Abstract

In the present study, we report on an optimized method for fatty acid methyl esters (FAME) production from castor and jatropha seeds. In order to identify the most effective biodiesel production method, we have compared three two-stage methods, each consisting of oil extraction (the first step) and FAME production by transesterification (the second step), with the same three techniques each conducted in one stage, i.e., direct transesterification. The three techniques are conventional heating, sonochemistry, and microwave radiation. The FAME product was analyzed by 1H NMR spectroscopy and GC-MS. The SrO catalyst was reused successfully, together with seeds containing oil residues, for 10 cycles. The highest yield of FAME, 57.2 % of the total weight of the castor seeds, and a conversion of castor oil to FAME of 99.95 % were achieved in a one-stage method lasting 5 min using microwave radiation as a heat source. Using jatropha seeds leads to a yield of 41.1 % and a 99.7 % conversion of triglyceride to FAME under microwave irradiation in a one-stage method. The direct transesterification by sonication resulted in yields of 48.2 % and 32.9 %, and a 93.6 % conversion from castor and jatropha seeds, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biodiesel is an alternative fuel produced by the transesterificaion of oils. The most common way to produce biodiesel is to transesterify triglycerides of vegetable oil with alcohol in the presence of an alkali or acid catalyst [1–3]. Biodiesel, which consists of fatty acid methyl esters (FAME), has lower CO and hydrocarbon emissions. In addition, it is nontoxic, biodegradable, and produced from renewable sources and contains insignificant amounts of sulfur [4–6].

In order to optimize and reduce considerably the cost of biodiesel production, several parameters should be taken into consideration. The first parameter refers to a renewable biological source for triglycerides. The most common source for biodiesel production is a vegetable oil such as soybean oil, sunflower, and rapeseed oil. However, vegetable oil refers to edible oils, about which there is concern regarding their use for biofuel production [7]. In order to overcome the problem of using edible oils, there are several nonedible oils extracted from castor and jatropha seeds which could be used as a source for biodiesel production. The benefit of castor and jatropha seeds for biodiesel production is a result of their fast growth rate and high oil content. For example, castor seeds can have up to about 55 % oil content and 35 % for jatropha seeds, and the extracted oil is nontoxic. Castor and jatropha seeds grow in various climates, soil types, and water and have a high resistance to pests and diseases. The extracted oil from castor seeds is viscous, pale yellow, and nonvolatile. The main component of castor oil is ricinoleic acid (80–90 %). It also contains a small amount of linoleic acid (3–6 %), oleic acid (2–4 %), and saturated fatty acids (1–5 %). As listed above, castor oil contains chemicals that make it attractive as a raw material for the preparation of several compounds for the pharmaceutical and chemicals industries [8, 9]. Biodiesel produced from castor oil has much higher viscosities than those prepared from more conventional oil sources, and as a result, a mixture can be made including the biodiesel derived from castor oil and fossil diesel, or less viscous biodiesels [10, 11]. The presence of ricinoleic acid contains both a double bond and a hydroxyl group, can afford an increase in lubricity as compared to conventional vegetable oils, and becomes a prime candidate as an additive for diesel fuel [12, 13].

The second parameter that should be taken into account in biodiesel production is the catalyst. The most commonly used catalysts in the transesterification reaction are base catalysts such as KOH, NaOH, and H2SO4 as an acidic catalyst. These catalysts have many drawbacks. The hydroxides, the base catalysts, cause saponification, which is an undesirable side reaction. Saponification complicates the separation of the FAME (biodiesel) phase from other phases, decreases the biodiesel yield, and makes catalyst recycling more difficult [14–16]. In addition, using an acidic catalyst increases the biodiesel yield, but on the other hand, it slows down the transesterification under high temperature and pressure [17, 18]. In order to prevent these drawbacks, many types of alkaline earth metal oxide catalysts have been explored for transesterificaion reactions such as BaO, SrO, CaO, and MgO [19–21]. The BaO catalyst activity is the highest. However, BaO is noxious and can be dissolved by methanol, and therefore, BaO is not suitable for biodiesel production [22]. SrO as a catalyst was found to be the most suitable catalyst for biodiesel production by a transesterification reaction, as reported elsewhere [23, 24]. It is insoluble in vegetable oil, methanol, and FAME and accelerates the transesterification reaction from hours to seconds [25]. However, SrO tends to absorb water vapor in the presence of air to form Sr(OH)2. In addition, SrO in the presence of air absorbs CO2 to form SrCO3. In order to prevent the formation of SrCO3 and Sr(OH)2, which causes undesirable saponification, SrO should undergo thermal treatment before biodiesel production. In addition, transesterification in the presence of SrO should occur under argon atmosphere. Currently, the use of argon during the transesterification reaction is difficult to implement into industry but may be achieved by further research.

