Abstract

Independent down-regulation of genes encoding p-coumarate 3-hydroxylase (C3H) and hydroxycinnamoyl CoA:shikimate/quinate hydroxycinnamoyl transferase (HCT) has been previously shown to reduce the recalcitrance of alfalfa and thereby improve the release of fermentable sugars during enzymatic hydrolysis. In this study, ball-milled lignins were isolated from wild-type control, C3H, and HCT gene down-regulated alfalfa plants. One- and two-dimensional nuclear magnetic resonance (NMR) techniques were utilized to determine structural changes in the ball-milled alfalfa lignins resulting from this genetic engineering. After C3H and HCT gene down-regulation, significant structural changes had occurred to the alfalfa ball-milled lignins compared to the wild-type control. A substantial increase in p-hydroxyphenyl units was observed in the transgenic alfalfa ball-milled lignins as well as a concomitant decrease in guaiacyl and syringyl units. Two-dimensional 13C–1H heteronuclear single quantum coherence correlation NMR, one-dimensional distortionless enhancement by polarization transfer-135, and 13C NMR measurement showed a noteworthy decrease in methoxyl group and β-O-4 linkage contents in these transgenic alfalfa lignins. 13C NMR analysis estimated that C3H gene down-regulation reduced the methoxyl content by ~55–58% in the ball-milled lignin, while HCT down-regulation decreased methoxyl content by ~73%. The gene down-regulated C3H and HCT transgenic alfalfa lignin was largely a p-hydroxyphenyl (H) rich type lignin. Compared to the wild-type plant, the C3H and HCT transgenic lines had an increase in relative abundance of phenylcoumaran and resinol in the ball-milled lignins.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Public, commercial, and scientific interest is acutely focused on the search for renewable energy and materials as viable alternatives to nonrenewable petroleum resource to meet the increasing societal demand for sustainable development as well as to shift the society’s dependence away from petroleum to renewable resources [1–5]. Lignocellulosic biomass is considered as a low-cost feedstock for biofuels production with the potential of being cost competitive with fossil fuels, and substantial efforts have been made to explore and develop biomass utilization processes that convert biomass into liquid fuels and chemicals [6–8]. Several routes toward the production of biofuels and renewable chemicals are being pursued through thermochemical or biological processes, including pyrolysis, gasification, catalytic dehydration–hydrogenation, and fermentation [7]. Of these technologies, the fermentation route is considered as one of the most developed and promising. However, due to the recalcitrance of lignocellulosics, the overall cost of converting lignocellulosic biomass to biofuels through fermentation route is higher than well-established commercial starch to bioethanol processes. This has remained a challenge for practical and sustainable production of biofuels [9, 10].

The recalcitrance of lignocellulosic biomass, i.e., the difficulty of converting biomass into accessible sugars, is reviewed as a key bottleneck in the process of biofuels production and the most significant obstacle to the cost-effective establishment of a cellulosic biofuels industry [11–13]. Pretreatment prior to addition of hydrolytic enzymes for saccharification of cellulose or hemicelluloses has been applied to overcome biomass recalcitrance by disrupting the naturally resistant carbohydrate–lignin shield and altering the biomass structures, thus making the cellulose and hemicellulose more accessible and amenable to hydrolytic enzymes [14–16]. These pretreatments can be mechanical, chemical, and thermochemical. The most studied lignocellulosics pretreatments include steam explosion [17, 18], hydrothermolysis [19–21], dilute acid [22–24], lime [25, 26], ammonia [27, 28], and organosolv [29, 30] pretreatment. Although considerable efforts have been made to improve the effectiveness of pretreatment technologies, it remains a costly step in the overall lignocellulosic biofuels process [16]. It is clear that new approaches are needed that overcome the recalcitrance of lignocellulosic biomass and reduce the cost of a cellulosic biofuels production [31, 32].

Genetic engineering of plant bioresources has been reported as a promising approach to reducing biomass recalcitrance for the biological conversion process [33–37]. Perturbing plant biomass deposition by targeted modification of key genes integral to major cell wall pathways can provide significant opportunities for improved lignocellulosics utilization. The forest product industry has extensively explored the use of plant genetics to tailor the composition, structures, and reactivity of plant biopolymers, especially lignin [33–35]. Lignin comprises the second most abundant biopolymer in the biosphere and is considered a key component in the determination of biomass recalcitrance [7]. Alteration of lignin content and its monolignol composition in plant biomass via genetic engineering has been shown to significantly impact delignification efficiency and pulp bleachability for chemical pulping. For example, Huntley et al. demonstrated that increased syringyl lignin in transgenic poplars, by overexpressing ferulate 5-hydroxylase, resulted in an increase in chemical pulping by 60% [33]. Likewise, Lapierre et al. reported that transgenic poplar with low cinnamyl alcohol dehydrogenase activity exhibited improved kraft pulping properties [34, 35].

