Abstract

The Air Quality Monitor (AQM), formerly called the microAnalyzer™, showed great promise in ground testing and preflight preparation to replace the aging Volatile Organic Analyzer (VOA) on the International Space Station (ISS). The atmosphere in the ISS is mostly scrubbed and recirculated (a partially closed environmental system), and for this reason the measurement of volatile organic compounds (VOCs) in its atmosphere is an important function to protect crew health and safety. Evaluation of the AQM in ground testing was impressive, but the unique environment of ISS required a thorough in-situ vetting of the capability. In May 2009, the first two AQMs arrived on ISS as an experiment to evaluate their performance and assess methods and crew procedures. In total, three AQMs have been operated aboard ISS spanning almost 3 years. After the first year of operation, the decision was made to build operational AQM units as a replacement for VOA, which was removed from ISS in August 2009. This paper presents the AQM data used to make the decision to build an operational version of the hardware. As an experiment of new hardware it was expected that some performance issues would arise, but it was also deemed necessary that solutions to these problems would not substantially change the form, function, or cost of the operational version. The identified issues and their solutions that related directly to the AQM’s analytical performance during the first year of the experiment are discussed briefly with the focus on how these changes are expected to improve the performance of the operational version. Recent AQM data from ISS will be presented to illustrate how some changes in software and methods are already improving the AQM’s analytical performance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The International Space Station (ISS) is home to astronauts from many countries for a minimum of 6 months, but it is not uncommon for crewmembers to remain on ISS for as long as 9–12 months. The longer residence on ISS comes about as a result of launch delays of transport vehicles, and currently the only means of return is the Russian Soyuz. The environment of ISS is a semi-closed system and although the crew lives in this atmosphere for 24 h a day (with no options to “open windows to allow in fresh air); archival air samples are returned only once every 3 or 4 months. Furthermore, National Aeronautics and Space Administration (NASA), in collaboration with the National Research Council, has established air quality criteria called Spacecraft Maximum Allowable Concentrations (SMACs) [1–3] and a means must be available to verify that the spacecraft atmosphere meets these requirements. The SMACs are established by reviewing toxicological studies in the literature for the compound, selecting the key studies, and adjusting the values for species (study animals) and the microgravity environment. A compound’s SMAC is a series of values related to the length of exposure. For instance, short-term SMACs (1 h and 24 h) permit reversible effects (e.g. mucosal irritation) during emergencies (fire, toxic release), but the long-term SMACs (7d- 1000d) are set to values at which there are no adverse human health effects [4]. Archival air sampler data is used to determine the acceptability of air quality aboard the spacecraft [5], but the longer intervals between returned samples from ISS compromises the value of identifying and responding to pollutants that are slowly degrading ISS air quality. Additionally, contingency events (i.e., overheated components/wiring or strong odors) demand a more immediate analysis that only real-time, onboard monitors can provide. It is important to monitor trace Volatile Organic Compounds (VOCs) in the spacecraft to complement major constituents (O2, N2, CO2, etc.) analysis in order to gain a complete picture of the spacecraft air quality. The VOCs were monitored on ISS by the Volatile Organics Analyzer (VOA), which was a gas chromatograph/ion mobility spectrometer [6–8]. The VOA provided real-time data on VOCs from 2001 to July 2009 (with the exception of a 2 year gap from 2003 to 2005).