The third parameter to be considered is the heating source. The transesterification reaction can be conducted by a conventional reflux technique, sonication, or microwave irradiation, methods that were compared in our previous work. Microwave irradiation was found to be the most efficient method for lipid extraction and biodiesel production from a microalgae biomass of Nannochloropsis [26]. The last parameter that must be considered in biodiesel production is alcohol. The use of methanol as the alcohol in the transestrification reaction is more common than ethanol because of its low cost. However, several researchers prefer using ethanol derived from sugar cane in the transestrification reaction [27, 28].

Various methods have already been used for biodiesel production from castor and jatropha seeds. The most popular methods consist of two separate stages, the first being oil extraction and the second, biodiesel production by the transesterification of oil seeds using either an acid or an alkali as a catalyst [29, 30]. Recently, a one-stage method has been reported that provides the direct transesterification of castor seeds without the extraction step using conventional heating for 1 h with KOH as a catalyst [13]. The described method resulted in a conversion of only 65.9 %. The current work demonstrates the optimization of a one-stage method using the combination of microwave or sonochemical irradiation as the heating source and SrO as the catalyst. This combination improves considerably the direct conversion of castor and jatropha seeds to biodiesel. Microwave and sonochemical irradiation accelerate both the release of oil and the subsequent transesterification reaction. The current report provides a comparison between the conventional method for FAME production from castor and jatropha seeds, which consist of two stages, with a technique that uses a one-stage process.

Methods

Materials and Methods

Castor and jatropha seeds were provided by the Plant Sciences Institute, Agricultural Research Organization (Volcani Center, Beit-Dagan, Israel). Methanol, chloroform (Bio Lab), and strontium oxide (99.5 %, Alfa Aesar) were used as obtained. Three heating methods have been compared for FAME production. (1) Microwave irradiation was performed in a domestic microwave oven (DMO, SHARP R-390F) operating at 2.45 GHz, which was used for transesterification reactions in a batch mode. The output of the domestic microwave reactor was 1,100 W. The microwave oven was operated at 70 % power (cycle mode of 21 s on and 9 s off), a cycle mode function provided by the oven's manufacturer. The MW oven was modified to accommodate a distillation column that is connected to a round-bottom flask. The changes in the MW have been described elsewhere [31]. This modification, passing a distillation column through the MW oven, is aimed at enhancing safe operation by preventing the liquid from splashing. The MW oven was also modified to stir the reaction cell using a magnetic stirrer. The modification was performed by replacing the bottom part of the oven with a rounded aluminum plate. The plate was carefully attached to the framework to allow magnetic stirring, as described elsewhere [32]. (2) Sonication (Sonics and Materials, VC-600, 20 kHz, 0.5-in. Ti horn at 40 % amplitude) [33]. (3) A conventional reflux technique consists of a reflux condenser connected to a round-bottom flask that was immersed in an oil bath. A hot plate was used as a heating source. We also conducted a stirred reaction at room temperature. The stirred reaction is similar to a conventional reflux technique, but the reaction presented here occurred without heating. The three methods mentioned above were conducted under argon atmosphere in order to protect the SrO catalyst from the formation of Sr(OH)2 by the reaction of the oxide with water vapor [25].

Oil Extraction

Castor and jatropha seeds were broken separately and manually at room temperature with a hammer in order to achieve the optimum oil extraction from the core of the seeds. The contents of the broken seeds (1 g) were mixed with methanol–chloroform (1:2 v/v) for oil extraction using the three extraction methods, a microwave oven, sonication, and a conventional reflux technique for 5 min. The ratio of seeds to liquid was 1:19 g/g. We also conducted a room temperature reaction. At the end of the reaction, the chloroform–methanol phase that contained the extracted oil was separated from the seed powder by filtration using a funnel with a slight suction, followed by the evaporation of the solvent. The mass of the oil obtained from each sample was determined gravimetrically. The temperature in the microwave reaction and in conventional reflux was 60 °C. During the sonication process, the temperature was kept at 50 °C.

