Abstract

Based on a sol-gel procedure, a molecularly imprinted polymer (MIP) for 2, 4-dichlorophenoxyacetic acid (2, 4-D) was synthesized, using phenyltrimethoxysilane (PTMOS), aminopropyltriethoxysilane (APTES) as monomers and tetraethoxysilane (TEOS) as cross-linking agent. In addition to the amount of the template, some factors in the sol-gel process: TEOS/APTES/PTMOS molar ratio, H2O/Si molar ratio, CH3CH2OH/Si molar ratio, etc. were investigated in detail. Results show that the optimum conditions for the preparation of the MIPs were 20:1.5:1 (TEOS: APTES: PTMOS), ca. 4 (H2O/Si), ca. 4 (CH3CH2OH/Si), respectively. Effects of various parameters involved in the adsorption process of 2, 4-D on MIP such as incubation time, pH, etc. were also evaluated. It is found that the adsorption attained equilibrium within 3 h, the optimum pH for adsorption was about 7 and the adsorption obeyed Langmuir model. Test results also demonstrated that the present MIP for 2, 4-D had large adsorption capacity (the maximum adsorption concluded from Langmuir model reached 243.3 mg/g) and good selectivity.

A molecularly imprinted polymer (MIP) for 2, 4-dichlorophenoxyacetic acid (2, 4-D) was synthesized used aminopropyltriethoxysilane (APTES), phenyltrimethoxysilane (PTMOS) as functional monomers and tetraethoxysilane (TEOS) as cross linking agent through sol-gel procedure. When 2, 4-D was removed from the formed polymer, templates with specific cavities which can selectively adsorb were left.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

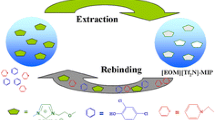

Molecular imprinting technology (MIT) which arises from molecular recognition is now a well-established technique for developing artificial receptors possessing strong affinity for specific target molecules.[1–3] In the presence of a template, monomers are arranged and co-polymerized to form a cross-linked polymer. After removal of the template, a cavity complementary with the template in shape, size and interaction is left. In general, the imprinting process involved three basic steps: 1) formation of the complex between template and functional monomers; 2) polymerization of the complex in the presence of a cross-linking agent; 3) removal of the template from the formed polymer by extraction, leaving specific cavities which can selectively adsorb the templates.[4,5]

Compared to biological receptors, imprinted materials possess inherent advantages like: 1) easy preparation; 2) good mechanical stability due to highly cross-linked structure; 3) repeated uses without loss of molecular recognition capability.[6,7] So, they have potential application in many fields, such as chromatography,[8,9] sensors,[10,11] and solid-phase extraction.[9,12] So far, most MIPs are obtained through radical polymerization.[13–16] These polymerizations are extensively used in imprinted field and have satisfactory results. But this method requires a severe condition in preparation process.

A sol-gel method is another strategy to prepare MIPs.[17–21] Compared to the radical polymerization method, the sol-gel method has some advantages: 1) MIPs could be synthesized under mild conditions; 2) different morphologies could be obtained, e.g., bulk solids, fibers, films, etc.; 3) the surface of the cavity could be easily modified with organic groups; 4) obtained polymer possesses several superiorities in physical aspect, as they exhibit porous, rigid, good optical properties.[22,23]

2, 4-Dichlorophenoxyacetic acid (2, 4-D) is a chief component of commonly used herbicides which has been frequently detected in water. It is harmful to human beings and threatens our health.[24,25] Recently, there are many reports about molecularly imprinted polymer for 2, 4-dichlorophenoxyacetic acid.[26–29] Han et al. have reported a surface-imprinted amino-functionalized silica gel sorbent for 2, 4-D using silica gel as the support, aminopropyltriethoxysilane (APTES) and tetraethoxysilane (TEOS) as reacting monomers.[29] The procedure of bulk polymerization is simple and results are relatively satisfactory. Here, we employed bulk polymerization using tetraethoxysilane (TEOS) as a cross-linking agent, phenyltrimethoxysilane (PTMOS), aminopropyltriethoxysilane (APTES) as functional monomers to synthesize a sol-gel-based MIP for selective adsorption of 2, 4-D in the present study. Results showed that MIPs fabricated by this method possess a better selectivity to 2, 4-D.