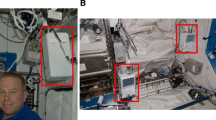

A potential replacement for the aging VOA was the Sionex microAnalyzer™, which was an instrument based upon gas chromatography/differential mobility spectrometry (GC/DMS). The microAnalyzer™ possessed a number of advantages compared to the VOA, the most important of which was a vastly reduced size and mass [9]. The flight preparation of the first microAnalyzers™ delivered to ISS was detailed in a recent publication [10]. The two units (39 and 40) were sent to ISS in March 2009 and unit 40 (Fig. 1) began operating in May of 2009, 2 months before the VOA was removed from ISS. The microanalyzers™ (now known as the Air Quality Monitors-AQMs) were sent to ISS as an experiment (Station Development Test Objective-SDTO) to determine if the excellent ground based performance, observed prior to and during flight preparation, could be maintained in the more challenging ISS environment. Although challenge mixtures used to assess the microAnalyzer’s readiness for flight do mimic the ISS atmosphere, it is impossible to duplicate the exact composition or the small changes that occur in the environment (i.e., pressure, temperature, oxygen concentration, humidity). The AQM/SDTO (formal acronym for the flight experiment units) performance was assessed by comparing its results to those from returned archival samples (Grab Sample Containers-GSCs). A 6–12 month timeline was estimated to acquire a sufficient number of GSCs to properly evaluate the AQM/SDTO. More recently, mini-GSCs have been used to evaluate the AQM/SDTO, because the smaller mini-GSCs are more compatible with Soyuz sample returns. In addition to analytical performance, an equally important objective of the experiment was to assess crew procedures, methods files, and general instrument operational parameters (i.e., sample volumes). Since these first units arrived on ISS, the AQM/SDTO has been monitoring the cabin atmosphere for targeted, trace VOCs continuously for almost 3 years. In that time period, three units (39, 40, and 36) have been employed to monitor the air and one instrument, unit 39, has been operated in two different time periods on ISS.

The Air Quality Monitor (AQM)/Station Development Test Objective (SDTO) is shown (circled in red) attached to the Crew Health Care System (CHeCS) rack located in the center of the International Space Station’s LAB module. The Volatile Organic Analyzer (VOA) was still in the rack just to the right of the AQM power supply (large silver box)

This paper will provide an in-depth presentation and discussion of the results from the first year of the AQM/SDTO (unit 40) operation. The first year of operation was critical, because these data were used for the decision to proceed with an operational (Government Furnished Equipment-GFE) version of the AQM/SDTO. The operational version (AQM/GFE) will be relied upon for operational decisions in nominal and contingency situations [11]. A short discussion of lessons learned from the AQM/SDTO will be included, along with recent AQM/SDTO (unit 39) data from the fall of 2011. The unit 39 data is presented to illustrate how some of the Unit 40 analytical issues have been addressed. These types of procedural/software changes combined with slight hardware modification will greatly enhance the analytical capability of the AQM/GFE.

Experimental

Instrument design

Each AQM/SDTO unit has an instrument method, which defines the timing for sample acquisition, preconcentrator heating/desorption, and GC temperature heating profile. The GC temperature profile (rate of heating and/or length of the GC run) is the only variation in the instrument methods between units. Each AQM/SDTO has a number of instrument methods (clean, no sample, long and short, 5 s and 10 s sample runs) and scan methods (sets scanning parameters). Additionally, a set of unique GC methods (no sample, long, short, 5 s, and 10 s sample runs) are loaded on to each instruments. The GC methods contain the parameters for locating the peak for each compound in the target list. Each AQM/SDTO unit has a unique set of GC methods, although many parameters are very similar.

A block diagram (Fig. 2) of the AQM/SDTO highlights the essential components of the instrument. A sample pump acquires an air sample for 5 seconds (s) or 10 s at ~70 milliliters (mL) per minute (min). The sample flows through a preconcentrator sorbent bed composed of 60/80 mesh Carbopack B and Carboxen 1000 (Table 1). When sampling is completed, a valve switches to flow the GC carrier gas through the preconcentrator as the preconcentrator is rapidly heated to 300 °C for 30 s to desorb the VOCs trapped from the air sample. During clean cycles, the preconcentrator is heated to 325 °C for 40 s.