Thermal Decomposition of Sr(OH)2

The commercial SrO, which contains a small amount of Sr(OH)2, underwent thermal decomposition in order to obtain a clean SrO catalyst without residues of Sr(OH)2, as reported in our previous work and described elsewhere on the paper [25]. Commercial SrO was introduced into the quartz test tube, which was placed at the center of a tube furnace under argon atmosphere. The temperature was raised at a rate of 10 °C/min to 710 °C and was held at this temperature under pumping for 1 h. The sample was cooled gradually to room temperature. After the thermal decomposition process, a mixture of the SrO in methanol was prepared under argon atmosphere and was added to a 50-ml round-bottom flask containing castor/jatropha oil or castor/jatropha seeds under argon atmosphere.

Transesterification Process

For the transesterification of seed oil (extracted castor or jatropha oil), a mixture of methanol–chloroform (1:2 v/v) and SrO (0.3 g) was added to the seed oil, with the reaction resulting from the above-mentioned three methods, microwave irradiation, sonication, and conventional reflux. Each of these processes lasted for 2 min. After the reaction was completed, the samples were centrifuged and filtered to separate the methanol–chloroform phase that contained the FAME from the glycerol and the catalyst. The solution of methanol–chloroform was evaporated, and the mass of the FAME was determined gravimetrically.

Transesterification Process Directly on the Broken Castor and Jatropha Seeds

Broken castor or jatropha seeds (1 g) were mixed with methanol–chloroform (1:2 v/v) and a SrO catalyst (0.3 g). The reaction mixture took place using the three above-mentioned methods, microwave irradiation, sonication, and conventional reflux, for 5 min. After the completion of the reaction, the samples were centrifuged and filtered to separate the methanol–chloroform phase that contained the FAME from the seed oil, the glycerol, and the catalyst. The methanol–chloroform solution was evaporated, and the FAME mass was determined gravimetrically. The temperature in the microwave reaction was measured by a pyrometer (M.R.C., Ltd.) as soon as the reaction was completed. The temperature was found to be 60 °C for the direct transesterification conducted by microwave irradiation. During the sonication process, the temperature was measured by placing a digital thermocouple in the reaction cell. The temperature was found to be 50 °C. Therefore, we also conducted transesterification at 60 °C by conventional reflux using the conventional protocol.

Recycling the SrO Catalyst in a Direct Transesterification Reaction

In order to reuse the SrO catalyst after each cycle following completion of the reaction, together with the residues of the castor or jatropha seeds, the reaction mixture was centrifuged and filtered to separate the catalyst and the seeds from the methanol–chloroform phase that contained the FAME and glycerol. In a recycling experiment, the solid mixture is mixed with a fresh amount of castor seeds and SrO, methanol, and chloroform. The relative amount of reactants is kept constant in all the cycles. The SrO with seed residues was reused for a total of 10 cycles. Each cycle occurred under the optimal conditions for FAME production, namely, direct transesterification using microwave as a source of heating for 5 min. The activity of SrO was studied by calculating the FAME conversion of seed oils and the oil yield of the seeds' biomass in each cycle.

Characterization

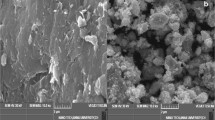

The oil yield was evaluated by its weight relative to the weight of the seeds' biomass. A FAME product was analyzed by 1H NMR spectroscopy (Bruker) and recorded on a 200- or 300-MHz spectrometer. The chemical shifts were referenced to CDCl3. The conversion percentage was calculated directly from the integrated areas of the triglyceride and FAME signals. The composition of FAME contained in the biodiesel was further analyzed via GC-MS (Varian 431-GC, 220-MS). The FAME products were dissolved in hexane, and the nature of the fatty acid composition in the castor and jatropha seeds was determined by GC-MS analysis. The GC conditions, the column used, the profile of the oven temperature, and the MS conditions are demonstrated in Table 1. Compounds were identified by a comparison of the retention time and mass spectra with a library data of mass spectra compounds. Before recycling by transesterification and after the seventh recycle, the SrO catalyst was also characterized by Scanning Electron Microscopy (SEM, JSM-840, JEOL). Each reaction described in this paper was repeated three times. Identical results were always obtained for the major product (FAME). The 1H NMR spectrum didn't show any impurity in all our products. However, the detection limit of the NMR is about 3 %. On the other hand, in the GC-MS, small amounts of <1 % of impurities were detected. They are reported below in Table 2.

