Abstract

In present research work, pultrusion process is used to develop jute fibre-reinforced polyester (GFRP) composite and experiments have been performed on an indigenously developed pultrusion experimental setup. The developed composite consists of natural jute fibre as reinforcement and unsaturated polyester resin as matrix with hybrid filler containing bagasse fibre, carbon black and calcium carbonate (CaCO3). The effect of weight content of bagasse fibre, carbon black and calcium carbonate on tensile strength of pultruded GFRP composite is evaluated and the optimum hybrid filler composition for maximizing the tensile strength is determined. Different compositions of hybrid filler are prepared by mixing three fillers using Taguchi L9 orthogonal array. Fifteen percent of hybrid filler of different composition by weight was mixed in the unsaturated polyester resin matrix. Taguchi L 9 orthogonal array (OA) has been used to plan the experiments and ANOVA is used for analysing tensile strength. A regression model has also been proposed to evaluate the tensile strength of the composite within 7% error by varying the above fillers weight. A confirmation experiment was performed which gives 73.14 MPa tensile strength of pultruded jute fibre polymer composite at the optimum composition of hybrid filler.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

It has become a challenging task for researchers all over the world to develop engineering materials with high strength to weight ratio from renewable resources. Environmentally-sound natural fibres having several ecological benefits have been used and established as filler materials in manufacturing automobile parts. Reinforcement of natural fibres like sisal, jute, kenaf, coir and palm has been proved to be good in thermoset and thermoplastic matrices [1–4]. Among various natural fibres, jute fibre seems to be the most promising one and it enjoys the right potential for usage in composites due to its high aspect ratio, toughness, tensile strength and good specific modulus. The jute composites have proved to be very cost-effective materials particularly, for building and construction industry, packaging, railway coach interiors and automobile, and storage devices. In the recent years, lot of work has been done to develop new composites by using different fibres and fillers which have improved strength to weight ratio and better mechanical properties. The composite can be developed by judicious selection of matrix and reinforcing material, which will have comparable or even better strength and modulus than the conventional metallic materials. The addition of filler into polymer resin has been proved to be a better alternative for altering the properties of the resultant composites. Particulate fillers are of considerable interest, not only from an economic viewpoint, but also as modifiers especially for the physical properties of the polymer. It has been found by many researchers that addition of particulate fillers such as CaCO3, glass fibre and carbon black into the polymer matrix can alter stiffness and elastic modulus, and also reduce costs of polymer composite [5–8].

Polymer composites have shown an improved performance by addition of particulate filler materials and thus, attracted the interest of researchers. Specific fillers (additives) are added to enhance and modify the quality of composites. Unsaturated polyester resin (UPR) is a widely used thermoset resin due to its ease of processing, moulding and curing characteristics [9]. Borkar et al[10] have shown in their study that the addition of silica and calcium carbonate as filler in the polyester resin matrix reduces the tensile strength in the range of 3–15% for 25–50% fillers in hand layup process.

Sudhir and Chandan [11] have used hybridization of fibre with fillers to investigate the properties of bagasse and jute fibre composites by varying the bagasse loading in composite. Furfuryl alcohol-grafted bagaase fibre loading from 20 to 50% in modified jute fibre epoxy composite shows 43, 52 and 59% improvement in tensile strength, flexural strength and impact strength, respectively. Gupta et al[12] have investigated the effect of bagasse fibre, carbon black and calcium carbonate as filler in glass fibre polyester resin composite. It has been observed that as the bagasse fibre content increases, the tensile strength of pultruded glass fibre reinforced polyester (GFRP) composite increases and tensile strength reduces with the increase in content of CaCO 3 and carbon black. Murty and De [13] investigated the effect of silica and carbon black to the adhesion between jute and natural rubber and found that minimum loading of jute fibre to achieve reinforcement is reduced in the presence of carbon black. It was also found that clay impairs the properties of jute fibre rubber composites. Abdul Khalil et al[14] have shown in their study that the carbon black epoxy composites give better flexural properties than the pure epoxy due to improved adhesion between the carbon black and the epoxy resin. While pultrusion is a very popular method for producing continuous long profile of fibre-reinforced plastic (FRP) composites, but there is very limited work undertaken to study the effect of fillers on tensile strength of pultruded jute composite. Pultruded composite is always associated with high strength and stiffness particularly due to high fibre content, i.e., up to 70%. The advantages of pultrusion over other forms of composite moulding are low capital and operating cost, few finishing and deflashing operations and the better physical properties of product [6,7].