In recent years, extensive attempts have been made to genetically engineer low-recalcitrance plants by lowering lignin content and/or altering lignin structures, thus tailoring plants to microbial and enzymatic deconstruction [36–38]. A recent report by Davison et al. [36] has demonstrated that changes in lignin content and syringyl/guaiacyl ratios of a second generation Populus significantly benefited xylose release upon dilute sulfuric acid hydrolysis. Chen and Dixon [37] analyzed alfalfa plants that were independently down-regulated for six lignin biosynthesis enzymes [39, 40]. They reported that p-coumarate 3-hydroxylase (C3H) and hydroxycinnamoyl CoA:shikimate/quinate hydroxycinnamoyl transferase (HCT) down-regulated alfalfa lines demonstrated improved fermentable sugar yields without acid pretreatment when compared to wild-type (WT) plants that had been subject to acid pretreatment [37]. These plants were shown to have comparable increased digestibilities with different lignin concentrations, thus indicating that more than just lignin content is important. These results highlight the potential to genetically alter plant cell wall composition and lignin structures in plant biomass, which can confer benefits in subsequent enzymatic operations and more attractively could bypass or minimize the severity of a pretreatment and thereby facilitate bioprocess consolidation for biofuel production. However, the application of this approach in a broad sense has been hindered, in part, due to lack of understanding of cell wall biosynthesis at the molecular level and of how genetically engineered lignin modification influences biomass recalcitrance. Herein, we investigated the effects of C3H and HCT down-regulation on alfalfa lignin structures, attempting to determine how the genetic modification influences lignin structures and the resulting plant recalcitrance.

Methods

Plant Materials

WT and transgenic alfalfa (Medicago sativa cv. Regen SY) plants down-regulated in C3H and HCT enzyme activity were generated as reported previously [39, 40]. The WT control plant was generated from transformation process with no transformation vector (labeled as CTR1), and transgenic lines were transformed with constructs independently harboring antisense constructs targeting C3H and HCT enzymes, respectively. Two C3H transgenic lines C3H4a and C3H9a with different levels of down-regulation (supplementary Table 1) [39] and one HCT3a transgenic line [40] were used in this study.

Chemicals

All chemicals used were purchased either from VWR International or Aldrich and used as received except 1,4-dioxane, which was distilled over NaBH4 prior to use.

Lignin Isolation

All the plant lines were grown in the greenhouse until they reached the late flowering stage. Mature stems were harvested (the first seven internodes from the top were discarded), dried in an oven at 55°C, and ground in a Wiley mill to pass through a 60-mesh screen and then stored at <0°C until use. Ball-milled lignin was isolated according to modified literature methods described previously [41–44]. In brief, the Wiley-milled alfalfa samples were Soxhlet-extracted with benzene–ethanol (2:1, v/v) for 24 h and then dried under vacuum overnight. The dried alfalfa (10.0 g) was ball-milled in a porcelain jar (1.00 L) with ceramic balls using a rotatory ball mill running at 96 rpm for 7 days. A ceramic balls/biomass weight ratio of 30:1 was used. The ball-milled cell wall powder was then extracted twice with dioxane–water (96:4, v/v; 10 mL/g alfalfa) under stirring for 48 h in the dark. The extracted mixture was centrifuged, and the supernatant was collected. The collected dioxane–water solution was roto-evaporated to reduce the volume to ~20 mL at 40°C under reduced pressure. Deionized water (~10 mL) was added into the mixture, freeze-dried, and the crude ball-milled lignin was collected. The crude lignin was dissolved in acetic acid–water (90:10, v/v; 50 mg/mL) and precipitated in deionized water (200 mL), centrifuged, and freeze-dried. For further purification, the solid product was dissolved in minimum quantity of 1,2-dichloroethane-ethanol mixture (2:1, v/v) and precipitated in diethyl ether (200 mL), centrifuged, washed with petroleum ether, dried overnight under vacuum at 40°C, and stored in a desiccator over P2O5 prior to analysis. The ball-milled lignin yield was ~7.8%, 10.1%, 16.3%, and 22.0% based on the AcBr lignin content for the WT, C3H9a, C3H4a, and HCT3a transgenic plants, respectively.

Heteronuclear Single Quantum Coherence NMR

Two-dimensional heteronuclear single quantum coherence (HSQC) correlation NMR spectra were recorded in a Bruker DRX 500 NMR spectrometer fitted with a 5-mm broadband probe with a gradient field in the Z direction. The lignin (60~100 mg) was placed into a 4-mL vial and dissolved in deuterated dimethyl sulfoxide (DMSO-d6) (0.50 mL). The mixture was allowed to shake in a Vortex shaker for dissolution. The sample was then transferred into a 5-mm NMR tube. A standard Bruker HSQC pulse sequence was used, and the experimental acquisition parameters were as follows: spectra width of 11 ppm in F2 (1H) dimension with 1,024 time of domain and 210 ppm in F1(13C) dimension with 256 time of domain; a 1.5-s interscan delay; a 1 J C–H of 145 Hz (i.e., CNST2); and 16 or 32 scans. The central solvent peak (δ c 39.5 ppm; δ H 2.5 ppm) was used for chemical shifts calibration. Relative interunit linkage levels in lignins were estimated semiquantitatively using volume integration of contours in HSQC spectra. Though this approach is not quantitative, it has been used in a semiquantitative way to provide a relative comparison of interunit linkage levels in lignins and to compare structural features of lignin in alfalfa, eucalyptus, and poplar [45–48]. The well-resolved α-carbon contours were used for volume integration for β-O-4, phenylcoumaran, and resinol linkages (see Fig. 3 for structures) [45, 48]. The relative abundance of interunit linkages was then calculated as the percentage of each linkage type with respect to the linkages total.

Distortionless Enhancement by Polarization Transfer NMR

Distortionless enhancement by polarization transfer (DEPT) NMR spectra was recorded using a Bruker Avance/DMX 400 MHz NMR spectrometer equipped with a 5-mm QNP (1H/13C/19F/31P) probe. The same samples from HSQC analysis were used. Standard Bruker pulse DEPT-135 was employed with the following acquisition conditions: spectral width of 2,0161 Hz, time of domain of 32,769, eight dummy scans, recycle delay of 2 s, acquisition time of 0.81 s, and 12,288 scans. DMSO central peak (δ c, 39.5 ppm) was used for chemical shift calibration.