This block diagram of the MicroAnalyzer™ shows the sample flow through the instrument’s major components. The pump sends air to the preconcentrator (enhance detection limits), where organics are trapped, and then these organics are moved to the gas chromatographic (GC) column for separation before eluting from the column and into the differential mobility spectrometer for detection. The microprocessor controls all instrument functions (including detection and quantification), but the innovative feature of the device is that the air (internally scrubbed and recirculated) is used as the GC carrier gas

The trapped VOCs are transferred from the preconcentrator to the GC column by the carrier gas flow. The GC column is a Varian 624MS, which is 15 m × 0.25 mm and coated with a 1.4 μm liquid phase. The liquid phase is 6 % cyanopropyl/phenyl and 94 % PDMS (polydimethylsiloxane). Two types of GC methods are performed: long and short. The temperature program for both runs begins with a 120 s isothermal period at 35 °C. In the short run, the GC column is ramped to 140 °C over 85 s (~1.2 °C/s) and the run ends at 230 s. The timing for the long run has increased since the first units arrived on ISS. All three units had a temperature ramp from 35 °C (isothermal temperature) to 140 °C in 120 s and Unit 40 maintained this temperature for another 130 s. After the ramp, the Unit 36 GC method heated the GC column to 150 °C and stayed there for another 90 s to clean the column. Upon its return to ISS in 2011, the unit 39 GC method heated the GC column (following the nominal temperature ramp) from 140 °C to 150 °C and then remained at that temperature for 190 s to accommodate detection and quantification of decamethycyclopentasiloxane (DMCPS).

As the analyte compounds elute from the GC column, they are swept into the DMS ionization region by the GC carrier gas, where an additional gas (make-up) joins the GC carrier gas to achieve sufficient gas flow through the detector. The GC column gas flow was calculated at approximately 1 mL/min and the make-up gas flow was ~350 mL/min. The 63Ni ionization source produces ions (positive and negative) by transferring charge from a reactant ion peak (RIP) to the analyte. The RIPs in air, at atmospheric pressure, are hydrated protons (positive mode) and O −2 (negative mode). The detector acquires two important parameters for detection of each analyte: the GC retention time and the compensation voltage (Vc). During their transit through the DMS, the ions are subjected to cycles of an asymmetric RF voltage field that displace most ions perpendicular to the gas flow. In order for the gas flow to deliver an ion to the detector, the Vc (a small DC voltage) must be applied. The magnitude of the Vc for an ion is related to the ion cluster’s interaction with the RF field [12, 13]. Scan runs (sweeping all Vcs), at different RFs, provide the optimal parameters (RF voltage, GC retention time, and Vc) loaded into the GC method for the detection and quantification of each target compound.

The recirculation system is innovative because it uses air for the GC carrier gas and detector make-up gas. The required GC column pressure is obtained when, at initial start-up, the recirculation pump pulls air from the environment until the specified pressure is obtained. The air is cleaned continuously as it flows through a scrubber after exiting the DMS cell. The scrubbers contain 20/45-mesh molecular sieves (HCRMS) and a small amount of Carboxen 569, to remove moisture and VOCs, respectively.

The Expert software (Sionex) for controlling the instrument parameters (such as temperatures and pressures) and performing the data reduction is resident on a separate computer. The method files (including data reduction) are uploaded from the computer to the AQM/SDTO unit. Results are processed on the unit and can be displayed on the graphical user interface (GUI), but thus far the data has been down linked for ground based analyses since this was an experiment. However, with the exceptions noted in the discussion section, the data are still derived from running an automated classifier file. The classifier file identifies the peak and converts the peak area (or peak height) to concentration.

AQM/SDTO in-flight performance assessment

Historically air quality instruments used for measuring trace VOCs have been evaluated by comparing the instrument’s results to analyses of GSCs, where the GSC sample was acquired close to the device and within 1–2 h of the instrument’s sample session. The GSC (Summa™ treated) and the mini-GSCs (silonite®-coated) are evacuated stainless steel canisters (Fig. 3) from SIS [14] and Entech [15], respectively. These archival samplers have been proofed clean, evacuated, and dosed with surrogates prior to shipment for launch to ISS. Archival sample data associated with unit 40 was derived from GSCs and data related to unit 39 was obtained from the mini-GSCs. A sample of air is pulled into the archival samplers by its vacuum. Sampling occurs once per month, but ISS logistics can, at times, interfere with the simultaneous sampling by archival samplers and air quality instruments. Sampling variability (timing and location), hardware issues, and procedural missteps mean data from at least six GSCs are needed to properly assess instrument performance. The archival samplers are returned to the ground and analyzed in the Johnson Space Center (JSC) Toxicology Laboratory.

