Abstract

In the past decade, interest in the production of recombinant pharmaceutical proteins in plants has tremendously progressed because plants do not harbor mammalian viruses, are economically competitive, easily scalable, and capable of carrying out complex post-translational modifications required for recombinant pharmaceutical proteins. Mucuna bracteata is an essential perennial cover crop species widely planted as an underground cover in oil palm and rubber plantations. As a legume, they have high biomass, thrive in its habitat, and can fix nitrogen. Thus, M. bracteata is a cost-efficient crop that shows ideal characteristics as a platform for mass production of recombinant protein. In this study, we established a new platform for the transient production of a recombinant protein in M. bracteata via vacuum-assisted agro-infiltration. Five-week-old M. bracteata plants were vacuum infiltrated with Agrobacterium tumefaciens harboring a plasmid that encodes for an anti-toxoplasma immunoglobulin (IgG) under different parameters, including trifoliate leaf positional effects, days to harvest post-infiltration, and the Agrobacterium strain used. Our results showed that vacuum infiltration of M. bracteata plant with A. tumefaciens strain GV3101 produced the highest concentration of heterologous protein in its bottom trifoliate leaf at 2 days post-infiltration. The purified anti-toxoplasma IgG was then analyzed using Western blot and ELISA. It was demonstrated that, while structural heterogeneity existed in the purified anti-toxoplasma IgG from M. bracteata, its transient expression level was two-fold higher than the model platform, Nicotiana benthamiana. This study has laid the foundation towards establishing M. bracteata as a potential platform for the production of recombinant pharmaceutical protein.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Plant molecular farming using genetically engineered plants has become a new strategy to mass-produce high-value recombinant pharmaceutical proteins, such as monoclonal antibodies, vaccines, and enzymes. Although most of the clinically available proteins and drugs are derived from mammalian cells, microbes, and yeast, the long period of scaling up and high costs of the existing production systems to meet the high demand of biopharmaceuticals are the limiting factors for the manufacturing capacity of these conventional cell-based expression systems. Furthermore, the use of mammalian cells as a production platform also raises concerns about its safety. Although microbial hosts offer a lower production cost than mammalian cells, they may not be suitable for post-translational processing, which affects the biological properties of the processed proteins [1].

In comparison, plants can produce complex functional proteins with therapeutic activity, such as human serum proteins, growth regulators, antibodies, vaccines, and hormones, due to their ability to perform post-translational modifications that make these recombinant proteins fold correctly and maintain their structural and functional integrity [2]. Moreover, plant-based systems offer more straightforward growth requirements and little to no risk of contamination with human pathogens compared to cultured mammalian cells [3]. Several plant-based production platforms for recombinant proteins, including transgenic plants (using both stable and transient expression), hydroponic culture [4], and in vitro culture systems, such as cell suspensions and hairy roots, have been developed [5]. The first plant-made recombinant pharmaceutical protein that was approved and commercialized for human use since 2012 was ELELYSO (recombinant glucocerebrosidase) in cultures of carrot cells for the treatment of Gaucher’s disease [6]. Numerous plant-derived therapeutic proteins are now in various stages of clinical phases such as the H5 flu vaccines in tobacco, interferon alpha in duckweed to treat hepatitis C, and recombinant lactoferrin in rice to treat inflammatory bowel disease [7].

Despite the progress, several challenges need to be addressed to achieve comparable efficiency as the mammalian system. The relatively low transformation frequency poses one of the main challenges in promoting plants as a significant recombinant protein production system. Inconsistent expression levels, long lead time, and disputable biosafety issues are also affecting the use of plant systems as biofactories for recombinant proteins. The production of recombinant protein through transient expression is becoming the preferred method compared to stable transgenic lines [8]. Several other strategies to enhance the production of plant-based recombinant proteins include increasing the efficiency of protein extraction in downstream processing [9], protein engineering [10], reducing proteolytic activity that degrades recombinant protein [11], and rhizosecretion in hydroponic culture [4].

The selection of plant host is an equally important strategy because each species harbors unique biological characteristics that can influence recombinant protein expression and downstream processing [12]. For example, lettuce is a leafy crop with high biomass. The organized structure of the lettuce head makes it more efficient for agro-infiltration compared to the unorganized leaves of tobacco [13]. However, since tobacco is a non-food and feed plant, the ethical, environmental, and biosafety issues could be alleviated. On the other hand, the disadvantage of tobacco is the generation of heterogeneous N-glycan structures compared to that of alfalfa [14]. Based on these findings, the selection of host plants for therapeutic protein production should be carefully determined to achieve the full potential of the system and also to avoid any undue risks [15].

We selected Mucuna bracteata as the platform for the production of mouse-human chimeric immunoglobulin (IgG) against Toxoplasma gondii. M. bracteata belongs to the family Fabaceae (Leguminosae). It is an aggressive vine that grows and spreads fast with high biomass that climbs on the canopy of forest trees [16]. Leaves from the Mucuna species, particularly in Mucuna pruriens, have been reported to contain high protein content compared to other leguminous plants, such as the butterfly pea (Centrosema pubescens), flamboyant flower (Delonix regia), Bauhinia tomentosa, and coast wattle (Acacia auriculiformis) [17]. It has become the cover crop of choice for rubber and oil palm plantations in South India and Southeast Asia due to its vigorous growth and ability to tolerate drought and shade conditions [18, 19]. Additionally, M. bracteata is a non-food, non-feed crop and is unable to produce seeds outside of its native climatic region [20]. This will significantly reduce the chances of food chain contamination.

In this study, we have established a transient transformation protocol for M. bracteata via a vacuum-assisted agro-infiltration method to express mouse-human chimeric immunoglobulin (IgG) against T. gondii. This would also be the first report on the transient expression of the heterogeneous protein in M. bracteata.

Materials and Methods

Plasmid Construction

The heavy chain and light chain sequences of anti-toxoplasma antibody (GenBank: JN104602.1) from the plasmids pTRAkc-Hc and pTRAkc-Lc [21], respectively, were digested with EcoRI and BamHI and ligated into the rfp region of pTRA plant expression vector, pTRAkc-rfp-ERH, to construct pTRAkcHcTg130 and pTRAkcLcTg130. pTRAkcHcTg130 was then digested with SphI and PmeI, whereas pTRAkcLcTg130 was digested with AscI and SphI. The larger fragments from both restriction digests were ligated to generate a tandem heavy chain and light chain expression plasmid, pTRAkcHcLcTg130 (Fig. 1). The heavy chain fragment carries C-terminal KDEL as an endoplasmic reticulum retention signal. Numerous studies reported that the inclusion of KDEL localization signal will retain the protein in endoplasmic reticulum [22,23,24]. pTRAkcHcLcTg130 was maintained in NEB® 5-alpha F′ Iq E. coli (New England Biolabs, USA) and introduced into Agrobacterium tumefaciens strains GV3101, EHA105, and LBA4404 by heat shock method. The transformants were stored as a 20% (v/v) glycerol suspension at − 80 °C.