13C NMR Analysis

Quantitative 13C NMR spectra were acquired using a Bruker Avance/DMX 400 MHz spectrometer operated at frequency of 100.59 MHz for the 13C nucleus. A 5-mm QNP (1H/13C/19F/31P) probe was used. The lignin samples used were the same as for HSQC analysis. The quantitative acquisition was carried out at 323°K using a 90° pulse with an inverse-gated decoupling pulse sequence and a 12-s pulse delay. A minimal of 12,288 scans was accumulated for each sample. The recorded free induction decay signals were Fourier-transformed, and a manual phase correction was applied. The central solvent peak (δ c, 39.5 ppm) was used as internal reference for chemical shift calibration. The Fourier-transformed spectra were integrated and analyzed in accordance with reported chemical shifts for lignin functional groups [44, 49–52]. The structural moieties were quantified as the number of carbon atoms per aromatic ring (/Ar). The typical limit of error for the 13C NMR estimation is ~3%.

Results

HSQC Correlation NMR Analysis

Two-dimensional 13C-1H HSQC correlation spectrum correlating protons with their attached carbons is an effective NMR tool for the detailed elucidation of the various lignin structures. The HSQC spectra of WT and transgenic alfalfa ball-milled lignins were summarized in Figs. 1 and 2 illustrating the 13C-1H correlations in aromatic and aliphatic side-chain ranges. The cross-peaks were assigned by comparing with the literature [45–47, 51, 53, 54] and presented in Table 1. In the aromatic region of the lignin 13C-1H HSQC correlation spectra, aromatic resonances arising from syringyl, guaiacyl, and p-hydroxyphenyl lignin units were well separated, and conspicuous changes in the H/S/G signal intensities were readily apparent (Fig. 1). The WT alfalfa lignin showed prominent correlation signals for guaiacyl units at C2/H2 (δ c/δ H 111.0/6.98 ppm), C5/H5 (δ c/δ H 115.1/6.72 and 6.98 ppm) and C6/H6 (δ c/δ H 119.1/6.80 ppm), and syringyl unit at C2,6/H2,6 (δ c/δ H 103.8/6.70 ppm), as well as a weak signal corresponding to C2,6/H2,6 correlations in p-hydroxyphenyl unit at δ c/δ H 128.0/7.17 ppm. A very low amount of the H lignin unit was reported in WT alfalfa lignin using thioacidolysis [37, 40]. The WT alfalfa lignin was a typical guaiacyl-rich, guaiacyl–syringyl lignin containing trace amount of p-hydroxyphenyl component, which was consistent with previous reports [45]. Relatively weak correlations from vinyl carbon–carbon double bond in cinnamaldehyde (E in Fig. 3) were also observed for \( {{\text{C}}_\alpha}/{{\text{H}}_\alpha} \) at δ c/δ H 153.6/7.62 and \( {{\text{C}}_\beta}/{{\text{H}}_\beta} \) at δ c/δ H 128.2/6.75 ppm in WT alfalfa lignins. Weak but diagnosable signals at δ c/δ H 128.3/6.45 and 6.25 ppm in WT alfalfa lignin were assigned to \( {{\text{C}}_\alpha}/{{\text{H}}_\alpha} \) and \( {{\text{C}}_\beta}/{{\text{H}}_\beta} \) correlations arising from two olefinic carbons in cinnamyl alcohol (F in Fig. 3). Correlation signals attributed to C2,6/H2,6 in p-hydroxybenzoate (D in Fig. 3) around δ c/δ H 130.6/7.65 and 7.87 ppm were enhanced for transgenic alfalfa lignins. Compared to WT, C3H and HCT down-regulated alfalfa lignins showed significantly increased correlation signals of p-hydroxyphenyl along with a substantial decrease in the intensities of syringyl and guaiacyl correlations. This suggested substantial differences in the aromatic nature of the lignins in the WT and transgenic alfalfa plants. The C3H and HCT gene down-regulated transgenic alfalfa lignins were largely p-hydroxyphenyl (H) rich lignin.

The aliphatic side-chain region of HSQC spectra revealed detailed information regarding the types and distribution of interunit linkages present in the lignins. The cross-correlation signals from methoxyl group and β-O-4 interunit linkage were the most prominent ones for WT and transgenic lignins. The C–H correlations in β-aryl ethyl (β-O-4) linkage (A in Fig. 3) were readily observed for \( {{\text{C}}_\alpha}/{{\text{H}}_\alpha} \), \( {{\text{C}}_\alpha}/{{\text{H}}_\alpha} \), and \( {{\text{C}}_\alpha}/{{\text{H}}_\alpha} \) at δ c/δ H 71.4/4.76, 83.7/4.31, and 59.8/3.28(3.62) ppm, respectively. The presence of phenylcoumaran (B in Fig. 3 ) and resinol (C in Fig. 3) substructure units was confirmed by their C/H correlations at α-, β-, and γ-C positions (Fig. 2 and Table 1). This is consistent with the previous report that alfalfa lignin is rich in β-aryl ethyl unit with modest amounts of phenylcoumaran and resinol units [45]. A correlation signal at δ c/δ H 61.7/4.09 ppm was assigned to Cγ/Hγ arisen from side-chain end group of cinnamyl alcohol (F in Fig. 3); its relative strong signal intensity was reported to attribute to the sharpness caused by the relative invariance of proton and carbon chemical shifts in such structures where the bonding on the aromatic ring is well distant from the γ-position [45].