The gas chromatography/mass spectrometry (GC/MS) analyses of the archival samples followed a modified version of the Environmental Protection Agency’s TO-15 protocol [16]. The TO-15 protocol was modified by reducing (or eliminating) the number of controls, replicates, and duplicates to accommodate the restrictions imposed by spaceflight constraints. However, ground-control GSCs were still a vital part of the overall quality assurance program for archival sample analysis. The Toxicology Laboratory closely followed TO-15 procedures for tuning, calibration, and verification of instrument performance. In assessing the AQM/SDTO performance, the AQM/SDTO results were required to be within ±40 % of the archival sampler results. However, the archival sampler data was deemed absolute; therefore, the GC/MS errors were not considered when assessing if AQM/SDTO met the ±40 % criteria. Given that GC/MS deviations can be 10 % or more (30 % is allowable in TO-15), the criteria for AQM/SDTO performance was quite rigorous.

The AQM/SDTO target compound list (Table 2) was the basis for assessment of the instrument’s capability. As an experiment, the goal was a target compound list representative of the various types of pollutants (polar, non-polar, low and high molecular weight) needed for the expanded detection capability of the AQM/GFE. Another compound, DMCPS, was added to the target list for AQM/SDTO (unit 39) currently on orbit. DMCPS is one of series of cyclic siloxane compounds that have garnered great toxicological interest in the past few years. These compounds are found in many consumer products such as shampoo and deodorants.

Results and discussion

AQM/SDTO operations on ISS

Each AQM/SDTO sample session was initiated by the crew when they selected “autorun” from the Expert GUI screen on the computer. The autorun button started a sequence of methods, which are defined as “scripts”. The autorun script was a series of runs, which included clean, no sample, and sample scan method runs, followed by various types of GC method runs (clean, no sample, and sample runs). Short and long GC method runs were performed at 5 and 10 s sample volumes. The GC sample runs were repeated in the autorun script. The duration of the runs were 190 s (clean runs), 220 s (short runs), and 430 s (long runs). The long runs for unit 39 were extended to 600 s to allow elution of DMCPS. Once the sample regime was completed, it was repeated, so the total session lasted approximately 4.5 h. This script rigorously exercised the instrument and provided the maximum amount of data for the allowable session run time. The AQM/SDTO results compared to the GSC analysis were derived from the GC formatted runs (Fig. 4). The GC method (Fig. 5) established GC windows for each target compound and set the detector’s parameters (RF voltage, polarity, and Vc) for each GC window. These parameters provided maximum selectivity and sensitivity for each compound. A classifier file automatically searches for each specified peak within the GC window provided by the GC method. The classifier narrows the search area for the peak within the GC window to better guard against incorrect compound identification. The integration parameters and a response versus concentration lookup table (built from instrument calibration runs) are loaded into the classifier file. When the completed classifier is automatically applied to a GC run, it confirms the target compound’s identity and determines its concentration by comparing the peak area or peak height to the lookup table.

