Abstract

Both Top Runner in Japan and Ecodesign in the European Union are schemes to set requirements on the energy efficiency (minimum efficiency performance standards, MEPS) of a variety of products. This article provides an overview of the main characteristics and results of both schemes and gives recommendations for improving them. Both schemes contribute significantly to the energy efficiency targets set by the European Commission and the Japanese government. Although it is difficult to compare the absolute levels of the requirements, comparison of the relative improvements and of the savings on household electricity consumption (11 % in Japan, 16 % in the EU) suggest they are in the same range. Furthermore, the time needed to set or review requirements is in both schemes considerable (between 5 and 6 years on average) and the manageability increasingly will become a challenge. The appeal of the Top Runner approach is that the most efficient product (Top Runner) sets the standard for all products at the next target year. Although the Ecodesign scheme includes the elements for a Top Runner approach, it could exploit this principle more explicitly. On the other hand, the Top Runner scheme could benefit by using a real minimum efficiency performance standard instead of a fleet average. This would make the monitoring and enforcement more simple and transparent, and would open the scheme for products where the market situation is less clear.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Product efficiency policy is an important part of energy policy and minimum efficiency standards are regarded as one of the most effective product efficiency policies (Geller et al. 2006). Every product efficiency standard policy has to find answers to the following questions (adapted from Turiel et al. (1997, p. 36)):

-

Which products are in the scope?

-

Where, at what level, to set the requirements (standards)?

-

Which test methods are to be used?

-

When to review and update the requirements?

-

How to ensure that the requirements are met in practice (monitoring and enforcement)?

The answers to these questions not only concern the results but also deal with the process. In this article, we will answer these questions for two major product efficiency standard schemes: the EU Ecodesign Directive and the Japanese Top Runner programme. Both schemes set energy efficiency requirements for products, albeit in a different way. The reason for comparing the Ecodesign and the Top Runner scheme is that the Top Runner scheme has appealed as a product efficiency standard policy to several countries in Europe (Germany (Jepsen et al. 2011), UK, the Netherlands) and the European Parliament (see, e.g. Report A7-0219/2011 (European Parliament 2011)). Moreover, whereas the EU Ecodesign scheme is comparable to other product efficiency standards schemes in the world, e.g. US DOE standards (http://www1.eere.energy.gov/buildings/appliance_standards/) and the Australian MEPS programme (http://www.energyrating.com.au/meps1.html), the Japanese Top Runner programme has some unique features. This might indicate opportunities to learn from each other, other than fine tuning on aspects that are more or less the same.

Therefore, the aim of this article is to explore opportunities for improving the Ecodesign and the Top Runner scheme by analysing and comparing these schemes. The benefits of, e.g. improving the Ecodesign scheme, are large: tapping even a few percent more of the potential savings would mean extra savings for the EU Ecodesign scheme in the order of 5–10 TWh/year in 2020. This is especially true for structural improvements in the scheme, i.e. improvements that are set as principles to be followed by all measures.

The article is organised as follows. First the main characteristics and results of the Top Runner and Ecodesign scheme are presented. Special attention is paid in trying to present the (expected) results of both schemes in such a way that they can be compared. Second, the article contrasts the differences between the two schemes, following the questions above. Finally we discuss the differences and similarities found in the analysis, draw conclusions and provide recommendations on how to improve both schemes.

Characteristics and results of the Top Runner programme

Main characteristics

In principle, the Top Runner approach is simple. Assessing the energy consumption of products available on the market reveals the “Top Runner” product, i.e. the product with the highest energy efficiency. This product then sets the standard which all manufacturers have to meet for the (sales weighted) average of their products after a number of years (the target year). Then the cycle starts again with the assessment of the (new) Top Runner product.

The main characteristics of the Top Runner programme are (METI 2010, p. 6–7):

-

The Top Runners set the standards.

-

The standards setting process is dynamic, with stakeholder input.

-

The standards refer to a fleet average.

-

The standards are mandatory.

Besides these main characteristics, the Top Runner programme has other aspects which are dealt with at the end of the section.

The Top Runner programme is part of the Japanese Law concerning the rational use of energy (Energy Conservation Law). Starting with 11 products in 1999 (Murakoshi et al. 1999), since 2009 the programme specifies standards for 23 products including means of transport, appliances, lighting, ICT equipment, heating and cooling equipment and transformers. To be eligible for the Top Runner programme, a product must meet the following requirements (METI 2010, p. 11): the product is used in large quantities in Japan, the product consumes (in total) a considerable amount of energy while in use and there is potential to improve the energy efficiency.

The Top Runners set the standards

In principle, the standard for the target year is set at the value of the most energy-efficient product (the Top Runner) at the time of market analysis. Because the standard is based upon data from existing products, it can be said that the standard is market driven, i.e. no standard is set that is not (yet) available in a product on the market. This is the general principle, however, standard setting takes into account technological innovation and diffusion and product price. The latter means that products with a high price will not be used to set the standard if the price difference, corrected for reductions due to larger production volumes, is not compensated for by lower running costs during the life time of the product. The standard should not be set by a unique product using patented technology; on the other hand, if technological innovation indicates more room for improvement, the standard can be set above the value of the Top Runner product as was done for DVD players.

Furthermore in setting the standard categorisation of products plays an important role, i.e. the standard value is not the same for a product but varies by category, e.g. DVD players with or without hard disk, or in relation to a main functional parameter, e.g. screen size for monitors (METI 2010, p. 13–16). Also specialty goods, e.g. custom made to order products in small quantities or products that use specific technologies with low market share (METI 2010, p. 18), are excluded when setting standard values for a category. It is explicitly indicated that target values for consumer electronics and office equipment should take into account reduction of standby power consumption.