Results and Discussion

Analysis of the FAME Produced from Castor and Jatropha Seeds

GC-MS Analysis

The analysis was conducted on the products of the direct transesterification reactions using microwave radiation and sonication, as mentioned in Table 2. According to Table 2, the major composition of FAME produced from castor seeds consists of methyl ricinoleate, which is sensitive to oxidation. Direct transesterification from castor seeds using microwave, yielded a lower percentage of methyl ricinoleate, as compared to the sonication technique. Methyl ricinoleate is known as a compound sensitive to oxidation. On the other hand, the microwave method yielded a higher percentage of saturated fatty acids than in the sonoreaction. Saturated fatty acids are known to impart a good oxidation resistance to biodiesel. The major composition of biodiesel produced from jatropha seeds consists of methyl 12-octadecenoate and methyl palmitate, which represent the saturated fatty acids which yield is higher in the FAME produced by the microwave method. All the analyzed FAME products have low content of undesirable polyunsaturated fatty acids. The low percentage of polyunsaturated molecules is necessary for preventing oxidation and polymerization, leading to gum formation. Table 2 shows that all the FAME samples consist of a carbon chain of no more than 18 carbons, which guarantees a low viscosity for the biodiesel. The small amounts of fatty acids obtained from different samples can change slightly from sample to sample (see Table 2) because they are taken from different seeds. Each seed may contain a slightly different sort of fatty acid. Using the 1H NMR technique, it is difficult to identify other components in the biodiesel phase at a low concentration of <3 % (weight). As a result, these other components (impurities) were identified by performing the GC-MS technique as presented in Table 2.

1H NMR Results

After each production of FAME from castor and jatropha seeds using different methods, as mentioned below, the FAME product was analyzed by 1H NMR spectroscopy. 1H NMR analysis provided important information, i.e., the progress of the transesterification reaction. 1H NMR spectroscopy enables the simultaneous detection of the product (FAME) and the precursor (oil), and as a result, the progress of the transesterification reaction can be monitored. Secondly, a 1H NMR spectrum can identify whether the resulting product is pure or perhaps includes impurities such as glycerol, methanol, chloroform, acetone, or other extracted components in addition to the extracted oil phase. Thirdly, the conversion of castor or jatropha oil to FAME can be calculated. The conversion of seed oil to FAME might be calculated by the integration of 1H NMR signals. The relevant signals chosen for integration were those of the methoxy groups in the FAME (3.65 ppm, singlet) and those of the α-methylene protons present in all the triglyceride derivatives (2.29 ppm, triplet) of the seed oil (Scheme 1). The decision to use the described signals resulted from the fact that selected signals are distinct, compared to other signals in the spectrum. As a result, the integration value can be estimated with a low percentage error in integration.

Using the measured signals illustrated in Scheme 1, the conversion was calculated by the integration of the 1H NMR signals using Eq. 1 as reported in the literature [34]:

According to Eq. 1, Conversion(%) related to the percentage conversion of oil to the corresponding methyl ester, I Me is the integration value of the protons of the methyl esters (the strong singlet), and I CH2 presents the integration value of the methylene protons. Factors 2 and 3 were derived from the fact that the methylene carbon possesses two protons and the methanol carbon has three attached protons.