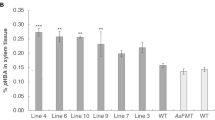

The C3H and HCT transgenic alfalfa lignins showed clear differences in relative signal intensities in the aliphatic side-chain regions of HSQC spectra when compared to WT lignin. The transgenic alfalfa lignins demonstrated a decreased correlation intensity of methoxyl group (δ c/δ H 55.7/3.70 ppm). Other noticeable changes in signal intensities observed were from β-O-4 ethyl linkage (A in Fig. 3), phenylcoumaran (B in Fig. 3), and resinol (C in Fig. 3) interunit substructures. C3H and HCT transgenic alfalfa plants had a decreased β-O-4 ethyl linkage and enlarged phenylcoumaran and resinol substructure signal intensities in the ball-milled lignins. Volume integration of correlations in HSQC spectra was applied to semiquantitatively estimate relative abundances of interunit linkages in lignins. The relative abundance of alfalfa lignin interunit linkages was indicated in Fig. 4. The β-O-4 linkages were observed to decrease in relative abundance in the C3H- and HCT-deficit lignins. The C3H4a lignin showed a greater reduction in β-O-4 linkages than C3H9a. C3H and HCT gene down-regulations led to enhanced relative abundance of phenylcoumaran and resinol in the alfalfa lignins (Fig. 4). C3H transgenic alfalfa lignin had an increase in relative level of phenylcoumaran unit by ~1-fold in C3H9a, ~1.5-fold in C3H4a, while HCT transgenic lignin increased by ~2-fold. Relative abundance of resinol was increased by ~1-fold in C3H9a, ~1.6-fold in C3H4a transgenic lignin, and nearly 2-fold in HCT transgenic lignin.

DEPT NMR Analysis

The DEPT-135 NMR technique was employed to investigate the structures of alfalfa ball-milled lignins, and the resulting spectra are presented in Fig. 5. Only carbons attached to protons were detected with the signals from the methine and methyl carbons out of phase with the methylene carbons. Consistent with the HSQC data, the WT alfalfa lignin was a guaiacyl–syringyl type lignin as observed in DEPT spectra, with guaiacyl unit showing three aromatic carbons from 6-, 5-, and 2-position methane groups (CH) at δ118.6, 114.5, and 111.1 ppm and syringyl unit with two aromatic carbons from 6- and 2-position CH groups at δ103.8 ppm. A small peak at δ128.1 ppm was attributed to overlapped signals arising from 6- and 2-position CH groups in p-hydroxyphenyl unit and side-chain olefinic \( {{\text{C}}_\alpha}/{{\text{H}}_\alpha} \) groups in cinnamaldehyde (E in Fig. 3) as well as \( {{\text{C}}_\alpha}/{{\text{H}}_\alpha} \) and \( {{\text{C}}_\alpha}/{{\text{H}}_\alpha} \) in cinnamyl alcohol (F in Fig. 3). A minor peak at δ193.3 ppm was diagnosed and assigned to the side-chain γ-C from CHO group in cinnamaldehyde, further confirming the existence of trace amounts of cinnamaldehyde unit in alfalfa lignins. Similar to the observations in HSQC spectra, the signals arising from aromatic carbons demonstrated a dramatic change in monolignol composition of lignin in C3H and HCT down-regulated alfalfa. Compared to the control WT alfalfa lignin, the transgenic lignins showed substantially greater portion of H unit signals at δ128 ppm (CH groups at aromatic C6/2 position) and δ104 ppm (CH groups at C3/5 positions), associated with only weak signals remained from G and S units, which was in agreement with the HSQC results that the C3H and HCT gene down-regulated transgenic alfalfa lignins were p-hydroxyphenyl (H) rich lignins. HCT and C3H4a transgenic alfalfa lignins were almost depleted of G and S lignin signals. The peak at δ53.5 resulted from side-chain carbon (CβH) in phenylcoumaran and resinol substructures were observed to increase signal intensities for C3H and HCT transgenic lignins. This confirmed the HSQC results that C3H and HCT gene down-regulation led to enhanced relative abundance of phenylcoumaran and resinol in the alfalfa lignins. It was also clearly evident that signal assigned to γ-CH2 (δ c = 59.8 ppm) in β-O-4 linkages decreased its intensity for transgenic C3H and HCT plants. The methoxyl group signal (δ c = 55.7 ppm) was also observed to lessen its signal intensity for the transgenic alfalfa lignins.

Quantitative 13C NMR

The HSQC and DEPT-135 NMR spectra analyses provided structural information about the alfalfa lignin in a qualitative manner. 1H NMR can provide reliable quantitative information about the molecular structures; however, the extensive signal overlapping in a narrow chemical shift range (i.e., 0–12 ppm) has limited its usage in analysis of lignin. 13C NMR spectroscopy is a useful technique especially for the characterization of lignin, offering improved chemical shift resolution (i.e., 0–220 ppm). The 13C NMR spectra were recorded under quantitative conditions, and signal intensity can be correlated to the amount of these specific carbon atoms present in lignin. The quantitative 13C NMR spectra of alfalfa ball-milled lignin samples are presented in Fig. 6.