This chromatogram is an example of a long run GC format from the unit 40 calibration runs. This was a 10 s sample volume run of the highest calibration mixture. The target compound peaks are identified. The remaining target compounds (methanol, dichloromethane, and 2-butanone) are detected and quantified in the short run

This is the GC method file used to produce the chromatogram in Fig. 4. Shown are the parameters used to define the GC/Vc detection window for the target compounds. The Vrf window sets the RF field for the GC window (“start” and “end” times in milliseconds). The value selected will affect response (less at higher RF) and separation (more at higher RF) in Vc space. All runs in this paper used Sampling scheme 1. Advanced detection techniques, such as detecting two peaks at different Vcs in the same GC window, use Sampling scheme 5 or 6. The VcD(S) and VcW(E) define the Vc (identical value for scheme 1) for detecting the peak. Channel refers to the polarity of the ion being detected. Tuning, steps, and size define the scanning parameters

Unit 40 was the first unit to be deployed and it was located on the Crew Health Care System (CHeCS) rack located in the center of the LAB module. The AQM/SDTO remained in this location until late August 2009, at which time the CHeCS rack was removed and the AQM/SDTO was relocated to Node 2 near the end of the LAB module (Fig. 6). The AQM/SDTO has remained near this location since August 2009.

The first parameter to assess from the flight experiment data is the reproducibility of the GC retention times, because great variability in the GC retention time would hamper proper identification of the target compounds. The other peak identification parameter, Vc, must be reproducible as the peak otherwise would not be detected in the GC window.

The excellent reproducibility of GC retention times is shown in Table 3 for the first year of unit 40 operation on ISS. The AQM/SDTO maintained a relative standard deviation of <1 % for its first year on orbit, during which it operated approximately twice per week with the exception of January–February 2010 when unit 39 was being evaluated. The AQM/SDTO did not detect peaks for three of the 16 target compounds: hexane, dichloromethane (DCM), and Octamethylcyclotetrasiloxane (OMCTS). Benzene is a special case that will be discussed in the quantification section. Results from GSC samples confirmed that hexane is not present in the ISS atmosphere, but DCM and OMCTS were detected in GSC samples.

The first runs down linked from unit 40 in May 2009 showed that the negative mode RIP had shifted from a Vc (RF 900 V) of −15.56 to −10.56. Unit 40 had been on orbit for 2 months prior to its use and it had been inactive for another 2 months prior to arrival on ISS. Upon activation in late December 2009, after 8 months on ISS, unit 39 showed a similar shift (−16.11 to −10.00 at RF 900 V) in the negative mode RIP and other signs of an exhausted sieve material (hence its short 3-month operation during its first trip to ISS). Unit 36 was activated soon after it arrived on ISS in June 2010 and the data from the first month (Fig. 7) provided an important clue as to what was happening to the negative mode. The stepwise shift of the negative mode suggested that a contaminant was increasing in the detector and forming an ever-larger complex with the RIP (O −2 ). A subsequent study (unpublished work) showed the contaminant to be carbon dioxide (CO2), which was present in ISS at high concentrations (on average ~4500 part per million by volume-ppm). The CO2 entered the systems each time the AQM/SDTO was activated, when ISS air was drawn in to achieve the necessary GC column head pressure. Although the air was scrubbed prior to use (and each time it exits the detector), the concentration of CO2 in the atmosphere simply overwhelmed the scrubbers and that accounted for the changing negative mode RIP observed in unit 36. Due to acoustic concerns, the AQM/SDTO was permitted only 5 h operation per day. After design changes to reduce certain sound frequencies, the AQM/GFE has been approved for continuous operation and this along with replaceable sieve packs should maintain the negative mode RIP as O −2 .

This graph illustrates the shifting position of the unit 36 negative mode RIP at RF 900v. The plot of the dichloromethane (DCM) concentration (right-hand axis) shows the effect on the ionization efficiency with the changes in the RIP. Nominally, the concentration of DCM is relatively constant on ISS