Figure S1a (see Online Resource) presents a 1H NMR spectrum of the extracted castor oil from castor seeds by the microwave oven technique obtained after 5 min. We detected strong peaks in the range of 4–4.4 ppm (CH2 groups (–CH2-O-COR) of triglycerides) in the castor oil. The 1H NMR spectrum of the FAME produced directly from castor seeds without the extraction step, using a microwave oven technique, is presented in Fig. S1b (see Online Resource). The triplet at 2.29 ppm resulted from α-methylene protons in the triglyceride structure, whereas the strong singlet at 3.65 ppm is assigned to the methyl ester group of FAME. The signals in the range of 4–4.4 ppm are attributed to the CH2 groups (CH2-O-COR) of triglycerides. The weak intensity of these peaks, in comparison with the strong intensity of the methyl ester peak, is a good indication of the high yield of FAME. The conversion was calculated by the integration of 1H NMR signals, as described above. It should be emphasized that according to the 1H NMR spectra, the products of the oil extraction process as well the FAME produced by the direct transesterification reaction obtained from the castor seeds didn't contain any impurity. The 1H NMR spectrum of jatropha oil extracted by the microwave oven technique is presented in Fig. S2a (see Online Resource ), and the 1H NMR spectrum of FAME production from jatropha seeds after direct transesterification using a microwave oven is demonstrated in Fig. S2b (see Online Resource). The common result for the 1H NMR spectra of the product of the direct transesterification of castor and jatropha seeds is a drastic decrease of the peaks in the 4–4.4 ppm region and the appearance of the methyl ester peak around 3.65 ppm. The 1H NMR results indicate the efficient catalytic activity of the SrO, the microwave heating source as a tool for transesterification, and the success of the direct conversion of castor and jatropha seeds to FAME without the extraction step. In addition, 1H NMR spectra of extracted oil and biodiesel obtained by direct transesterification from castor and jatropha seeds show the absence of nonglyceride material (see Online Resource).

Comparison Between FAME Productions in the Three Different Methods

Comparison of FAME Production from Castor Seeds

Our main goal was to find the best method for biodiesel production from castor and jatropha seeds. The best method means the fastest technique leading to the highest conversion percentage into FAME. The three different techniques outlined above were carried out for this purpose. In a recent report, biodiesel production directly from the microalgae biomass of Nannochloropsis using different heating sources was described [26]. The optimal method was a direct transesterification reaction using microwave heating, resulting in the 99.9 % conversion of the triglyceride to FAME in 5 min. The lipid content in the microalgae was 37.1 % [26]. The lipid content in the castor or jatropha seeds was higher than in the microalgae. Scheme 2 illustrates the three methods employed in the current research for the production of FAME from castor and jatropha seeds in one and two stages. We carried out a comparison between six different reactions. Figure 1a shows the oil yields and FAME conversions of the various reactions conducted on the castor seeds. The yield of oil was estimated by its weight relative to the weight of the castor seeds. The conversion of castor oil to FAME was calculated by the integration of 1H NMR signals, as described above. As shown in Fig. 1, the reaction performed by the two separate steps, extraction and transesterification, using sonication yielded 46.7 % oil, whereas using microwave irradiation resulted in a higher oil yield of 52.7 %. Moreover, a direct transesterification reaction using microwave resulted in an even higher oil yield of 57.2 %. The direct transesterification by sonication resulted in an oil yield of 48.2 %. The direct transesterification by reflux yielded 24.7 %. It is worth mentioning that the one-step direct transesterification conducted at room temperature with stirring yielded only a 3.1 % conversion to FAME. According to Fig. 1a, when using direct transesterification by microwave irradiation, we reach the highest conversion (99.95 % conversion) of the triglyceride to FAME. The stirred room temperature reaction demonstrated only a 12.8 % conversion. These results reveal the importance of microwave irradiation or sonochemistry in accelerating the transesterification reaction. As compared to the reflux technique, they have a shorter reaction time and their yields are higher, leading to larger amounts of FAME.

Oil yield of a castor and b jatropha seeds. The yield is related to the total weight of the seeds. FAME conversion of a castor and b jatropha oil using various techniques. The conversion percentage is the measure of the amount of FAME obtained from the known amount of oil in the seeds. Six reactions were performed for FAME production: Ex-Trans MW the two steps of extraction and transesterification reaction performed separately using microwave, Direct MW direct transesterification without the initial extraction step using microwave, Ex-Trans Sono extraction and transesterification reaction steps carried out separately using sonication, Direct Sono direct transesterification without the initial extraction step using sonication, Ex-Trans Reflux extraction and transesterification reaction steps conducted separately using reflux, Direct Reflux direct transesterification without the initial extraction step using a conventional reflux technique