2 Experimental

2.1 Reagents and apparatus

2, 4-Dichlorophenoxyacetic acid (2, 4-D, 99% + ), 2, 4-dichlorophenylacetic acid (DCPA, 98% + ) phenoxyacetic acid (PA, 99% +), and 2,4-dichlorophenol(DCP, 99% + ) were purchased from ACROS. Tetraethoxysilane (TEOS, AR) was purchased from Tianjin Damao Chemical Reagent Factory, China. Phenyltrimethoxysilane (PTMOS, 98%), and aminopropyltriethoxysilane (APTES, 98%) were purchased from Sigma-Aldrich Co.

Adsorption spectra and optical densities of solutions were recorded using a Shimadzu UV-2550 spectrophotometer. The FT-IR spectra (4000-400 cm−1) in KBr were recorded by VERTEX-70 infrared spectrometer. HPLC analysis was performed on a Shimadzu system with LC-20AT pump, DGU-20A5 online degasser system, SPD-20A UV-detector, SIL-10AF auto sampler and a reverse phase C18 VP-ODS column (250 × 4.6 mm, 5 μm). The mobile phase was composed of methanol/water (7:3, V/V), and its flow rate was 1 mL min−1.

2.2 Preparation of MIPs

Figure 1 depicts the development of MIPs. In the procedure, three monomers (TEOS, 20 mmol; APTES, 1.5 mmol; PTMOS, 1 mmol) were first mixed with 5.0 mL ethanol in a 50 mL glass beaker until homogenity, followed by addition of 150 μl concentrated hydrochloric acid and 1.5 mL distilled water. The resulting mixture was kept stirring at 30∘C for 30 min. After that, the template 2, 4-D was added into the solution and the reaction going for another 2.5 h. Finally, the obtained gel was dried at 80∘C for 12 h in a vacuum oven to form a sol-gel monolith. The resultant monolith was then crushed and Soxhlet extracted first with ethanol/acetic acid (9:1, v/v) for 12 h and then with ethanol for 8 h to remove any unreacted reagents and the template. For comparison, the non-imprinted polymer (NIP) was also prepared under the same conditions with the exception that no template was added.

2.3 Measurement of adsorption capacities

In a 5 mL plastic tube, 10.0 mg MIP or NIP was mixed with 2.0 mL 2, 4-D solution of a known concentration (C0) and pH. The mixtures were then kept shaking in a thermostatic shaker bath until an equilibrium was reached at 30∘C. After centrifugation, the supernate was filtered with porous membrane (pore size = 0.45 μm), the concentration (Ce) of 2, 4-D in the filtrate was then determined with a UV-visible spectrophotometer at λ= 283 nm. These experiments were conducted in triplicate, and an average was used for the calculation of the adsorption capacity. The amount of 2, 4-D adsorbed by MIP or NIP was obtained by following equation:

where Q e (mg/g) is adsorption capacity at equilibrium, V (L) is the volume of the 2, 4-D solution and m (g) is the weight of the adsorbent.

The selectivity coefficient K was obtained using equation (2).

QMIP and QNIP were the adsorption capacities of MIP and NIP toward 2, 4-D, respectively.

The relative selectivity coefficient K’ was obtained using equation (3).

QMIP,2,4−D and QMIP,analogue were the adsorption capacities of MIP toward 2, 4-D, and MIP toward 2, 4-D’ analogues respectively in competitive adsorption.

To study the effect of incubation parameters such as medium pH, incubation time, etc. on the adsorption capacity of MIP or NIP toward 2, 4-D, batch experiments under similar conditions were conducted using the same procedure mentioned above. Detailed conditions were given in the figures or tables.