Striking changes in the alfalfa lignin structures were observed from the 13C NMR spectra after C3H and HCT gene down-regulations. Coinciding with the observations from HSQC and DEPT spectra, the most notable difference observed was the substantial increase in the signal intensity of the p-hydroxyphenyl (H) monolignol units for the C3H and HCT genes down-regulated alfalfa, accompanied with a large decrease in signal intensities of guaiacyl (G) and syringyl (S) lignin structures. The H/S/G unit composition in alfalfa lignin was estimated using 13C spectra analysis and shown in Fig. 7. The alfalfa lignin had an H/S/G unit ratio of 2.3:33:65 for WT ball-milled lignin (Table 2). After C3H gene down-regulation, the H/S/G ratio was changed to 38:22:40 for C3H9a line (residual enzyme activity of 20%) and to 68:17:15 for C3H4a line (residual enzyme activity of 4%), respectively. The H units increased approximately 16-fold when C3H gene activity was down-regulated to 20% and up to 29-fold when C3H gene activity down-regulated to 4%. The H unit in HCT transgenic alfalfa ball-milled lignin was observed to increase ~31-fold.

It was also evident that transgenic alfalfa lignins had a significant decrease in signal intensities of methoxyl group compared to the WT alfalfa lignin. The methoxyl group content estimated using 13C NMR was shown in Fig. 8. C3H gene down-regulation led to a reduction in methoxyl content by ~55% for C3H9a and ~58% for C3H4a, respectively, while HCT gene down-regulation decreased methoxyl content by ~73% in the ball-milled lignin. Another prominent change observed for the transgenic alfalfa lignins was the reduced peak intensity at δ59.7 ppm, which was assigned to Cγ in β-O-4 linkages that was no carbonyl group at α-C position. 13C NMR analysis estimated a reduction of these β-O-4 linkages by ~21% for C3H9a and ~61% for C3H4a transgenic alfalfa ball-milled lignin, respectively. The HCT transgenic plant showed a reduction of the β-O-4 linkage level by ~40% when compared to the WT control (Fig. 8). The peaks at δ53.6 and 53.1 ppm were assigned to \( {{\text{C}}_\alpha}/{{\text{H}}_\alpha} \) in resinol (β-β) and phenylcoumaran (β-5) groups, respectively [50–52]. It was observed that the signal intensities of resinol and phenylcoumaran increased after C3H and HCT gene down-regulation, confirming the HSQC and DEPT results. Since the signals for resinol and phenylcoumaran were not well resolved in the 13C spectra, no quantitative comparison of these peaks was attempted. As revealed in HSQC and DEPT spectra, a small peak of cinnamaldehyde (δ193.3 ppm) was also observed in 13C spectra, with its amount being 0.02/Ar, 0.06/Ar, 0.03/Ar, and 0.05/Ar for the WT, C3H9a, C3H4a, and HCT transgenic alfalfa lignins, respectively.

Discussion

The NMR spectra analysis revealed that there were substantial structural differences in the lignins isolated from the WT and C3H and HCT gene down-regulated alfalfa plants. The normal WT alfalfa lignin was a guaiacyl–syringyl type lignin, while the C3H and HCT transgenic plants had a rich p-hydroxyphenyl component as revealed by HSQC, DEPT-135, and quantitative 13C NMR spectra. Compared to the WT, the C3H and HCT transgenic alfalfa plants demonstrated a reduction in methoxyl group and β-O-4 linkage, and an increase in phenylcoumaran and resinol substructures in the ball-milled lignins.

The C3H gene down-regulated transgenic alfalfa lignins were largely p-hydroxyphenyl-rich lignin. The observed increase in H units in C3H transgenic alfalfa was in consistence with the previous study by Ralph et al. [45] that reported a massive rise of p-hydroxyphenyl unit in acetylated lignins isolated from a heavily down-regulated C3H-deficient alfalfa. In this study, NMR analysis of ball-milled lignins isolated from two C3H transgenic lines with a varying C3H gene activity demonstrated that the observed monolignol changes in lignin structures were related to the degree of C3H gene down-regulation. Compared to C3H9a plant (residual C3H gene activity ~20%), the C3H4a line (residual C3H gene activity ~4%) had more H units and less G and S units in the ball-milled lignins (Table 2). The C3H4a also exhibited a greater impact on lignin interunit linkage distribution, including a reduction of β-O-4 linkage and increased phenylcoumaran and resinol content in the alfalfa plant. A trace amount of spirodienone and dibenzodioxocin substructures has been reported in WT alfalfa lignins [45]; however, their presence was not apparent in the HSQC spectra in this study.

Similar to C3H gene down-regulation, the HCT gene down-regulation resulted in a significant increase of H units and decrease of G and S units in the alfalfa ball-milled lignin as well. This was not surprising as C3H and HCT were in the synthetic pathway to both S and G lignin monomer formation. The HCT-deficit alfalfa ball-milled lignin also had a decrease in β-O-4 linkage and methoxyl group and an increase in phenylcoumaran and resinol unit contents compared with the WT. Hoffmann et al. used virus induced gene silencing to inhibit HCT accumulation in the tobacco (Nicotiana tabacum) and observed a decrease in syringyl units and an increase in p-hydroxyphenyl units in the silenced plant (Table 2) [55]. The HCT silenced tobacco had lower content of β-O-4 units determined by thioacidolysis analysis. Wagner et al. investigated the effects of HCT silencing in tracheary element formation in Pinus rediata callus cultures via RNA interference (RNAi) and documented that the RNAi-mediated silencing of the putative HCT gene had a strong effect on lignin monolignol composition and interunit linkage distribution [56]. The increase in p-hydroxyphenyl units from trace amounts in WT controls to up to 31% in transgenic Pinus radiata was identified using both thioacidolysis and two-dimensional correlation NMR analysis (Table 2). The transgenic P. radiata also demonstrated an increase in resinols, a reduction in dibenzodioxocins, and presence of glycerol end groups in its acetylated enzymatic lignin [56]. The HCT silencing led to an increase in H units in lignin in all the three species studied. The depletion of G-type lignin in P. radiate, S-type in N. tabacum, G- and S-type lignin in M. sativa (this study), and the increase in H units in all the three species as well as the observed changes in interunit linkage distribution established that the HCT had a substantial impact on lignin structures in both angiosperm and gymnosperm species.