A great advantage of this approach is that it is relatively easy to implement: the data are in most cases readily availableFootnote 1 and the analysis can be kept straightforward. Furthermore, no full life cycle cost analysis of design options is required (METI 2010, p. 6). However, the expected price of products is taken into account when setting the standards, as are costs for manufacturers when setting the target year taking into account product development cycles and investment for new production equipment.

The standard setting process is dynamic, with stakeholder input

The standard setting process is dynamic, i.e. the revision of the criteria is triggered when the target year for a product group approaches, or earlier when the criteria have been met well before the target year. The time span between setting the standards and the target year is between 3 and 11 years, with an average of 5.6 years (see Murakoshi et al. (2005, Table 2)). The process of setting the standards takes up to 2.5 years, especially when measurement methods for energy consumption and/or performance have not been established (METI 2010, p. 12).

The standard setting process is organised through subcommittees of the Advisory Committee for Natural Resources and Energy, an advisory body for all energy conservation policies to the Minister of Economy, Trade and Industry. For the Top Runner programme, the Energy Efficiency Standards Subcommittee was established. This subcommittee decides for which products Top Runner standards will be set, and for each product, an Evaluation Standard Subcommittee is established. These subcommittees consist of representatives from various stakeholders: industry, academia, trade unions and consumer organisations. The Evaluation Standard Subcommittees prepare and discuss draft standards supported by specific working groups carrying out preparatory studies on, e.g. measurement methods. Subcommittees and working groups are assisted and administered by the Energy Efficiency and Conservation Division of the Agency for Natural Resources and Energy. The meetings of the Evaluation Standards Subcommittees are partially closed to the public to preserve confidentiality of industry data. However, an interim report is made public on the internet and the subcommittee takes into account the comments when writing the final report. This report is sent to the Energy Efficiency Standards Subcommittee; after approval of this subcommittee, the draft Top Runner standard for the product is established. English versions of (summaries of) these reports can be found on www.eccj.or.jp/top-runner/. The standard comes into force after authorization by the Advisory Committee for National Resources and Energy.

The standards refer to a fleet average

The fleet average of products, excluding exports, of a manufacturer shall comply with the standard. This means that the Top Runner approach is formally not a minimum efficiency performance standard: not all products of a manufacturer have to fulfil the target, but the sales-weighted average has to. The fleet average provides flexibility for manufacturers, especially for products where several platforms co-exist and are sequentially updated as is the case for many consumer electronic and ICT products. Another advantage is that—in principle—no models are banned from the market. Even low efficiency products can be produced and sold provided they are compensated for by the sales of high efficiency models.

The standards are mandatory

Mandatory standards can and should be enforced; otherwise, they are in practice a voluntary agreement. As indicated in the previous paragraph, the fleet average approach provides special challenges regarding enforcement. So far, the Top Runner programme has been dominated by manufacturers and importers who are members of the respective industry associations, the majority of whom are Japanese. Enforcement within the Top Runner programme relies on “blame and shame” by the government which works well in Japan with Japanese manufacturers and importers. It is uncertain how effective this type of enforcement is when non-Japanese or manufacturers with less known brands obtain a larger market share.

Other aspects

The Top Runner approach is complemented by related policy instruments, such as information to consumers, the use of Top Runner standards in public green procurement and award schemes and a tax reduction scheme for cars. Some of these instruments are mandatory, e.g. information provided by manufacturers, others are voluntary, e.g. the labelling scheme and the award scheme for retailers (Murakoshi et al. 2005). The labelling program covers 18 of the 23 products, notable exceptions are cars and vans. Since October 2006, for five products a “Uniform Energy Saving Label” is specified. Retailers have to display this label on or nearby the product in the shop.

Tojo (2005, p. 62) notes that especially the Green Procurement Law promoted earlier application of environmental technologies because the law came into force before the target years set for the Top Runner programme were reached.

Results of the Top Runner programme

Although information on sales-weighted averages is scarce, except for computers and cars, figures regarding the number of models placed on the market that comply with the Top Runner standards indicate that in general these standards have been met (Tojo 2005, p 40, 42; Table 1).

METI (2010) summarizes results on improvements for all products; see Table 2 for a summary overview and the Annex shows more details based on the reports approved by the Energy Efficiency Standards Subcommittee. Realized improvements are based on market data as supplied by manufacturers and importers for the reference year and the target year. Expected, targeted improvements are calculated based on data for the reference year and estimations of the average consumption of products shipped in the target year, assuming that products meet the target values. For example, for refrigerators, the sales-weighted average energy consumption in 2005 is 572 kWh/year and the average energy consumption in 2010 is 542 kWh/year, assuming that the distribution of sales over the various categories will not change, resulting in an improvement of (572 − 452)/572 × 100 % = 21 %.

At first instance, these tables illustrate that the Top Runner approach is successful. However, since the targets have been (easily) met,Footnote 2 it could also mean that the Top Runner standards were not strict enough. Tojo (2005, p 44) pays some attention on the relative stringency of the Top Runner standards, concluding that “manufacturers must be at least as well equipped with technologies as their counterparts abroad when it comes to meeting and exceeding the Top Runner standards”.

Estimates of energy savings, i.e. the avoided end-use energy consumption, resulting from Top Runner are scarce. Nordqvist (2006, p. 22) cites expected savings by 2010 of over 200 PJ for the residential and commercial sector and between 200 and 350 PJ for the transportation sector, but warns that these figures are unreliable, i.e. it is not clear what the baselines for the savings are. In total, the savings contribute between one sixth and one fourth of the national energy efficiency savings target.