3 Results and discussions

3.1 Preparation and FT-IR characterization of MIPs

Different compositions of MIPs labeled as P1-P13 (table 1) were obtained. Of the three precursors, TEOS acted as cross-linking agent, PTMOS and APTES acted as functional monomers. Both PTMOS and APTES were involved in the gelation process in addition to immobilizing the template molecule 2, 4-D. It is believed that PTMOS interacts with the template 2, 4-D through hydrophobicity and π−π stacking, but APTES interacts with 2, 4-D through electrostatic interaction and hydrogen bond.

The FT-IR spectra of P3 and its corresponding NIP were shown in figure 2a. The broad peaks at ca. 3250 cm−1 is due to the stretching vibrations of O-H (residual Si-OH and adsorbed water), N-H and C–H. Peaks at 1650 cm−1 and 1560 cm−1 originated from O-H and N-H bending vibrations. Peaks at ca. 1100 cm−1 and 976 cm−1 are attributed to the stretching vibrations of Si-O-Si and Si-O-H, and the peaks at ca. 780 cm−1 and 490 cm−1 result from Si-O bending vibrations. It can be seen that the spectrum of P3 is very similar to that of its NIP, indicating that the templates 2, 4-D have been removed completely.

On comparison of the FT-IR spectra of P3, P6 and P10 (figure 2b), it is found that the spectrums of P6 is different from P3 or P10 (the latter two is very similar in sharp, peak position and peak intensity) at 1560 cm−1 which originated from N-H bending vibrations. This is due to the absence of –NH2 group in P3, which correspond to their compositions.

3.2 Parameters affecting the selectivity coefficients K of MIPs

3.2.1 The proportion of three kinds of monomers

Figure 3 shows the selective adsorption of different MIPs. It can be seen that both APTES and PTMOS have great impacts on Qe and selectivity coefficients K, but the APTES dependent changes were larger than the PTMOS dependent changes; i.e., the APTES seems to play a more important role than PTMOS does in building-up process of MIPs. The best Qe and K values occurred at the molar ratio of 20:1.5:1 (TEOS: APTES: PTMOS).

3.2.2 The amount of 2, 4-D

It can also be found that the amount of the template 2, 4-D has some influences on the performance of MIPs (table 2). At low concentration of 2, 4-D, the adsorption capacity of MIPs increased with the increase of the amount of 2, 4-D. When the molar ratio value of the monomers to the template reached 6.25, the MIPs had a maximum adsorption capacity. This trend may be related to the micro-structure of the MIPs. It is accepted that the fewer the templates, the smaller the porosity of MIPs. In the presence of large amount of templates, the structure of MIP becomes too loose to be able to maintain a three-dimensional structure of the cavities.

3.2.3 The molar ratio of H2O to the precursors

The amount of the precursors (including TEOS, APTES, PTMOS) influences the performance of MIPs. Table 3 shows the effect of the molar ratio of H2O to the precursors (H2O/Si) on the performance of MIPs. In sol-gel process, the amount of water is a key parameter that determines the structure and properties of the MIPs. The maximum value of K occurs at a H2O/Si ratio of ca.4. If H2O/Si is small, there will be a large number of organic group residues on the surface which cannot participate in hydrolysis. It is these residuals that lead to a large adsorption capacity for both MIP and NIP, and therefore lower the K values. When the H2O/Si is large, the excessive water that does not participate in the hydrolysis will act as a pore-forming agent and remain in the gel. After evaporation, non-specific binding cavities are formed, resulting in lower K values.

3.2.4 The molar ratio of CH3 CH 2OH to the precursors

Ethanol was used here as a co-solvent which not only enabled uniform mixing of water and monomers but also affected the sol viscosity and gelation time. It is advised that the amount of ethanol added should be kept at a moderate value due to the fact that small amount of ethanol will result in immiscibility of the monomers with water, but large amount of ethanol will inhibit the hydrolysis reaction (ethanol is a by-product of the hydrolysis). Table 4 shows that the maximum value of K occurs at the ratio of ethanol to monomer between 2 and 4.