Pultrusion is the combination of two words ‘pull’ and ‘extrusion’ and long continuous fibres (jute fibre, glass fibre, carbon fibre, etc.) were wetted in resins, such as polyester, polyurethane, vinyl ester epoxy resins, etc. are pulled through a shaping die. Fibre is wetted or impregnated with resin bath and passed through the cold die for removal of excess resin and initial shaping of profile. Initially, shaped wetted fibre is passed through a precisely machined and chromed heated steel die which cures the thermosetting resin and the cured pultruded FRP composite profile is pulled by pulling mechanism. Generally, additive and fillers are used in the pultrusion process to solve the production difficulty, enhance the physical and mechanical properties and to reduce the production cost [8]. In the present study, the effects of three fillers i.e., carbon black, bagasse fibre and calcium carbonate are investigated on the tensile strength of pultruded jute-reinforced unsaturated polyester resin composite.

2 Experimental

An indigenously designed and developed pultrusion setup is used for experimental work. The complete pultrusion setup for the pultrusion of test specimen is shown in figure 1.

The whole set up is assembled on an ‘H’ iron section as shown in figure 1 and consists of the following parts:

-

(1)

Preformer: It is a cold die which provides the initial shape to resin impregnated jute fibre; it also squeezes out the extra resin from fibre as shown in figure 1.

-

(2)

Hot die: A stainless steel split die has been used for pultrusion of jute fibre-reinforced composite strip as shown in figure 1. The split die facilitates easy cleaning and maintenance. A protective surface of 25 μm thick hard chrome plating is done to avoid abrasion of die due to the pultrusion of hard filler particles. For heating the die, an electric heater is provided with temperature controller. To measure and control the die temperature, a thermocouple is set at the parting line of the die.

-

(3)

Puller assembly: The puller assembly is shown in figure 1. This assembly consists of four parts:

-

(i)

1 HP AC motor of 3 Φ.

-

(ii)

Arrangement for controlling the speed of pultru(i)sion.

-

(iii)

)(a) AC frequency drive for 1 HP motor and(b) 1:60 speed ratio gear box.

-

(iv)

Pulling rollers: 3 sets.

-

(i)

2.1 Material used

-

(1)

Unsaturated polyester resin is used as a matrix.

-

(2)

Jute yarn of Tex unit of 2200 g km −1 as reinforcement is used in this experiment.

-

(3)

Fillers:

-

(i)

Sugar cane Bagasse fibre (13.0 μm in diameter and 60 ∼30 μm in length),

-

(ii)

carbon black of 50 μm particle size,

-

(iii)

CaCO3 of 100 μm particle size.

-

(i)

-

(4)

Cobalt naphthelate of 6% concentration as accelerator.

-

(5)

Methyl ethyl ketone per oxide as catalyst.

The design parameters as well as their chosen levels were decided as per the pilot tests. It was observed during the pilot experiment that high viscosity of the filler-resin blend produces difficulty in impregnation of jute fibre into resin-filler blends. So, the total filler weight content cannot go beyond certain limit. The various process parameters and selected levels for Taguchi L9 OA experiment are listed in table 1.

The weight fractions of bagasse, carbon black and CaCO 3 were selected as variable process parameters to study the effect of filler on tensile strength of jute fibre-reinforced polyester (JFRP) in pultrusion process. The parameters kept constant during the entire experimentation are: pulling speed, 50 mm min −1; die temperature, 190 ∘C; jute fibre to resin ratio by weight, ∼0.95–0.96.

2.2 Formation of compound

The three fillers i.e., bagasse, carbon black and CaCO 3 in the particulate forms were properly mixed according to the each experiment run given in table 2. After proper mixing of these fillers, nine compositions of hybrid fillers were prepared and from this 15% of the resin weight is mixed in the resin with the help of hand blender to make resin blend. The jute fibre bundles were wetted in this resin blend bath for pultrusion.

Jute fibre bundles of 1500 mm length and 160–165 g in weight are formed manually instead of using several creels to achieve the thickness of composite and to avoid wastage of fibre as the use of creels causes wastage of certain length of fibre at every new start. After the preparation of these bundles, the pulling speed of the pultrusion setup was adjusted to 50 mm min−1 and the hot die temperature was kept 190 ∘C. This setting of the setup is kept constant during the entire experiment. The jute yarn bundles are wetted with resin filler compound by dipping into the resin bath and then pulled against the hot die; thus GFRP composite strip of size 25 × 10 × 1500 mm is formed as shown in figure 2.