Comparison of GSC and AQM/SDTO results

In the first year of the AQM/SDTO operation, there were ten GSCs acquired at times and positions allowing them to be used to evaluate the performance of unit 40. The comparison of AQM/SDTO and GSC results for target compounds consistently detected above the GSC’s method detection limit (MDL) are summarized in Table 4. Four of the six compounds in Table 4 had 50 % or more of their results match the GSCs within the goal (±40 %) and two agreed >90 % of the time. If the VOA criteria (±50 %) were applied, then unit 40 matched the GSCs for all compounds at least 50 % of the time. Although this goal for such an instrument appears rather lax, there are two caveats that show just how difficult it can be to meet the stated criteria. First, as mentioned earlier, the GSC value is considered absolute, but observe the difference in the number of matching values between unit 40 and the GSCs if the goal is changed to ±50 %. Furthermore, most compounds (the exception being ethanol) were very close to the MDLs for both techniques. In fact, the 1-butanol concentration never exceeded twice the MDL. Secondly, when unit 40 was in the middle of the LAB module, where the GSC sample was acquired, it was more likely that the GSC sample was representative of the sample acquired by the AQM/SDTO. When unit 40 (and all subsequent units) was positioned at the end of the LAB near Node 2 and sampling remained for a time at the center of the LAB, it did raise questions as to whether the GSC sample represented the AQM/SDTO sample. Although previous GSC results indicated good airflow and “mixing” in the LAB (and Service Module) the position of the AQM/SDTO (and its surroundings) could have impacted results. For instance, if the crew were exercising (which they do) near the AQM/SDTO, then metabolic products such as acetone and 1-butanol might be higher in this region than the center of the LAB where the GSC was acquired. Finally, recent views (Fig. 8a and b) demonstrate how the AQM/SDTO’s surrounding environment can change and this certainly may have affected the match with GSCs, even when the GSCs were acquired near the AQM/SDTO. These issues aside, the results for acetaldehyde and methanol need improvement and the addition of a “purge” [17] to remove water vapor from the preconcentrator should allow much more accurate quantification of these two compounds.

Except for benzene, and hexane (not detected), all of the other target compounds (DCM, toluene, xylenes, ethyl acetate, and 2-butanone) were detected at trace concentrations (identifiable, but below the MDL) in the GSCs. The unit 40 results matched closely with the GSCs for these compounds except for benzene, 2-butanone, and occasionally ethyl acetate. The reasons for the AQM/SDTO discrepancies compared to the GSCs were two contaminants in the ISS atmosphere. Although large concentrations were detected by unit 40 for benzene and 2-butanone, one look at the overlaid chromatograms (Fig. 9) from flight and from the preflight calibration show the source of the results were unidentified peaks eluting close to the target compound peaks. The peak interfering with 2-butanone and ethyl acetate was trimethysilanol (TMS), but the peak interfering with benzene has yet to be identified. In all three cases, narrowing the peak search window in the classifier has eliminated the interferences. However, this issue demonstrated the need for a 2nd unit with a different GC column (DB-5) and this has become part of the AQM/GFE operational strategy.

These are chromatograms from the unit 40 AQM/SDTO calibration (black and brown traces) and from operations on ISS (red trace). Notice that the peak apex alignment for compounds such as ethanol, acetone, and 1-butanol is very precise between all three chromatograms. However, most noticeably for ethyl acetate, but also benzene, the peaks from the inflight run do not align with the calibration runs. This was strong evidence of an interfering peak, which was found to be trimethylsilanol near ethyl acetate. The peak near benzene is at very low concentration and remains unidentified

The overall performance of the unit 40 AQM/SDTO was considered very good and led to a decision to build an operational version (AQM/GFE). There was confidence in detection and quantification of four target compounds (ethanol, 2-propanol, acetone, and 1-butanol) and confident detection of five compounds (xylenes-3, toluene, hexane) at trace levels or those not detected in the GSCs. This gave a total of 9/16 and the issues with the other compounds had been identified and solutions proposed. Additionally, there were other data that supported the confidence in the AQM technology, namely the consistency of results (those not matched to GSCs), which corresponded to historical ISS data showing a rather stable contaminant load. Also, the AQM/SDTO demonstrated the capability to follow changes in the target compound concentrations several times in the past 3 years, i.e., when Node 2/Cuppola was attached to ISS in February 2010 (Fig. 10).