3.3 Parameters affecting the adsorption performance of MIPs

3.3.1 Incubation time

Figure 4 shows that the amount of 2, 4-D adsorption on P3 increases with time. It is shown that the adsorption capacity increases first rapidly and then it remains constant after a contact time of 3 h. Adsorption equilibrium can be reached in a relatively short period of time, indicating the stronger force and the less mass transfer resistance between P3 and 2, 4-D.

3.3.2 pH of media

The pH value of the 2, 4-D solution is an important parameter that affects the adsorption of MIPs toward 2, 4-D because the charges of the functional groups on 2, 4-D as well as on MIPs vary with the pH value (the hydrophobic interaction and π−π stacking between 2, 4-D and P3 seemed to be not sensitive to the pHs). As shown in figure 5, the maximum adsorption capacity of P3 toward 2, 4-D appears at pH ≈ 7. At low pHs, the -COOH of 2, 4-D can hardly dissociate, so few anions are produced and the contribution from the electrostatic attraction of cationic -NH\(_{3}^{+}\) of MIP toward 2, 4-D is therefore small. While at high pH values, the dissociation degree of -COOH increases but the protonization degree of the –NH2 on P3 decreases; the electrostatic interaction is also weak and the adsorption capacity of P3 toward 2, 4-D reduced greatly. At pH ≈ 7, more cations and anions were produced, which resulted in a strongest electrostatic interaction between 2, 4-D and MIP. And therefore, a maximum Qe was attained.

3.4 Selectivity of P3 for 2, 4-D over the structurally similar compounds

2, 4-dichlorophenylacetic acid (DCPA) and 2, 4-dichlorophenol (DCP) that structurally similar to 2, 4-D were chosen as the analogues of 2, 4-D and the selectivity of P3 was investigated in a competitive binding experiment using an aqueous 2, 4-D, 2, 4-dichlorophenylacetic acid (DPAC) and 2, 4-dichlorophenol (2, 4-DCP) mixture. The result (figure 6) showed that P3 has highly larger adsorption capacities for 2, 4-D over DCPA and DCP. The ratio of capacities of 2, 4-D and DCP on P3 (K’) reached 28.15 which indicated that the polymers possess good selectivity.

3.5 Adsorption mechanism

Adsorption isotherms are helpful for understanding the adsorption mechanism. Figure 7 was the plots of the equilibrium adsorption capacity of P3 and its corresponding NIP toward 2, 4-D versus the initial concentration of 2, 4-D.

Followed, adsorption isotherm model Langmuir equation was used to fit the data. According to Langmuir equation:

where Ce (mg/L) is the equilibrium concentration of 2, 4-D, Qe (mg/g) is the amount of 2, 4-D adsorbed on MIPs at a given concentration, Qmax (mg/g) is the maximum adsorption capacity, and KL (L/mg) is Langmuir constant related to the affinity of the binding sites on MIPs. When Ce/Qe was plotted against Ce, KL and Qmax could be obtained via a linear regression. In our system, the Qmax and KL were determined to be 243.3 mg/g and 0.0242 L/mg, respectively (figure 8). The adsorption well-represented by Langmuir isotherm indicated that 2, 4-D on MIPs was monolayer adsorption.

3.6 Repeated use of MIPs

The 2, 4-D saturated MIP (P3) was Soxhlet extracted first with a mixed solvent (ethanol: acetic acid: water = 7: 2: 1) (12 h, twice), followed by ethanol (12 h, twice). After centrifugation, the resulting P3 was dried and then transferred into new tubes for the adsorption experiment. Results (table 5) showed that the adsorption capacity of P3 remained almost unchanged after several recycles, indicating its good reusability.