Based upon available data on household electricity consumption for 2009 (METI 2009) and the expected improvements in Table 2, the following estimate of savings from Top Runner products on household electricity consumption can be made (see Table 3). Applying the expected improvement percentages of Table 2 to the 2009 consumption of the respective Top Runner products results in savings for the situation where all products in the stock have been replaced by more efficient products according to the Top Runner standards. These savings are a conservative estimate because, although except for rice cookers and microwave ovens the target year is beyond 2009, already until 2009 products that are more efficient will have been sold and have therefore reduced the consumption in 2009. To obtain better estimates would require the use of bottom-up stock models.

Characteristics and results of the Ecodesign scheme

Main characteristics

As a consequence of the single market in the European Union, products are regulated at the EU level rather than the individual 27 Member States. The Ecodesign Directive 2009/125/EC of 21 October 2009Footnote 3 establishes a framework for setting requirements to relevant environmental characteristics of energy related products.Footnote 4 Also the Directive contains selection criteria for the products for which requirements are to be set (Article 15(2)): significant volume of sales and trade (>200,000 units per year in the EU), significant environmental impact and significant improvement potential. Working plans are established to select and prioritize the products for which requirements will be set. The Directive itself does not contain requirements for individual products; these are set in implementing measures (Regulations) or by self-regulation.

The main characteristics of the Ecodesign scheme are:

-

Selection of aspects for which requirements are to be set by means of life cycle assessment.

-

Setting of requirements is based on technical, environmental and economical analysis.

-

Extensive stakeholder consultation.

-

Enforcement is Member State responsibility.

For several product groups, the Ecodesign requirements are complemented by other policies which are dealt with at the end of this section.

Selection of aspects for which requirements are to be set

Ecodesign not only deals with energy efficiency but with all relevant environmental aspects that can be significantly improved. Therefore, a life cycle assessment is carried out to determine which are the relevant environmental aspects. Given that the products that have been subject to analysis so far are energy using products,Footnote 5 i.e. products that are dependent upon energy input to work as intended, it is no surprise that emissions related to the energy consumption during use have been found to be the most relevant environmental aspect and all Ecodesign implementing measures published so far contain energy (efficiency) requirements. However, also water use (washing machines, dish washers), noise (air conditioners) and mercury (lamps) have been identified as relevant environmental aspects for which requirements have been set. Furthermore, requirements can be set for performance aspects to prevent that products are placed on the market that comply with the environmental requirements but have a poor performance. Examples are cleaning performance for dish washers and washing machines and lamp life time for lamps.

Setting of requirements based on technical, environmental and economical analysis

The methodology for setting specific Ecodesign requirements is provided in Annex II of the Directive, elaborated in more detail in Kemna et al. (2005); this methodology is used in all preparatory studies for Ecodesign implementing measures. The main part of this analysis runs as follows.

A technical, environmental and economic analysis will:

-

Select a number of representative variants of the product

-

Identify the technical options for improving the environmental performance of the product (conditions: economic viability, no significant loss of performance or usefulness for consumers)

-

Identify, for the environmental aspects under consideration (i.e. energy efficiency), the best-performing products and technology available on the market

-

Take into consideration the performance of products available on international markets and benchmarks set in other countries’ legislation

Concerning energy consumption in use, the level of energy efficiency or consumption will be set aiming at the life-cycle cost minimum to end-users for representative variants, taking into account the impact on other environmental aspects. Furthermore a sensitivity analysis covering the relevant factors will be carried out to check if there are significant changes and if the overall conclusions are reliable. Finally, the date of entry into force of the requirement will take the redesign cycle for the product into account.

Thus the analysis prescribed in the Ecodesign Directive takes into account the best performing products, legislation in other countries (i.e. outside the EU) and sets the target at the life-cycle cost minimum at a date taking into account the redesign cycle of the product. One way to accommodate for this is a tiered approach: requirements for the first tier, which mostly comes into force 1 year after the publication of the Regulation in the Official Journal, are modest whereas more stringent requirements come into force in the second tier, mostly 3 or 4 years after publication.

Annex VII, item 9 of the Ecodesign Directive requires implementing measures to state a date for the evaluation and possible revision of the implementing measure, taking into account the speed of technological progress. Also, almost all implementing measures published so far provide in an (indicative) Annex the benchmark values of the best performing products on the market.

Extensive stakeholder consultation

The process of setting Ecodesign requirements for a product is a three-stage process. The first stage is a preparatory study which is carried out by consultants hired by the European Commission. StakeholderFootnote 6 input is encouraged by sending out questionnaires and draft reports for comments and organizing stakeholder meetings. The study results in a report including policy options; however, these options are not binding for the Commission. The second stage starts with the Commission writing a working document that contains a proposal for an implementing measure including an explanatory note explaining the choices made or options given in the working document. This working document is discussed with stakeholders in the Consultation Forum. The first two stages are largely informal, i.e. apart from at least one meeting of the Consultation Forum (as requested in article 18 of the Directive) there is no formal procedure for these stages. The third stage can be considered the formal stage of the process. It starts when the Commission after successfully going through its internal review process (inter service consultation) sends a (final) proposal for an implementing measure to the members of the Regulatory Committee, consisting of EU Member States experts. The Committee discusses the proposal and can amend it. At the end of the meeting, the proposal is voted upon. If adopted with a qualified majority, the text is then sent to the Council and the European Parliament for scrutiny. If both of them do not object, the implementing measure is adopted by the Commission and published in the Official Journal. The first and second stages are public, i.e. documents are available on public accessible websites and the meetings are open for all registered stakeholders, the third stage is restricted to Member State experts, Council members, members of the European Parliament and the Commission.