Schematic view of anti-toxoplasma IgG plant expression cassettes (pTRAkcHcLcTg130). LB, left border; pAnos’, nopaline synthase gene polyadenylation signal; nptII, neomycin phosphotransferanse II; Pnos, nopaline synthase promoter; SAR, scaffold attachment region of the tobacco RB7 gene (GenBank U67919); P35SS, CaMV 35S promoter with duplicated transcriptional enhancer; CHS, chalcone synthase 5′-untranslated region; LPH, codon-optimized murine signal peptide of mAB24; Lc, light chain sequence of anti-toxoplasma IgG; pA35S, CaMV 35S polyadenylation signal; Hc, heavy chain sequence of anti-toxoplasma IgG; KDEL, endoplasmic reticulum retention signal; RB, right border

M. bracteata Germination and Cultivation

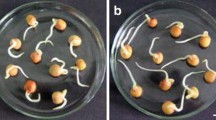

The seeds of M. bracteata were germinated according to the protocol by Aziz et al. [25]. Briefly, the seeds were cleaned thoroughly by rinsing twice with tap water followed by distilled water for 10 min and dried at room temperature for 2 days. The dried seeds were then scarified in concentrated sulfuric acid for 30 min and rinsed five times with sterile distilled water (sdH2O) prior to imbibition in sdH2O for 6 h in dark condition at room temperature. The seeds were then laid out on double layers of cotton roll moistened with 10 mL of sdH2O supplemented with 0.1% (w/v) activated charcoal and maintained in dark condition at room temperature. Five-day-old germinated seedlings were transferred to polybags containing garden soil in a greenhouse at the University of Malaya, Malaysia. The seedlings were fully covered with perforated transparent plastic bags before gradually removed after 2 weeks of culture. The plants were watered twice a day.

Preparation of Agrobacterium Strains Harboring pTRAkcHcLcTg130 for Infiltration

A. tumefaciens GV3101 harboring pTRAkcHcLcTg130 (100 µL) was cultured in 50 mL of YEB supplemented with 100 µg/mL of carbenicillin, 50 µg/mL of rifampicin, and 50 µg/mL of G418 disulfate, whereas A. tumefaciens strains EHA105 or LBA4404 harboring pTRAkcHcLcTg130 was cultured in 50 mL of YEB supplemented with 50 µg/mL of carbenicillin and 50 µg/mL of rifampicin in a 250 mL flask. The cultures were incubated at 28 °C in dark condition and agitated at 120 rpm for overnight. These cultures with an OD600 of 0.03 were scaled up to 500 mL in fresh YEB medium containing respective concentration of antibiotics and maintained under similar culture conditions. The cultures were harvested after reaching OD600 of 1.9 by centrifugation at 7000 rpm for 4 min at room temperature. The pellet was resuspended in 1 L of infiltration buffer (10 mM MgCl2, 10 mM MES, pH 5.7) supplemented with 150 µM acetosyringone and the OD600 was adjusted to about 1.0. The culture was incubated at 28 °C without agitation for at least 1 h prior to infiltration.

Vacuum Infiltration of M. bracteata

Five-week-old M. bracteata with three trifoliate leaves were vacuum infiltrated with 1 L of infiltration buffer containing A. tumefaciens strains GV3101, EHA 105, or LBA4404 harboring pTRAkcHcLcTg130 for 30 min (Fig. 2). Vacuum time was recorded once the pressure reached − 25 inches of Hg/− 0.84 BAR (100 × kPa). The bottom, intermediate , and top trifoliate leaves were harvested at 2, 4, and 6 days post-infiltration. The leaves were snap frozen in liquid nitrogen and kept at − 80 °C until use. Each parameter consisted of three individual plants and the experiment was repeated three times. Non-infiltrated plants were considered as negative control.

Setup for vacuum-assisted agro-infiltration of M. bracteata. a Trifoliate leaves position on a 5-week-old M. bracteata plant. b Five-week-old M. bracteata plant was submerged in 1 L of infiltration buffer containing Agrobacterium suspension and vacuum was applied for 30 min. c Five-week-old M. bracteata with three trifoliate leaves was selected for infiltration (Bar = 1 cm). d Non-infiltrated leaflet of M. bracteata (Bar = 1 cm). e Infiltrated leaflet of M. bracteata as indicated by the dark green patches (Bar = 1 cm)

Syringe Infiltration of N. benthamiana

The seeds of N. benthamiana were sowed directly into polybags containing garden soil in a greenhouse at the University of Malaya, Malaysia. The sixth leaf from above of 40-day-old N. benthamiana was syringe infiltrated according to the optimized method of Leuzinger et al. [26]. The A. tumafeciens strain GV3101 harboring pTRAkcHcLcTg130 suspended in infiltration buffer (OD600 = ~ 1.0) was injected into the leaf intercellular space with a syringe without a needle until the entire leaf was infiltrated. Non-infiltrated plants were considered as negative control. The leaves were harvested after 6 days post-infiltration, snap frozen in liquid nitrogen, and kept at −80 °C until use.

Protein Extraction

Lyophilized leaves were pulverized to fine powder in the presence of liquid nitrogen. Total soluble protein (TSP) was extracted from the finely ground powder in two volumes of phosphate buffered saline (PBS) or PBS supplemented with 0.5% (v/v) Triton X-100, 5% (v/v) glycerol, 1% (w/v) polyvinylpolypyrrolidone (PVPP), and 2% (w/v) polyvinylpyrrolidone (PVP) K30 (NEB buffer). The crude extract was centrifuged at 13,000 rpm for 20 min at 4 °C. The supernatant was centrifuged again for 20 min at 4 °C. TSP in the supernatant was quantified through Bradford assay.

Protein Purification and Quantification

Anti-toxoplasma IgG protein was purified from TSP (400 µg) using NAb Protein A spin column (Cat number: 89952) (Thermo Scientific, MA, USA) according to the manufacturer’s instructions. The concentration of anti-toxoplasmosis protein was quantified by measuring the absorbance at 280 nm using a nanophotometer (Implen, Munchen, Germany) and quantified based on the following formula:

where C prot is the protein concentration (mg/mL), Abs. 280 is the absorbance (AU) of proteins, A280 factor is the molecular weightprot/molar extinction coefficient (M−1 * cm−1) prot., Lid factor is the dependent on the used dilution lid.

