobic sequencing batch reactors. Biores Technol 98:2819–2823

Merz H-U, Trösch W (1989) Vergleichende untersuchungen zur N-Bilanz unter Dactylis glomerata L. nach Gülle-, biogas-Gülle- und mineraldüngung. 2. Mitteilung: nitratauswaschung und nährstoffgehalte im Boden. D wirtschaftseig Futter 35:226–237

Messner H (1988) Düngewirkung anerob fermentierter und behandelter Gülle. Doctoral thesis, Technical University, München, Germany

Messner H, Amberger A (1987) Composition, nitrification and fertilizing effect of anaerobically fermented slurry. Proc. 4th CIEC Symp. Braunschweig-Völkenrode, vol 1, pp 125–130

Meyer-Aurich A, Schattauer A, Hellebrand HJ, Klauss H, Plöchl M, Berg W (2012) Impact of uncertainties on greenhouse gas mitigation potential of biogas production from agricultural resources. Renew Energy 37:277–284

Miguez FE, Bollero GA (2006) Winter cover crops in Illinois: evaluation of ecophysiological characteristics of corn. Crop Sci 46:1536–1545

Möller K, Schulz R, Müller T (2011) Effects of setup of centralized biogas plants on crop acreage and balances of nutrients and soil humus. Nutr Cycl Agroecosyst 89:303–312

Möller K, Schulz R, Müller T (2011) Substrate inputs, nutrient flows and nitrogen loss of two centralized biogas plants in southern Germany. Nutr Cycl Agroecosyst 87:307–325

Möller K, Stinner W (2010) Effects of organic wastes digestion for biogas production on mineral nutrient availability of biogas effluents. Nutr Cycl Agroecosyst 87:395–413

Möller K, Vogt N (2003) Einfluss der Zugabe von Rohphosphat in den Biogasfermenter auf die Düngewirkung fermentierter Rindergülle. In: B Freyer (ed) Beiträge zur 7. Wissenschaftstagung zum Ökologischen Landbau, 24–26 February 2003, Vienna, Austria, pp 519–520

Monaco S, Hatch DJ, Sacco D, Bertora C, Grignani C (2008) Changes in chemical and biochemical soil properties induced by 11-yr repeated additions of different organic materials in maize-based forage systems. Soil Biol Biochem 40:608–615

Moors EJ, Jacobs CMJ, Jans W, Supit I, Bernhofer C, Buchman N et al (2010) Variability in carbon exchange of European croplands. Agric Ecosyst Environ 139:325–335

Mosier A, Kroeze C, Nevison C, Oenema O, Seitzinger S, van Cleemput O (1998) Closing the global N2O budget: nitrous oxide emissions through the agricultural nitrogen cycle. Nutr Cycl Agroecosyst 52:225–248

Nevens F, Reheul D (2001) Crop rotation versus monoculture; yield, N yield and ear fraction of silage maize at different levels of mineral N fertilization. Neth J Agric Sci 49:405–425

Nevens F, Reheul D (2002) The nitrogen- and non-nitrogen-contribution effect of ploughed grass leys on the following arable forage crops: determination and optimum use. Eur J Agron 16:57–74

Nielsen DA, Nielsen LP, Schramm A, Revsbech NP (2010) Oxygen distribution and potential ammonia oxidation in floating, liquid manure crusts. J Environ Qual 39:1813–1820

Novak SM, Fiorelli JL (2010) Greenhouse gases and ammonia emissions from organic mixed crop-dairy systems: a critical review of mitigation options. Agron Sustain Dev 30:215–236

Petersen SO (1999) Nitrous oxide emissions from manure and inorganic fertilizers applied to spring barley. J Environ Qual 28:1610–1618

Petersen SO, Ambus P (2006) Methane oxidation in pig and cattle slurry storages, and effect of surface crust moisture and methane availability. Nutr Cycl Agroecosyst 74:1–11

Petersen SO, Andersen AJ, Eriksen J (2012) Effects of cattle slurry acidification on ammonia and methane evolution during storage. J Environ Qual 41:88–94

Petersen SO, Sommer SG (2011) Ammonia amd nitrous oxide interactions: roles of manure organic matter management. Anim Feed Sci Tech 166–167:503–513

Plöchl M, Heiermann M (2002) Ökologische bewertung der bereitstellung landwirtschaftlicher kosubstrate zur biogaserzeugung. Bornimer Agrartechnische Ber 32:98–106, http://www.b3-bornim.de/doc/15_PLOECHL_2.pdf. Accessed 16 Mar 2012

Plöchl M, Heiermann M (2006) Biogas farming in Central and Northern Europe: a strategy for developing countries? Agricultural Engineering International: the CIGR Ejournal. Invited overview no. 8, vol VIII

Plöchl M, Heiermann M, Linke B, Schelle H (2009) Biogas crops—Part II: balance of greenhouse gas emissions and energy from using field crops for anaerobic digestion. Agricultural Engineering International: the CIGR Ejournal. Manuscript number 1086, vol 11, 2009

Pöschl M, Ward S, Owende P (2010) Evaluation of energy efficiency of various biogas production and utilization pathways. Appl Energ 87:3305–3321

Pötsch E (2005) Abschlussbericht zum Forschungsprojekt BAL 2941. Nährstoffgehalt von Gärrückständen aus landwirtschaftlichen Biogasanlagen und deren Einsatz im Dauergrünland. http://www.raumberg-gumpenstein.at/c/index.php?option=com_fodok&Itemid=100033&task=detail&filter_publnr[]=639. Accessed 30 Oct 2011

Quakernack R, Pacholski A, Techow A, Herrmann A, Taube F, Kage H (2012) Ammonia volatilization and yield response of energy crops after fertilization with biogas residues in a coastal marsh of Northern Germany. Agric Ecosyst Environ. doi:10.1016/j.agee.2011.05.030

Reinhardt G, Köppen S (2010) Nachhaltige Produktion und Nutzung von Biogas: Quo vadis? (Sustainable production and use of biogas: quo vadis ?). In: Conf. Proceed. 19. Jahrestagung Fachverband Biogas e.V., Biogas—die Energie künftiger Generationen’, 2–4 Feb 2010, Leipzig, Germany, pp 41–48

Roth U, Döhler H, Hartmann S, Wulf S (2011) Treibhausgasbilanzen und CO2eq-Vermeidungskosten landwirtschaftlicher Biogasanlagen. In: KTBL (ed) Biogas in der Landwirtschaft—Stand und Perspektiven. KTBL-Schrift 488, pp 196–208