Due to—amongst others—the extensive stakeholder consultation the time between the start of the preparatory study and the coming into force of the first tier requirements is quite long. For the 12 implementing measures published so far, the time span varies between 3.5 and 6.7 years, with an average of almost 5 years. The time span from the start to the second tier varies between 5.25 years and 9.25 years with an average of almost 7 years.

Enforcement is Member State responsibility

The enforcement of the Ecodesign regulations is the responsibility of the EU Member States. In each Member State an enforcement authority has to be appointed that carries out activities to ensure that products comply with the requirements. Products that do not comply with the requirements can be withdrawn from the market by the enforcement authorities and the manufacturers of those products can be penalized. The Ecodesign Directive specifies in Article 20 that the penalties shall be “effective, proportionate and dissuasive, taking into account the extent of non-compliance and the number of units placed on the Community market.”

Member States are required by the Directive to cooperate with each other and the Commission regarding enforcements (Article 12). This is realized by the AdCo group where enforcement authorities of the Member States and the Commission meet twice a year and discuss enforcement strategies, plans and results.

Other policies for energy-related products

For several product groups, the Ecodesign requirements are complemented by other policies, e.g. the EU energy label, the EU ecolabel and the EU Energy Star programme (see, e.g. the Energy Efficiency Plan 2011 (European Commission 2011b)). Especially the energy label for a product is developed in the same process as the Ecodesign requirements, i.e. both share the same preparatory study. Furthermore, at the Member State level various other policies exist, which mainly relate to voluntary programmes for promoting higher efficiency appliances.

Results of the Ecodesign scheme

Although the Ecodesign directive itself came into force in 2005 and the first measures were published in 2008 and 2009, evaluation results are few (see, e.g. CSES 2011). Notably exception is the Selina project that measured standby and off mode power consumption of around 6000 products in shops to check whether the products (already) complied to Regulation 2008/1025/EC on standby and off mode consumption (Almeida et al. 2011). They found that 81.5 % of the products complied with the off mode requirement and 69.0 % with the standby mode requirement even when measured in most cases before the requirements entered into force.Footnote 7

The results presented in this section are based on the preparatory studies and the impact assessments for the products (http://ec.europa.eu/energy/efficiency/ecodesign/legislation_en.htm).

The products for which an implementing measure has been published cover 30 % of the total primary energy consumption in the EU projected as Business As Usual (BAU) consumption in 2020.Footnote 8 The measures are expected to result in a saving of 14 % of the BAU consumption in 2020 and result in a 22 % contribution to the 20 % energy efficiency target in 2020 of the European Union (European Commission 2011a).Footnote 9 However note that water heaters and boilers are not listed in Table 4; from these products alone, primary energy savings of 680 TWh/year are expected according to the preparatory studies (Kemna et al. 2007a, b).

Savings for household products are 179 TWh/year in 2020. However, these products are also partly used in the commercial, public and industrial sector, so not all savings can be attributed to households. A comparison with the data in Bertoldi and Atanasiu (2009, p. 13) suggests that 156 TWh/year can be attributed to households. These savings are to be related to the BAU household electricity consumption in 2020. An estimate for this consumption can be made with the assumption provided by Capros et al. (2008, p. 50) that “Electricity consumption … is projected to increase almost as fast as disposable income.”, where the income in the residential sector increases with 2 % per year in the period 2005–2030. Since the residential electricity consumption in 2007 is 800 TWh/year, an increase of 25 % in the period 2008–2020 results in a consumption of 1,000 TWh/year in 2020. Thus savings of 156 TWh/year amount to 16 % of total household electricity consumption.

Table 5 shows the expected improvements for the products for which an implementing measure has been published. Because of the complexity of the requirements, an improvement percentage cannot be provided for tertiary lighting and non-directional lighting.

Comparing Top Runner and Ecodesign

Scope of the scheme

Table 6 lists the products that are covered by the Top Runner programme and the products for which a preparatory study in the framework of the Ecodesign Directive has been or is carried out. Note that this table can only provide a global indication of the products covered by each of the schemes; even when the product group names are identical, the coverage will differ when looking at the exact definitions as specified in the implementing measures.

From Table 6, it can be concluded that the number of products covered by Ecodesign is larger than the number of products covered by Top Runner. For the products covered by Top Runner but not by Ecodesign, there are two different explanations. First transport products are explicitly excluded from the Ecodesign scope (Article 1(3)); however other European regulations set efficiency and environmental requirements for, e.g. cars (http://ec.europa.eu/enterprise/sectors/automotive/documents/directives/motor-vehicles/index_en.htm). Second electric toilet seats and electric rice cookers do not fulfil the criterium of significant volume of sales and trade to be eligible for an implementing measure under Ecodesign. For the products covered by Ecodesign but not by Top Runner, there are different explanations. First, several products have a small total energy consumption in Japan (e.g. dishwashers, washing machines, coffee machines). Second, for electric motors and products with an electric motor, e.g. circulators and pumps, stimulating the use of inverter control was more important than setting targets for the efficiency of the motor. However electric motors are now under consideration for the Top Runner programme. Third, for other product groups, mainly in the commercial and industrial sector setting standards is considered too complex because of product diversity and/or lack of measurement methods.

Both schemes play an important role in meeting the energy efficiency targets as set by the European Union and Japan.

Where to set the requirements?

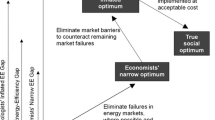

The difference between the Top Runner and Ecodesign approach on setting requirements is indicated by Fig. 1. The start of the axis is the efficiency at the time of setting the requirements.