In this calculation, the A280 factor was 0.71 for IgG.

A280 factor | 0.71 |

|---|---|

Molecular weight (g/mol) | 150,000 |

Molar extinction coefficient (M−1*cm−1) | 210,000 |

The lid factor which was dependent on the used dilution lid was 10. A mixture of 400 µL binding buffer and 40 µL neutralization buffer was used as a blank for the measurements.

Concentrating Anti-toxoplasma IgG and Buffer Exchange

The eluate fractions from the NAb Protein A spin columns were concentrated and buffer exchanged with PBS using Pierce Protein Concentrator, PES 3 K (Thermo Scientific, MA, USA) according to the manufacturer’s instructions. For both procedures, the samples were centrifuged at 5000×g at 25 °C until the retentate volume was less than 10% of the original volume.

Western Blot Analysis

The purified protein samples were boiled at 100 °C for 5 min in a 1:1 ratio of samples and 2× loading sample buffer (100 mM Tris–HCl, pH 6.8), 20% (w/v) glycerol, 4% (w/v) SDS, 0.05% (w/v) bromophenol blue, 0.25% (v/v) 2-mercaptoethanol. The samples were centrifuged at 17,000×g for 2 min prior to loading on 4% stacking and 12% separating SDS–polyacrylamide gel (SDS-PAGE) electrophoresis under reducing conditions and blotted onto nitrocellulose membrane. The membrane was blocked for an hour with 5% (w/v) bovine serum albumin (BSA). The binding of the primary antibody was detected using the monoclonal anti-human IgG Fab fragment antibody (Cat number: ab771) (Abcam, Cambridge, UK) diluted 1:1,000, whereas the binding of the secondary antibody was detected using a goat anti-mouse IgG Fc conjugated to horseradish peroxidase (HRP) (Cat number: ab20043) (Abcam, Cambridge, UK) diluted 1:5,000. The membrane was washed three times with TBS containing 0.1% (v/v) Tween-20, developed using the WesternBright™ Quantum Chemiluminescent HRP Substrate (Advansta, CA, USA) kit and imaged using Bio-Rad Chemidoc MP system (Bio-Rad, CA, USA).

ELISA

The functionality of the purified and concentrated anti-toxoplasmosis protein from M. bracteata and N. benthamiana was analyzed using Human Anti-Toxoplasma gondii IgG ELISA Kit (Abcam, Cambridge, UK). All samples were diluted with IgG Sample Diluent at 1:100. Each standard and diluted sample (100 µL) were loaded into appropriate wells. One well was left for substrate blank purpose. The content from each well was aspirated after incubated at 37 °C for 1 h and the wells were washed three times with 300 µL of 1× washing solution. After the last wash, the remaining 1× washing solution was removed by aspiration. The plate was inverted and blotted against clean paper towels to remove excess liquid. Toxoplasma gondii anti-IgG HRP conjugate (100 µL) was added into all wells except for the blank well. The wells were incubated at room temperature for 30 min in darkness. Washing step was repeated before adding 100 µL of TMB substrate solution into all wells and incubated at room temperature for 15 min in the dark. The reaction was stopped by adding 100 µL of stop solution. The absorbance was measured at 450 nm within 30 min after adding stop solution using microplate reader (Tecan, Männerdorf, Switzerland).

Results and Discussion

Vacuum-Assisted Infiltration is Necessary for M. bracteata

Syringe infiltration and vacuum-assisted infiltration are important transient transformation methods widely used in many plant genetic engineering studies [26]. Syringe infiltration is normally used in bench scale infiltration by injecting a small volume of Agrobacterium suspension into the intercellular space in leaf. On the other hand, vacuum-assisted infiltration is commonly applied for large scale infiltration. In vacuum-assisted infiltration, plant tissue is submerged in Agrobacterium suspension, followed by vacuum application to permeate Agrobacterium suspension into the intercellular space in leaf. This method has been used for different types of plant tissues such as the seeds of pea [27], nodal explants of Withania somnifera [28], whole plant of Nicotiana benthamiana [29], and detached sunflower leaves [30]. While syringe infiltration allows versatility in the experimental design, such as requiring only a small volume of culture to infiltrate several Agrobacterium cultures that may harbor different constructs on separate segments of the same leaf [31, 32], the vacuum-assisted infiltration method appears to be dependent on the type of leaf or plant species. This was in agreement with our unsuccessful attempt to syringe infiltrate the leaves of M. bracteata. The leaves of M. bracteata are brittle and easily damaged when too much pressure was applied during syringe infiltration. Even with extreme caution during the application of pressure, the infiltrated area did not expand beyond the syringe nozzle area. This could be attributed to the leaf structure and architecture [31]. King et al. [33] reported similar difficulties for legume soybean leaves. The authors found that agro-infiltration could only be achieved with the combination of sonication, reducing agent, and vacuum treatment. Our preliminary test on vacuum infiltration of M. bracteata plant with Agrobacterium suspension has shown promising results as indicated by the presence of dark green patches (Fig. 2b–e). Even though these patches were erratic, vacuum-assisted infiltration was more convenient and feasible method for routine study in M. bracteata compared to arduous syringe infiltration. Thus, this study aimed to establish an efficient transient transformation method using vacuum-assisted infiltration for M. bracteata.

Trifoliate Leaves Position Affects the Expression Level of Anti-toxoplasma IgG

Five-week-old M. bracteata plant typically has three sets of trifoliate leaves. The oldest trifoliate leaf is located at the bottom of the stem, and the leaves become increasingly younger towards the top (Fig. 2a). This indirectly allowed us to study the effect of leaf age on the transient expression of anti-toxoplasma IgG in M. bracteata. Various studies have shown that the expression levels of heterologous protein varied according to leaf age and position [32, 34,35,36]. Since M. bracteata starts to branch out after 6 weeks of planting, 5-week-old M. bracteata was used in this study to avoid incoherent and inconclusive comparisons between individuals.

In this study, the bottom trifoliate leaves of 5-week-old M. bracteata produced ~ 1.5-fold higher concentration of anti-toxoplasma IgG (314.9 ± 49.8 µg/g fresh weight leaf) compared to the trifoliate leaves at other positions (Fig. 3). There is no significant difference between the intermediate (199.0 ± 31.2 µg/g fresh weight leaf) and the top position (191.6 ± 24.5 µg/g fresh weight leaf). The bottom trifoliate leaf is the first true leaf in M. bracteata. Wroblewski et al. [31] demonstrated that a higher level of heterologous protein expression was observed in the first true leaves of lettuce, tomato, and Arabidopsis than the leaves produced later. However, tobacco exhibited the highest transient heterologous protein expression either in intermediate or top leaves, where rapid cell expansion with high levels of protein synthesis occurred [34, 36]. It is well established that transient heterologous protein expression pattern was species-dependent [34, 37].