The reason why MW radiation is more effective can be a temperature effect, i.e., higher temperatures obtained in a MW oven due to overheating than in the sonochemical reaction. Another reason for MW efficiency may relate to the ionic nature of the transition state of the transesterification reaction. This helps to couple the MW to the reacting molecules and cause the acceleration of the chemical reaction [26]. Heating the reaction mixture in MW is faster than in a conventional reflux and accelerates the transesterification reaction. Because the mixture of oil, methanol, and catalyst contains both polar and ionic components, rapid heating is observed upon microwave irradiation, and because the energy interacts with the sample on a molecular level, very efficient heating can be obtained. In addition, because the MW photons interact with the molecules at a very fast rate, the molecules do not have time to relax and the heat generated can be, for short times, much greater than the overall recorded temperature of the bulk reaction mixture. In essence, there will be instantaneous localized superheating. Thus, the bulk temperature may not be an accurate measure of the temperature at which the actual reaction is taking place. Microwave heating compares very favorably over conventional methods where heating can be relatively slow and inefficient because transferring energy into a sample depends upon convection currents and thermal conductivity of the reaction mixture. The reason for the short reaction time under MW is due to the higher temperature obtained under MW of the super heated liquids [4]. Although the temperature of the sonochemical process is lower than in conventional heating by reflux, the oil yield and conversion of the triglyceride to FAME of the sonochemical process is much higher than regular reflux. The efficiency of the sonochemical process is due to the effect of the collapsing bubbles that causes a local very high temperature, leading to the breaking of more seeds into smaller clusters, to oil release, and to a fast transesterifcation reaction.

Comparison of FAME Production Methods from Jatropha Seeds

Figure 1b shows the FAME yields of the various reactions conducted on the jatropha seeds. The yield of oil was estimated by its weight relative to the weight of the jatropha seeds. As shown in Fig. 1b, the most efficient reaction is a direct transesterification reaction using microwave, resulting in the highest oil yield of 41.1 %. The direct transesterification by sonication resulted in an oil yield of 32.9 %. The direct transesterification by reflux yielded 19.9 %. The stirred room temperature reaction yielded only 2.5 % in the one-step direct transesterification. According to Fig. 1b, when using direct transesterification by microwave irradiation, we reach the highest conversion (99.7 % conversion) of the triglyceride to FAME. The stirred room temperature reaction demonstrated only a 12.5 % conversion. According to the results presented in Fig. 1a and Fig. 1b, the optimal method for FAME production is direct transesterification using microwave irradiation. The second best method is the direct transesterification using sonication. The reasons for the microwave being the most efficient technique were explained above.

The Influence of Recycling the Catalyst in the Direct Transesterification Reaction on the FAME Yield

Recycling the SrO catalyst in the direct transesterification of castor and jatropha seeds is essential for economic reasons. Therefore, we reused the catalyst for 10 cycles and studied its activity in each cycle. Before recycling, the SrO catalyst was treated for the elimination of Sr(OH)2, as described above. Figures 2a and 3a present intact castor and jatropha seeds before FAME production, with lengths of 1.8 cm and 2.1 cm, respectively. Figures 2b and 3b demonstrate broken seeds before they underwent direct transesterification. After the breaking process, the size of shell was around 3–15 mm, and the size of the white core containing the oil was around 0.5–5 mm. Figures 2c and 3c illustrate broken seeds with SrO after biodiesel production by direct transesterification using microwave. This powder of SrO and broken seeds was reused for 10 cycles. Figure 4 presents the effect of the repeated use of SrO with the castor or jatopha biomass on the FAME conversion and its yield in respect to the weight of the biomass. According to Fig. 4a, the oil conversion to FAME is high and quite stable for the first six recycles. From the seventh recycle, the FAME conversion slightly decreases from 99.5 % and 98.8 % to 97.8 % and 96.9 for the castor and jatropha seeds, respectively. Even after 10 cycles, the FAME conversion is still 97.8 % and 96.9 % for castor and jatropha seeds, respectively. The results confirm the stability and the sustained activity of SrO, which is of great importance for industrial application. Figure 5 shows the SEM micrographs of a SrO catalyst as received and after the seventh recycled use. The freshly obtained catalyst consists of dispersed particles, as opposed to the catalyst after the seventh reaction cycle, which appears in an aggregated form. The reason for the loss of 2–3 % in conversion might be due to the loss of the catalyst mass during the SrO recycling process. Figure 4b shows an increase in oil yield with an increase in the recycle number. After 10 cycles, the oil yield increases from 57.2 % and 41.1 % to 63.2 % and 44.8 % for castor and jatropha seeds, respectively. The increase in the yield during the recycling resulted from the fact that during direct transesterification, oil was extracted not only from the biomass of the fresh seeds but also from the residues of the biomass related to previous recycles.