The difference between Top Runner and Ecodesign is that the standard setting in Ecodesign varies on both efficiency and time, whereas for the Top Runner scheme the efficiency level is—in principle—fixed by the Top Runner product. The Ecodesign Directive specifies explicitly the factors that influence standard setting, including the date of entry into force. Since these factors can vary, the result can be pictured as an area in the time-efficiency diagram as shown in Fig. 1. This means that the (exact) point of the Ecodesign standard is not known beforehand. It can vary from the “best case” (standard with a high efficiency level on short time) to the “worst case” (standard with low efficiency level later on). In general, Ecodesign requirements tend to be relaxed during the process, i.e. they move in Fig. 1 from the top left hand area (proposal in preparatory study) in the direction of the bottom right hand (values and timing in regulation).

For the Top Runner scheme, the flexibility is in principle limited to the timing of the target year, which is set 3 to 10 years ahead. However the level of the standard can be moderated by the potential of technological innovation, patented technology to achieve the standard and high price of the Top Runner product. The Top Runner scheme is explicitly focussed on the Top Runner product to set the standard. However, the Ecodesign scheme takes into account best-performing products and benchmarks set in other countries legislation.

It is not possible to directly compare the absolute levels of the requirements between Top Runner (Table 2) and Ecodesign (Table 4) because the requirements are based on different definitions and measurements methods.Footnote 10 Table 7 compares the relative improvements for products for which both Ecodesign and Top Runner requirements exist.

Besides the general principles as indicated above there are other aspects when deciding upon the new target:

-

Interference with other environmental aspects

-

Interference with performance aspects

-

Differentiation between products from the same category

-

Dealing with increased performance

Decreasing energy consumption could interfere with improving other environmental aspects. Even if it is not directly conflicting, a strong focus on energy efficiency could absorb resources at manufacturers’ that otherwise could have been used to improve other environmental aspects. Tojo (2005, p. 64) indicates some issues regarding expanding the Top Runner programme towards other environmental aspects, especially setting the boundary and agreeing on parameters would not be straightforward. Regarding Ecodesign interference of energy efficiency with other environmental aspects has only been an issue for noise, where for dish washers and air conditioners it was argued by industry that stringent noise requirements would hamper (cost effective) energy efficiency improvements. First this is a result of Ecodesign being focussed on energy using products where the emissions related to the energy consumption in the use phase are the most important environmental aspect. Second there is other legislation in the EU (WEEE (Directive 2002/96/EC) and ROHS (Directive 2011/65/EU)) that deals with other environmental aspects of products. However, especially environmental NGOs have argued that Ecodesign implementing measures should pay (more) attention to these aspects.

Decreasing energy consumption could interfere with performance. Decreasing washing temperature could decrease the wash performance of a washing machine or dish washer. A longer wash cycle in a washing machine to maintain performance at decreased temperature could increase wear of the fabric. Therefore Ecodesign implementing measures contain requirements for important performance aspects. Top Runner standards do not include such requirements but rely on measurement standards for these aspects.

Another aspect is the differentiation between products from the same category but with a different type of performance, e.g. a television with a small screen compared to one with a large screen or a refrigerator with and without internet terminal. Differentiating the standards with regard to such performance aspects ensures that a wide range of products are available because there is no penalty for, e.g. a larger screens as such, but may result in increasing (absolute) energy consumption when consumers favour the larger products. Both the Top Runner and the Ecodesign scheme vary requirements according to performance, i.e. they set energy efficiency requirements. For some products, e.g. refrigerators, industrial fans and lighting, requirements are differentiated by technology. In general, this is to be avoided since it will keep on the market technologies that are less efficient. However, the main reason for differentiated requirements is a specific technology sometimes offers other important benefits. For example, absorption-type refrigerators that are much less efficient than compressor type refrigerators but offer noiseless operation. Both Ecodesign and Top Runner programme accommodate for this by allowing setting different standards for different categories.

Performance of products is changing constantly, both quantitative (e.g. a larger screen or larger storage volume) and qualitative (new or improved features, e.g. high definition, network capability). Regarding quantitative developments, both Ecodesign and Top Runner as indicated set energy efficiency requirements that take variation of performance into account. However, if the performance of the product increases dramatically during the period, the standard loses its guiding principle. Examples in the Top Runner programme include standards for hard disks and computers where the requirements are formulated in Watt per operations per second and Watt per memory capacity respectively. The emergence of new features with impact on energy consumption poses a challenge for setting requirements. In general both Top Runner and Ecodesign provide allowances for (new) features, e.g. the allowance for high definition encoding in the set top box regulation and for multiple tuners in the Top Runner television standard. Alternatives for allowances are switching off the features during the measurement of the power consumption if possible (see, e.g. IEC 62087 for measuring energy consumption of televisions), exempt products with new features from the requirements or provide no allowances at all. This aspect is especially challenging for requirements on ICT and consumer electronics products. It also means for the Top Runner approach that the Top Runner product at a certain point in time does not automatically set the standard for the next target year because it does not have (all) the features that products in the target year will have.

Concluding, while it is not possible to directly compare the absolute levels of the requirements between Top Runner and Ecodesign, the relative improvements are in the same range. Although in practice the setting of requirements encounters the same issues in both processes and finds solutions that provide more or less the same results, the Top Runner approach has the large conceptual advantage that the aim is clear from the start: the Top Runner product sets—in principle—the new standard.

Which test methods are to be used?

Both Ecodesign and Top Runner prefer test methods established in harmonized (international) standards. However such standards might not be available for all products, or the existing standards are outdated or not complete. For both schemes, the possibility exists when a harmonized standard is not available or not complete to specify (additional) measurement methods, including measurement conditions, in the measure. For Top Runner such a method should be objective and quantitative. For Ecodesign, the Commission will specify a mandate to the European Standardization bodies to adopt the missing standards or amend existing standards to suit the needs of the implementing measure.