Different leaf positions might produce different levels of protein expression due to the general changes in leaf physiology [32]. Younger leaves have thin leaf lamina that could impair infiltration efficiency [37], which led to variable expression levels due to uneven Agrobacterium infiltration [38]. This was corroborated by a study in potato plants conducted by Bhaskar et al. [39]. The authors found that the infiltration efficiency in younger plants (3–4-week-old) was significantly lower compared to older plants (5–6-week-old). Taken together, anti-toxoplasma IgG was extracted only from the bottom trifoliate leaf of a 5-week-old M. bracteata plant in our subsequent experiments.

Transient Expression Post-infiltration Diminished Over Time

The concentrations of anti-toxoplasma IgG at 2 days (271.68 ± 39.2 µg/g fresh weight leaf) and 4 days (234.78 ± 20.6 µg/g fresh weight leaf) post-infiltration were significantly higher compared to 6 days post-infiltration (155.8 ± 16.3 µg/g fresh weight leaf; Fig. 4). This finding was similar to other plants such as onion epidermis [40], rose petal [41], and tobacco [42], where transient heterologous protein expression decreased significantly after 2–3 days post-infiltration.

The diminished transient expression of post-infiltration is often associated with an active endogenous RNA silencing process and proteolytic degradation in plant cells [43, 44]. A study conducted by Wydro et al. [32] showed that the co-expression of RNA silencing suppressor led to a continuous increase in the expression of the heterologous protein. Instead of decreasing significantly after 2–3 days post-infiltration, transient expression continued to accumulate and achieved the highest peak of expression after 6–7 days post-infiltration. However, a shortened harvesting time and production cycle could decrease the downstream costs for a higher overall annual output [34], indicating the importance of cost–benefit analysis.

Many other recent studies have focused on the proteolytic degradation of plant-made pharmaceutical proteins, which remains a significant hurdle in plant molecular farming [45,46,47,48]. Several hundreds of endogenous proteases that may directly or indirectly involve in the proteolysis event ex planta or in planta have been identified in plants genome [49]. Future studies should aim to identify specific proteases that are responsible for the degradation of a given recombinant protein [46, 49]. These proteases activities may lead to partial or complete hydrolysis of the recombinant antibody; thus, affecting the final yield of intact recombinant proteins in plant systems [50]. Among the strategies that have been described to elude unintended proteolysis in plant systems include the downregulation of host protease expression [11, 46], the removal of protease-susceptible sites by targeted mutagenesis [51, 52], and co-expression of protease inhibitors [47].

Infiltration with A. tumefaciens Strain GV3101 Produced the Highest Concentration of Anti-toxoplasma IgG

A. tumefaciens strains GV3101, EHA105, and LBA4404 were used in this study to determine their effects on transient heterologous protein expression in M. bracteata. Both GV3101 (nopaline type) and EHA105 (succinamopine type) contain a C58 chromosomal background, whereas LBA4404 was octopine TiAch5 [53].

We found that the highest concentration of anti-toxoplasma IgG was observed when M. bracteata was infiltrated with A. tumefaciens strain GV3101 (368.92 ± 76.6 µg/g fresh weight leaf; Fig. 5). In contrast, the concentration of anti-toxoplasma IgG decreased by three-fold when M. bracteata was infiltrated with either A. tumefaciens strain EHA105 (119.90 ± 23.9 µg/g fresh weight leaf) or LBA4404 (112.46 ± 22.9 µg/g fresh weight leaf). This study suggested that Agrobacterium strains containing different chromosomal backgrounds might affect the efficiency of T-DNA delivery [54].

Other studies reported that the effectiveness of an Agrobacterium strain to infect and deliver the targeted genes into host plants was not only species- but also genotype-dependent [31, 55]. For example, EHA105 was more efficient in infecting reed compared to LBA4404 and GV3101 [56]. However, GV3101 produced higher transformation efficiency than EHA105, MP90, and AGL1 in tomato cultivar Micro-Tom [57]. Meanwhile, switchgrass transformation was most efficient when AGL1 was used compared to GV3101 and C58 [58]. In another study, Yasmin and Debener [41] reported no significant differences in the transformation efficiency between GV3101, EHA105, C58C1, and 80.1 infections on various rose genotypes.

The condition of the plant tissue post-infiltration is also an important factor in determining the most suitable Agrobacterium strain for infection. Unlike most studies, there was no visible necrotic lesion in the infiltrated M. bracteata leaves from any of the Agrobacterium strains tested. Certain Agrobacterium strain resulted in a higher mortality rate among the infected explants [57]. Transformation of the plant tissue using Agrobacterium may trigger innate defense response, which could lead to necrotic reaction and plant cell death [59, 60]. These were often observed in banana transformation, where rapid necrotic reaction led to a high rate of explants mortality and impeded the overall progress in banana transformation via Agrobacterium-mediated approach [61, 62].

Inclusion of Certain Components in the Extraction Buffer Enhanced the Purification of Anti-toxoplasma IgG

We evaluated two different extraction buffers, namely PBS and NEB (PBS supplemented with 0.5% (v/v) Triton X-100, 5% (v/v) glycerol, 1% (w/v) PVPP, and 2% (w/v) PVP K30), for crude protein extraction from M. bracteata leaves. We found that the concentration of anti-toxoplasma IgG obtained from the extraction using NEB (383.19 ± 22.1 µg/g fresh weight leaf) is two-fold higher than the extraction using PBS (181.14 ± 31.9 µg/g fresh weight leaf; Fig. 6).

We noticed that the crude protein extracted from M. bracteata using PBS often yielded a reddish-brown crude extract that sometimes precipitated after half an hour even when frozen or maintained at 4 °C. This might be due to the effect of “enzymic browning” where phenolic compounds formed irreversible covalent linkages with proteins, resulting in hydrophobic products that were more susceptible to protein aggregation and precipitation [63, 64]. In this study, we supplemented the protein extraction buffer with PVPP as a phenolic binding agent. PVPP is insoluble and can be easily removed from the extracts by centrifugation. It has been shown that the protein quality and quantity were enhanced when PVPP was used during protein extraction from recalcitrant plants [64,65,66]. In addition, water-soluble PVP was also incorporated to protect the extracted crude protein from unnecessary reaction with free phenolic. Indeed, crude protein extraction from M. bracteata using NEB produced a green protein extract that did not precipitate. These observations suggested that the “enzymic browning” effect in M. bracteata crude protein extract could be reduced by incorporating phenolic adsorbents in the extraction buffer to minimize protein–phenolic unspecific binding.