2.3 Testing of specimen

After manufacturing the composite strip of 1500 mm length, three specimens for testing the tensile strength were prepared according to the ASTM D638 [15] as shown in figure 3.

Tensile tests were conducted according to ASTM D638 on computerized universal testing machine manufactured by Fine Manufacturing Industry Miraj (Maharashtra), India. The results of tensile test are reported in table 2 and figure 4, which shows the average tensile strength and signal-to-noise (S/N) ratio for each experiment.

A jute fibre-reinforced strip is also pultruded with pure polyester resin and tested for reference. The tensile strength of the jute fibre-reinforced composite with pure resin (resin without filler) was found to be 80.7 MPa.

Figure 5 shows the macro aspect of the tensile ruptured pultruded jute fibre-reinforced specimens. The composite specimen with or without hybrid filler shows brittle fracture and also exhibits that the fracture tips are much non-uniform in case of specimen with hybrid filler as compared to the specimen without filler. During the tensile test, it was observed that as the load increases, some of the fibres pop out from the specimen edge due to deboning from polyester resin matrix causing crack propagation at the fibre/matrix interface. As the fibre content in all the specimens is almost the same, hence, the nature of fracture is also the same. This mechanism of fracture is further supported by the scanning electron microscope (SEM) observations.

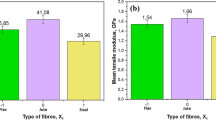

To estimate the fibre content in pultruded jute-reinforced composite laminates, three pieces of 50 g of composite are cut from the pultruded composite for each sample. ASTM 3171 standard [16] was used for acid digestion test and nitric acid is used as a hot digestion medium to dissolve the resin of the composite specimen. The residue is filtered, dried and weighed. The residue was further rinsed with a water jet and filtered by sintered glass filters, so that all the particulate fillers were washed-out and only jute fibre remains as residue, which is further dried and weighed again. The mass loss of fillers and jute fibre were found to be negligible. The result of digestion tests are given in figure 6. It is clear from figure 6 that the weight% of jute fibre in every specimen is nearly the same. The calculated weight% of the each filler in different experiments is given in figure 7.

In the present study, the tensile strength data were analysed to determine the effect of the various design parameters with the help of L9 Taguchi orthogonal array. The experimental results were then transformed into S/N ratio. According to Taguchi, S/N ratio is the measure of the quality characteristics deviating from the desired values. For the analysis of the S/N ratio, quality characteristics can be divided into three categories i.e., lower-the-better, higher-the-better and nominal-the-best. The greater S/N ratio corresponds to better-quality characteristic regardless of the category of the quality characteristic. Therefore, the greatest S/N ratio corresponds to the optimal levels of the process parameters. The tensile strength as response falls under the category of higher-the-better type and the S/N ratio for the same can be computed as [17,18]:

here, Y k (k = 1, 2, …, n) are the values of response under trial conditions with repeated R times.

Statistically significant process parameters were identified by performing analysis of variance (ANOVA) and main effect plots were used to predict the optimal combinations of the process parameters.

3 Results and discussion

The average tensile strength and the S/N ratio values for each parameter at levels L1, L2 and L3 are calculated and are given in table 3. The ANOVAs for S/N ratio and raw data are reported in tables 4 and 5, respectively. The values from table 3 have been plotted in figure 8 giving the variations of tensile strength with levels of the process parameters.

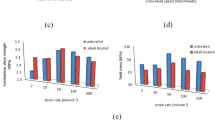

The properties of composites were highly influenced by loading of short bagasse fibre. The effect of fibre ends plays a significant part in the fracture of hybrid composites. Thus, it becomes necessary to optimize the fibre loading for a particular fibre/matrix system so that the best properties can be achieved. It is evident from figure 8a that as the content of bagasse fibre increases from level 1 to level 2, the tensile strength increases as the short bagasse fibre provides interlocking with jute fibre. This could increase the effective stress transfer at the interface and also reduce the voids in the composite. But tensile strength decreases considerably with increase in content of bagasse fibre from level 2 to level 3. This is due to the fact that higher loading of bagasse fibre leads to greater fibrillation, owing to comparatively larger quantity of fibre ends available for crack initiation. This could lower the effective stress transfer at the interface [11]. This can also be understood with SEM images of specimens 1, 5 and 9 shown in figures 9a, b and c, respectively. It is evident from figure 9a that the bagasse fibre is at level 1 in experiment 1, so there is some cavity and fibre pullout. Figure 9b demonstrates sample of experiment 5, where the bagasse is at level 2; there is no fibre pullout and voids but the fibre filament gets damaged due to erosion by carbon black as it is at level 3. The SEM image of sample of experiment 8 shows that there is crack initiation due to hard particles of CaCO 3 and more number of bagasse fibre ends.