The C3H9a plant, with 20% residual C3H activity, was of normal size and showed delayed flowering by only 1~2 days [39]. The HCT3a line was around 50% the height of the control WT line when grown in parallel to early bud stage and exhibited delayed flowing by about 1~2 days [40]. The increase of H-type lignin and depletion of G- and S-type lignin in alfalfa suggested that, without enough access to the two primary monolignols, coniferyl and sinapyl alcohols, the alfalfa plant incorporated a high level of p-hydroxyphenyl alcohol into its lignin structure to help maintain its growth phenotype.

The C3H and HCT down-regulated alfalfa plants demonstrated an improved fermentable sugar yield when subjected to enzymatic hydrolysis (supplementary Fig. 1) [37]. Without pretreatment, a ~166% increase in sugar production was observed for HCT transgenic alfalfa plant [37]. The biomass sugar conversion performance was considered to be related to lignocellulosic biomass recalcitrant features, including lignin type/composition, lignin content, cellulose crystalline/crystallinity, associated lignin–carbohydrates complexes, and role of acetylated hemicellulose structures. C3H and HCT gene down-regulation resulted in a decrease in AcBr lignin content (supplementary Table 1). HCT down-regulated plants showed the greatest reduction in lignin content (approximately 50% reduction of AcBr lignin). For the genetically engineered alfalfa plants through lignin modification, the most notable changes occurred in the reduction of lignin content and structures. The improved sugar conversion performance for gene down-regulated transgenic plants was therefore, at least partially, related to the reduced lignin content and its structure modification in the transgenic plants. Reducing β-O-4 ether linkage in plants was proposed to reduce lignin–carbohydrate cross-linking [45], which might contribute to lessen the carbohydrate–lignin shield and facilitate the accessibility of enzymes to cellulose and hemicellulose, thus reducing the recalcitrance of biomass and enhancing cell walls enzymatic degradability. The H lignin units were observed to account for ~38–68% and ~74% in the C3H and HCT gene down-regulated alfalfa plants. Nevertheless, the fate of H-type lignin and the kind of role it played on reduced recalcitrance of biomass and enhanced sugar release performance need further investigation. Plant lines with identical lignin contents but altered H unit compositions would help to elucidate the contribution of H lignin during enzymatic hydrolysis and produce insights on future improvements in plant cell wall design for enhanced sugar production for biofuels.

Conclusion

The down-regulation of C3H and HCT genes in alfalfa produced plants with substantial structural differences in their lignins. A significant increase in p-hydroxyphenyl unit content was observed in the transgenic alfalfa ball-milled lignins as well as a concomitant decrease of guaiacyl and syringyl units. Methoxyl group and β-O-4 linkage contents in the alfalfa ball-milled lignins were observed to decrease after C3H and HCT genetic engineering. 13C NMR analysis estimated that C3H gene down-regulation reduced the methoxyl content by ~55–58% in the ball-milled lignin, while HCT down-regulation decreased methoxyl content by ~73%. Compared to the WT, the C3H and HCT transgenic alfalfa plants demonstrated an increase in relative level of phenylcoumaran and resinol substructures in the ball-milled lignins.

Abbreviations

- C3H:

-

p-Coumarate 3-hydroxylase

- HCT:

-

Hydroxycinnamoyl CoA:shikimate/quinate hydroxycinnamoyl transferase

- NMR:

-

Nuclear magnetic resonance

- HSQC:

-

Heteronuclear single quantum coherence

- DEPT:

-

Distortionless enhancement by polarization transfer

- WT:

-

Wild-type

- /Ar:

-

Per aromatic ring

- H:

-

p-Hydroxyphenyl

- G:

-

Guaiacyl

- S:

-

Syringyl

References

Ragauskas AJ, Williams CK, Davison BH et al (2006) The path forward for biofuels and biomaterials. Science 311:484–489

Horvath IT, Anastas PT (2007) Innovations and green chemistry. Chem Rev 107:2169–2173

Holdren JP (2007) Energy and sustainability. Science 315:737

Hoffert MI, Caldeira K, Benford G et al (2002) Advanced technology paths to global climate stability: energy for a greenhouse planet. Science 298:981–987

Chow J, Kopp RJ, Portney PR (2003) Energy resources and global development. Science 302:1528–1531

Clark JH, Budarin V, Deswarte FEI et al (2006) Green chemistry and the biorefinery: a partnership for a sustainable future. Green Chem 8:853–860

Pu Y, Zhang D, Singh PM, Ragauskas AJ (2008) The new forestry biofuels sector. Biofuels Bioproducts Biorefining 2:58–73

Ragauskas AJ, Nagy M, Kim DH et al (2006) From wood to fuels integrating biofuels and pulp production. Ind Biotechnol 2:55–65