An additional component, such as detergent (Triton X-100), was included to disrupt cellular membranes and maximize protein release into the extraction buffer during protein extraction. Triton X-100 is a mild non-ionic detergent with a low tendency to denature proteins and break up protein complexes [67]. Another component that was added into the NEB was glycerol to stabilize the extracted proteins. Glycerol is one of the most widely used polyols and is routinely used in protein refolding and crystallization [68]. Glycerol prevents protein aggregation by inhibiting protein unfolding and stabilizing aggregation-prone intermediates [68].

M. bracteata Produced At Least Two-Fold Higher Concentration of Anti-toxoplasma IgG than N. benthamiana

N. benthamiana is widely used as a model plant for the production of plant-derived heterologous protein due to its high susceptibility to Agrobacterium infection and high leaf to plant biomass ratio [69, 70]. In this study, we evaluated the production of anti-toxoplasma IgG using optimized methods in N. benthamiana [26] and M. bracteata. We found that M. bracteata consistently produced at least a two-fold higher concentration of anti-toxoplasma IgG (591.10 ± 52.5 µg/g fresh weight leaf) compared to N. benthamiana (276.61 ± 9.52 µg/g fresh weight leaf; Fig. 7). This antibody yield from M. bracteata was also comparatively higher than previous reports using N. benthamiana as a transient-based expression system [71, 72]. However, numerous studies have demonstrated that transient expression levels varied not only between species but even among the genotypes of the same species [30, 31, 37, 40, 41].

It is noteworthy that the parent plasmids, namely pTRAkc-Hc and pTRAkc-Lc, used in the construction of pTRAkcHcLcTg130 in this study were used by Lim et al. [21] to transiently express anti-toxoplasma IgG through the co-transformation method in N. benthamiana. The authors obtained anti-toxoplasma IgG at the concentrations of 33–72 µg/g fresh weight leaf. The higher antibody yield achieved in this study might be due to the usage of antibody tandem constructs pTRAkcHcLcTg130. Co-transformation of separate constructs often yields lower expression level than tandem constructs due to independent integration into the host genome in co-transformation [73].

Anti-toxoplasma IgG in M. bracteata Showed Structural Heterogeneity But Retained Its Biological Activity

Anti-toxoplasma IgG that was extracted and purified from M. bracteata and N. benthamiana were analyzed via Western blot using an anti-human IgG Fab fragment antibody. A band with an estimated molecular mass of ~ 58 kDa was detected in both infiltrated plants (Fig. 8a, b). In contrast, the estimated molecular mass based on the amino acid sequence of anti-toxoplasma IgG is ~ 51 kDa. The deviation from the theoretical molecular size could be attributed to glycosylation. One of the advantages of using plants as a production platform to produce recombinant pharmaceutical protein is its capability to perform complex post-translational modifications as eukaryotes. Glycosylation is the most common form of modification in eukaryotic cells, where at least 50% of human proteins are glycosylated [74]. N-linked glycosylation pathways in plants are relatively well-characterized and share a high degree of homology with other eukaryotic organisms [74].

Western blotting analysis of purified anti-toxoplasma IgG from the agro-infiltrated leaves of aM. bracteata and bN. benthamiana. EZRun Prestained Rec Protein Ladder (Fisher Bioreagents, PA, USA) was used as marker in both blots. c ELISA analysis of purified anti-toxoplasma IgG from agro-infiltrated leaves of 5-week-old M. bracteata plant and 40-day-old N. benthamiana plant. Analysis was carried out using Human Anti-Toxoplasma gondii IgG ELISA kit (Abcam, Cambridge, UK) according to the manufacturer’s protocol. The bars indicate mean ± standard errors. Mean followed by the same letter are not statistically significant according to Duncan’s multiple-range analysis at p < 0.05

Structural heterogeneity was observed in the purified anti-toxoplasma IgG from M. bracteata, but not from N. benthamiana (Fig. 8a, b). The presence of an additional band in M. bracteata with an estimated molecular mass of ~ 51 kDa (Fig. 8a), similar to the theoretical molecular mass, suggested the existence of anti-toxoplasma IgG devoid of any glycan moiety (Fig. 8a). The lack of glycan moiety could be an indication that some recombinant protein in M. bracteata experienced incomplete post-translational modification. However, it was suggested that structural heterogeneity resulted predominantly from degradation rather than partial assembly within the cells [50]. The glycan moiety could have been cleaved off either in planta (during protein synthesis) or ex planta (during protein extraction or purification) by one of the various proteases that exist in the plants [75]. The previous study showed that residual protease activity could still occur even in highly purified monoclonal antibodies [76]. It was worthy to note that the ~ 51 kDa band was less intense compared to the ~ 58 kDa band. This suggested that there was more glycosylated than non-glycosylated anti-toxoplasma IgG in M. bracteata. Nonetheless, even though the purified anti-toxoplasma IgG from M. bracteata suggested the presence of structural heterogeneity, the purified product demonstrated biological activity at a comparable level with anti-toxoplasma IgG extracted from N. benthamiana in ELISA (Fig. 8c). This underlines the importance of future work to better understand the post-translational mechanisms and proteolytic degradation in M. bracteata, as product authenticity and homogeneity are one of the major concerns for plant-derived recombinant pharmaceutical protein.

Conclusion

A transient expression system via agro-infiltration is a rapid and convenient method for the production of recombinant pharmaceutical protein in plants. It is an alternative to the arduous and inefficient process of generating stable transgenic lines as regeneration of transformed explants is often slow, especially in legume species. We have successfully established a reproducible transient transformation protocol to express anti-toxoplasma IgG in the leguminous and fast growing M. bracteata. This protocol could also be used to facilitate the future application of the -omic technologies in the study and utilization of M. bracteata. This is the first report of heterologous protein expression in M. bracteata via vacuum-assisted Agrobacterium infiltration. Our study showed that vacuum infiltration of a 5-week-old M. bracteata plant with A. tumefaciens strain GV3101 produced the highest concentration of heterologous protein in its bottom trifoliate leaf at 2 days post-infiltration. M. bracteata consistently produced at least two-fold higher concentration of heterologous protein when compared to the model plant, N. benthamiana. This study has laid the foundation towards establishing M. bracteata as one of the potential platforms for the production of recombinant pharmaceutical protein.