AQM/SDTO unit 39 was operating when the hatch was opened to the newly attached Node 3/Cuppola (hereafter Node 3). This graph shows the increase in 2-propanol at the location of unit 39: juncture of Node 2 and the LAB module. Four samples were acquired and analyzed by the AQM/SDTO over approximately a 2-h period and results showed a steadily increasing concentration of 2-propanol. A GSC sample obtained soon after the hatch was opened showed a highly elevated 2-propanol concentration. The AQM/SDTO’s last 2-propanol value (~2.3 mg/m3) is very close to calculated values for the concentration at this location, given the starting concentration in Node 3 (4.2 mg/m3) and the dilution volume between Node 3 and the AQM/SDTO position

Finally, subsequent development work on the AQM/GFE prototypes verified the solutions that were developed to mitigate the problems encountered by the AQM/SDTO, such as the purge for improving quantification of acetaldehyde and methanol and the addition of a 2nd unit, with a different GC column phase, to reduce the potential for interference by co-eluting peaks. These AQM/GFE studies will be the subject of a subsequent paper in the near future. However, even now, slight method modifications and software improvements have permitted improved detection capability for the latest AQM/SDTO (unit 39) used on ISS. For example, instead of detecting OMCTS in the negative mode, it is now detected in the positive mode and DCM is quantified by using improved software to determine peak areas in the scan mode. As the name implies, a scan mode scans the entire Vc range (−40 v to 15 v) throughout the GC run. Two scan mode runs are performed in each AQM/SDTO session for the purpose of detecting non-target pollutants that may arise in the ISS atmosphere. The RF 900 V scan mode (Fig. 11) supplies more energy than the GC mode (where DCM is detected at RF 600 V) and that extra energy appeared to supply the activation energy needed by DCM to attach an electron [18] from this RIP. DCM is not detected at RF900 V in the GC method, because in a clean detector the RIP would not be shifted by the contaminant (CO2), and the Vc of the nominal RIP (O −2 ) and DCM would be indistinguishable.

In Table 5, AQM/SDTO unit 39 results are shown comparing data from the fall of 2011 to the most recent GSC returned from ISS. Only acetaldehyde continues to be far outside the quantification criteria (±40 %), but the purge is not present on the AQM/SDTO units. Note that ethyl acetate was quite elevated in the November 8 sample and this was verified by the GSC results. Again, this is an example of the AQM/SDTO’s ability to follow changes in the contaminant concentrations on ISS. Also, Unit 39 has been providing excellent agreement with GSC results for the new target compound, DMCPS. There was good agreement between unit 39 and GSC results for the remaining target compounds, which were either not detected (benzene and hexane) or at trace concentrations (2-butanone, xylenes, OMCTS, and toluene). The GSC results did not detect DCM, but manually obtained data from the unit 39 scan runs showed a DCM concentration just above trace level (~0.08 mg/m3).

Conclusion

The AQM/SDTO experiment has been operating on ISS for almost 3 years and during that time three different instruments have been employed. The objectives of this experiment were to assess the technology’s capability and to identify hardware or procedural modifications that would be required to enable this type of monitor to function as an operational air quality monitor on ISS. Although several compounds, such as acetaldehyde and methanol, were difficult for the AQM/SDTO to accurately quantify, the overall performance of the device was sufficient to warrant building operational units (AQM/GFE). The AQM/GFE will contain software, procedural, and hardware improvements, including a purge system and replaceable sieve packs, to address issues related to loss of sensitivity in the negative mode and poor quantification of compounds (acetaldehyde and methanol) co-eluting with water. The inclusion of a 2nd AQM/GFE unit, with a different GC column, will enable detection of an expanded target compound list and further reduce the potential for misidentification due to co-elution of non-target air contaminants. It was also shown that some of the issues observed at the beginning of the experiment in 2009 have already been addressed with the latest AQM/SDTO instrument (unit 39).