Figure 8b shows that as the carbon black content increases in the composite, the tensile strength decreases. It is seen in SEM image that the distribution of carbon black filler becomes relatively non-uniform as the carbon black content increases. However, lower carbon black content in the composite shows better carbon black agglomerates dispersion as in figure 9a. The tensile strength of the composite decreases with increase of the carbon black content because the hard particles of carbon black during curing in pultrusion process have damaged some of jute fibre filament. This phenomenon can be seen in SEM image of specimen no. 5 in figure 9c. It is also observed that due to the discontinuity in the matrix produced by carbon black agglomerates causes the stress concentration and hence, decreases the tensile strength of composite.

The tensile strength variation of composite with CaCO 3 content is shown in figure 8c. The tensile strength of the composite reduces as the weight content of CaCO 3 increases because the particulates of filler practically act as crack initiator and this phenomenon is more pronounced when there is a possibility of clustering of CaCO 3 particles. The SEM image shows that the particles of CaCO 3 get dissolved partially, but as the CaCO 3 content increases the undissolved particles of CaCO 3 also increase and cause crack initiation in the composite as shown in figures 9b and c. It was observed in the present study that as the content of CaCO 3 increases, the shrinkage of composite strip was less and the dimensional stability was better.

It was observed in the present work that the dimensional stability of the pultruded profile is much better as compared with other methods like hand layup, resin transfer molding (RTM) or compression moulding. It was also found that the tensile strength of the pultruded jute fibre polyester resin composite was on the higher side as compared with hand layup or vacuum compression moulding with same fibre content. Desh et al[19] have reported in their study that jute polyester resin composite prepared by using solution impregnation and hot curing methods with 60% fibre loading was having highest tensile strength. SEM micrographs of the tensile fracture of the pultruded composite show clearly that the polyester resin has penetrated the jute fibres used as reinforcement material and surrounded each and every fibre causing very less void formation in composite as compared with jute reinforced polyester resin composite manufactured by other methods like hand layup process, resin transfer moulding, vacuum-assisted resin transfer moulding, compression moulding, etc. as reported by different researchers [20–22].

3.1 Calculation of optimum tensile strength

The optimum value of tensile strength was predicted at the selected levels of significant parameters A2, B1 and C1 (tables 3 and 5). The estimated mean of the response, i.e., tensile strength was determined as in equation (1):

where T avg, overall mean of tensile strength = 58.78 MPa (table 2); T A2= average tensile strength at the second level of bagasse content (A2) = 61.25 MPa; T B1= average tensile strength at the first level of carbon black content (B1) = 66.86 MPa; T C1= average tensile strength at the first level of CaCO 3 (C1) = 62.30 MPa.

The following equations were used for calculating 95% confidence interval (CI) of confirmation experiments (CI CE) and 95% confidence interval of population (CI pop):

and

where F β (1, f error) is the F ratio at the confidence level of (1 − β) against degree of freedom 1 and error degree of freedom (DOF) f error, N the total number of results = 27 (treatment = 9, repetition = 3), R the sample size for confirmation experiments = 3, V error the error variance = 1.02 (table 5), and f error= error DOF = 20 (table 5).

So, CI CE=± 5.6 and CI pop=± 0.96.

The predicted optimal range for a confirmation run (three repetitions) is: Mean tensile strength −CI CE < tensile strength < mean tensile strength + CI CE: 67.25 < tensile strength < 78.45. The predicted optimal range for the population is as follows: mean tensile strength −CIpop < tensile strength < mean tensile strength +CIpop: 71.89 < tensile strength < 73.81.

The optimal composition of hybrid filler for the predicted ranges of tensile strength is as follows:

- ᅟ:

-

Second level of bagasse content (A2) = 25 g,

- ᅟ:

-

First level of carbon black content (B1) = 5 g,

- ᅟ:

-

First level of CaCO 3 (C1) = 25 g.

3.2 Confirmation experiments

All fillers are mixed properly according to the optimum level i.e., bagaase at 2nd level (A2), carbon black 1st level (B2) and CaCO 3 1st level (C1), and 15% of the resin weight of this hybrid filler was mixed in resin. Then keeping the resin and fibre ratio and other process parameters constant, the jute fibre composite strip was pultruded. Three specimens were cut from this strip and tensile tests were performed on universal testing machine. The results are given in table 6.