References

Egelkrout, E., Rajan, V., & Howard, J. A. (2012). Overproduction of recombinant proteins in plants. Plant Science,184, 83–101.

Obembe, O. O., Popoola, J. O., Leelavathi, S., & Reddy, S. V. (2011). Advances in plant molecular farming. Biotechnology Advances,29(2), 210–222.

Ma, S., & Wang, A. (2012). Molecular farming in plants: An overview. In A. Wang & S. Ma (Eds.), Molecular farming in plants: Recent advances and future prospects (pp. 1–20). Dordrecht: Springer.

Madeira, L. M., Szeto, T. H., Henquet, M., Raven, N., Runions, J., Huddleston, J., et al. (2016). High-yield production of a human monoclonal IgG by rhizosecretion in hydroponic tobacco cultures. Plant Biotechnology Journal,14(2), 615–624.

Xu, J., Dolan, M. C., Medrano, G., Cramer, C. L., & Weathers, P. J. (2012). Green factory: Plants as bioproduction platforms for recombinant proteins. Biotechnology Advances,30(5), 1171–1184.

Stoger, E., Fischer, R., Moloney, M., & Ma, J. K. (2014). Plant molecular pharming for the treatment of chronic and infectious diseases. Annual Review of Plant Biology,65, 743–768.

Khatodia, S., & Paul Khurana, S. M. (2018). Chapter 5—Genetic engineering for plant transgenesis: Focus to pharmaceuticals. In D. Barh & V. Azevedo (Eds.), Omics technologies and bio-engineering (pp. 71–86). Cambridge: Academic Press.

Krenek, P., Samajova, O., Luptovciak, I., Doskocilova, A., Komis, G., & Samaj, J. (2015). Transient plant transformation mediated by Agrobacterium tumefaciens: Principles, methods and applications. Biotechnology Advances,33(6), 1024–1042.

Łojewska, E., Kowalczyk, T., Olejniczak, S., & Sakowicz, T. (2016). Extraction and purification methods in downstream processing of plant-based recombinant proteins. Protein Expression and Purification,120, 110–117.

Zischewski, J., Sack, M., & Fischer, R. (2016). Overcoming low yields of plant-made antibodies by a protein engineering approach. Biotechnology Journal,11(1), 107–116.

Duwadi, K., Chen, L., Menassa, R., & Dhaubhadel, S. (2015). Identification, characterization and down-regulation of cysteine protease genes in tobacco for use in recombinant protein production. PLoS ONE,10(7), e0130556.

Jamal, A., Ko, K., Kim, H. S., Choo, Y. K., Joung, H., & Ko, K. (2009). Role of genetic factors and environmental conditions in recombinant protein production for molecular farming. Biotechnology Advances,27(6), 914–923.

Negrouk, V., Eisner, G., Lee, H.-I., Han, K., Taylor, D., & Wong, H. C. (2005). Highly efficient transient expression of functional recombinant antibodies in lettuce. Plant Science,169(2), 433–438.

Bardor, M., Loutelier-Bourhis, C., Paccalet, T., Cosette, P., Fitchette, A. C., Vezina, L. P., et al. (2003). Monoclonal C5–1 antibody produced in transgenic alfalfa plants exhibits a N-glycosylation that is homogenous and suitable for glyco-engineering into human-compatible structures. Plant biotechnology journal,1(6), 451–462.

Ma, J. K., Drake, P. M., & Christou, P. (2003). The production of recombinant pharmaceutical proteins in plants. Nature Reviews Genetics,4(10), 794–805.

Sathyanarayana, N., Vikas, P., & Rajesha, R. (2008). In vitro clonal propagation of Mucuna pruriens var. utilis and its evaluation of genetic stability through RAPD markers. African Journal of Biotechnology,7(8), 973–980.

Agbede, J. O. (2006). Characterisation of the leaf meals, protein concentrates and residues from some tropical leguminous plants. Journal of the Science of Food and Agriculture,86(9), 1292–1297.

Mathews, C. (1998). The introduction and establishment of a new leguminous cover crop, Mucuna bracteata under oil palm in Malaysia. Planter,74(868), 359–368.

Mendham, D. S., Kumaraswamy, S., Balasundaran, M., Sankaran, K. V., Corbeels, M., Grove, T. S., et al. (2004). Legume cover cropping effects on early growth and soil nitrogen supply in eucalypt plantations in South-Western India. Biology and Fertility of Soils,39(5), 375–382.

Chiu, S. B. (2007). Botany, habits and economic uses of Mucuna bracteata DC. ex Kurz. In K. J. Goh & S. B. Chiu (Eds.), Mucuna bracteata: A cover crop and living green manure. Ampang: Majujaya Indah Sdn. Bhd.

Lim, S. S. Y., Chua, K. H., Nölke, G., Spiegel, H., Goh, W. L., Chow, S. C., et al. (2018). Plant-derived chimeric antibodies inhibit the invasion of human fibroblasts by Toxoplasma gondii. PeerJ,6, e5780.

Arcalis, E., Stadlmann, J., Rademacher, T., Marcel, S., Sack, M., Altmann, F., et al. (2013). Plant species and organ influence the structure and subcellular localization of recombinant glycoproteins. Plant Molecular Biology,83(1), 105–117.

Mann, D. G. J., Abercrombie, L. L., Rudis, M. R., Millwood, R. J., Dunlap, J. R., & Stewart, C. N. (2012). Very bright orange fluorescent plants: Endoplasmic reticulum targeting of orange fluorescent proteins as visual reporters in transgenic plants. BMC Biotechnology,12(1), 17.

Martínez, C. A., Giulietti, A. M., & Rodríguez Talou, J. (2011). Expression of a KDEL-tagged dengue virus protein in cell suspension cultures of Nicotiana tabacum and Morinda citrifolia. Plant Cell, Tissue and Organ Culture (PCTOC),107(1), 91–100.

Abd Aziz, N., Tan, B. C., Othman, R. Y., & Khalid, N. (2018). Efficient micropropagation protocol and genome size estimation of an important cover crop, Mucuna bracteata DC. ex Kurz. Plant Cell, Tissue and Organ Culture,132(2), 267–278.

Leuzinger, K., Dent, M., Hurtado, J., Stahnke, J., Lai, H., Zhou, X., et al. (2013). Efficient agroinfiltration of plants for high-level transient expression of recombinant proteins. JoVE (Journal of Visualized Experiments),77, e50521.

Fan, Y., Li, W., Wang, J., Liu, J., Yang, M., Xu, D., et al. (2011). Efficient production of human acidic fibroblast growth factor in pea (Pisum sativum L.) plants by agroinfection of germinated seeds. BMC Biotechnology,11(1), 45.