When to update the requirements?

Both Top Runner and Ecodesign have clear indications on when to update the requirements. For Top Runner this is (at least) the target year, whereas for Ecodesign each individual regulation specifies when the Commission will present a review to the Consultation Forum. Most Ecodesign regulations have a two or even multi-tier approach. In most cases, the review is planned after the last tier has come into force. However for some products (lighting, electric motors and dish washers) the review will be carried out before the last tier comes into force. The reason is that at the time of setting the requirements it was not completely certain whether especially small and medium size enterprises could achieve the requirements on time. Although the review aims at updating the requirements for both Top Runner and Ecodesign, an update will only occur if there is still (substantial) improvement potential.

Table 8 compares the dynamics of updating between Top Runner and Ecodesign. Note that the figure for Top Runner has been calculated from actual updates whereas the figure for Ecodesign is based upon revisions to come.

Monitoring and enforcement

The Top Runner scheme requires manufacturers (and importers) to provide both energy (efficiency) and sales data for all products covered by the scheme at the target year. Because the fleet average needs to comply with the target, data from individual products cannot be conclusive regarding whether a manufacturer complies with the target for a certain product category. This means that the Top Runner scheme regarding monitoring and enforcement is highly dependent on co-operation from manufacturers and on confidential data. In practice this means that independent enforcement is not possible. Furthermore it requires a stable market situation in which manufacturers or importers do not change quickly. Second, it means that consumer purchasing behaviour is still important. Whereas with minimum efficiency performance standards (MEPS) you can be sure that every product meets the standard, the fleet average approach goes wrong if too many customers buy products with low efficiency, which are then not compensated for by products bought with a high efficiency.

For the Ecodesign scheme, independent enforcement is possible: every product shall meet the requirements. Every Ecodesign regulation contains an Annex on how to carry out enforcement activities, including the procedure how to decide whether a product complies or not. The challenges for enforcement lie in the fact that enforcement is a responsibility of each EU Member State individually; there is, e.g. no European enforcement authority. Since there is no requirement for manufacturers or importers to register products or to send product data to the authorities, it depends on the activities of individual enforcement authorities in Member StatesFootnote 11 to check whether products comply with the requirements. In practice, these activities have a small scale or are even non-existent in several Member States (CSES 2011).

Discussion

One of the aims of this article is to investigate what the Top Runner and Ecodesign scheme could learn from each other, especially in the light of interest in Europe for the Top Runner scheme.

First, what this article shows is that both schemes have more in common than is sometimes suggested; this especially holds for the dynamic aspect where Top Runner is perceived as being continuously updated (e.g. Nordqvist (2006, p. 5)) and Ecodesign as being slow (Spengler and Jepsen 2010, p. 4). However, both Top Runner and Ecodesign are dynamic (tiered approach and/or updates) and the time needed to set or review the requirements is in both schemes considerable and highly comparable. Although it is difficult to compare the absolute levels of the requirements, comparison of the relative improvements and of the savings on household electricity consumption suggest they are in the same range.

The common aspects suggest that the schemes could learn and benefit more from each other when they would be more harmonized. Harmonization of criteria and measurement methods would make it possible to compare the requirements and the results which could drive the ambitions of both schemes. Products where this harmonization is most easily realized are those that are produced and sold for a worldwide market and already have a single-accepted measurement method, e.g. televisions.

Second, both schemes face some of the same limitations, which stem primarily from the condition that setting requirements is determined by the efficiency of the products on the market when setting the requirements, albeit that this can be the most efficient products. This means that for both schemes it is difficult to “force” innovations. Related to this is the condition that the market must be competitive enough to prevent manufacturers from concerted action to slow down efficiency improvements. Also, both schemes have difficulties in dealing with new or improved features and variations in functionality (Kimura 2010). A consequence is that an automatic update of making requirements more stringent is hardly possible for many products unless the claim of extra energy consumption by new or improved product features is denied.

Third, for both schemes the manageability increasingly will become a challenge. Several factors contribute. First the number of products (23 for Top Runner, 13 for Ecodesign with around 15 to come), second the success of the schemes combined with the intensive preparation and stakeholder consultation and third the type of products targeted. Although not all standards will be revised, e.g. the Top Runner standard for VCRs, with an average time span for updating of around 5 years, this means that in the years to come every year four to five products need to be revised. The familiarity with and success of the schemes result in more stakeholders more intensively participating in the process, which is as such a good thing but makes the management of the scheme more complex and time-consuming. Revision of standards on one hand might be easier and quicker because it “only” requires an update of the work already done, on the other hand for several products functionality, technology and/or the market may have changed dramatically so that in fact the preparations have to start from scratch. Regarding the type of products, especially expanding the scheme will create challenges. Both schemes have in the beginning dealt with relatively simple products, i.e. products for which measurement methods were available, which were already subject to other legislation (e.g. energy labelling in the EU) and for which the market was well organized.

Unfortunately there is no quick fix for the manageability challenge. Freeing more resources (money, persons) for the scheme is an obvious solution but might be politically less acceptable or realizable. The Ecodesign scheme allows for self-regulation instead of implementing measures; although this might decrease the workload for the administrators, the workload for industry is more or less the same. Furthermore self-regulation is in many cases not suitable or desired by industry, because self-regulation will not cover all market players (the three self-regulatory initiatives so far cover between 75 % and 98 % of their market). Improvements can be made regarding the planning of the process, e.g. the Ecodesign process is notorious for the delays in delivering the implementing measures, but this will probably only provide a small relief. Another suggestion would be to have more horizontal requirements, like for (network) standby in Ecodesign resulting in one regulation covering a large number of products, or to restrict the requirements to the most important products, i.e. to raise the eligibility criteria.