References

(1996) Guidelines for developing spacecraft maximum allowable concentrations for space station contaminants. National Academy Press, Washington, DC

Garcia H, Limero T, James JT (1992) Setting spacecraft maximum allowable concentrations for 1 h or 24 h contingency exposures to airborne chemicals. 22nd International Conference on Environmental Systems, Technical Paper 921410, Seattle, WA, 1992

(1994) Spacecraft maximum allowable concentrations for selected airborne contaminants, vol. 1–5. National Academy Press, Washington, DC

James JT (2008) Spacecraft maximum allowable concentrations for airborne contaminants (JSC-20684)

James JT, Limero T, Boyd J, Martin M, Beck S, Covington P, Peters R (2002) Toxicological Assessment of International Space Station Atmosphere from Mission 5A to 8A. 32nd International Conference on Environmental Systems, SAE Technical Paper 2002-01-2299, San Antonio, TX, 2002

Brittain A, Bass P, Breach J, Limero T (2000) Instrumentation for analyzing volatile organic compounds in inhabited enclosed environments. 30th International Conference on Environmental Systems, SAE Technical Paper 2000-01-2434, Toulouse, France, 2000

Limero T (2003) Validation of the Volatile Organic Analyzer (VOA) aboard the International Space Station. 33rd International Conference on Environmental Systems, SAE Technical Paper 2003-01-2646, Vancouver, BC, 2003

Limero T, Reese E (2002) First operational use of the ISS-VOA in a potential contingency event. Int J Ion Mobil Spectrom 5(3):27–30

Limero T, Cheng P, Reese E, Trowbridge J (2010) Results of the air quality monitor’s experiment to measure volatile organic compounds aboard the international space station, 40th International Conference on Environmental Systems, American Institute of Aeronautics and Astronautics Technical Paper: AIAA 2010-6278, Barcelona, Spain, July 2010

Limero T, Reese E, Cheng P, Trowbridge J (2011) Preparation of a gas chromatograph-differential mobility spectrometer to measure target volatile organic compounds on the international space station. Int J Ion Mobil Spectrom 14:81–91

James J (2009) A history of space toxicology mishaps: lessons learned and risk management, 39th International Conference on Environmental Systems, Technical Paper 2009-01-2591, Savannah, GA, 2009

Limero T (2006) Evaluation of gas chromatography-differential mobility spectrometry for the measurement of air contaminants in spacecraft. 36th International Conference on Environmental Systems, SAE Technical Paper 2006-01-2153, Norfolk, VA, 2006

Eiceman G, Krylov E, Krylova N, Douglas K, Porter L, Nazarov E, Miller R (2002) A molecular and structural basis for compensation voltage. Int J Ion Mobil Spectrom 5(3):1–6

Scientific Instrumentation Specialists, P.O. Box 8941, Moscow, Idaho, 83843

(2006) Entech Instruments Incorporated, http://www.entechinst.com/Op.cit., Limero

Air toxics–monitoring methods (TO-1, TO-14, TO-14a and TO-15). U.S. Environmental Protection Agency, http://www.epa.gov/ttnamti1/airtox.html

Limero T, Cheng P, Reese E, Jones J, Wallace W (2011) Operational air quality monitor: scientific studies in preparation for flight, 41st International Conference on Environmental Systems, American Institute of Aeronautics and Astronautics Technical Paper: AIAA-2011-5024, Portland, OR., July 2011

Limero T, Chen E, Cheng P, Boyd (2007) Differential mobility spectrometry: preliminary findings on determination of fundamental constants, Proceedings of the 16th International Society for Ion Mobility Spectrometry Conference, Mikkeli, Finland, July 2007

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Limero, T., Reese, E., Wallace, W.T. et al. Results from the air quality monitor (gas chromatograph-differential mobility spectrometer) experiment on board the international space station. Int. J. Ion Mobil. Spec. 15, 189–198 (2012). https://doi.org/10.1007/s12127-012-0107-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12127-012-0107-z