Sivanandhan, G., Dev, G. K., Theboral, J., Selvaraj, N., Ganapathi, A., & Manickavasagam, M. (2015). Sonication, vacuum infiltration and thiol compounds enhance the Agrobacterium-mediated transformation frequency of Withania somnifera (L.) Dunal. PLoS ONE,10(4), e0124693.

Houdelet, M., Galinski, A., Holland, T., Wenzel, K., Schillberg, S., & Buyel, J. F. (2017). Animal component-free Agrobacterium tumefaciens cultivation media for better GMP-compliance increases biomass yield and pharmaceutical protein expression in Nicotiana benthamiana. Biotechnology Journal,12(4), 1600721.

Jung, S. K., Lindenmuth, B. E., McDonald, K. A., Hwang, M. S., Bui, M. Q. N., Falk, B. W., et al. (2014). Agrobacterium tumefaciens mediated transient expression of plant cell wall-degrading enzymes in detached sunflower leaves. Biotechnology Progress,30(4), 905–915.

Wroblewski, T., Tomczak, A., & Michelmore, R. (2005). Optimization of Agrobacterium-mediated transient assays of gene expression in lettuce, tomato and Arabidopsis. Plant Biotechnology Journal,3(2), 259–273.

Wydro, M., Kozubek, E., & Lehmann, P. (2006). Optimization of transient Agrobacterium-mediated gene expression system in leaves of Nicotiana benthamiana. Acta Biochimica Polonica-English Edition,53(2), 289.

King, J. L., Finer, J. J., & McHale, L. K. (2015). Development and optimization of agroinfiltration for soybean. Plant Cell Reports,34(1), 133–140.

Buyel, J., & Fischer, R. (2012). Predictive models for transient protein expression in tobacco (Nicotiana tabacum L.) can optimize process time, yield, and downstream costs. Biotechnology and Bioengineering,109(10), 2575–2588.

Bashandy, H., Jalkanen, S., & Teeri, T. H. (2015). Within leaf variation is the largest source of variation in agroinfiltration of Nicotiana benthamiana. Plant Methods,11(1), 47.

Sack, M., Rademacher, T., Spiegel, H., Boes, A., Hellwig, S., Drossard, J., et al. (2015). From gene to harvest: Insights into upstream process development for the GMP production of a monoclonal antibody in transgenic tobacco plants. Plant Biotechnology Journal,13(8), 1094–1105.

Sheludko, Y., Sindarovska, Y., Gerasymenko, I., Bannikova, M., & Kuchuk, N. (2007). Comparison of several Nicotiana species as hosts for high-scale Agrobacterium-mediated transient expression. Biotechnology and Bioengineering,96(3), 608–614.

Yang, Y., Li, R., & Qi, M. (2000). In vivo analysis of plant promoters and transcription factors by agroinfiltration of tobacco leaves. The Plant Journal,22(6), 543–551.

Bhaskar, P. B., Venkateshwaran, M., Wu, L., Ané, J.-M., & Jiang, J. (2009). Agrobacterium-mediated transient gene expression and silencing: a rapid tool for functional gene assay in potato. PLoS ONE,4(6), e5812.

Xu, K., Huang, X., Wu, M., Wang, Y., Chang, Y., Liu, K., et al. (2014). A rapid, highly efficient and economical method of Agrobacterium-mediated in planta transient transformation in living onion epidermis. PLoS ONE,9(1), e83556.

Yasmin, A., & Debener, T. (2010). Transient gene expression in rose petals via Agrobacterium infiltration. Plant Cell, Tissue and Organ Culture,102(2), 245–250.

Zheng, L., Liu, G., Meng, X., Li, Y., & Wang, Y. (2012). A versatile Agrobacterium-mediated transient gene expression system for herbaceous plants and trees. Biochemical Genetics,50(9–10), 761–769.

Johansen, L. K., & Carrington, J. C. (2001). Silencing on the spot. Induction and suppression of RNA silencing in the Agrobacterium-mediated transient expression system. Plant Physiology,126(3), 930–938.

Voinnet, O., Rivas, S., Mestre, P., & Baulcombe, D. (2003). An enhanced transient expression system in plants based on suppression of gene silencing by the p19 protein of tomato bushy stunt virus. The plant journal,33(5), 949–956.

Donini, M., Lombardi, R., Lonoce, C., Di Carli, M., Marusic, C., Morea, V., et al. (2015). Antibody proteolysis: A common picture emerging from plants. Bioengineered,6(5), 299–302.

Niemer, M., Mehofer, U., Torres Acosta, J. A., Verdianz, M., Henkel, T., Loos, A., et al. (2014). The human anti-HIV antibodies 2F5, 2G12, and PG9 differ in their susceptibility to proteolytic degradation: Down-regulation of endogenous serine and cysteine proteinase activities could improve antibody production in plant-based expression platforms. Biotechnology Journal,9(4), 493–500.

Jutras, P. V., Marusic, C., Lonoce, C., Deflers, C., Goulet, M.-C., Benvenuto, E., et al. (2016). An accessory protease inhibitor to increase the yield and quality of a tumour-targeting mAb in Nicotiana benthamiana leaves. PLoS ONE,11(11), e0167086.

Hehle, V. K., Paul, M. J., Drake, P. M., Ma, J. K., & van Dolleweerd, C. J. (2011). Antibody degradation in tobacco plants: A predominantly apoplastic process. BMC Biotechnology,11, 128.

Mandal, M. K., Ahvari, H., Schillberg, S., & Schiermeyer, A. (2016). Tackling unwanted proteolysis in plant production hosts used for molecular farming. Frontiers in Plant Science,7, 267.

Hehle, V. K., Lombardi, R., van Dolleweerd, C. J., Paul, M. J., Di Micco, P., Morea, V., et al. (2015). Site-specific proteolytic degradation of IgG monoclonal antibodies expressed in tobacco plants. Plant Biotechnology Journal,13(2), 235–245.

Hehle, V. K., Paul, M. J., Roberts, V. A., Dolleweerd, C. J. V., & Ma, J. K. C. (2016). Site-targeted mutagenesis for stabilization of recombinant monoclonal antibody expressed in tobacco (Nicotiana tabacum) plants. The FASEB Journal,30(4), 1590–1598.

Grosse-Holz, F., Madeira, L., Zahid, M. A., Songer, M., Kourelis, J., Fesenko, M., et al. (2018). Three unrelated protease inhibitors enhance accumulation of pharmaceutical recombinant proteins in Nicotiana benthamiana. Plant Biotechnology Journal,16(10), 1797–1810.