Although the differences between Top Runner and Ecodesign are more gradual than black and white, for each of the schemes, there is at least one point where each of the schemes can learn from the other. For the Ecodesign scheme, this is the principle that the Top Runner product sets the next requirements. The ingredients for applying this principle are already in the current scheme: the (indicative) benchmark values and the date of review. To apply the principle would mean that when reviewing the regulations the benchmark values in the existing regulation would be checked against the actual market situation and then be set as the basis for the revised regulation. As indicated above, unlike Top Runner, Ecodesign explicitly refers to the point of least life cycle costs (LLCC) to set specific requirements. However, since this point moves in time (the longer the time before the standard comes into force, the more ambitious the LLCC can be) as with Top Runner, the time variable can be used to match the point of LLCC with the benchmark (= Top Runner) values. This would provide the revision of Ecodesign regulations with a clear target from the start of the process.

The Top Runner scheme could benefit from switching to a real MEPS scheme instead of a fleet average. The fleet average requires that manufacturers (or importers) send both the energy efficiency data and sales data for the target year to the authorities. Such a scheme is difficult to check and enforce because measuring an individual product does not conclude about the total suite of products from a manufacturer complying with the requirements. A MEPS approach would open the scheme for products where the market situation is less clear. This might however also require changes in the way stakeholders are consulted in the Top Runner programme.

Regarding the European interest in a Top Runner approach, the following can be said based on the analysis in this article. It seems that the appeal of the Top Runner approach is to a large degree conceptual and to a certain extent even more based on an ideal picture than on facts. An example of the latter is the confusion that the dynamic nature of Top Runner implies a short updating cycle, whereas in fact the time between two subsequent requirements is longer for Top Runner than foreseen for Ecodesign. On the question whether the update can be faster the Top Runner approach as such does not provide an answer. The conceptual appeal mainly relates to the principle that the Top Runner product sets the next requirements. As we have indicated above, it is possible to make more explicit this principle in the Ecodesign revision process.

Finally, placing Top Runner and Ecodesign in a broader energy policy perspective, it is noted that a product approach, by definition, targets energy consumption of individual products. However, total household and commercial electricity consumption is not (completely) controlled with such an approach. First, not all products that are used in households are included in, e.g. the Top Runner approach. Second, even if all products were included, the approach does not control the number of products in use, nor their size, nor the duration of their use. So, neither Top Runner nor Ecodesign, nor any other product-oriented approach can be the single “silver bullet” regarding energy saving and CO2 reduction (Siderius 2004).

Conclusions and recommendations

Top Runner is a Japanese programme which addresses energy use in the transport, commercial and private sectors. It is effective in the sense that in general the standards that were set have been met. The appeal of the approach is embedded in the following characteristics: the simple assessment of the standards (Top Runners) based upon data from products available on the market and its dynamic nature. Moreover the name of the programme has a positive connotation: the most efficient product on the market is the Top Runner.

The EU Ecodesign Directive provides a framework for setting minimum requirements on significant environmental aspects for products placed on the EU market. For 12 product groups from the household, commercial and industrial sectors, requirements on energy efficiency (MEPS) and other aspects have been set and it is expected that in the next years, MEPS for another 15–20 products will follow. The requirements have a tiered approach and will be reviewed (on average) after almost 5 years.

Both Ecodesign and Top Runner contribute significantly to the energy efficiency targets set by the European Commission and the Japanese government respectively. Comparing the Top Runner approach with the approach offered by the Ecodesign Directive reveals that most of the characteristics of the Top Runner approach can also be found in the Ecodesign Directive although that the “top runner” aspect is somewhat hidden. However, the Ecodesign scheme could exploit the top runner aspect more explicitly by making the benchmark values in the implementing measures starting point for revisions. The Top Runner scheme could benefit from switching to a real MEPS instead of a fleet average. Both schemes would benefit from cooperation through harmonization of measurement methods and criteria. Further harmonization of the test methods will allow better comparison to find the international top runner to set MEPS. A common limitation is the difficulty in dealing with variations in product functionality and with new or improved features. Finally the largest challenge for both schemes is the manageability. Improved planning can provide some relief here, but the main choice is between spending more resources or restricting the scheme to the most important products.

Notes

If not at the first analysis then certainly for the second and following analysis; otherwise, monitoring and enforcement would not be possible.

Except for transformers due to a market shift to larger transformers which have larger absolute losses.

This Directive is the recast of the original Ecodesign Directive from 2005. The main difference is that the scope of the Directive is extended from energy using products to energy related products.

An energy related product is a product that has an impact on energy consumption during use (Article 2(1)), including both products that comsume energy during use themselves (e.g. a refrigerator, a television or an electric motor) and products that impact the energy consumption during use of other products (e.g. a window or a shower head).

Although the scope of the Directive has been extended to energy related products no implementing measures for such products are being prepared yet.

Stakeholders are industry representatives, NGOs and EU member state experts.

Because the measurements were carried out in shops, it was not known when the products measured were placed on the market and therefore it could not be established with certainty whether the products measured should have been compliant with the requirements. Products placed on the market before the requirements went into force can be legally sold after the entry into force date.

Total primary energy consumption in 2020 is estimated at 1968 Mtoe (European Commission 2011a, p. 21), equivalent to 22 888 TWh. Final consumption (all electricity) of products covered by Ecodesign measures converted to primary energy with factor 2.5 results in 6790 TWh.

The 20 % energy efficiency target (in primary energy) results in 368 Mtoe (European Commission 2011a, p. 21), equivalent to 4,273 TWh. Savings (all electricity) in 2020 of products covered by Ecodesign converted to primary energy with factor 2.5 result in 965 TWh.