Schell DJ, Riley CJ, Dowe N et al (2004) A bioethanol process development unit: initial operating experiences and results with a corn fiber feedstock. Bioresour Technol 91:179–188

Eggeman T, Elander RT (2005) Process and economic analysis of pretreatment technologies. Bioresour Technol 96:2019–2025

Lynd LR, Wyman CE, Gerngross TU (1995) Biocommodity engineering. Biotechnol Prog 15:777–793

Himmel ME, Ding SY, Johnson DK et al (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315:804–807

Lynd LR, Laser MS, Bransby D et al (2008) How biotech can transform biofuels. Nat Biotechnol 26:169–172

Yang B, Gray MC, Liu C et al (2004) Unconventional relationships for hemicellulose hydrolysis and subsequent cellulose digestion. In: Saha BS, Hayashi K (eds) Lignocellulose biodegradation. ACS symposium series 889. American Chemical Society, Washington, pp 100–125

Yang B, Wyman CE (2008) Pretreatment: the key to unlocking low-cost cellulosic ethanol. Biofuels Bioproducts Biorefining 2:26–40

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M et al (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Glasser WG, Wright RS (1998) Steam-assisted biomass fractionation II fractionation behavior of various biomass resources. Biomass Bioenergy 14:219–235

Ballesteros I, Negro MJ, Oliva JM, Cabanas A, Manzanares P, Ballesteros M (2006) Ethanol production from steam-explosion pretreated wheat straw. Appl Biochem Biotechnol 129–132:496–508

Liu C, Wyman CE (2004) Impact of fluid velocity on hot water only pretreatment of corn stover in a flowthrough reactor. Appl Biochem Biotechnol 113–116:977–987

Allen SG, Spencer MJ, Antal MJ Jr, Laser MS, Lynd LR (1997) Hot liquid water pretreatment of lignocellulosics at high solids concentrations. In: Bridgwater AV, Boocock DGB (eds) Developments in thermochemical biomass conversion, vol 1. Blackie, London, pp 765–772

van Walsum GP, Allen SG, Spencer MJ, Laser MS, Antal MJ, Lynd LR (1996) Conversion of lignocellulosics pretreated with liquid hot water to ethanol. Appl Biochem Biotechnol 57(58):157–170

Lloyd TA, Wyman CE (2005) Combined sugar yields for dilute sulfuric acid pretreatment of corn stover followed by enzymatic hydrolysis of the remaining solids. Bioresour Technol 96:1967–1977

Yang B, Wyman CE (2004) Effect of xylan and lignin removal by batch and flowthrough pretreatment on the enzymatic digestibility of corn stover cellulose. Biotechnol Bioeng 86(1):88–95

Kim SB, Lee YY (2002) Diffusion of sulfuric acid within lignocellulosic biomass particles and its impact on dilute-acid pretreatment. Bioresour Technol 83:165–171

Chang VS, Nagwani M, Holtzapple MT (1998) Lime pretreatment of crop residues bagasse and wheat straw. Appl Biochem Biotechnol 74:135–159

Chang VS, Nagwani M, Kim CH, Holtzapple MT (2001) Oxidative lime pretreatment of high-lignin biomass: poplar wood and newspaper. Appl Biochem Biotechnol 94:1–28

Kim TH, Lee YY (2005) Pretreatment and fractionation of corn stover by ammonia recycle percolation process. Bioresour Technol 96:2007–2013

Teymouri F, Laureano-Perez L, Alizadeh H, Dale BE (2005) Optimization of the ammonia fiber explosion (AFEX) treatment parameters for enzymatic hydrolysis of corn stover. Bioresour Technol 96:2014–2018

Pan X, Kadla JF, Ehara K, Gilkes N, Saddler JN (2006) Organosolv ethanol lignin from hybrid poplar as a radical scavenger: relationship between lignin structure extraction conditions and antioxidant activity. J Agric Food Chem 54:5806–5813

Hasegawa I, Tabata K, Okuma O, Mae K (2004) New pretreatment methods combining a hot water treatment and water/acetone extraction for thermo-chemical conversion of biomass. Energy Fuels 18:755–760

Dale BE (2008) Biofuels: thinking clearly about the issues. J Agric Food Chem 56:3885–3891

Wyman CE (2008) Cellulosic ethanol: a unique sustainable liquid transportation fuel. MRS Bull 33:381–383

Huntley SK, Ellis D, Gilbert M, Chapple C, Mansfield SD (2003) Significant increases in pulping efficiency in C4H–F5H-transformed poplars: Improved chemical savings and reduced environmental toxins. J Agric Food Chem 51:6178–6183

Pilate G, Guiney E, Holt K, Petit-Conil M, Lapierre C, Leple JC et al (2002) Field and pulping performances of transgenic trees with altered lignification. Nat Biotechnol 20:607–612

Lapierre C, Pollet B, Petit-Conil M et al (1999) Structural alterations of lignins in transgenic poplars with depressed cinnamyl alcohol dehydrogenase or caffeic acid O-methyltransferase activity have an opposite impact on the efficiency of industrial kraft pulping. Plant Physiol 119:153–163

Davison BH, Drescher SR, Tuskan GA, Davis MF, Nghiem NP (2006) Variation of S/G ratio and lignin content in a Populus family influences the release of xylose by dilute acid hydrolysis. Appl Biochem Biotechnol 129–132:427–435

Chen F, Dixon RA (2007) Lignin modification improves fermentable sugar yields for biofuel production. Nat Biotechnol 25:759–761