Hellens, R., Mullineaux, P., & Klee, H. (2000). Technical focus: A guide to Agrobacterium binary Ti vectors. Trends in Plant Science,5(10), 446–451.

Deeba, F., Hyder, M. Z., Shah, S. H., & Naqvi, S. M. S. (2014). Multiplex PCR assay for identification of commonly used disarmed Agrobacterium tumefaciens strains. SpringerPlus,3(1), 358.

Zottini, M., Barizza, E., Costa, A., Formentin, E., Ruberti, C., Carimi, F., et al. (2008). Agroinfiltration of grapevine leaves for fast transient assays of gene expression and for long-term production of stable transformed cells. Plant Cell Reports,27(5), 845–853.

Kim, Y. G., Sharmin, S. A., Alam, I., Kim, K. H., Kwon, S. Y., Sohn, J. H., et al. (2013). Agrobacterium-mediated transformation of reed (Phragmites communis Trinius) using mature seed-derived calli. Gcb Bioenergy,5(1), 73–80.

Chetty, V., Ceballos, N., Garcia, D., Narváez-Vásquez, J., Lopez, W., & Orozco-Cárdenas, M. (2013). Evaluation of four Agrobacterium tumefaciens strains for the genetic transformation of tomato (Solanum lycopersicum L.) cultivar Micro-Tom. Plant Cell Reports,32(2), 239–247.

Chen, X., Equi, R., Baxter, H., Berk, K., Han, J., Agarwal, S., et al. (2010). A high-throughput transient gene expression system for switchgrass (Panicum virgatum L.) seedlings. Biotechnology for Biofuels,3(1), 9.

Pruss, G. J., Nester, E. W., & Vance, V. (2008). Infiltration with Agrobacterium tumefaciens induces host defense and development-dependent responses in the infiltrated zone. Molecular Plant-Microbe Interactions,21(12), 1528–1538.

Gohlke, J., & Deeken, R. (2014). Plant responses to Agrobacterium tumefaciens and crown gall development. Frontiers in Plant Science,5, 155.

Khanna, H. K., Paul, J.-Y., Harding, R. M., Dickman, M. B., & Dale, J. L. (2007). Inhibition of Agrobacterium-induced cell death by antiapoptotic gene expression leads to very high transformation efficiency of banana. Molecular Plant-Microbe Interactions,20(9), 1048–1054.

Zhang, W.-J., Dewey, R. E., Boss, W., Phillippy, B. Q., & Qu, R. (2013). Enhanced Agrobacterium-mediated transformation efficiencies in monocot cells is associated with attenuated defense responses. Plant Molecular Biology,81(3), 273–286.

Pierpoint, W. S. (2004). The extraction of enzymes from plant tissues rich in phenolic compounds. In Protein purification protocols (pp. 65–74). Berlin: Springer.

Charmont, S., Jamet, E., Pont-Lezica, R., & Canut, H. (2005). Proteomic analysis of secreted proteins from Arabidopsis thaliana seedlings: Improved recovery following removal of phenolic compounds. Phytochemistry,66(4), 453–461.

Yao, Y., Yang, Y. W., & Liu, J. Y. (2006). An efficient protein preparation for proteomic analysis of developing cotton fibers by 2-DE. Electrophoresis,27(22), 4559–4569.

Wang, X., Li, X., Deng, X., Han, H., Shi, W., & Li, Y. (2007). A protein extraction method compatible with proteomic analysis for the euhalophyte Salicornia europaea. Electrophoresis,28(21), 3976–3987.

Brown, R. B., & Audet, J. (2008). Current techniques for single-cell lysis. Journal of the Royal Society Interface,5(suppl_2), S131–S138.

Vagenende, V., Yap, M. G., & Trout, B. L. (2009). Mechanisms of protein stabilization and prevention of protein aggregation by glycerol. Biochemistry,48(46), 11084–11096.

Holtz, B. R., Berquist, B. R., Bennett, L. D., Kommineni, V. J., Munigunti, R. K., White, E. L., et al. (2015). Commercial-scale biotherapeutics manufacturing facility for plant-made pharmaceuticals. Plant biotechnology journal,13(8), 1180–1190.

Pillay, P., Kunert, K. J., van Wyk, S., Makgopa, M. E., Cullis, C. A., & Vorster, B. J. (2016). Agroinfiltration contributes to VP1 recombinant protein degradation. Bioengineered,7(6), 459–477.

Melnik, S., Neumann, A. C., Karongo, R., Dirndorfer, S., Stübler, M., Ibl, V., et al. (2018). Cloning and plant-based production of antibody MC 10E7 for a lateral flow immunoassay to detect [4-arginine] microcystin in freshwater. Plant biotechnology Journal,16(1), 27–38.

Teh, A. Y. H., Maresch, D., Klein, K., & Ma, J. K. C. (2014). Characterization of VRC 01, a potent and broadly neutralizing anti-HIV mAb, produced in transiently and stably transformed tobacco. Plant Biotechnology Journal,12(3), 300–311.

Heitzer, M., & Zschoernig, B. (2007). Construction of modular tandem expression vectors for the green alga Chlamydomonas reinhardtii using the Cre/lox-system. BioTechniques,43(3), 324–332.

Webster, D. E., & Thomas, M. C. (2012). Post-translational modification of plant-made foreign proteins; glycosylation and beyond. Biotechnology Advances,30(2), 410–418.

Benchabane, M., Goulet, C., Rivard, D., Faye, L., Gomord, V., & Michaud, D. (2008). Preventing unintended proteolysis in plant protein biofactories. Plant Biotechnology Journal,6(7), 633–648.

Gao, S. X., Zhang, Y., Stansberry-Perkins, K., Buko, A., Bai, S., Nguyen, V., et al. (2011). Fragmentation of a highly purified monoclonal antibody attributed to residual CHO cell protease activity. Biotechnology and Bioengineering,108(4), 977–982.

Acknowledgements

The authors would like to acknowledge University of Malaya PPP Grant (Grant No: PG254-2016A) and High Impact Research Programme of University of Malaya, Malaysia (UM.C/625/1/HIR/MOHE/SCI/18).

Author information

Authors and Affiliations

Contributions

NAA designed the experiments, conducted the experiments and analyzed data; NAA, BCT, NAR, RYO, NK conceived the idea and wrote the paper. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abd-Aziz, N., Tan, B.C., Rejab, N.A. et al. A New Plant Expression System for Producing Pharmaceutical Proteins. Mol Biotechnol 62, 240–251 (2020). https://doi.org/10.1007/s12033-020-00242-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12033-020-00242-2