The IEA 4E (efficient electrical end-use equipment) implementing agreement has an Annex (Mapping and Benchmarking) to undertake such international comparisons.

And some Member States, e.g. Spain and Germany, have delegated the enforcement to lower levels in their hierarchy so that they have multiple enforcement authorities.

References

Almeida, A. de, Patrão, C., Rivière, P., da Silva, D., Schlomann, B., Harrison, B. (2011). Standby and off-mode power demand of new appliances in the market. EEDAL 2011 conference proceedings. Can be downloaded from http://re.jrc.ec.europa.eu/energyefficiency/EEDAL/index.htm.

Bertoldi, P., & Atanasiu, B. (2009). Electricity consumption and efficiency trends in European union—status report 2009. Luxembourg: Publications Office of the European Union.

Capros, P., Mantzos, L., Papandreou, V., & Tasios, N. (2008). European energy and transport—trends to 2030, update 2007. Luxembourg: Office for Official Publications of the European Communities.

CSES (2011). Evaluation of the Ecodesign Directive (2009/125/EC)—first findings report. Can be downloaded from http://www.cses.co.uk/upl/File/CSES-eco-design-evaluation-first-progress-report-Revised-version-05-05.pdf.

Directive 2005/32/EC of the European Parliament and of the Council of 6 July 2005 establishing a framework for the setting of ecodesign requirements for energy-using products and amending Council Directive 92/42/EEC and Directives 96/57/EC and 2000/55/EC of the European Parliament and of the Council. OJ L191, p. 29–58, 22.07.2005.

Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 establishing a framework for the setting of ecodesign requirements for energy-related products (recast). OJ L285, p. 10–35, 31.10.2009.

Directive 2010/30/EU of the European Parliament and of the Council of 19 May 2010 on the indication by labelling and standard product information of the consumption of energy and other resources by energy-related products (recast). OJ L153, p. 1–12, 18.06.2010.

European Parliament (2011). Report A7-0219/2011. Can be downloaded from http://www.europarl.europa.eu/sides/getDoc.do?type=REPORT&reference=A7-2011-0219&language=EN.

European Commission (2011a). Energy Efficiency Plan 2011; Impact Assessment. SEC(2011) 277 final. Brussels.

European Commission (2011b). Energy Efficiency Plan 2011. COM(2011) 109/4. Brussels.

Geller, H., Harrington, P., Rosenfeld, A. H., Tanishima, S., & Unander, F. (2006). Polices for increasing energy efficiency: thirty years of experience in OECD countries. Energy Policy, 34, 556–573.

Jepsen, D., Spengler, L., Reintjes, N., Rubik, F., Schomerus, T. (2011). Product-related top runner approach at EU level. Federal Environment Agency (Umweltbundesamt), Dessau-Rosslau. Can be downloaded from http://www.uba.de/uba-info-medien/4122.html.

Kemna, R., van Elburg, M., Li, W., & van Holsteijn, R. (2005). MEEUP methodology report. Delft: Van Holsteijn en Kemna for European Commission.

Kemna, R., van Elburg, M., Li, W., & van Holsteijn, R. (2007a). Eco-design of CH-Boilers. Delft: Van Holsteijn en Kemna.

Kemna, R., van Elburg, M., Li, W., & van Holsteijn, R. (2007b). Eco-design of water heaters. Delft: Van Holsteijn en Kemna.

Kimura, O. (2010). Japanese Top Runner Approach for energy efficiency standards. SERC Discussion Paper, CRIEPI. Can be downloaded from: http://criepi.denken.or.jp/jp/serc/discussion/index.html.

METI (2009). Household electricity consumption by equipment in 2009 (in Japanese), downloaded at 28 October 2011 from http://www.meti.go.jp/committee/summary/0004310/016_05_02.pdf.

METI (2010). Top Runner Program—developing the world’s best energy-efficient appliances, March 2010. Can be downloaded from http://www.asiaeec-col.eccj.or.jp/top_runner/index.html.

Murakoshi, C. et al. (1999). Revision of Japanese Appliance Energy Efficiency Standards, ECEEE 1999 Summer Study Proceedings, Panel 1.10.

Murakoshi, C. et al. (2005). New challenges of Japanese energy efficiency program by Top Runner approach, ECEEE 2005 Summer Study Proceedings, 767–777.

Nordqvist, J. (2006). Evaluation of Japan’s Top Runner programme, AID-EE project. Can be downloaded from: http://www.aid-ee.org/documents/018TopRunner-Japan.PDF.

Siderius, H-P. (2004). The End of Energy Efficiency Improvements = The Start of Energy Savings?!, ACEEE 2004 Summer Study on Energy Efficiency in Buildings, 11-165–11-176.

Spengler, L., & Jepsen, D. (2010). Auswirkungen und Potenzial der Durchführungsmassnahmen der Ökodesign-Richtlinie. Hamburg: Ökopol GmbH.

Tojo, N. (2005). The Top Runner Program in Japan—its effectiveness and implications for the EU, Naturvardsverket, Report 5515, Stockholm.

Turiel, I., Chan, T., & McMahon, J. E. (1997). Theory and methodology of appliance standards. Energy and Buildings, 26, 35–44.

Author information

Authors and Affiliations

Corresponding author

Annex

Annex

Rights and permissions

About this article

Cite this article

Siderius, P.J.S., Nakagami, H. A MEPS is a MEPS is a MEPS: comparing Ecodesign and Top Runner schemes for setting product efficiency standards. Energy Efficiency 6, 1–19 (2013). https://doi.org/10.1007/s12053-012-9166-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-012-9166-6