Jackson LA, Shadle GL, Zhou R et al (2008) Improving saccharification efficency of alfalfa stems through modification of the terminal stages of monolignol biosynthesis. Bioenerg Res 1:180–192

Reddy MSS, Chen F, Shadle G, Jackson L, Aljoe H, Dixon RA (2005) Targeted down-regulation of cytochrome P450 enzymes for forage quality improvement in alfalfa (Medicago sativa L.). Proc Natl Acad Sci USA 102:16573–16578

Chen F, Reddy MSS, Temple S, Jackson L, Shadle G, Dixon RA (2006) Multi-site genetic modulation of monolignol biosynthesis suggests new routes for formation of syringyl lignin and wall-bound ferulic acid in alfalfa (Medicago sativa L.). Plant J 48(1):113–124

Holtman KM, Chang H, Jameel H, Kadla J (2006) Quantitative 13C NMR characterization of milled wood lignins isolated by different milling techniques. J Wood Chem Technol 26:21–34

Ikeda T, Holtman K, Kadla JF, Chang H, Jameel H (2002) Studies on the effect of ball milling on lignin structure using a modified DFRC method. J Agric Food Chem 50:129–135

Bjorkman A (1956) Finely divided wood. I. Extraction of lignin with neutral solvents. Svensk Papperstidn 59:477–485

Hallac B, Sannigrahi P, Pu Y, Ray M, Murphy RJ, Ragauskas AJ (2009) Biomass characterization of Buddleja davidii: a potential feedstock for biofuel production. J Agric Food Chem 57:1275–1281

Ralph J, Akiyama T, Kim H et al (2006) Effects of coumarate 3-hydroxylase down-regulation on lignin structure. J Biol Chem 281:8843–8853

Rencoret J, Marques G, Gutierrez A, Ibarra D, Li J, Gellerstedt G et al (2008) Structural characterization of milled wood lignins from different eucalypt species. Holzforschung 62:514–526

del Rio JC, Rencoret J, Marques G, Gutierrez A, Ibarra D, Santos JI et al (2008) Highly acylated (acetylated and/or p-coumaroylated) native lignins from diverse herbaceous plants. J Agric Food Chem 56:9525–9534

Stewart JJ, Akiyama T, Chapple C, Ralph J, Mansfield SD (2009) The effects on lignin structure of overexpression of ferulate 5-hydroxylase in hybrid poplar. Plant Physiol 150:621–635

Pu Y, Ragauskas AJ (2005) Structural analysis of acetylated hardwood lignins and their photoyellowing properties. Can J Chem 83:2132–2139

Robert D (1992) Carbon-13 nuclear magnetic resonance spectrometry. In: Lin SY, Dence CW (eds) Methods in lignin chemistry. Springer, New York, pp 250–273

Ralph SA, Ralph J, Landucci LL (2004) NMR database of lignin and cell wall model compounds. http://ars.usda.gov/Services/docs.htm?docid=10491. Accessed 15 March 2009

Capanema EA, Balakshin MY, Kadla JF (2005) Quantitative characterization of a hardwood milled wood lignin by nuclear magnetic resonance spectroscopy. J Agric Food Chem 53:9639–9649

Zhang L, Gellerstedt G (2000) Achieving quantitative assignment of lignin structure by combining 13C and HSQC NMR technologies. In: Proceedings of sixth European workshop on lignocellulosics and pulp, Bordeaux, France, 3–6 September 2000

Zhang L, Gellerstedt G (2008) 2D heteronuclear (1H–13C) single quantum correlation (HSQC) NMR analysis of Norway spruce bark components. In: Hu TQ (ed) Characterization of lignocellulosic materials. Blackwell, Oxford, pp 3–6

Hoffmann L, Besseau S, Geoffroy P, Ritzenthaler C, Meyer D, Lapierre C et al (2004) Silencing of hydroxycinnamoyl-coenzyme a shikimate/quinate hydroxycinnamoyltransferase affects phenylpropanoid biosynthesis. Plant Cell 16(6):1446–1465

Wagner A, Ralph J, Akiyama T, Flint H, Phillips L, Torr K et al (2007) Exploring lignification in conifers by silencing hydroxycinnamoyl-CoA:shikimate hydroxycinnamoyltransferase in Pinus radiata. Proc Natl Acad Sci USA 104(28):11856–11861

Acknowledgment

We thank Drs. Richard A. Dixon and Mark Davis for their suggestion of the manuscript. The BioEnergy Science Center (BESC) is a US Department of Energy Bioenergy Research Center supported by the Office of Biological and Environmental Research in the DOE Office of Science. The authors would like to gratefully acknowledge the financial support from DOE Office of Biological and Environmental Research through the BioEnergy Science Center (DE-AC05-00OR22725).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM Table 1

Wild type and transgenic alfalfa plants (PDF 1221 kb).

ESM Fig. 1

Sugar release performance for alfalfa biomass subject to enzymatic hydrolysis (total sugar released as a percentage of total sugar in the cell wall residue) [37]. WT wild type control, filled biomass without acid pretreatment, blank biomass that was first acid pretreated (PDF 1221 kb).

Rights and permissions

About this article

Cite this article

Pu, Y., Chen, F., Ziebell, A. et al. NMR Characterization of C3H and HCT Down-Regulated Alfalfa Lignin. Bioenerg. Res. 2, 198–208 (2009). https://doi.org/10.1007/s12155-009-9056-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-009-9056-8