4 Conclusions

In the present study, TEOS, APTES and PTMOS were selected to synthesize an MIP toward 2, 4-D based on the hydrogen bonding and electrostatic attraction between APTES and 2, 4-D as well as the hydrophobicity and π−π stacking between PTMOS and 2, 4-D. Our results showed that in addition to the molar ratio of the three monomers, the amount of the templates, water and ethanol had great effects on the adsorption performance of the prepared MIPs with the optimum molar ratios of TEOS to APTES to PTMOS, of H2O to the three monomers, and of ethanol to the three monomers being 20:1.5:1, ca. 4, and ca. 4, respectively. The MIP prepared under optimum conditions (P3) had large adsorption capacity and high selectivity. The adsorption of 2, 4-D on P3 obeyed Langmuir model.

References

Steinke J, Sherrington D C, and Dunkin I R 1995 Adv. Polym. Sci. 123 81

Mayes A G and Mosbach 1997 Trends Anal. Chem. 16 321

Andersson L I 2000 J. Chromato. B 745 3

Urraca J L, Carbajo M C, Torralvo M J, Gonzalez-Vazquezc J, Orellanad G M, and Moreno-Bondia C 2008 Biosens. Bioelectron. 24 155

Kriz D, Kempe M, and Mosbach K 1996 Sens. Actuat. B 33 178

Ansell R J, Kriz D, and Mosbach K 1996 Curr. Opin. Biotech. 7 89

Piletsky S A, Alcock S, and Turner A P F 2001 Trends Biotech. 19 9

Tamayo F G, Turiel E, and Martin-Esteban A 2007 J. Chromato. A 1152 32

Wang S, Xu Z X, Fang G Z, Zhang Y, and He J X 2008 J. Sep. Sci. 31 1181

Yeh W M and Ho K C 2005 Analytic. Chimica Acta 542 76

Patel A K, Sharma P S, and Prasad B B 2009 Int. J. Pharma 371 47

Zhu X L, Yang J, Su Q D, Cai J B, and Gao Y 2005 J. Chromato. A 1092 161

Lu Y, Li C X, Wang X D, Sun P C, and Xing X H 2004 J. Chromato. B 804 53

Cacho C, Turiel E, and Perez-Condea C 2009 Talanta 78 1029

Bjarnason B, Chimuka L, and Ramstrom O 1999 Analytic. Chem. 71 2152

Caro E, Marce R M, Cormack P A G, Sherrington D C, and Borrull F 2005 Analytic. Chimica Acta 552 81

Diaz-Garcia M E and Laino R B 2005 Microchimica Acta 149 19

Dickey F H 1949 Proc. Natl. Acad. Sci. 35 227

Hsu C W and Yang M C 2008 Sens. Actuat. B 134 680

Marx S and Liron Z 2001 Chem. Mat. 13 3624

Olwill A, Hughes H, O’Riordain M, and McLoughlin P 2004 Biosens. Bioelectr. 20 1045

Gupta R and Kumar A 2008 Biotech. Adv. 26 533

E Lofgreen J and A Ozin G 2014 Chem. Soc. Rev. 43 911

Yu Y H, Ma J, and Hou Y J 2006 J. Env. Sci. 18 1043

Ayar N, Bilgin B, and Atun G 2008 Chem. Engn. J. 138 239

Liu Y L, He Y H, Jin Y L, Huang Y Y, Liu G Q, and Zhao R 2014 J. Chromato. A 1323 11

Yang W J, Jiao F P, Zhou L, Chen X Q, and Jiang X Y 2013 App. Surf. Sci. 284 692

Jiang G S, Zhong S A, Chen L, Blakey L, and Whitaker A 2011 Rad. Phys. Chem. 80 130

Han D M, Jia W P, and Liang H D 2010 J. Env. Sci. 22 237

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

SUN, Y. Molecularly imprinted polymer for 2, 4-dichlorophenoxyacetic acid prepared by a sol-gel method. J Chem Sci 126, 1005–1011 (2014). https://doi.org/10.1007/s12039-014-0672-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12039-014-0672-2