The average tensile strength of test was found to be 73.14 MPa, which was within the confidence interval of the predicated optima of tensile strength.

3.3 Regression analysis

The mathematical model for weight content in grams of bagasse fibre, carbon black and calcium carbonate in the composite as process parameters is obtained from regression analysis using MINITAB 14 statistical software to predict the tensile strength of jute-reinforced composite. Table 7 shows the regression analysis model.

The regression equation is

where a = bagasse fibre (g), b = carbon black (g) and c = CaCO 3 (g). The difference between predicted value of tensile strength by regression model and experimental value of confirmation test at optimal level is shown in table 8.

In this study, the results obtained for final tensile strength are in good agreement with regression model (R 2 > 0.80) as R 2 is value of the correlation coefficient and should be between 0.8 and 1 in multiple linear regression analysis.

4 Conclusions

The effect of three fillers bagasse fibre, carbon black and CaCO 3 on tensile strength of the jute fibre-reinforced composite was investigated. The following conclusions can be drawn from the study:

-

(i)

The optimum composition of hybrid filler contains: bagasse fibre = 25 g, carbon black = 5 g, CaCO 3= 25 g.

-

(ii)

The tensile strength at the optimum composition of hybrid filler with 15% weight content of filler in resin is 73.12 MPa.

-

(iii)

Experiments also exhibit that within the testing levels the tensile strength decreases with the increasing contents of carbon black and CaCO 3.

-

(iv)

The regression model developed to predict the tensile strength of composite with variation of bagasse fibre, carbon black and CaCO 3 content is in good agreement with the experimental results. The estimated tensile strength at optimum level was found to be 68.74MPa.

-

(v)

The estimated optimal range for tensile strength is CI pop: 71.89 < tensile strength (MPa) < 73.81.

-

(vi)

The 95% confidence interval of predicted mean for tensile strength is 67.25 < tensile strength (MPa) < 78.45.

References

Joseph K, Thomas S and Pavithran C 1996 Polymer 37 5139

Varma I K, Ananthakrishnan S R and Krishnamoorthi S 1989 Composites 20 383

Geethamma V G, Thomas Mathew K, Lakshminarayanan R and Thomas S 1998 Polymer 39 1483

Sreekala M S, Kumaran M G and Thomas S 1997 J. Appl. Polym. Sci. 66 8

Alamri H and Low I M 2012 Polym. Test. 31 810

Zhou S S, Wu L M, Sun J and Shen W 2002 Prog. Org. Coat. 45 33

Baral D, De P P and Nando G B 1999 Polym. Degrad. Stab. 65 47

Sare I R, Mardel J I and Hill A J 2001 Wear 250 1

Katz H S and Milewskin J V 1978 Handbook of fillers and reinforcements for plastics 1st edn (New York: Van Nostrand Reinhold)

Borkar S P, Senthil Kumar V and Mantha S S 2007 Indian J. Fibre Text. Res. 32 251

Sudhir S K and Datta Chandan 2009, BioResources 4 1455

Gupta A, Singh H and Walia R S 2015 Indian J. Eng. Mater. Sci. 22 62

Murty V M and De S K 1982 J. Appl. Polym. Sci. 27 4611

Khalil H A, Firoozian P, Bakare I O, Akil H M and Noor A M 2010 Mater. Des. 31 3419

D638 2010 ASTM International, Standard test method for tensile properties of plastics

D3171-99 2004 ASTM International, Standard test methods for constituent content of composite materials

Ross P J 1998 Taguchi techniques for quality engineering (New York: McGraw-Hill Book Company).

Walia R S, Shan H S and Kumar P 2006 Mater. Manuf. Process. 21 907

Dash B N et al 1999, Polym. Compos. 20 62

O’Dell and Jane L 1997 Natural fibres in resin transfer molded composites Fourth International Conference on Woodfibre-plastic composites

Saravana B D and Mohan K G C 2013 Proc. World Congress Eng. 3 2091

Naveenkumar R et al 2015, Int. J. Appl. Sci. Eng. Res. 4 250

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

GUPTA, A., SINGH, H. & WALIA, R.S. Hybrid filler composition optimization for tensile strength of jute fibre-reinforced polymer composite. Bull Mater Sci 39, 1223–1231 (2016). https://doi.org/10.1007/s12034-016-1248-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-016-1248-1