Castor seeds before and after biodiesel production. a Intact castor seeds before biodiesel production with length of 1.8 cm. b Broken castor seeds before biodiesel production. The size of shell is around 3–15 mm, and the size of the white core containing the oil is around 0.5–5 mm. c Broken castor seeds with SrO after biodiesel production by direct transesterification using microwave

Jatropha seeds before and after biodiesel production. a Intact jatropha seeds before biodiesel production with a length of 2.1 cm. b Broken jatropha seeds before biodiesel production. The size of shell is around 3–15 mm, and the size of the white core containing the oil is around 0.5–5 mm. c Broken jatropha seeds with SrO after biodiesel production by direct transesterification using microwave

Conclusions

FAME production from castor and jatropha seeds can be accomplished by the conventional method of two separated stages, namely, oil extraction followed by transesterification of oil seeds or by a one-stage method referred to as direct transesterifcation using different heating sources. Microwave as a heating source accelerates the release of oil from the seeds and further speeds up FAME production. Carrying out the direct transestrification in MW is not only a shorter process than the two-stage process, but it also yields more FAME than in the two-stage processes. The SrO catalyst is an ideal catalyst for the transesterification reaction, which can be easily separated from the reaction mixture and reused in many cycles. The results reveal that using the MW oven for FAME production from castor or jatropha seeds, in one-stage with SrO, can achieve a 100 % conversion to FAME in 5 min.

References

Vicente G, Martinez M, Aracil J (2005) Optimization of Brassica carinata oil methanolysis for biodiesel production. J Am Oil Chem Soc 82:899–904

Kalbande SR, More GR, Nadre RG (2008) Biodiesel production from non-edible oils of jatropha and karanj for utilization in electrical generator. Bioenerg Res 1:170–178

Peiro LT, Mendez GV, Durany XG (2008) Exergy analysis of integrated waste management in the recovery and recycling of used cooking oils. Environ Sci Technol 42:4977–4981

Barnard TM, Leadbeater NE, Boucher MB, Stencel LM, Wilhite BA (2007) Continuous-flow preparation of biodiesel using microwave heating. Energy Fuel 21:1777–1781

Monteiro MR, Ambrozin ARP, Lião LM, Ferreir AG (2009) Determination of biodiesel blend levels in different diesel samples by 1H NMR. Fuel 88:691–696

Valente OS, Silva MJd, Pasa VMD, Belchior CRP, Sodrĕ JR (2010) Fuel consumption and emissions from a diesel power generator fuelled with castor oil and soybean biodiesel. Fuel 89:3637–3642

Berchmans HJ, Hirata S (2008) Biodiesel production from crude Jatropha curcas L. seed with a high content of free fatty acids. Bioresour Technol 99:1716–1721

Ogunniyi DS (2006) Castor oil: a vital industrial raw material. Bioresour Technol 97:1086–1091

Meneghetti SMP, Meneghetti MR, Wolf CR, Silva EC, Lima GES, Coimbra MA, et al. (2006) Ethanolysis of castor and cottonseed oil: a systematic study using classical catalysts. J Am Oil Chem Soc 83:819–822

Santana GCS, Martins PF, da Silva N, Batistella CB, Maciel-Filho R, Wolf-Maciel MR (2010) Simulation and cost estimate for biodiesel production using castor oil. Chem Eng Res Des 88:626–632

da Costa BD, Serra TM, Meneghetti SMP, Meneghetti MR (2010) Biodiesel production by ethanolysis of mixed castor and soybean oils. Fuel 89:3791–3794

Ramezani K, Rowshanzamir S, Eikani MH (2010) Castor oil transesterification reaction: a kinetic study and optimization of parameters. Energy 35:4142–4148

Hincapié G, Mondragón F, López D (2011) Conventional and in situ transesterification of castor seed oil for biodiesel production. Fuel 90:1618–1623

Wenlei X, Hong P, Ligong C (2006) Transesterification of soybean oil catalyzed by potassium loaded on alumina as a solid-base catalyst. Appl Catal A: Gen 300:67–74

Yang FX, Su YQ, Li XH, Zhang Q, Sun RC (2008) Studies on the preparation of biodiesel from Zanthoxylum bungeanum maxim seed oil. J Agric Food Chem 56:7891–7896

Rashid U, Anwar F (2008) Production of biodiesel through base-catalyzed transesterification of safflower oil using an optimized protocol. Energy Fuel 22:1306–1312

Serio MD, Cozzolino M, Giordano M, Tesser R, Patrono P, Santacesaria E (2007) From homogeneous to heterogeneous catalysts in biodiesel production. Ind Eng Chem Res 46:6379–6384

Talukder MMR, Wu JC, Lau SK, Cui LC, Shimin G, Lim A (2009) Comparison of Novozym 435 and Amberlyst 15 as heterogeneous catalyst for production of biodiesel from palm fatty acid distillate. Energy Fuel 23:1–4

Seki T, Kabashima H, Akutsu K (2001) Mixed Tishchenko reaction over solid base catalysts. J Catal 204:393–401

Cantrell DG, Gillie LJ, Lee AF, Wilson K (2005) Structure–reactivity correlations in MgAl hydrotalcite catalysts for biodiesel synthesis. Appl Catal A: Gen 287:183–190

Xuejun L, Huayang H, Yujun W, Shenlin Z (2007) Transesterification of soybean oil to biodiesel using SrO as a solid base catalyst. Catal Commun 8:1107–1111

Buyevskaya OV, Baerns M (1998) Catalytic selective oxidation of propane. Catal Today 42:315–323

Patil DP, Deng S (2009) Transesterification of Camelina sativa oil using heterogeneous metal oxide catalysts. Energy Fuel 23:4619–4624

Patil DP, Gude VG, Camacho LM, Deng S (2010) Microwave-assisted catalytic transesterification of Camelina sativa oil. Energy Fuel 24:1298–1304

Koberg M, Abu-Much R, Gedanken A (2011) Optimization of bio-diesel production from soybean and wastes of cooked oil: combining dielectric microwave irradiation and a SrO catalyst. Bioresour Technol 102:1073–1078

Koberg M, Cohen M, Ben-Amotz A, Gedanken A (2011) Bio-diesel production directly from the microalgae biomass of Nannochloropsis by microwave and ultrasound radiation. Bioresour Technol 102:4265–4269

Ma F, Hanna M (1999) Biodiesel production: a review. Bioresour Technol 70:1–15

Zagonel G, Peralta-Zamora P, Ramos L (2004) Multivariate monitoring of soybean oil ethanolysis by FTIR. Talanta 63:1021–1025

Martín C, Moure A, Martín G, Carrillo E, Domínguez H, Parajó JC (2010) Fractional characterisation of jatropha, neem, moringa, trisperma, castor and candlenut seeds as potential feedstocks for biodiesel production in Cuba. Biomass Bioenergy 34:533–538

Olutoye MA, Hameed BH (2011) Synthesis of fatty acid methyl ester from crude jatropha (Jatropha curcas Linnaeus) oil using aluminium oxide modified Mg–Zn heterogeneous catalyst. Bioresour Technol 102:6392–6398

Groisman Y, Gedanken A (2008) Continuous flow, circulating microwave system and its application in nanoparticle fabrication and biodiesel synthesis. J Phys Chem C 112:8802–8808

Klan P, Hajek M, Cirkva V (2001) The electrodeless discharge lamp: a prospective tool for photochemistry: part 3. The microwave photochemistry reactor. J Photochem Photobiol A: Chem 140:185–189

Bang BJH, Suslick KS (2010) Applications of ultrasound to the synthesis of nanostructured materials. Adv Mater 22:1039–1059

Meher LC, Sagar DV, Naik SN (2006) Technical aspects of biodiesel production by transesterification—a review. Renew Sust Energy Rev 10:248–268

Acknowledgement

M. Koberg thanks the Ministry of Science and Technology for the Ashkol Scholarship. A. Gedanken thanks the Ministry of Science and Technology for a research grant No. 3-8793 supporting this study.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 79 kb)

Rights and permissions

About this article

Cite this article

Koberg, M., Gedanken, A. Direct Transesterification of Castor and Jatropha Seeds for FAME Production by Microwave and Ultrasound Radiation Using a SrO Catalyst. Bioenerg. Res. 5, 958–968 (2012). https://doi.org/10.1007/s12155-012-9210-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-012-9210-6